Preparation process of pultrusion composite material modularized gas cylinder support

A technology of pultrusion and composite materials, which is applied to frames, other household appliances, household appliances, etc., can solve the problems of low connection precision, cumbersome production process, poor maintenance performance, etc., and achieve low-cost mass production and reduce production costs , The effect of compressing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a preparation process for a pultruded composite material modular gas cylinder bracket, comprising the following steps:

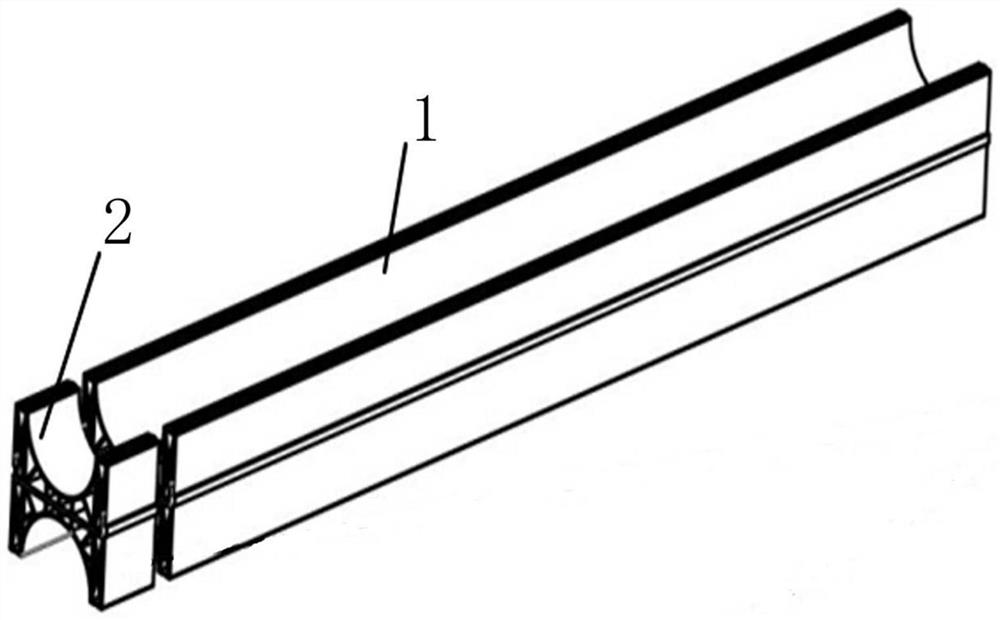

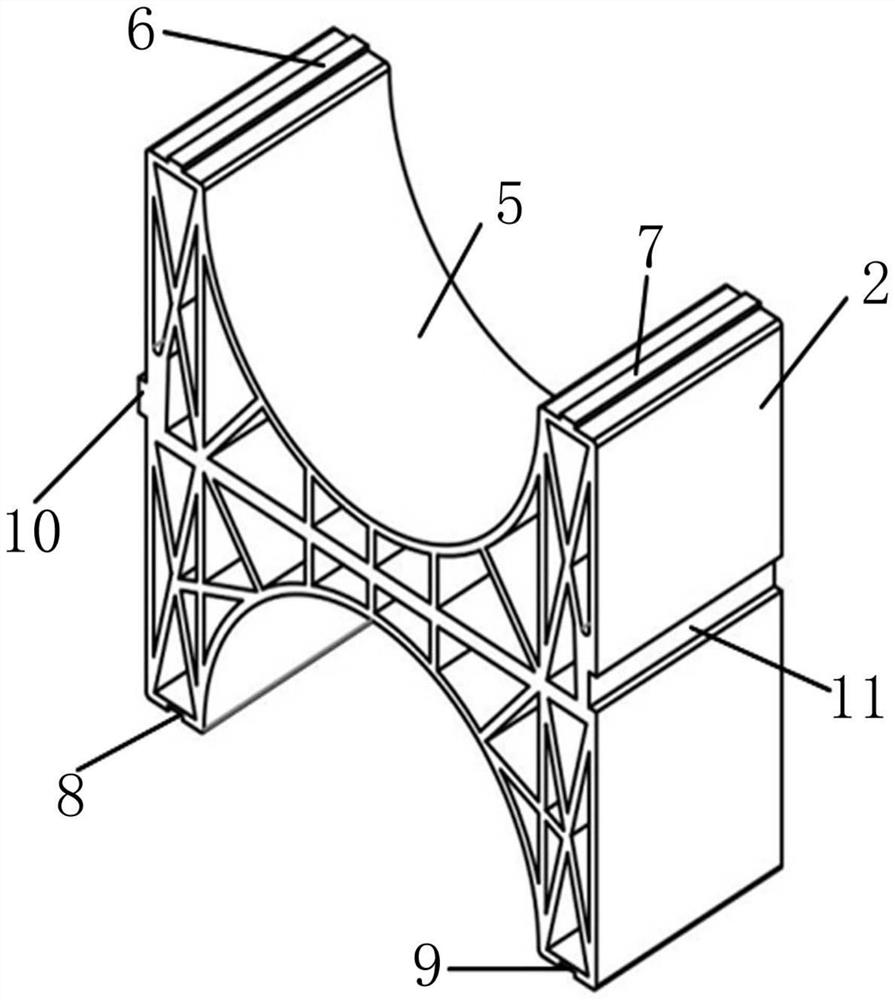

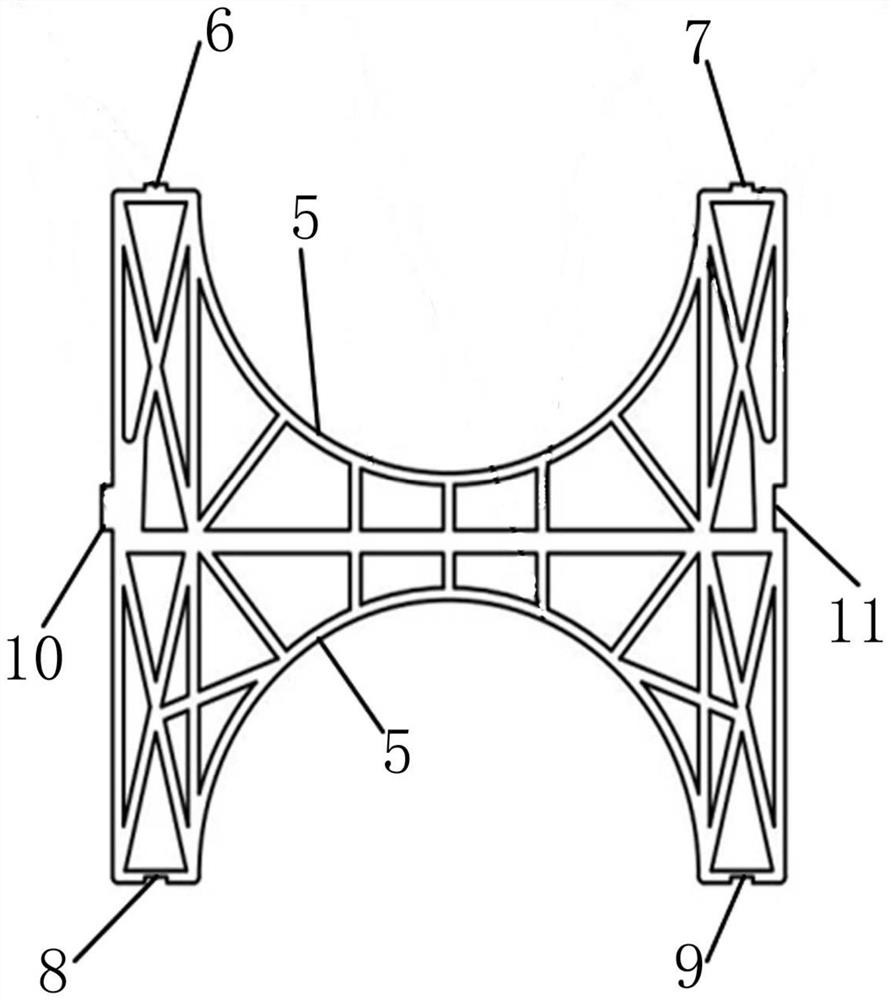

[0029] (1) Production module raw materials: use continuous fibers to impregnate the resin, and make the raw material 1 of the long rod-shaped gas cylinder bracket module with equal cross-section through mold pultrusion. The top surface and the bottom surface of the raw material 1 of the bottle bracket module are symmetrical up and down with the axis of the raw material 1 of the gas cylinder bracket module. The left and right sides of the top surface of the raw material 1 of the gas cylinder bracket module are both horizontal, and the top surface of the left side of the raw material 1 of the gas cylinder bracket module is provided with a first positioning piece 6, and the top surface of the right side is provided with a second positioning piece 7. The first positioning The first positioning member 6 and the second positioning mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com