Patents

Literature

45results about How to "Eliminate processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A copper adulterated aluminum complex flat line and its making method

ActiveCN101236798AImprove performanceEliminate processabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureCopperAluminum composites

The invention relates to a copper-clad aluminum composite flat wire and a preparation method thereof, relating to bimetal layered composite materials. The copper-clad aluminum composite flat wire is formed by composition of sandwich layer aluminum and clad copper, and the area ratio of the copper clad is 15 percent to 40 percent. The preparation steps are as follows: copper-clad aluminum composite blanks are directly compounded and formed by adoption of horizontal continuous casting; multi-pass groove rolling and / or multi-pass drawing is performed on the copper-clad aluminum blanks as required; the rolling speed of 3 to 60 meters per minute is adopted, and the single-pass relative percent reduction is 20 percent to 40 percent; or the drawing speed of 2 to 30 meters per minute is adopted, and the single-pass section scalage is 10 percent to 25 percent; under the condition of multi-pass processing and that the overall section scalage of the copper-clad aluminum composite materials reaches 75 percent to 95 percent, low-temperature intermediate annealing is performed on the copper-clad aluminum composite materials; the annealing temperature is 200 to 450 DEG C; the annealing time is 0.5 to 2 hours; the blanks after annealing are rolled or drawn further, and the copper-clad aluminum composite flat wire with required section shape and size is prepared. The invention not only can prepare the high performance copper-clad aluminum composite flat wire but also has high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

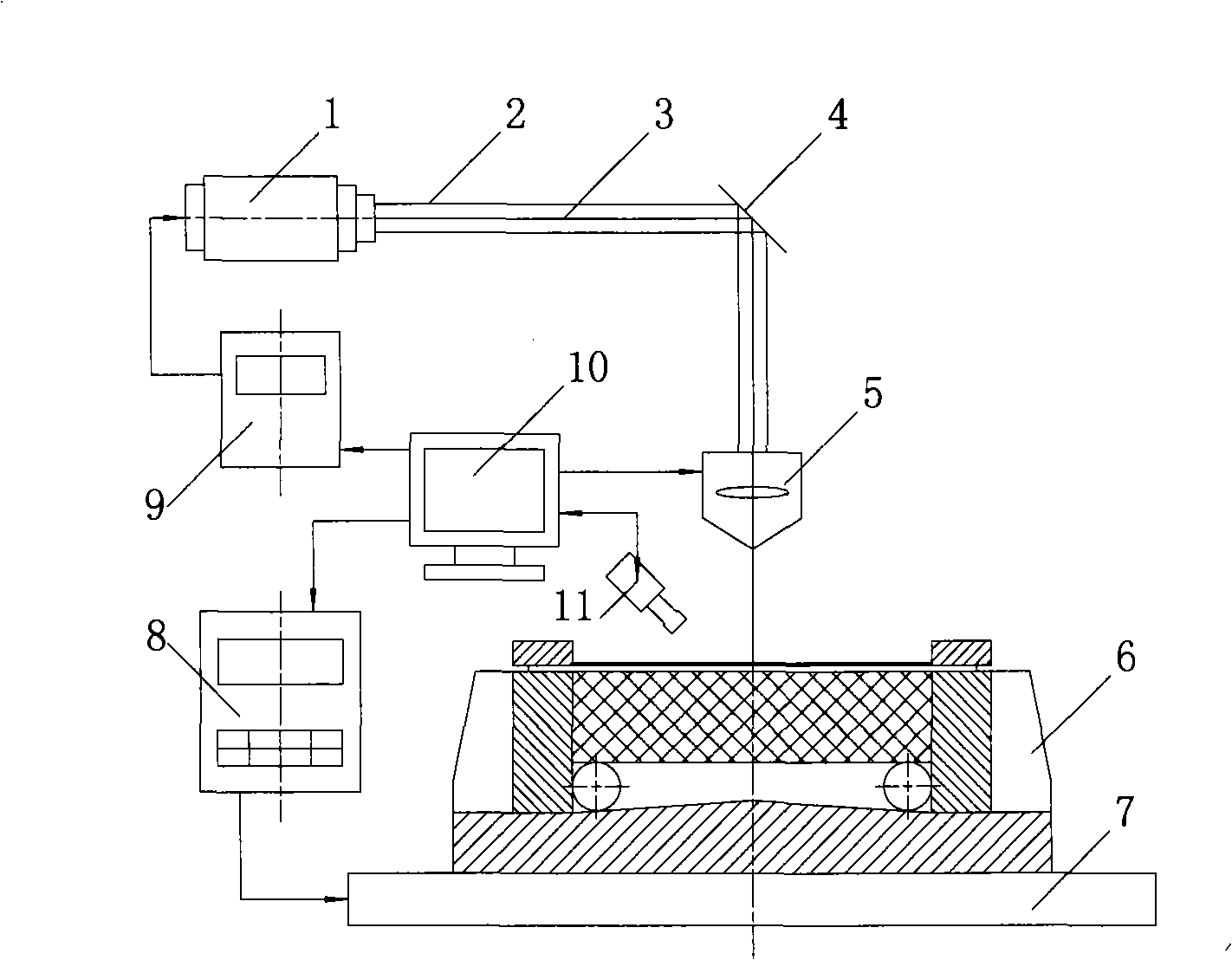

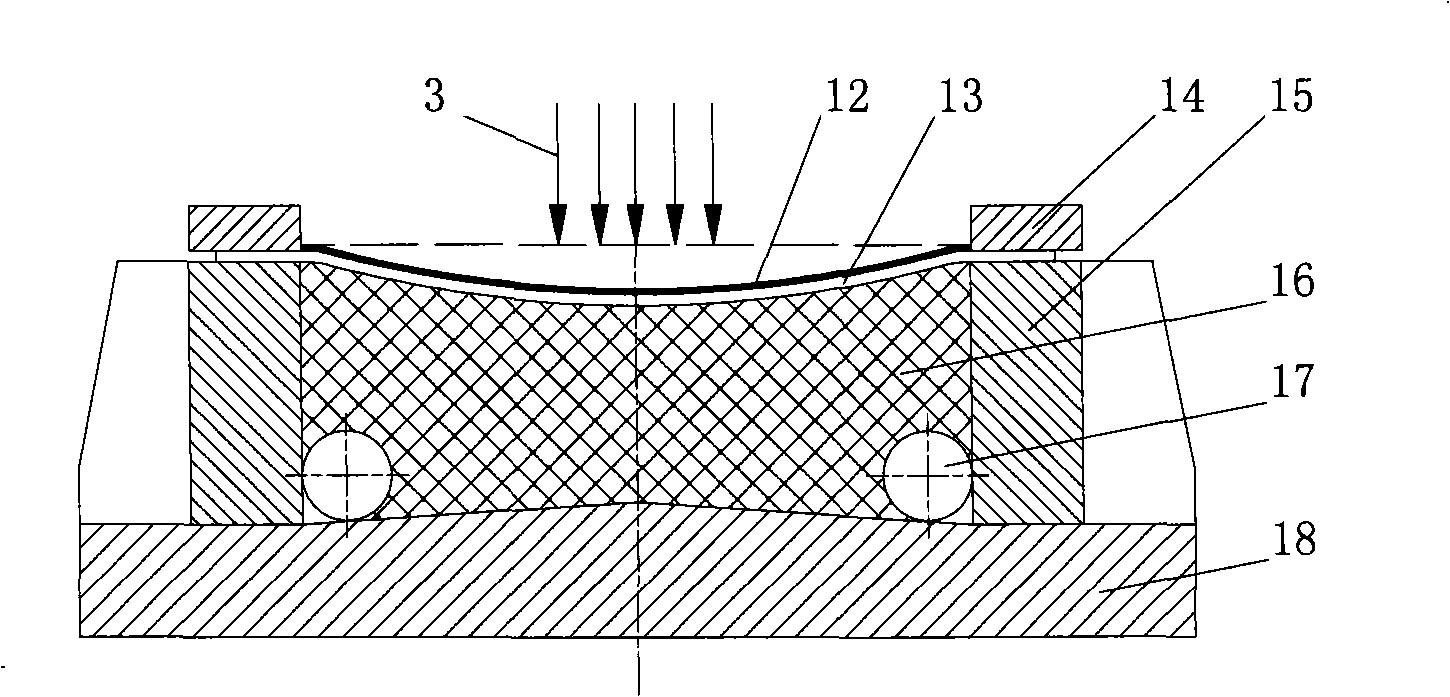

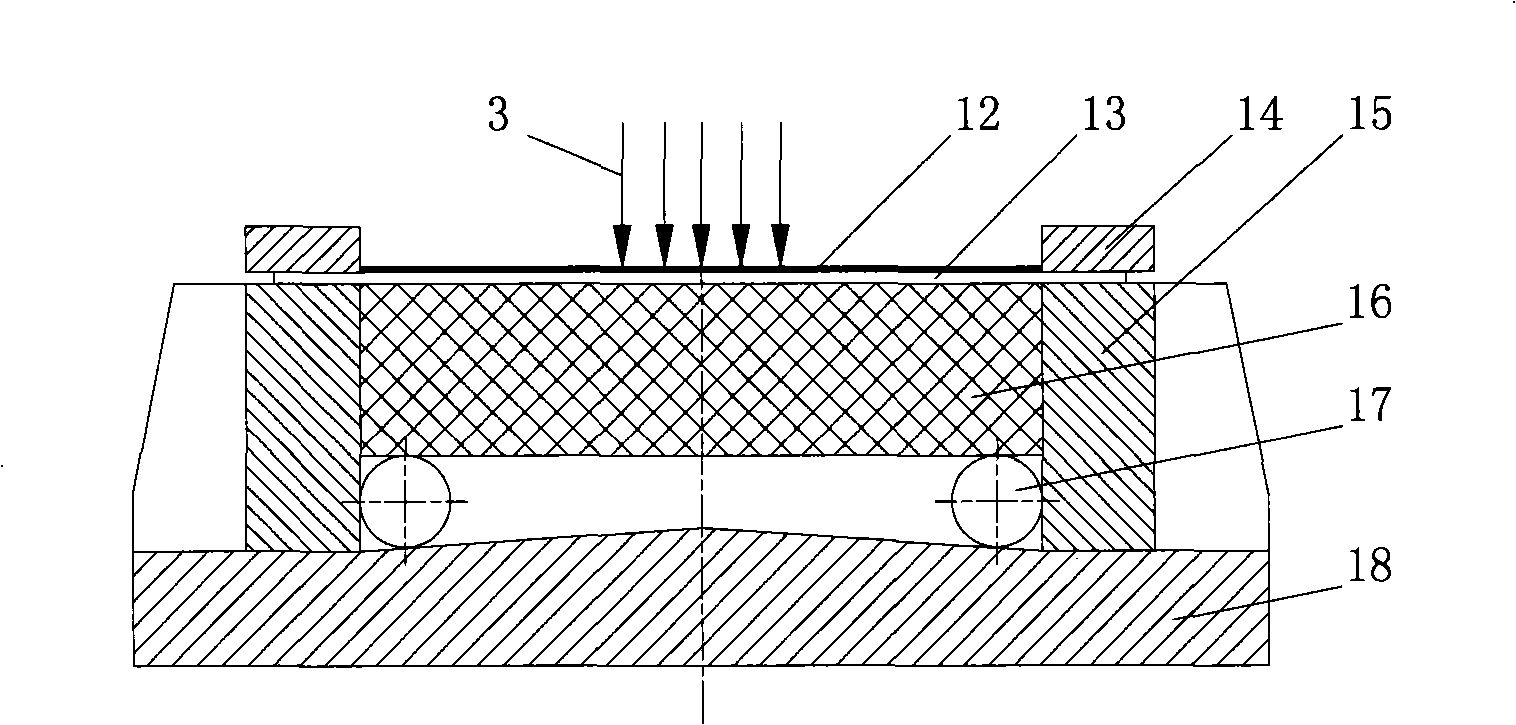

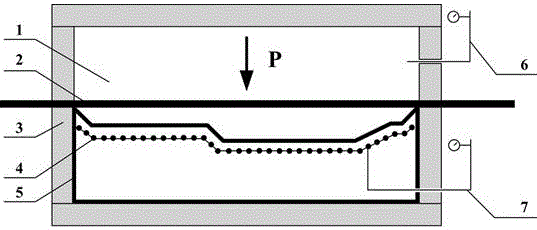

Method and device for laser shock forming on the basis of polyurethane rubber film

ActiveCN101524784APrecise large area impact formingPrecise and flexible levelingLaser beam welding apparatusShock waveStress conditions

The invention relates to a method and a device for laser shock forming on the basis of a polyurethane rubber film. The method is characterized in that shock waves induced by laser are used as a power source for forming; the polyurethane rubber film is used as a concave film for the laser shock forming; and the stress condition of a plate under the action of the shock waves is changed to achieve the shock forming of a complicated curved surface. The device comprises a laser generating device, a light guide system, a laser shock head, a polyurethane rubber film system and a control system and is also provided with a detection feedback system with a displacement measuring device. According to the requirement of the curved surface shape and forming rules of a plate, laser shock process parameters are optimized, the polyurethane rubber of proper hardness and thickness are selected, and the plate is deformed under the associative action of the shock waves and the polyurethane rubber. The device not only can achieve the complicated and precise forming of the plate, but also can carry out the flexible leveling of the plate, and also can be applied to the surface shock strengthening treatment of materials.

Owner:JIANGSU UNIV

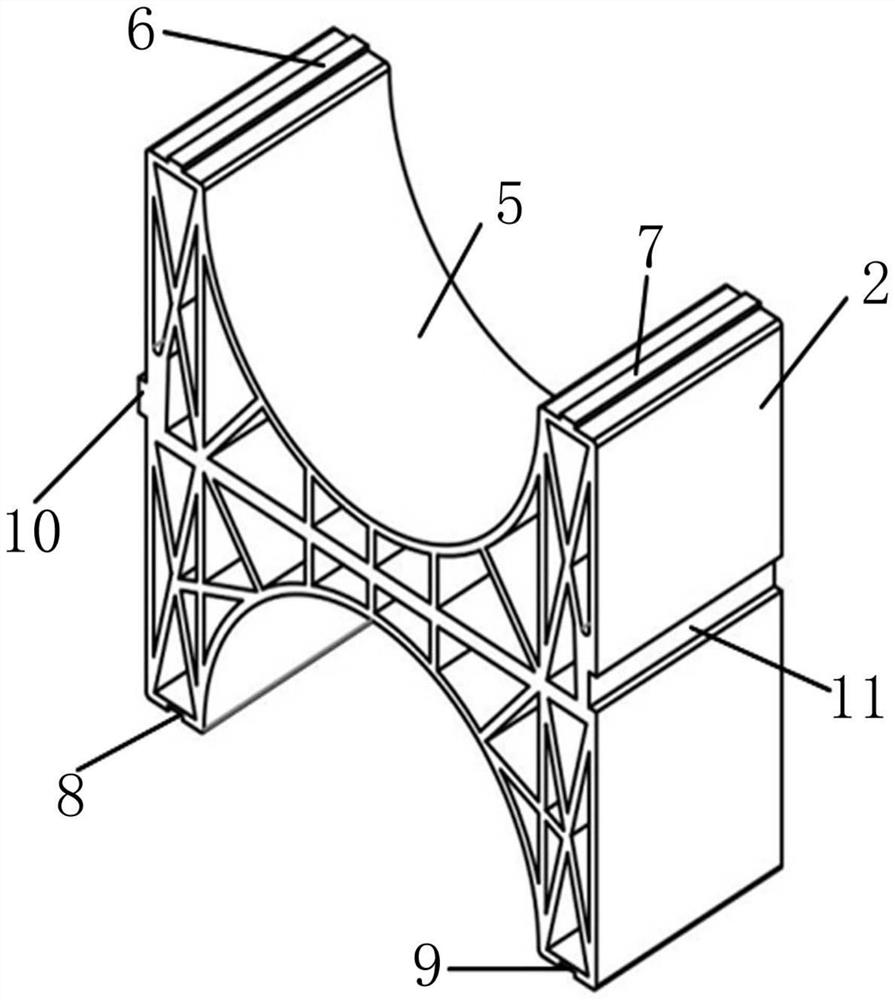

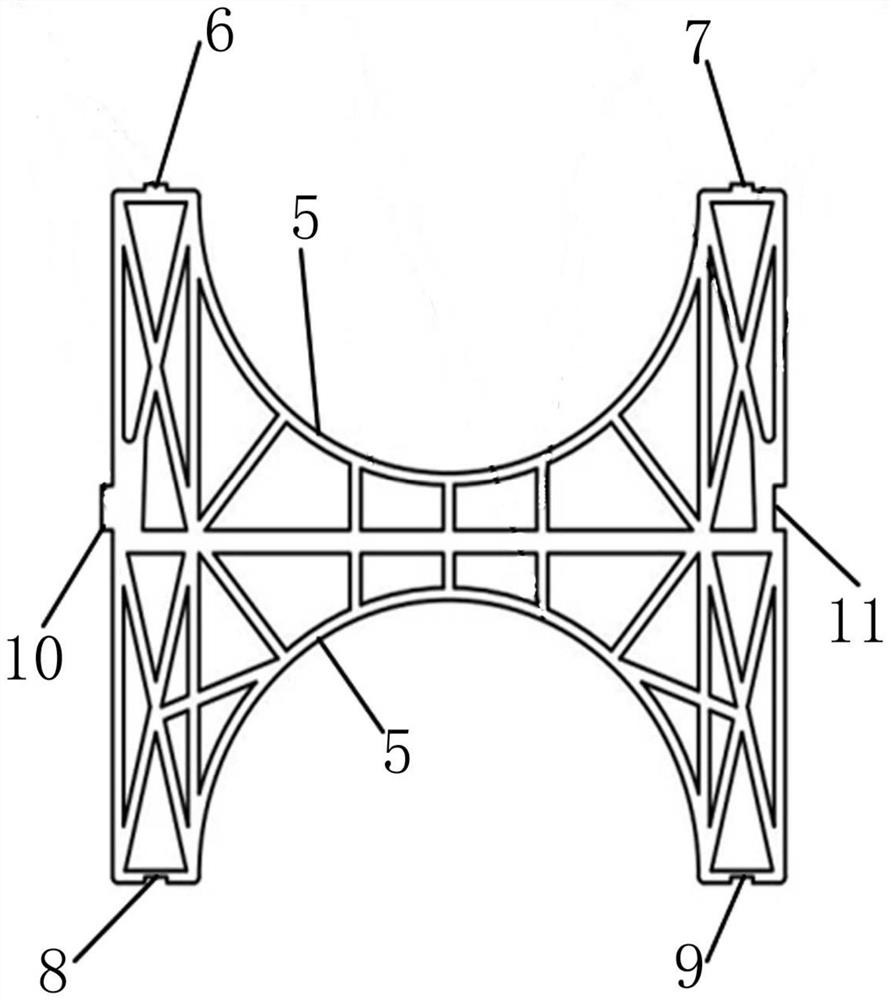

Integral column formwork based on 3d printing and used for concrete pouring and column pouring method

InactiveCN105926935AImprove protectionSave woodForms/shuttering/falseworksBuilding material handlingReinforced concrete columnEngineering

The invention discloses an integral column formwork based on 3d printing and used for concrete pouring. The integral column formwork is of a tubular structure formed through 3d printing and is composed of pipe walls and reinforcing ribs. The invention further discloses a column pouring method. The column pouring method comprises the steps that a column reinforcement cage is bound; the integral column formwork is arranged on the periphery of the column reinforcement cage; and after the integral column formwork is fixed properly, concrete is poured into the integral column formwork, and the poured concrete, the reinforcement cage and the integral formwork are combined into a whole to form a reinforced concrete column. Cement-based mortar is adopted by the column formwork, the column formwork is formed through 3d printing, wood materials are saved, and environment protection is facilitated. Processing and on-site installation processes of wooden formworks are omitted, and the procedures of dismounting and cleaning the formworks are omitted. The column poured through the integral formwork is good in integrity, firm, reliable, low in cost, convenient and easy to construct, and high in construction speed.

Owner:ZHEJIANG UNIV

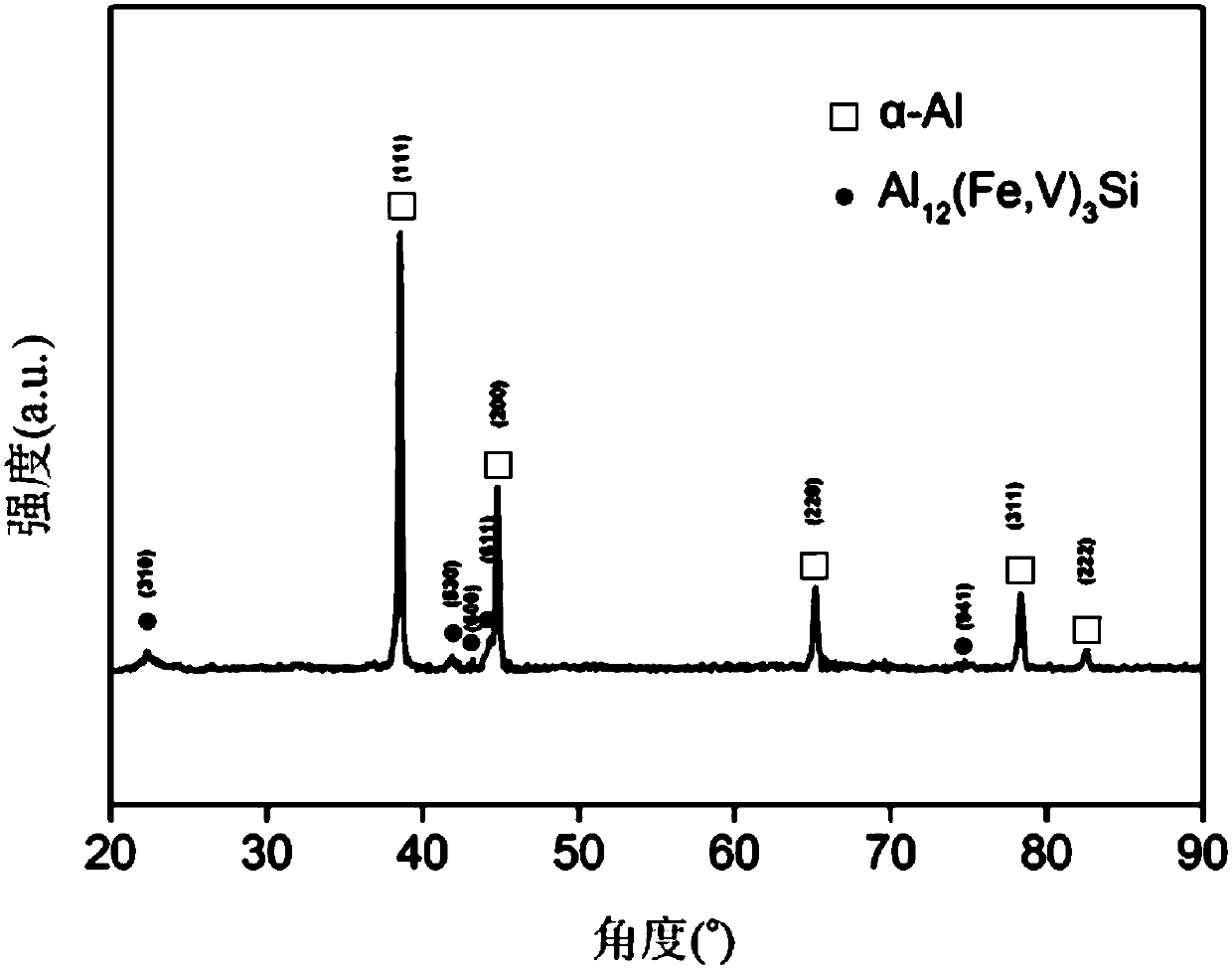

Method for preparing heat-resisting aluminum alloy

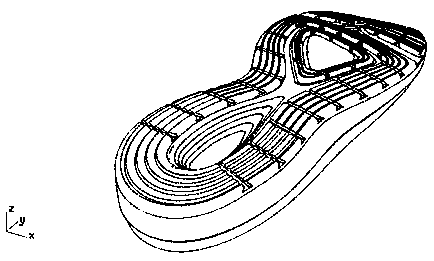

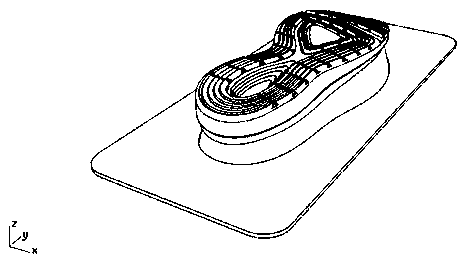

InactiveCN107649681ASave R&D cycleSave manufacturing cycleAdditive manufacturing apparatusIncreasing energy efficiencySlice thicknessControl table

The invention discloses a method for preparing a heat-resisting aluminum alloy, and belongs to the field of metal manufacturing. The method comprises the steps that according to the shape of an Al-Fe-V-Si alloy part to be processed, a three-dimensional model is established; layered slice cutting processing is conducted on the three-dimensional model, so that the preset slice thickness in the height direction is formed; a scanning path of each slice is determined according to the cross section profile information of each slice of the three-dimensional model; a layer of pre-alloy powder is laidin accordance with the slice thickness to form a powder layer; the current powder layer is scanned by using a laser beam according to the scanning path, thus a deposition layer corresponding to a slice of the three-dimensional model is made; a control table is controlled to be dropped to the distance of the thickness of a slice, and a layer of pre-alloy powder is laid on the deposition layer againof a formed substrate plate through a powder paving mechanism according to the slice thickness to form a powder layer; and repeating is conducted until processing is finished. The alloy part preparedby the method is high in surface forming precision and good in quality, the research and manufacture cycle can be effectively shortened, the production efficiency is improved, and the production costis reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Compound welding method of simultaneously explosive welding of multiple local parts in metal explosive welding

InactiveCN101607344AReduce usageAvoid Explosive Welding Composite PhenomenaNon-electric welding apparatusTitaniumEngineering

The invention discloses a compound welding method of simultaneously explosive welding of multiple local parts in metal explosive welding. A welding apparatus comprises a base layer metal plate, wherein a multiple-layer metal plate is arranged on the base layer metal plate, a multiple-layer liner-plate is arranged on the multiple-layer metal plate, and explosive and igniting device are arranged on the multiple-layer liner-plate. The welding method adopts the simultaneous explosion compound welding of a plurality of dot matrixes, localities and metals of any shape to reduce the usage amount of copper materials or other precious metals (gold, silver, titanium, tantalum, zirconium, nickel and the like) adopted as the multiple layers, thus greatly reducing construction cost of explosive welding and enhancing work efficiency.

Owner:安徽钛钴新金属有限公司

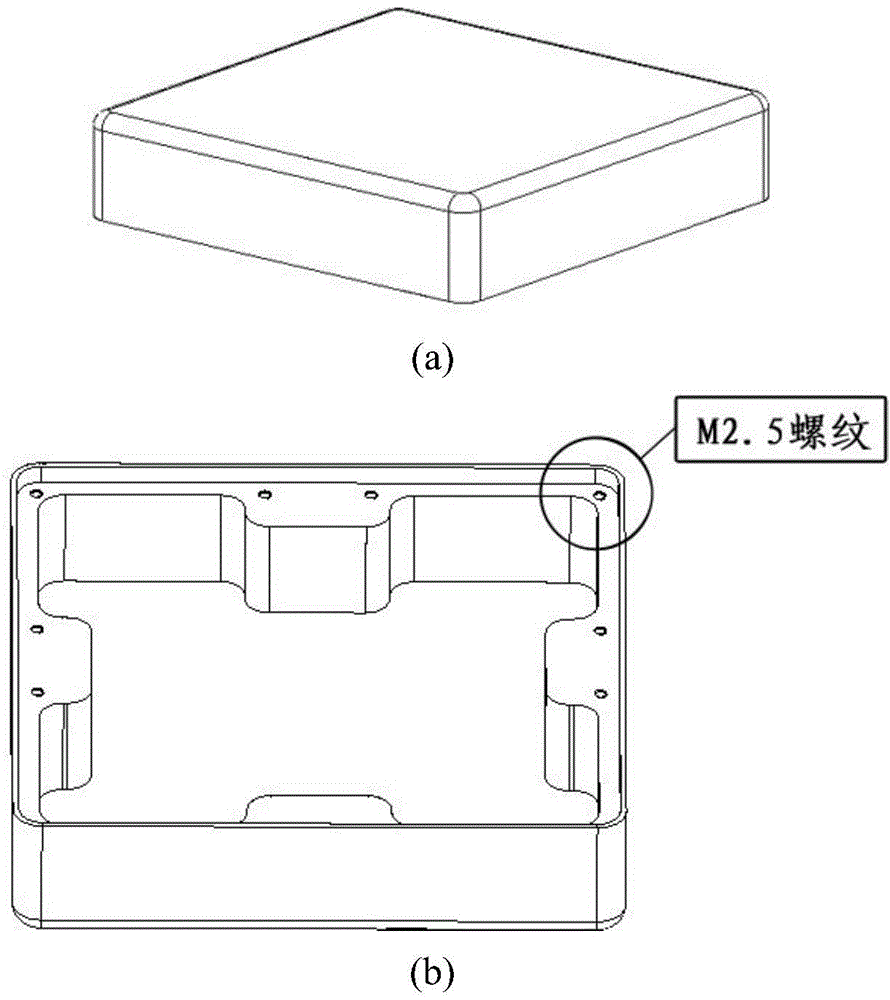

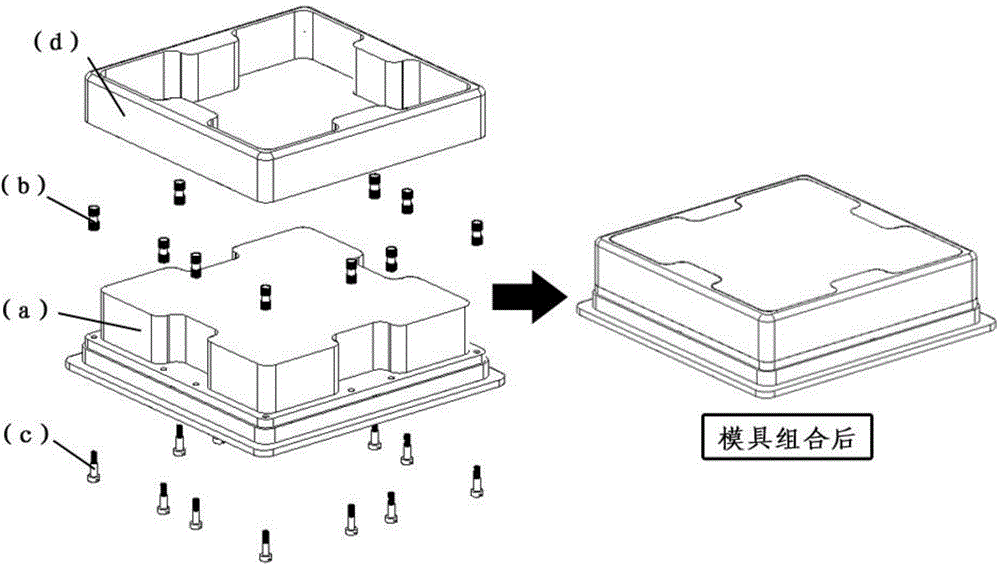

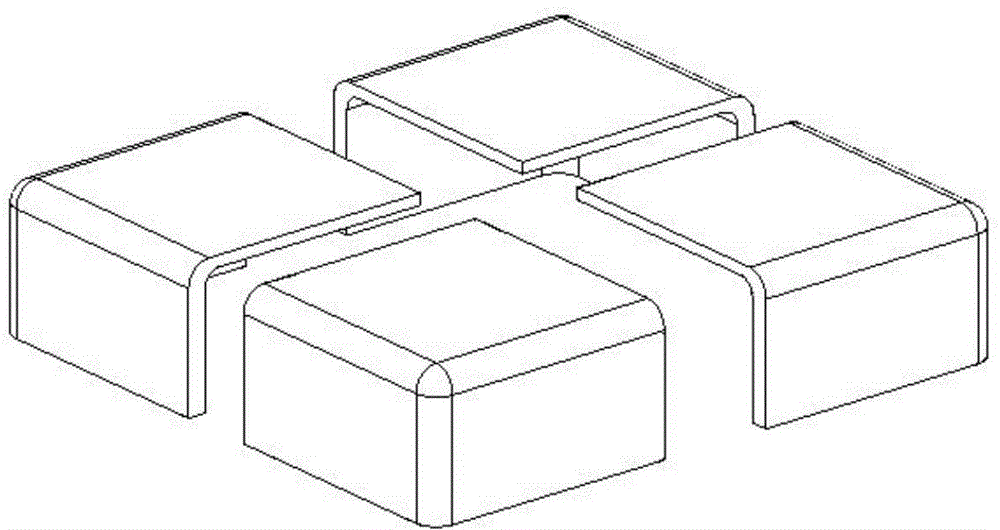

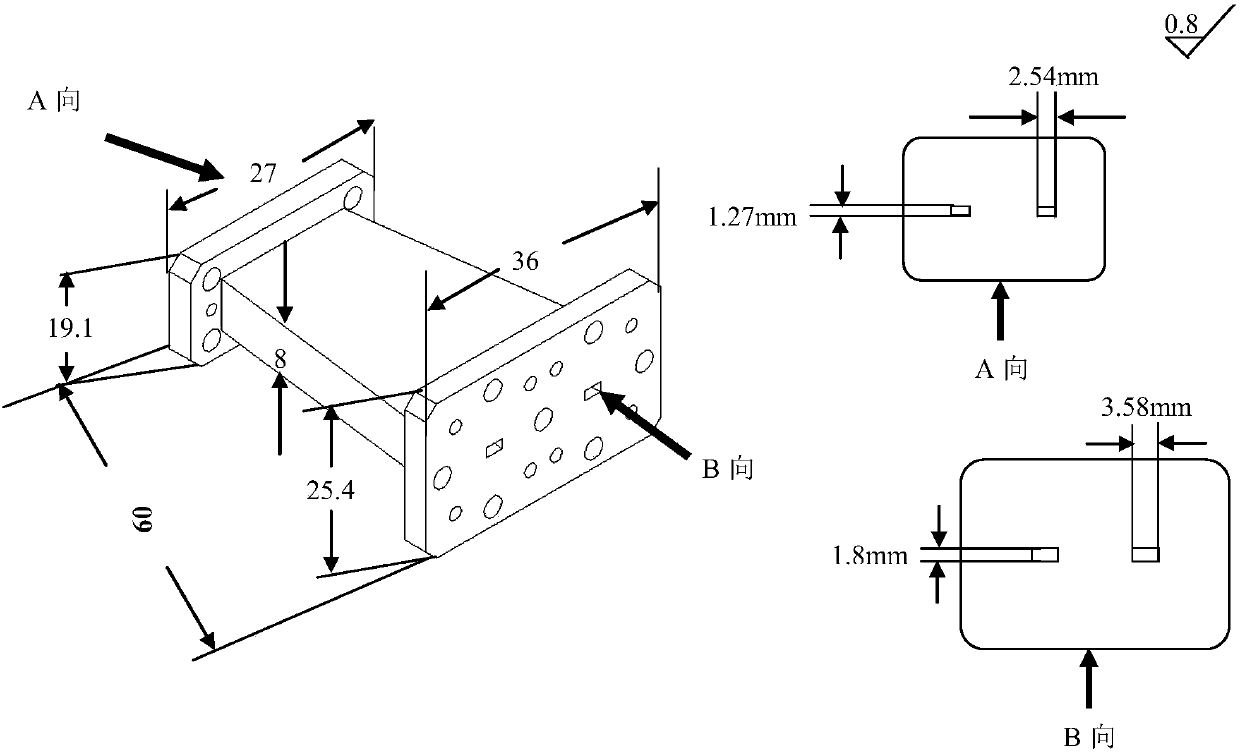

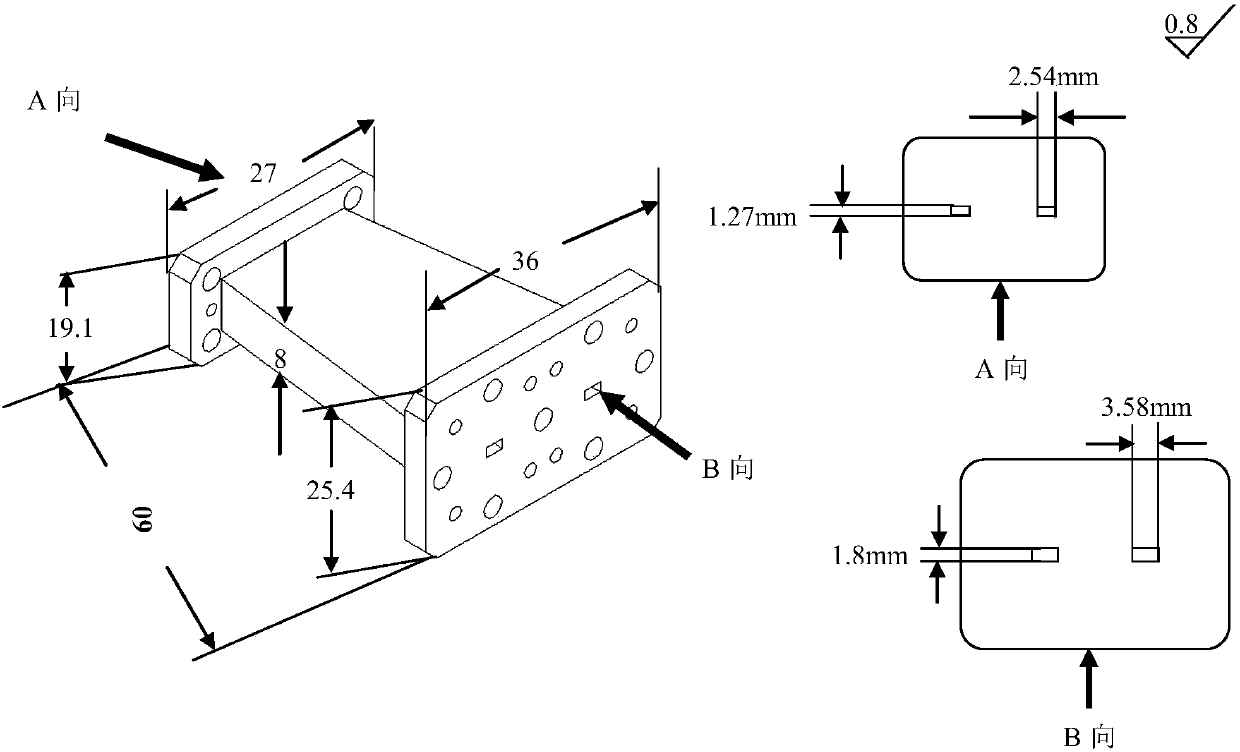

Integrated forming die and method for glass fiber reinforced plastic antenna housing

The invention relates to an integrated forming die and method for a glass fiber reinforced plastic antenna housing. The integrated forming die is composed of a main die (a), embedded circular nuts (b), special screws (c), a glass fiber reinforced plastic framework (d) and an outer die (e). A forming process comprises the following steps: (1) doing preparation work and assembling the dies; (2) preparing raw materials; (3) laying; (4) forming the antenna housing by an autoclave; and (5) releasing the dies and carrying out post-treatment. By adopting the integrated forming die, the embedded circular nuts (b) are synchronously glued and arranged in the forming process of the antenna housing and cracks caused by mechanical drilling when the embedding circular nuts are arranged by adopting a conventional method are avoided; drilling and secondary gluing procedures are eliminated, the operation difficulty is reduced and the splicing effect of the embedded circular nuts (b) is improved; and the main die (a) and the outer die (e) are combined so that the appearance quality requirements and the size precision requirements on the antenna housing are met when the antenna housing is formed and a manual polishing or machining procedure in a conventional forming method is eliminated.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

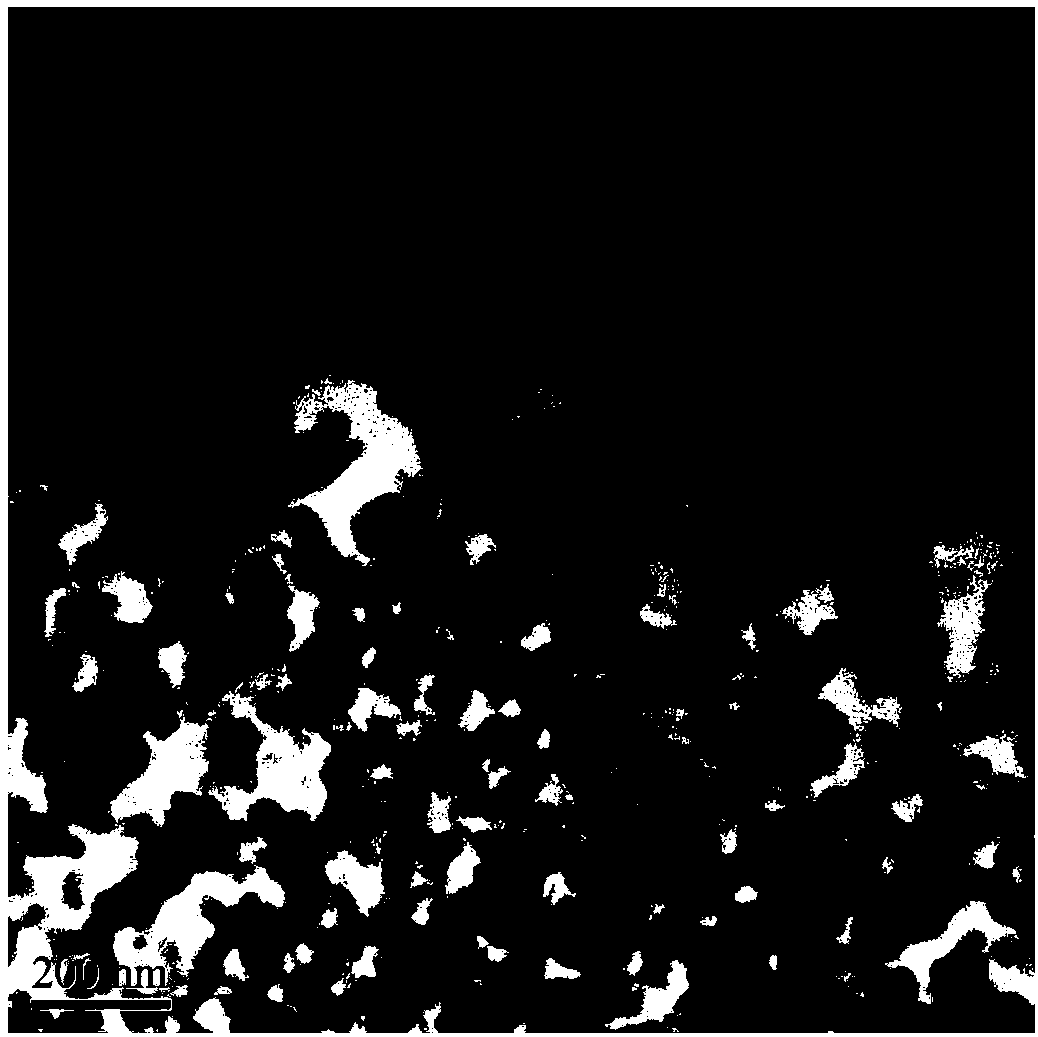

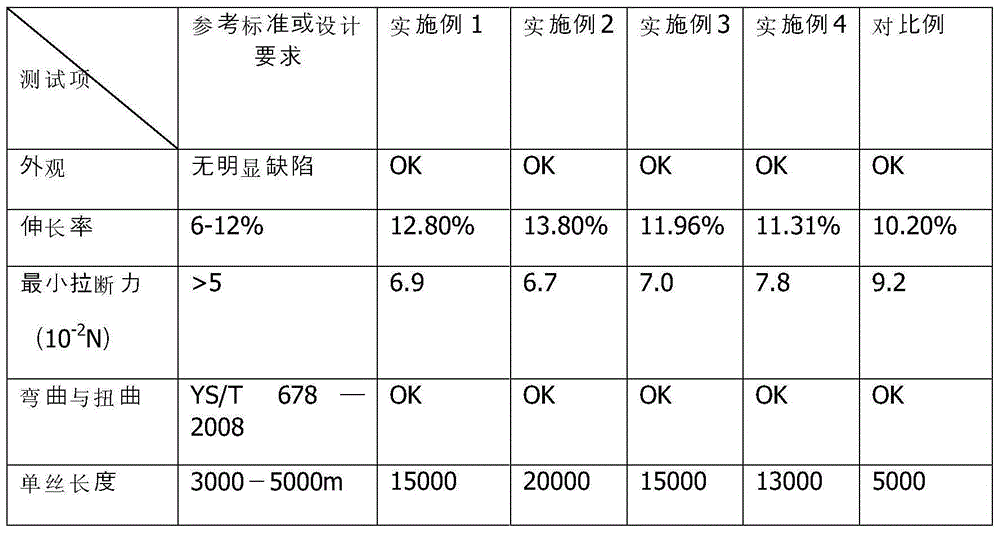

Ultra-thin copper alloy bonding wire for microelectronic packaging and preparing method of ultra-thin copper alloy bonding wire

InactiveCN105132735AImprove performanceImprove grain refinement effectSolid-state devicesSemiconductor devicesRare-earth elementImpurity

An ultra-thin copper alloy bonding wire for microelectronic packaging is characterized by being prepared from 10-50 wt.ppm of Ti, 10-50 wt.ppm of Li, 10-50 wt.ppm of Zr, 10-50 wt.ppm of Fe, 10-50 wt.ppm of Ag, 10-50 wt.ppm of B, 10-50 wt.ppm of a rare earth element and the balance copper and inevitable impurities, wherein the content of O and S in the impurities accounts for 5 wt.ppm or less in the whole copper alloy bonding wire, and the rare earth element is one of Eu, Y and Dy or a combination of Eu, Y and Dy. The invention further provides a preparing method of the ultra-thin copper alloy bonding wire for microelectronic packaging. The copper alloy bonding wire has the good oxidation resistance, good electric and heat conductivity, good weldability, large single wire length and other good performance, and the preparing method of the copper alloy bonding wire is easy and convenient to implement.

Owner:NICHE TECH KAISER SHANTOU

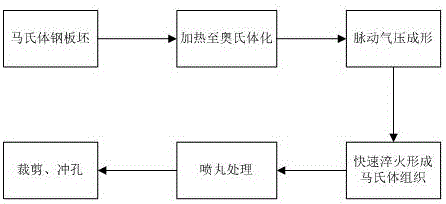

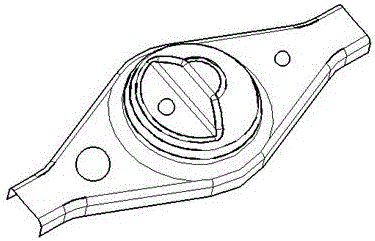

Thermal formation method of component with complex shape through martensitic steel board

ActiveCN106583543ARaise the forming limitSolve complex componentsFurnace typesHeat treatment furnacesAtmospheric pressureUltimate tensile strength

The invention discloses a thermal formation method of a component with complex shape through a martensitic steel board, and belongs to the field of advanced manufacturing and plastic formation of metal. The thermal formation method comprises the following steps: heating a martensitic steel sheet to reach the temperature of 930 to 950 DEG C in order to realize austenitizing; placing the austenitized steel sheet in a pneumatic formatting device; closing a die, and applying a certain die closing force; performing pulse pneumatic loading formation on the surface of the steel sheet until the surface of the steel sheet clings to a concave die so as to obtain the component with the complex shape; quickly quenching the component through a cooling system which is integrated with the die, so as to completely convert austenite into martensite; and performing laser hole punching and side cutting on the formed component so as to obtain the final martensite component. With the adoption of the thermal formation method, the problem of formation of the component with complex shape through an ultrahigh-strength martensite steel sheet can be effectively solved; the conversion rate of a martensite structure in the component can be further increased; the manufacturing cost of martensite steel can be decreased; and the thermal formation method is high in formation efficiency and high in engineering application value.

Owner:NANJING INST OF TECH

Square steel forging and pressing process

InactiveCN105251922AEasy to work hardenEliminate work hardeningExtrusion cleaning devicesHeating timeMetallurgy

The invention relates to a square steel forging and pressing process. The square steel forging and pressing process comprises the following steps that (1) a square steel heating curve graph is drawn, the horizontal ordinate of the square steel heating curve graph indicates the heating time, and the vertical coordinate indicates the heating temperature; (2) square steel is heated according to the square steel heating curve graph obtained in the step (1); and (3) upsetting treatment and drawing-out treatment are conducted on the heated square steel. By means of the square steel forging and pressing process, the process accuracy is high, the surface quality of the square steel is good, and a casting process is simple and reliable.

Owner:刘振宇

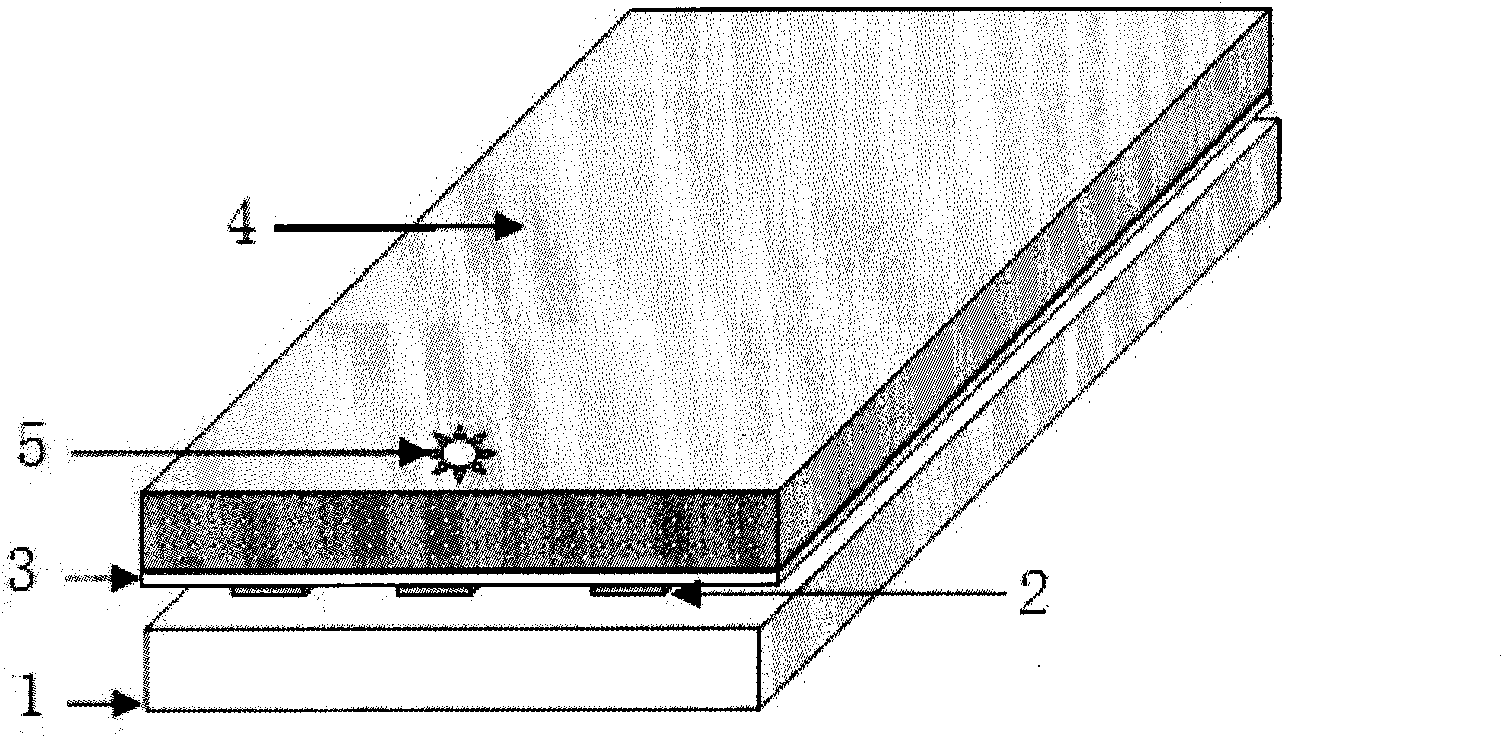

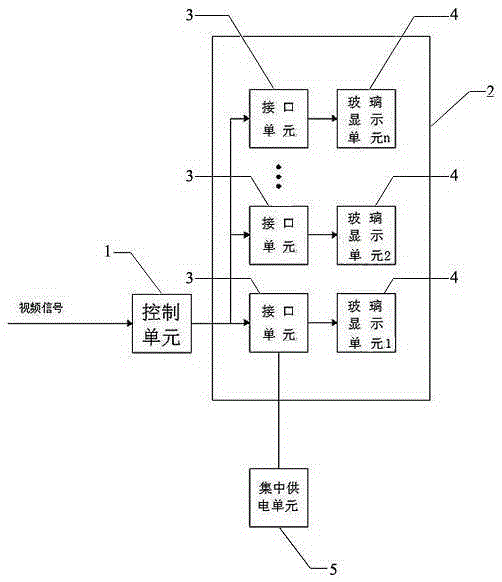

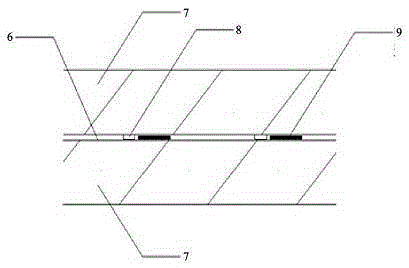

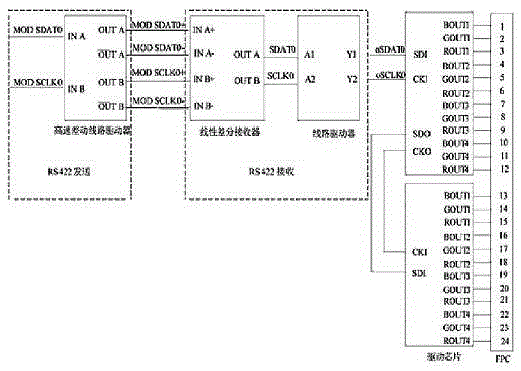

Intelligent full-color glass display screen

ActiveCN105304016AEliminate packaging processEliminate processabilityStatic indicating devicesIdentification meansWaferingLED display

The invention provides an intelligent full-color glass LED (Light Emitting Diode) display screen and a glass LED display unit. An unpackaged driving IC (Integrated Circuit) bare chip and an LED wafer are reversely arranged on an ITO (Indium Tin Oxides) circuit using glass as a base board, so that the packaging process of the existing LED lamp bead and the existing driving IC is omitted; and the processing and installing process of a conventional display screen module is also omitted. Therefore a circuit on the glass is very simple, and almost no power consumption or almost no temperature is generated on the ITO circuit, so that the display image of the display screen is stable, and the small-space intelligent full-color glass display screen can be realized on a single-layer circuit.

Owner:SHANGHAI TIEGE TECH CO LTD

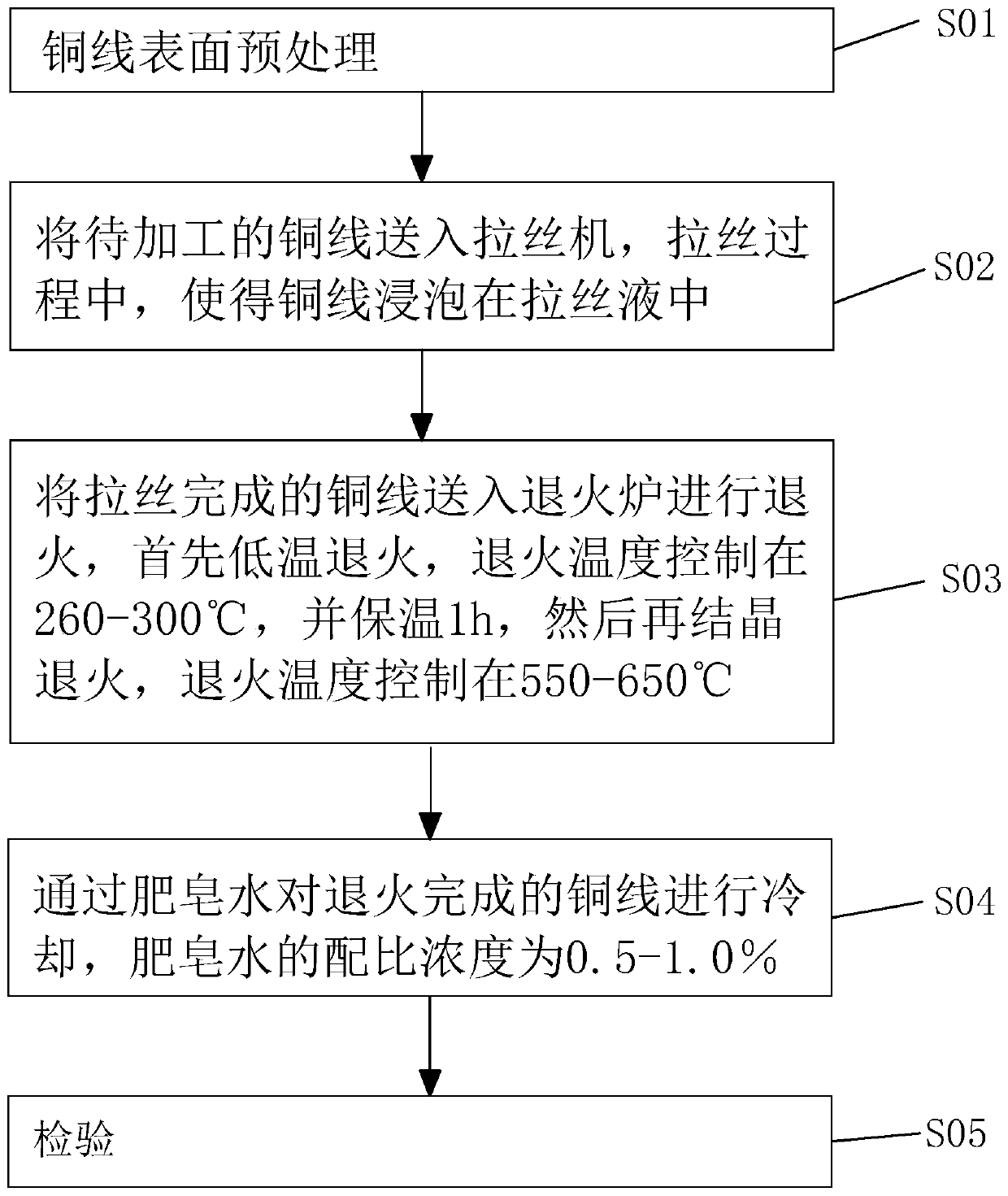

Copper wire drawing process

InactiveCN110711788AEliminate internal stressReduce stress corrosion crackingFurnace typesHeat treatment furnacesTemperature controlCopper wire

The invention relates to a copper wire drawing process. The process comprises the following steps of S1, pretreating a copper wire surface; S02, feeding a copper wire to be machined into a wire drawing machine, and in the wire drawing process, enabling the copper wire to be soaked in wire drawing liquid; S03, feeding the drawn copper wire into an annealing furnace to be annealed, firstly, performing low-temperature annealing, enabling the annealing temperature to be controlled at 260 to 300 DEG C, performing recrystallization annealing, and enabling the annealing temperature to be controlled at 550 to 650 DEG C; S04, through soapy water, cooling the annealed copper wire, and enabling the compounding concentration of the soapy water to be at 0.5 to 1.0%; and S05, inspecting. The process hasthe effects of removing copper wire inner stress to reduce cracking and wire breaking.

Owner:信电电线(深圳)有限公司

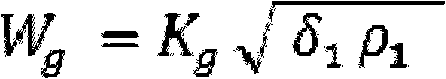

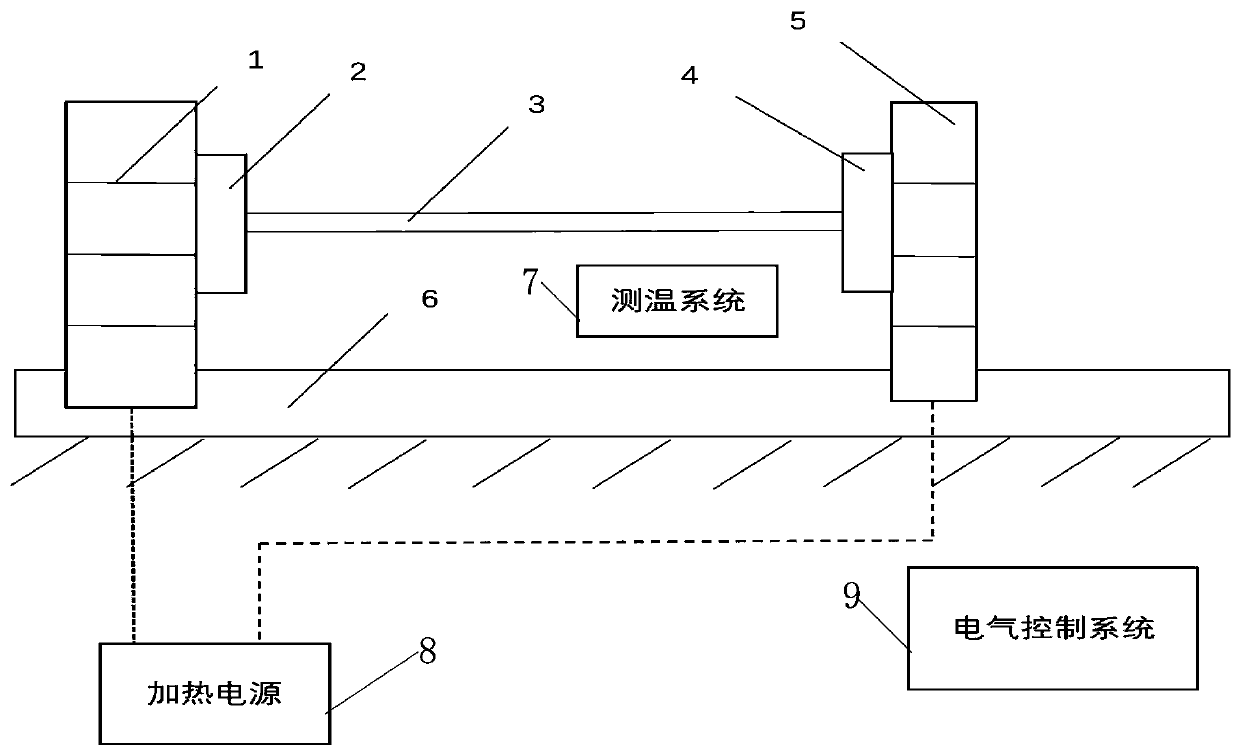

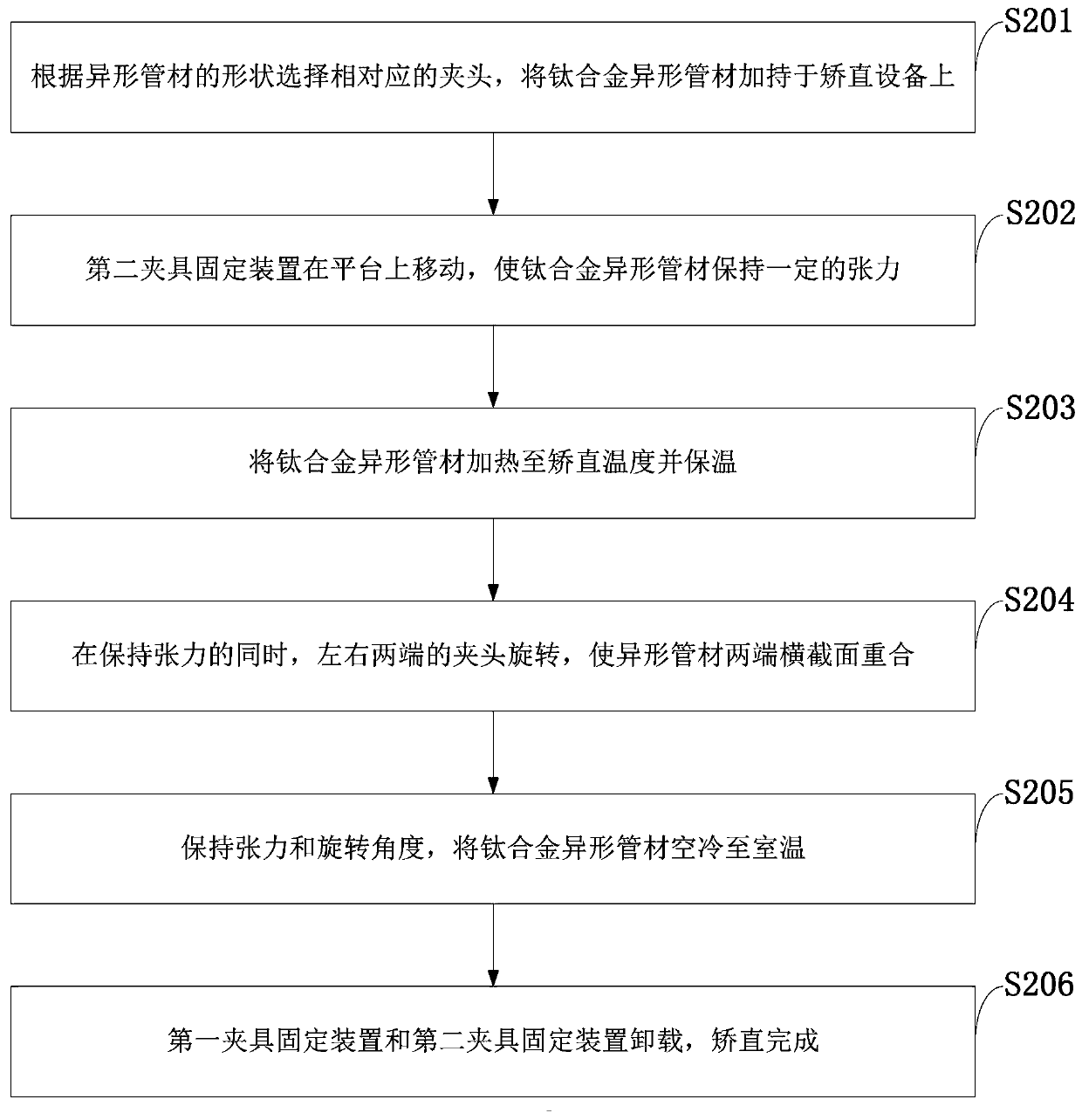

Pipe straightening control system and method and application of pipe straightening control method to titanium alloy pipe straightening

InactiveCN111389960AImprove straightnessEliminate processabilityShaping toolsMetal-working feeding devicesElectric heatingMachining process

The invention belongs to the technical field of titanium alloy pipe straightening, and discloses a pipe straightening control system and method and application of the pipe straightening control methodto titanium alloy pipe straightening. The two ends of a special-shaped pipe are clamped through a clamping device, the left end is fixed, the right end can be moved on a platform, and thus, the pipehas certain tension; and heating is conducted through an electric contact heating mode, residual stress of the titanium alloy special-shaped pipe is removed, meanwhile, under the tension condition, clamping heads at the two ends can be rotated, stress is thoroughly released, torsion of the pipe is eliminated, then, the tension and rotation angle are kept, the special-shaped pipe is cooled to the indoor temperature, fixtures at the two ends are dissembled, and straightening is completed. The torsion angle of the straightened titanium alloy special-shaped pipe is smaller than 1 degree; the straightening mode with drawing and rotating being conducted at the same time is adopted, and the problem that a high-torsion-degree titanium alloy special-shaped pipe is difficult to straighten is effectively solved; and by adopting electric heating straightening, work hardening and residual stress in the machining process of the titanium alloy special-shaped pipe are eliminated, and the problems of residual strain and resilience in the pressure straightening process are solved.

Owner:西安圣泰金属材料有限公司

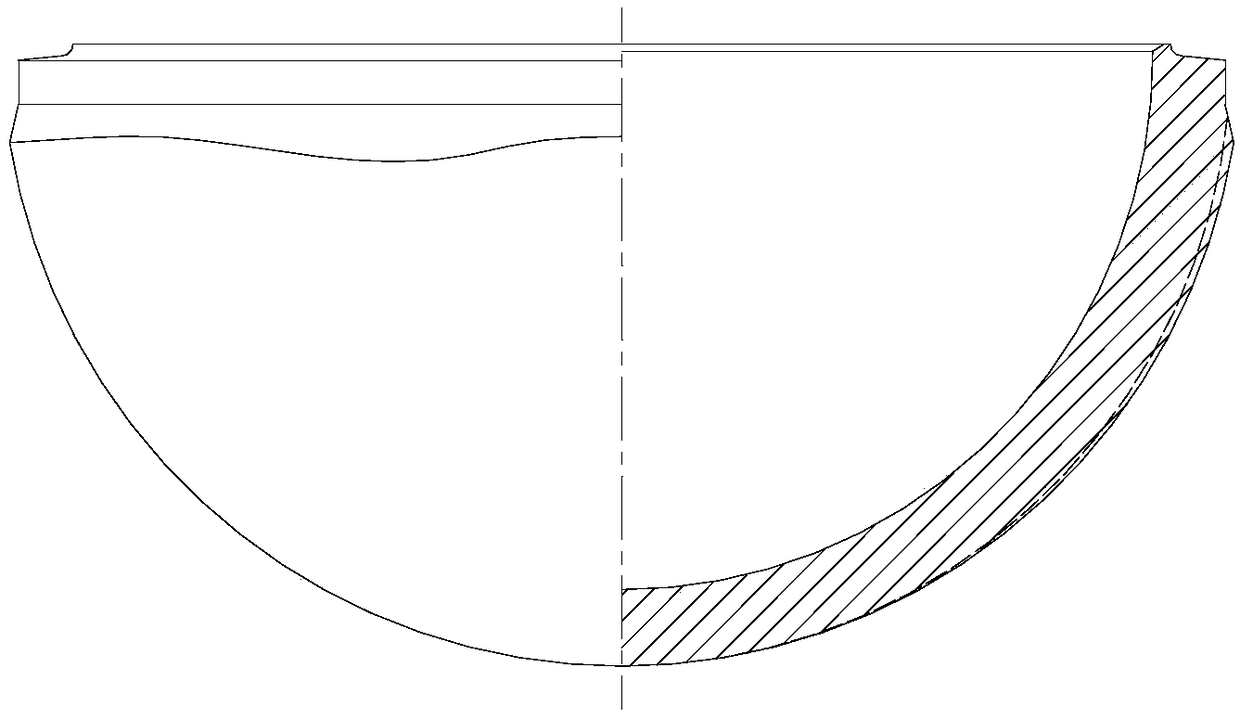

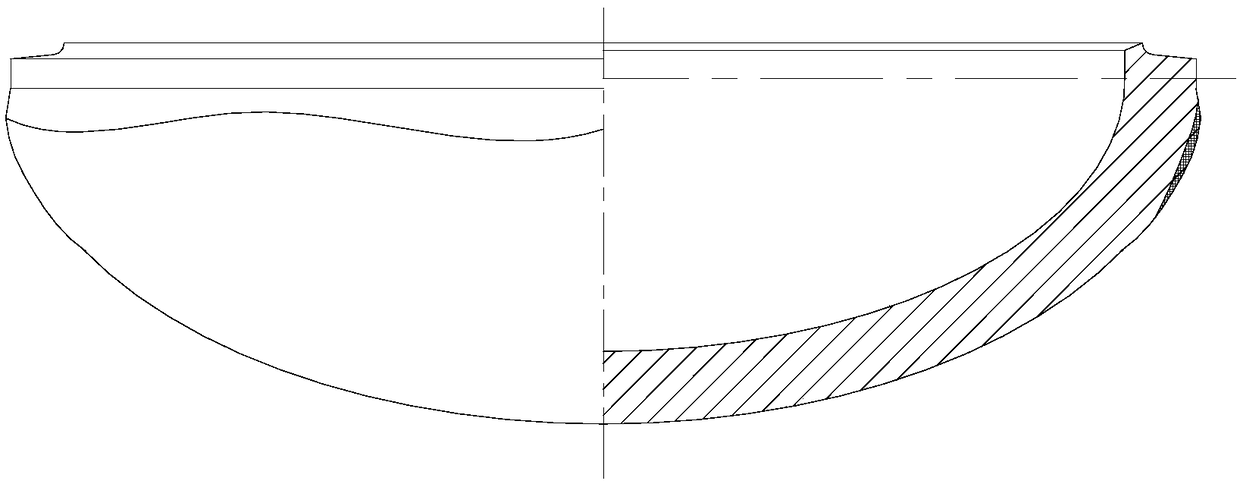

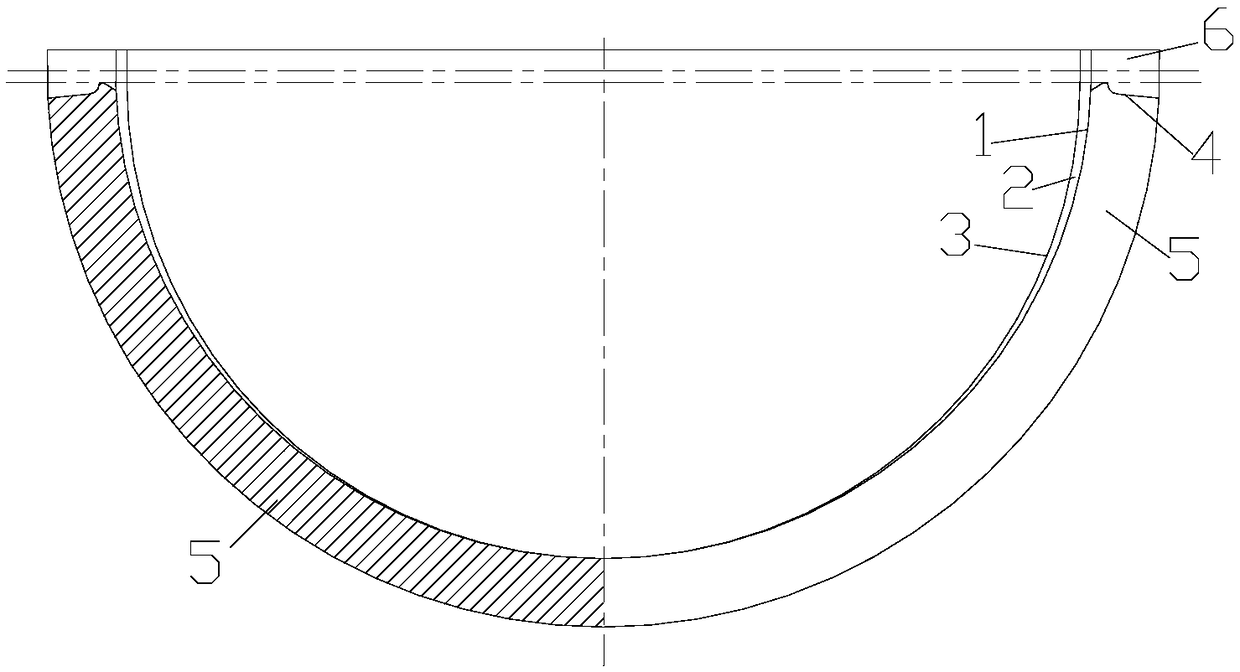

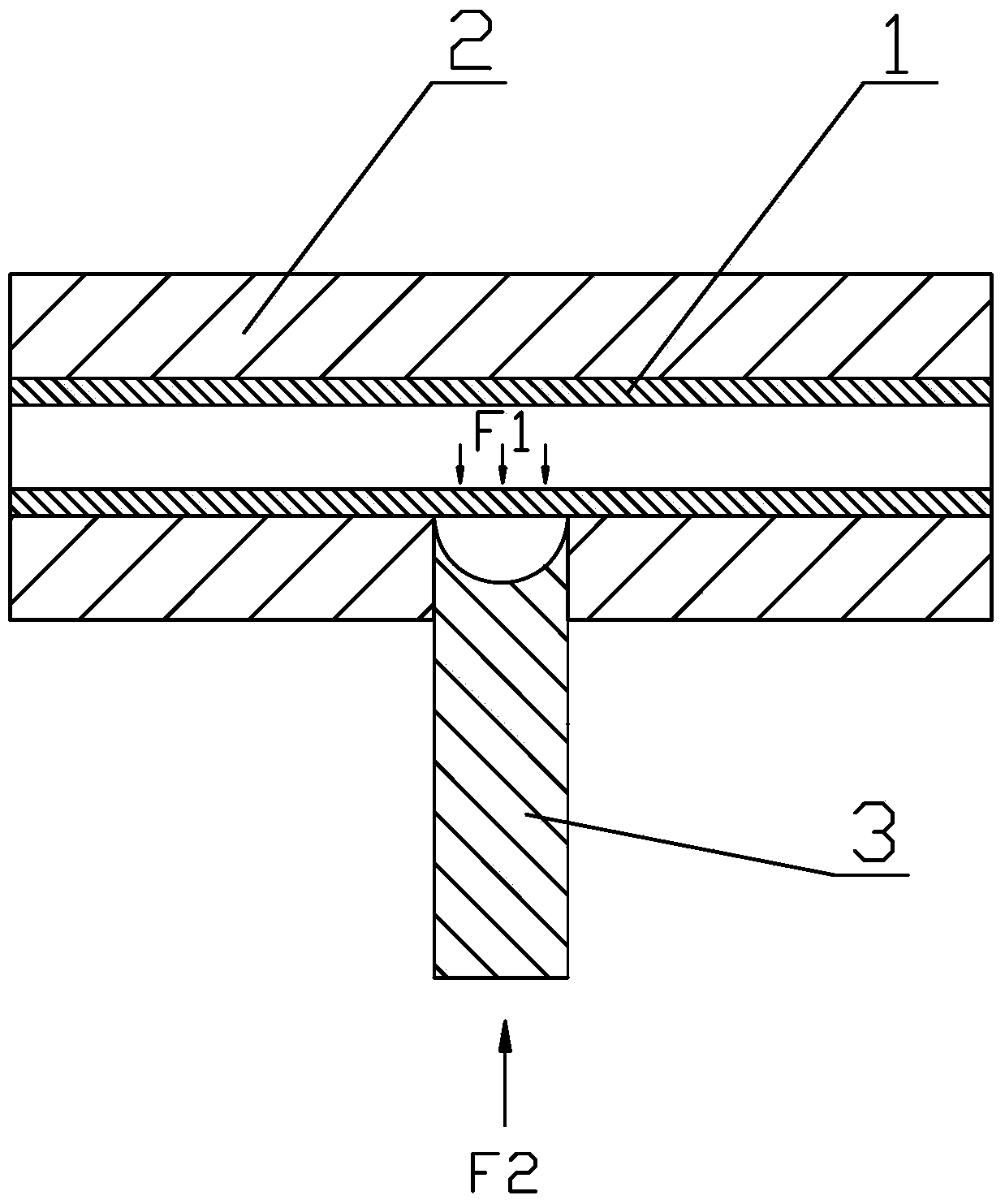

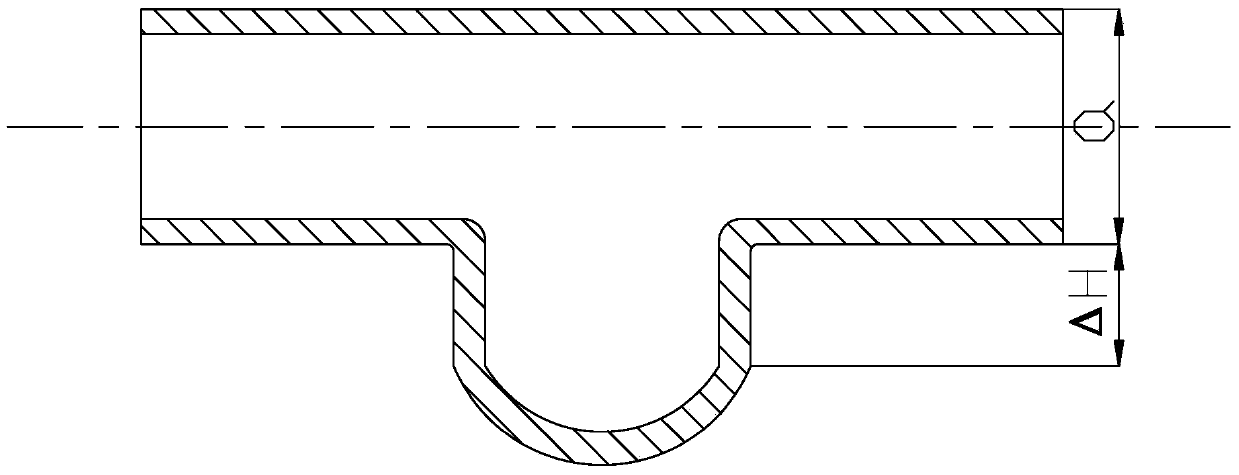

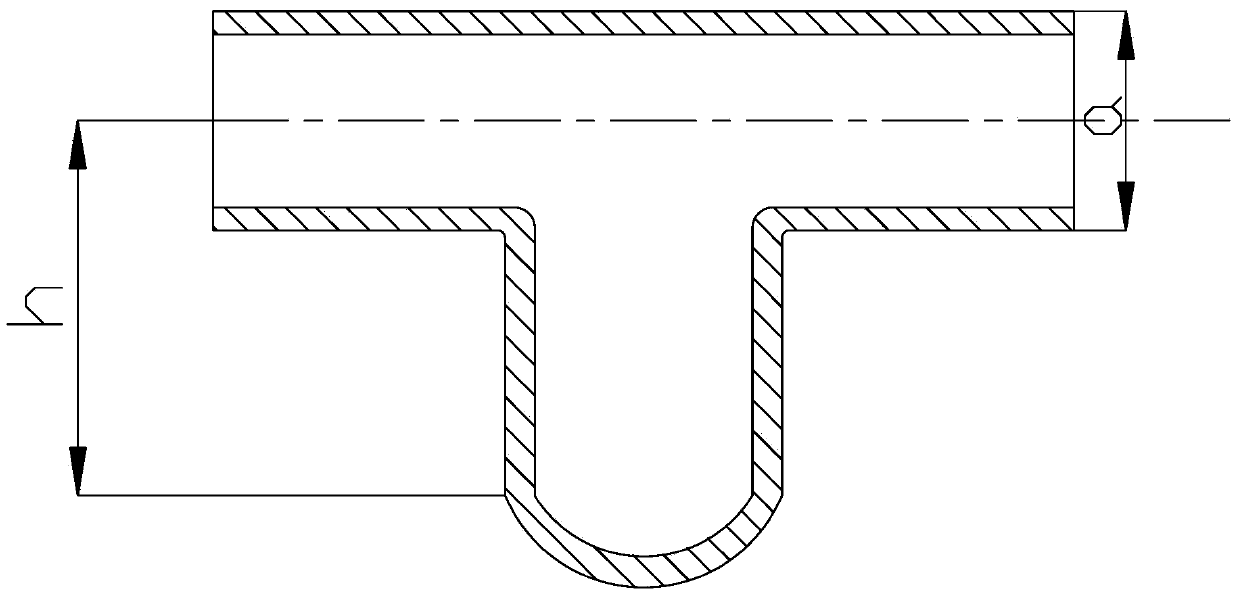

Manufacturing method of pressure-bearing equipment thick-wall seal head structure

The invention provides a manufacturing method of a pressure-bearing equipment thick-wall seal head structure. The problem of the discontinuity of the outer surface due to outer surface and slope machining or transition is solved. The main technological process includes the steps that re-inspection of a steel plate is qualified; workblank blanking is carried out; heating is carried out; a head is hot-pressed; heat treatment is carried out; edging is carried out; the shape and position dimensions of an inner sphere are inspected by a template; turning of a circular seam groove 4 and an inner surface 1 is carried out, and slight turning and finishing for the groove outside surface are carried out; and thickness measuring is carried out. The outer surface of the seal head is smooth and continuous, the ovality of the inner surface after machining is decreased, the size of an internal groove is even, and the inner and outer surfaces of the seal head are of good quality.

Owner:HARBIN BOILER

Hydraulic bulging forming method for colored metal three-way joint

ActiveCN103691795APrevent oxidationReduce or eliminate residual stressAbrasive blastingNonferrous metal

The invention discloses a hydraulic bulging forming method for a colored metal three-way joint. The method comprises the steps of 1, clearing and removing impurities and oil dirt attached to the inner surface and the outer surface of a colored metal pipe blank, and then smearing a lubricating agent on the outer surface of the colored metal pipe blank; 2, selecting a mold, and arranging the colored metal pipe blank with the lubricating agent into a mold cavity of the mold; 3, performing hydraulic bulging forming on the colored metal pipe blank arranged in the mold through a three-way hydraulic machine to obtain a semifinished three-way joint product; 4, performing thermal treatment on the semifinished three-way joint product; 5, repeatedly performing the step 2 and the step 3 on the semifinished three-way joint product subjected to the thermal treatment to obtain a formed piece; 6, performing stress removal thermal treatment on the formed piece; and 7, cutting off a branch pipe plug of the formed piece, then performing groove processing, and finally performing abrasive blasting to obtain a finished three-way joint product. According to the hydraulic bulging forming method disclosed by the invention, oxidization of the colored metal three-way joint in a manufacturing process is effectively prevented, the problems of residual stress and processing hardening in a forming process are alleviated or solved, and the yield of the product is obviously increased.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

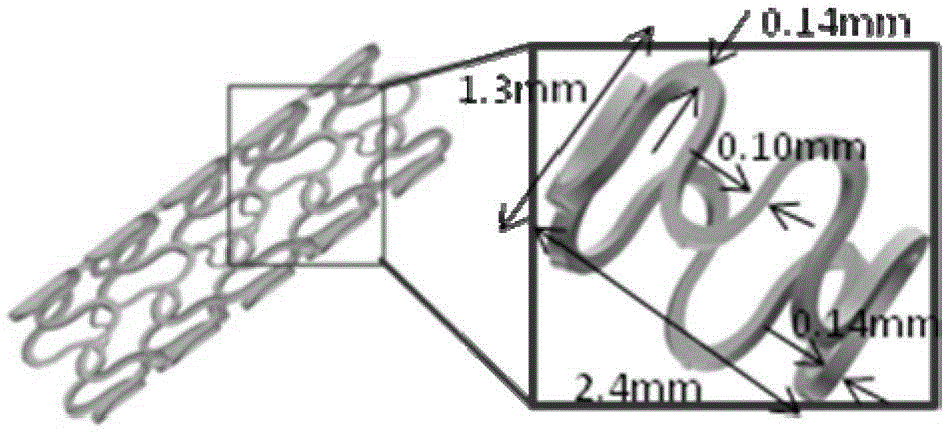

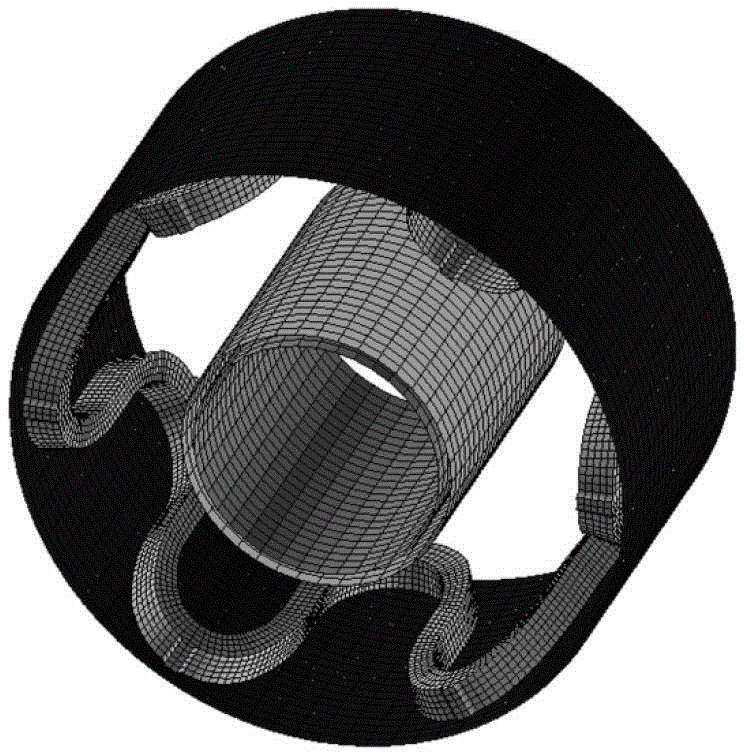

Method for improving usability of biomedical degradable magnesium alloy cardiovascular stent

ActiveCN103334070AEasy to useReduce residual stressSurgeryCardiovascular stentPercent Diameter Stenosis

The invention belongs to the technical field of biological materials and in particular provides a method for improving usability of a biomedical degradable magnesium alloy cardiovascular stent. The method is characterized by comprising the following steps of: firstly pre-press-holding the magnesium alloy cardiovascular stent until the diameter is 1.05-1.25 times the finally press-holding diameter, then carrying out full annealing treatment on the stent, treating the surface of the stent or coating a drug-loading coating after annealing treatment, then continuing press-holding the stent till the preset dimension so that the stent is closely attached to a sacculus and carrying out subsequent packaging and sterilizing. The method has the beneficial effects that the maximum stress of the press-holding expansion process, the residual stress of the stent after press-holding expansion and expansion resilience can be reduced by introducing the annealing process; the stress safety of the stent and the implantation success rate can be improved by reducing the maximum stress; by reducing the residual stress, the stress corrosion tendency and degradation rate of the stent are reduced and the supporting time of the stent is prolonged; and by reducing expansion resilience, the attachment properties of the stent and blood vessels are improved and the probability of vascular restenosis caused by stent implantation is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

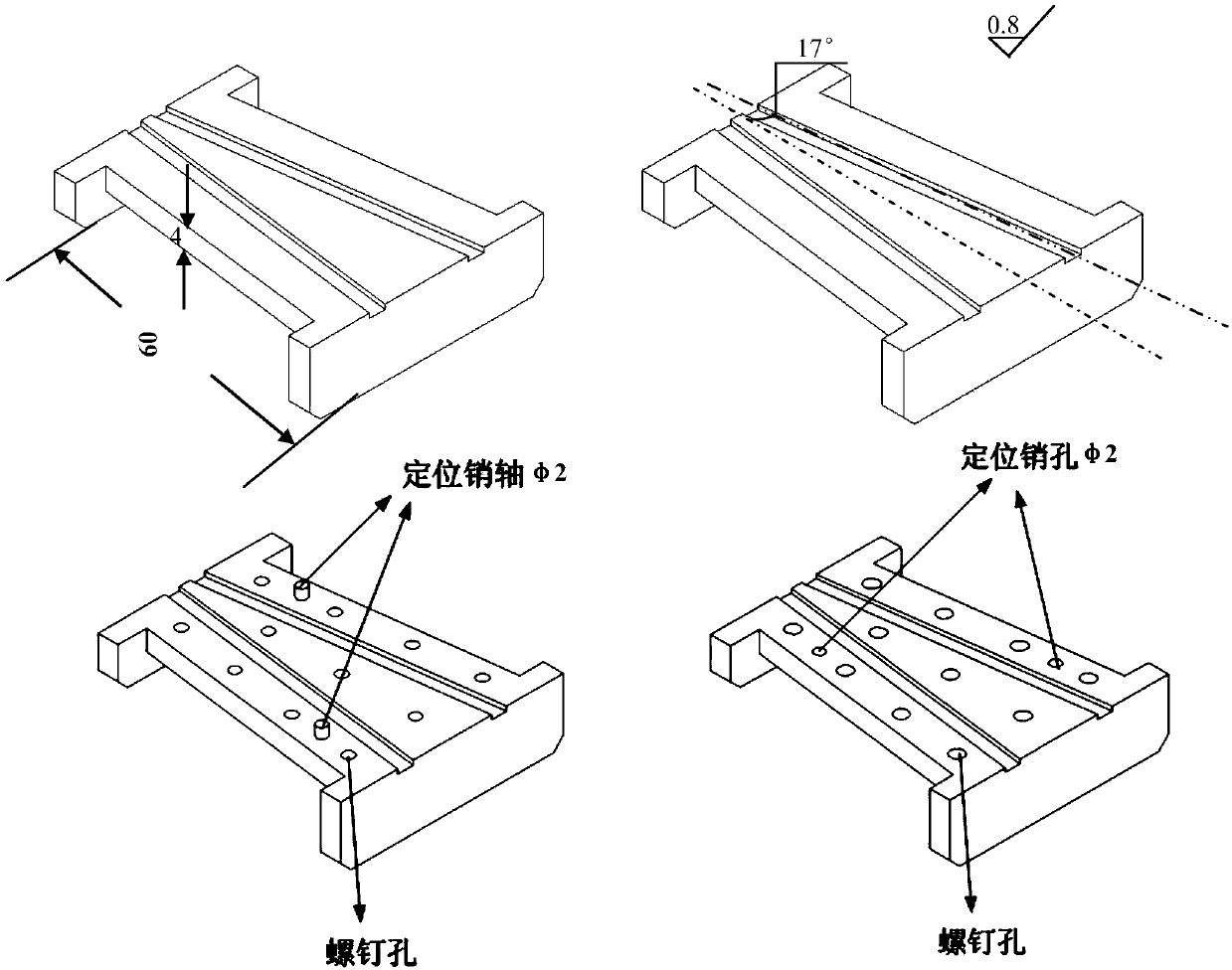

Integral waveguide cavity division machining method

InactiveCN107052709AImprove processing efficiencyReduced processing technology skill requirementsEngineeringWaveguide

The invention relates to an integral waveguide cavity division machining method. According to the method, during machining, an integral structure is firstly divided according to machining features, then multiple divided parts obtained through machining are precisely matched and assembled by pin shafts through locating pin holes in the pin shafts, and the ideal integral waveguide cavity part method is obtained.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

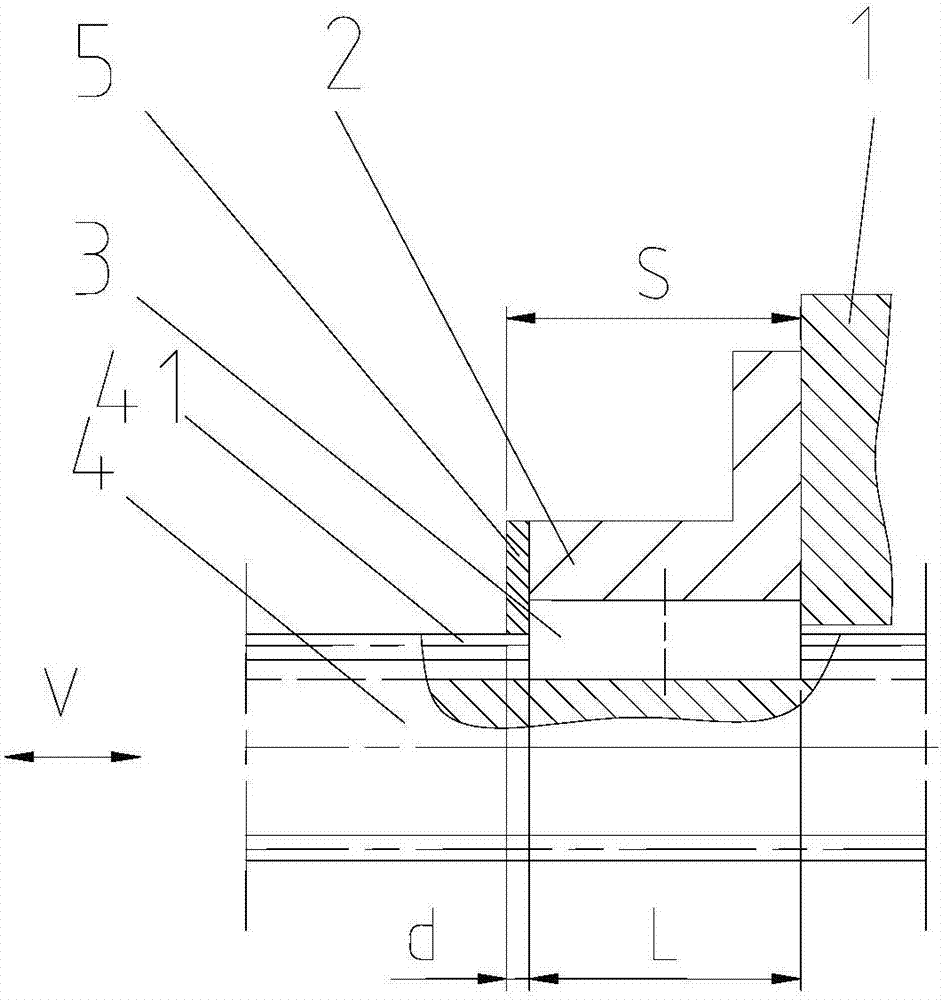

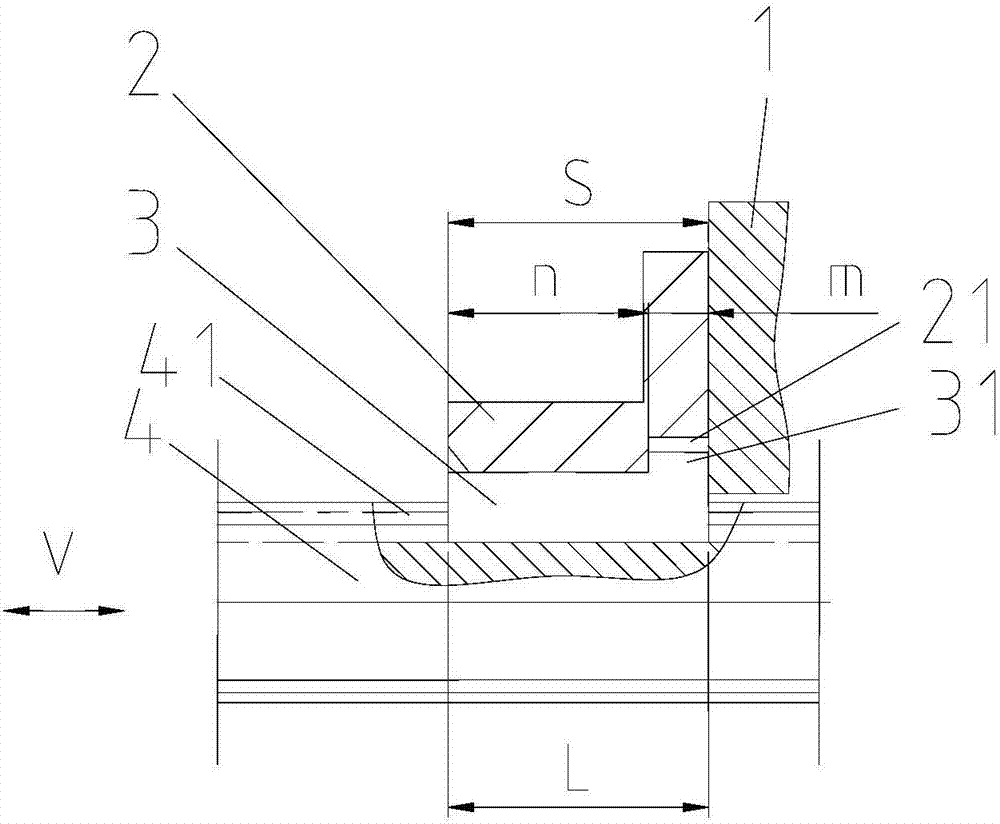

Lifter screw rod rotation-stopping structure

The invention discloses a lifter screw rod rotation-stopping structure, which comprises an end cover and a sliding key. The end cover is fixedly connected onto a machine base; a screw rod is provided with a sliding chute; the end cover is provided with the sliding key; the lower end of the sliding key is in sliding fit to the sliding chute; the upper end of the sliding key is embedded into the end cover so as to stop rotation; a sliding key shoulder part is arranged at the upper side of the right end of the sliding key; a groove matched with the sliding key shoulder part and used for inserting the sliding key shoulder part is formed in a position, corresponding to the sliding key shoulder part, on the end cover; the left end face of the sliding key shoulder part presses against the groove, and the right end face of the sliding key shoulder part presses against the machine base, so that the sliding key is positioned in a screw rod movement direction; and the upper end face of the sliding key presses against the end cover, and the lower end face of the sliding key presses against the sliding chute, so that the sliding key is positioned in a radial direction.

Owner:BEIJING XINLI MACHINERY

Method for rapidly manufacturing mold through 3D printing materials

InactiveCN105499562AFast preparationReduce manufacturing costAdditive manufacturing apparatusFoundry mouldsThin shellsMaterials science

The invention relates to a method for rapidly manufacturing a mold through 3D printing materials. The method includes the following steps that (1) a mold model is designed through CAD; (2) the CAD mold model is designed into a thin shell model; (3) a fixing part is arranged on the thin shell model of the mold, and then a mold cavity is printed through a 3D printing device; (4) an upper mold core is machined through a CNC; (5) the mold cavity and the upper mold core are fixed to a standard mold frame; (6) the back face of the mold cavity is filled with sand for solidification; (7) a cover plate is installed on the back face of the mold cavity and fixed to the standard mold frame through a first connecting piece; and (8) mold manufacturing is completed. According to the method, the mold can be rapidly manufactured, the production time is saved, the efficiency is improved, and the production cost is reduced.

Owner:东莞裕元模具有限公司

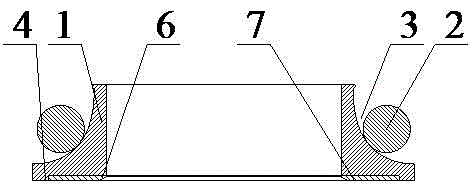

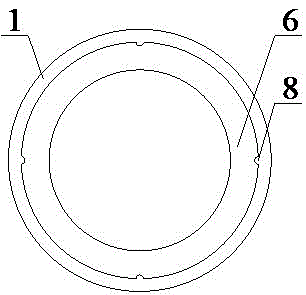

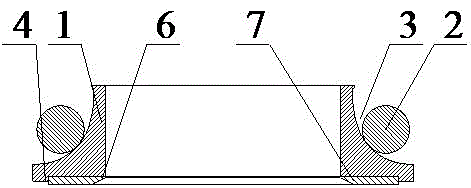

Floating oil seal with ceramic composite wear-resisting face and metal stamping ring bodies

InactiveCN105387215AImprove wear resistanceExtended service lifeEngine sealsCeramic compositePhase state

The invention provides a floating oil seal with a ceramic composite wear-resisting face and metal stamping ring bodies. The floating oil seal comprises the pair of sealing ring bodies of up-down symmetrical structures. The working face of each sealing ring body is provided with an annular groove used for containing a sealing face. The sealing ring bodies are formed through metal stamping. A circle of wear-resisting belt is fixedly assembled in a wear-resisting belt assembly groove. The wear-resisting belt is made of metal materials added with ceramic powder which is distributed in a dispersed phase state. The addition quantity of the ceramic powder is not larger than 5% of the total mass of the metal materials. The wear face of the wear-resisting belt is located on the same plane as the working faces of the sealing ring bodies or protrudes out relative to the working faces. According to the floating oil seal, the wear resistance degree of the working faces can be effectively improved, the service life can be prolonged, machining is easy, and the production cost is low.

Owner:李纯

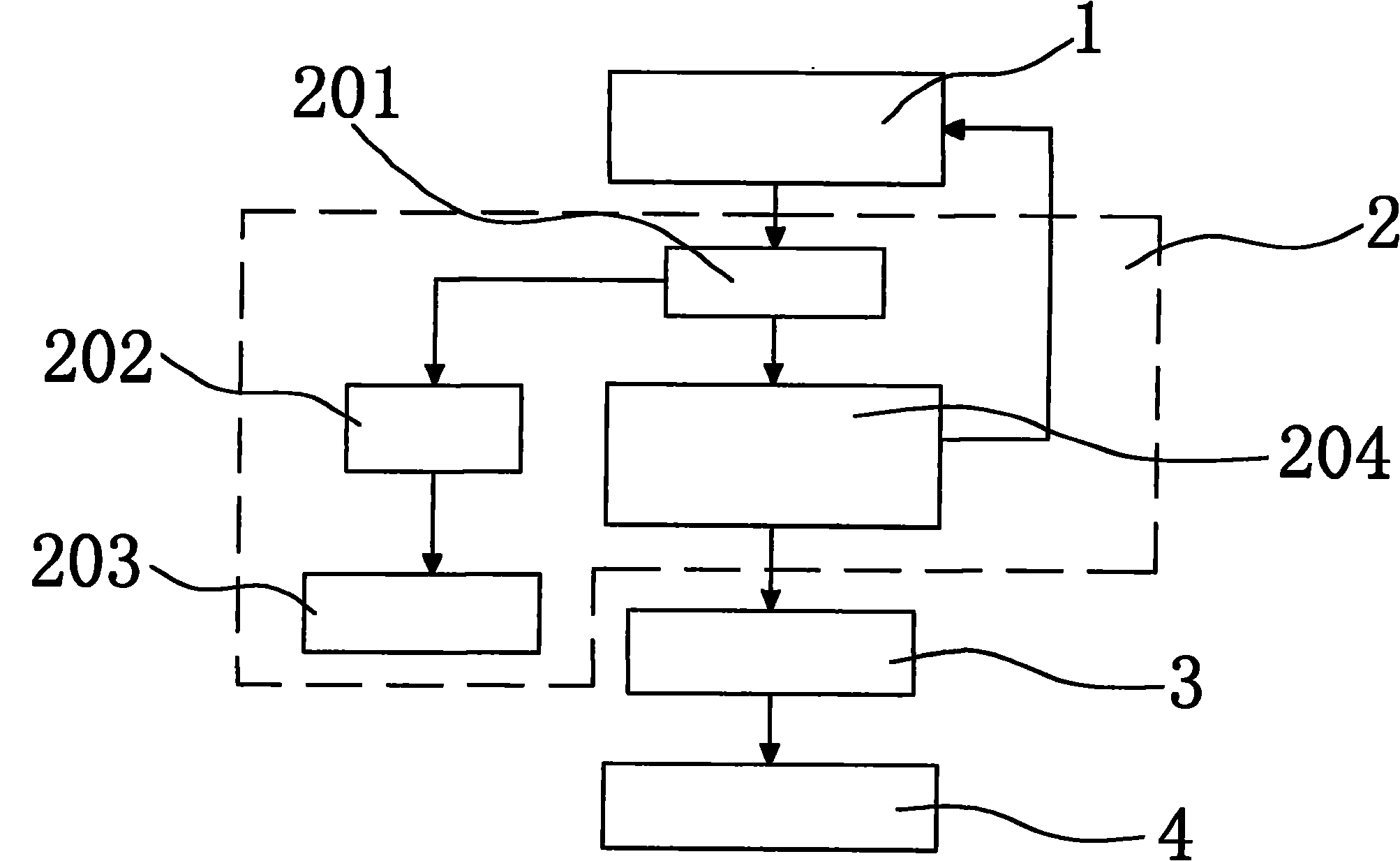

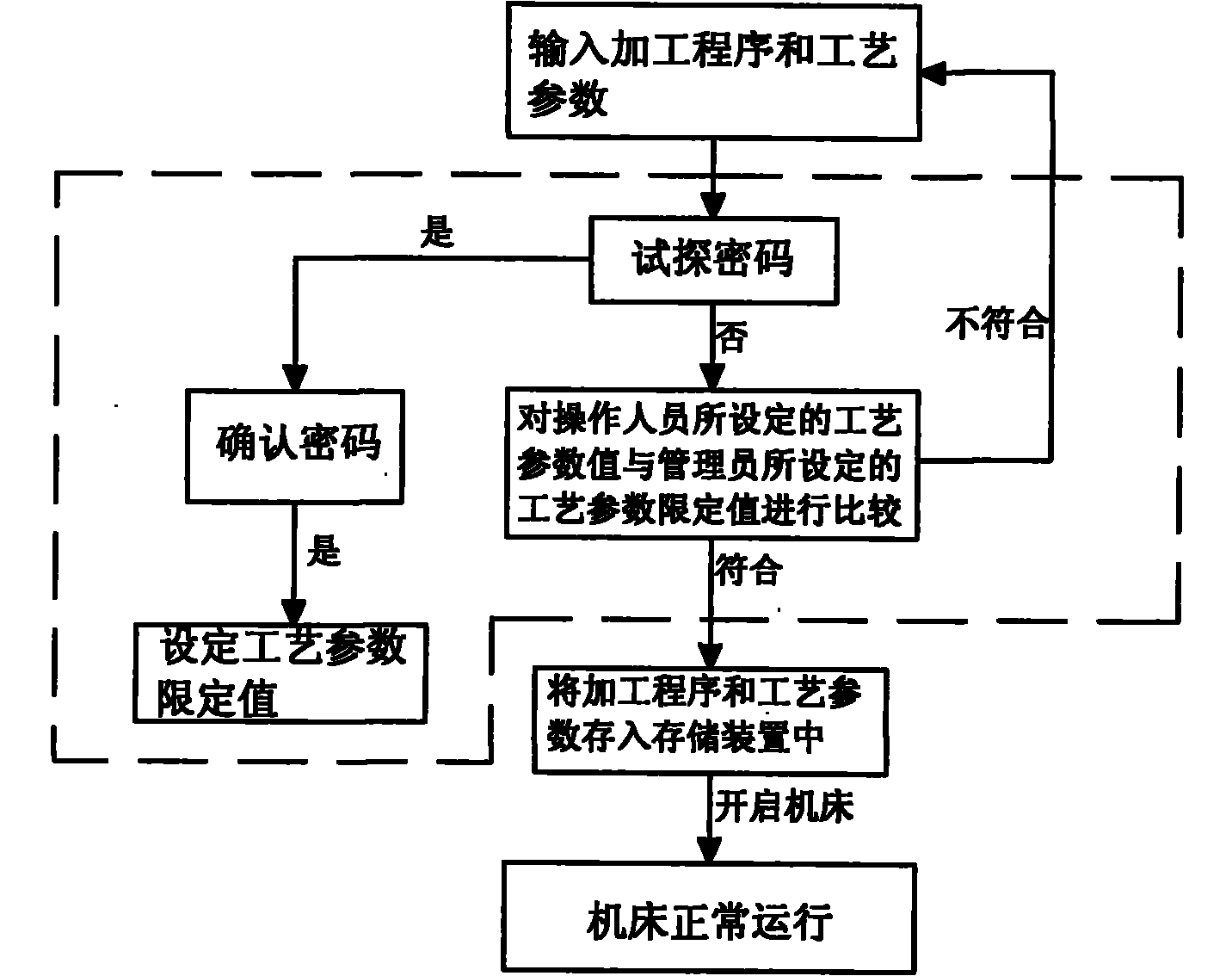

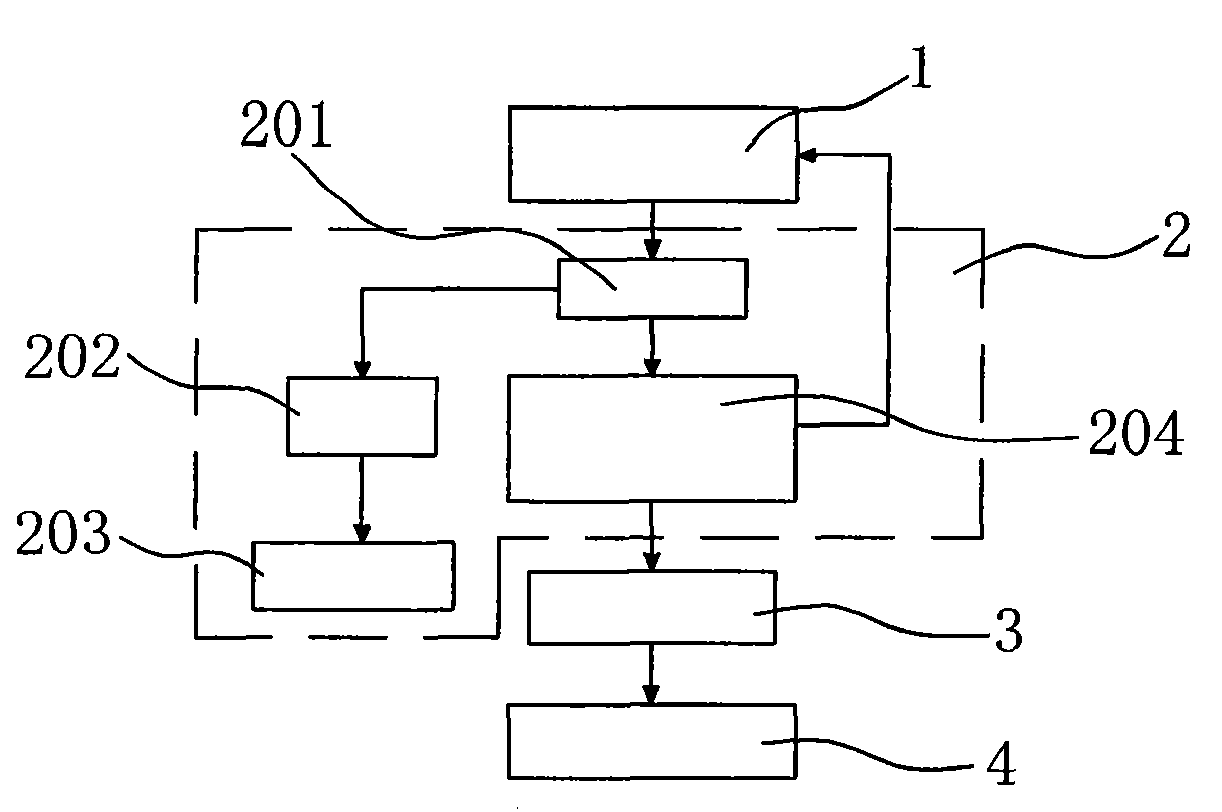

Bearing outer ring raceway grinding monitoring device

InactiveCN101887253AEliminate processabilityPut an end to craftProgramme controlComputer controlPasswordEngineering

The invention relates to a bearing outer ring raceway grinding monitoring device, which is designed in order to solve the technical problem of uneven machining quality of a product existing in a conventional machine tool because the machining procedure and technological parameters can be freely mastered by an operator. The design points are that: the main body of the bearing outer ring raceway grinding monitoring device is a programmable controller; and the programmable controller is provided with a password heuristic program, a password setting program, a technological parameter limit value setting program and a technological parameter value and technological parameter limit value comparison program. An input end of the bearing outer ring raceway grinding monitoring device is connected with a machining procedure and technological parameter setting device of the machine tool, while the output end is connected with a machining procedure and technological parameter storage device of the machine tool. The device has a simple structure, is convenient to use and operate, effectively prevents the operator from maliciously setting the machining procedure and the technological parameter of the machine tool, improves the machining quality of the product and is suitable to be installed on various machine tools of the same type.

Owner:田建军

Short-process and zero-drainage production method of refining industrial hemp

The present invention relates to a short-process and zero-drainage production method of refining industrial hemp. The scutched hemp is subjected to drafting, purification and carding processing through a jute garnett and a continuous carding machine and is subjected to one-bath degumming, bleaching and softening processing through a successive cylinder without water drainage; the degumming and thebleaching are performed in the same bath, the bath ratio is 1:5-20, the bleaching temperature in the high-temperature and the high-pressure bleaching cylinder is 98-135 DEG C, and the bleaching holding time is 5-60 minutes; the one-bath processing of the degumming and the bleaching is performed for 2-3 times; the scutched hemp is subjected to degumming and the bleaching, then drying, softening processing through the successive cylinder without water drainage, and microwave drying or low-temperature drying after the softening processing to become a finished product. The whiteness of the refining industrial hemp is larger than 60%, the separation degree of the industrial hemp raw materials below 36 Nms after processing is larger than 1500, and the separation degree of the industrial hemp raw materials above 36 Nms after processing is larger than 2000. The short-process and zero-drainage production method of refining industrial hemp can be directly used for fiber blending such as cotton,tel tencel, modal, mucilage glue and wool to manufacture blended yarns containing hemp.

Owner:苏州麻朵纺织科技有限公司 +1

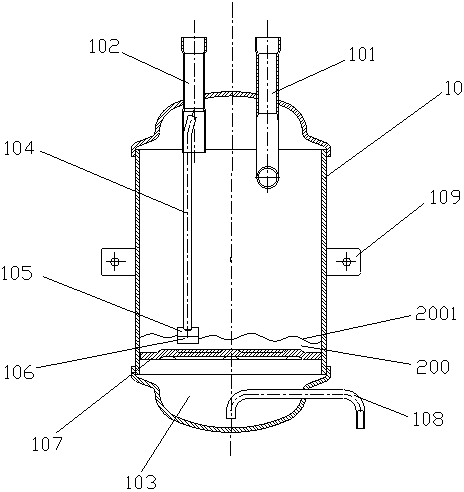

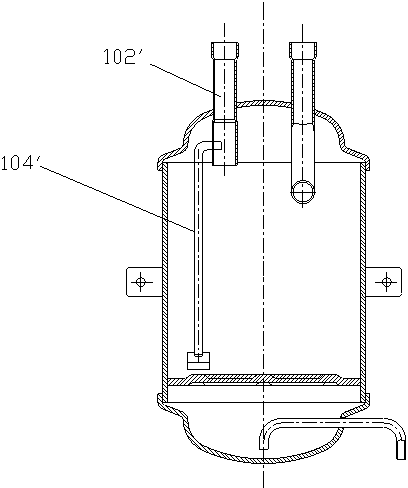

Gas/liquid separator

ActiveCN103307821AEliminate processabilityOmit fixationRefrigeration componentsVapor–liquid separatorEngineering

A gas / liquid separator includes a cylinder body, a gas separation inlet pipe and a gas separation outlet pipe both arranged at the top of the cylinder body, and an oil storage zone arranged at the bottom of the cylinder body, as well as an oil suction pipe with the diameter smaller than that of the gas separation outlet pipe, wherein one end of the oil suction pipe is placed in the oil storage zone, and the other end of the oil suction pipe extends into the gas separation outlet pipe; and a filter pipe is further arranged on the pipeline of the oil suction pipe. In the gas / liquid separator, the gas separation inlet pipe and the gas separation outlet pipe as well as the oil suction structure are directly formed through two straight pipelines, the complicated processing of a U-shaped pipe and a fixing part are left out, the design is simple and the function is reliable.

Owner:ZHEJIANG DUNAN COLD CHAIN SYST

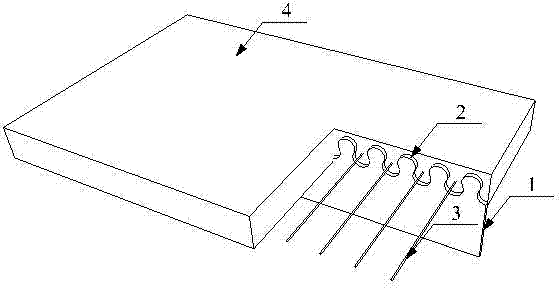

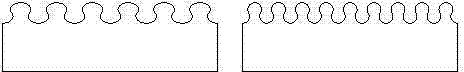

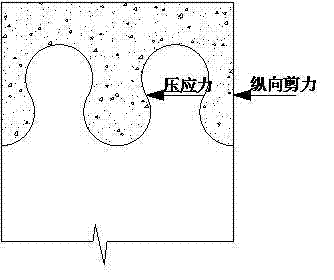

Serrated steel-concrete shear connector

InactiveCN104120794AChange definitionEliminate processabilityBuilding constructionsNumerical controlArchitectural engineering

The invention provides a serrated steel-concrete shear connector, and belongs to the field of civil engineering structural engineering. The serrated steel-concrete shear connector comprises a steel web, and streamline-shaped serrated shear connectors are formed by cutting operation at the top end of the steel web through a numerical control machine tool. The serrated steel-concrete shear connector comprises the serrated shear connectors, the serrated shear connectors are located on the steel web, and the serrated shear connectors are basically respectively of a streamline shape. The serrated steel-concrete shear connector comprises shear reinforcements which are arranged between the adjacent serrated shear connectors, one or more shear reinforcements can be arranged at the interval between every two adjacent serrated shear connectors, and the shear reinforcements are vertically located at inflection points of cutting lines. The serrated steel-concrete shear connector comprises concrete, the concrete is poured in a closed space formed by formworks and the steel web, and the shear reinforcements and the serrated shear connectors need to be poured into the concrete. The serrated shear connectors are innovatively directly arranged on the steel web, the machining, manufacturing and construction processes of traditional shear connectors are omitted, construction is convenient and quick, and connecting transmission between steel and concrete is reliable and effective.

Owner:TONGJI UNIV

Cable and plate dam

InactiveCN1680663ASuperiorLess material consumption for dam constructionBarrages/weirsWater flowEngineering

The invention consists of back guy and board. The back guy and board both are made of high tensile strength material. Both ends of back guy are anchored at the mountain body beside the river. The board is fixed on the back guy, and its bottom and broadside is building in riverbed and rock mass beside river by using cement concrete or mortar. With the invention, the dam can be built from top to bottom, and construction can not be influenced by water flow of river.

Owner:CHINA THREE GORGES UNIV +2

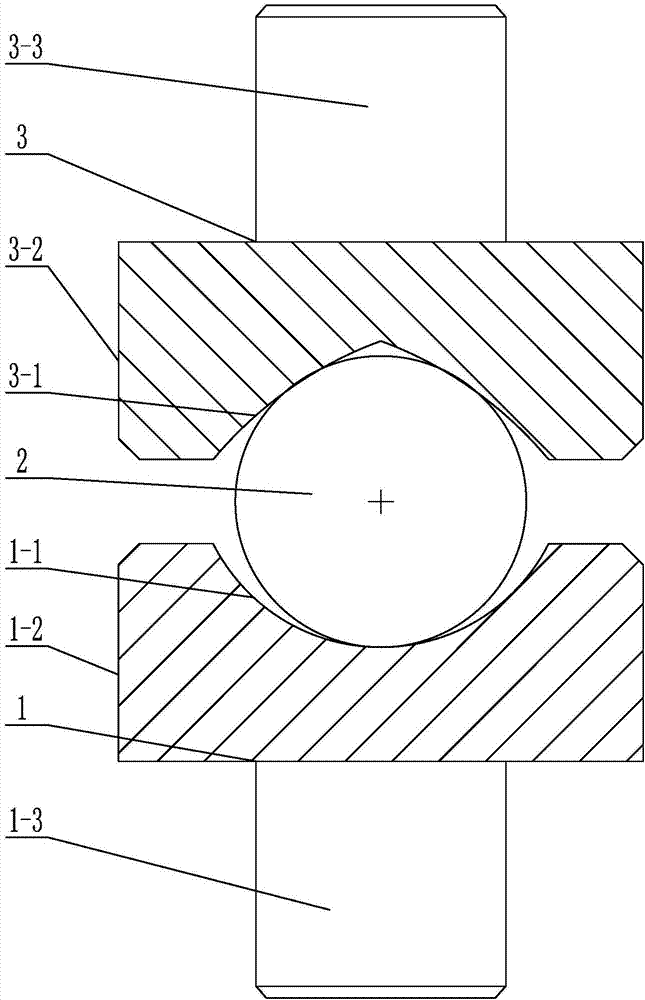

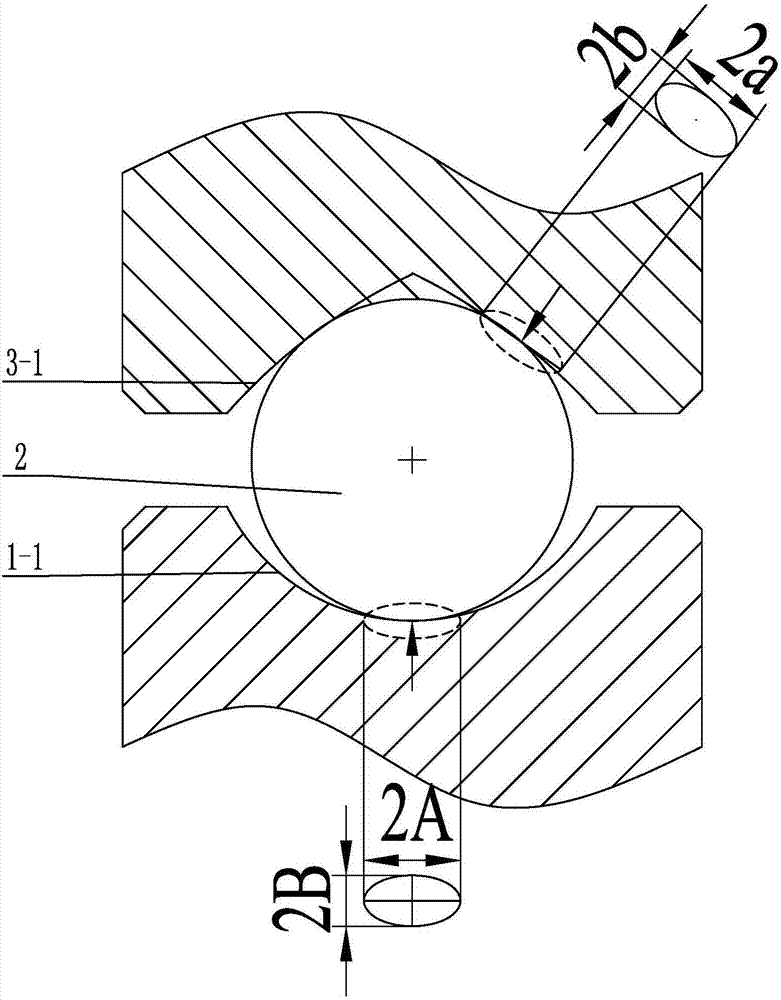

Gothic groove supporting device of mass center measurement equipment

InactiveCN107356371AReduce lateral forceHas full positioningStatic/dynamic balance measurementBiochemical engineeringMass center

The invention relates to a Gothic groove supporting device of mass center measurement equipment, relates to the measurement technology field and solves a problem of influence on measurement accuracy caused by poor stability of a supporting device of mass center measurement equipment in the prior art. The Gothic groove supporting device comprises a lower supporting body, a ball body and an upper supporting board which are sequentially arranged from up to down, the middle portion of an upper end surface of the lower supporting body is provided with a spherical groove, the middle portion of a lower end surface of the upper supporting body is provided with a groove in the horizontal direction, the groove bottom of the groove is a tip end, two side groove walls of the groove are arc-shaped structures, and the ball body is arranged between the spherical groove and the groove. The Gothic groove supporting device is applicable to object mass center measurement.

Owner:HARBIN INST OF TECH

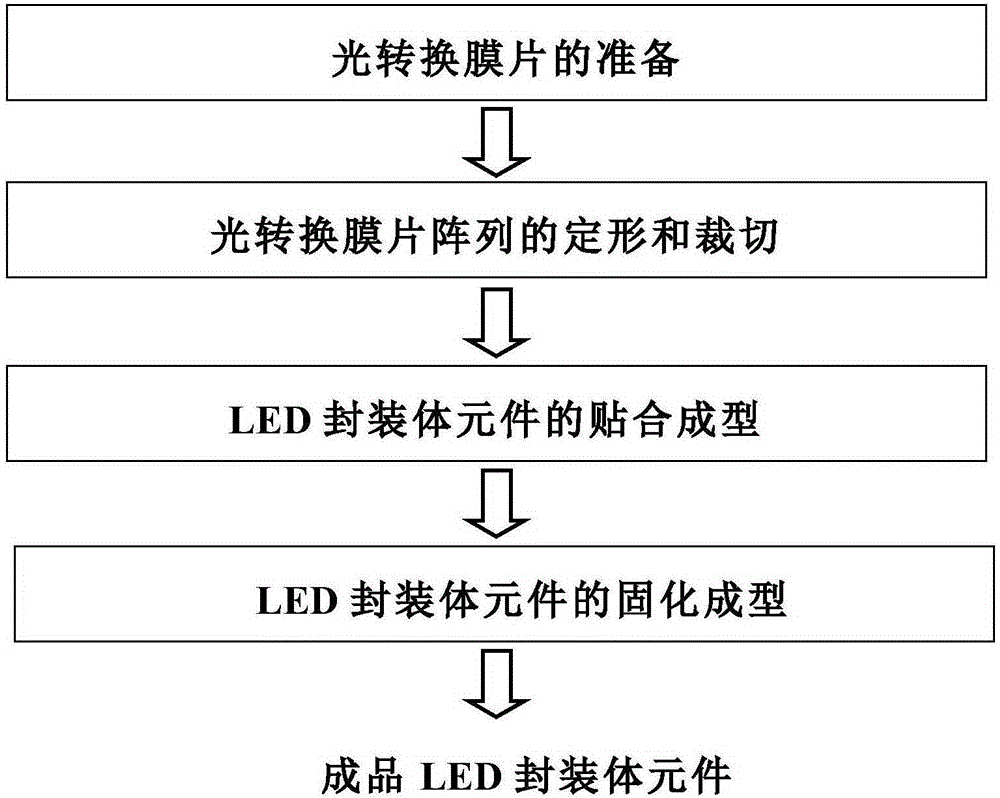

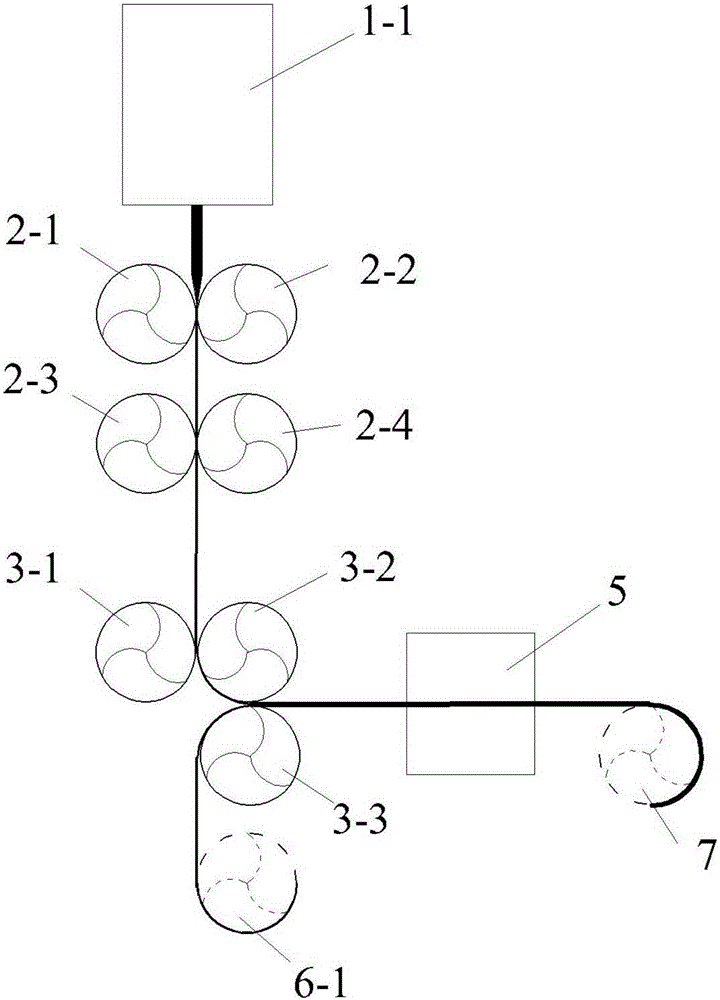

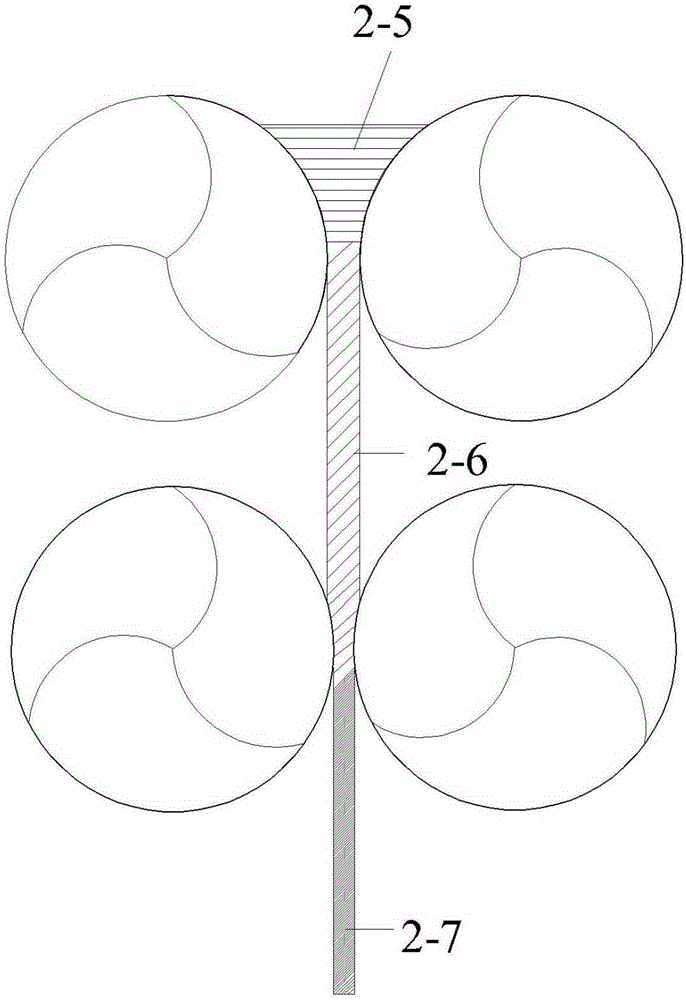

Equipment system for laminating and packaging LED based on rolling type thermoplastic resin light conversion body

ActiveCN106469774AOvercoming light extraction efficiencyOvercome the excellent rateSemiconductor devicesProcess equipmentMechanical engineering

The invention relates to an equipment system for laminating and packaging an LED based on a rolling type thermoplastic resin light conversion body. The characteristics lie in that the equipment system comprises a collaborative rolling shape-fixing and cutting device used for performing rolling shape-fixing and rolling cutting on a light conversion diaphragm so as to form a light conversion diaphragm array and a rolling laminating device used for laminating the light conversion diaphragm array and an LED flip chip array; the collaborative rolling shape-fixing and cutting device and the rolling laminating device sequentially form collaborative linkage process equipment; the collaborative rolling shape-fixing and cutting device comprises a rolling device 1 with a bump array and a rolling device 2 with a groove array which are oppositely arranged in an aligned manner; and the rolling laminating device comprises a rolling device 4 with a groove array and a rolling device 3 with the rolling surface being a smooth surface which are oppositely arranged in an aligned manner. The equipment system meets requirements of a technological method suitable for laminating and packaging the LED based on the thermoplastic resin light conversion body, so that the production efficiency and the superior quality product rate of industrial batch LED packaging are improved.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

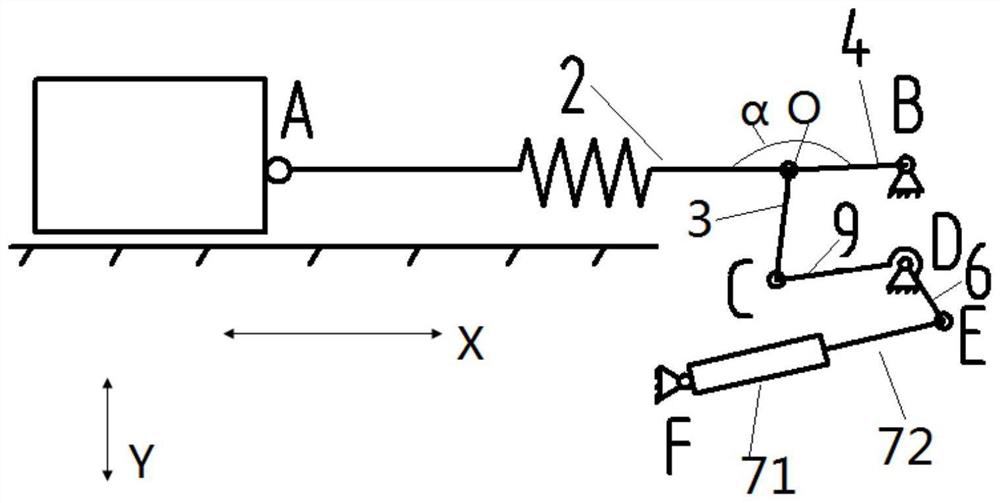

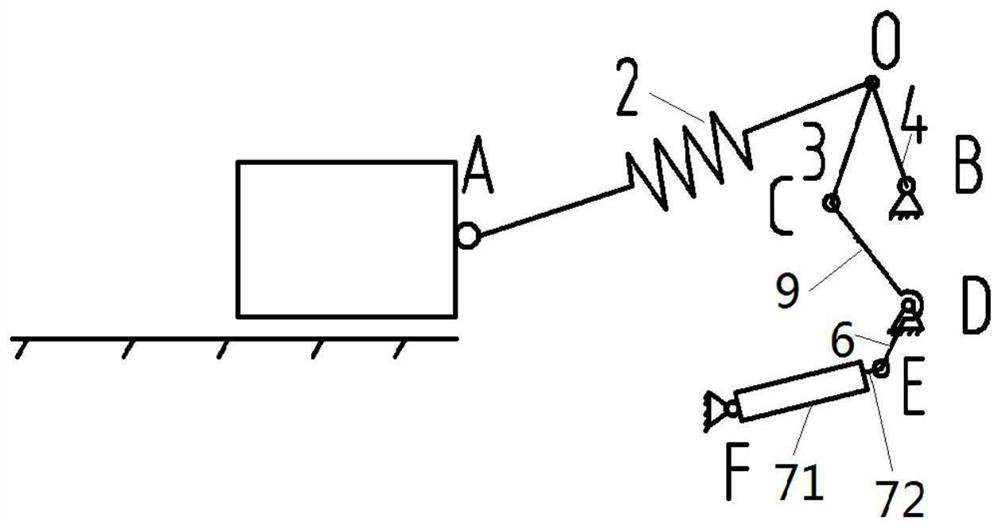

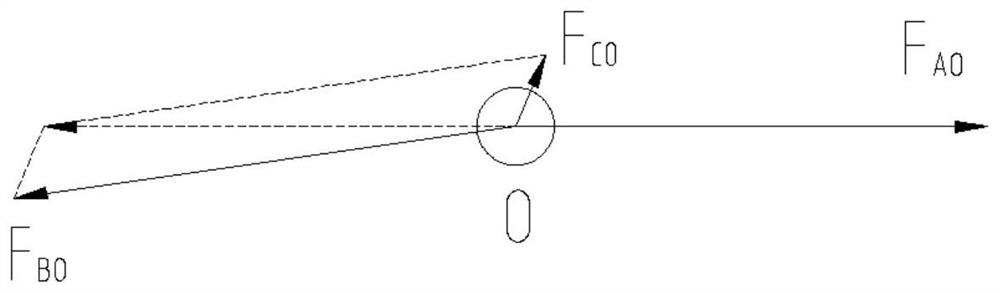

Electric car coupler pushing device

The invention provides an electric car coupler pushing device. The electric car coupler pushing device is mainly used for driving the normal coupling and separation of an electric car coupler, so as to complete the coupling and communication between two vehicles. The electric car coupler pushing device comprises a supporting frame (8), a driving mechanism (7), a transmission mechanism and a supporting arm (2), wherein the driving mechanism (7) comprises a fixing part (71) and a telescopic part (72) which are borne on the supporting frame (8), and the telescopic part can extend or retract fromthe fixing part (71) according to the different working states of the electric car coupler; the transmission mechanism is connected with the telescopic part (72); and one end of the supporting arm (2)is rotatably connected with the electric car coupler at a first shaft point (A), the other end of the supporting arm (2) is rotatably connected with the transmission mechanism at a second shaft point(O), and the transmission mechanism is arranged as that when the telescopic part (72) extends out from the fixing part (71), the second shaft point (O) moves to the direction of the side of the driving mechanism (7), and pushes the electric car coupler to a coupling position.

Owner:QINGDAO SRI TECH CO LTD

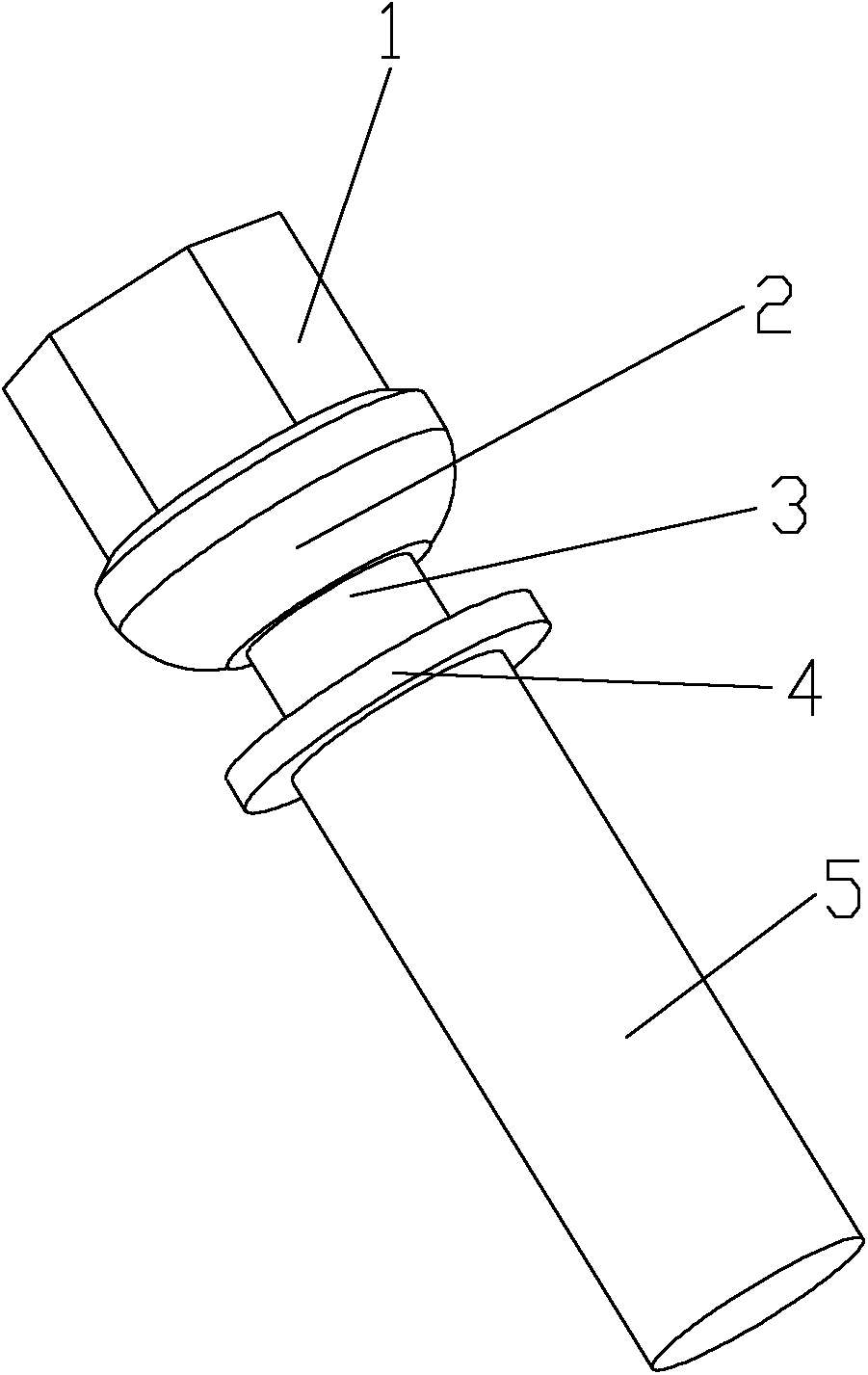

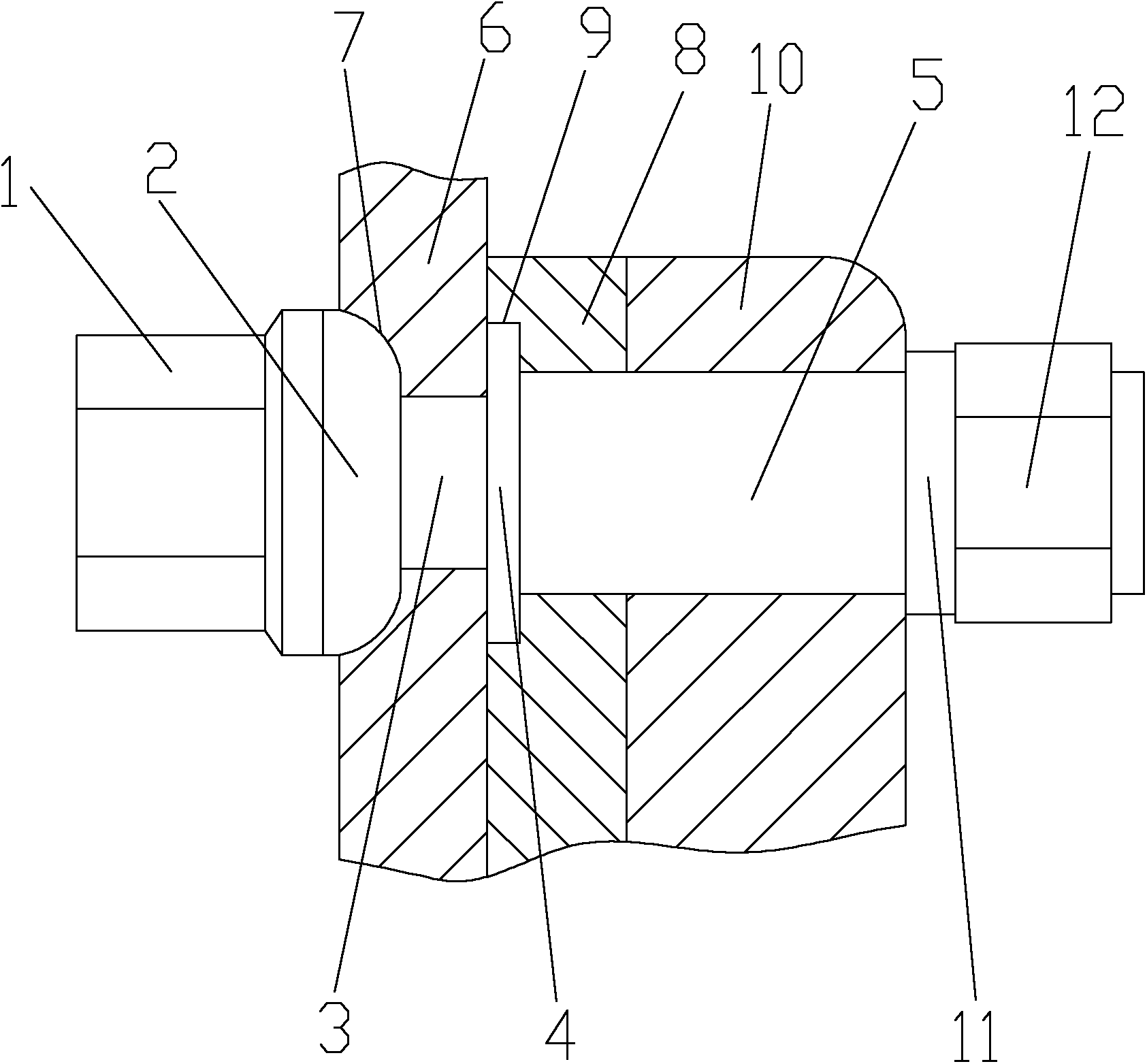

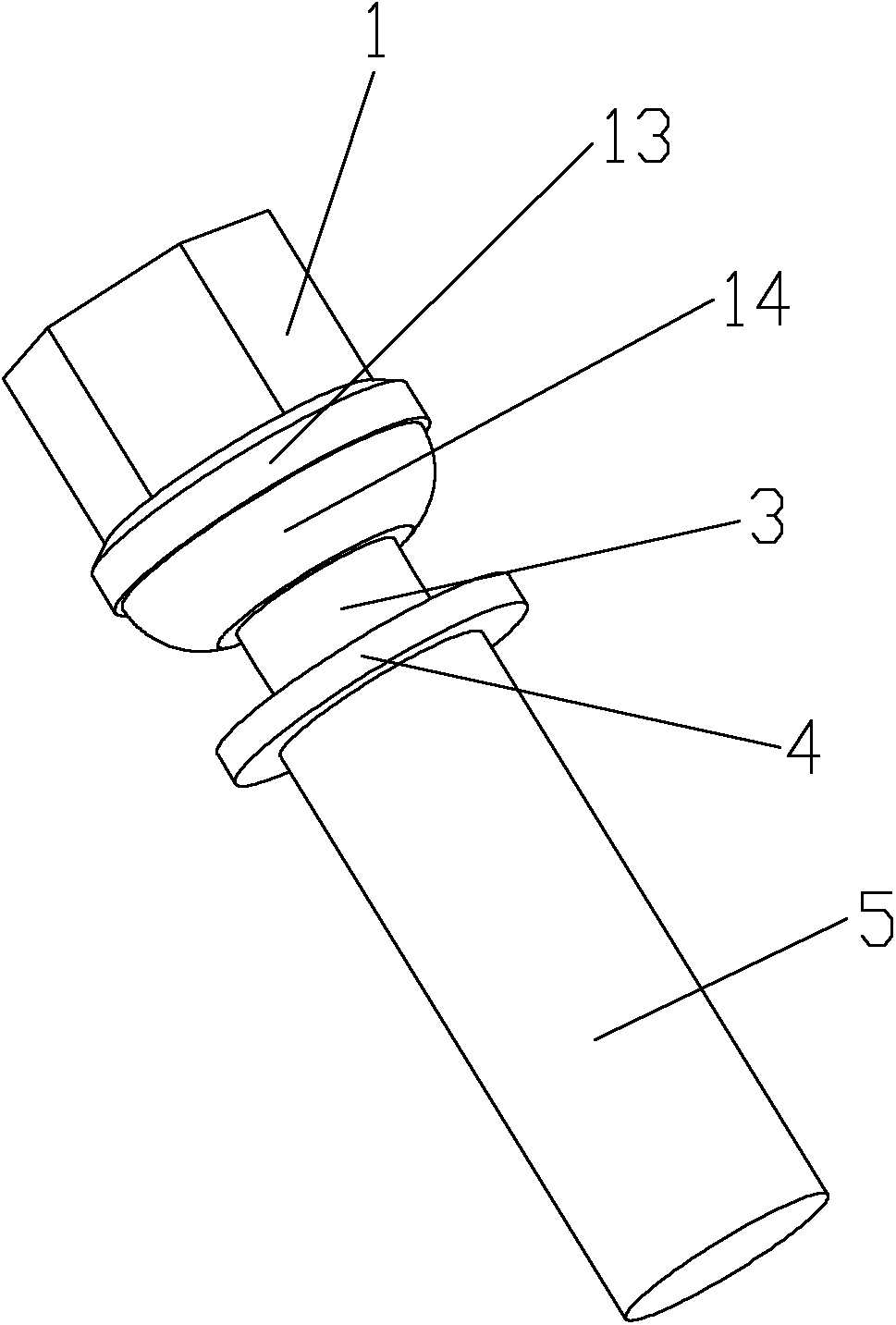

Rim bolt

The invention discloses a rim bolt, comprising a bolt body, wherein the bolt body is formed in a way that a bolt head, a first step, a first screw rod, a second step and a second screw rod are sequentially connected; the first screw rod is provided with a spherical elastic washer; the spherical elastic washer is located below the first step; and the spherical elastic washer is a spherical rubber washer; in the use process of the rim bolt provided by the invention, the spherical elastic washer can be automatically centered when in contact with a spherical concave surface of the rim so as to guarantee the fully contact with the spherical concave surface of the rim and remove the processing or assembling error; the rim bolt has good anti-loosening performance, guarantees the connection reliability, and improves the use performance of a wheel type loader.

Owner:SUZHOU MAIDER MACHINERY

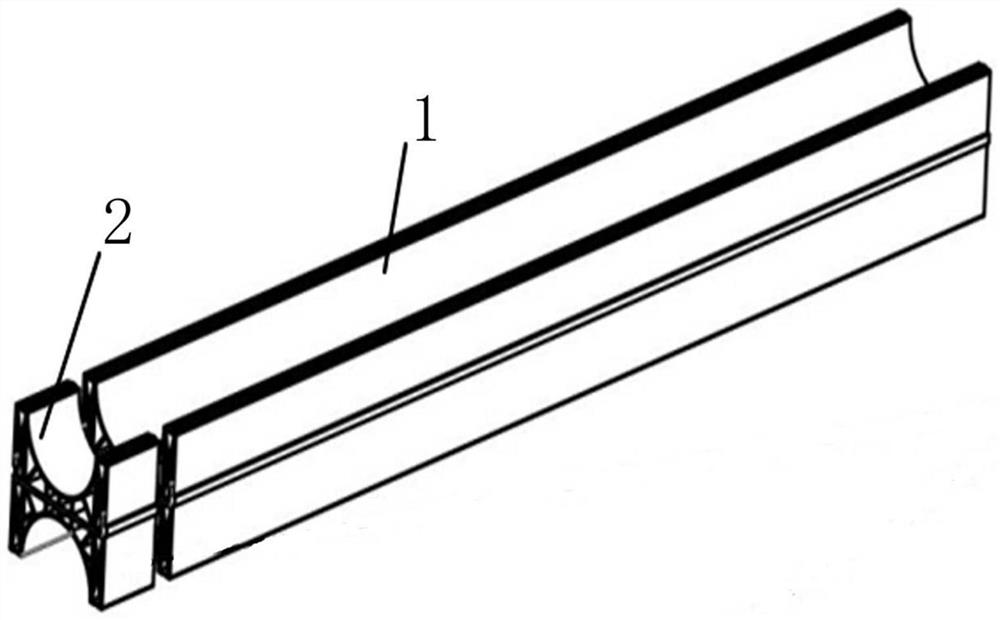

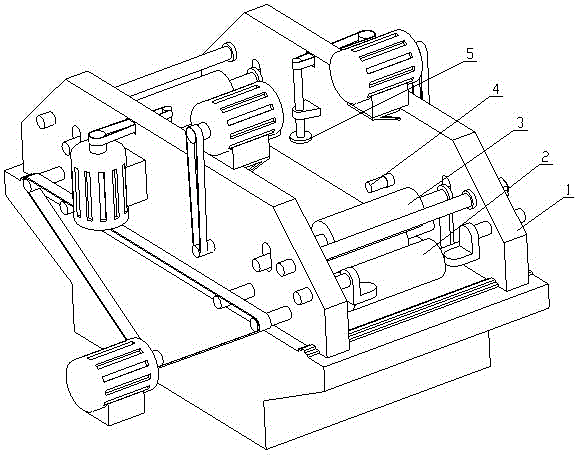

Preparation process of pultrusion composite material modularized gas cylinder support

The invention discloses a preparation process of a pultrusion composite material modularized gas cylinder support. The preparation process comprises the following steps that a uniform-section long-rod-shaped gas cylinder support module raw material is obtained through pultrusion of composite material, low-cost large-scale production is achieved, a gas cylinder support module, a module base and a module top cover can be obtained through simple cutting, the gas cylinders are arranged and assembled according to the requirement of a vehicle for the number of the gas cylinders, so that the production work of the gas cylinder support can be realized, the gas cylinders with different numbers can be assembled in different forms, the design and processing links of the traditional steel gas cylinder support are omitted, the production cycle is greatly shortened, the production cost is reduced, and the production efficiency is improved.

Owner:AVIC COMPOSITES

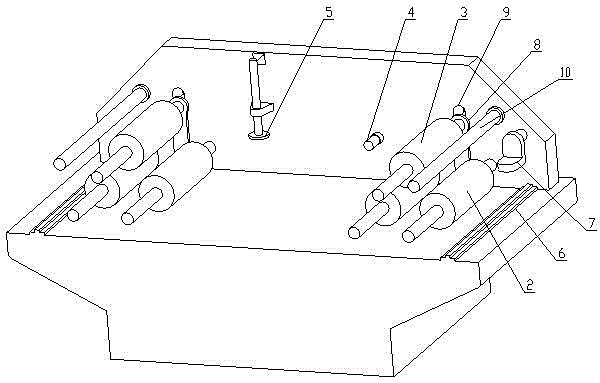

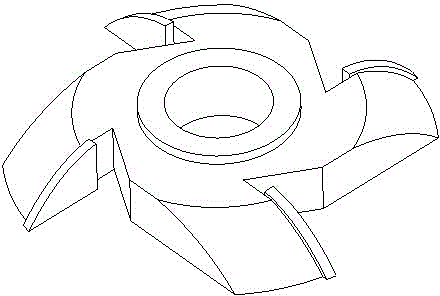

Wood floor chase mortise machining device

InactiveCN104476634AEasy to processHigh precisionWood mortising machinesWood slotting machinesMechanical engineeringMachining

The invention discloses a wood floor chase mortise machining device. The wood floor chase mortise machining device comprises a machine body (1), a conveying roller (2), a pressing roller (3), a first cutter (4) and a second cutter (5), wherein the conveying roller (2) is arranged at the lower part of the machine body (1), the pressing roller (3) is arranged at the upper part of the machine body (1) and is located above the conveying roller (2), the first cutter (4) is arranged at the middle part of the machine body (1) and is located at a horizontal position between the conveying roller (2) and the pressing roller (3), the second cutter (5) is arranged at the middle part of the machine body (1), and the center of the second cutter (5) and the center of the first cutter (4) are located at the same horizontal position. According to the wood floor chase mortise machining device, chase mortises of wood floors can be formed through machining in one time, and the wood floors of different widths and thicknesses can be machined; the wood floor chase mortise machining device has the advantages of high machining efficiency, high accuracy, low cost and product diversification.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com