Copper wire drawing process

A copper wire and wire drawing technology, which is applied in the field of copper wire drawing technology, can solve problems such as difficulty in eliminating internal stress of copper wire, cracking and breaking of copper wire, and lower product quality, so as to achieve good anti-crack effect, reduce pressure, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

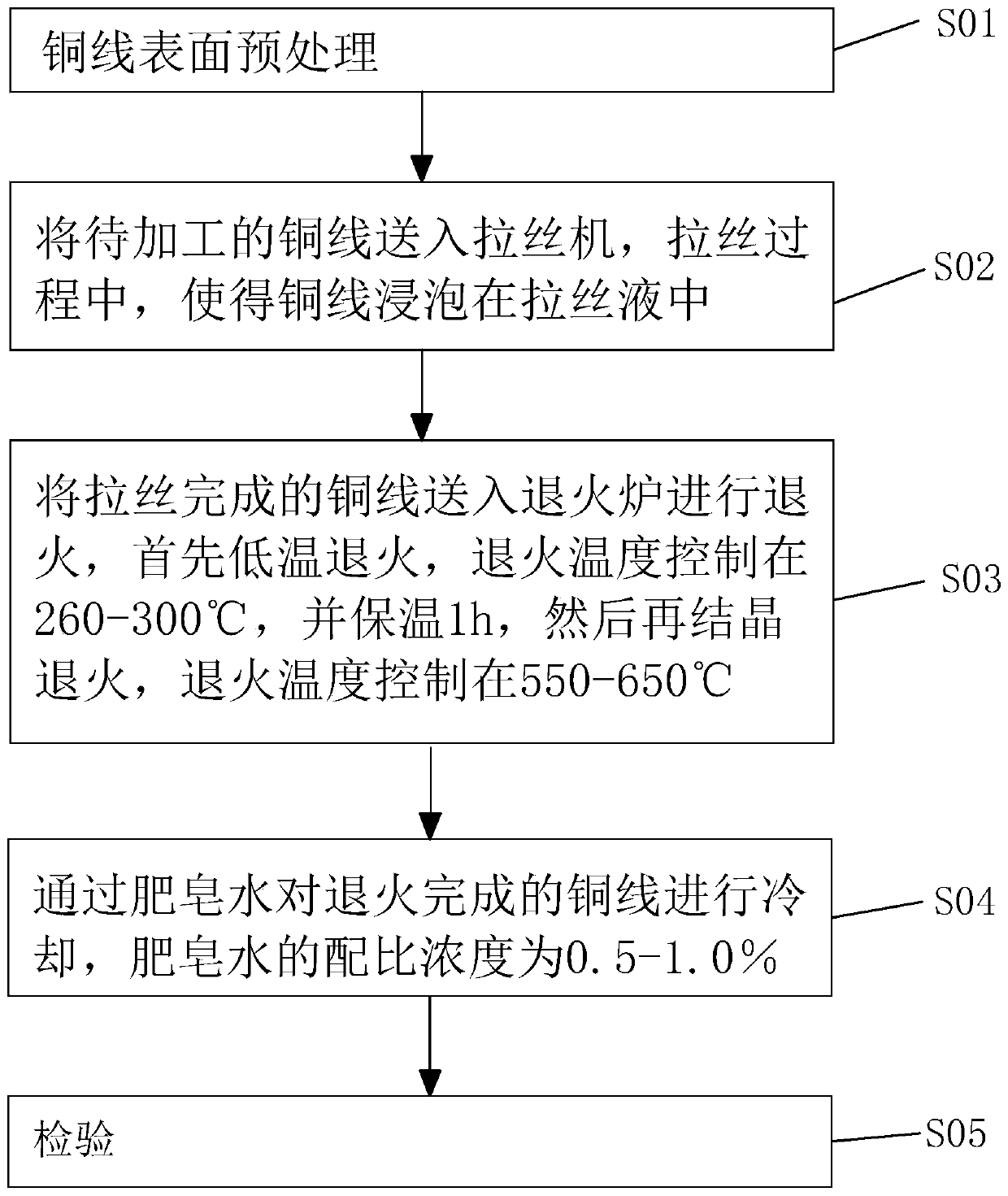

[0039] refer to figure 1 , is a kind of copper wire drawing process disclosed by the present invention, comprises the following steps:

[0040] S01, copper wire surface pretreatment, blow off the dust and copper scraps on the copper wire surface by compressed air;

[0041] S02, send the copper wire to be processed into the wire drawing machine. During the wire drawing process, the copper wire is soaked in the wire drawing liquid; select a suitable wire drawing machine according to the diameter of the copper wire, when the diameter of the copper wire is 0-0.12mm , choose a micro-drawing machine, and the concentration range of the drawing liquid is controlled at 2-3%; when the diameter of the copper wire is 0.12-0.6mm, use a fine-drawing machine, and the concentration range of the drawing liquid is controlled at 3-5%; When the diameter of the incoming copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com