Solid rocket engine inner insulation layer forming method

A solid rocket and molding method technology, which is applied in the field of forming a thermal protection inner insulation layer of a solid rocket motor, can solve the problems of multiple energy sources, use requirements and complicated operation processes, cost, etc., and achieve full utilization, reduce production process steps, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for forming the inner thermal insulation layer of the solid rocket motor comprises the following steps:

[0021] 1) Preparation before pressurization: brush the adhesive on the inner wall of the shell and dry it, and paste the rubber sleeve 3 of the heat insulation layer (120 mm in length, 50 mm in diameter, and 1 mm in thickness) into the corresponding bonding position of the solid rocket motor shell 2 (Ensure that the insulation layer rubber sleeve 3 is laid flat and without wrinkles);

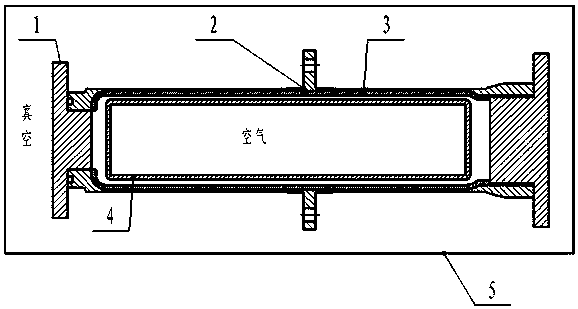

[0022] 2) Put the air bag 4 filled with air into the casing. Screw the port positioning tooling 1 at both ends of the shell to ensure the distance between the rubber sleeve of the heat insulating layer and the port of the shell, and put the shell into a vacuum container 5 (vacuum oven).

[0023] 3) Pressurization: Start to evacuate the vacuum oven, the air in the airbag 4 expands in the vacuum environment, apply a pressure of 0.1MPa to the rubber sleeve 3 of the heat insul...

Embodiment 2

[0027] The method for forming the inner thermal insulation layer of the solid rocket motor comprises the following steps:

[0028] 1) Preparation before pressurization: After brushing the adhesive on the inner wall of the shell and drying it, paste the rubber sleeve 3 of the heat insulating layer (300mm in length, 100mm in diameter, and 2mm in thickness) into the corresponding bonding position of the solid rocket motor shell 2 ( Ensure that the rubber sleeve 3 of the thermal insulation layer is laid flat and without wrinkles);

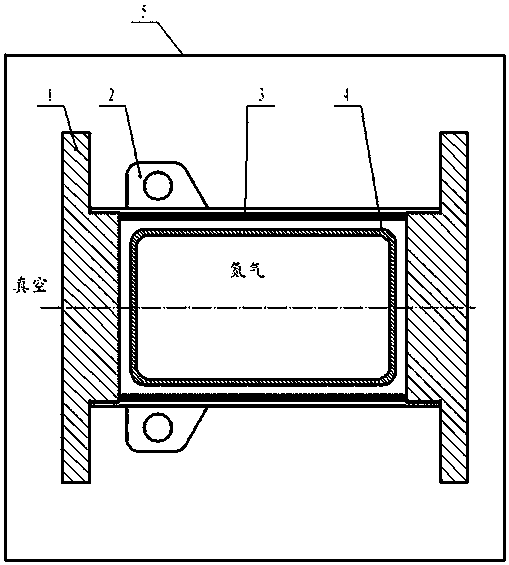

[0029] 2) Put the airbag 4 filled with nitrogen into the casing. Screw the port positioning tooling 1 at both ends of the shell to ensure the distance between the rubber sleeve of the heat insulating layer and the port of the shell, and put the shell into the vacuum container 5 (vacuum cylinder).

[0030] 3) Pressurization: start to vacuumize the vacuum cylinder, the nitrogen in the airbag 4 expands in a vacuum environment, apply a pressure of 0.1MPa ...

Embodiment 3

[0034] The method for forming the inner thermal insulation layer of the solid rocket motor comprises the following steps:

[0035] 1) Preparation before pressurization: After brushing the adhesive on the inner wall of the shell and drying it, paste the rubber sleeve 3 of the heat insulating layer (700mm in length, 150mm in diameter, and 3mm in thickness) into the corresponding bonding position of the solid rocket motor shell 2 ( Ensure that the rubber sleeve 3 of the thermal insulation layer is laid flat and without wrinkles);

[0036] 2) Put the air bag 4 filled with air into the casing. Screw the port positioning tooling 1 at both ends of the shell to ensure the distance between the rubber sleeve of the heat insulating layer and the port of the shell, and put the shell into the vacuum cylinder.

[0037] 3) Pressurization: start to evacuate the vacuum cylinder, the air in the airbag 4 expands in a vacuum environment, apply a pressure of 0.1MPa to the rubber sleeve 3 of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com