Patents

Literature

103results about How to "Low cost mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

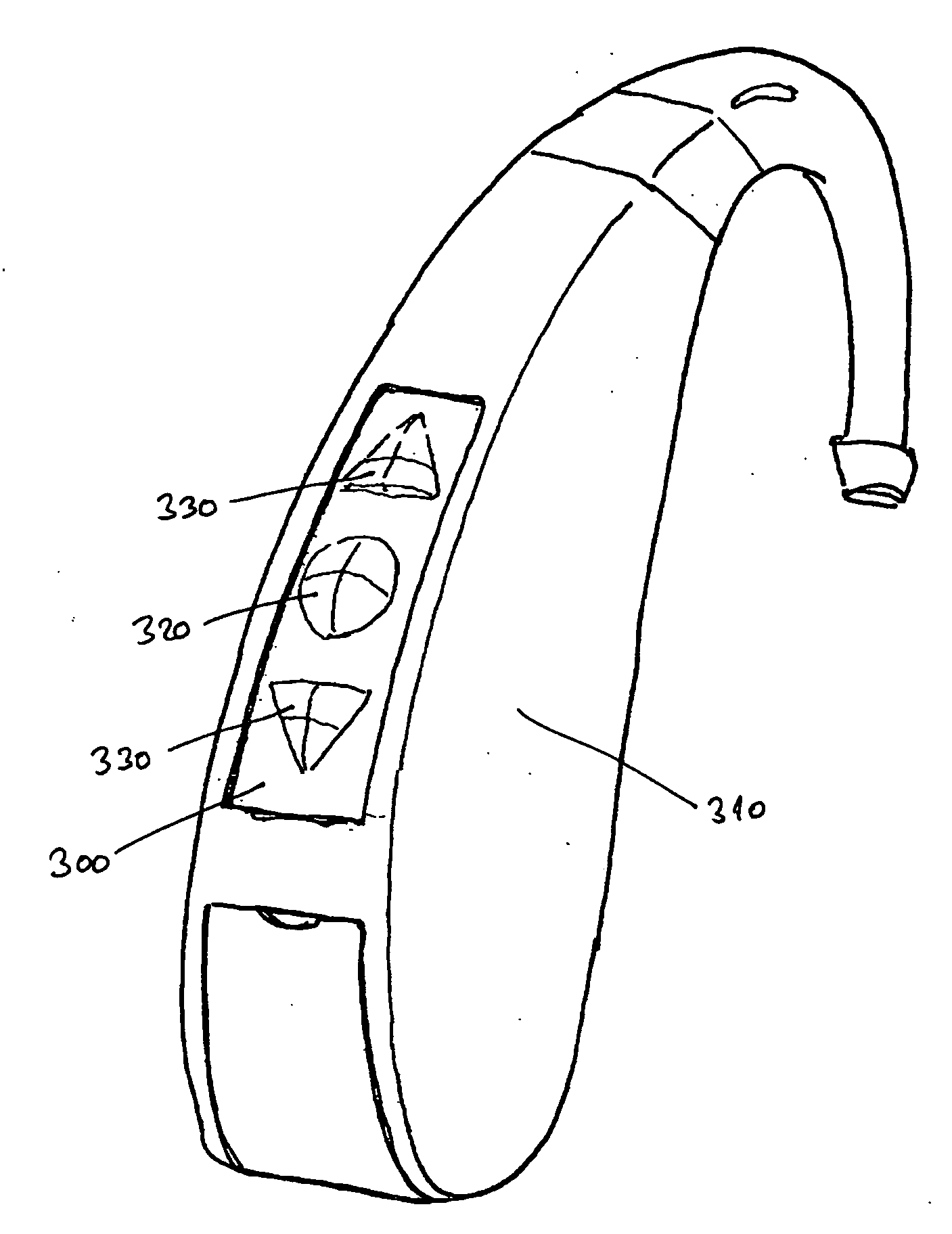

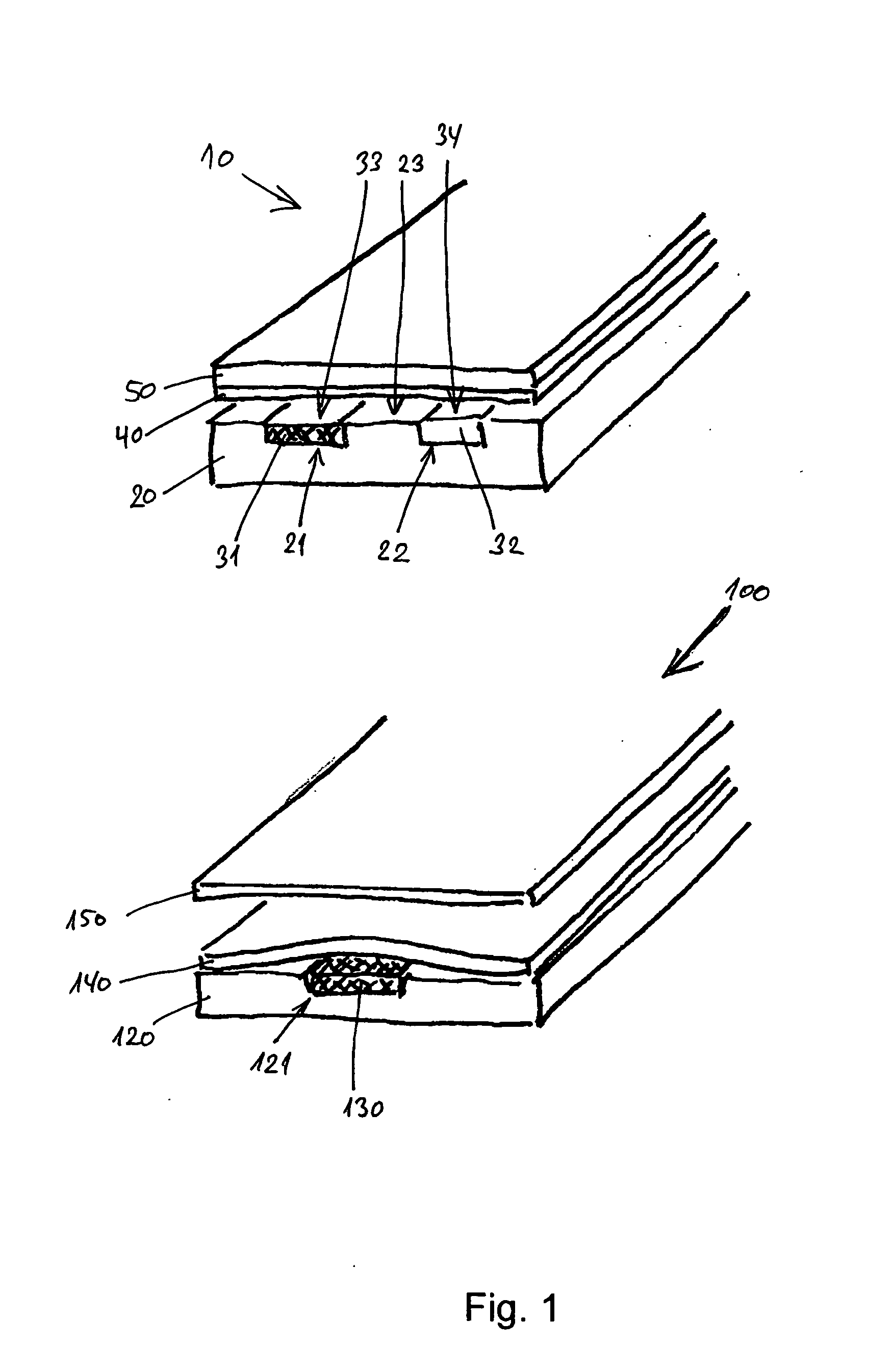

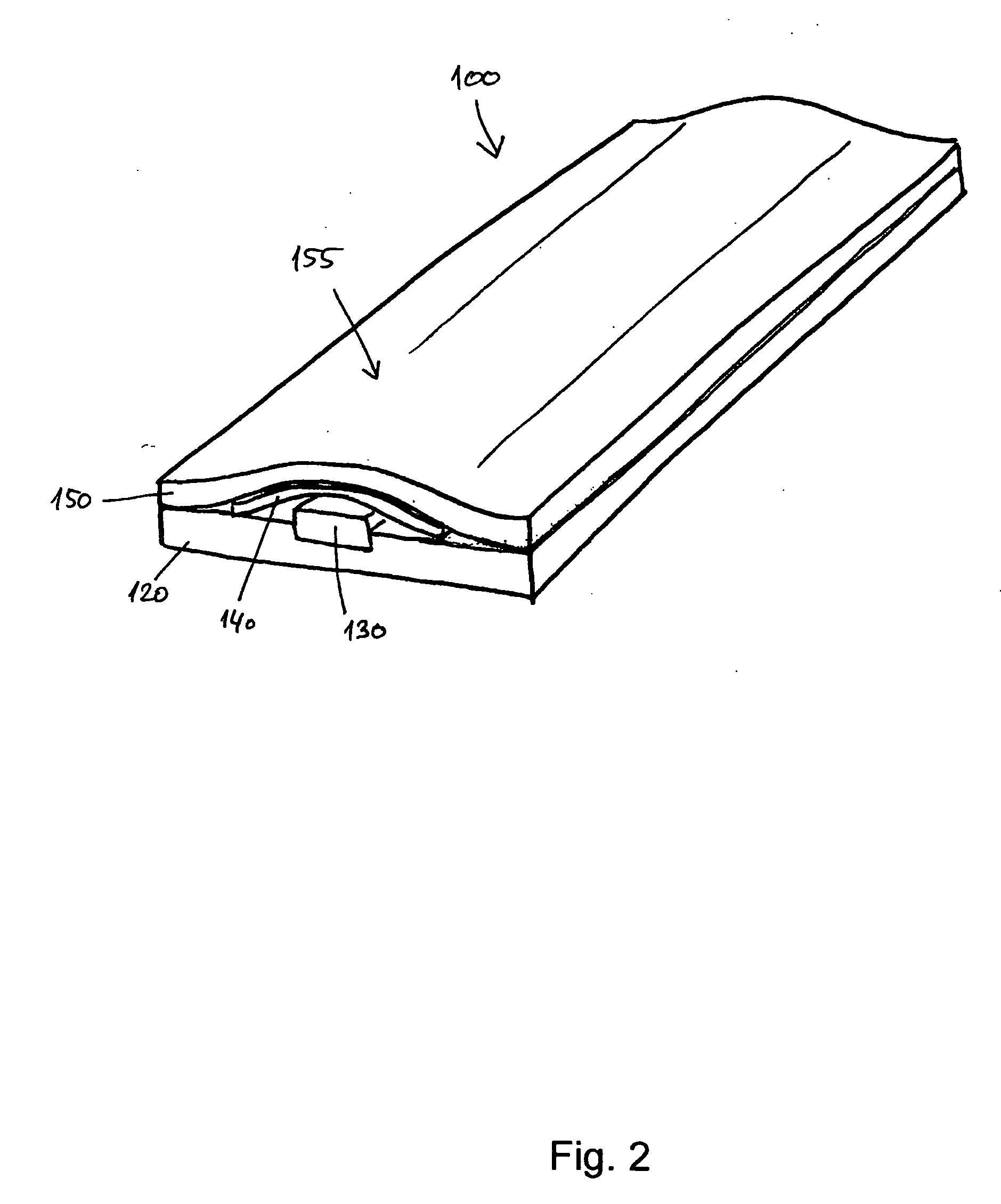

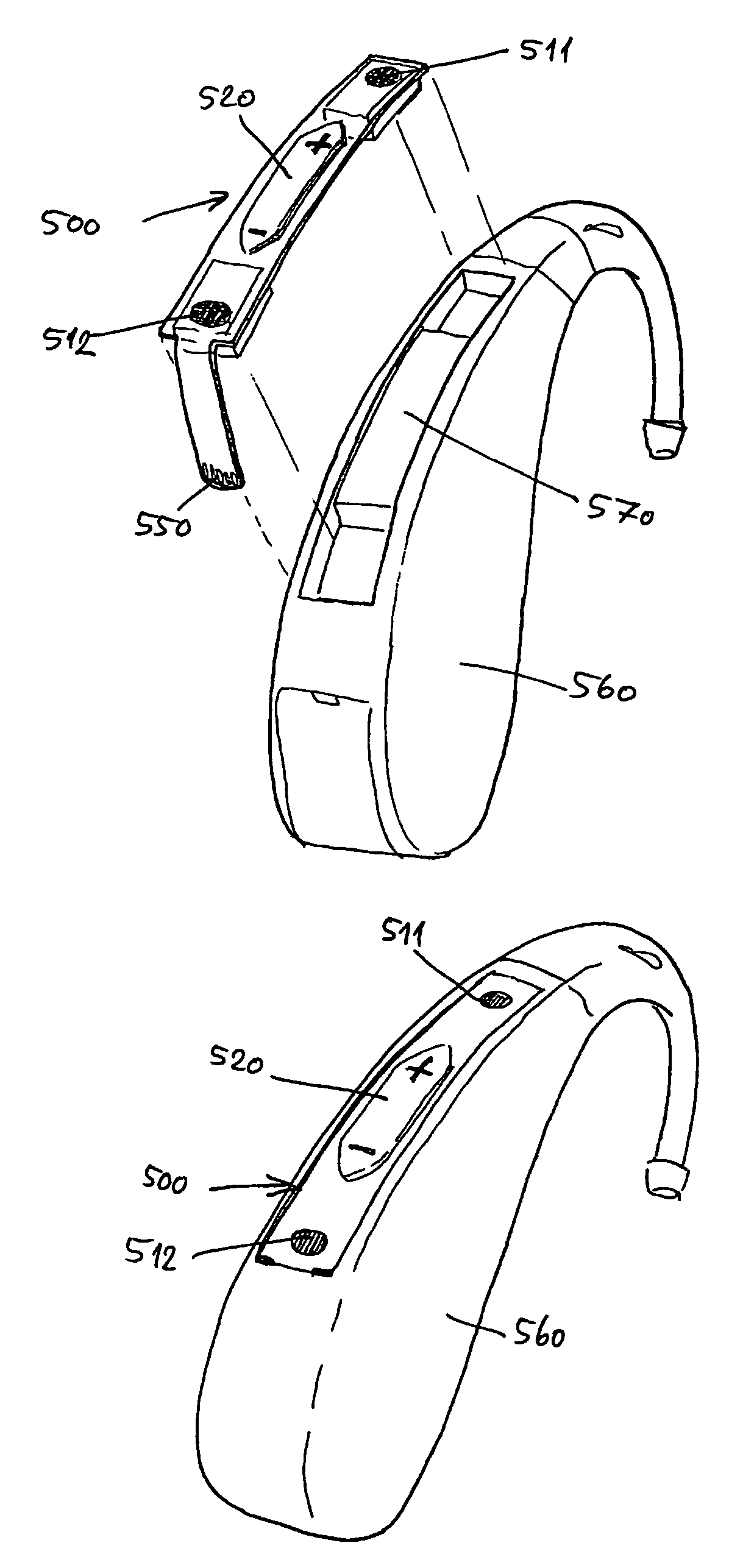

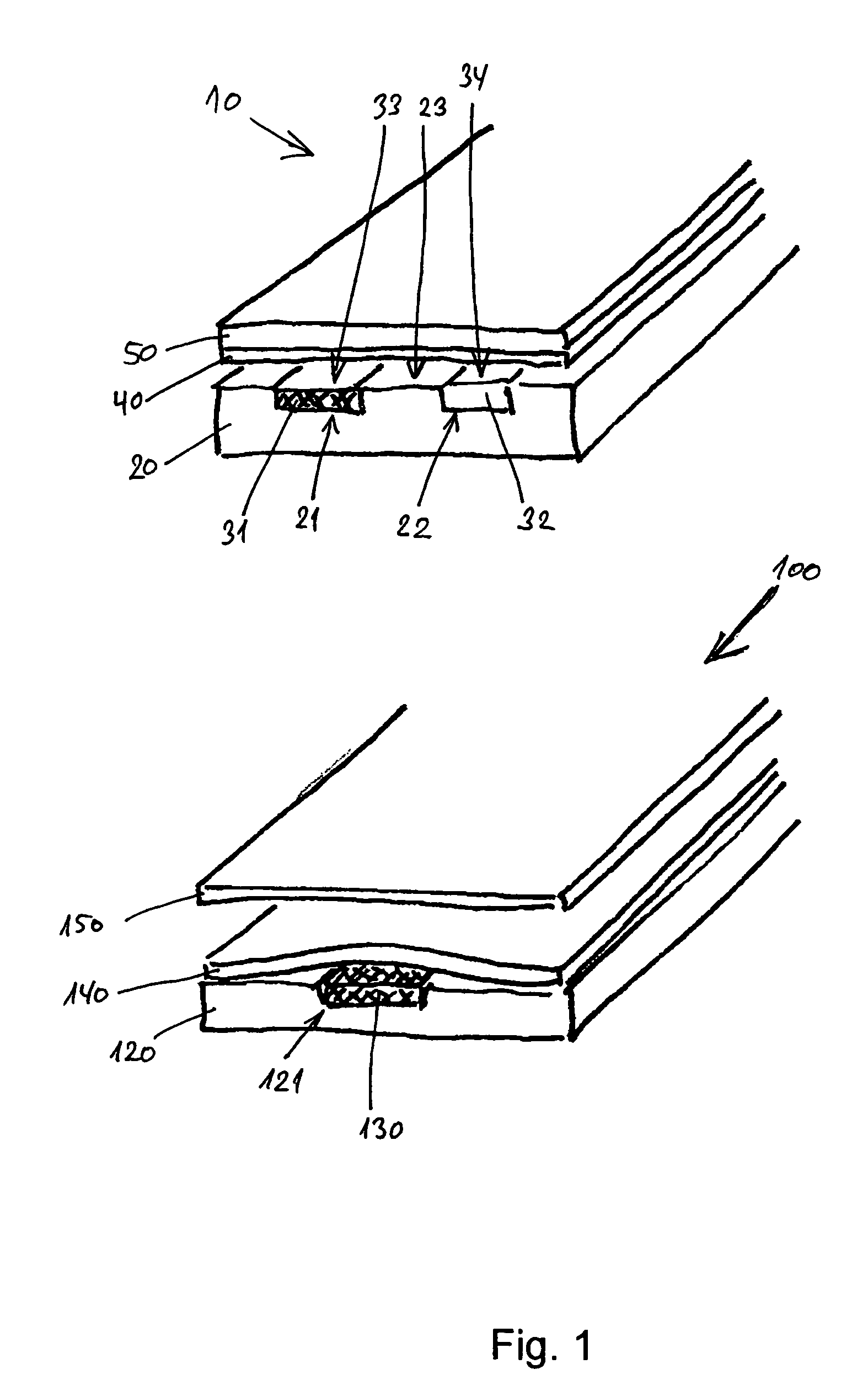

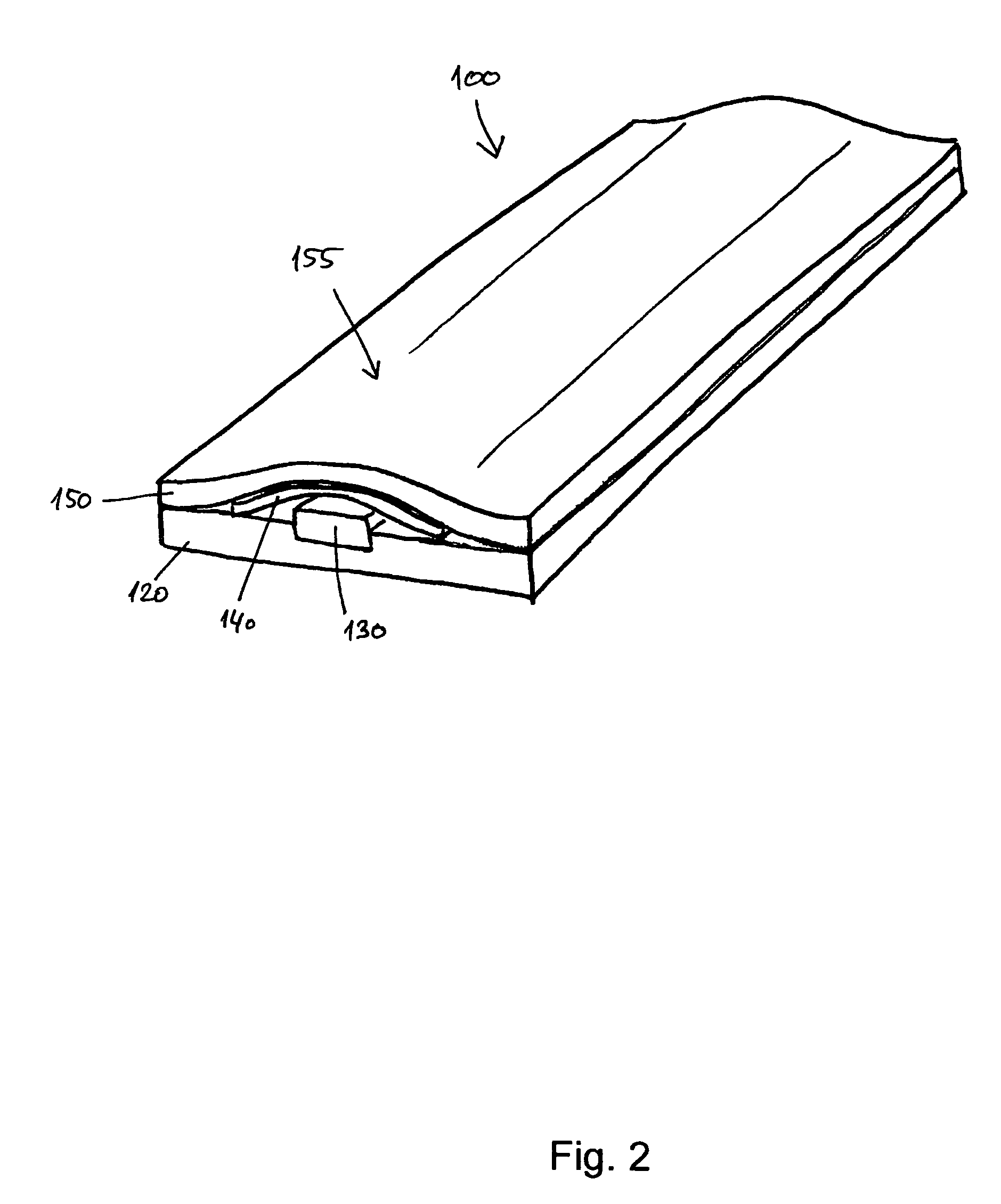

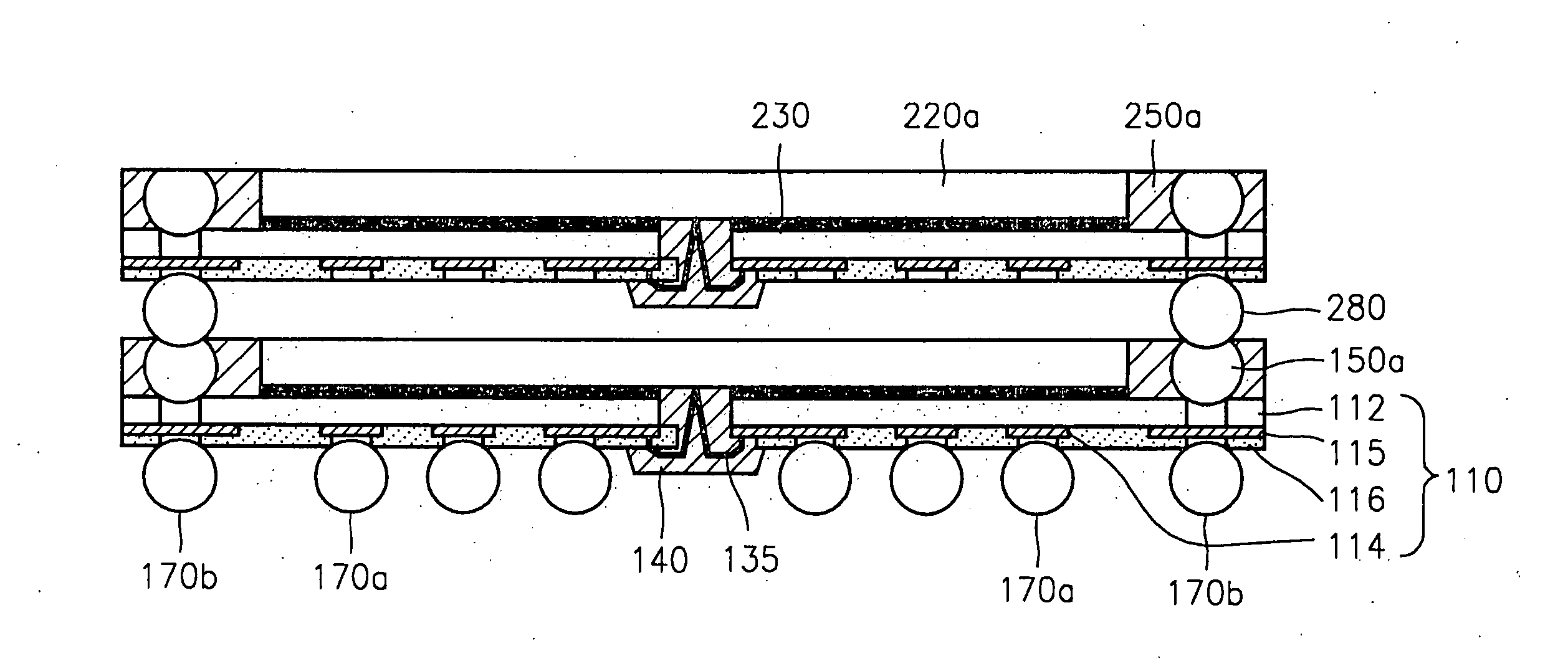

Control panel with activation zone

InactiveUS20050008178A1Easy to changeEasy to cleanOperation facilitationContact operating partsElectrical connectionEngineering

An interchangeable hearing aid control panel with at least one activation zone arranged in connection with a layered structure. The layered structure has an electrically non-conducting substrate, an electrically conducting path arranged in connection with the substrate, and an electrically conducting member, such as a conducting foil, arranged at a predetermined distance from the activation zone. The activation zone can be either in a deactuated or in an actuated state. In the actuated state the conducting member and the conducting path are electrically connected while disconnected in the deactuated state. Electrical connection to an associated hearing aid is by means of a connector, such as a plug, enabling the control panel to be easily changed. Preferably, the connector is formed by a piece of flexprint. The layered structure may comprise a second conducting path. In preferred embodiments activation zones are indicated by “poppel domes” formed by a surface layer covering the layered structure. The activation zones may form an MTO control or a volume control. To fit BTE hearing aids, the layered structure preferably has an elongated structure with a length of 1-4 cm. Other shapes can be formed to fit ITE, ITC and CIC hearing aids. In preferred embodiments, the control panel comprises one or more Silicon-based microphones protected behind a surface layer of the control panel.

Owner:SONION ROSKILDE

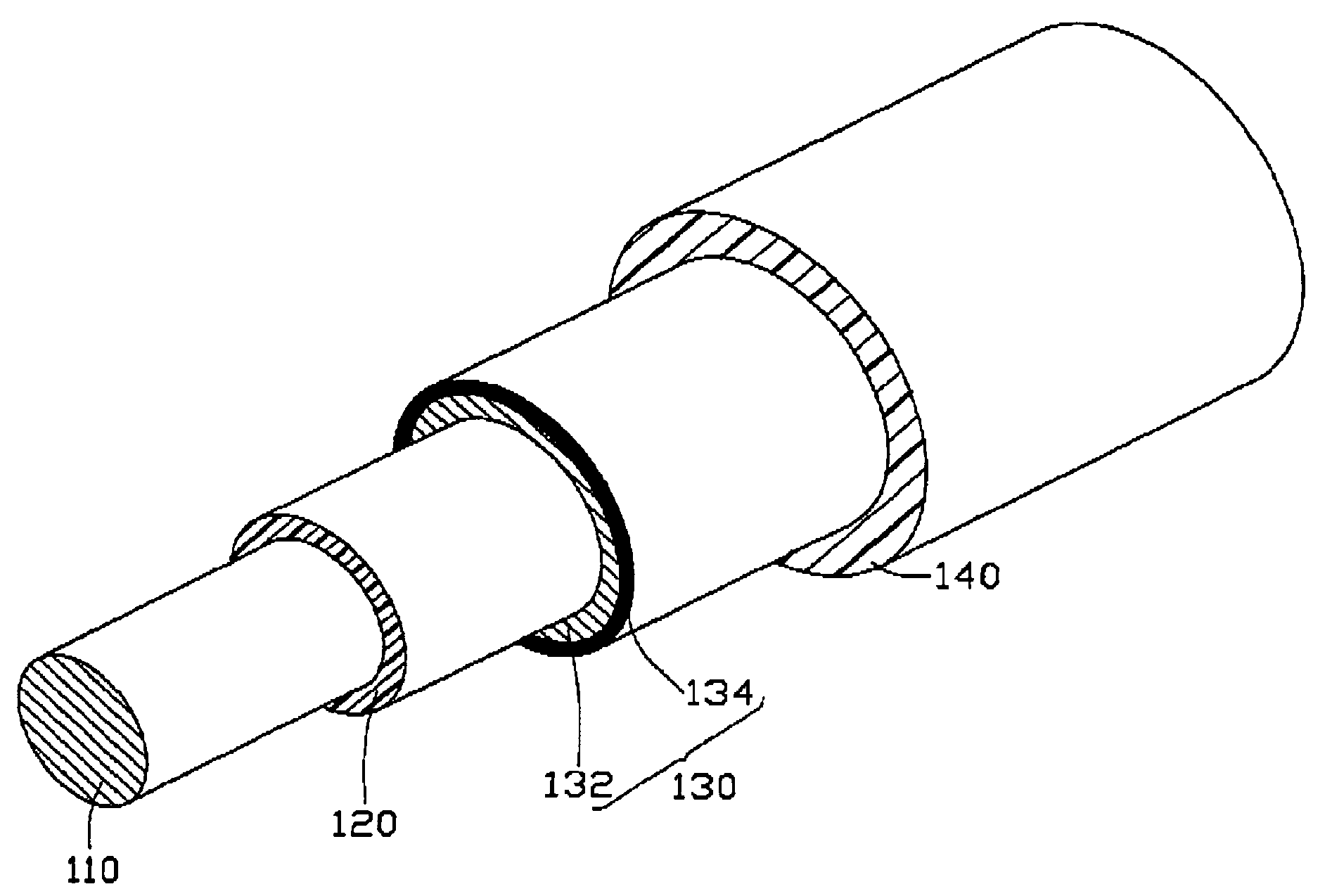

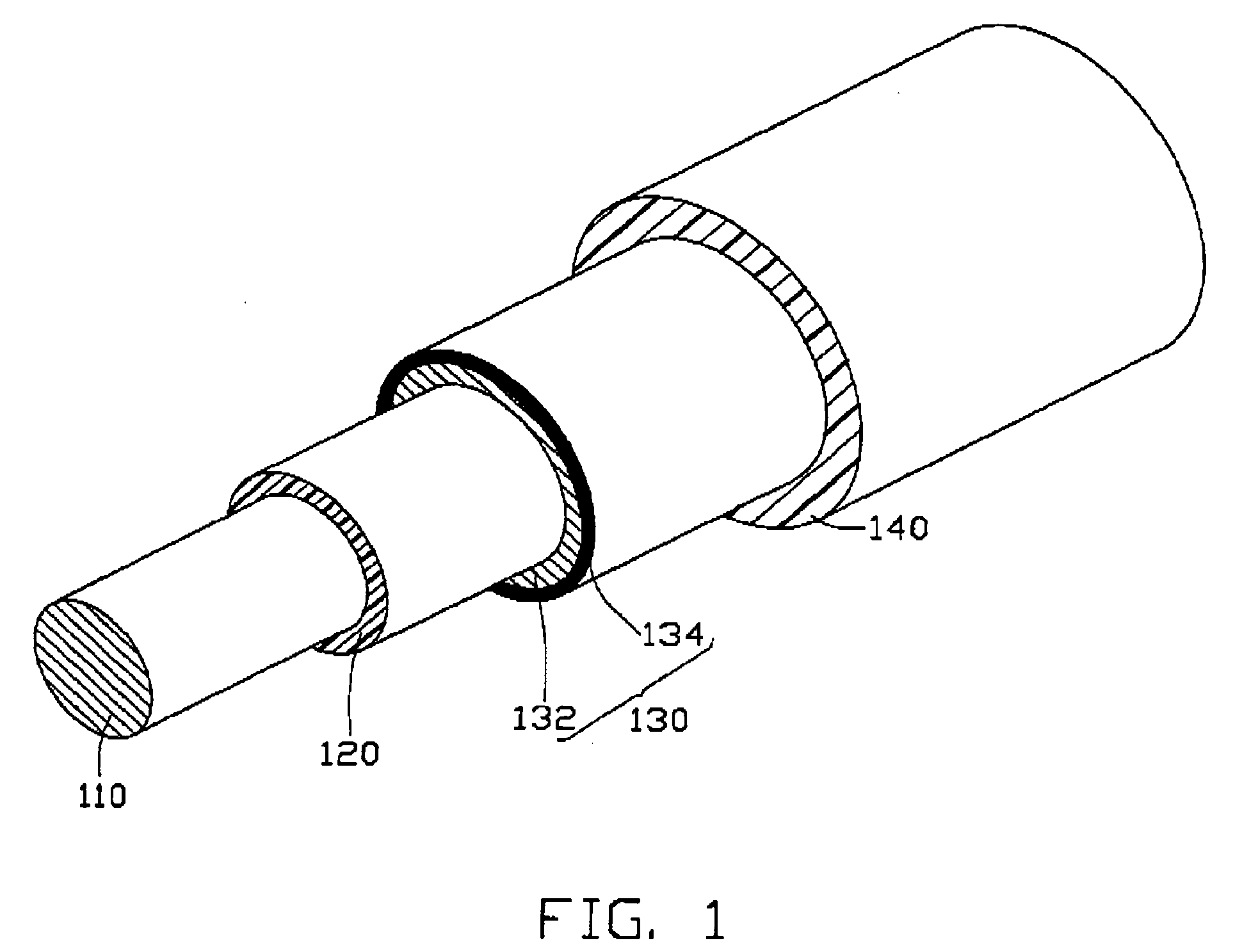

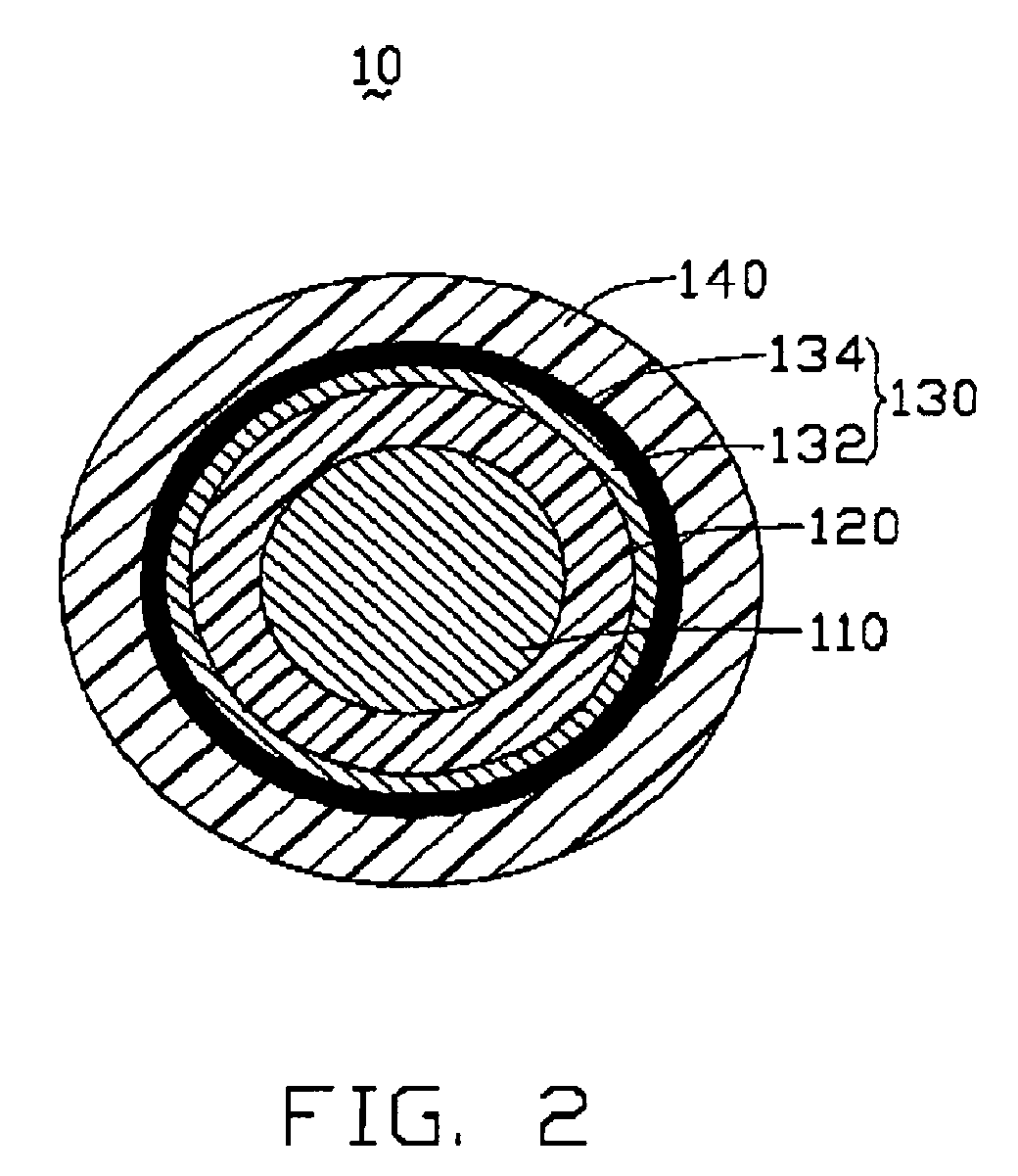

Coaxial cable

ActiveUS20080254675A1Great shield effectivenessLow cost mass productionElectrically conductive connectionsCable conductor constructionCoaxial cableCarbon nanotube

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a metal layer and a carbon nanotube film.

Owner:TSINGHUA UNIV +1

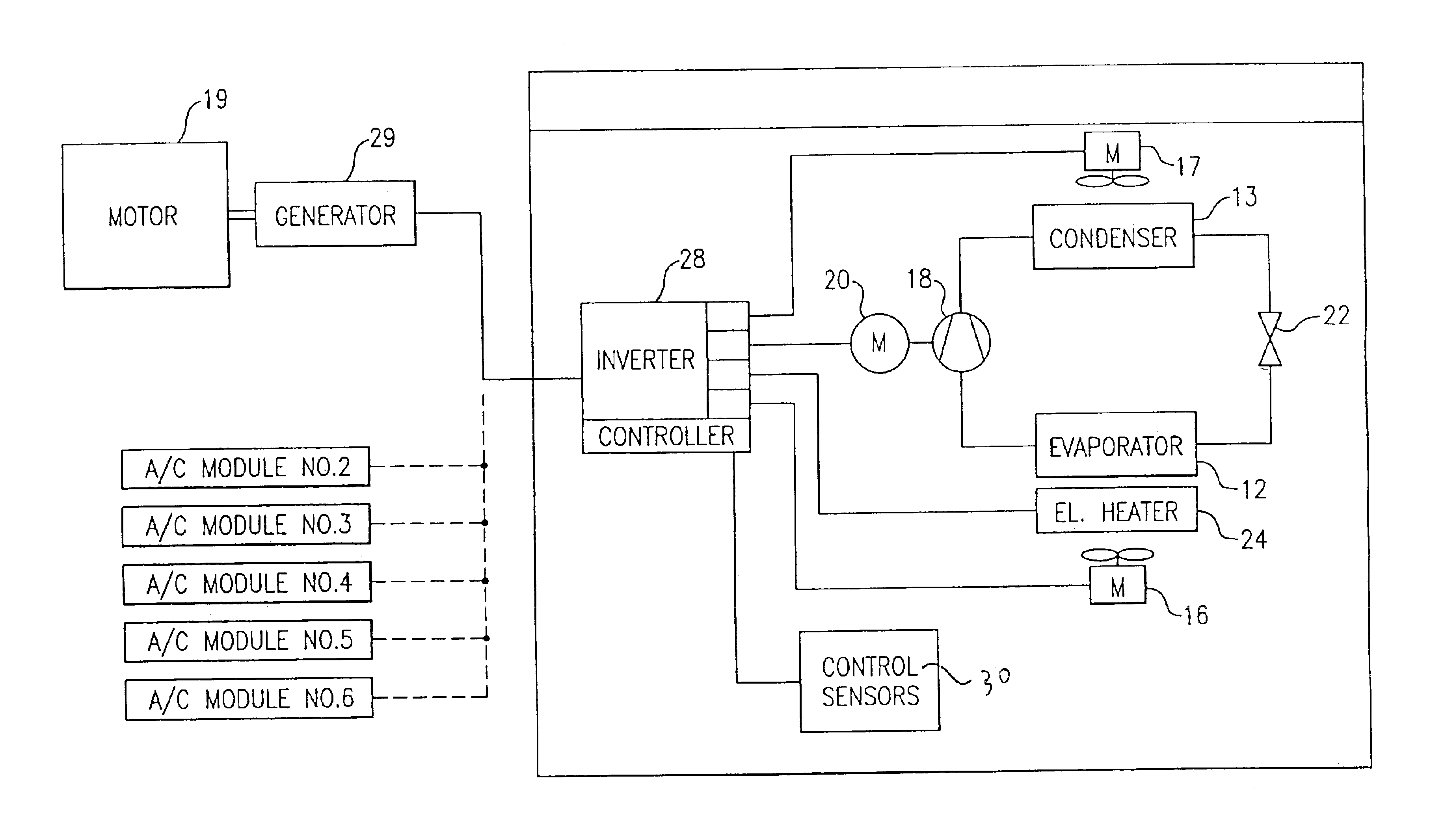

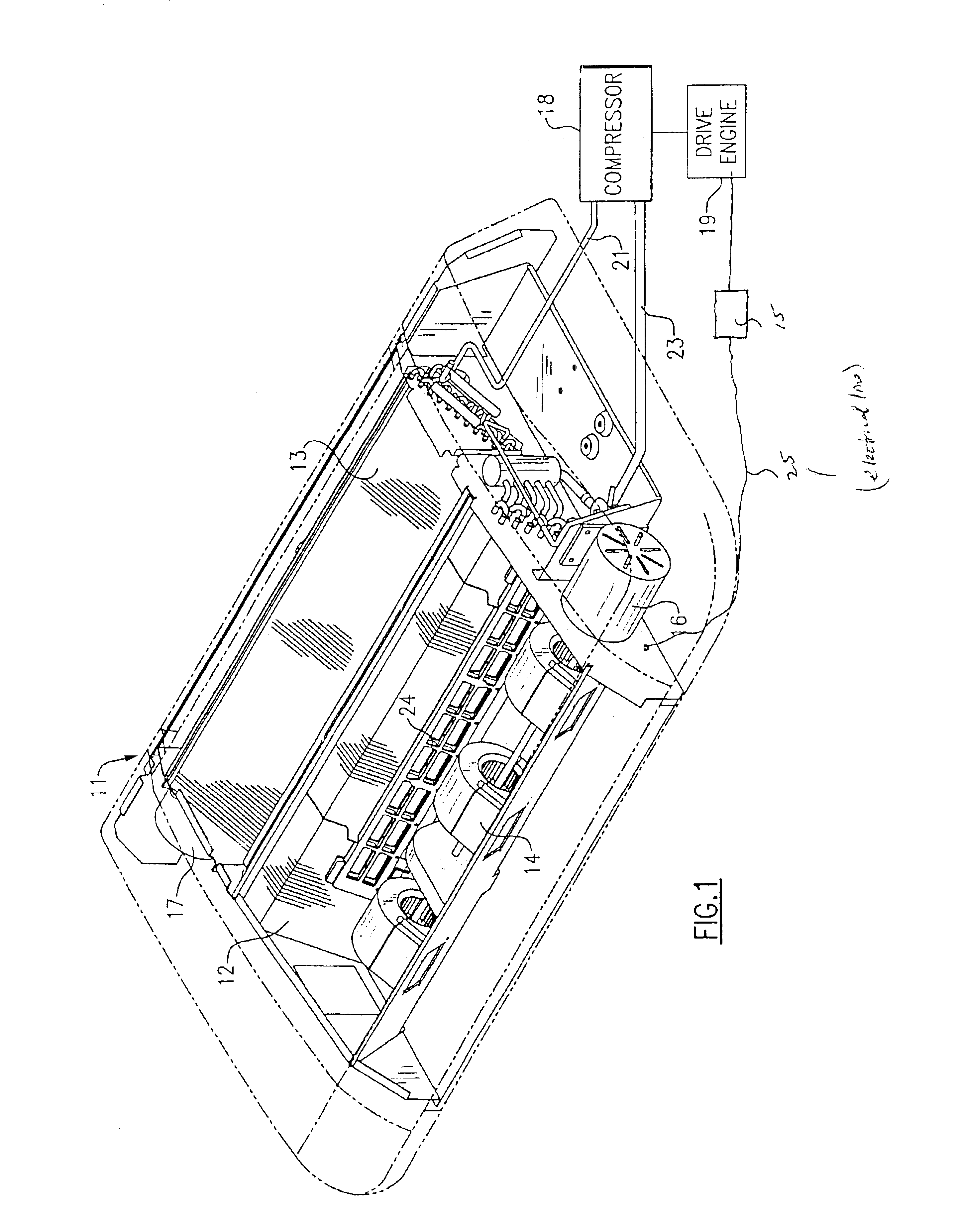

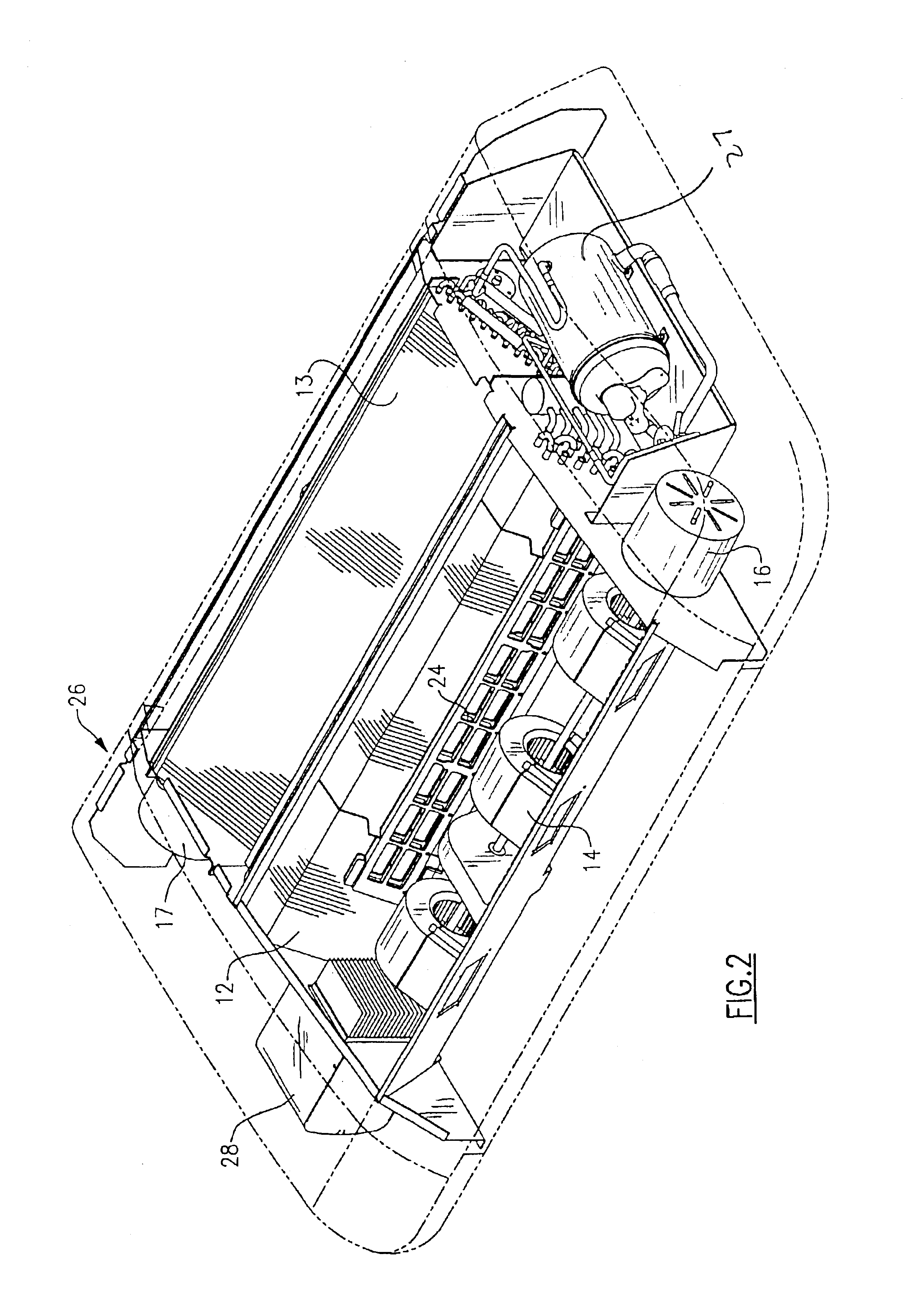

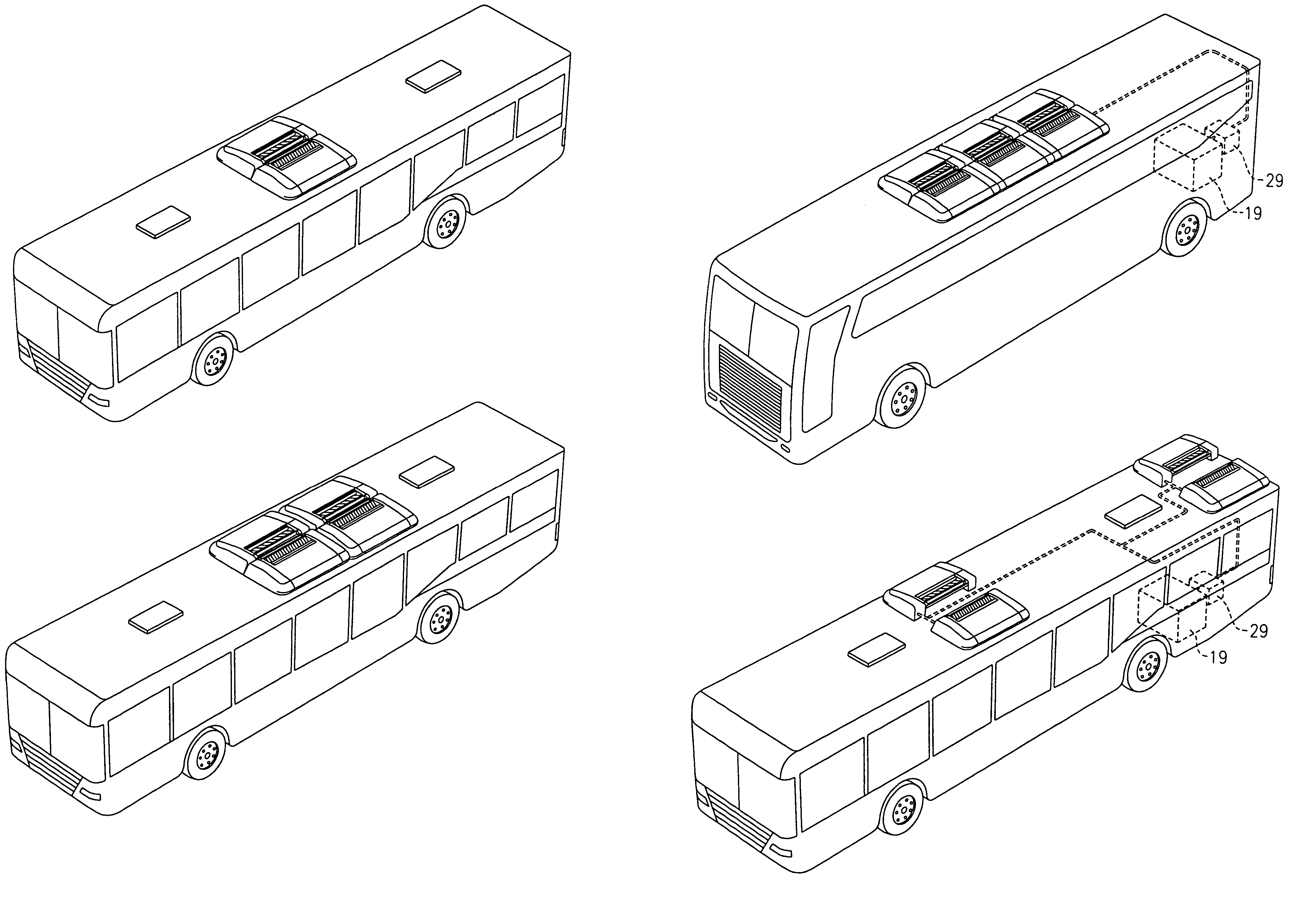

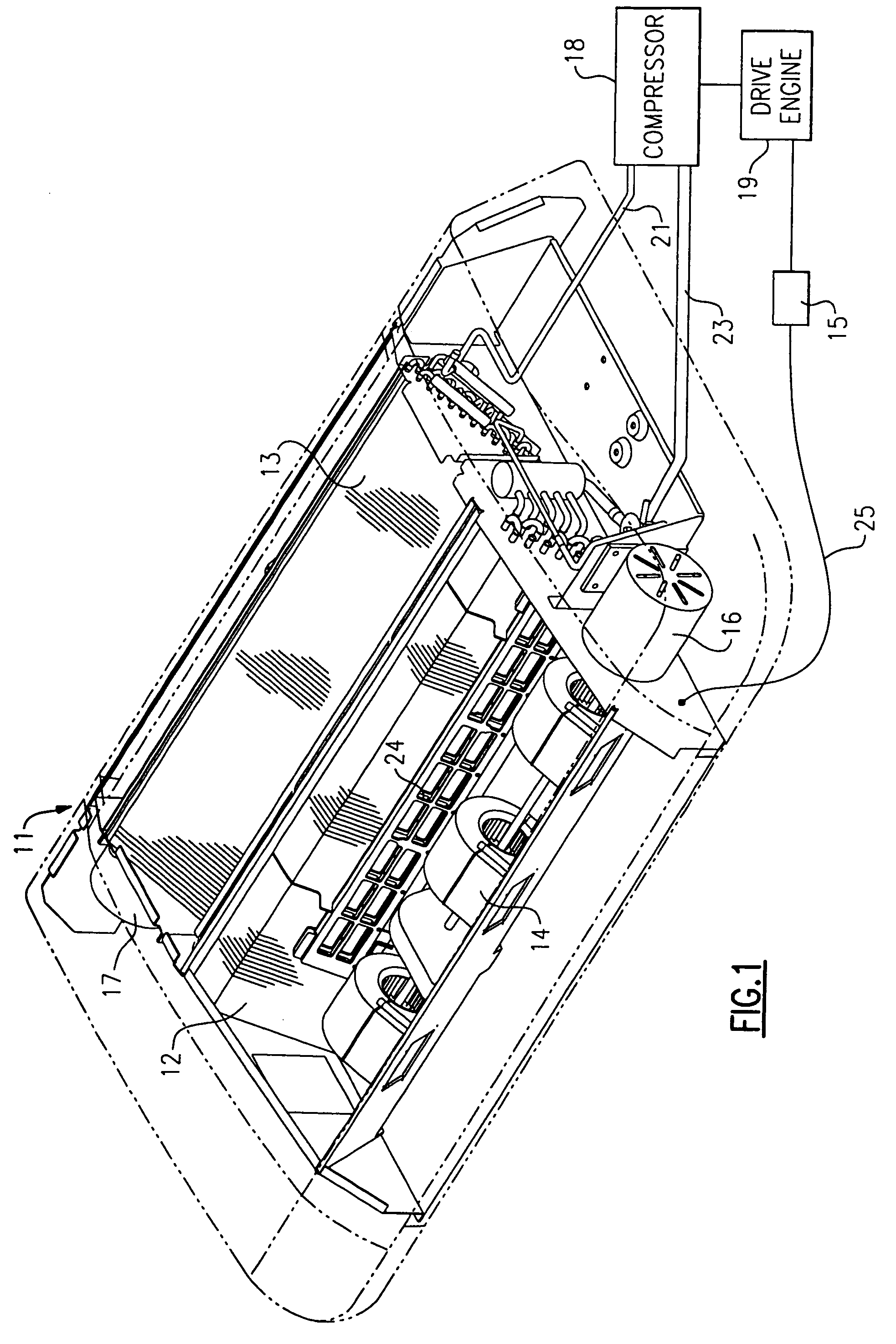

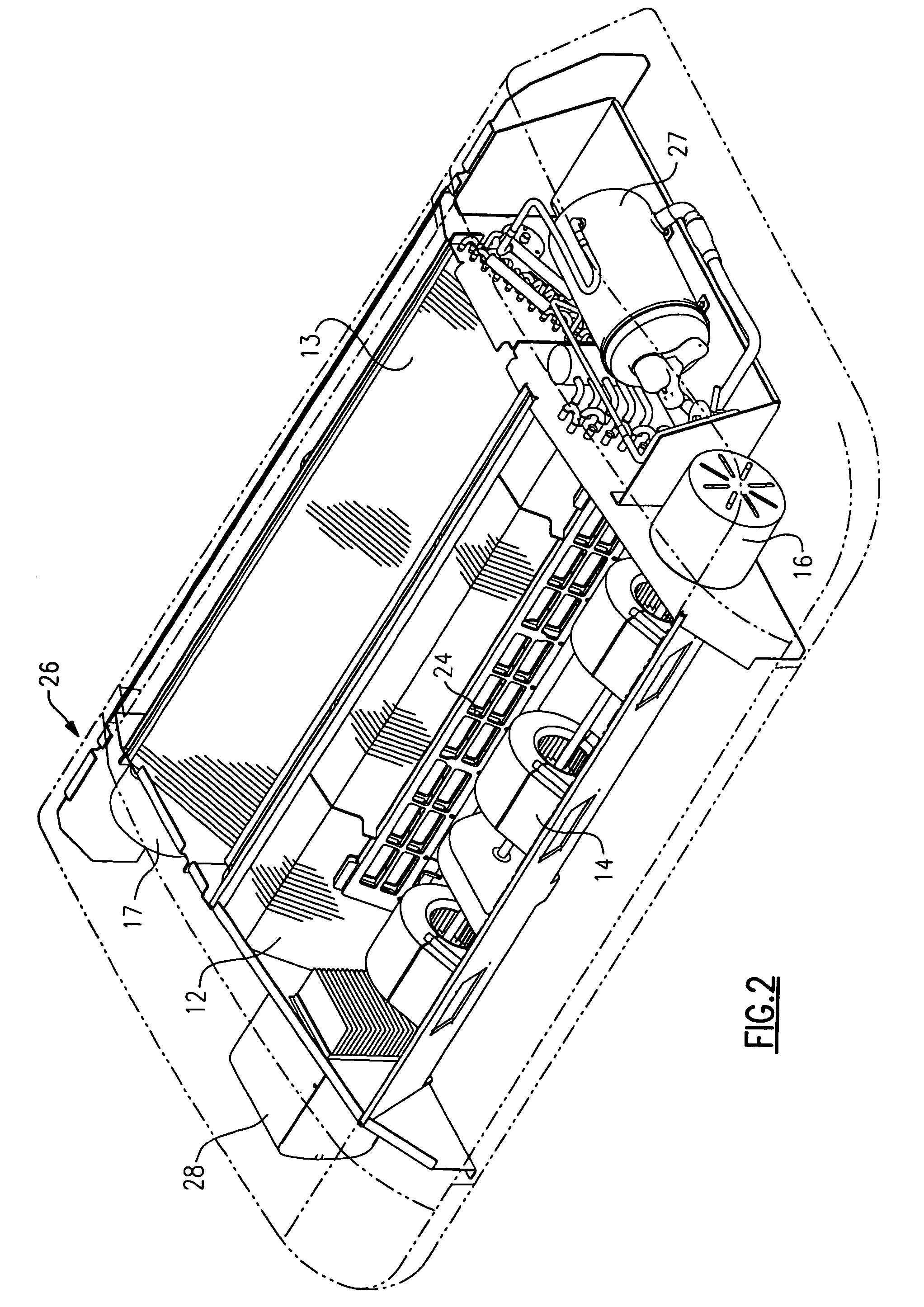

Modular bus air conditioning system

ActiveUS6925826B2Low costLow cost mass productionAir-treating devicesRailway heating/coolingAutomobile air conditioningModularity

A module for a bus rooftop air conditioner is self contained in that it has all the necessary components including a compressor, if desired, which when supplied with electrical power, can provide conditioned air to the passenger compartment of a bus. In addition, an electrically powered heater is provided in the air flowstream such that heated air can also be supplied to the passenger compartment when desired. Multiple units provide for incremental capacity requirements to be met as well as limp home capabilities.

Owner:CARRIER CORP

Control panel with activation zone

InactiveUS7394911B2Easy to changeEasy to cleanOperation facilitationContact operating partsSurface layerElectrical connection

Owner:SONION ROSKILDE

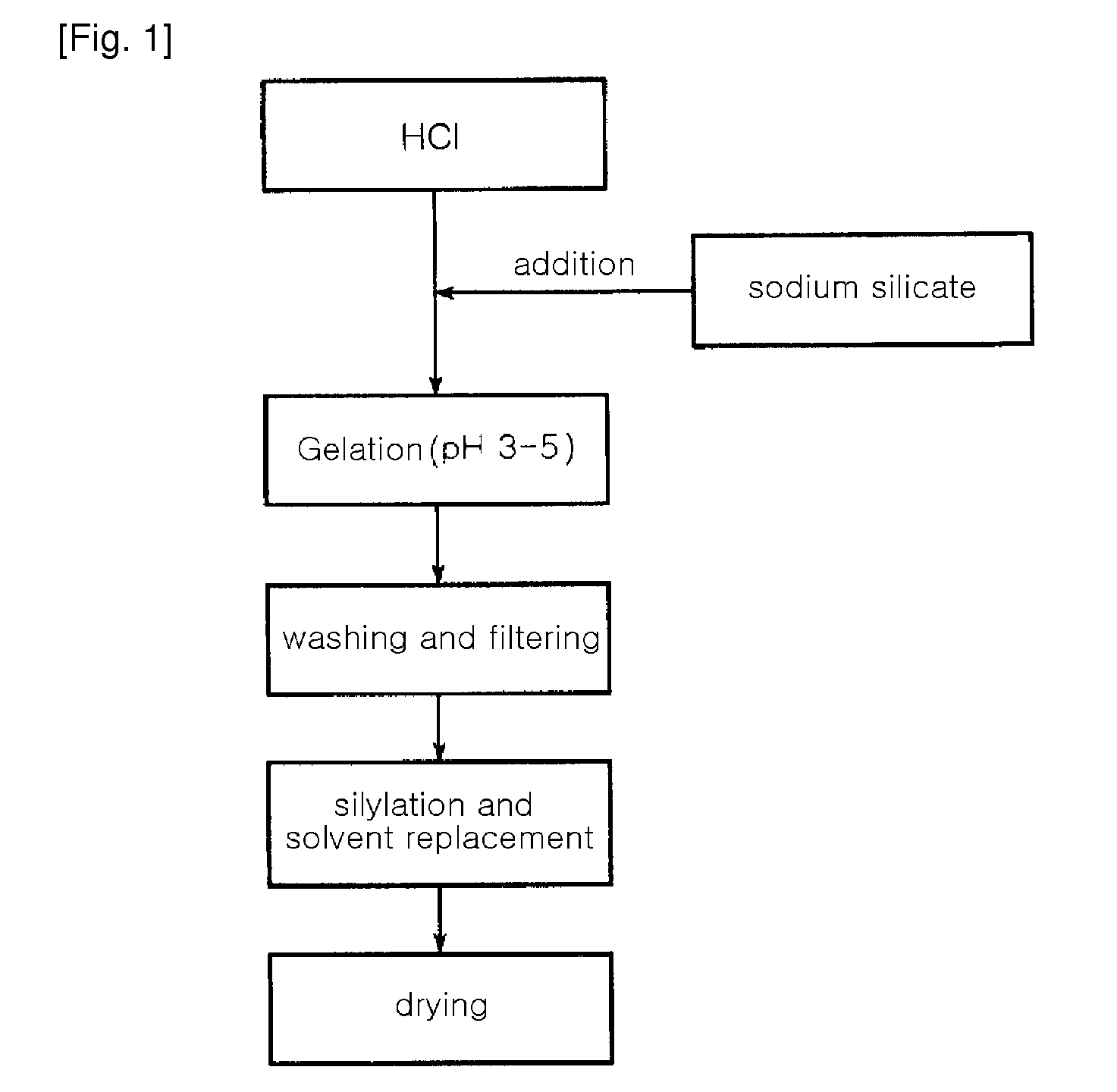

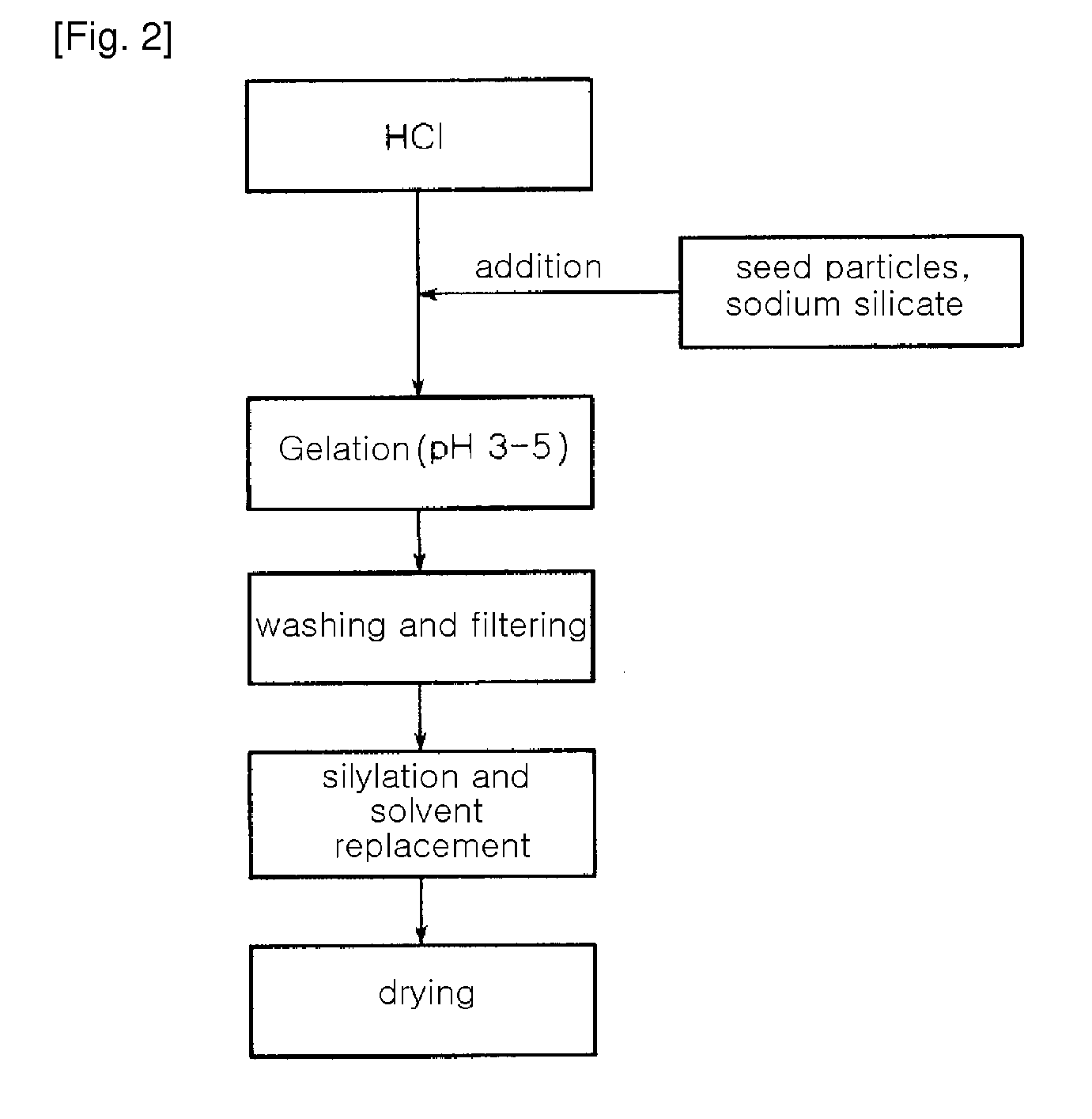

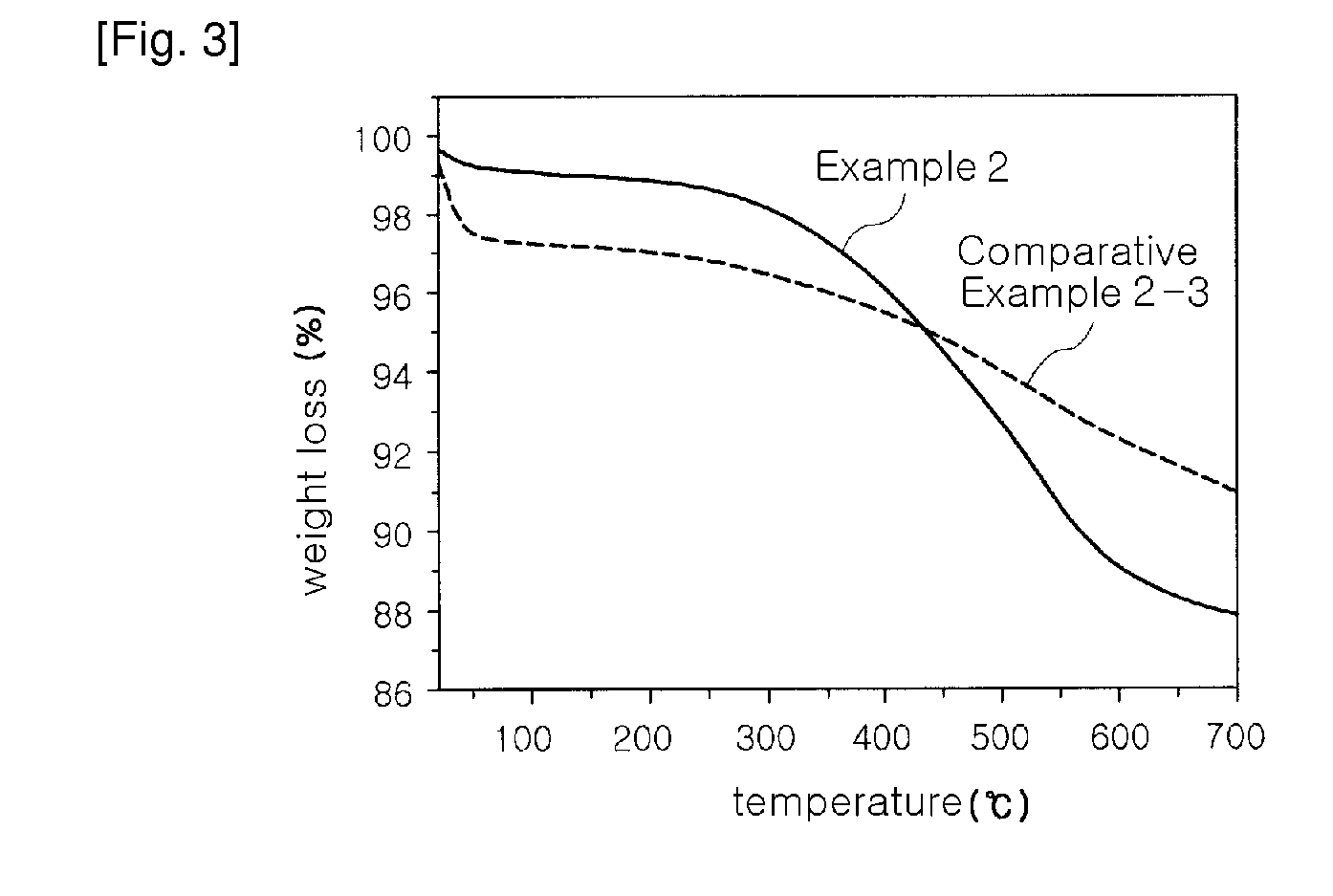

Method for preparing permanently hydrophobic aerogel and permanently hydrophobic aerogel prepared by using the method

A method for preparing permanently hydrophobic aerogel and permanently hydrophobic aerogel prepared by the method. The method comprises adding sodium silicate to HCl at 30 to 90° C. until an acidity reaches pH 3-5, to form silica hydrogel under acidic conditions of pH 3-5, washing the silica hydrogel with distilled water using a mixer, followed by filtering, adding the silica hydrogel to a silylating solution of silylating agent in n-butanol at pH 1-5 using an acid selected from hydrochloric acid, sulfuric acid, phosphoric acid and nitric acid, to simultaneously conduct silylation and solvent replacement, and drying the silica hydrogel; The method has the following advantages; i) silylation and solvent replacement can be simultaneously conducted, ii) n-butanol is used as a reaction solvent instead of methanol upon silylation, thus obtaining a thermal conductivity comparable to conventional aerogel powders, iii) silylation is conducted under improved conditions, i.e., strong acidic conditions of pH 1-5, and as a result, all of the aerogel powders can be reacted with a silylating agent, thereby obtaining permanently hydrophobic aerogel, iv) the washing with a mixer makes the amount of removed sodium ions uniform, thus it is suitable for mass-production, and v) the method provides a relatively simplified procedure and the use of the silylating agent in a small amount enables low costs and mass-production.

Owner:KOREA INST OF IND TECH

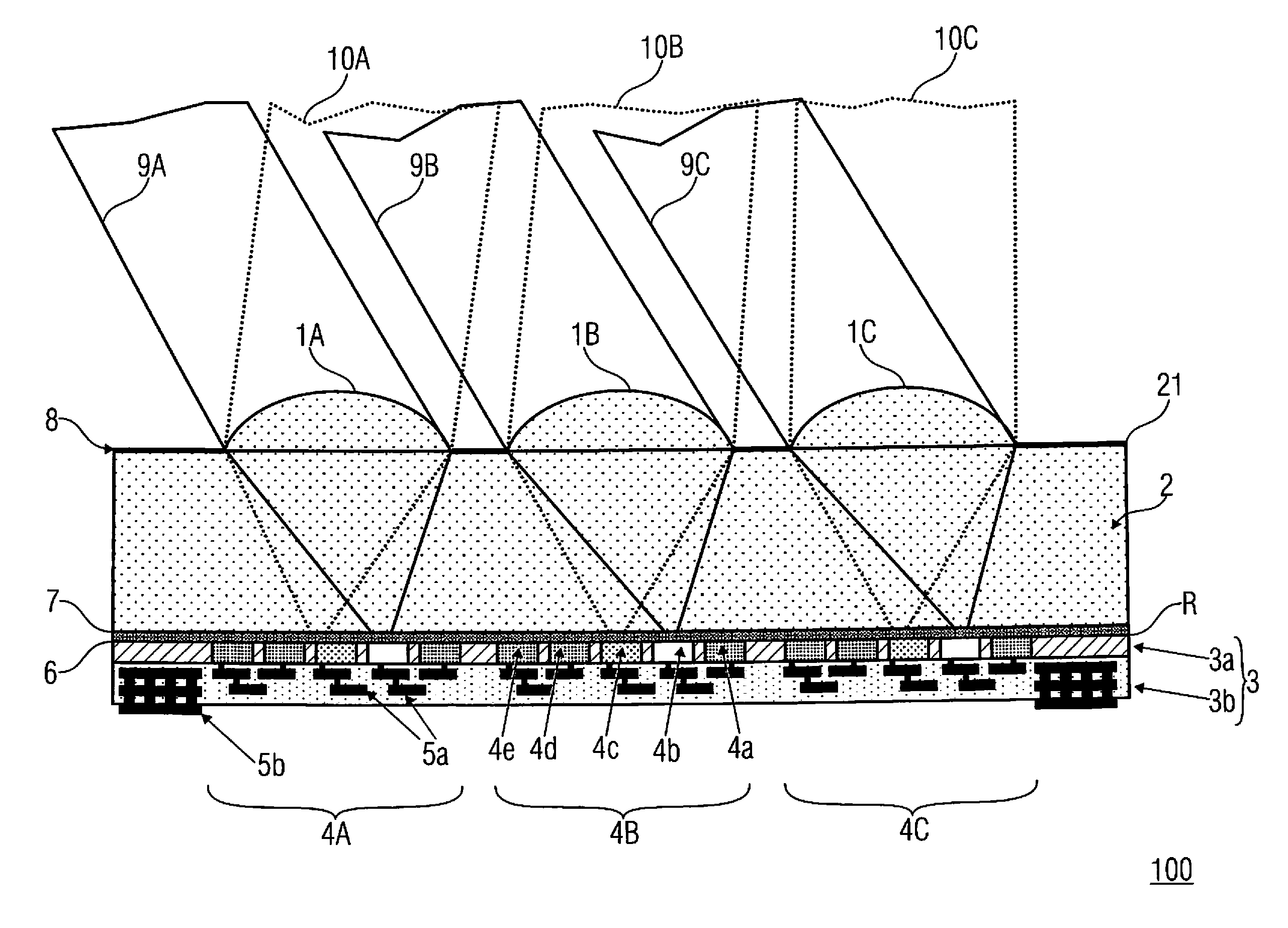

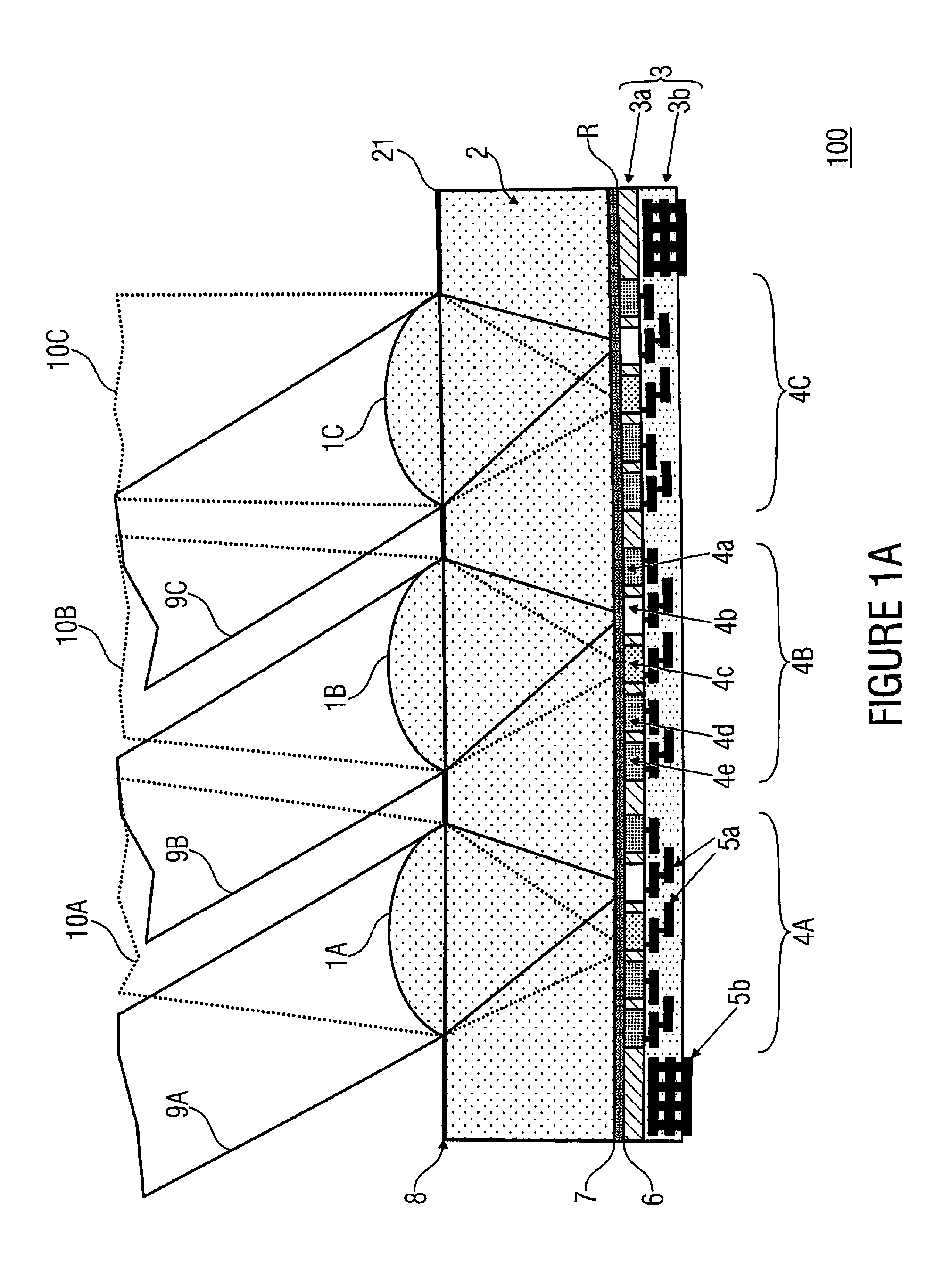

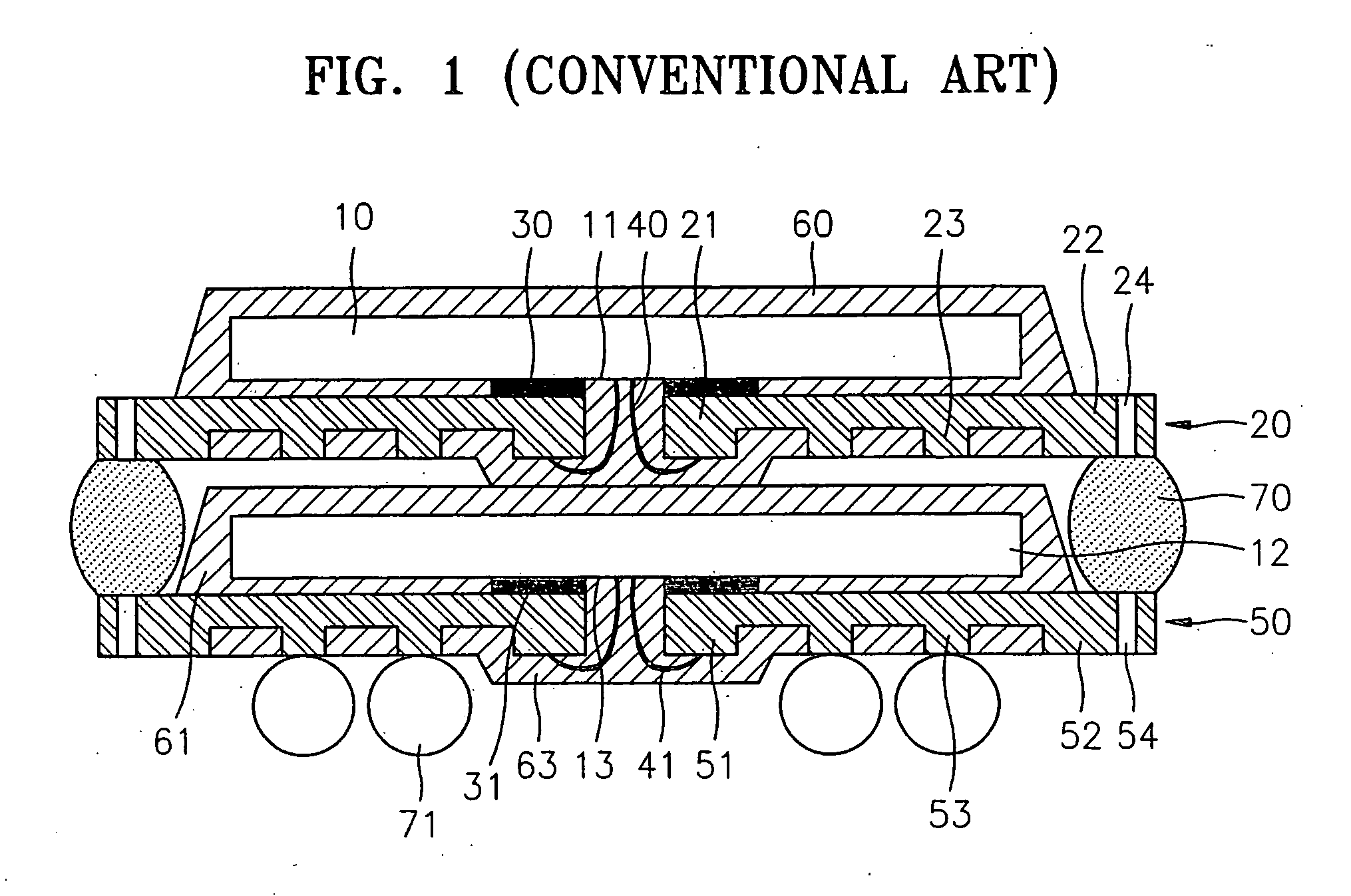

Method of manufacturing a multitude of micro-optoelectronic devices, and micro-optoelectronic device

ActiveUS20120091551A1Improve fill factorIncrease lightingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWafer stacking

A wafer stack that is diced to produce a multitude of micro-optoelectronic devices includes a first wafer including a semiconductor material; a second wafer including an optically transparent material; a multitude of light sensor arrangements in the semiconductor material of the first wafer for each of the micro-optical devices; the second wafer structured to form a multitude of micro-optical elements therein for each of the micro-optoelectronic devices; and a wafer stack produced wafer bonding, the wafer stack including the first wafer and the second wafer arranged above same, each of the micro-optical elements arranged and structured such that different portions of light incident on the micro-optical element are directed onto different light sensor elements of a light sensor arrangement at least partly arranged below the micro-optical element.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

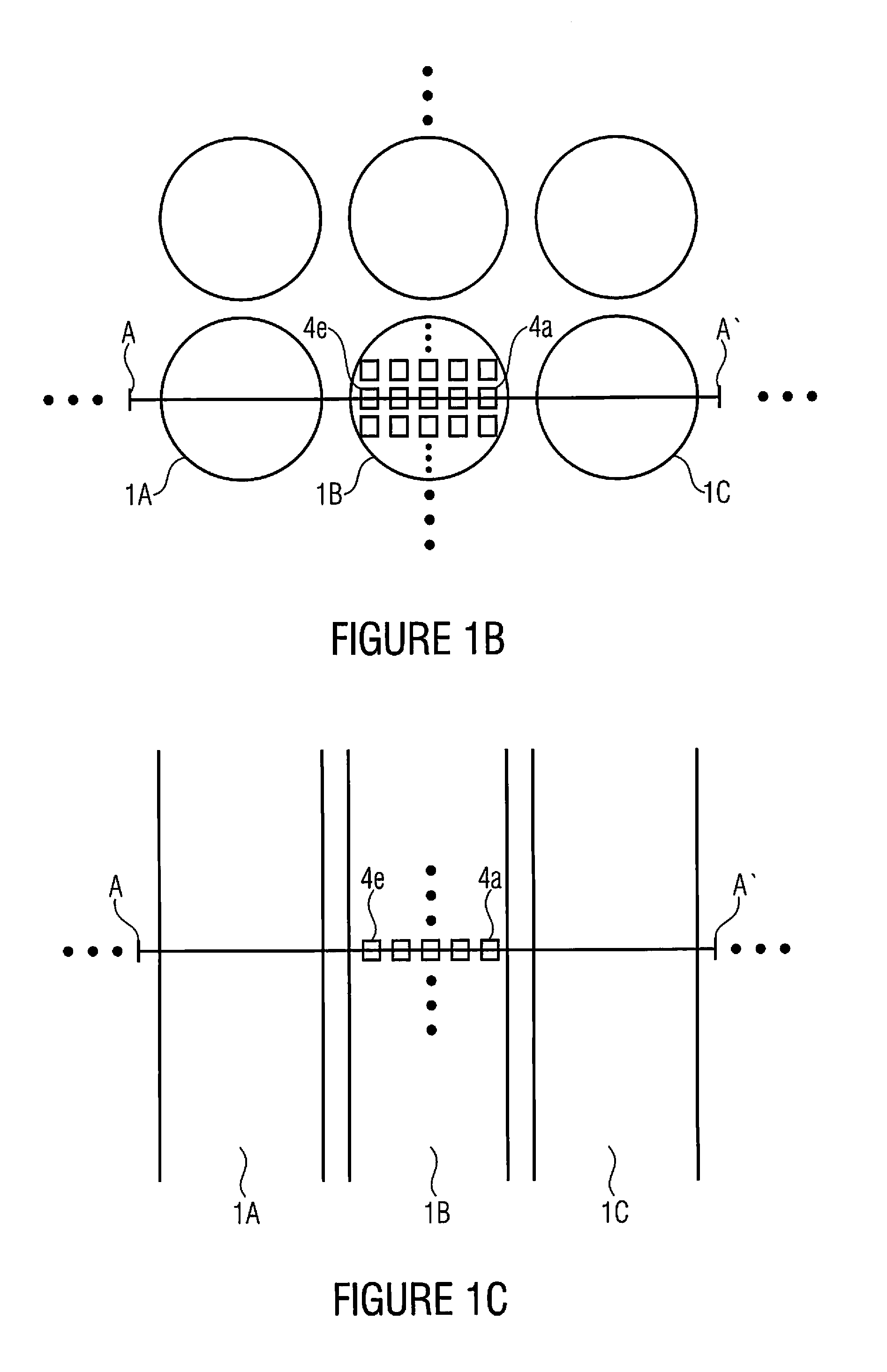

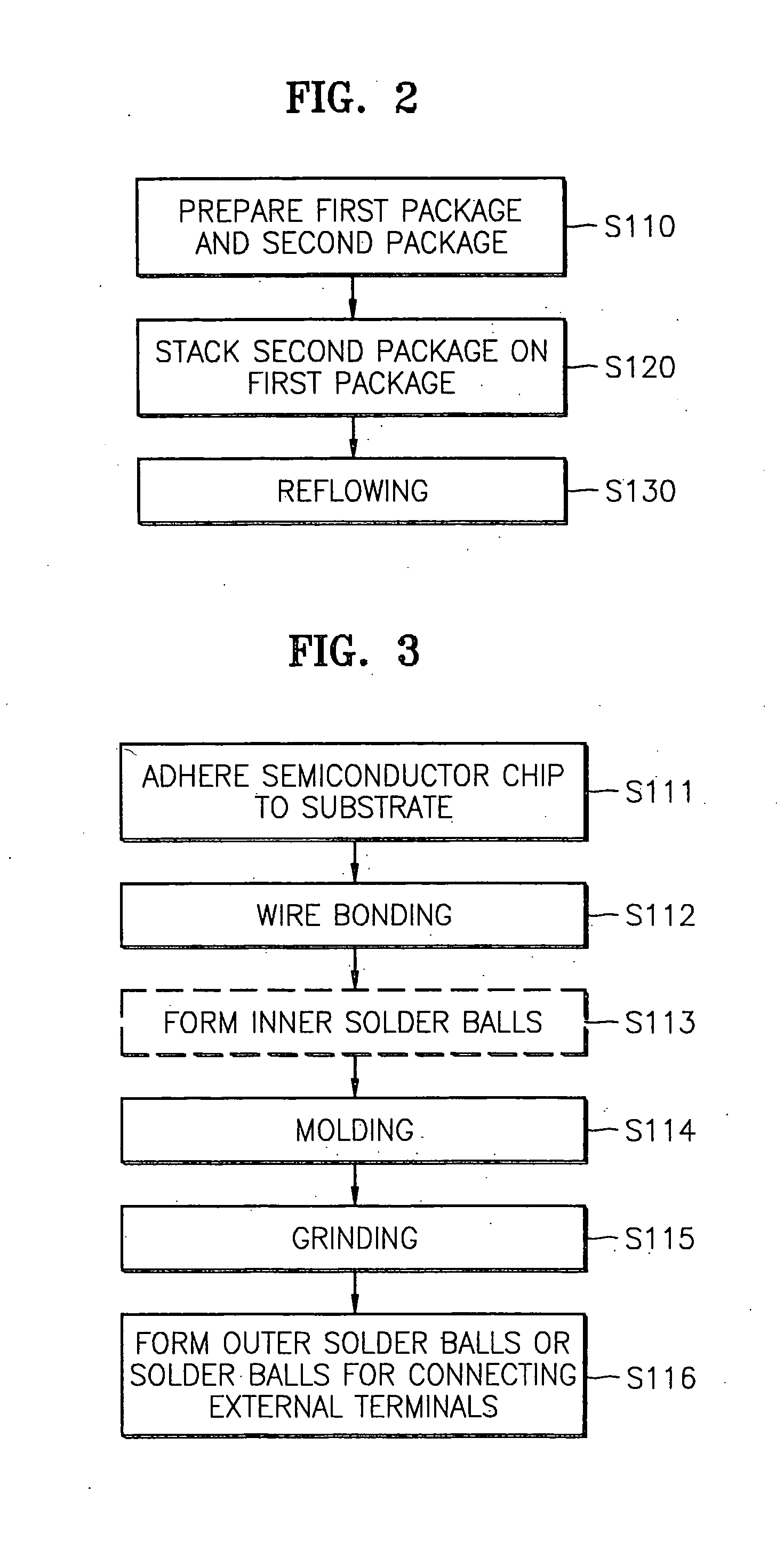

BGA package with stacked semiconductor chips and method of manufacturing the same

InactiveUS20070063332A1More reliableLow cost mass productionSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor chip

A package with two or more stacked semiconductor chips and a method of manufacturing the same. In the method, an upper semiconductor chip package and a lower semiconductor chip package are prepared. Solder balls are formed on a substrate of the lower package to connect the upper and lower packages. A semiconductor chip and the solder balls are molded and then ground until the solder balls are exposed. Solder balls are formed on the bottom of a substrate of the upper package. The upper package is stacked on the lower package such that the solder balls of the lower package are in contact with the solder balls of the upper package. A reflow process is performed on the lower package and the upper package, which are stacked, to physically connect the upper and lower packages.

Owner:SAMSUNG ELECTRONICS CO LTD

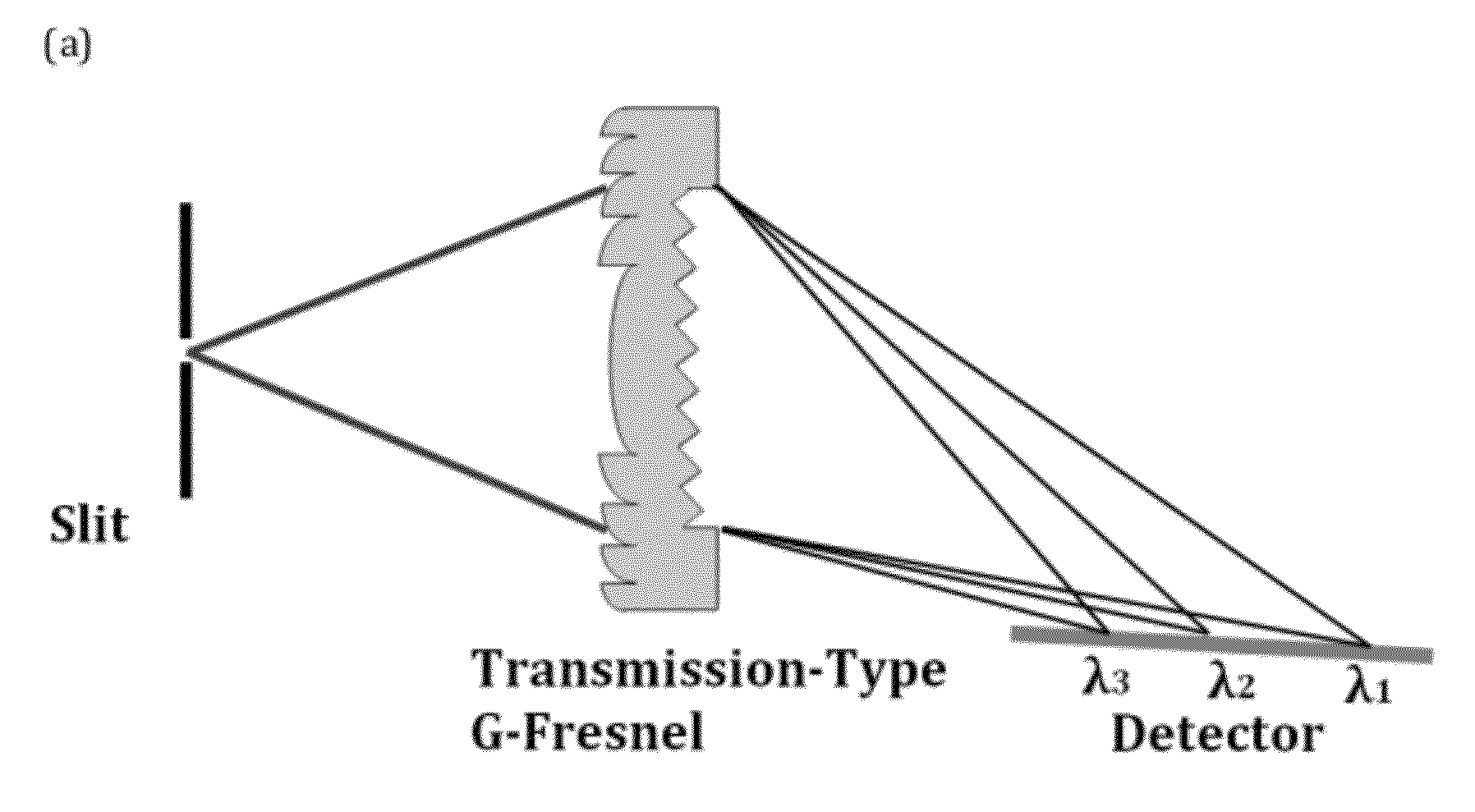

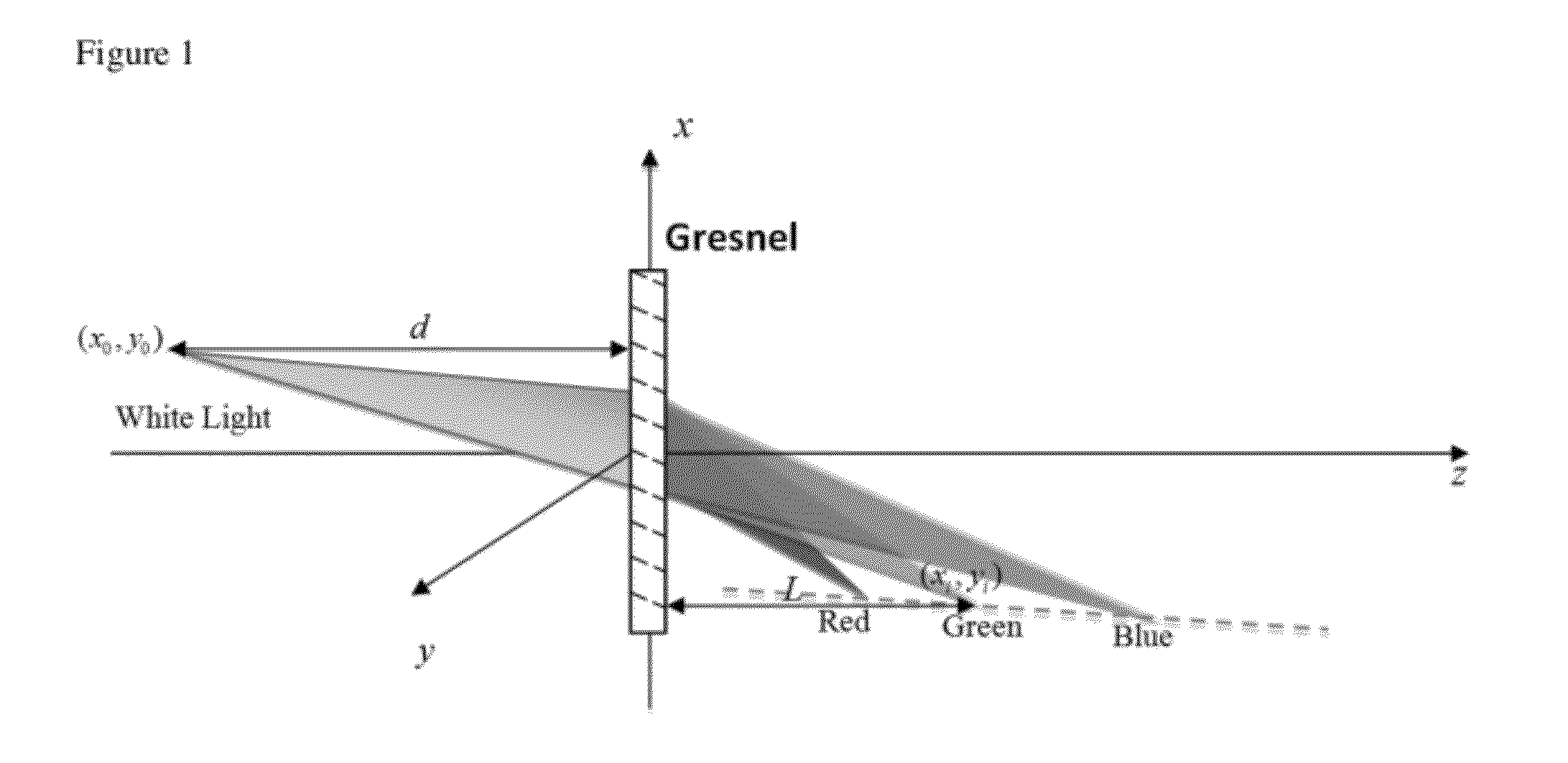

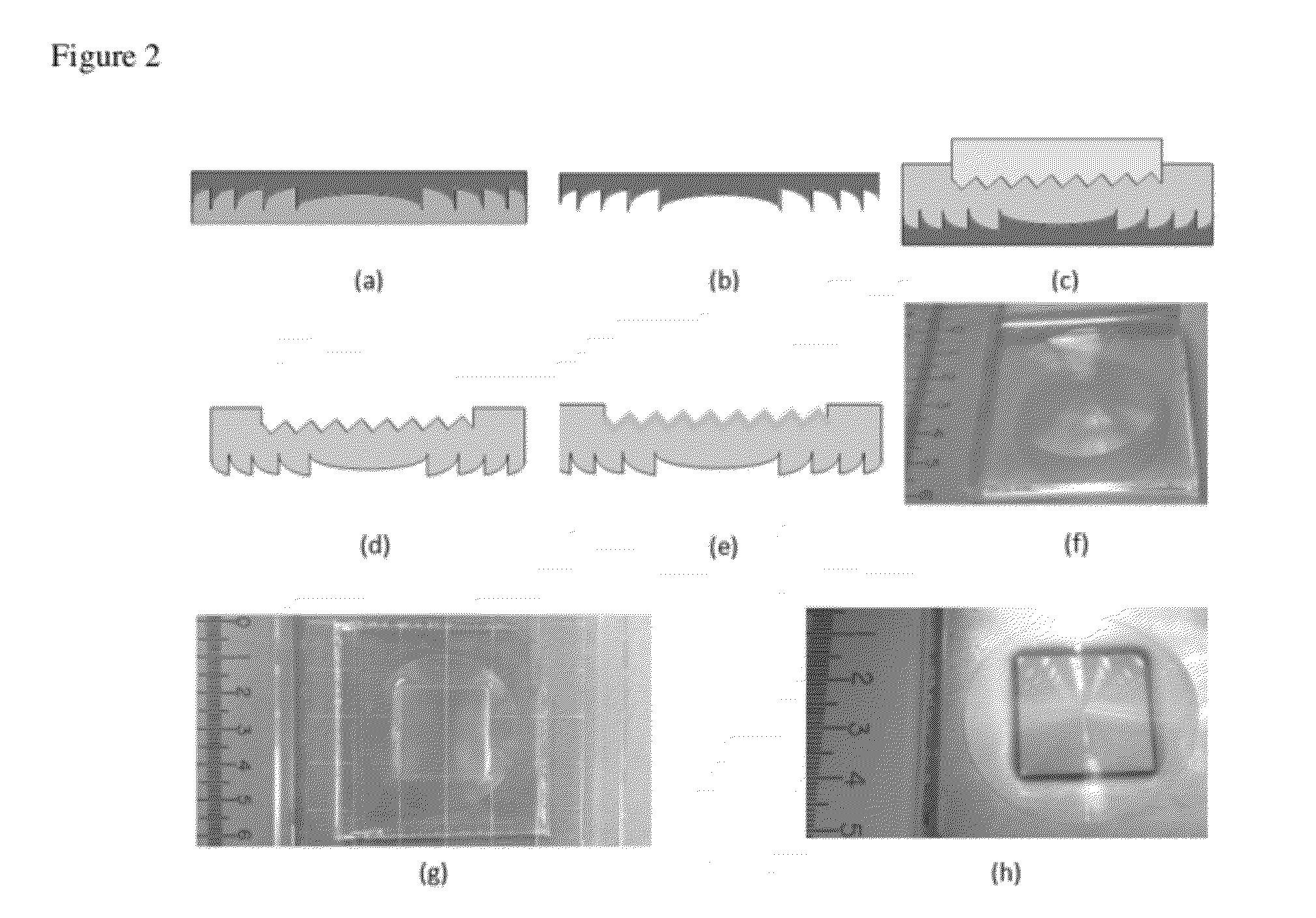

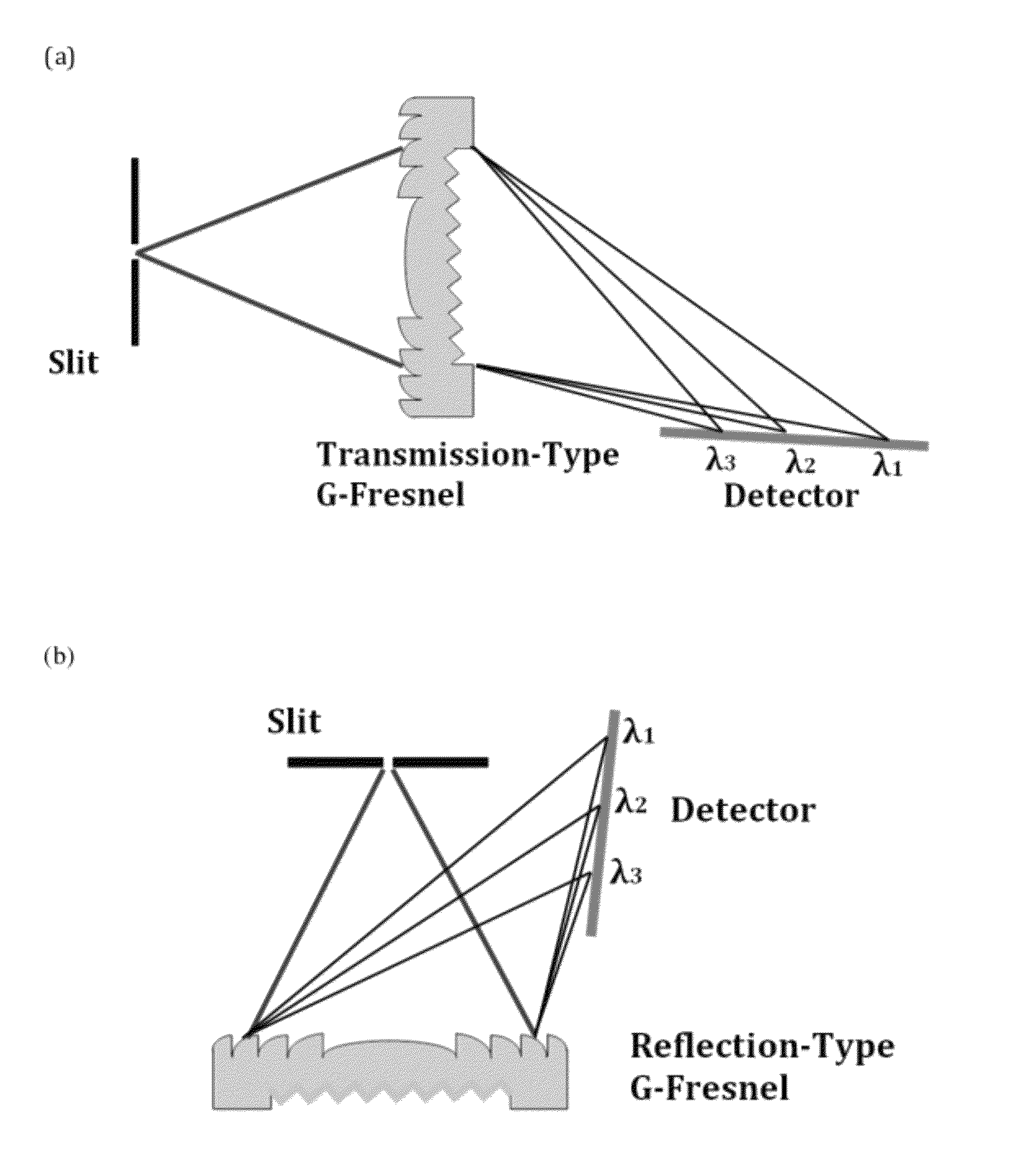

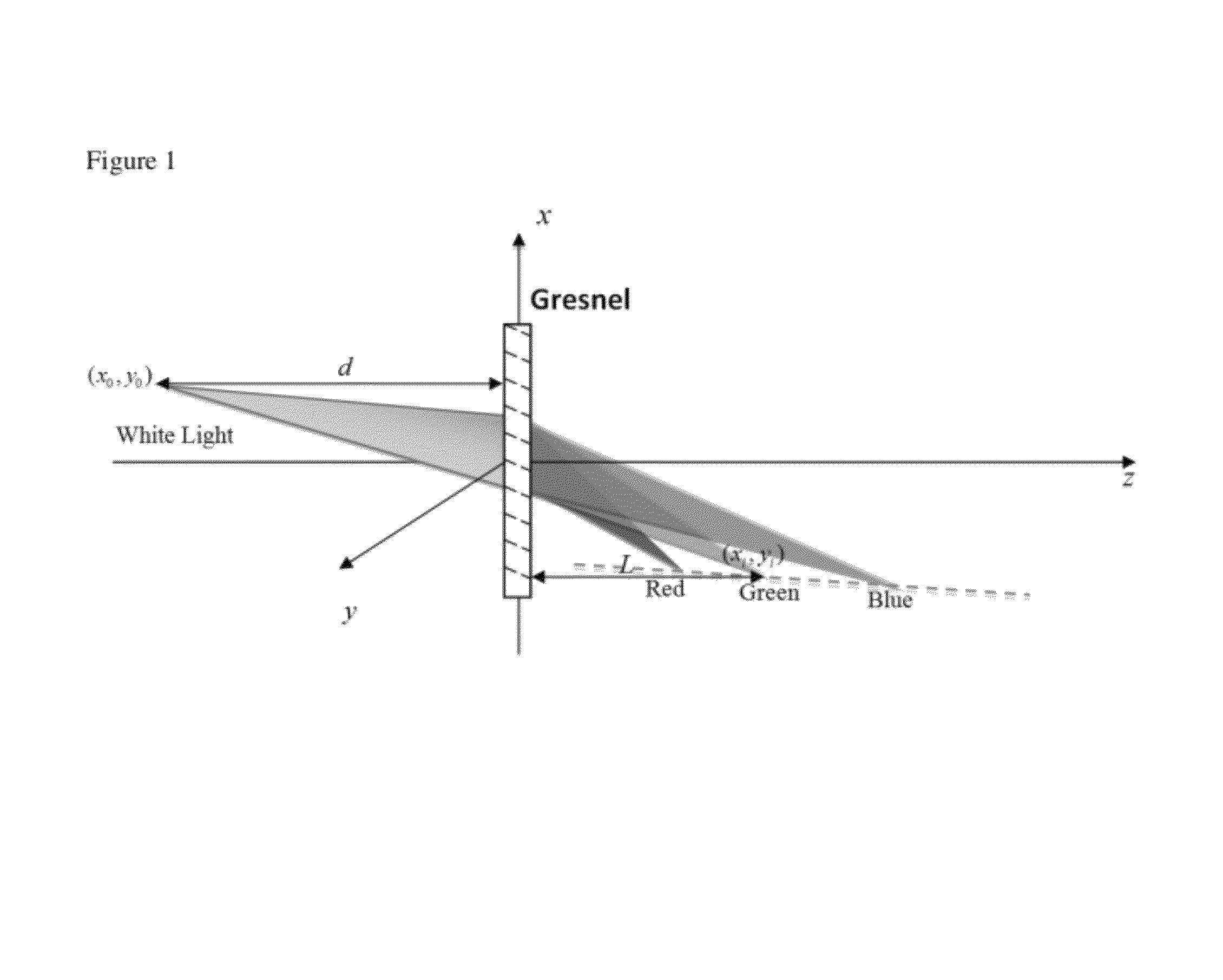

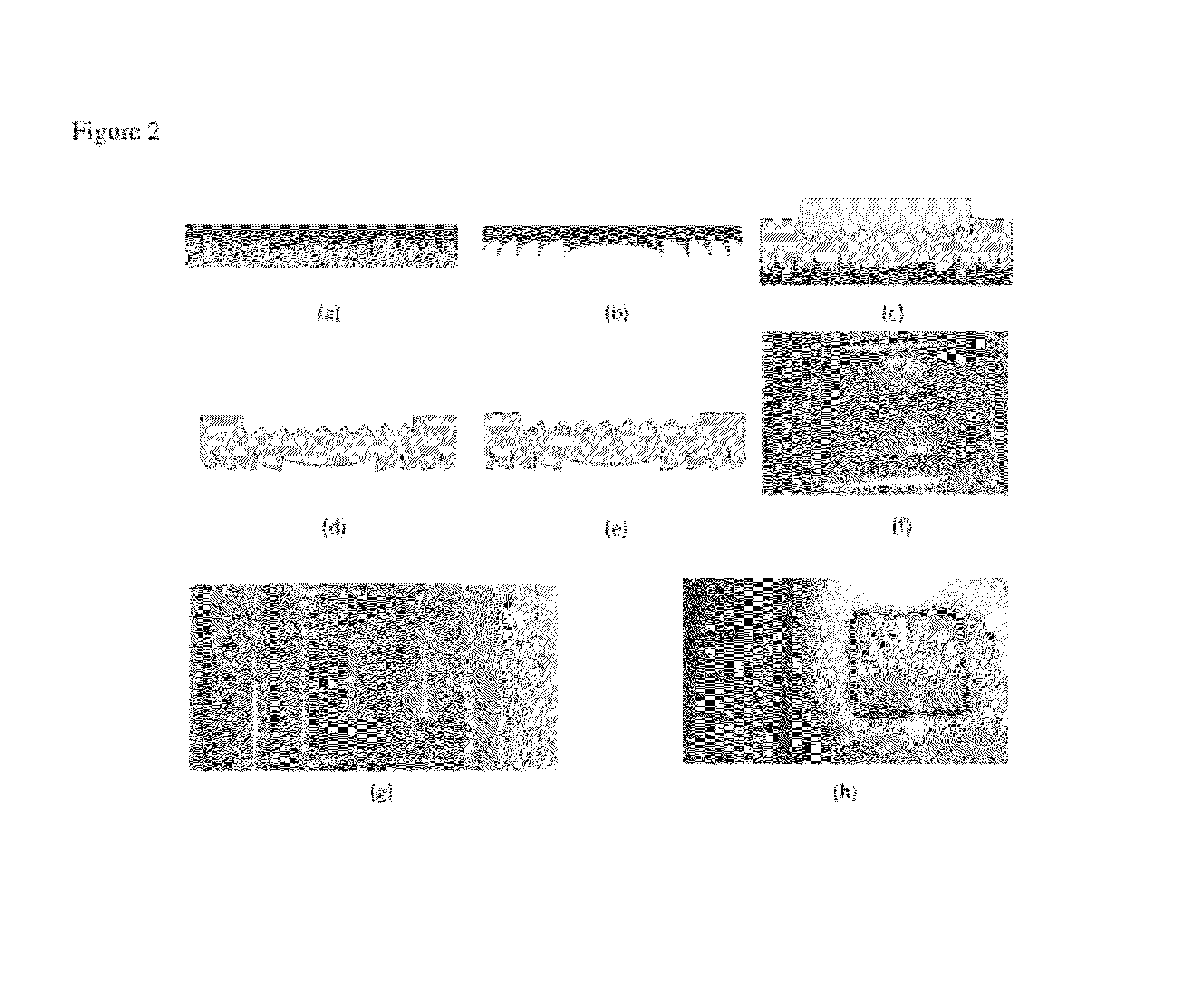

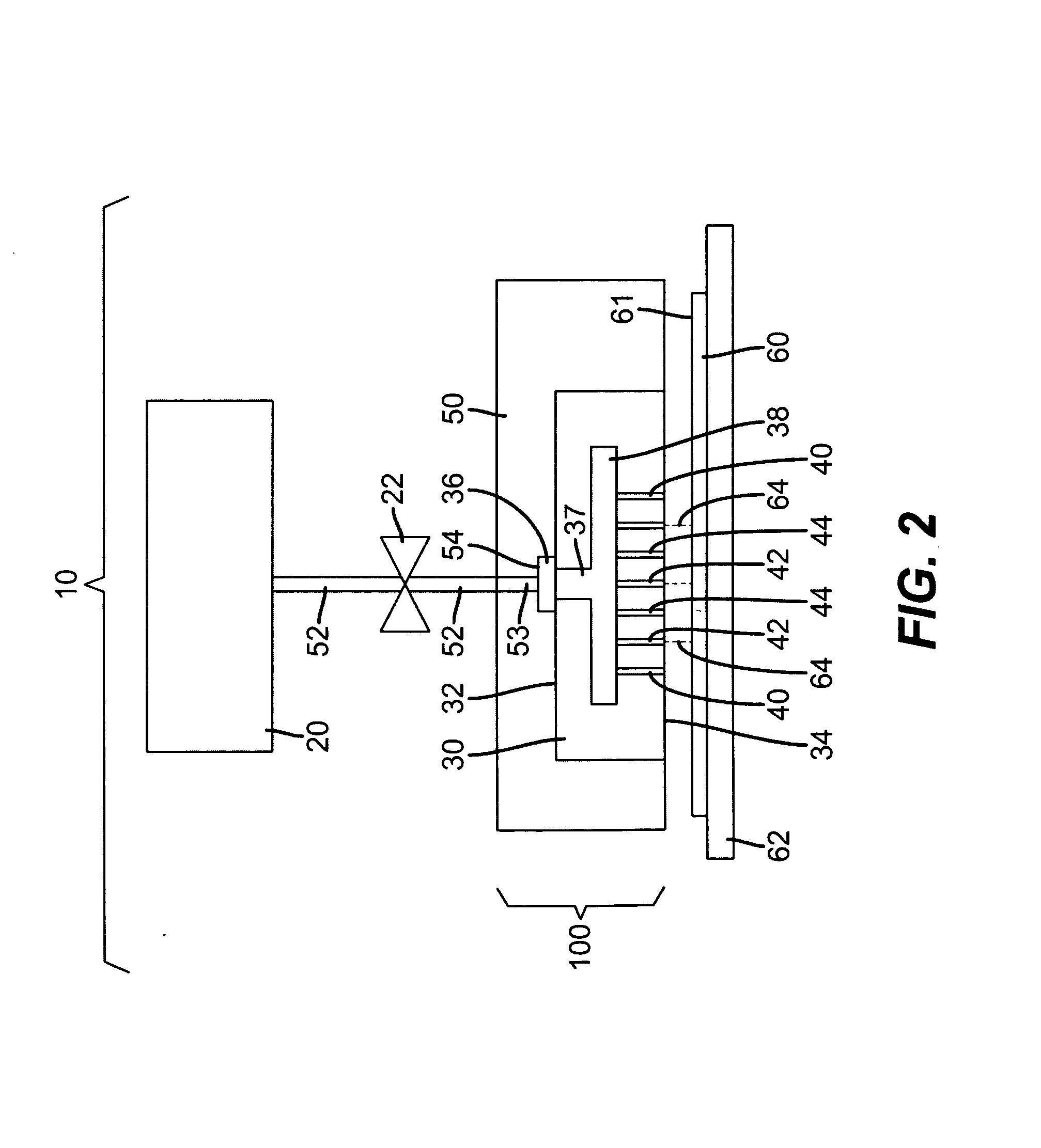

Compact Spectrometer Including a Diffractive Optical Element with Dual Dispersion and Focusing Functionality

ActiveUS20120038918A1Low cost mass productionRadiation pyrometrySpectrum investigationSoft lithographyMillimeter

Embodiments of the invention provide a device called a “G-Fresnel” device that performs the functions of both a linear grating and a Fresnel lens. We have fabricated the G-Fresnel device by using PDMS based soft lithography. Three-dimensional surface profilometry has been performed to examine the device quality. We have also conducted optical characterizations to confirm its dual focusing and dispersing properties. The G-Fresnel device can be useful for the development of miniature optical spectrometers as well as emerging optofluidic applications. Embodiments of compact spectrometers using diffractive optical elements are also provided. Theoretical simulation shows that a spectral resolution of approximately 1 nm can be potentially achieved with a millimeter-sized G-Fresnel. A proof-of-concept G-Fresnel-based spectrometer with subnanometer spectral resolution is experimentally demonstrated.

Owner:PENN STATE RES FOUND

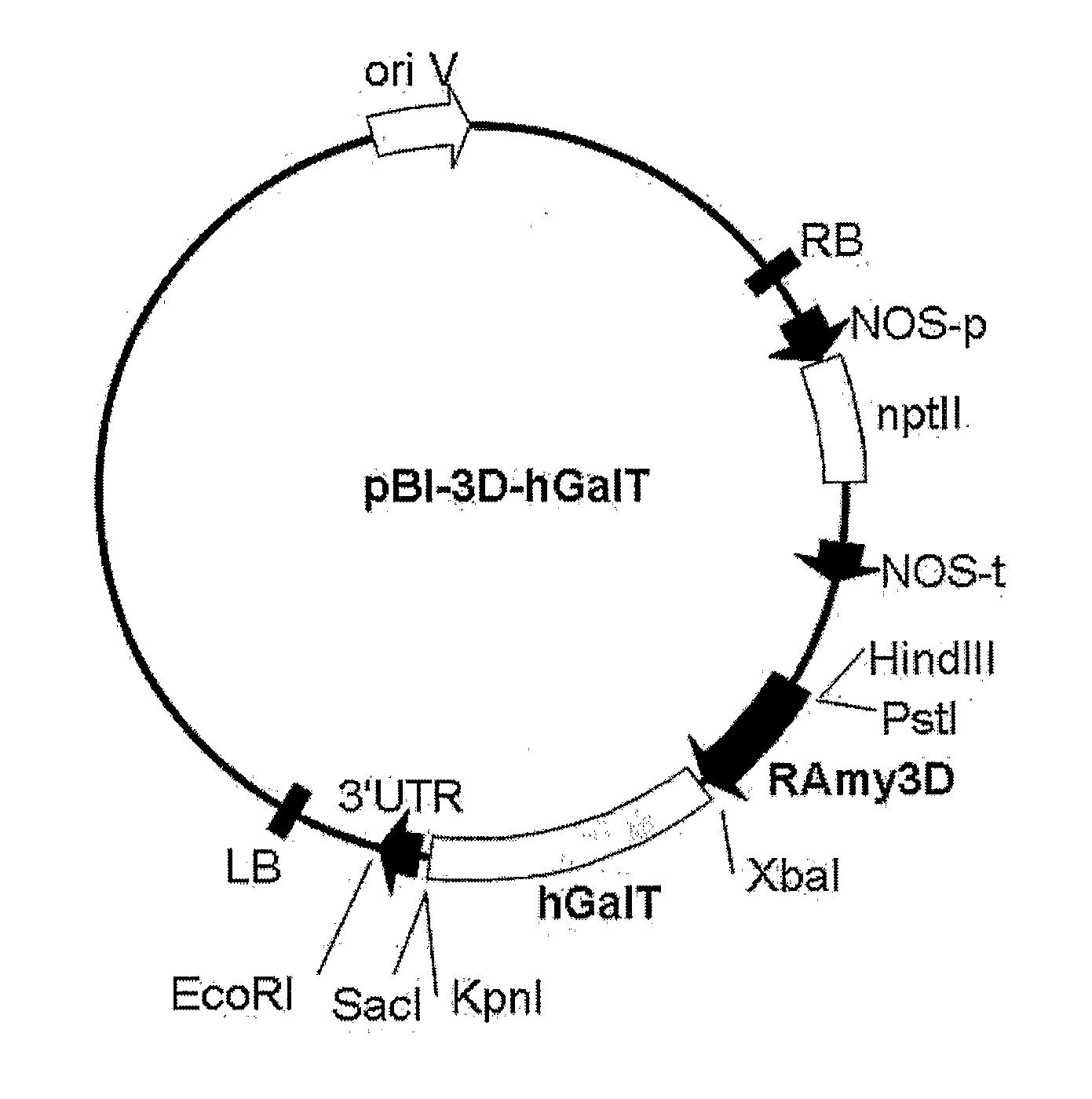

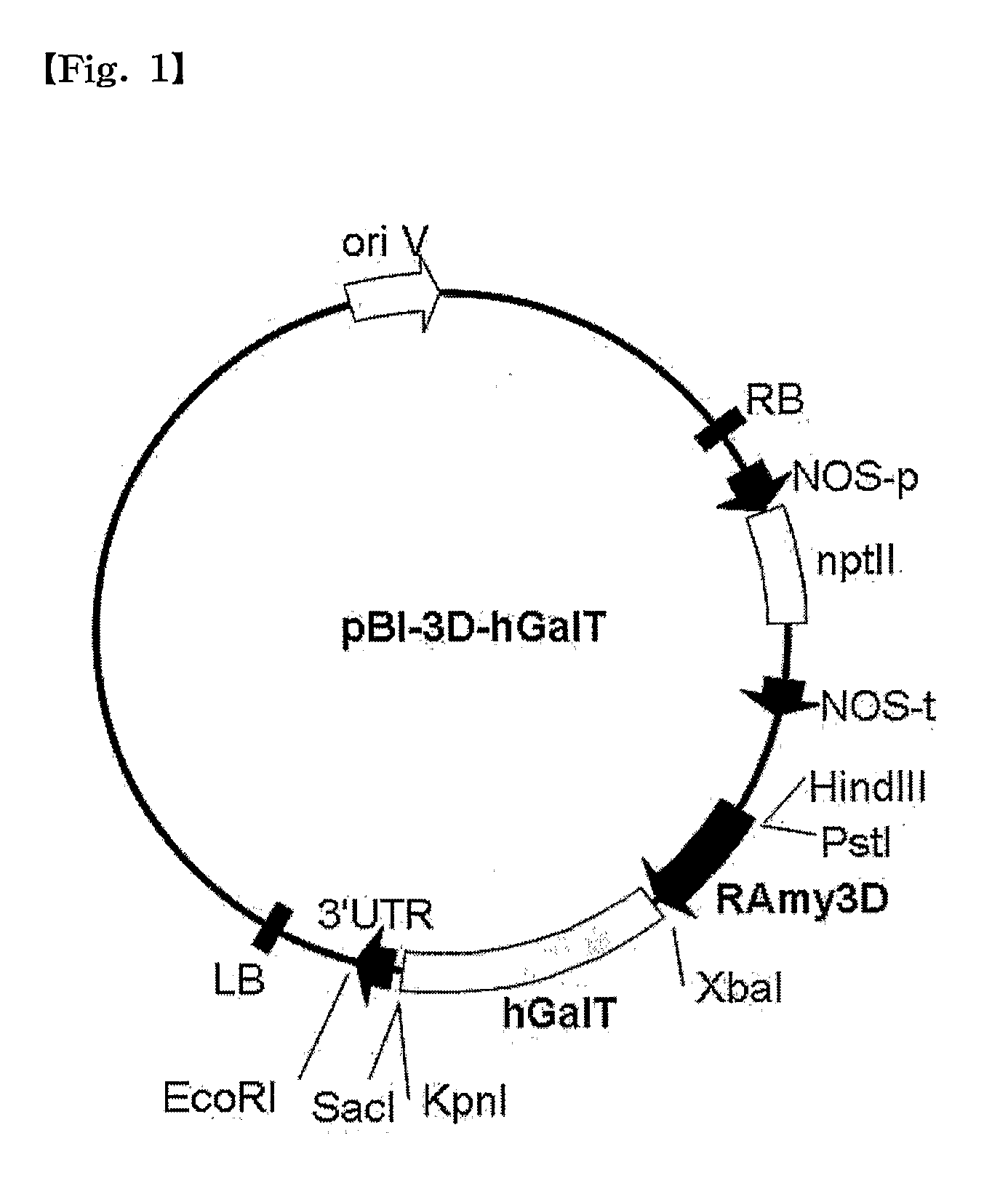

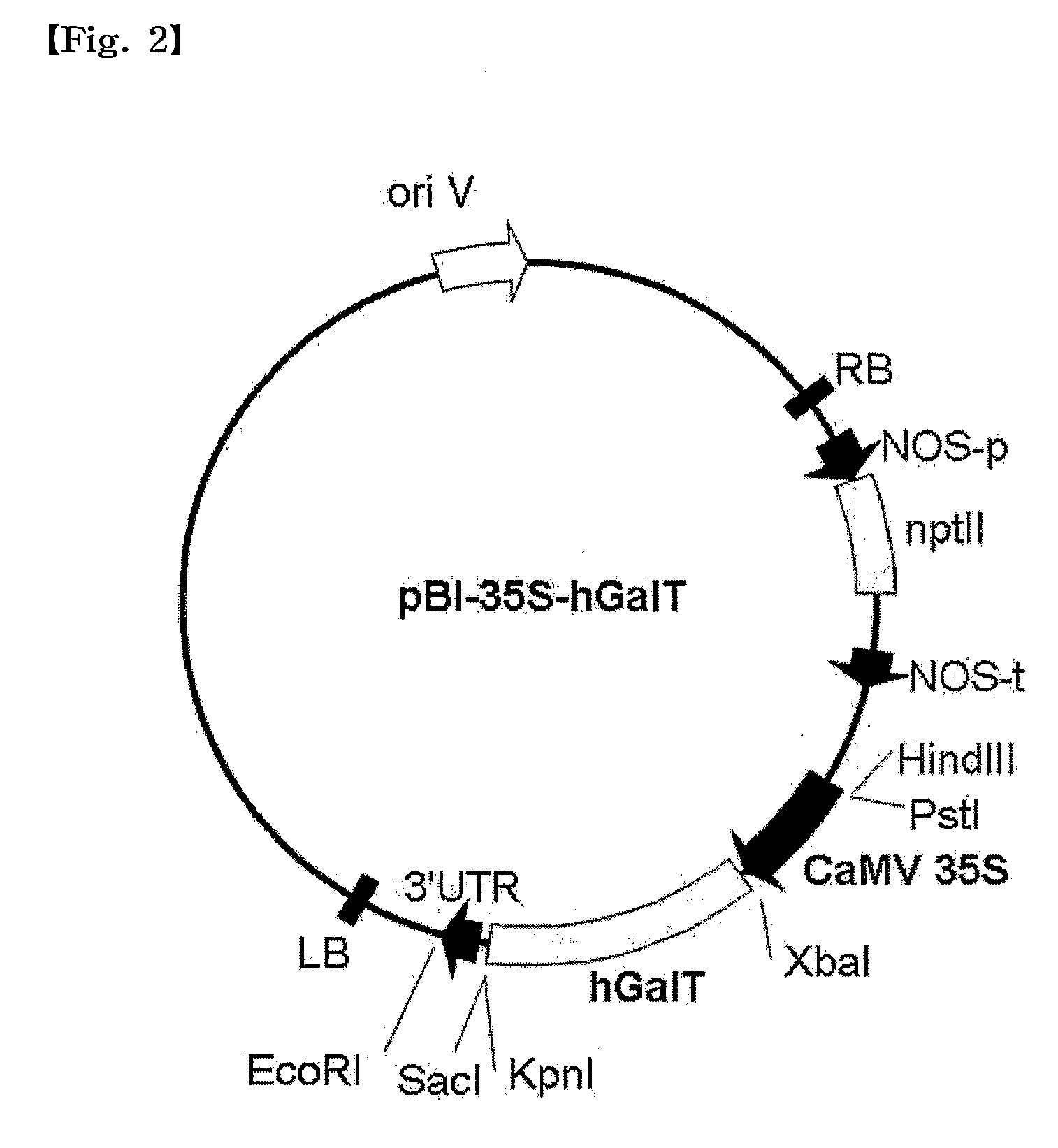

Plant Recombinant Human CTLA4IG and a Method for Producing the Same

InactiveUS20100189717A1Prolong half-life in vivoLow cost mass productionAntibody mimetics/scaffoldsHybrid cell preparationHalf-lifePlant cell

The present invention provides a recombinant vector pBI-3D-hGalT or pBI-35S-hGalT containing a human β1,4-galactosyltransferase gene; a cell line transformed with a recombinant vector pMYN414 containing a cytotoxic T-lymphocyte anti-gen A-immunoglobulin (CTLA4Ig) fusion protein gene and the recombinant vector pBI-3D-hGalT or pBI-355-hGalT; and a method for producing a plant-derived recombinant human CTLA4Ig (CTLA4Igp) fusion protein with a human glycan structure using the same. The plant cell-derived recombinant human CTLA4Ig fusion protein (CTLA4Igp), which has a human glycan structure and is produced according to the present invention, exhibits an improved in vivo half life as compared to conventional plant-derived proteins, due to the presence of a human-like glycan structure. Consequently, the present invention using the plant expression system enables low-cost mass production of a CTLA4Igp fusion protein having an immunosuppressive activity comparable to that of the CTLA4IgM fusion protein expressed in conventional animal cell expression systems.

Owner:BORYUNG PHARMA CO LTD

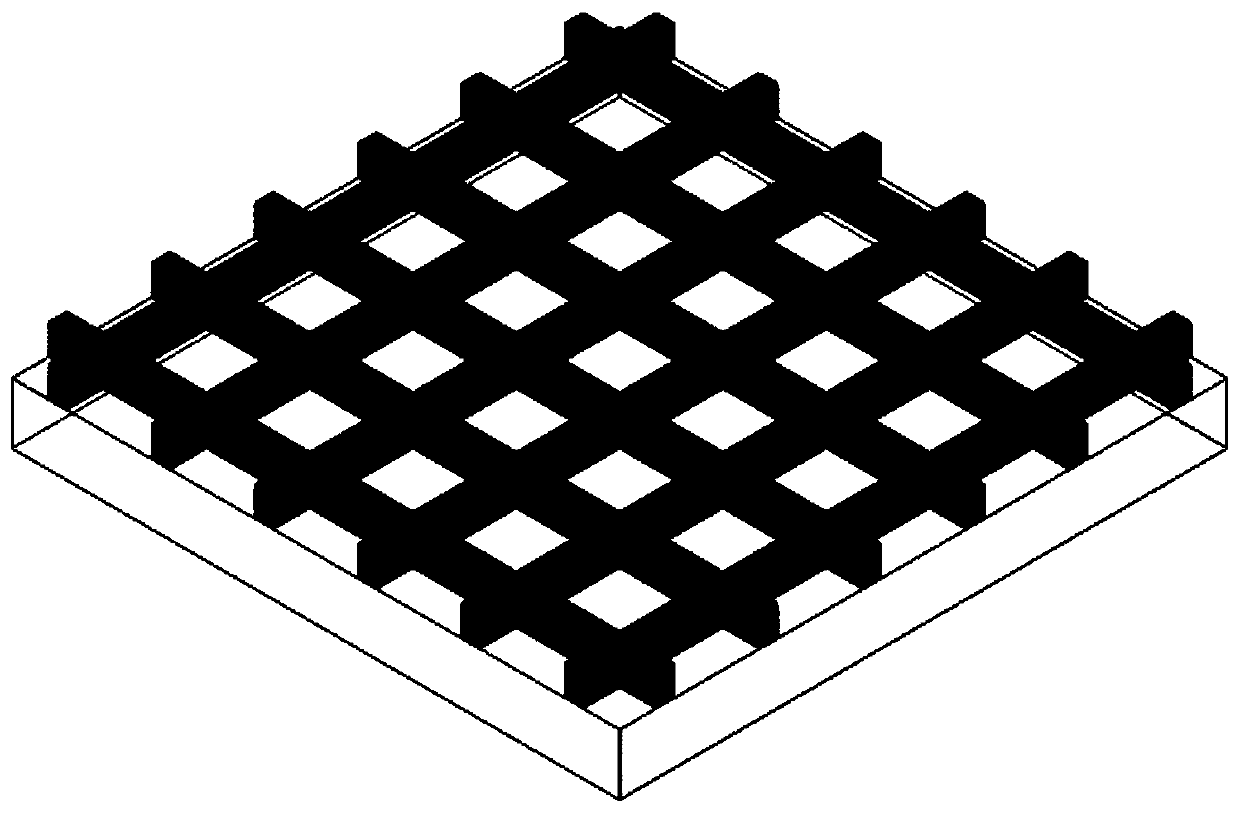

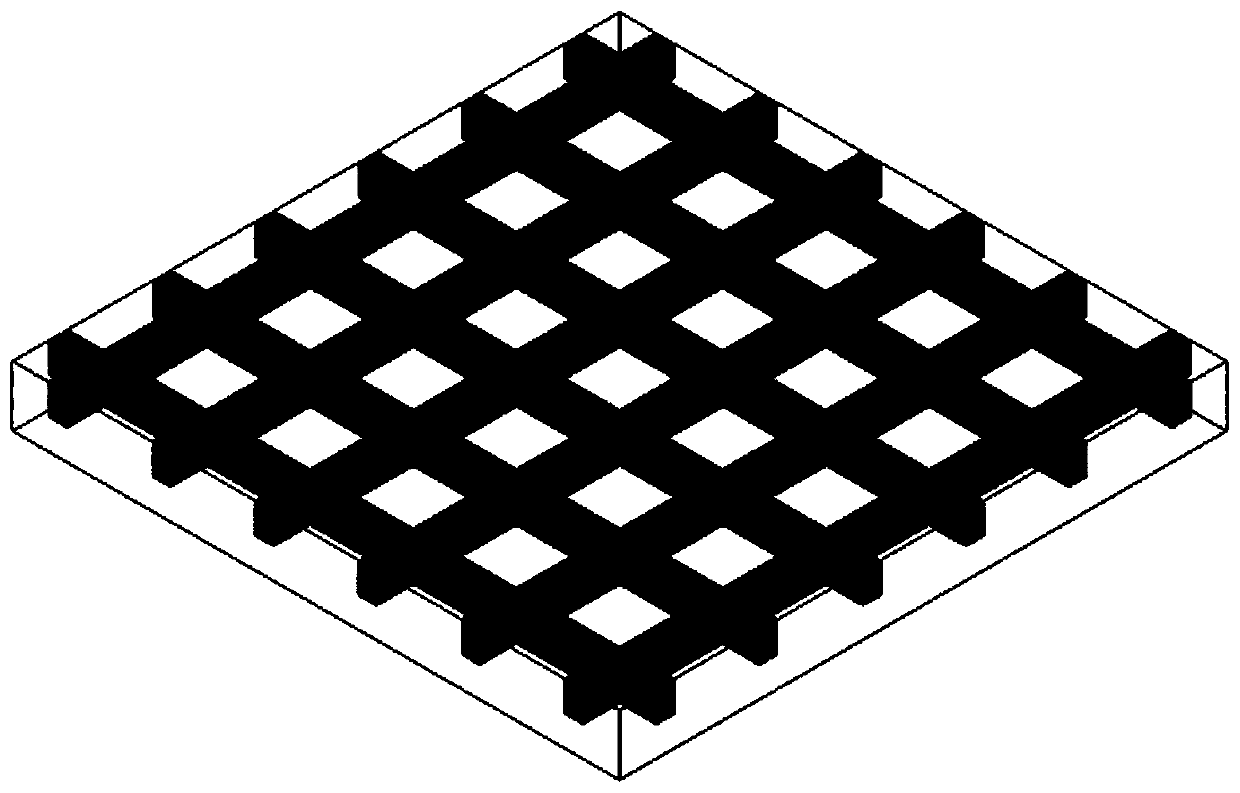

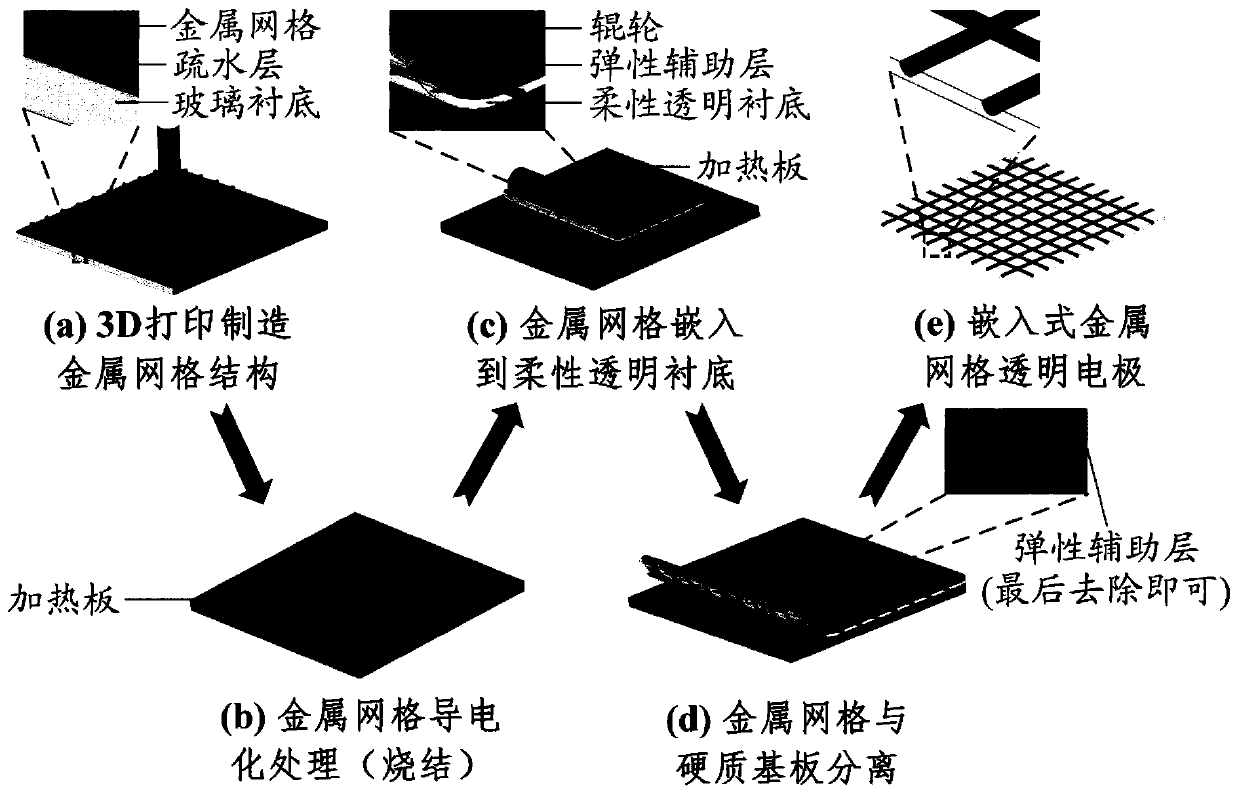

Manufacturing method and application of embedded metal grid flexible transparent electrode

ActiveCN110021462AIncrease profitNo wasteAdditive manufacturing apparatusConductive layers on insulating-supportsHot stampingMicro nano

The invention belongs to the field of flexible transparent electrodes, and particularly relates to a manufacturing method and an application of an embedded metal grid flexible transparent electrode. The method comprises the following steps: 1) by use of an electric field driven spray deposition micro-nano 3D printing technology, a metal grid transparent electrode is directly printed on a hard substrate; 2) conductive treatment is carried out on a printed metal grid structure by adopting a sintering process so as to realize conductive treatment of a metal grid; 3) a flexible transparent substrate and the hard substrate are heated to a set temperature, and a hot stamping process is adopted for completely embedding the metal grid structure on the hard substrate into the flexible transparent substrate; and 4) the metal grid which is completely embedded into the flexible transparent substrate is separated from the hard substrate to obtain the embedded metal grid flexible transparent electrode. According to the method, the electric field driven spray deposition micro-nano 3D printing technology is combined with the roller pair plane hot stamping technology to realize efficient and low-cost batch manufacturing of the large-sized embedded metal grid flexible transparent electrode; and the prepared transparent electrode also has excellent square resistance and light transmittance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

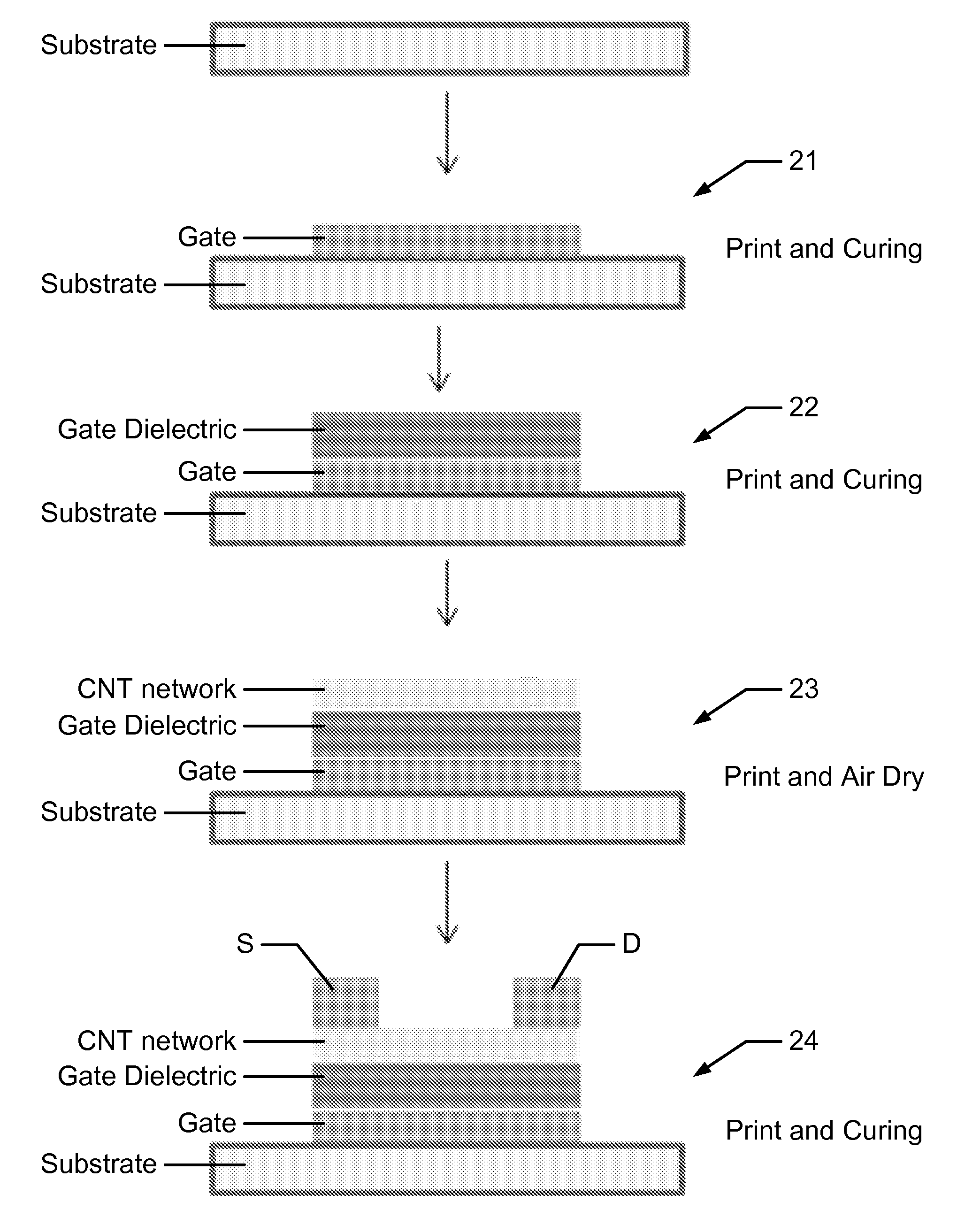

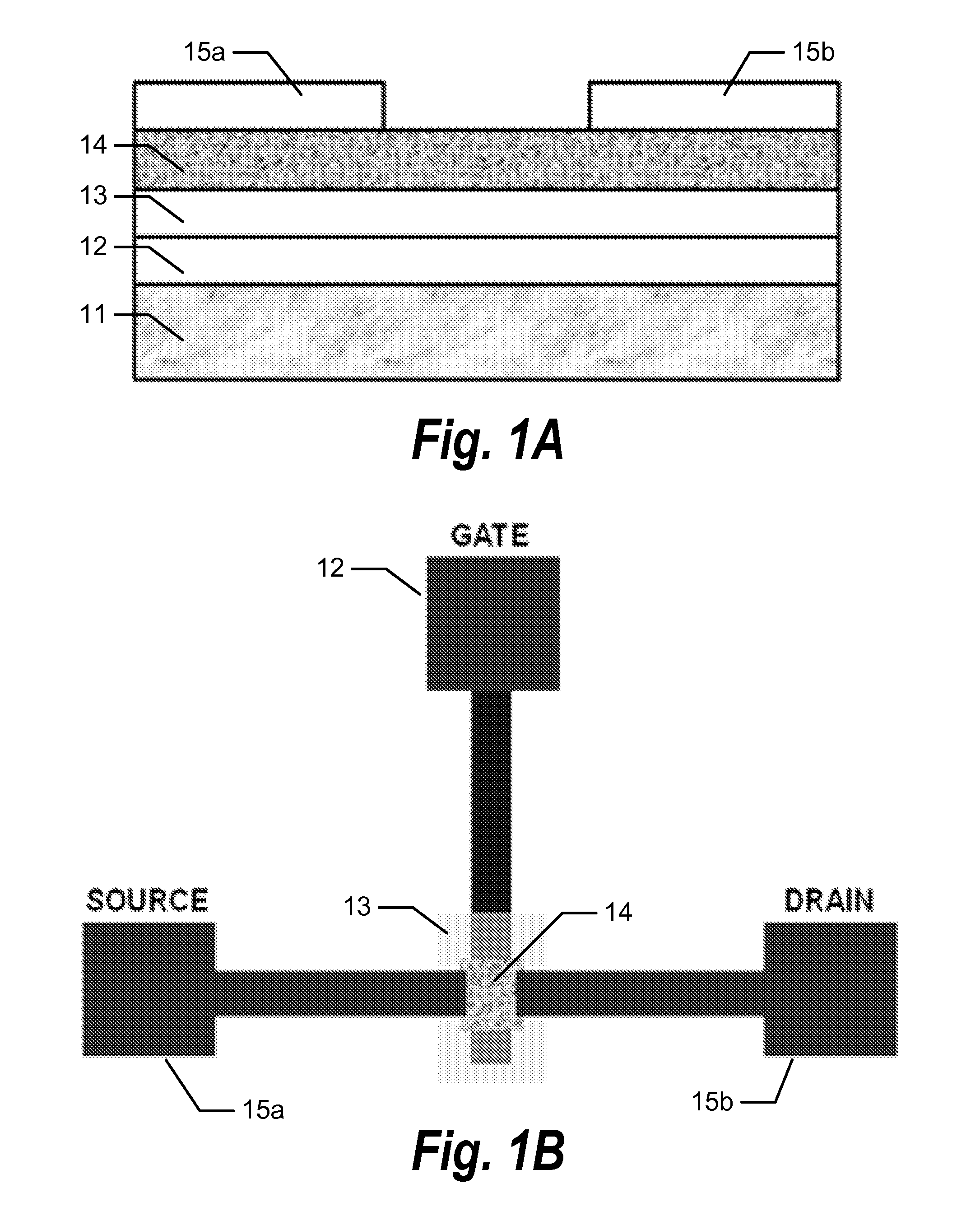

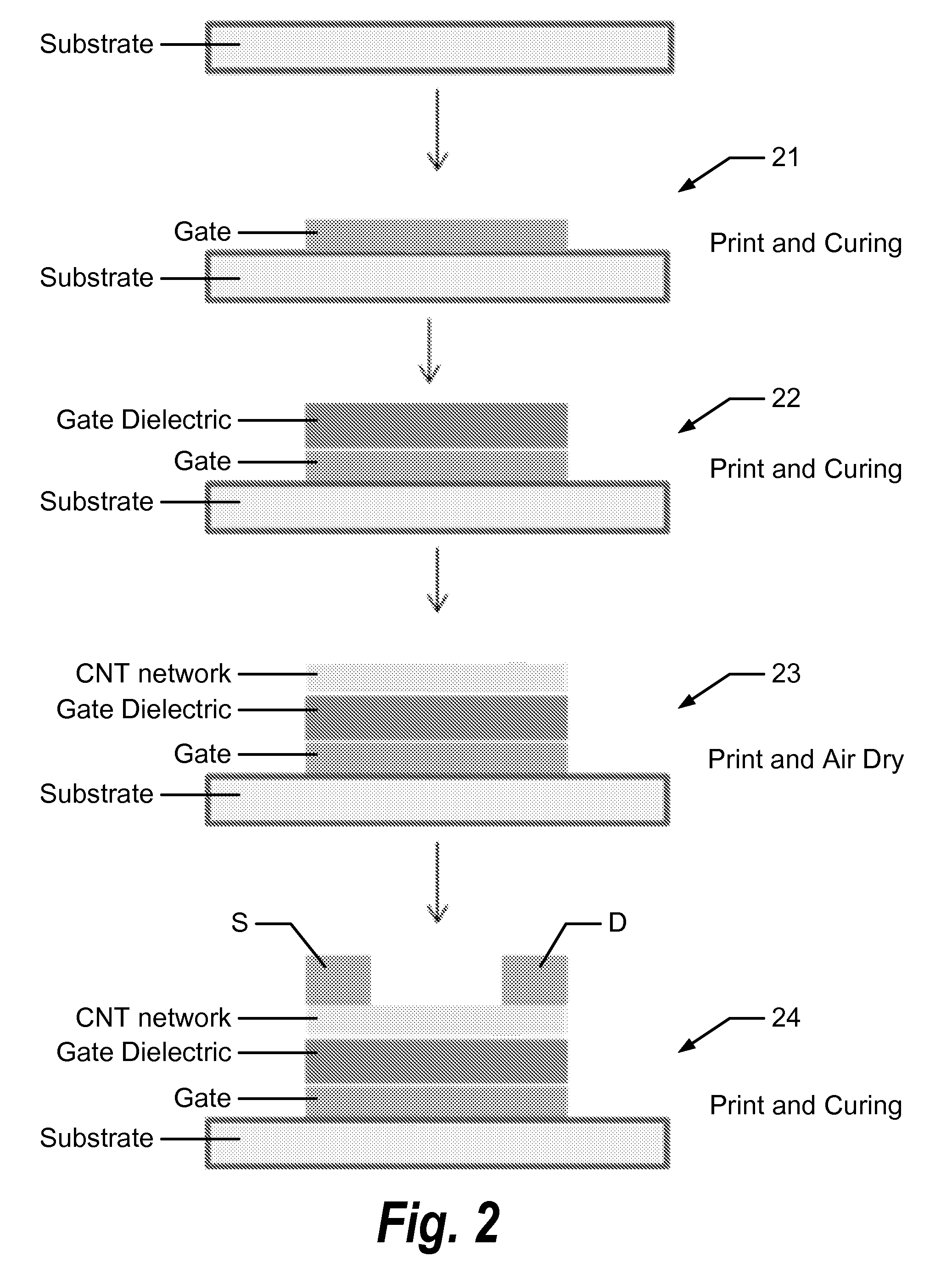

Carbon nanotube field effect transistor for printed flexible/rigid electronics

InactiveUS20110248243A1Eliminate needImprove throughputNanoinformaticsSolid-state devicesUV curingIsolation layer

Methods and devices for manufacturing carbon nanotube based field effect transistors are disclosed including providing a substrate; printing a gate electrode layer onto the substrate and sintering and / or UV curing; printing a gate isolation layer onto the gate electrode and air drying and / or UV curing; printing one or more carbon nanotube channel layers onto the gate isolation layer, wherein each carbon nanotube channel layer is air dried prior to subsequent printings; and printing a source and drain electrode layer onto the one or more carbon nanotube channel layers and sintering and / or UV curing. Other embodiments are described and claimed.

Owner:OMEGA OPTICS

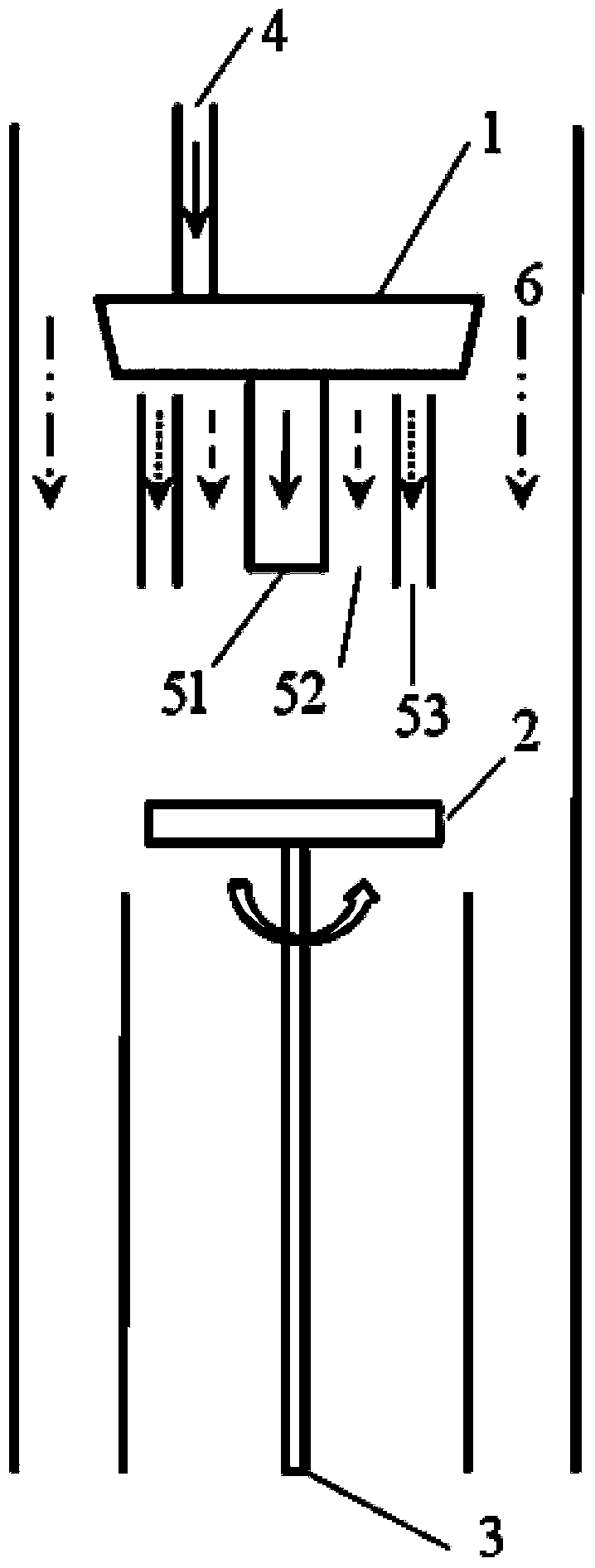

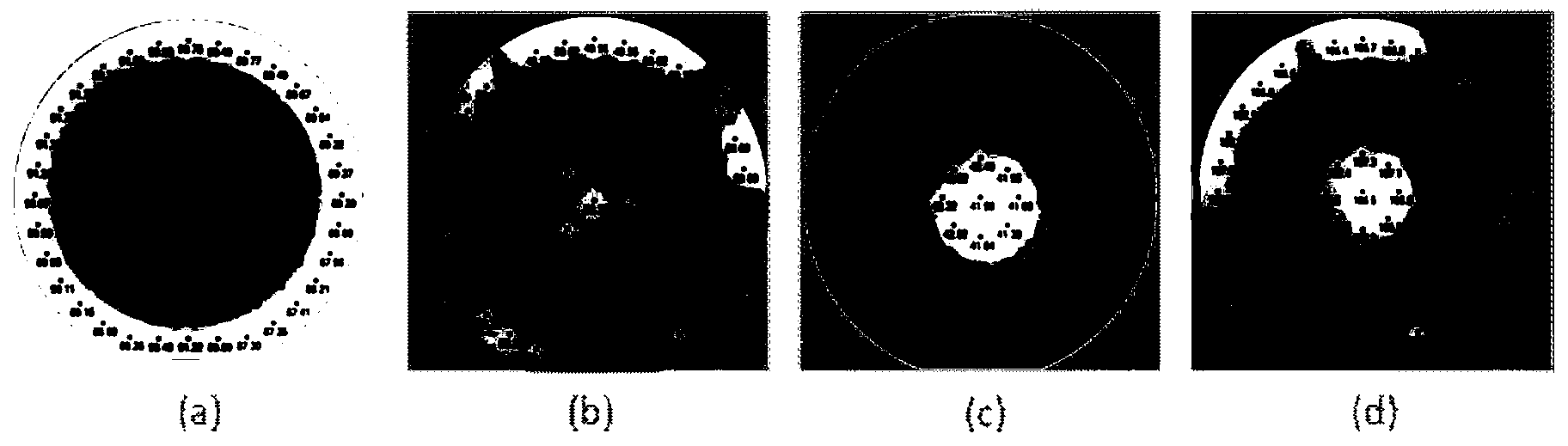

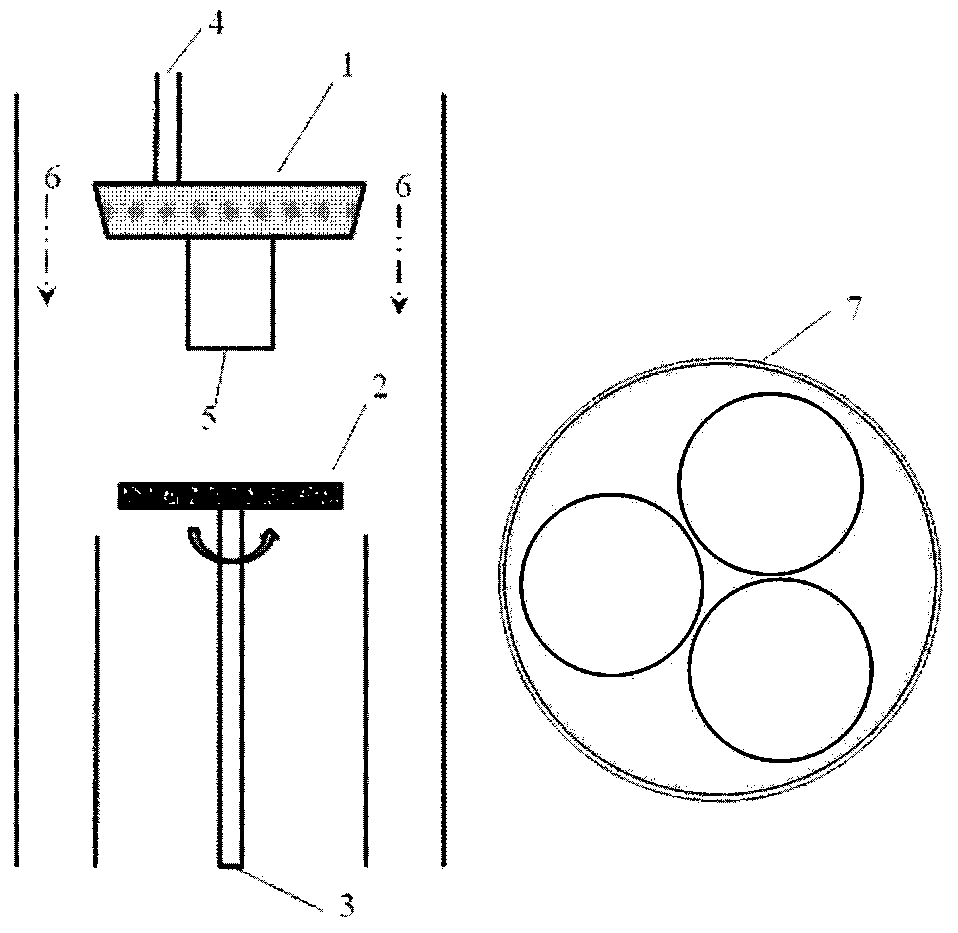

Hydride vapor deposition device and method for improving thickness distribution uniformity of multiple-piece epitaxial materials

ActiveCN103456593AImprove Utilization and Production EfficiencyLow cost mass productionElectric discharge tubesSemiconductor/solid-state device manufacturingSource materialEpitaxial material

The invention discloses a hydride vapor deposition device and method for improving thickness distribution uniformity of multiple-piece epitaxial materials. The method is used for improving growth uniformity of a large area of multiple-piece GaN thin-film materials. According to the method, a source gas conveying pipeline system of a system is improved, a plurality of sets of concentric circle precursor gas conveying systems formed by a metal precursor gas conveying pipeline, an inert diluent gas conveying pipeline and a nitride precursor conveying pipeline are designed according to the array of a plurality of substrates, therefore, the total distribution probabilities of reaction precursor gases on the surfaces of the substrates can be basically consistent, thus, the thickness uniformity of epitaxial layer thin films of the substrates can be adjusted, and the use ratio of source materials can be improved. The method is simple in process and easy to control, a plurality of pieces can be grown at the same time through one furnace, GaN self-supported substrates for homoepitaxy can be manufactured on a large scale at low cost, and the requirements for optical / microelectronic devices with high photoelectric properties can be met.

Owner:SINO NITRIDE SEMICON

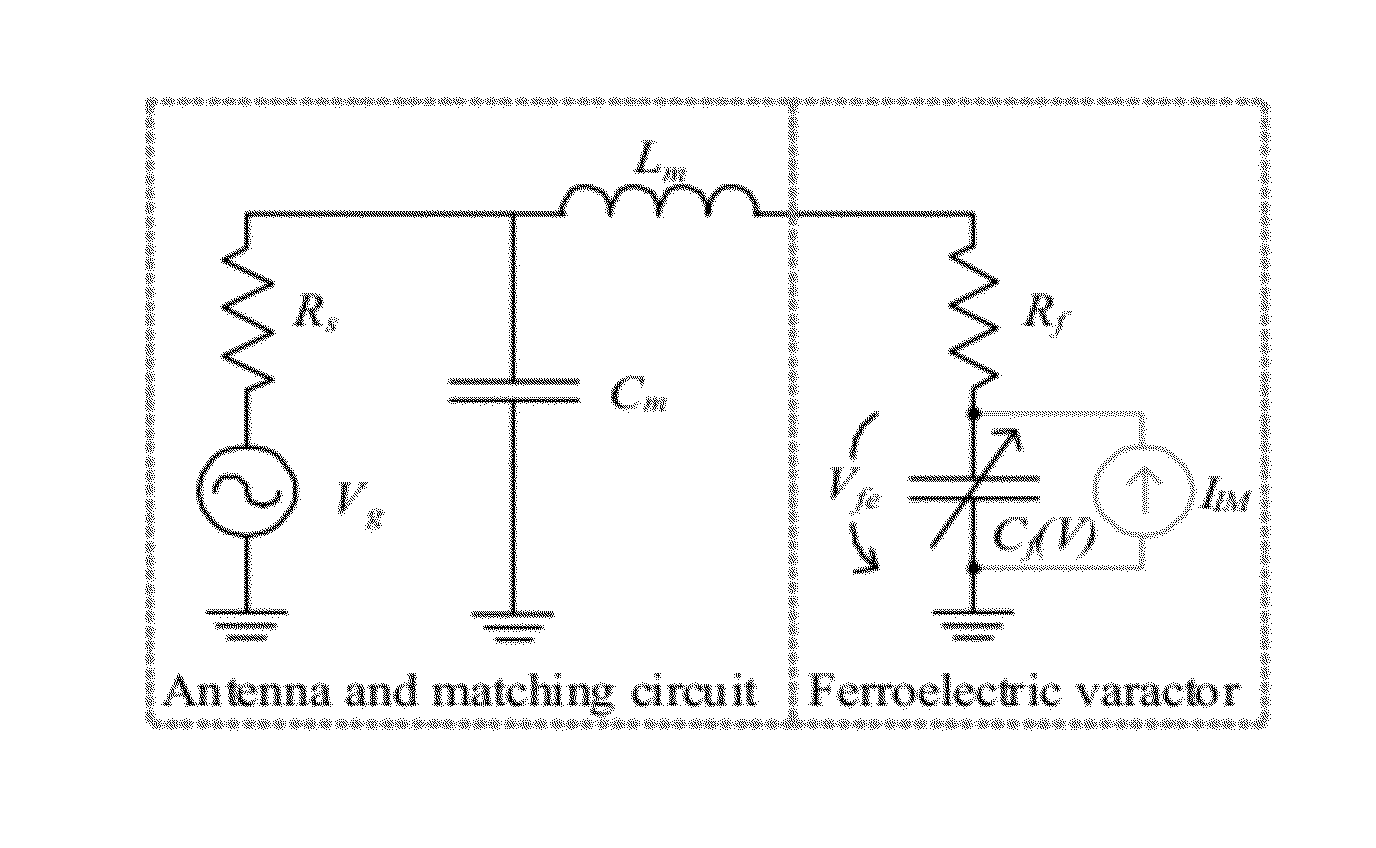

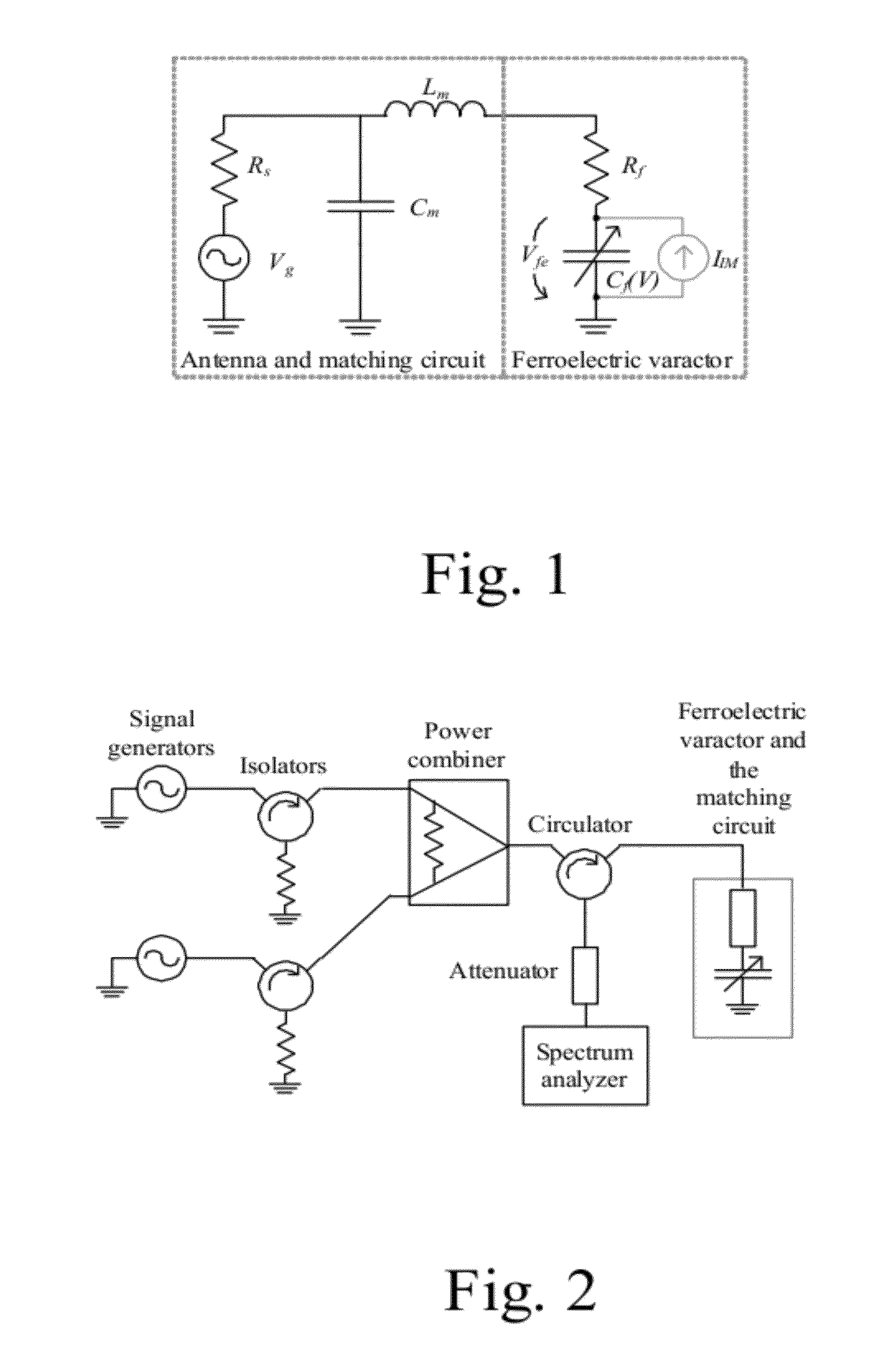

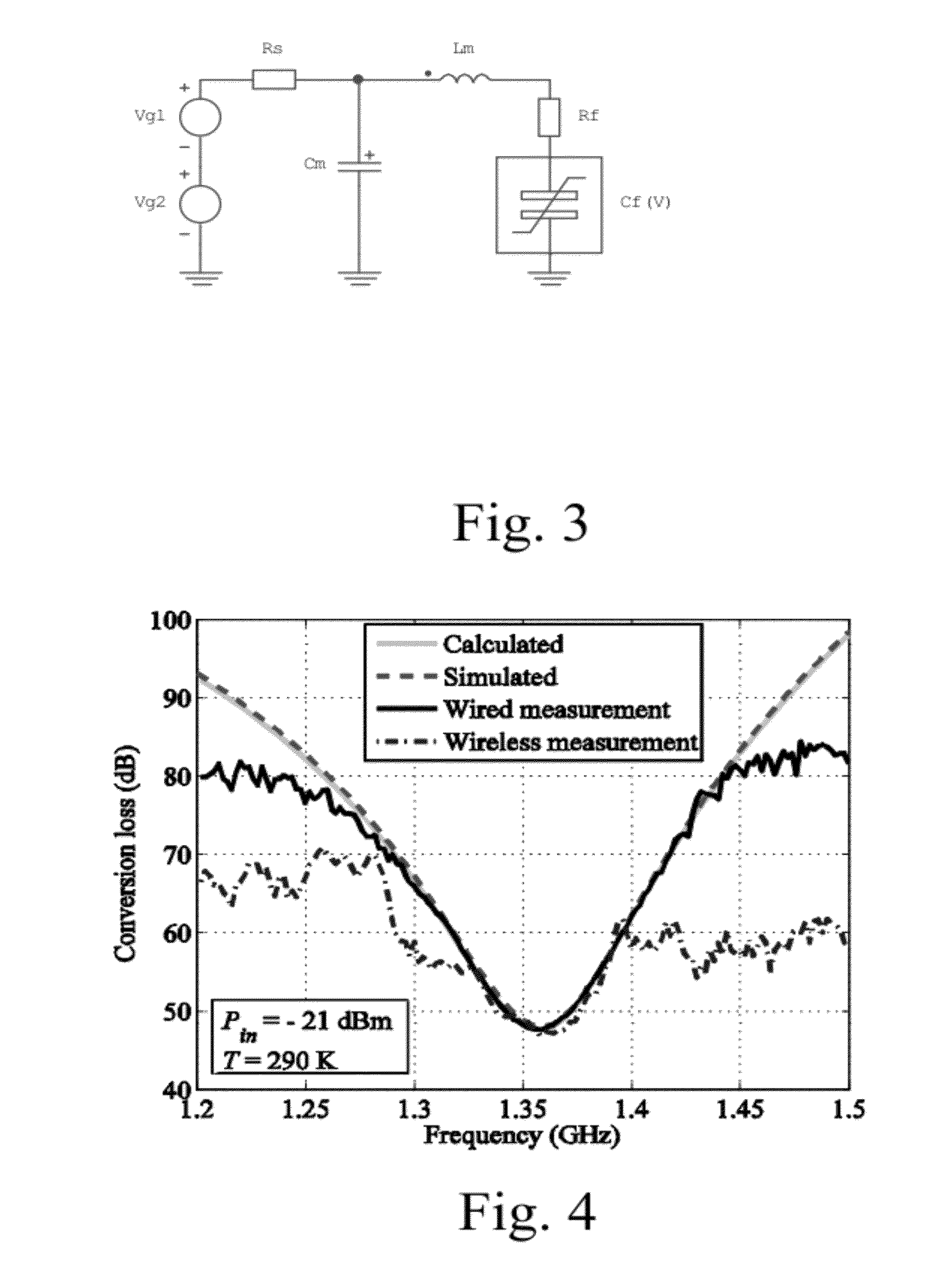

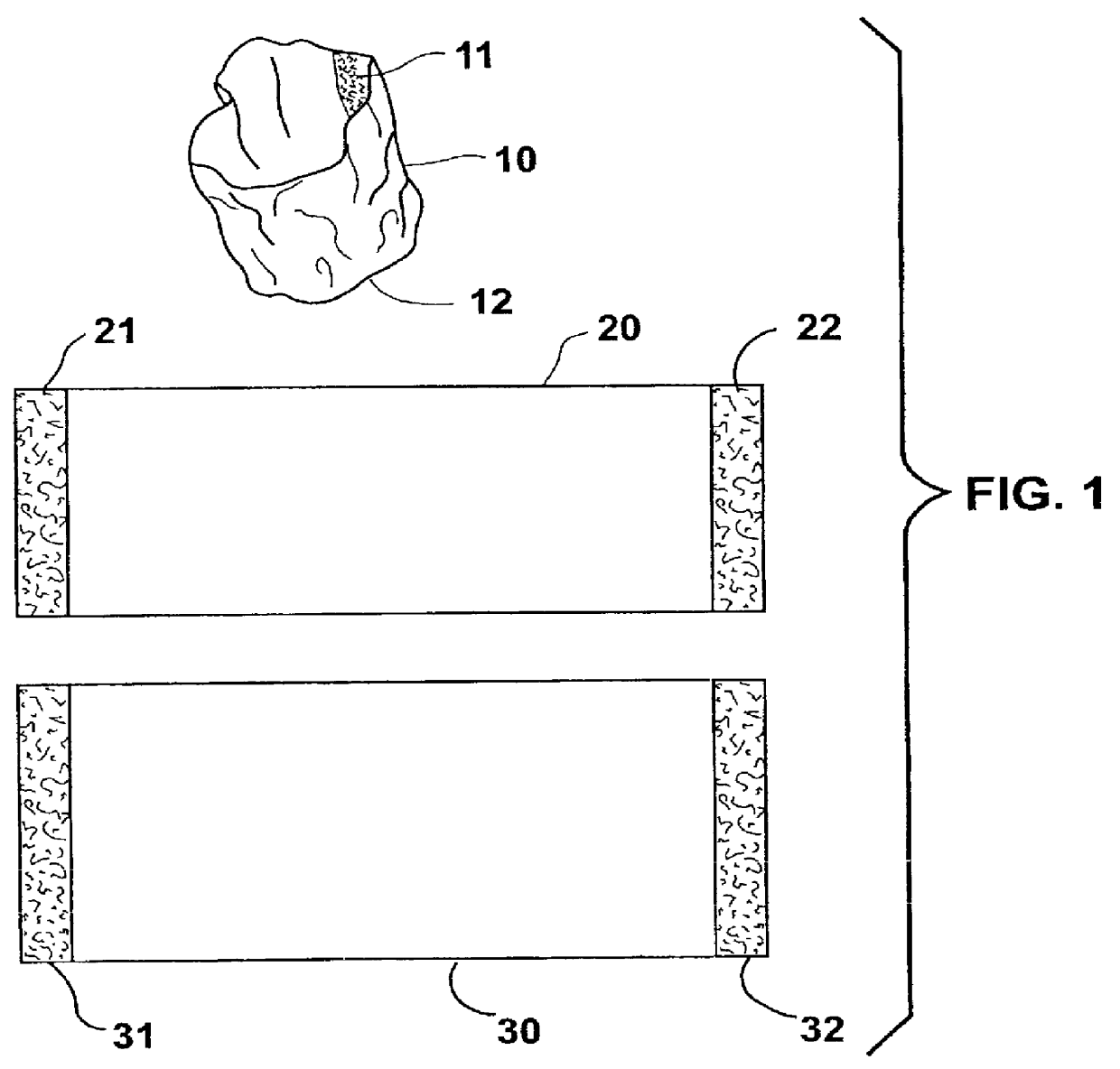

Non-linear resonating sensor and a method

ActiveUS20120235847A1Low cost mass productionCost of complexityRecord carriers used with machinesAntennasResistive sensorsEngineering

Described herein is a passive wireless resonating non-linear sensor that is typically based on a ferroelectric varactor. The sensor replies its data at an intermodulation frequency when a reader device illuminates it at two closely-located frequencies. Furthermore, described herein is a general intermodulation read-out principle for passive wireless sensors. A sensor utilizes a mixing element, such as a varactor and it can be equipped with a capacitive, inductive, or resistive sensor element. When the sensor is illuminated with signals with two frequencies it replies the sensor data at an intermodulation frequency.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

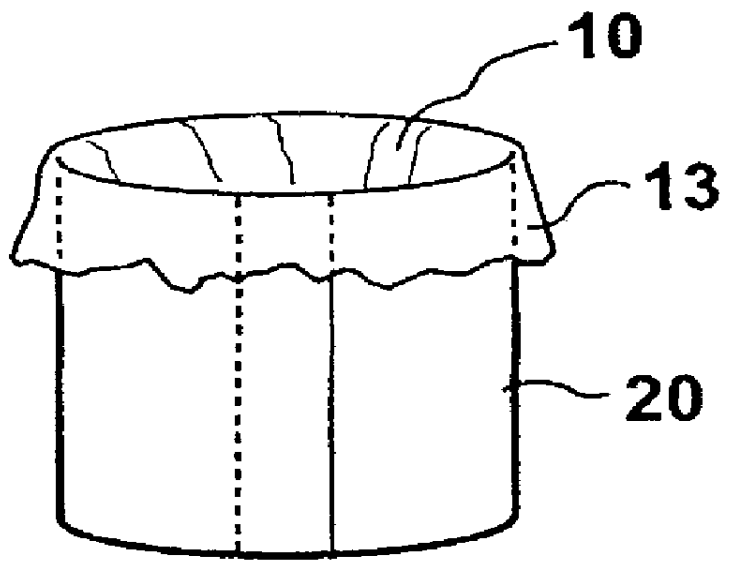

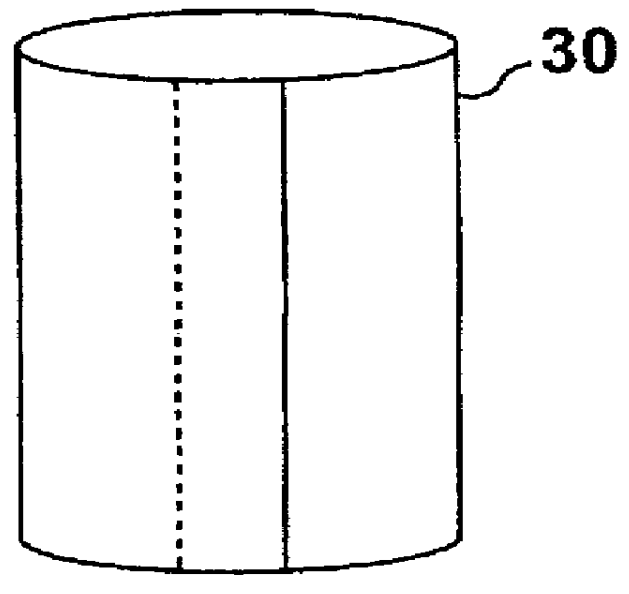

Waste container

InactiveUS6068155AEasy constructionLow cost mass productionLarge containersRefuse receptaclesJunk boxEngineering

A waste container includes a pliable plastic bag, and a rectangular sheet of stiff sheet material rolled and retained in the form of a cylinder open at its opposite ends and receiving the bag within it. The cylinder formed by the sheet encloses the bag, exposes the bottom of the bag enabling it to serve as the bottom of the waste container, and terminates short of the open top of the bag permitting a portion thereof to be turned out towards the bottom of the bag and to be draped over the corresponding open end of the cylinder. The described waste container also includes a second rectangular sheet of stiff sheet material rolled and retained in the form of a cylinder receiving the cylinder of the first-mentioned sheet, and firmly clamping the draped portion of the open top of the bag.

Owner:SICHERMAN ORNA

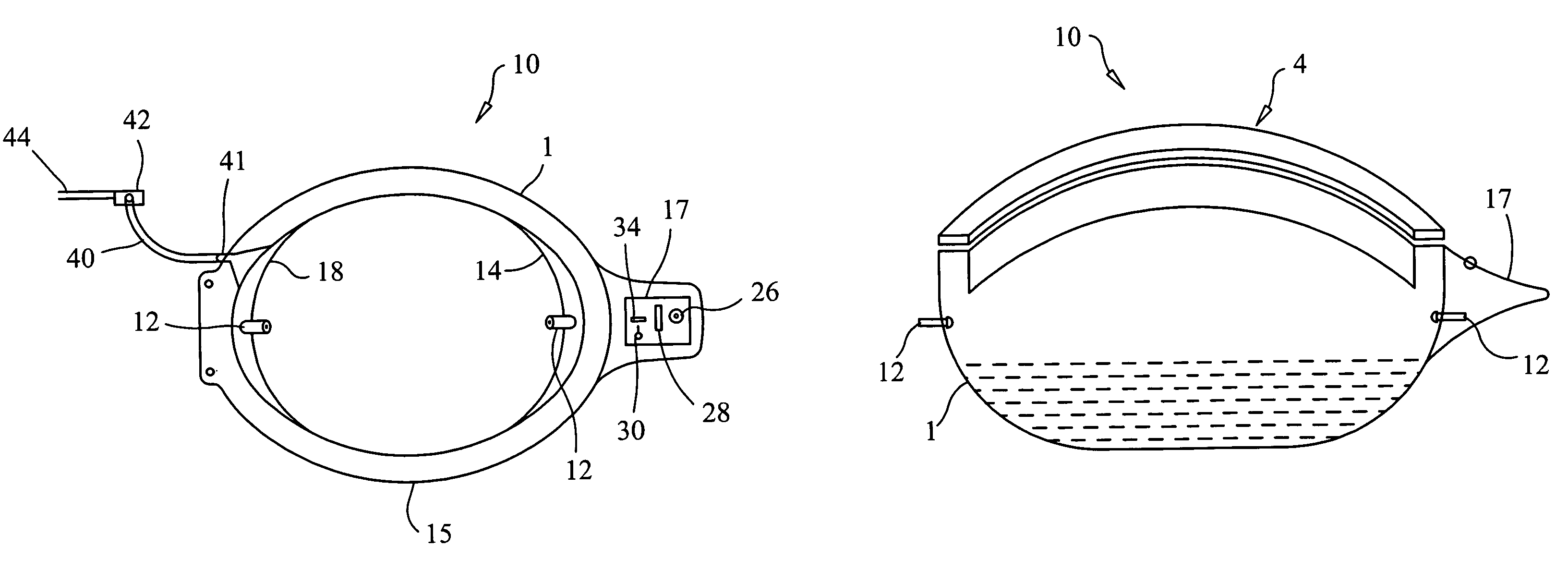

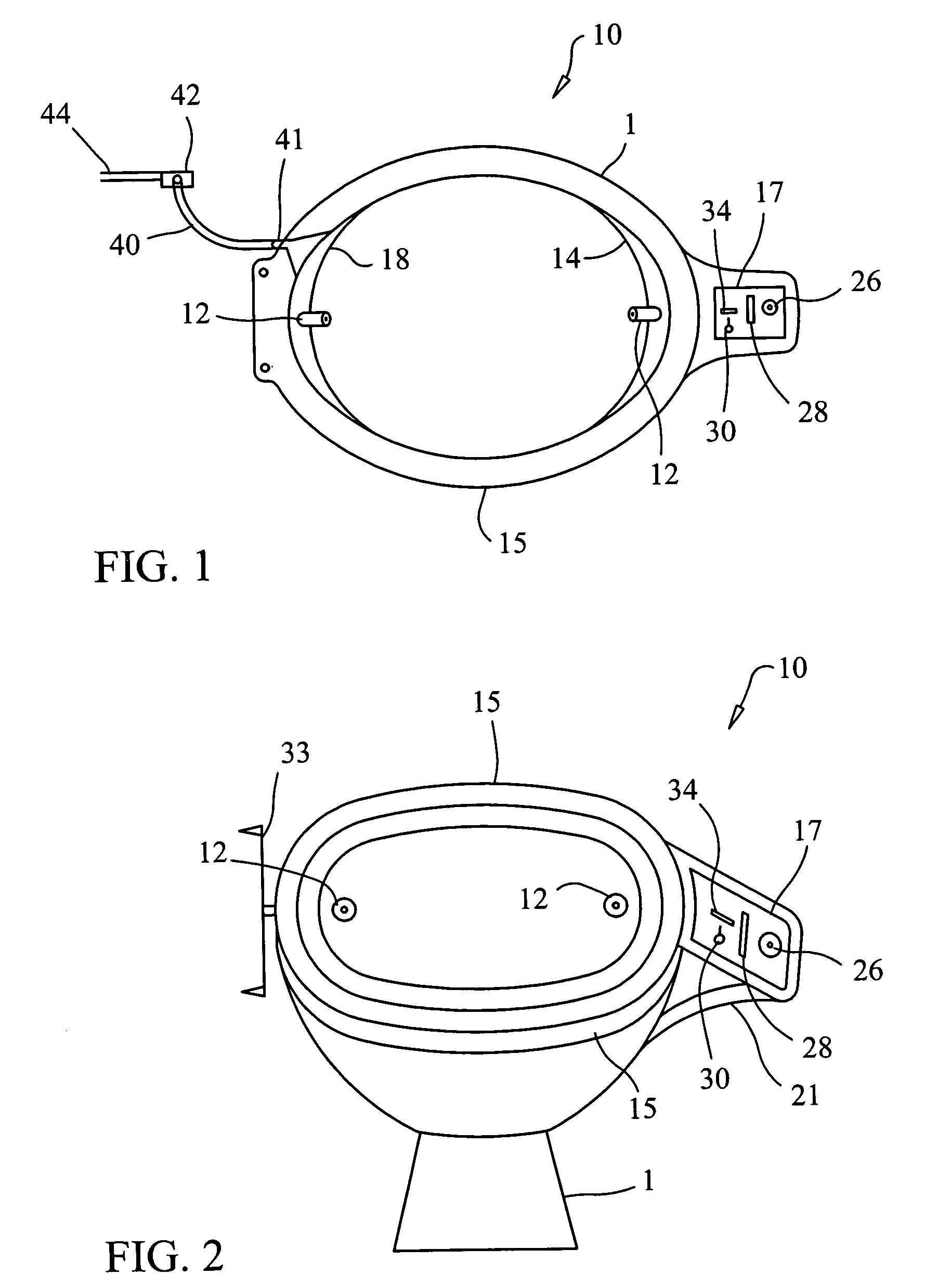

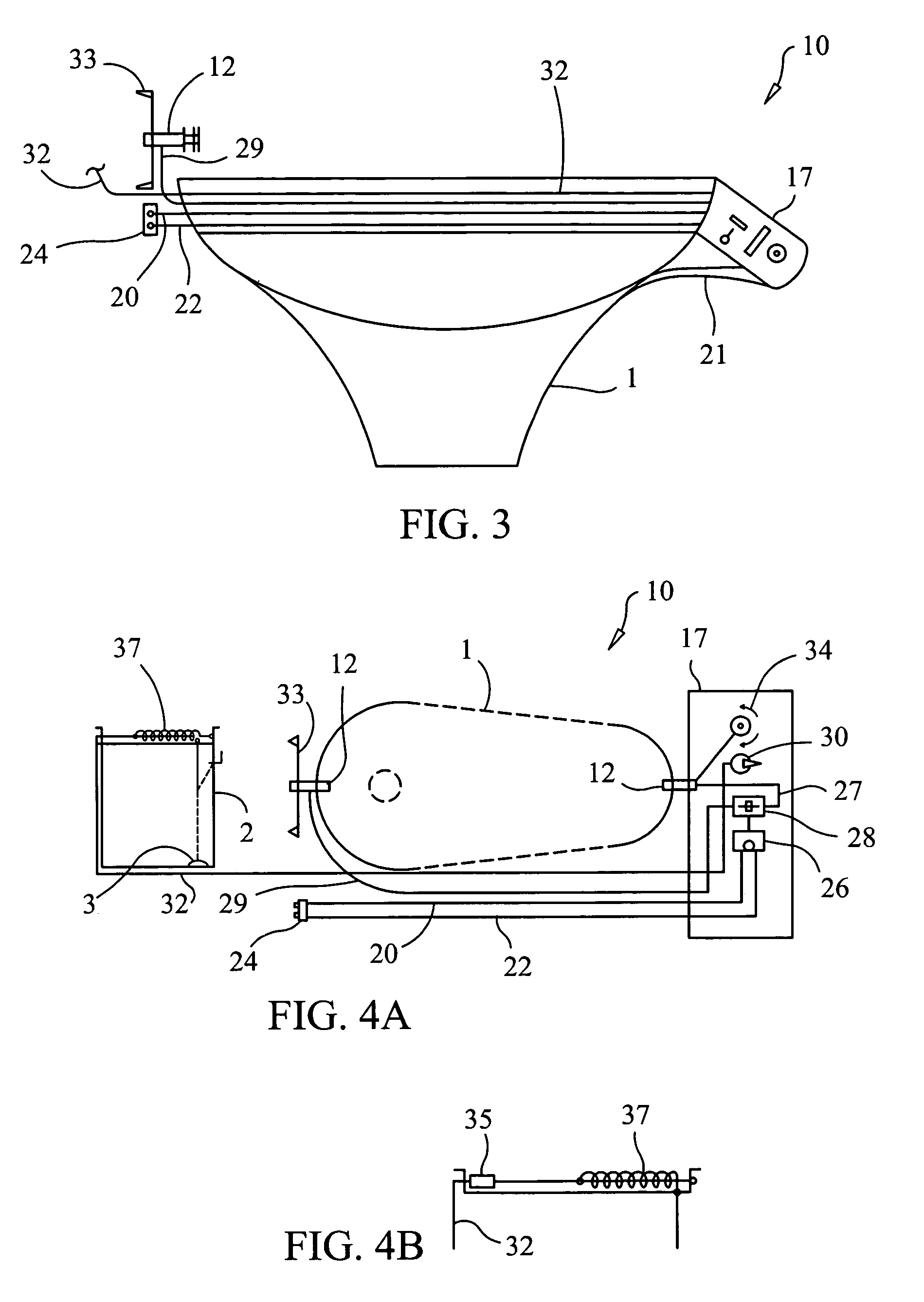

Toilet and bidet system

A combined toilet and bidet system that may be manufactured with a toilet or mounted and adapted to the design of an existing toilet comprising a first adjustable nozzle mountable near the front end of a toilet bowl, second adjustable nozzle mountable near the back end of the toilet bowl, faucet / valve system for receiving and controllably combining multiple water sources in a manner that controls the temperature of water outputted, conduit for delivering water from the selected water source(s) to the faucet / valve system, conduit for delivering water from the faucet / valve system to a splitter that outputs the water received to the nozzles, conduit for delivering the water from the splitter to the first and second nozzles, at least one directional control system for controllably adjusting the angle of at least one of and preferably all of the nozzles to dictate the direction(s) water is ejected therefrom and exhaust system for removing odors from the area of the toilet-bidet system.

Owner:SCALZI SAVERIO

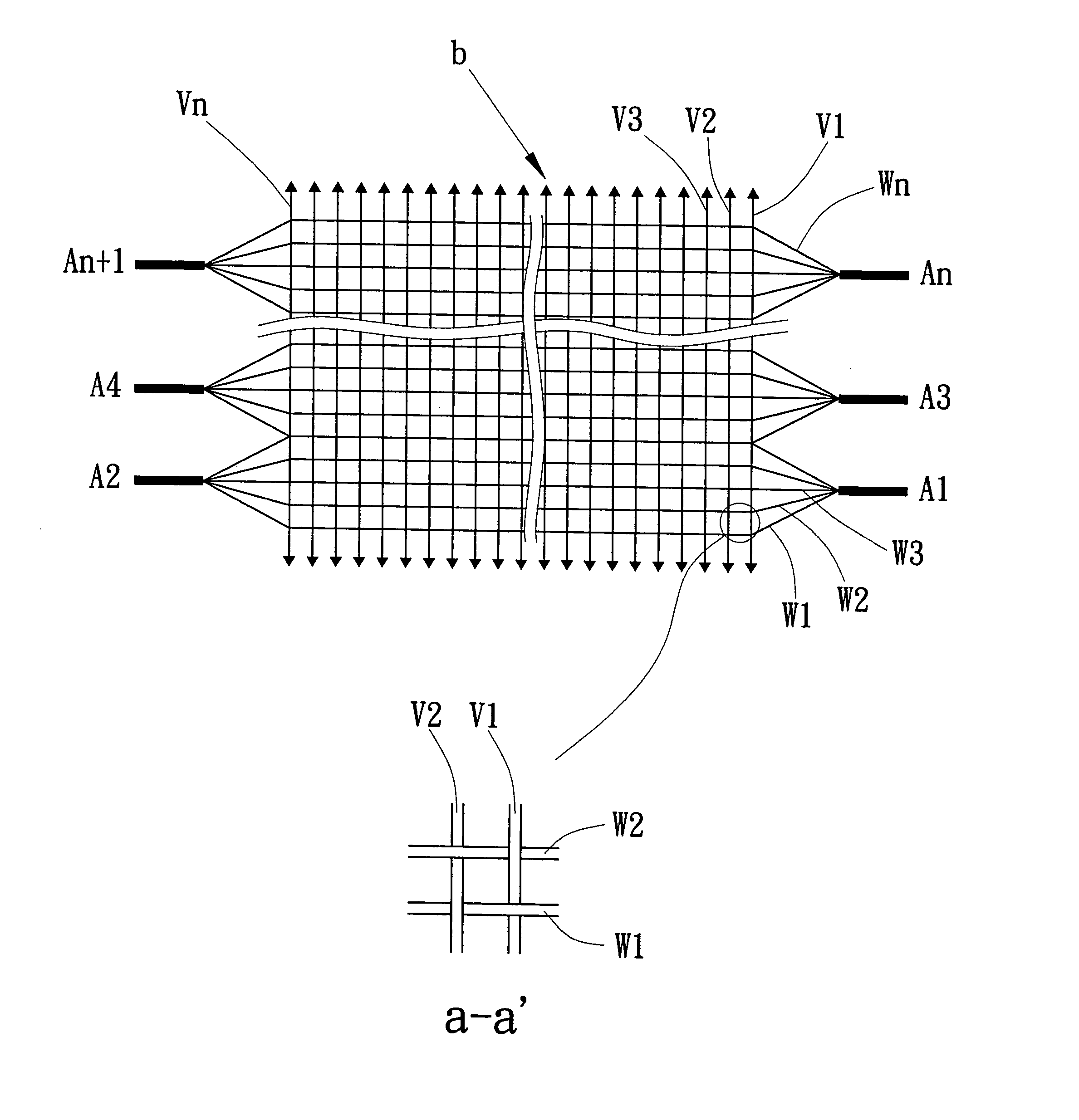

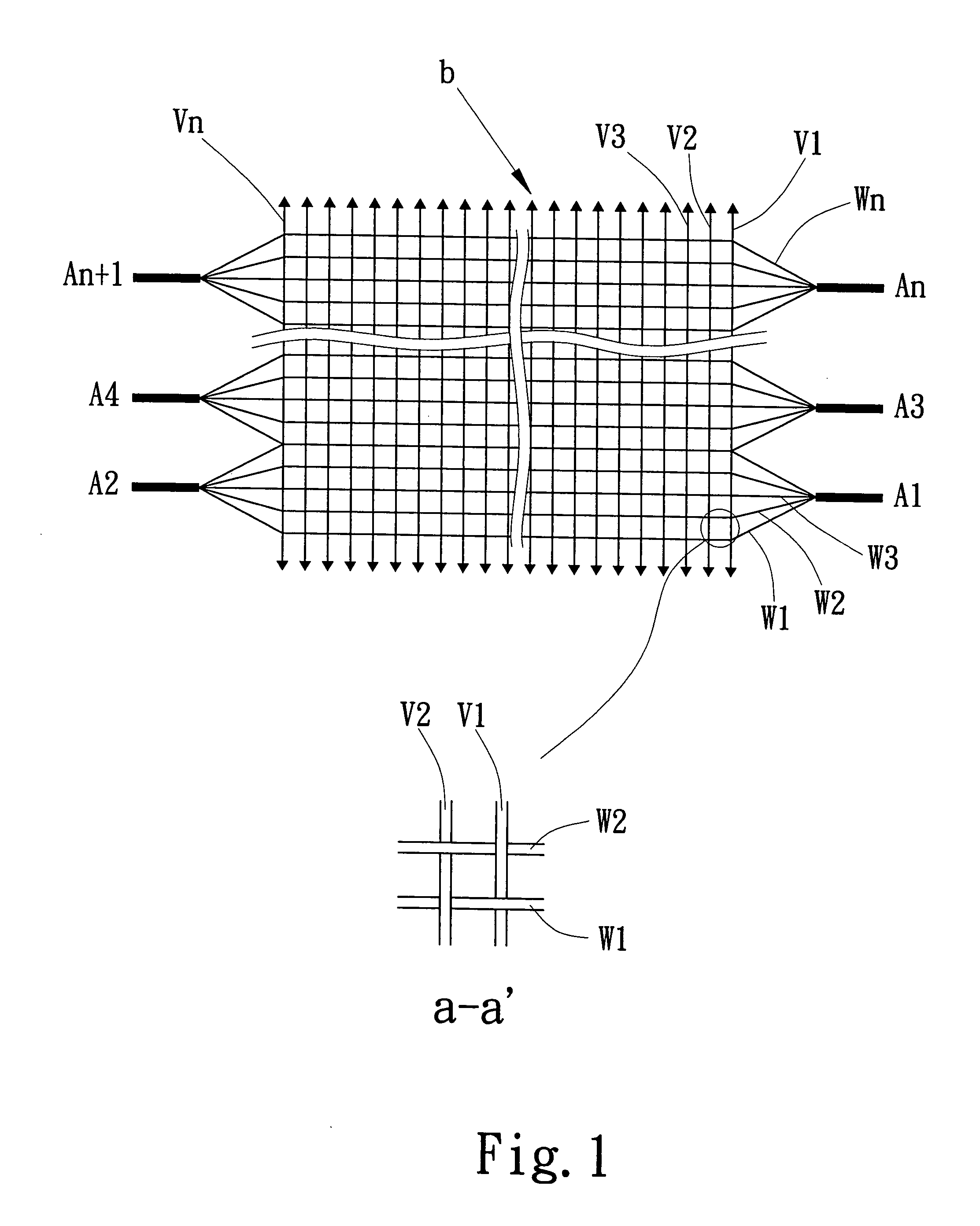

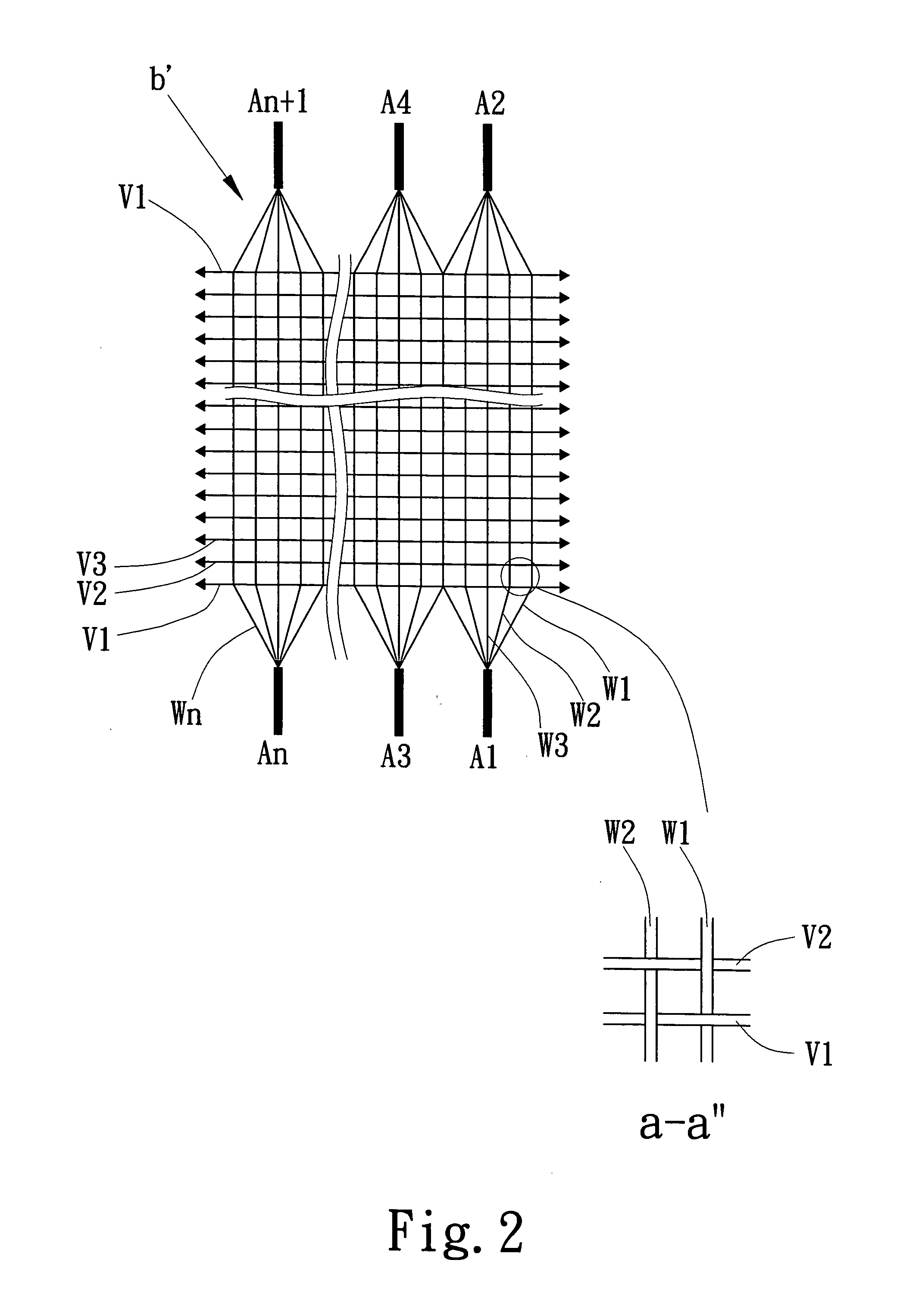

Luminescent vest equipped with plastic optical fibers

A luminescent vest equipped with plastic optical fibers having structural layers including a top layer of plastic film, a middle layer of plastic optical fibers and a bottom layer of a web-like structure. The middle woven layer has the following woven structure: (1) interwoven by lengthwise plastic optical fibers and crosswise plastic optical fibers; (2) interwoven by crosswise chemical fibers and lengthwise plastic optical fibers; (3) interwoven by lengthwise chemical fibers and crosswise plastic optical fibers. The three-layer structure is distributed at appropriate positions on the vest, while the top part of plastic film layer is arranged with letters or patterns serving to project light from the plastic optical fibers, and connected to electrical power to project alarm light effects. The present invention can be used in applications that include a traffic policeman's uniform, an environmental protection worker's uniform, a security guard's uniform and ordinary apparel.

Owner:BAYCOM OPTO ELECTRONICS TECH

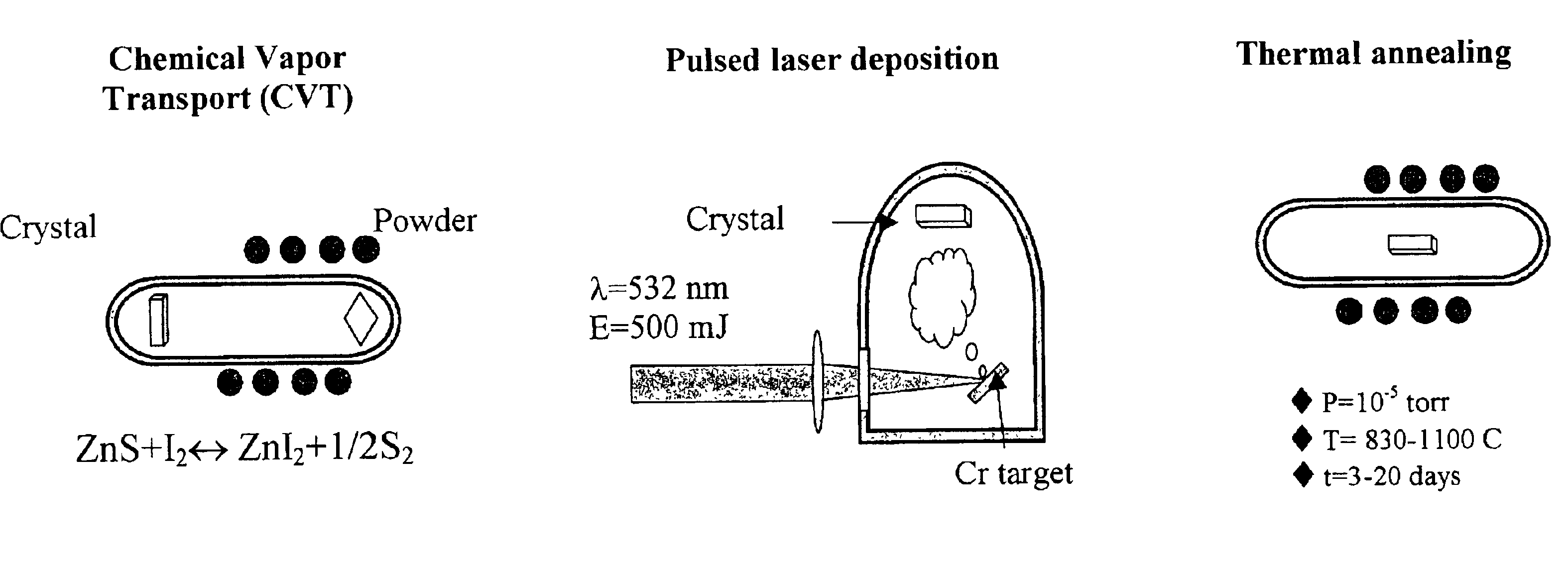

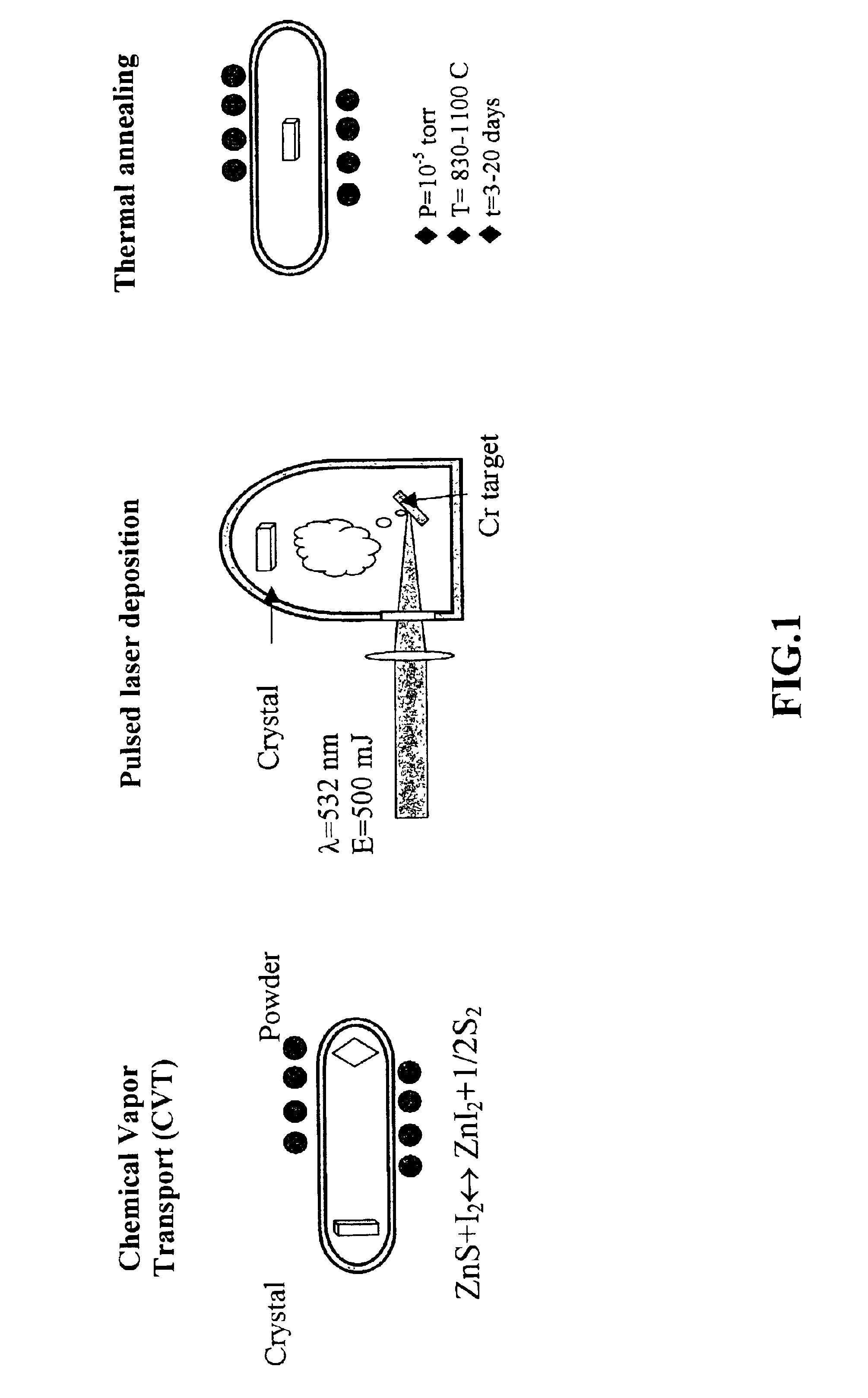

Mid-IR microchip laser: ZnS:Cr2+ laser with saturable absorber material

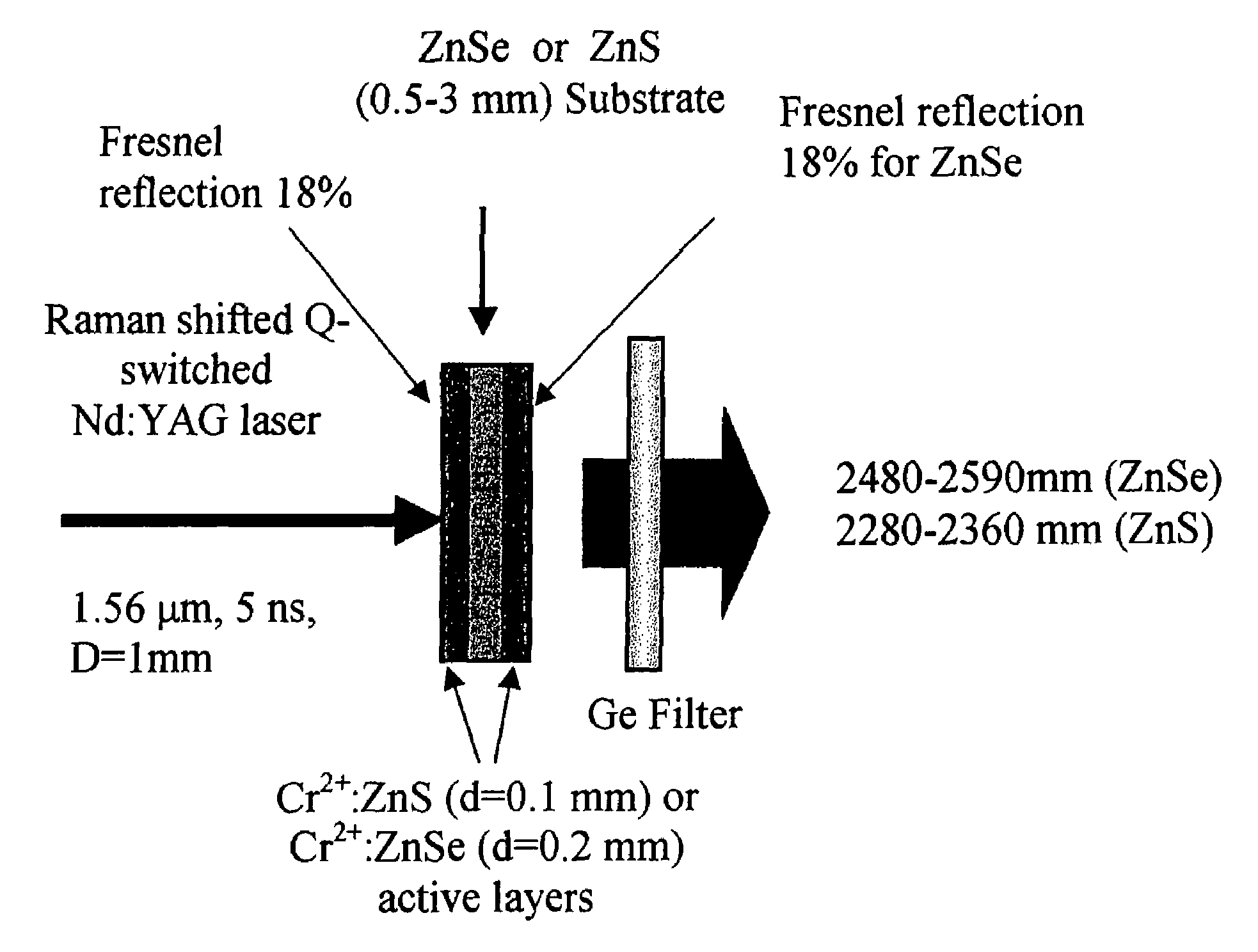

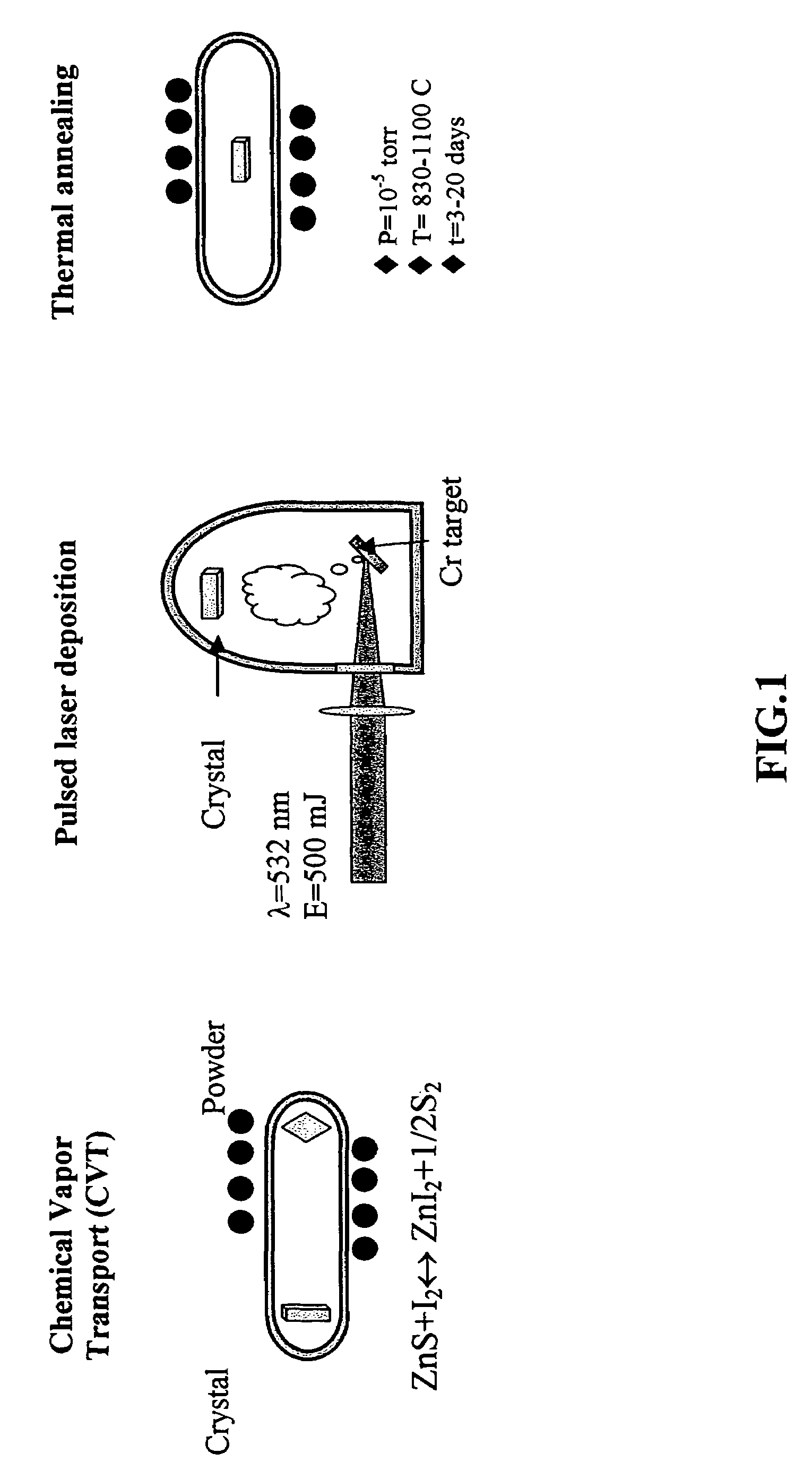

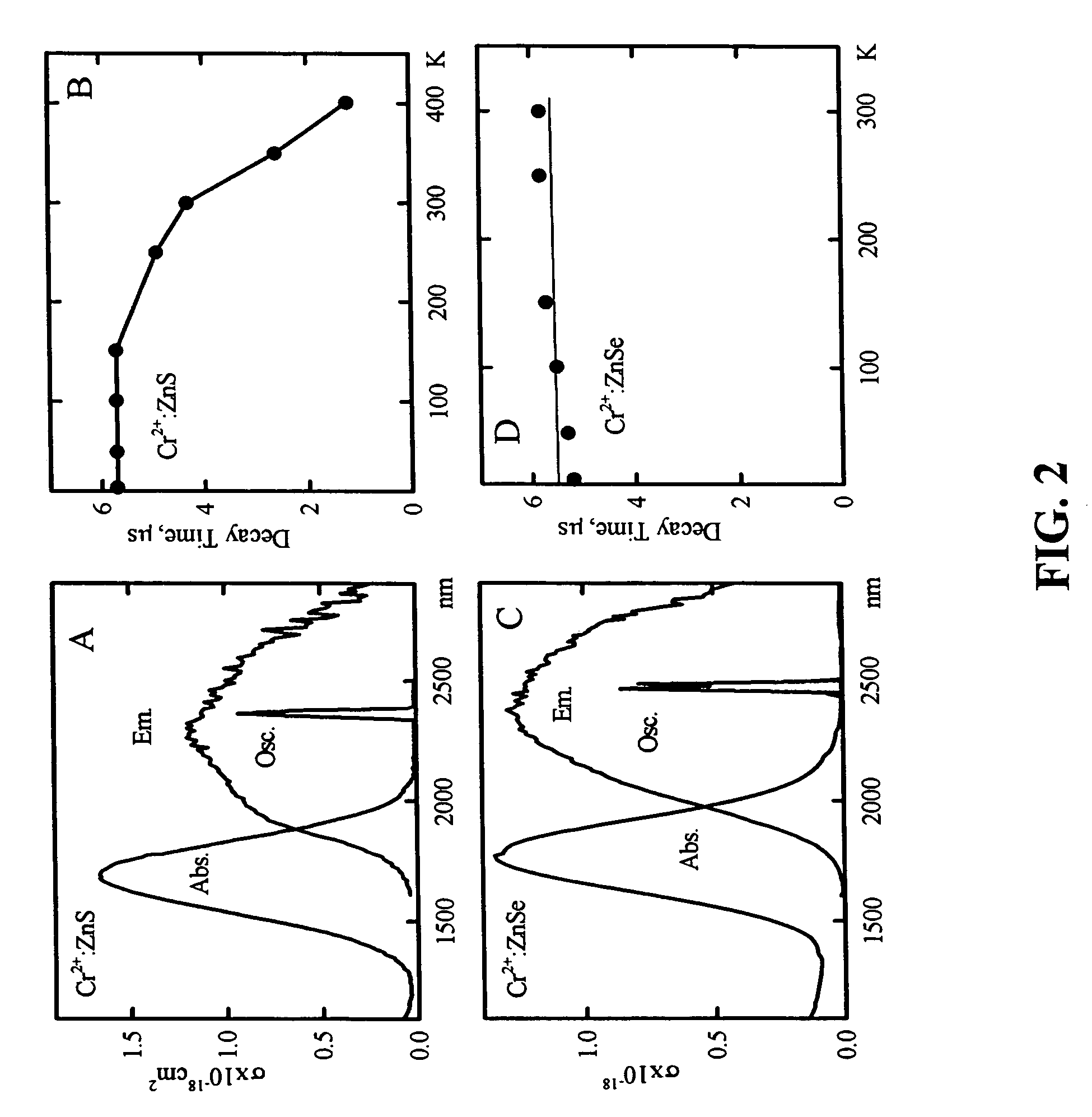

InactiveUS6960486B2Low cost mass productionImprove reliabilityPolycrystalline material growthDiffusion/dopingHigh concentrationMicrochip laser

A method of fabrication of laser gain material and utilization of such media includes the steps of introducing a transitional metal, preferably Cr2+ thin film of controllable thickness on the ZnS crystal facets after crystal growth by means of pulse laser deposition or plasma sputtering, thermal annealing of the crystals for effective thermal diffusion of the dopant into the crystal volume with a temperature and exposition time providing the highest concentration of the dopant in the volume without degrading laser performance due to scattering and concentration quenching, and formation of a microchip laser either by means of direct deposition of mirrors on flat and parallel polished facets of a thin Cr:ZnS wafer or by relying on the internal reflectance of such facets. The gain material is susceptible to utilization of direct diode or fiber laser pumping of a microchip laser with a level of power density providing formation of positive lens and corresponding cavity stabilization as well as threshold population inversion in the laser material. Multiple applications of the laser material are contemplated in the invention.

Owner:ALABAMA AT BIRMINGHAM RES FOUND UNIV OF

Modular bus air conditioning system

InactiveUS7051544B2Low costLow cost mass productionAir-treating devicesVehicle heating/cooling devicesModularityAutomobile air conditioning

Owner:CARRIER CORP

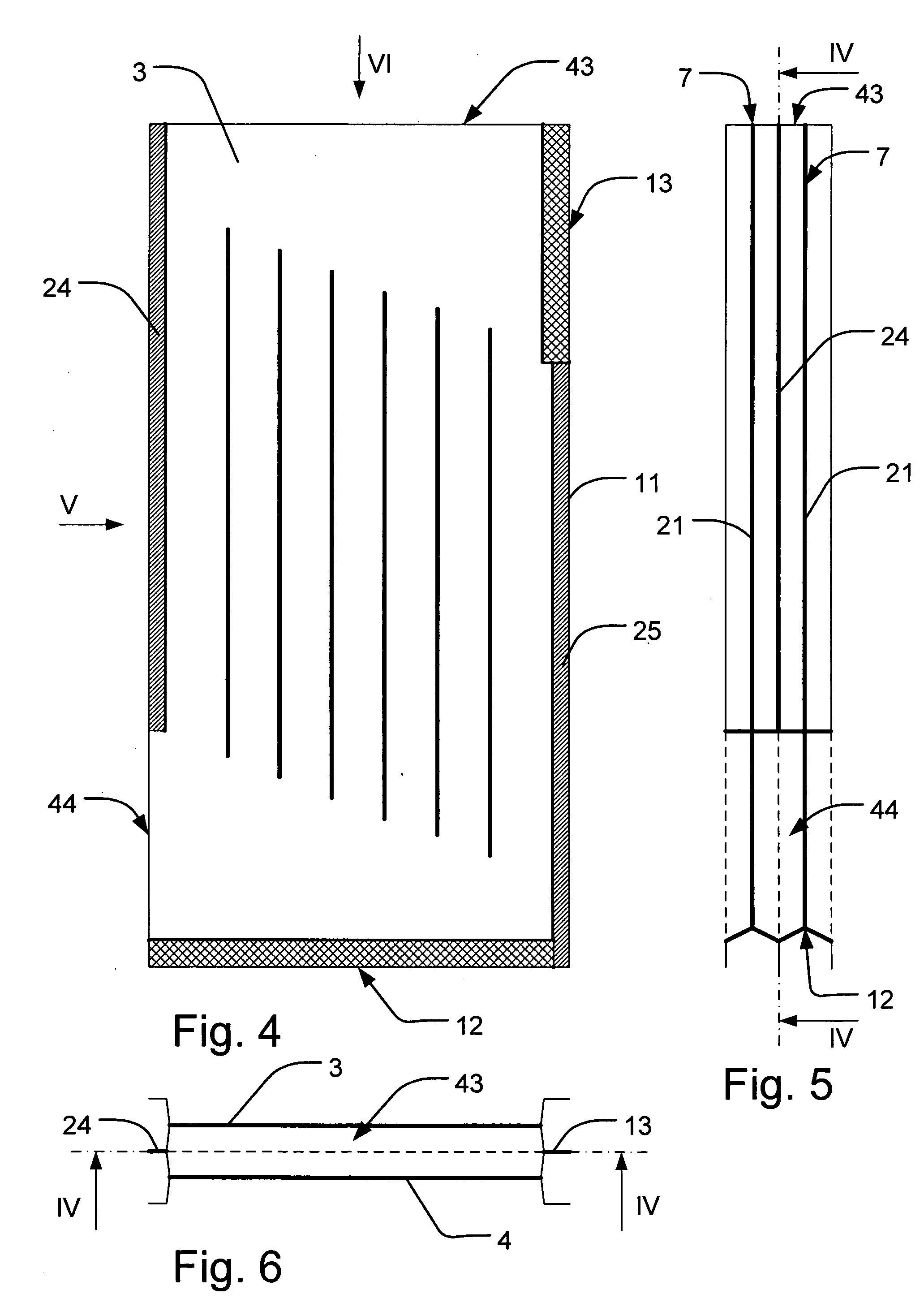

Method for manufacturing a heat exchanger

InactiveUS20090194268A1Quick assemblyCheap and fast and wayMetal-working apparatusDomestic articlesPlastic materialsEngineering

The method for manufacturing a heat exchanger from a plastic material comprises feeding of at least two sheet elements, and, by means of shaping means, shaping of said sheet elements to form heat exchanger plates. The shaping means are adapted to also undertake joining the sheet elements partly along edges so that a fluid inlet and outlet are created, whereby the sheet elements are pressed together. The heat exchanger plates are stacked and joined to a heat exchanger. The stack of heat exchanger plates is welded so that the fluid inlets are fluid outlets of the respective heat exchanger plates are combined to form a common fluid inlet and a common fluid outlet, and the sides of the heat exchanger plates are welded together, so that a fully functional heat exchanger is manufactured with plastic sheets as the only raw material.

Owner:DANTHERM AIR HANDLING

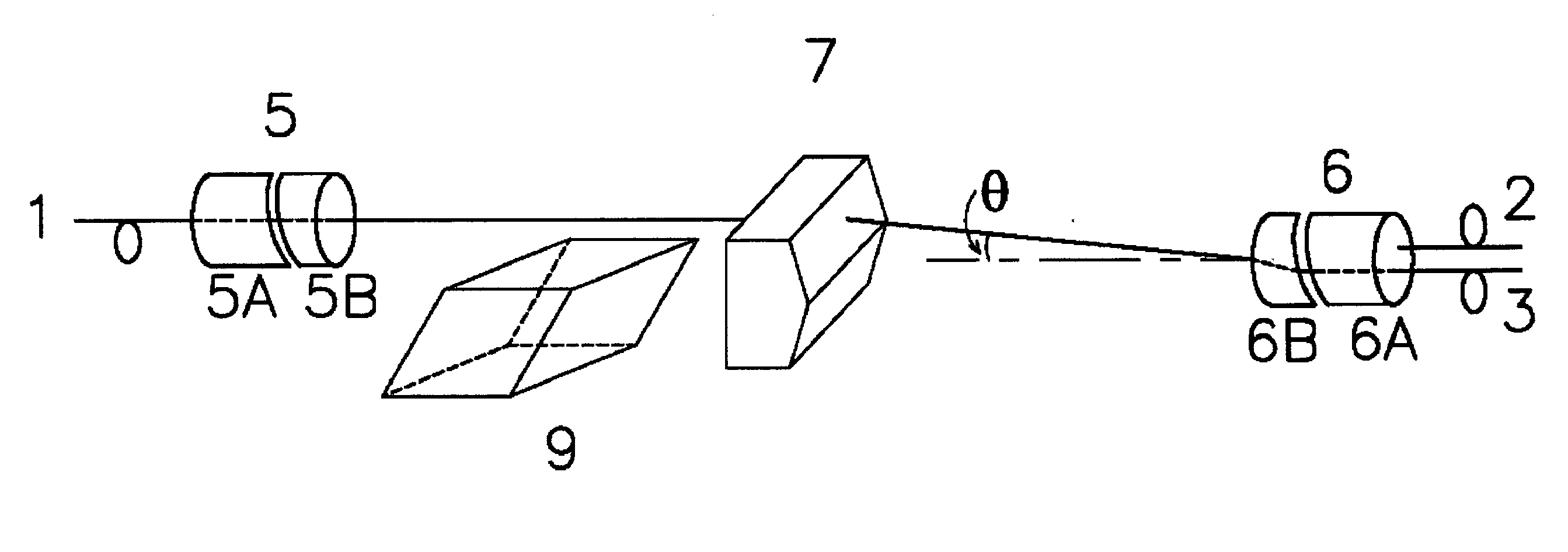

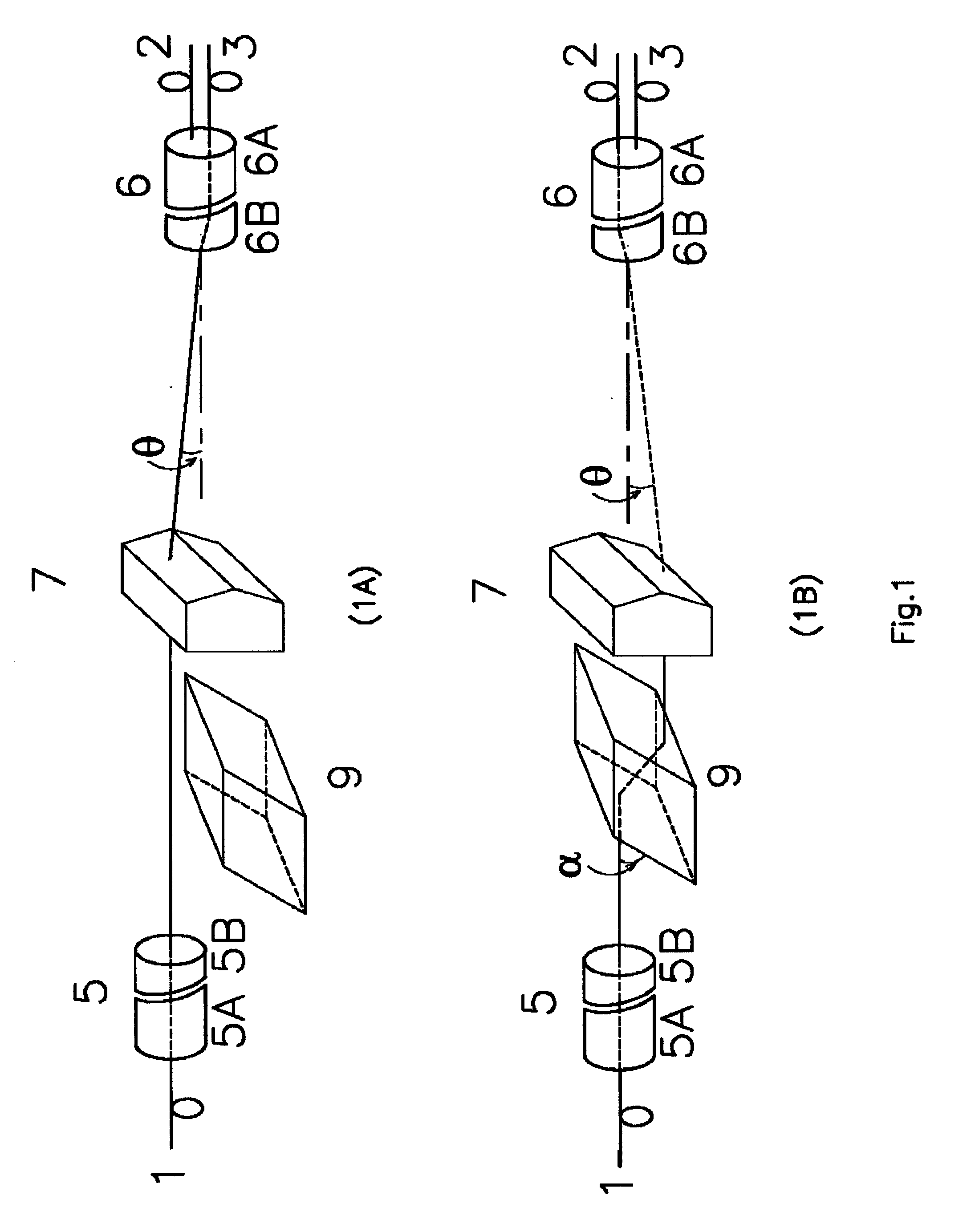

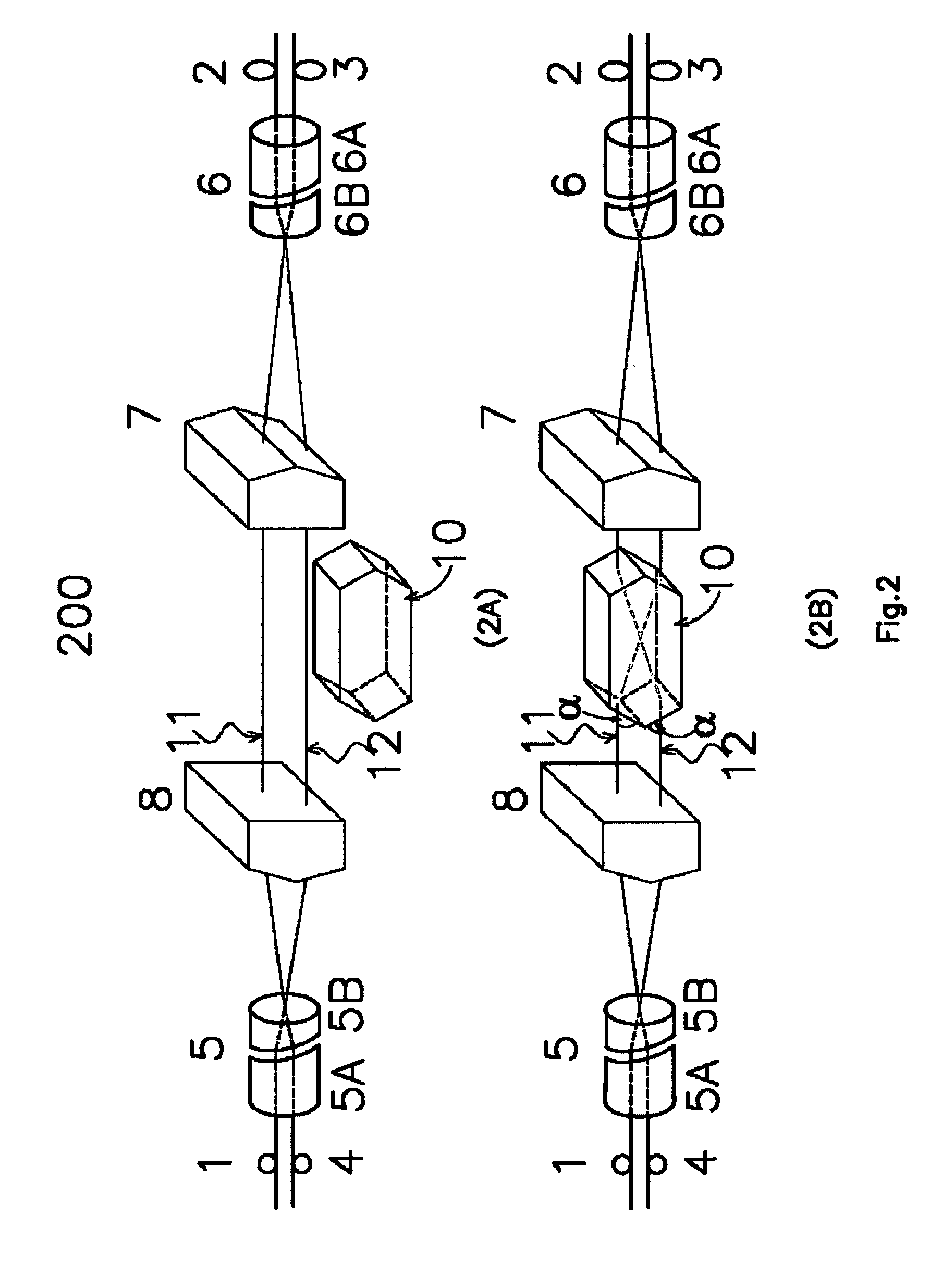

Highly stable opto-mechanic switches

InactiveUS20040013351A1Fewer alignment stepsAssembling tolerance is largeCoupling light guidesLight beamEngineering

The present invention provides improved optical switches in which only a spatial beam shifting of a small free space offset is required to direct optical pathways between plural fiber ports. This is achieved by spacing two fibers closely and collimating their beams with one imaging lens for compactness. Advantageously, the inventive switches incorporate beam correcting devices to render the beam propagations parallel, allowing light beams to be efficiently coupled into two fibers that sharing a single lens with substantially improved stability.

Owner:AGILTRON

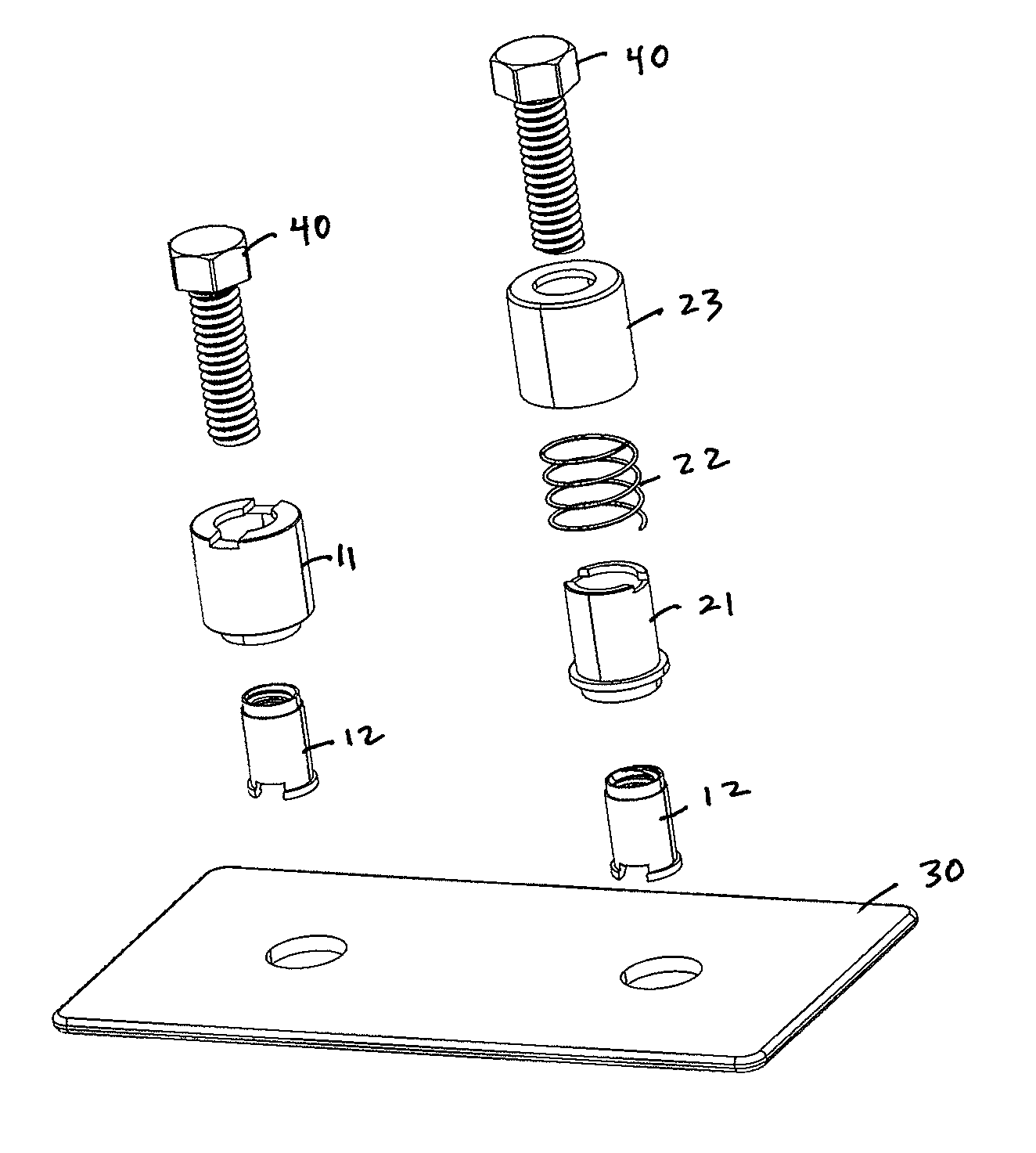

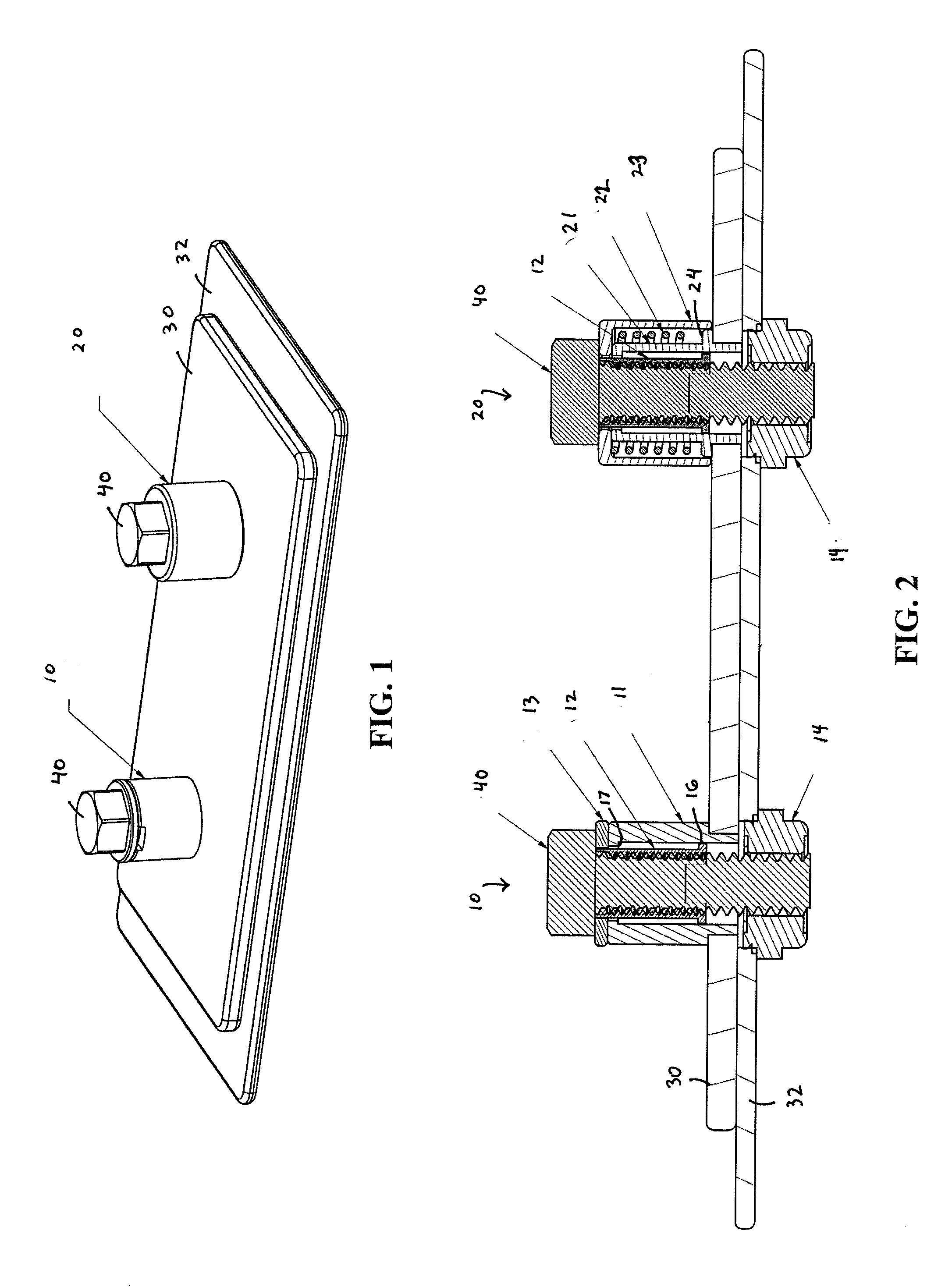

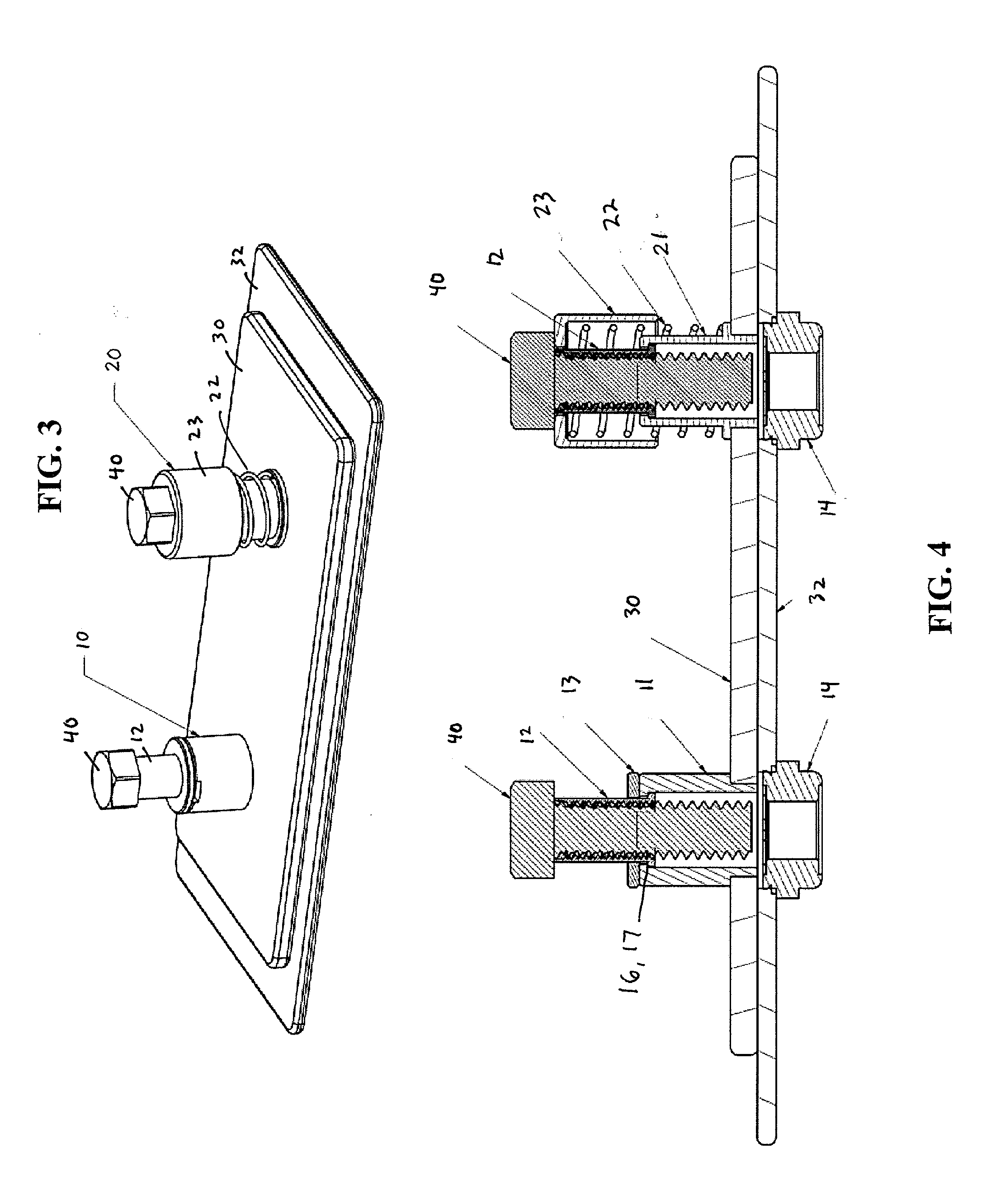

Screw Captivator

ActiveUS20120093609A1Simple and economical to manufactureEasy to useNutsBoltsFree rotationEngineering

A device for captivating a variety of fasteners relative to a first member. A captivator includes a body adapted to be secured to the first member and a retainer received within the body and having a surface engaging a captured fastener. Together the body and retainer maintain the captivated fastener in place relative to the first member. Keyway surfaces are provided upon the body or retainer or both and an external or internal key engages the keyway surfaces to selectively lock the body and retainer together, such as during installation or replacement of the captured fastener. Upon removal of the key, the retainer is free to rotate and translate relative to the body.

Owner:PRIMORDIAL SOUP

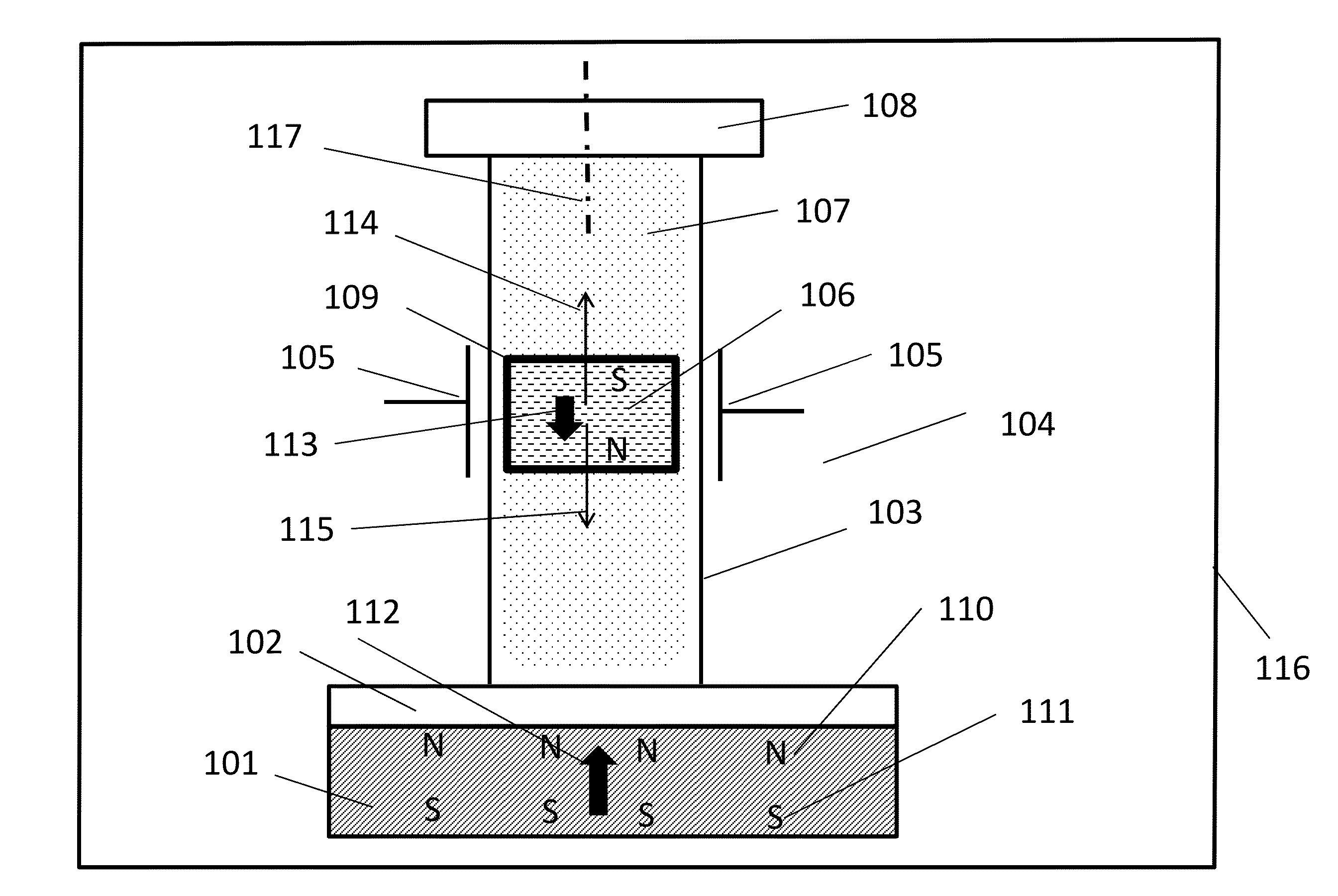

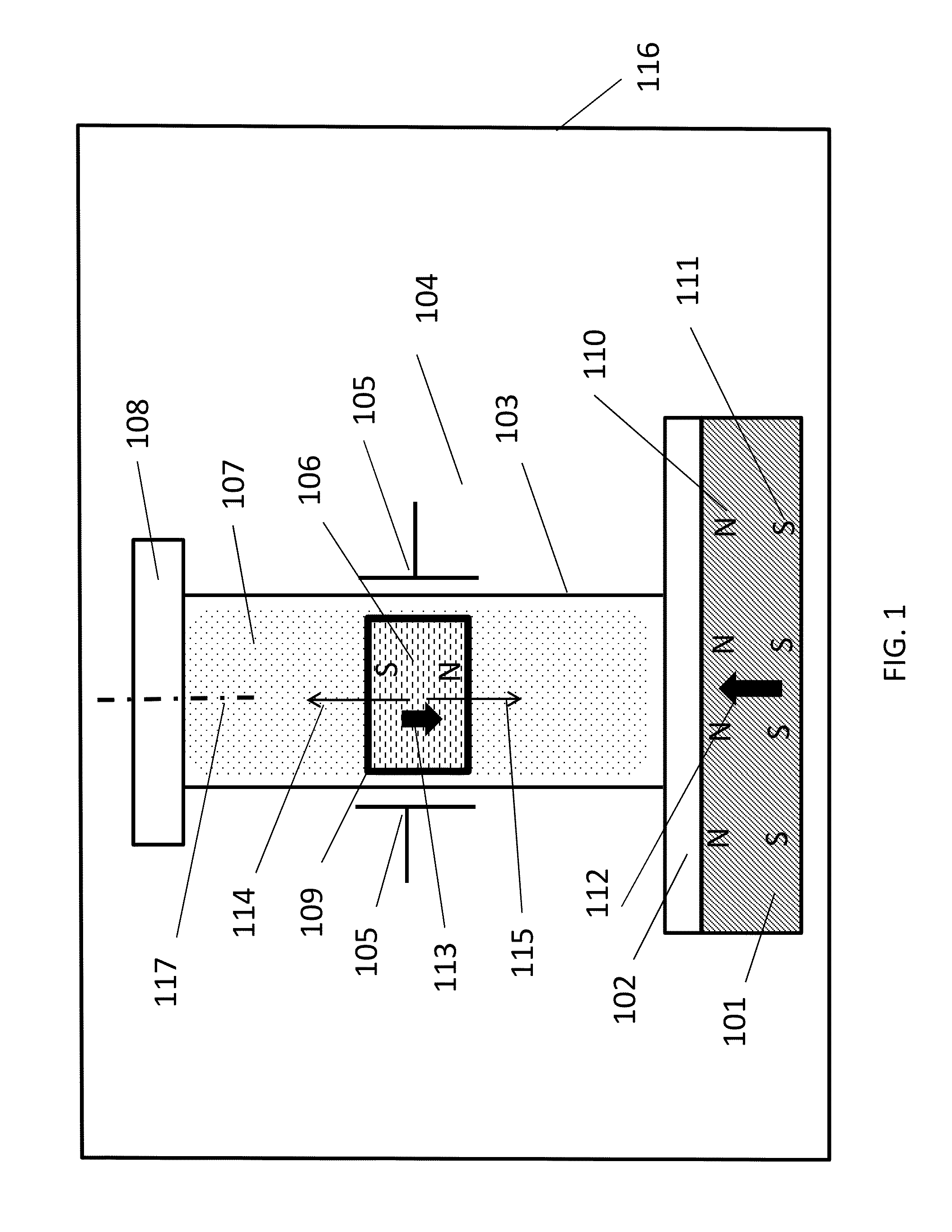

Fall Detection Method and System

ActiveUS20150228177A1Low cost mass productionAcceleration measurement using interia forcesDiagnostic recording/measuringCapacitanceCapacitive sensing

Fall detection method and systems with its unique designed sensors are disclosed. The capacitive sensing based systems use the abrupt changes of the capacitance value to detect whether a real fall event happens, while the reed sensor / or reed switch based systems work in power saving passive mode to detect the real fall event by analyzing the binary “on / off” signal available from the reed sensor / or reed switch. Both rely on the orientation change of the host body respects to local gravity direction during the falling process. The system can present either as a standalone system or a built-in component with supporting software installed on other devices.

Owner:GE YI +1

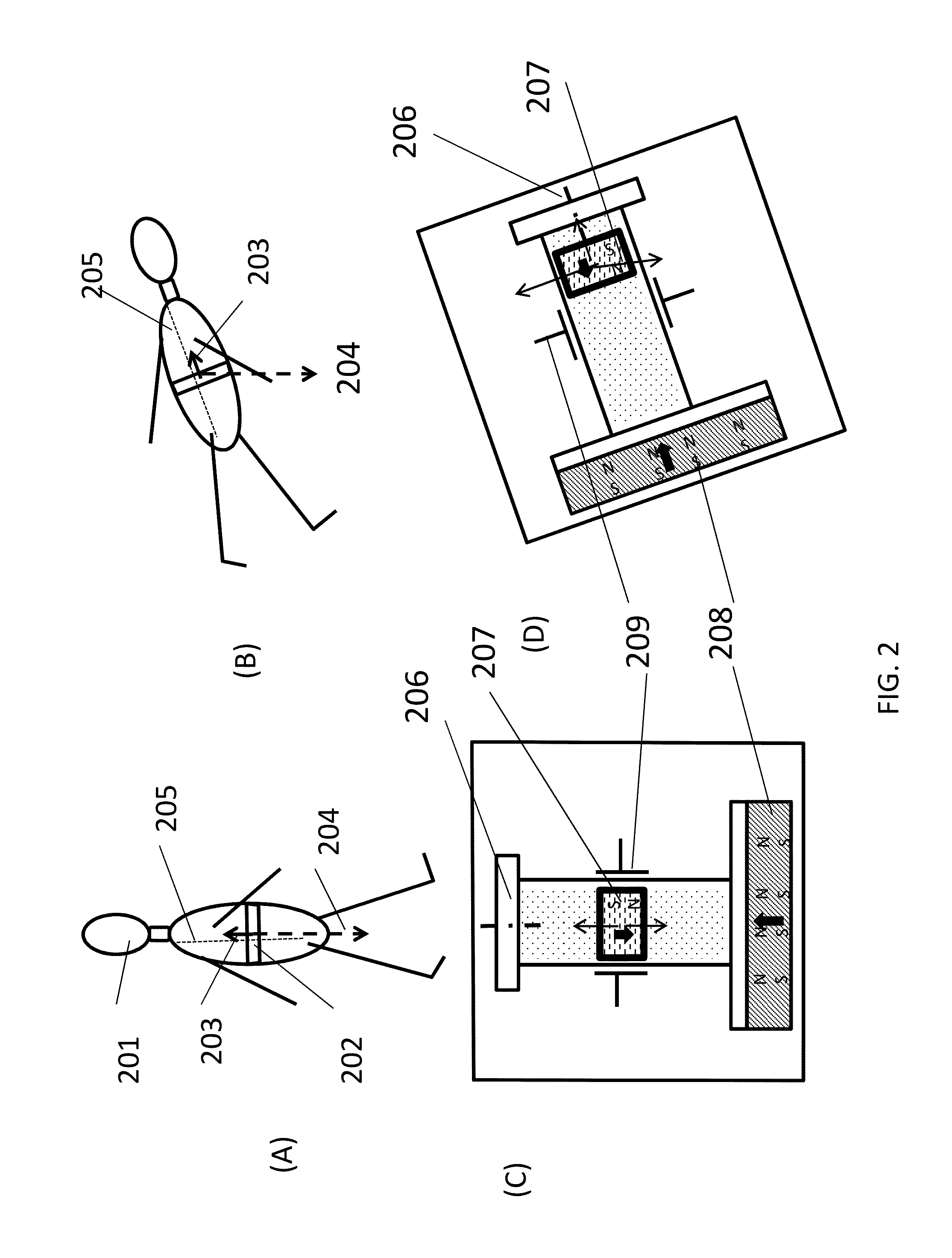

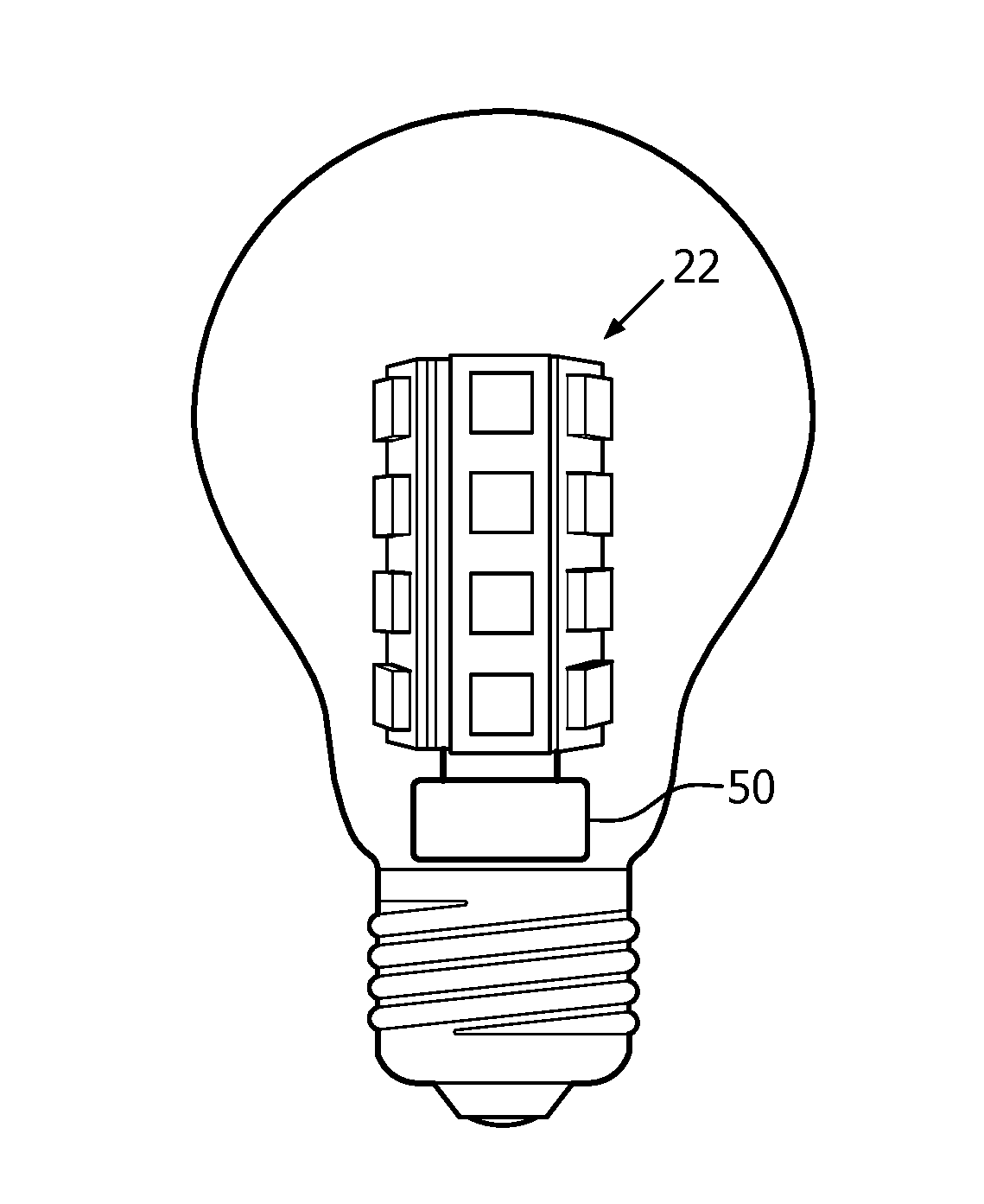

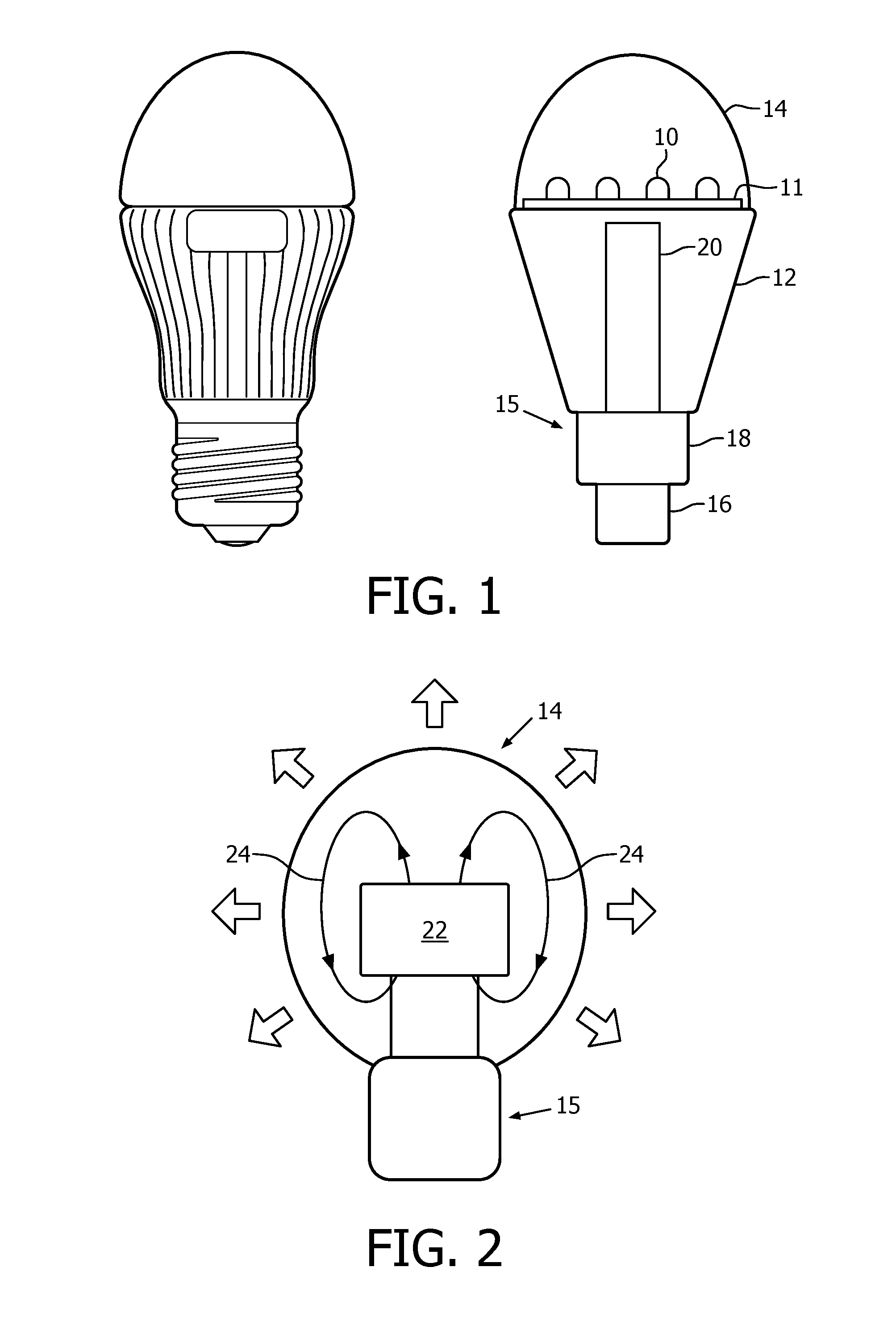

LED bulb

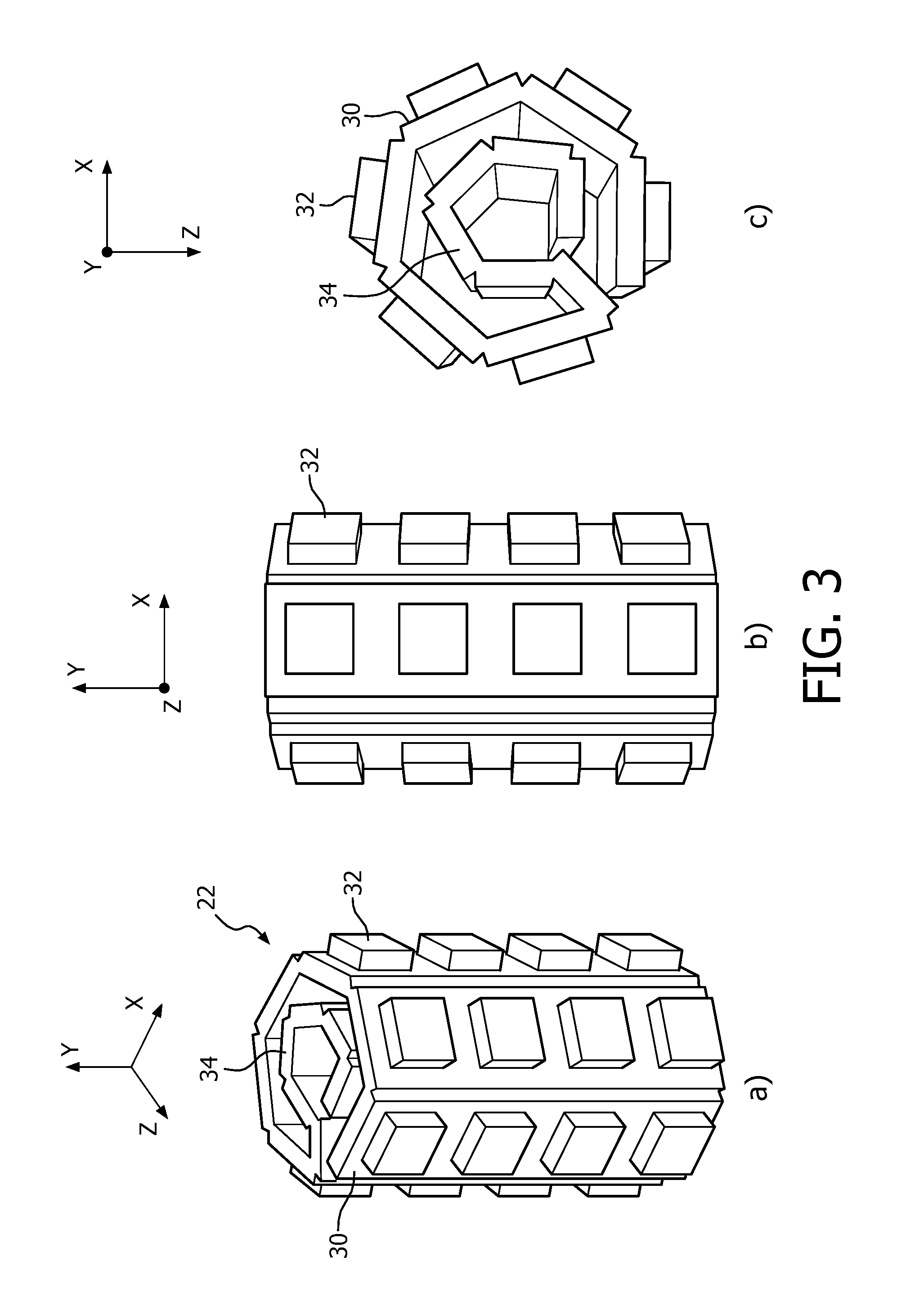

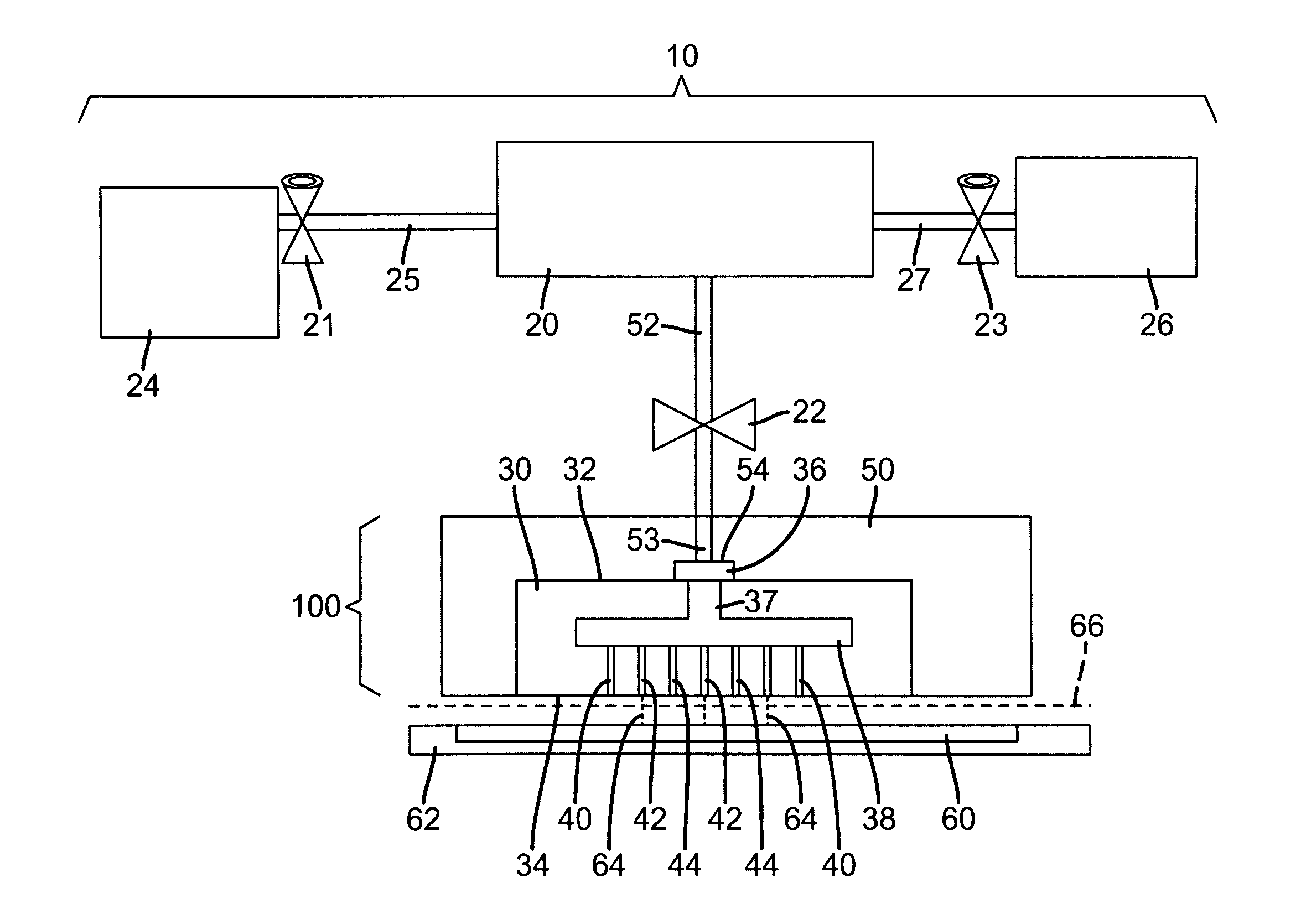

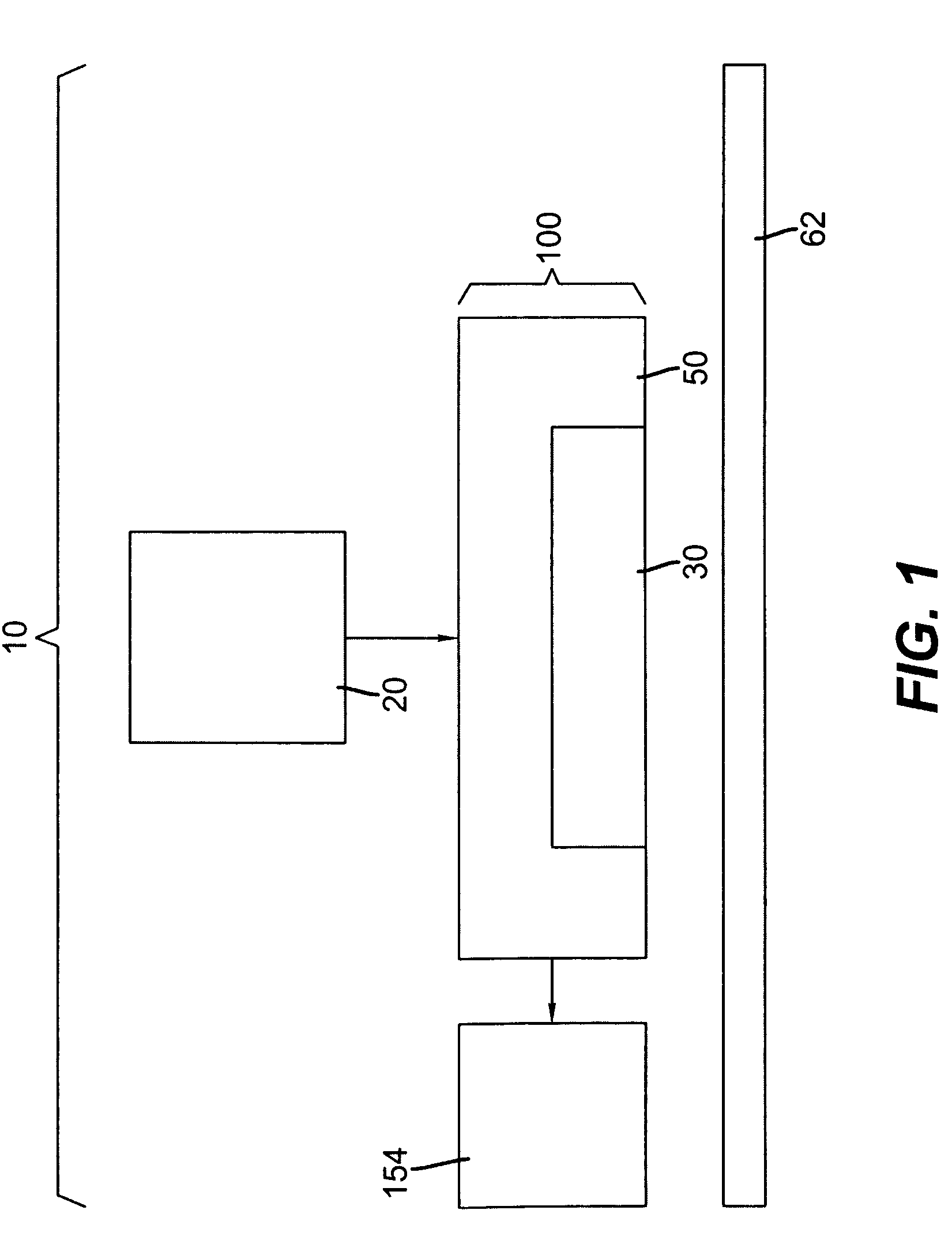

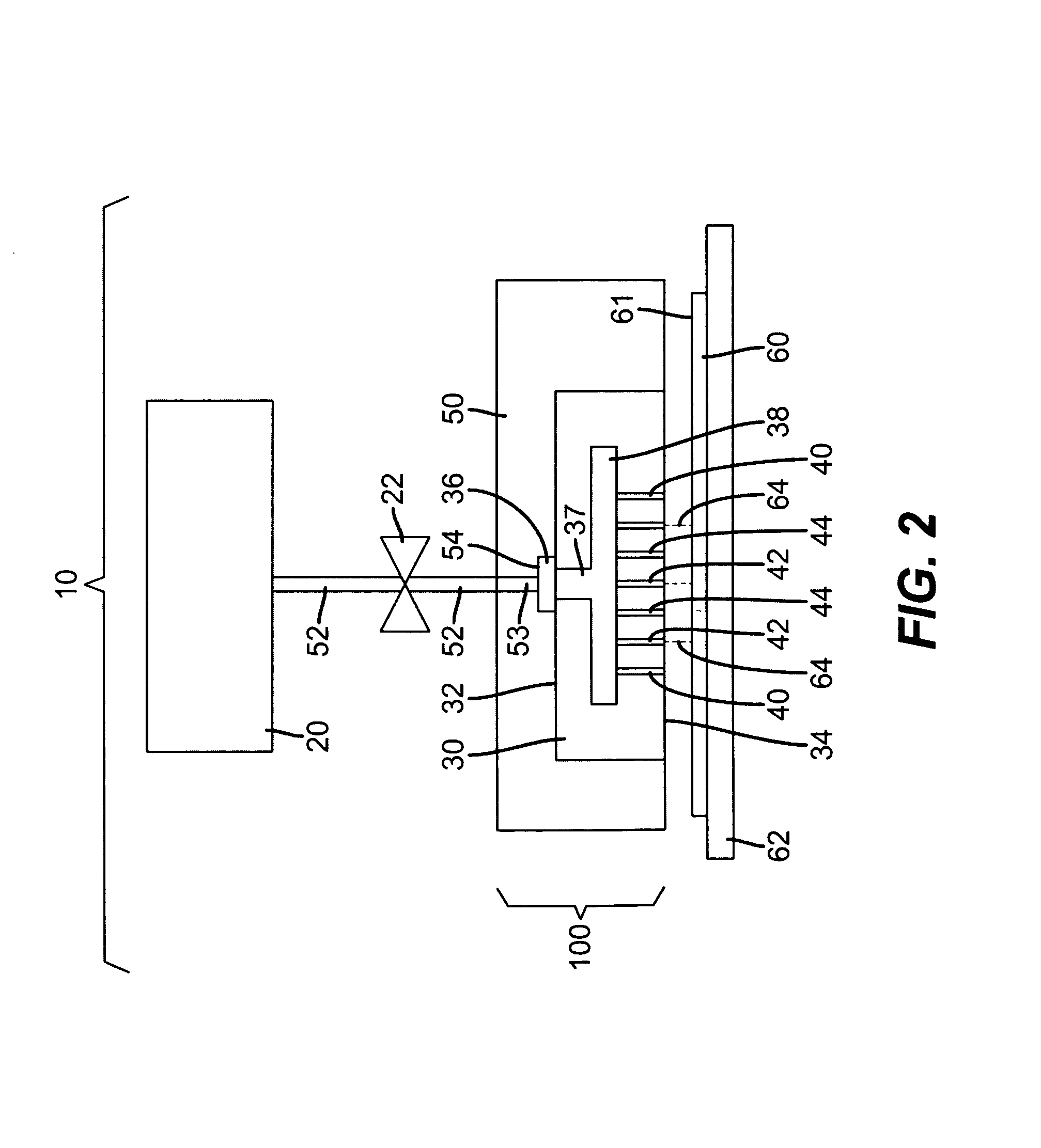

InactiveUS20160341370A1Maximum heat transferThermal resistanceElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLED lamp

An LED light bulb has LEDs (32) mounted on a tubular carrier (22) with open ends. The tube (22) functions as a chimney to promote cooling by creating convection currents through the chimney. The cooling can be entirely passive or it may be active by incorporating a fan (50).

Owner:SIGNIFY HLDG BV

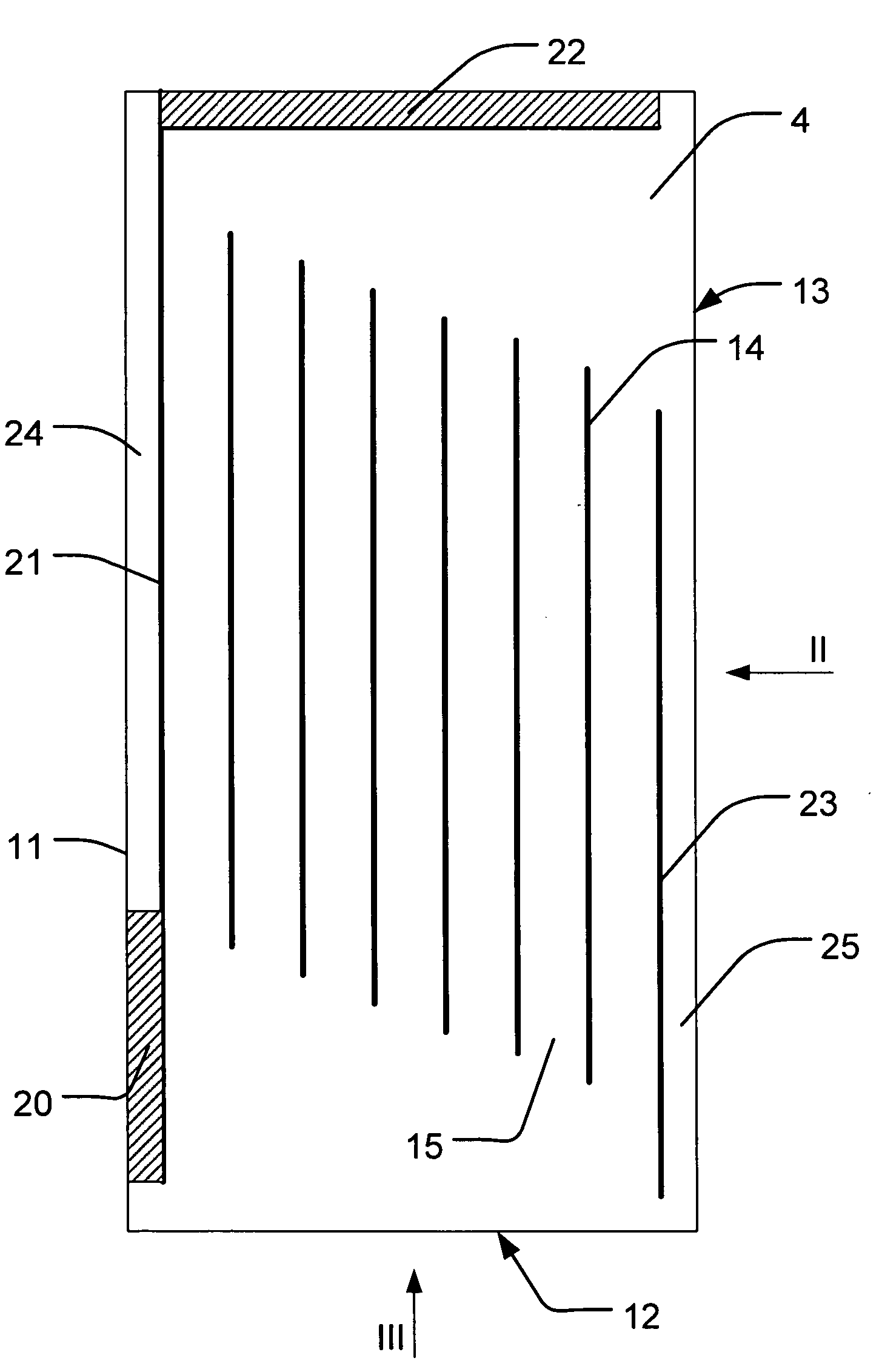

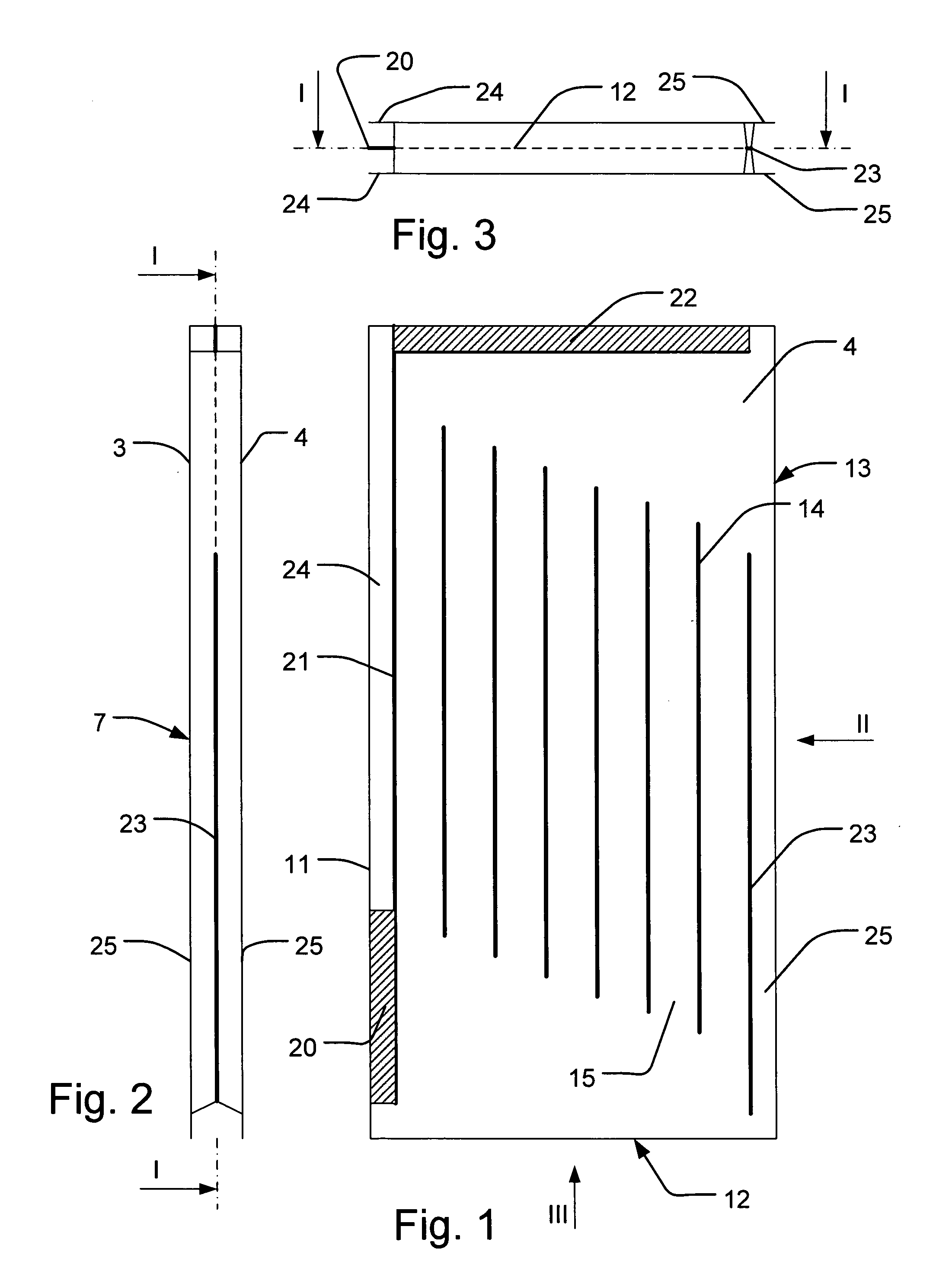

MEMS printhead based compressed fluid printing system

InactiveUS7762647B2Low cost mass productionOperational securityPrintingCompressed fluidHigh pressure

Owner:EASTMAN KODAK CO

Mid-IR microchip laser: ZnS:Cr2+ laser with saturable absorber material

InactiveUS7548571B2Low cost mass productionImprove reliabilityPolycrystalline material growthLaser active region structureMicrochip laserGain

A method of fabrication of laser gain material and utilization of such media includes the steps of introducing a transitional metal, preferably Cr2+ thin film of controllable thickness on the ZnS crystal facets after crystal growth by means of pulse laser deposition or plasma sputtering, thermal annealing of the crystals for effective thermal diffusion of the dopant into the crystal volume with a temperature and exposition time providing the highest concentration of the dopant in the volume without degrading laser performance due to scattering and concentration quenching, and formation of a microchip laser either by means of direct deposition of mirrors on flat and parallel polished facets of a thin Cr:ZnS wafer or by relying on the internal reflectance of such facets. The gain material is susceptible to utilization of direct diode or fiber laser pumping of a microchip laser with a level of power density providing formation of positive lens and corresponding cavity stabilization as well as threshold population inversion in the laser material. Multiple applications of the laser material are contemplated in the invention.

Owner:UAB RES FOUND INC

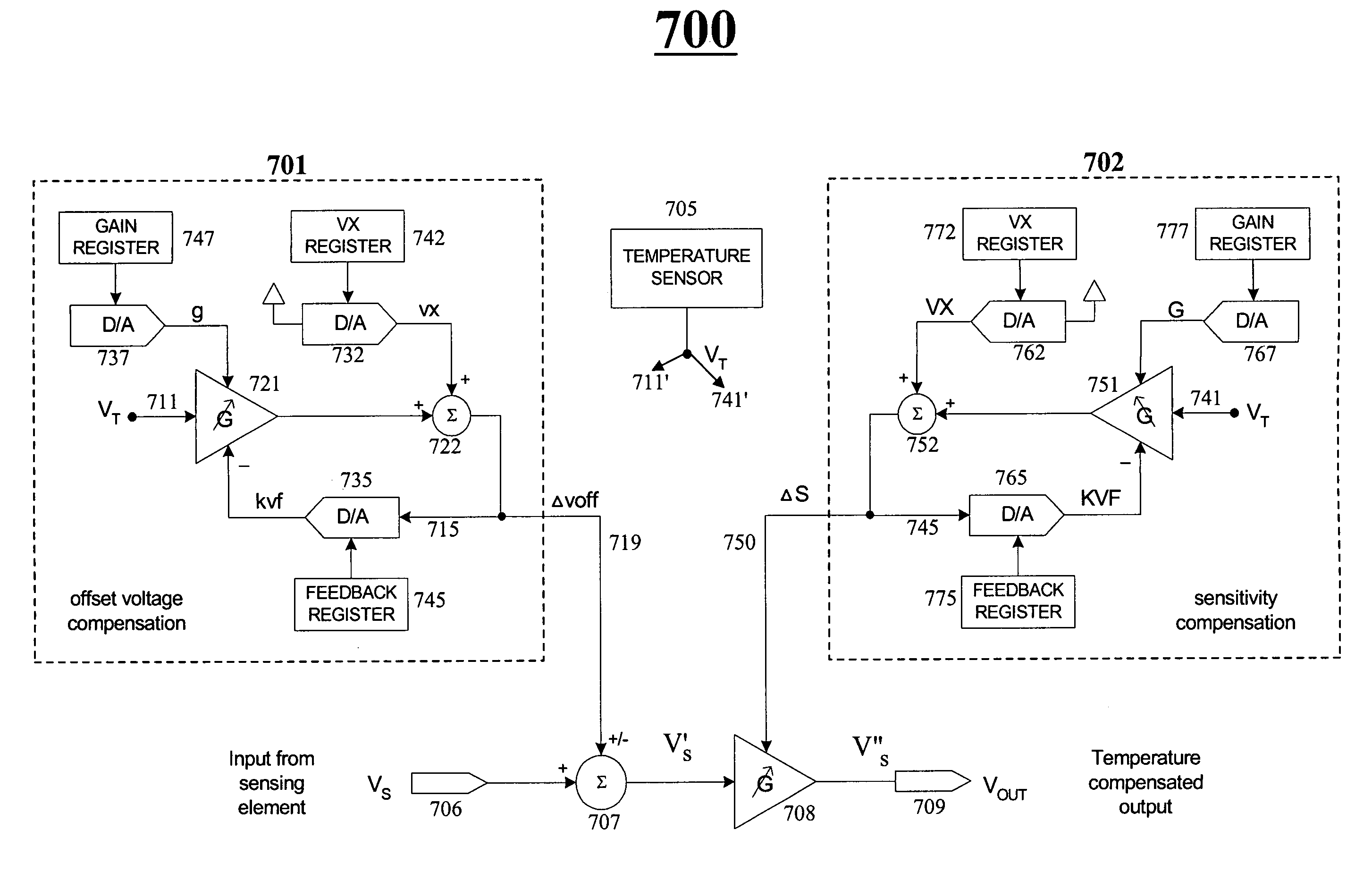

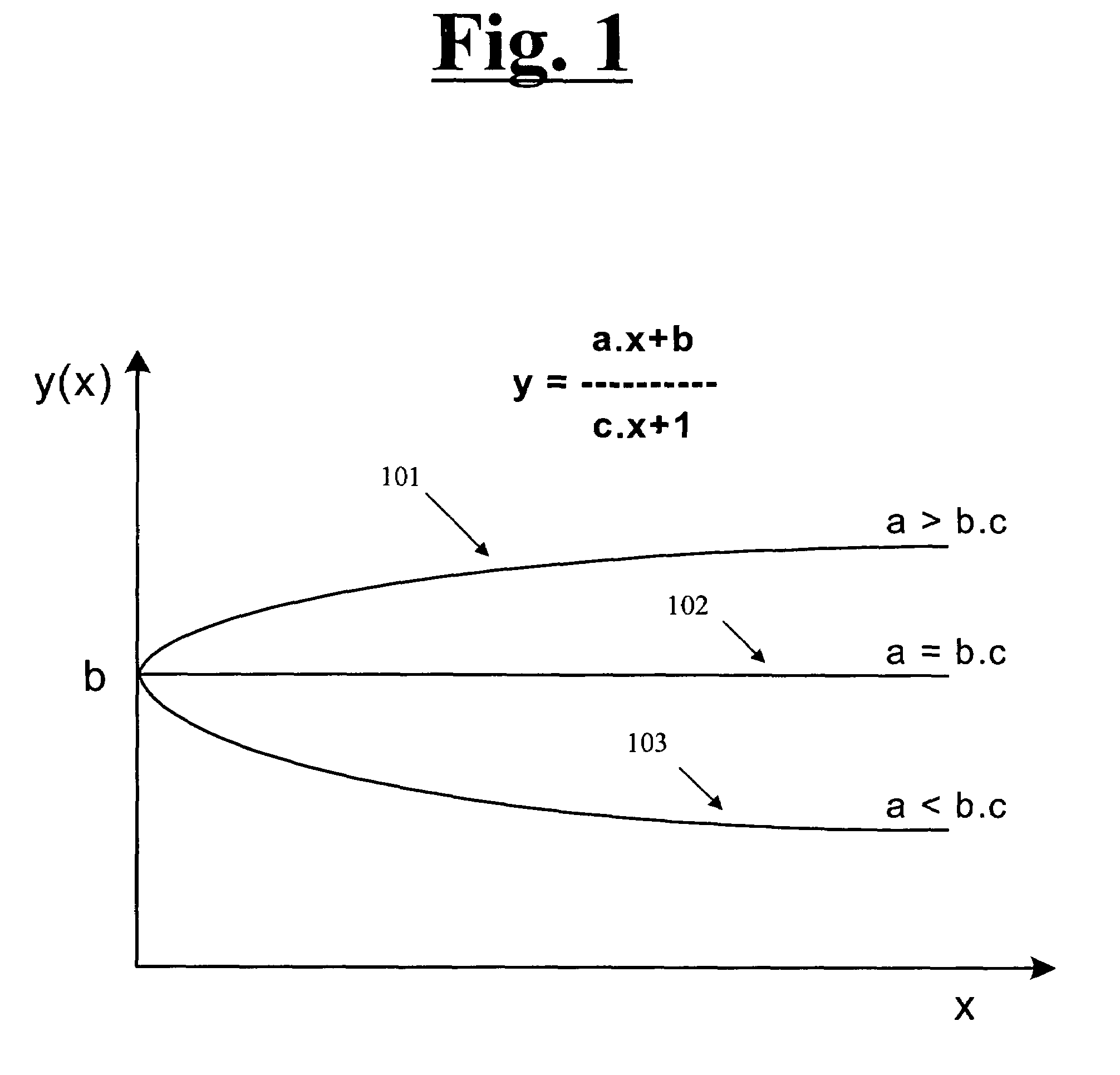

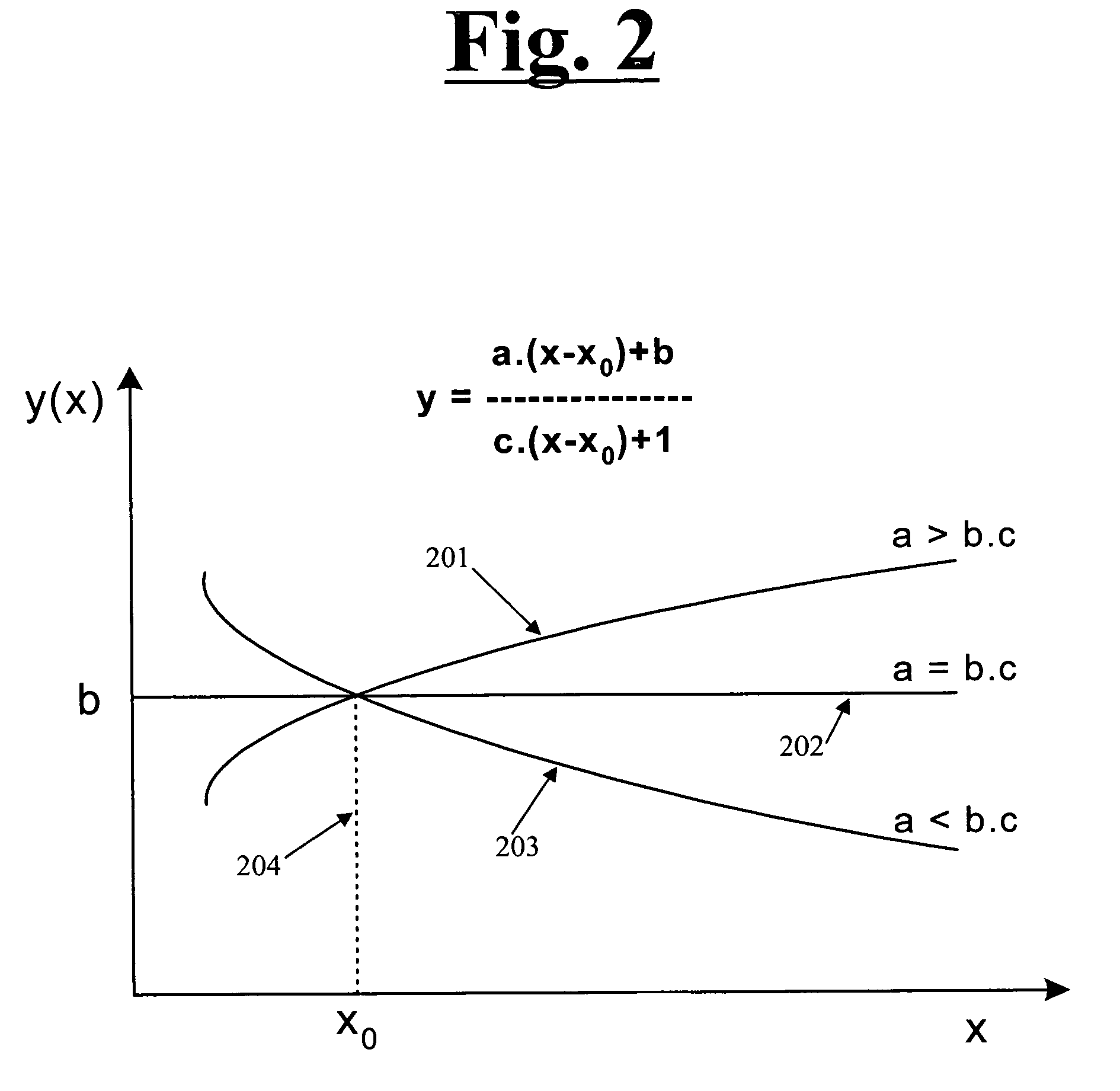

Providing nonlinear temperature compensation for sensing means by use of Padé approximant function emulators

ActiveUS7398173B2Easily made accurate and programmableEasy to implementThermometer testing/calibrationApparatus with stored calibration coefficientsTransducerEngineering

Owner:SEMICON COMPONENTS IND LLC

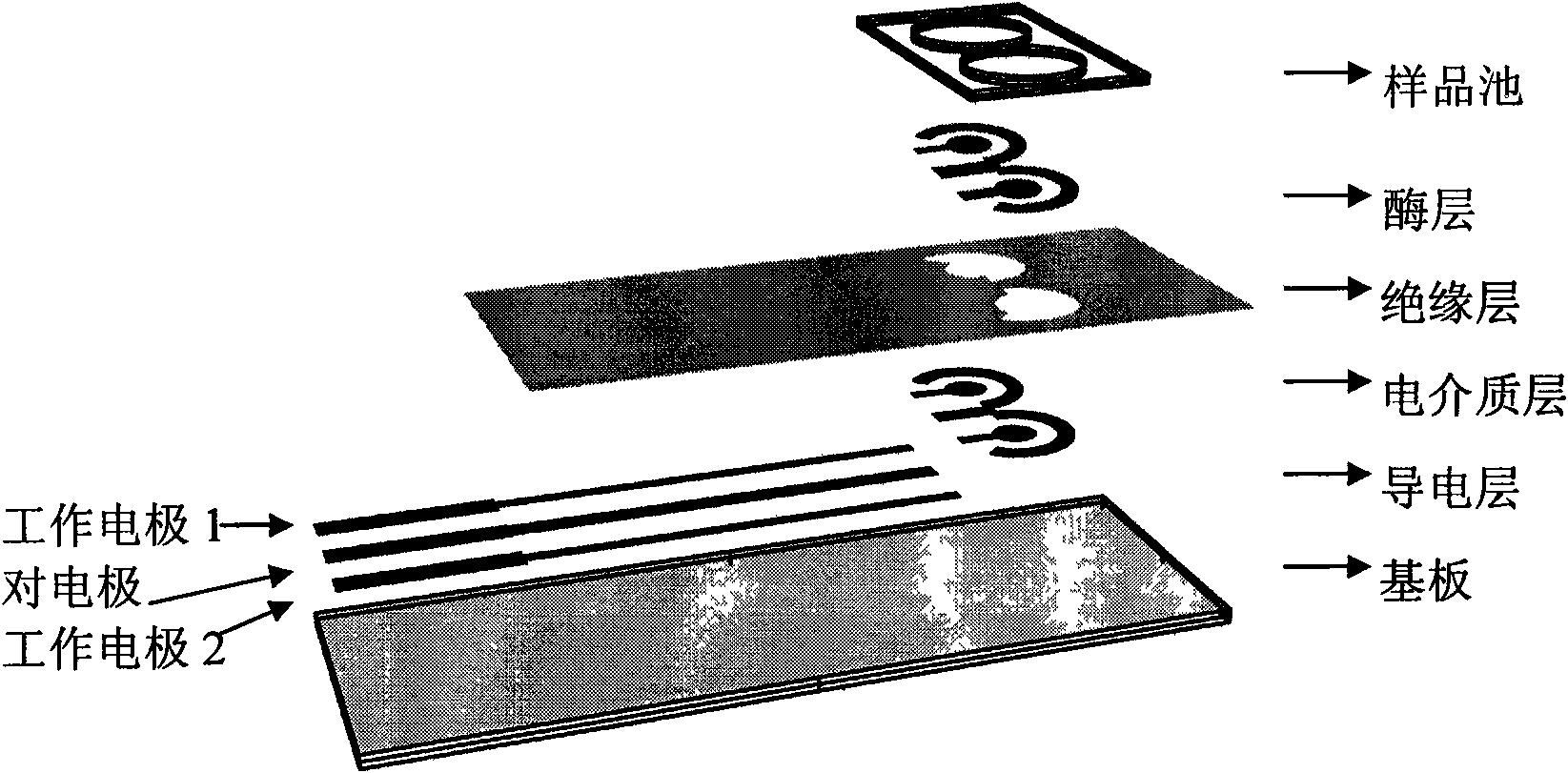

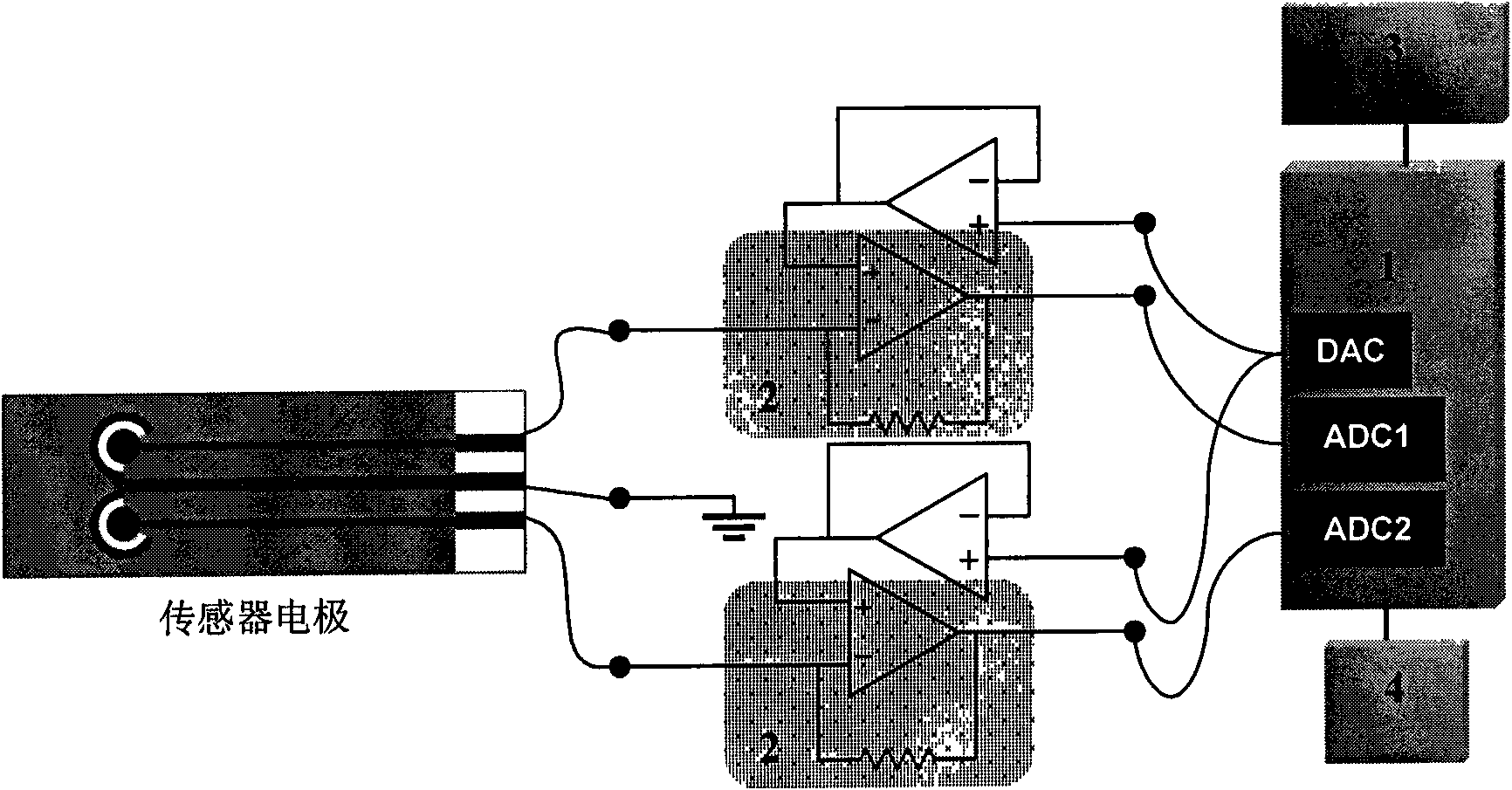

Portable electrochemical biosensor for fast detecting organophosphorus pesticide residue

InactiveCN101587092ALow cost mass productionSimplify the detection operation stepsMaterial analysis by electric/magnetic meansSingle useOrganophosphorus pesticides

A portable electrochemical biosensor for fast detecting organophosphorus pesticide residue mainly comprises disposable sensor electrode reagent strips and a portable detecting instrument. The sensor electrode reagent strips are manufactured by a screen printing technique and each provided with two working electrodes and a shared counter electrode to be able to detect check samples and working samples at the same time and effectively reduce the result inaccuracy resulted from bad consistency of the manufacturing of the reagent strips; and the portable detecting instrument is designed on the basis of embedded system of a microcontroller, has two paths of sampling channels, a liquid crystal display and the alarm and reminding functions of a buzzer, and is powered by batteries. The portable electrochemical biosensor for fast detecting organophosphorus pesticide residue is based on the principle of electrochemical ferment sensor, and can fast detect the suppression ratio of the organophosphorus pesticide residue to acetylcholinesterase on spot, so as to evaluate the pesticide residue in the samples.

Owner:左少华 +2

Compact spectrometer including a diffractive optical element with dual dispersion and focusing functionality

ActiveUS8861086B2Low cost mass productionRadiation pyrometrySpectrum investigationFresnel lensGrating

Owner:PENN STATE RES FOUND

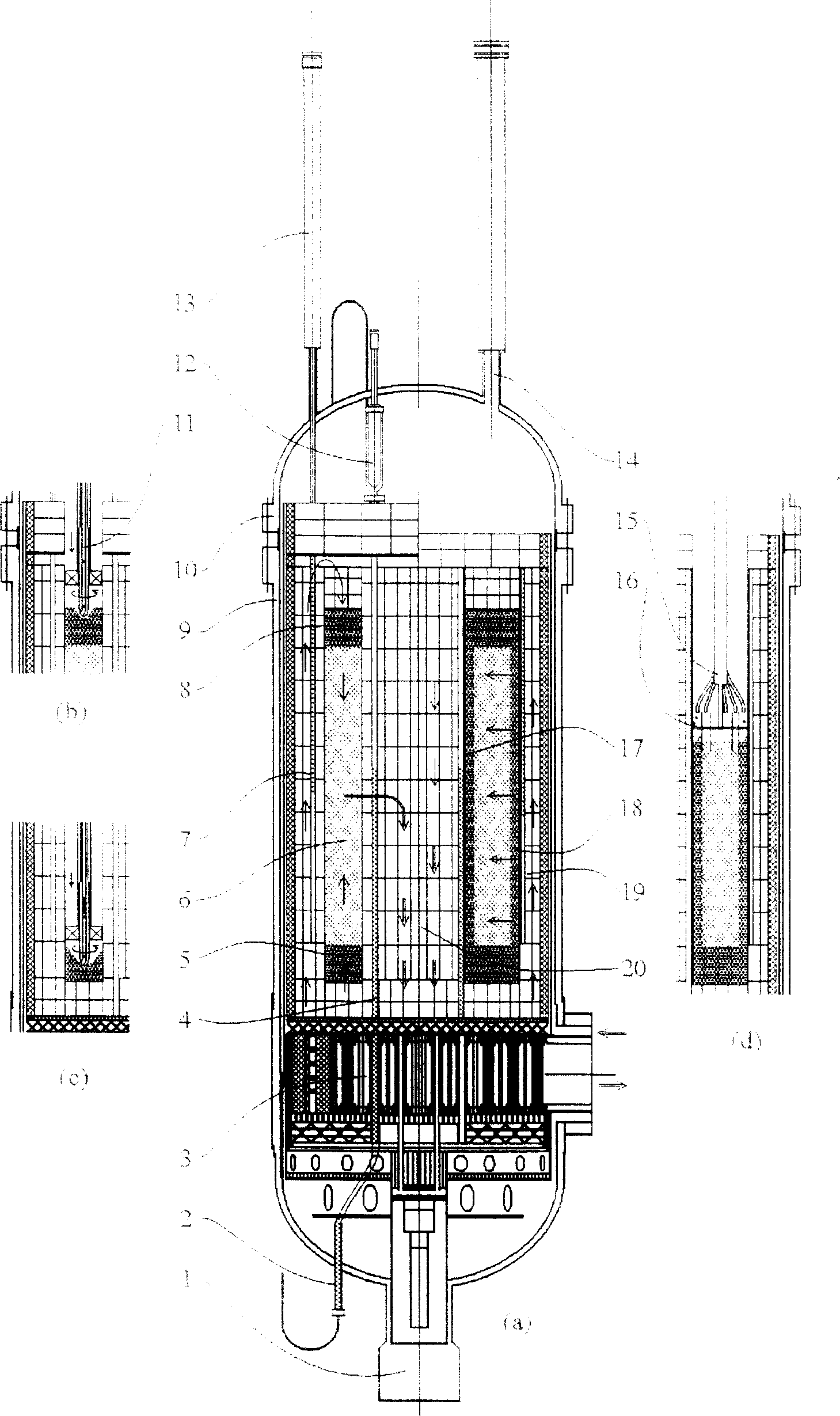

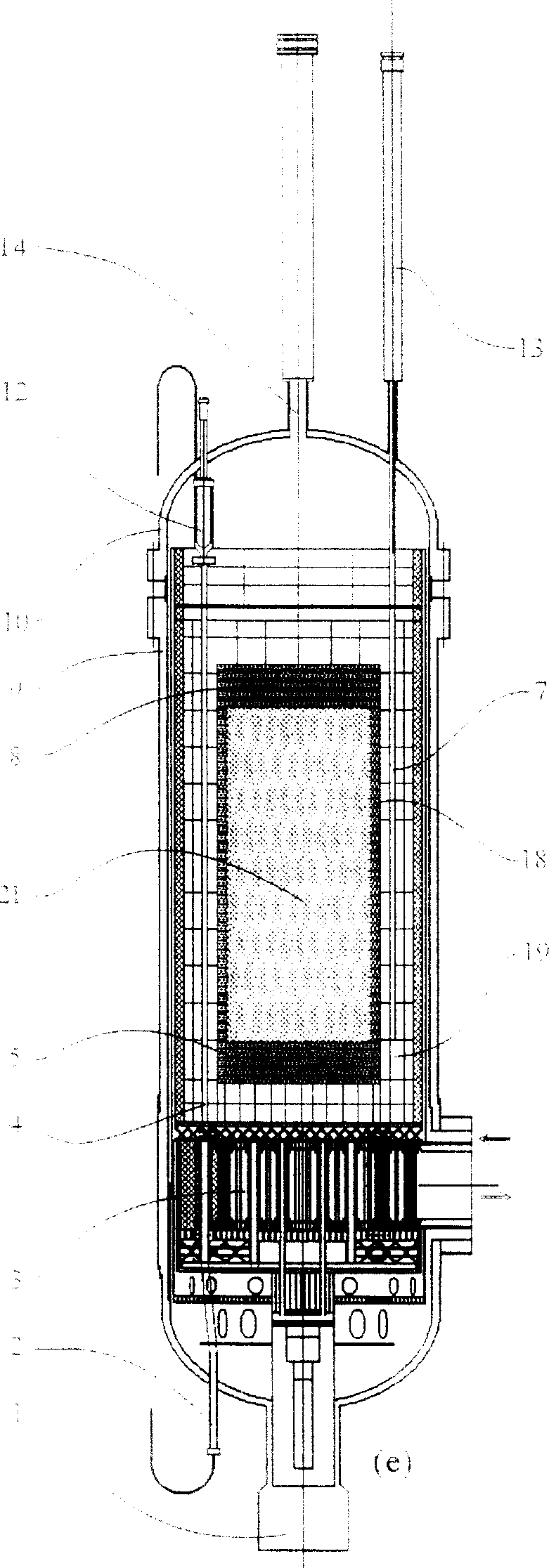

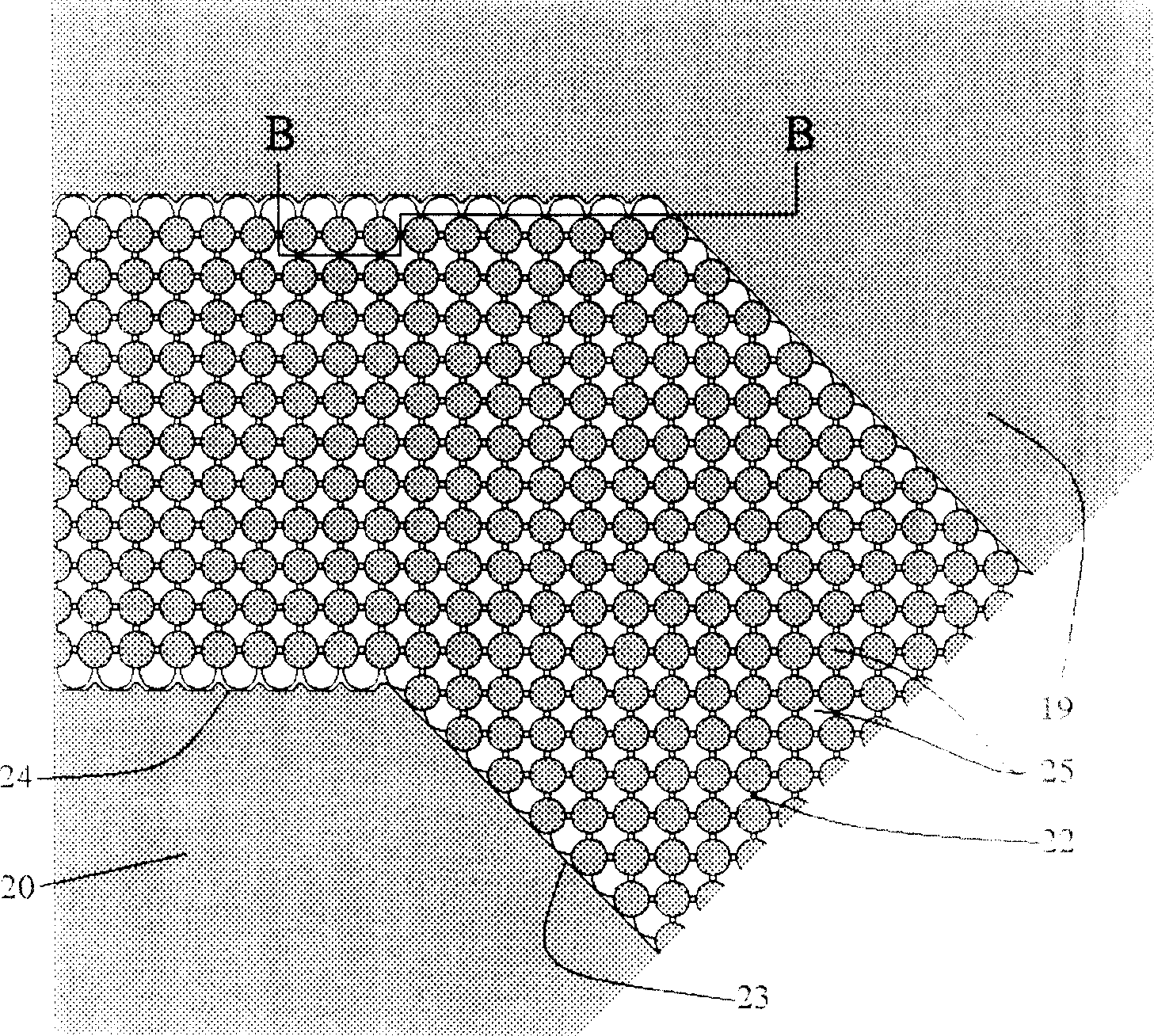

Regular bed modular high temperature gas cooled reactor and its fuel sphere disposal method

InactiveCN1731533AGood powerGood temperatureNuclear energy generationShieldingNuclear reactorGraphite

The invention relates to a rule bed module type high temperature gas-cooled reactor and fuel ball arranging method in the field of nuclear reactor technology. It arranges the helium inside the graphite block reflector. The control rod and the absorbing small ball are position inside the graphite block reflector. The flue ball is quadratic arranged on the level of the graphite block reflector hollow cavity, the center deck of each four balls can be used as the location of the second layer ball so as to form the rule bed with the up end and the down end is graphite block reflector.

Owner:田嘉夫

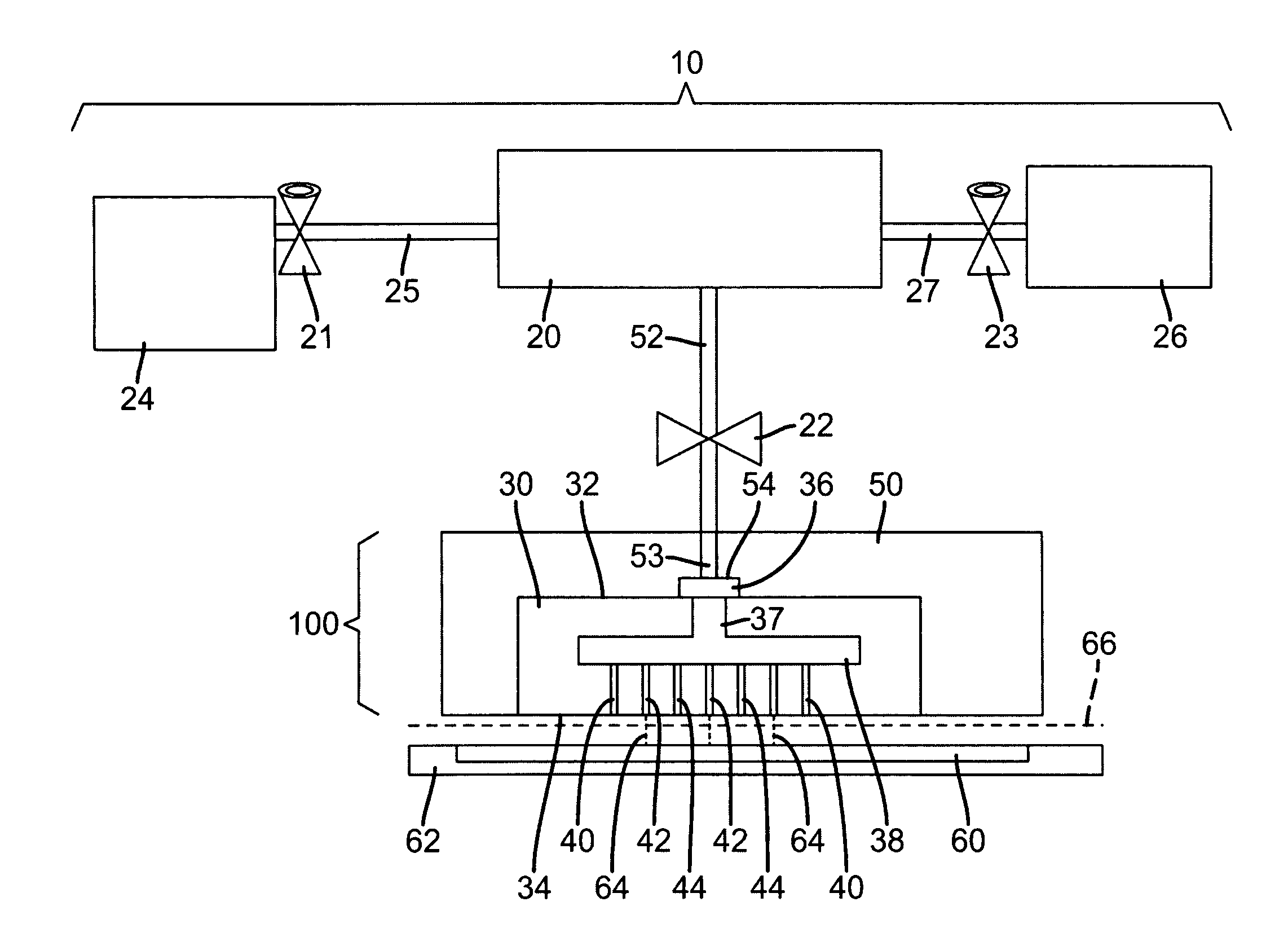

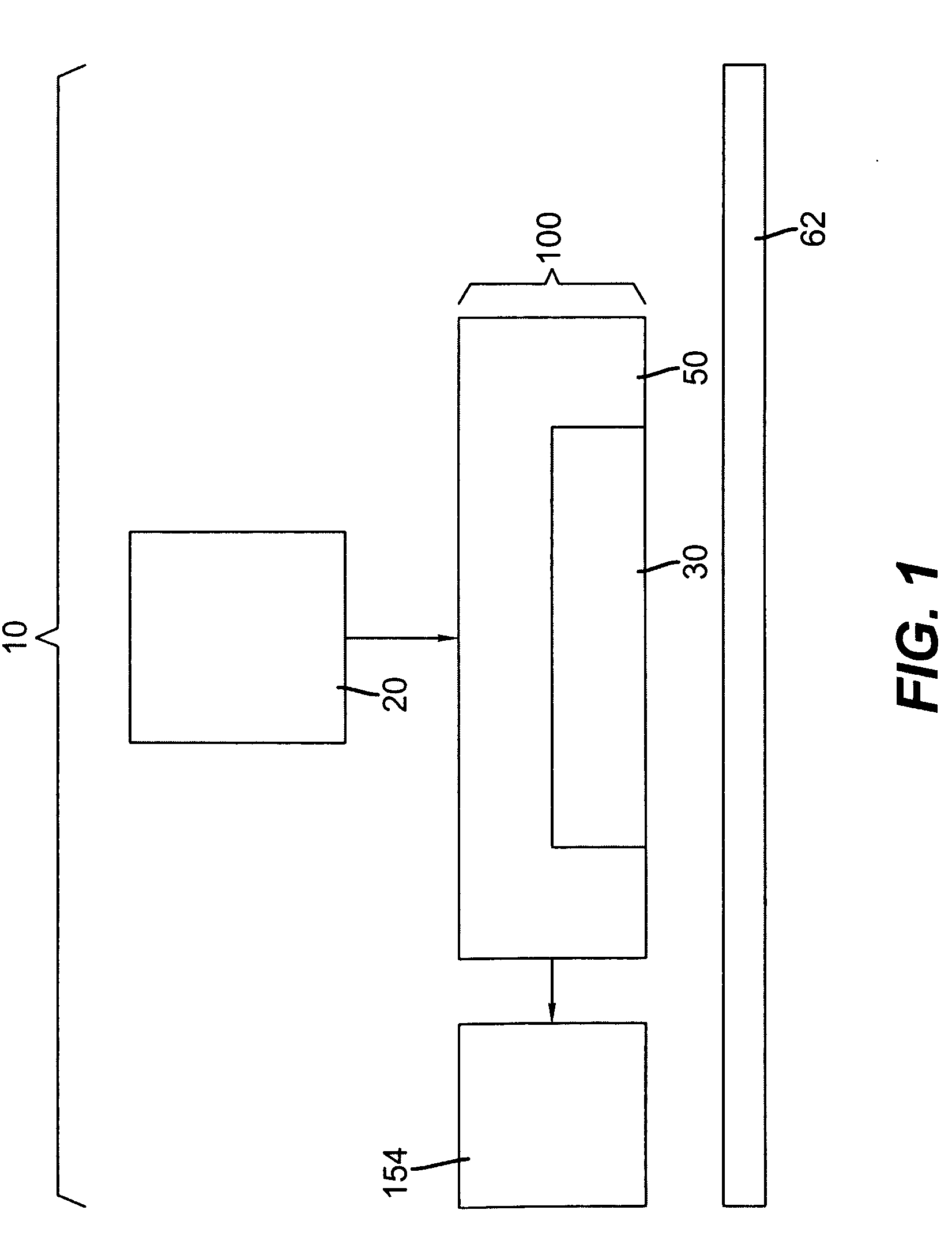

MEMS printhead based compressed fluid printing system

InactiveUS20090079783A1Low-cost mass productionOperational securityPrintingBiomedical engineeringEngineering

A method and apparatus for delivering a mixture of compressed fluid and marking material and depositing the marking material in a pattern onto a substrate, includes a high pressure source of a mixture of compressed fluid and marking material. A micro-machined manifold includes a plurality of micro-nozzles, a fluid chamber, and an entrance port with portions of a first surface of the micro-machined manifold defining the entrance port with the entrance port being connected in fluid communication with the fluid chamber. Each of the micro-nozzles having an inlet and an outlet with the inlet being connected in fluid communication with the fluid chamber and the outlet being located on the second surface of the micro-machined manifold. Each micro-nozzle is shaped to produce a directed beam of the mixture of compressed fluid and marking material beyond the outlet of the micro-nozzle. A housing is connected in fluid communication with the high pressure source and the entrance port of the micro-machined manifold with the connection being a sealed connection. Optionally, a device operable to capture marking material that does not adhere to the substrate can be included.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com