Integrated forming die and method for glass fiber reinforced plastic antenna housing

A glass fiber reinforced plastic radome and molding die technology, applied in the field of glass fiber reinforced plastic radome molding, can solve the problems of difficult gluing precision control, fiber damage, numerous processing procedures, etc., so as to eliminate manual grinding or mechanical processing procedures and reduce operation difficulty. , Improve the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention below in conjunction with specific embodiment:

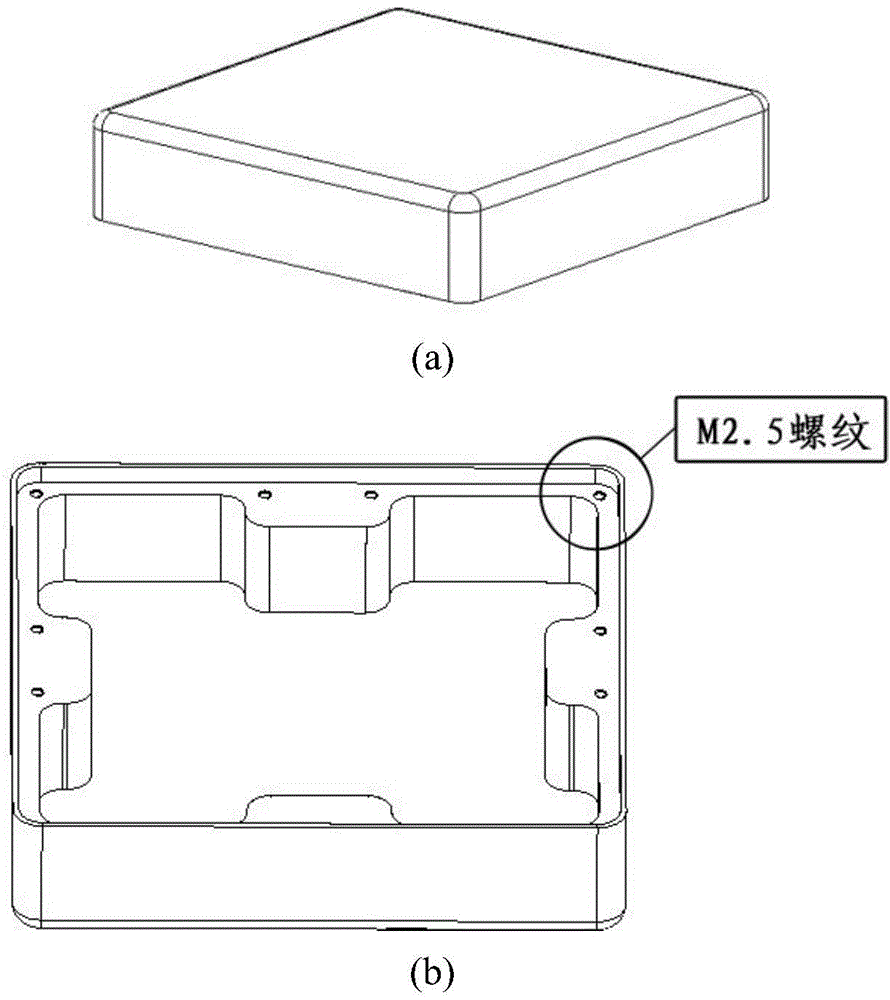

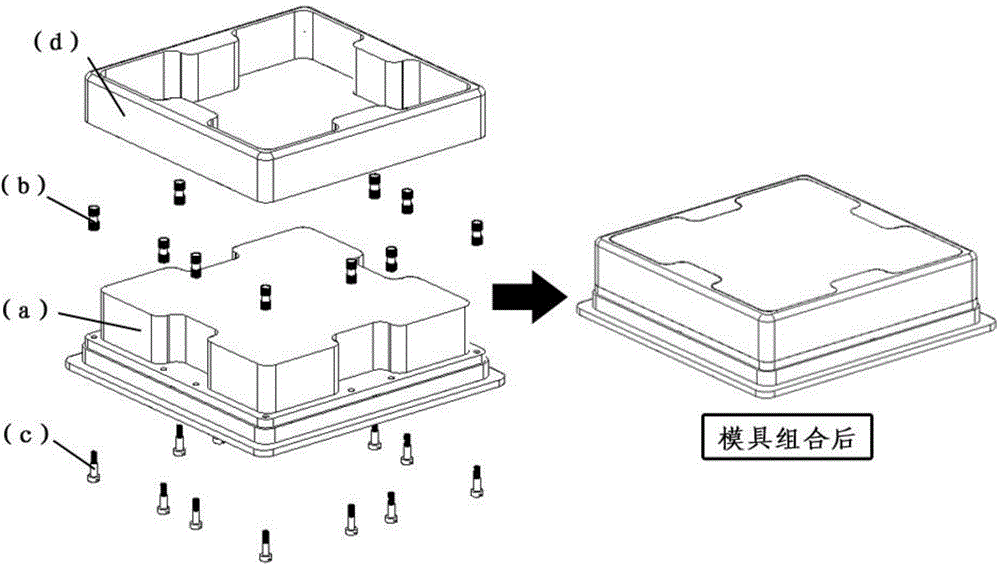

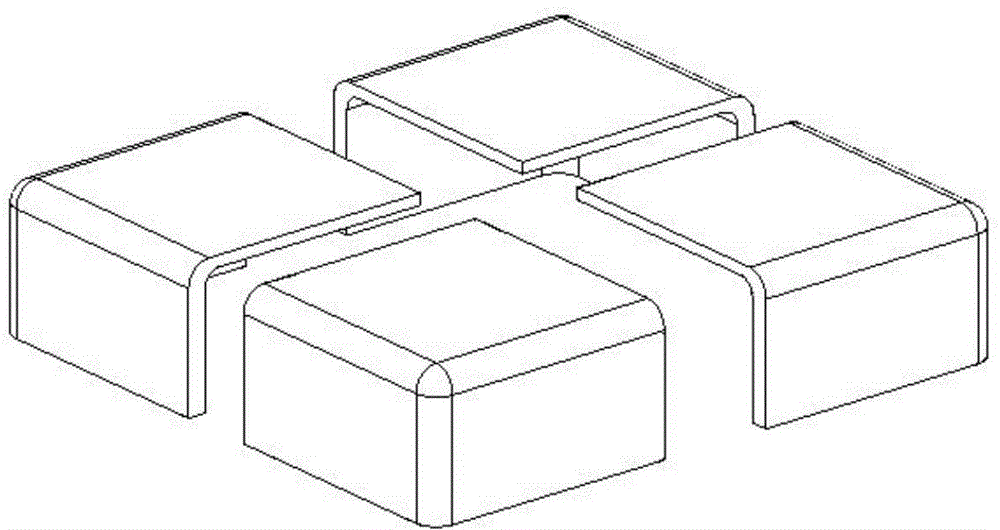

[0024] Refer to attached figure 2 , The integrated forming mold is composed of main mold (a), embedded round nut (b), special screw (c), glass fiber reinforced plastic skeleton (d) and outer mold (e). The main mold (a) is provided with a positioning hole and a demoulding hole, and the special screw (c) passes through the positioning hole to install and position the embedded round nut (b) on the main mold (a); There is an insertion hole for the embedded round nut (b), and there is a gap between the hole wall and the embedded round nut (b). The purpose is: when the radome is molded in the autoclave equipment, the high temperature resin will Under the action of impregnation and capillary force, the gap is automatically filled to achieve the purpose of synchronously bonding the embedded round nut (b) into the radome; the outer mold (e) is composed of four parts, which are combined to form a T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com