Patents

Literature

195results about How to "Reduce production process costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

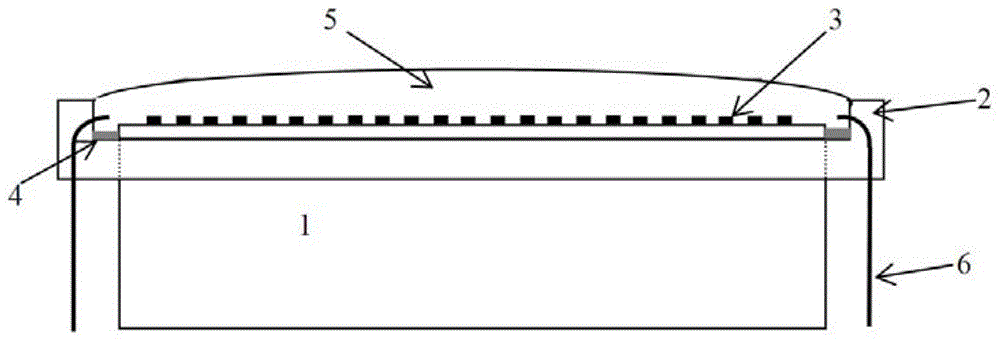

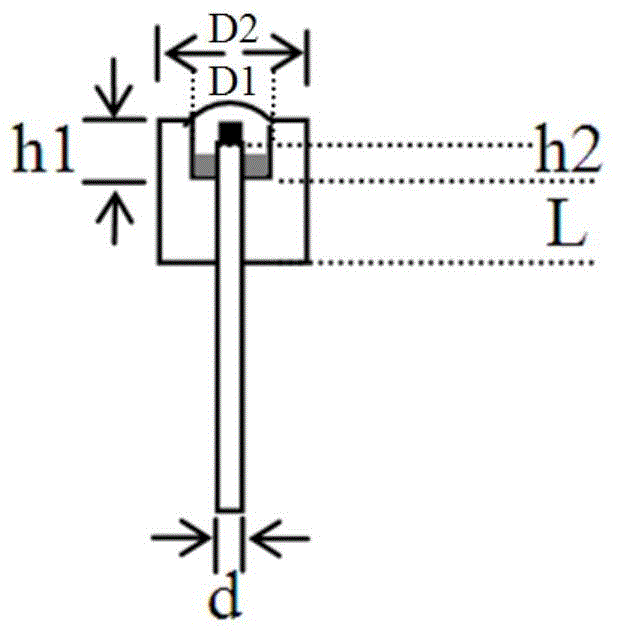

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

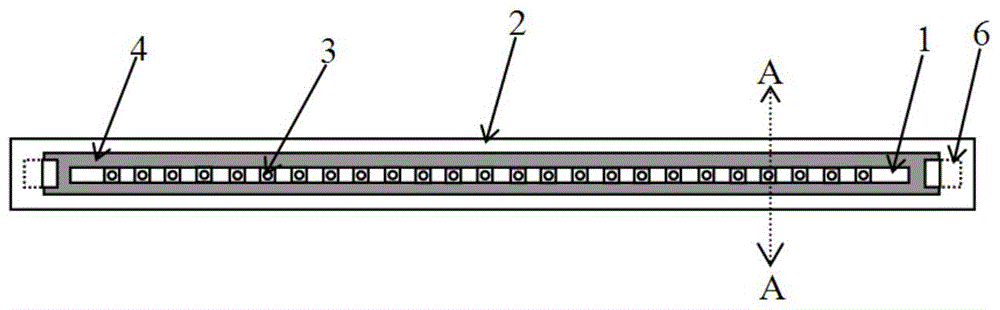

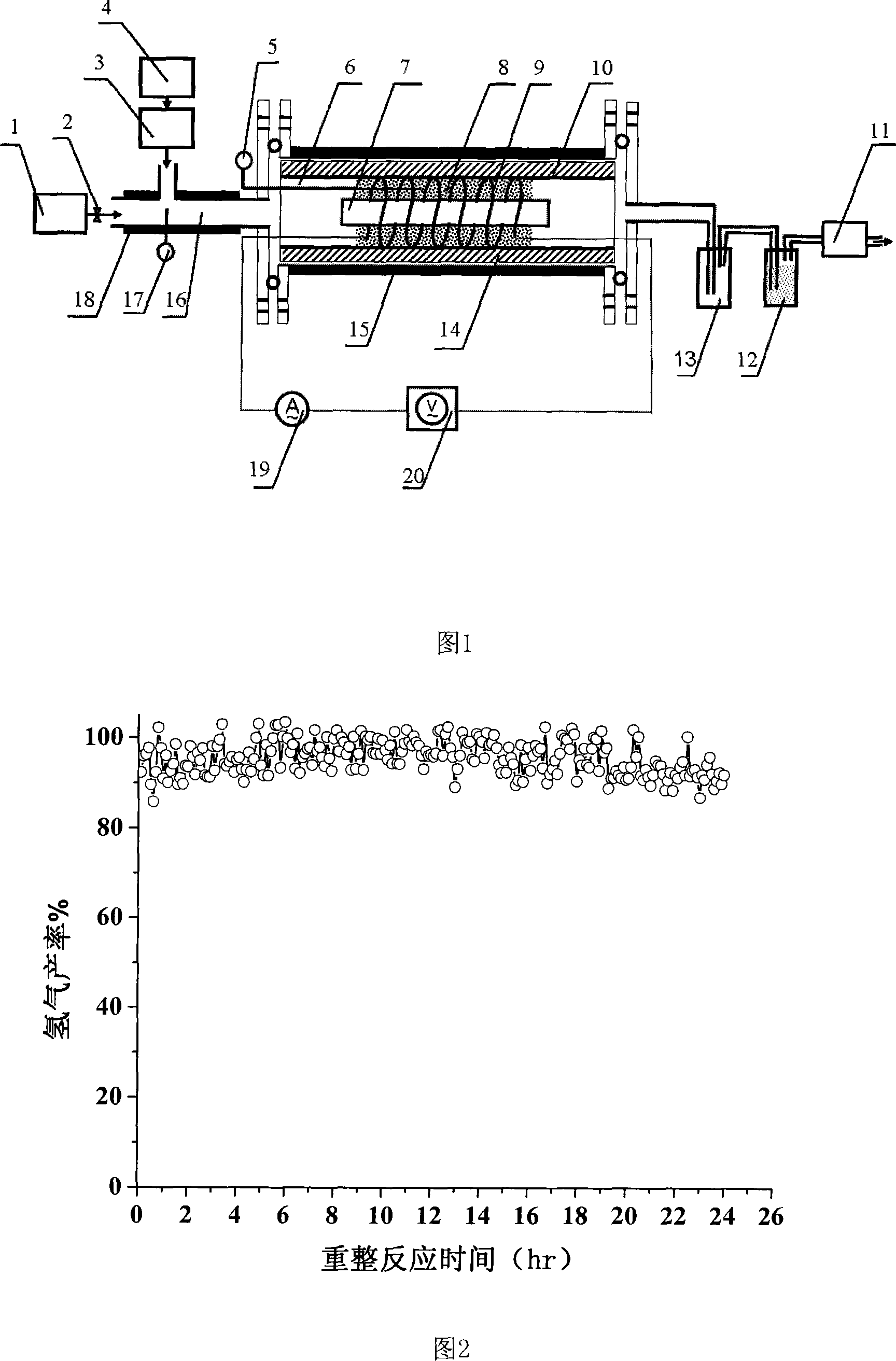

Device and method for preparing hydrogen by the electrocatalysis water vapour recapitalization biological oil

The invention relates to the technology of electrocatalytic reforming of organic compounds, in particular to a method and device for producing hydrogen from bio-oil by electrocatalytic steam reforming. The device includes a cylindrical reactor with a reforming catalyst and an external heating furnace, a bio-oil storage tank, a steam generator connected to an inlet pipeline with a preheating device, and a tail gas collection and purification system on the output pipeline. An electric furnace wire is arranged in the inner cavity of the device. When producing hydrogen, the external power supply of the electric furnace wire is first connected to heat the catalyst; then the mixed fluid of raw bio-oil and water vapor is passed into the inner cavity of the reactor, so that the bio-oil can be electrocatalyzed by water in a water vapor atmosphere and a medium temperature environment. Steam reforming reaction and water gas shift reaction convert carbon-hydrogen-oxygen-containing organic matter into hydrogen and carbon dioxide mixed gas. The invention utilizes heating electric furnace wire to provide hot electrons for the catalyst surface to dissociate and degrade various complex carbon-hydrogen-oxygen macromolecules in bio-oil, and obtain high hydrogen yield and bio-oil conversion under the condition of 450-550°C Rate.

Owner:UNIV OF SCI & TECH OF CHINA

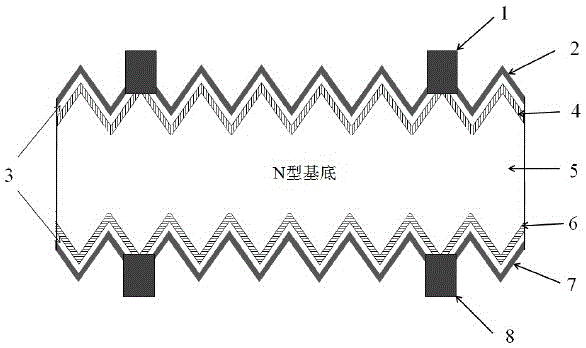

Double-sided N-type crystalline silicon cell and preparation method thereof

InactiveCN105047742AIncrease the open circuit voltageImprove current efficiencyFinal product manufacturePhotovoltaic energy generationChemical solutionBack surface field

The invention discloses a double-sided N-type crystalline silicon cell comprising a front AgAl electrode, a front antireflection film, a boron emitter passivation layer, a boron emitter p+ layer, an N-type silicon wafer, a phosphorus diffusion n+ back surface field layer, a back passivation layer, a back antireflection film, and a back Ag electrode. The front and the back of the cell are textured surfaces, and both sides can receive light and generate electricity. The boron emitter passivation layer and the back passivation layer are prepared at the same time by growing SiO2 layers through thermal oxidation in a low-temperature dry method, which reduces the interface-state density and the rate of interface recombination. A laminated film composed of a borosilicate glass layer and a silicon nitride layer formed in the diffusion process is used as a boron emitter protection layer. Therefore, boron diffusion surface etching and phosphorous diffusion cross contamination caused by chemical solution are prevented effectively, multiple times of etching and mask deposition in the process are reduced, and the technological process is simplified.

Owner:中国东方电气集团有限公司

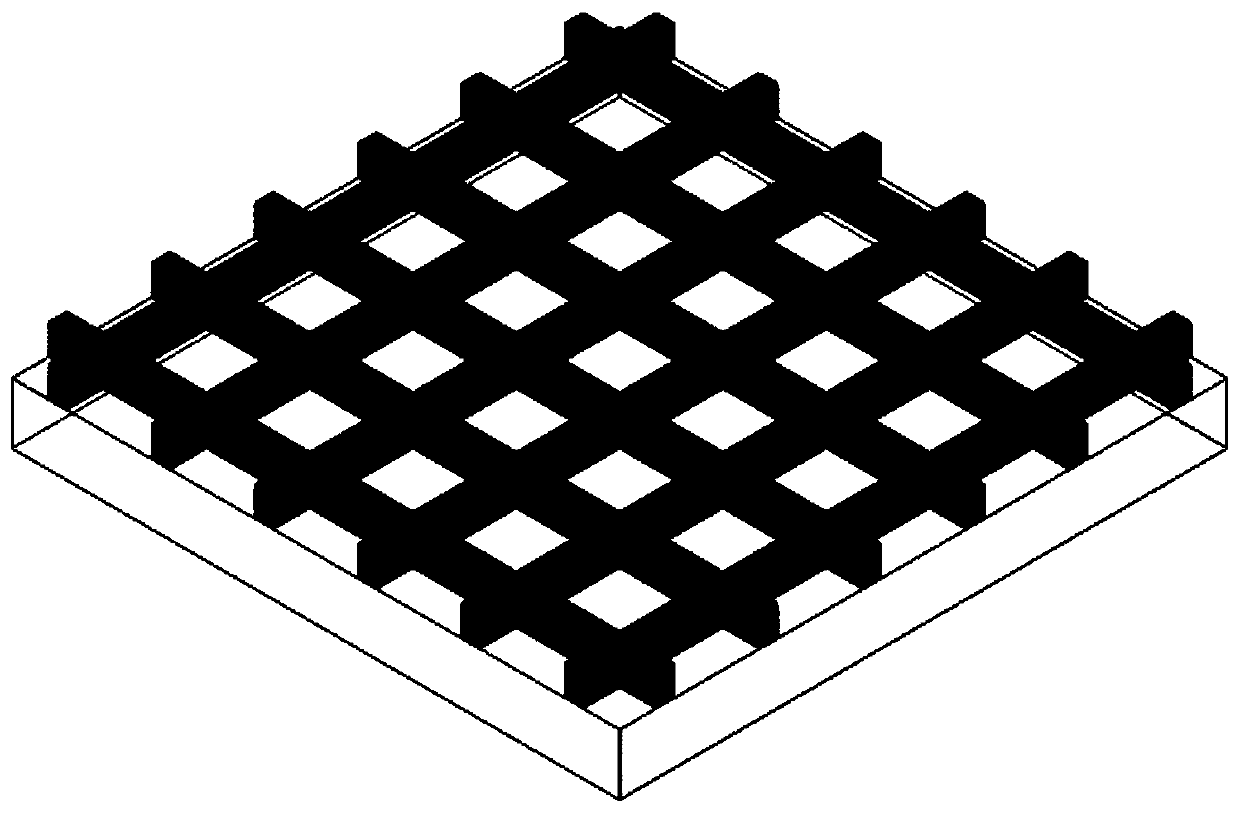

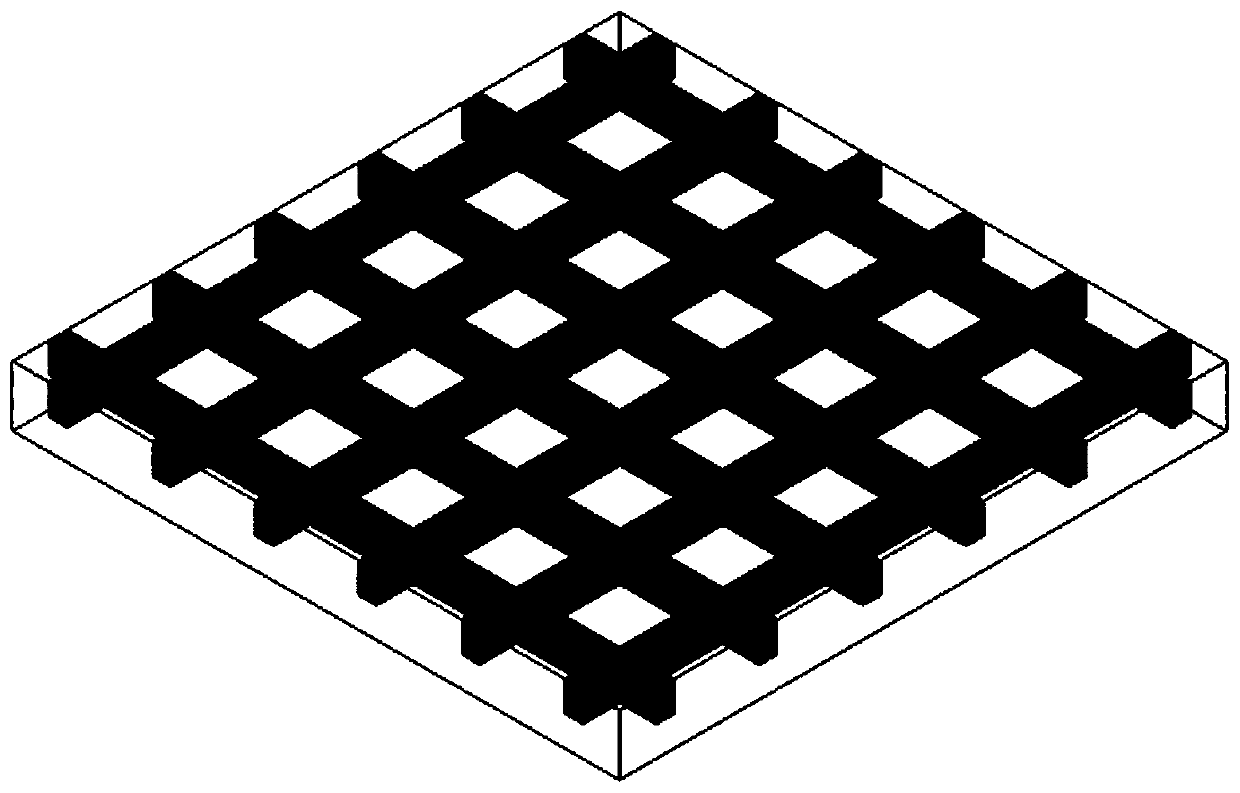

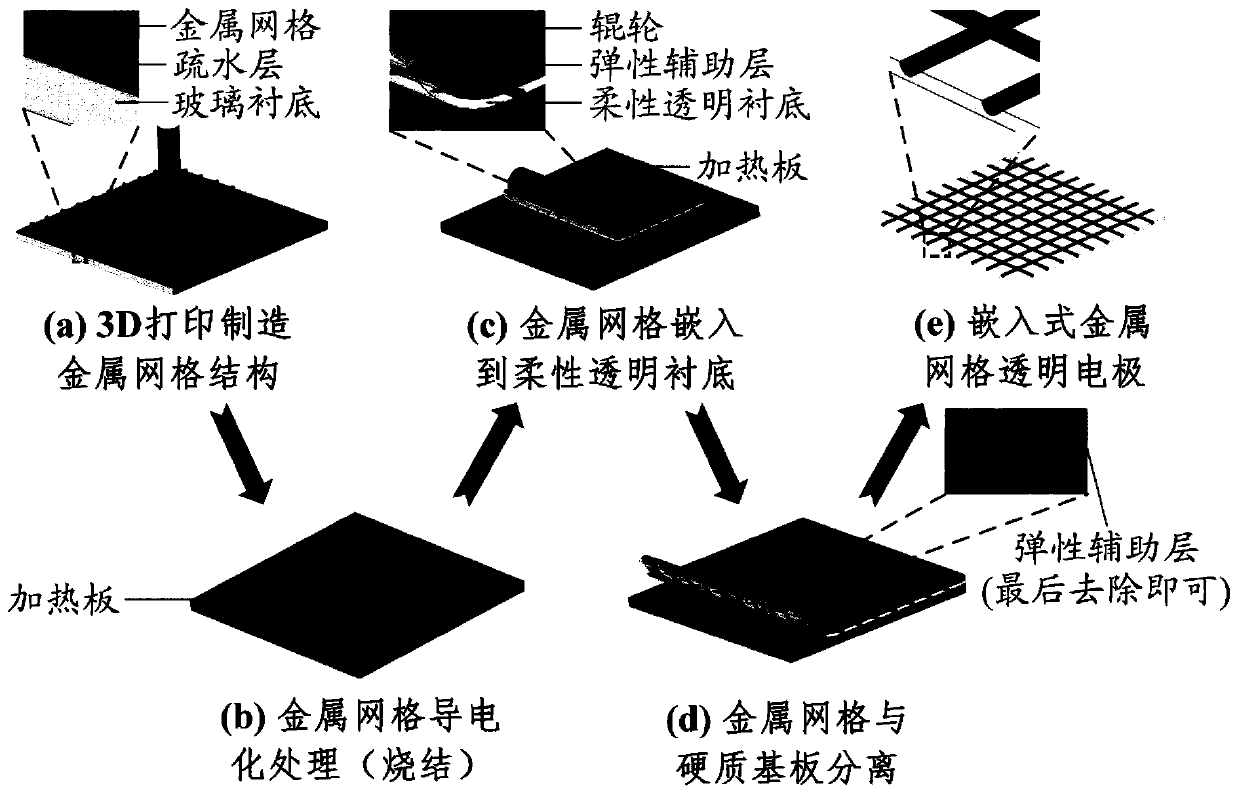

Manufacturing method and application of embedded metal grid flexible transparent electrode

ActiveCN110021462AIncrease profitNo wasteAdditive manufacturing apparatusConductive layers on insulating-supportsHot stampingMicro nano

The invention belongs to the field of flexible transparent electrodes, and particularly relates to a manufacturing method and an application of an embedded metal grid flexible transparent electrode. The method comprises the following steps: 1) by use of an electric field driven spray deposition micro-nano 3D printing technology, a metal grid transparent electrode is directly printed on a hard substrate; 2) conductive treatment is carried out on a printed metal grid structure by adopting a sintering process so as to realize conductive treatment of a metal grid; 3) a flexible transparent substrate and the hard substrate are heated to a set temperature, and a hot stamping process is adopted for completely embedding the metal grid structure on the hard substrate into the flexible transparent substrate; and 4) the metal grid which is completely embedded into the flexible transparent substrate is separated from the hard substrate to obtain the embedded metal grid flexible transparent electrode. According to the method, the electric field driven spray deposition micro-nano 3D printing technology is combined with the roller pair plane hot stamping technology to realize efficient and low-cost batch manufacturing of the large-sized embedded metal grid flexible transparent electrode; and the prepared transparent electrode also has excellent square resistance and light transmittance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

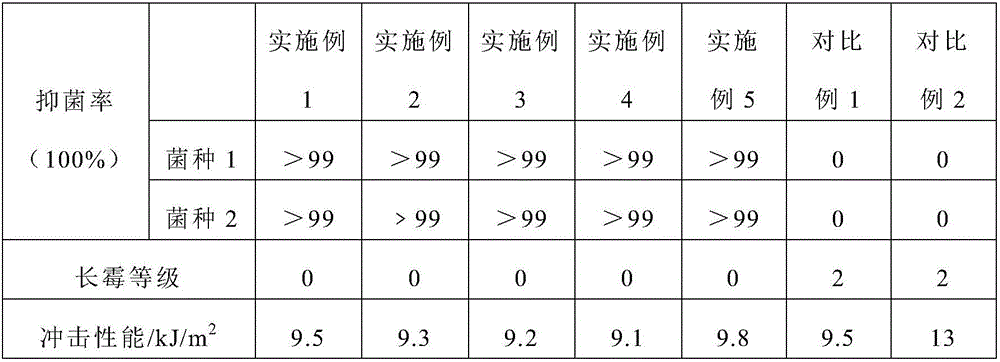

Transparent plastic with antibacterial and mouldproof capacity and preparing method thereof

The invention discloses transparent plastic with antibacterial and mouldproof capacity and a preparing method thereof and belongs to the field of functional polymer materials and inorganic-organic nanocomposite. The transparent plastic is prepared from, by mass, 85-97% of transparent resin, 1-10% of antibacterial agent, 1-10% of mouldproof agent, 0.1-1.0% of complex antioxidant and 0.1-1.0% of dispersing agent. The preparing method comprises the steps of 1, conducting physical mixing according to mass percentage; 2, adding evenly mixed raw materials into a twin-screw extruder for melting granulation. According to the transparent plastic, light transmittance is larger than 85%, escherichia coli inhibition rate is larger than 99%, staphylococcus aureus inhibition rate is larger than 99%, and fungi-growth grade is 0. Furthermore, the preparing method is simple, implementation is convenient, and production cost is low.

Owner:武汉威雷博科技有限公司

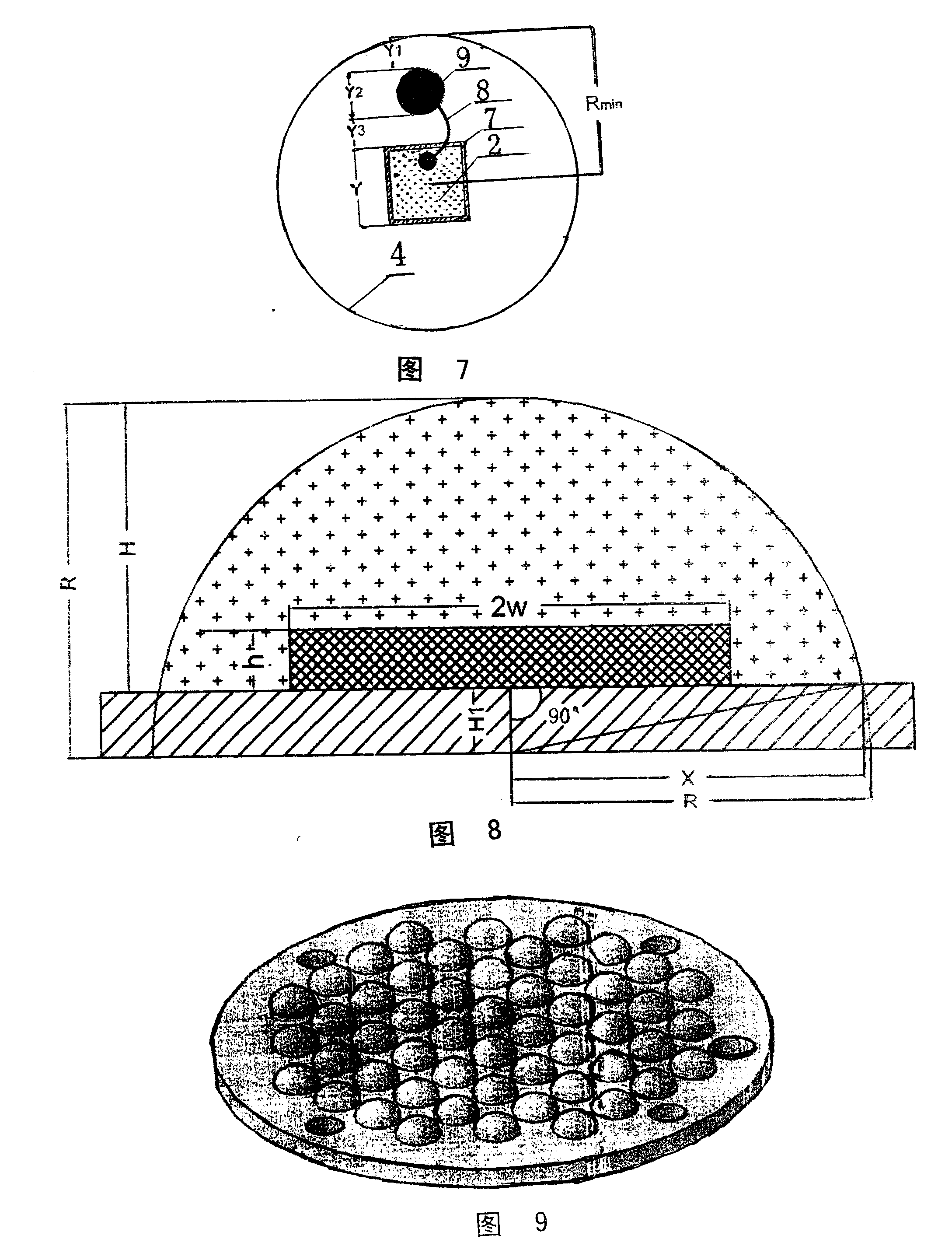

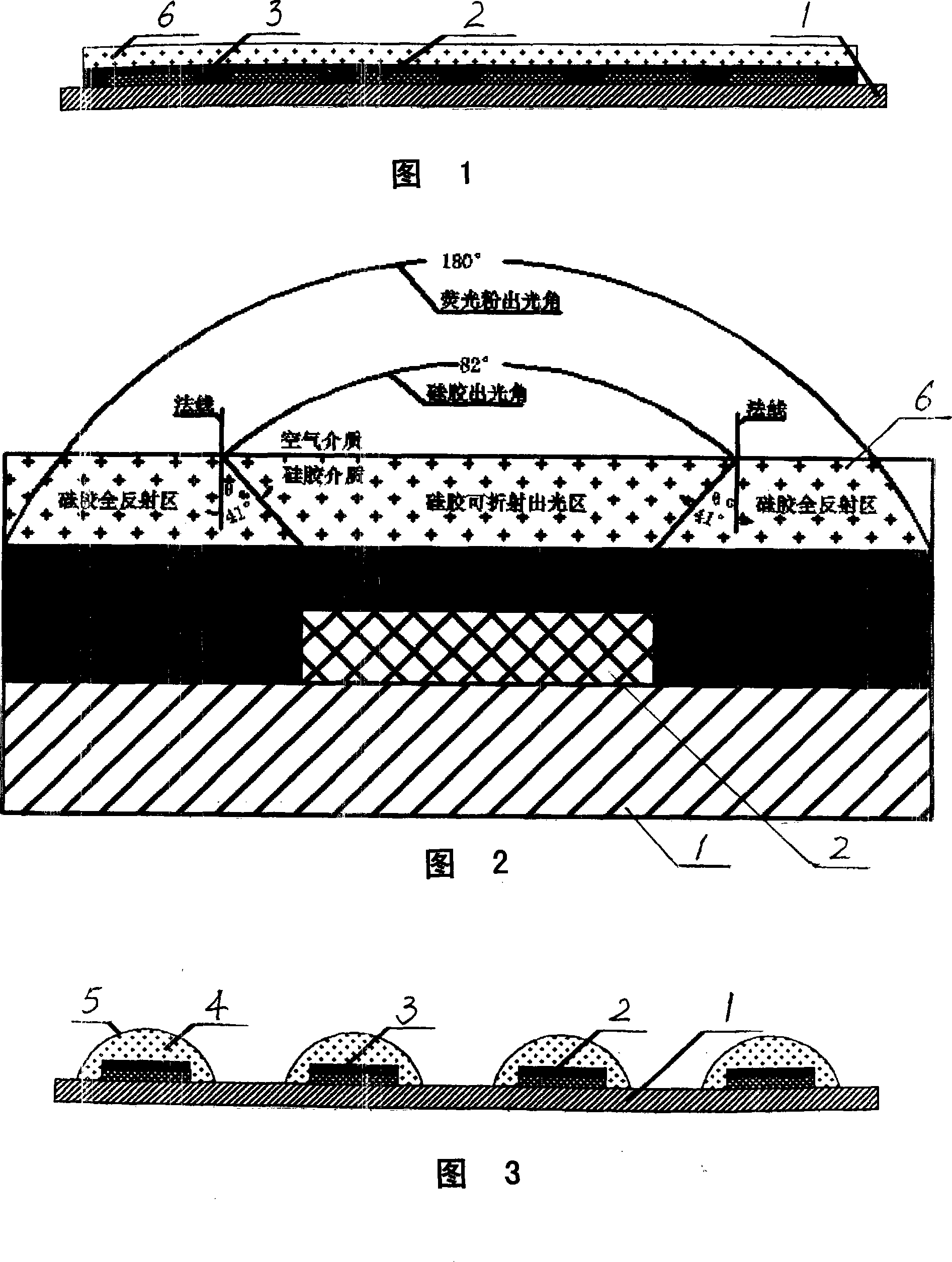

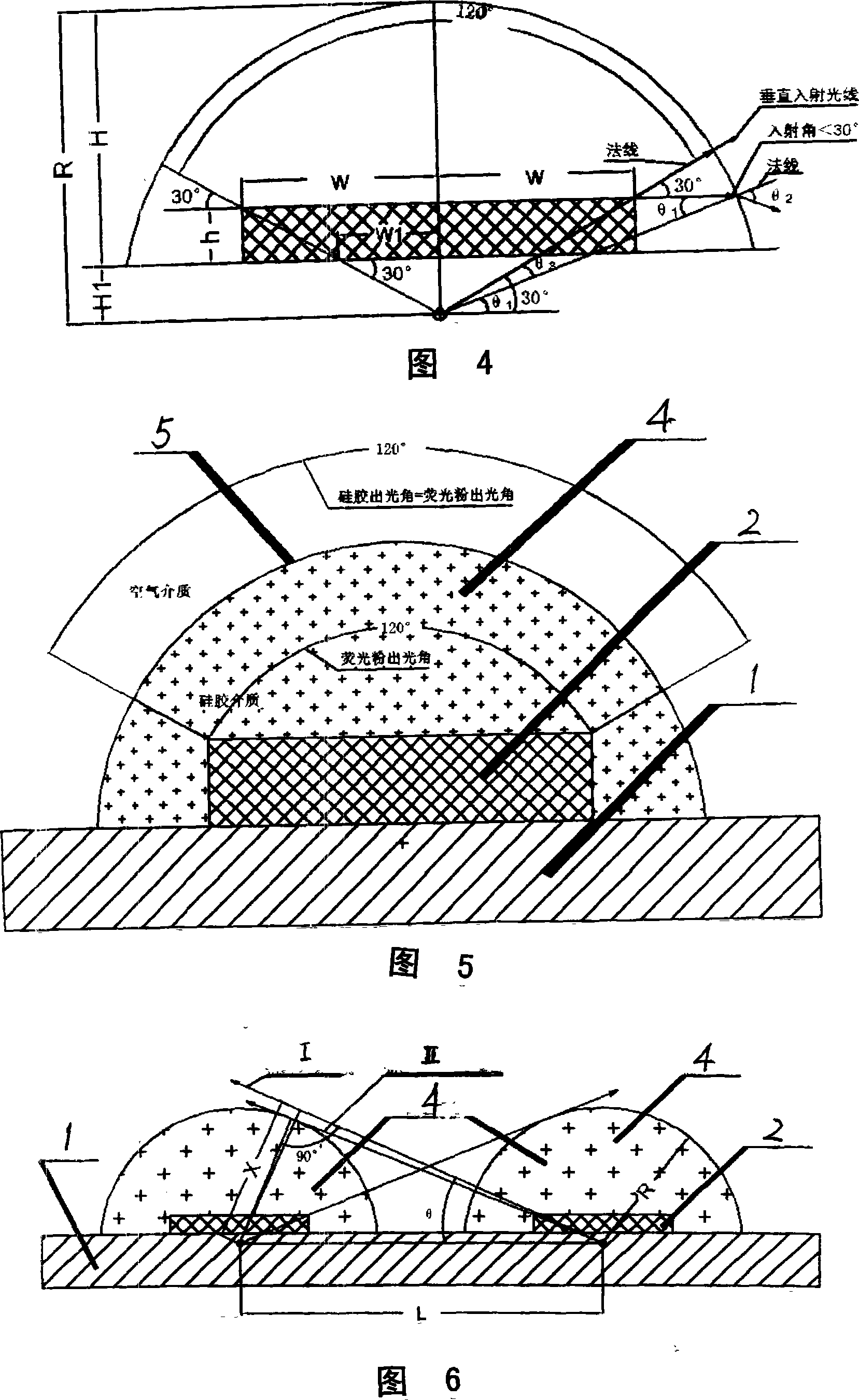

Non-reflection high light extracting rate unit WLED power expanding type high power WLED light source

InactiveCN101173758AIncreased beam angleLight interference is smallElectrical apparatusPoint-like light sourceEffect lightSilica gel

The invention relates to a no-reflection high-efficient-luminescence unitary-WLED power-capacity-expansion high-power light source. A plurality of blue-light BLED chips are welded on a radiating base plate. The surfaces of the BLED chips are coated with silica gel phosphor powder, which forms white-light WLED illuminants. The high-light-transmittance and high-intensity industrial plastic PC is made into a thin isopachous hemisphere-shaped casing. The PC casing is filled with high-transparency silicon gel which has the same light transmittance as the PC, which forms a silica gel hemispherical lens. The silica gel lens is packaged above the phosphor powder along the centre to form the no-reflection and high-efficient-luminescence unitary WLED light source. A plurality of unitary WLED light sources are assembled to a high-power WLED light source by capacity expansion. The light source can be make into a street lamp, an emergency lighting lamp, a safety lighting lamp for mine roadway, a mine cap lamp, a safety lighting lamp for subway and airport, an indoor lighting lamp and other WLED lighting lamps. The invention has the advantages of scientifically reasonable structure, low production cost, good radiating property, low power consumption, high efficient luminescence, long service life and other advantages.

Owner:西安锐泽克斯光电科技有限公司

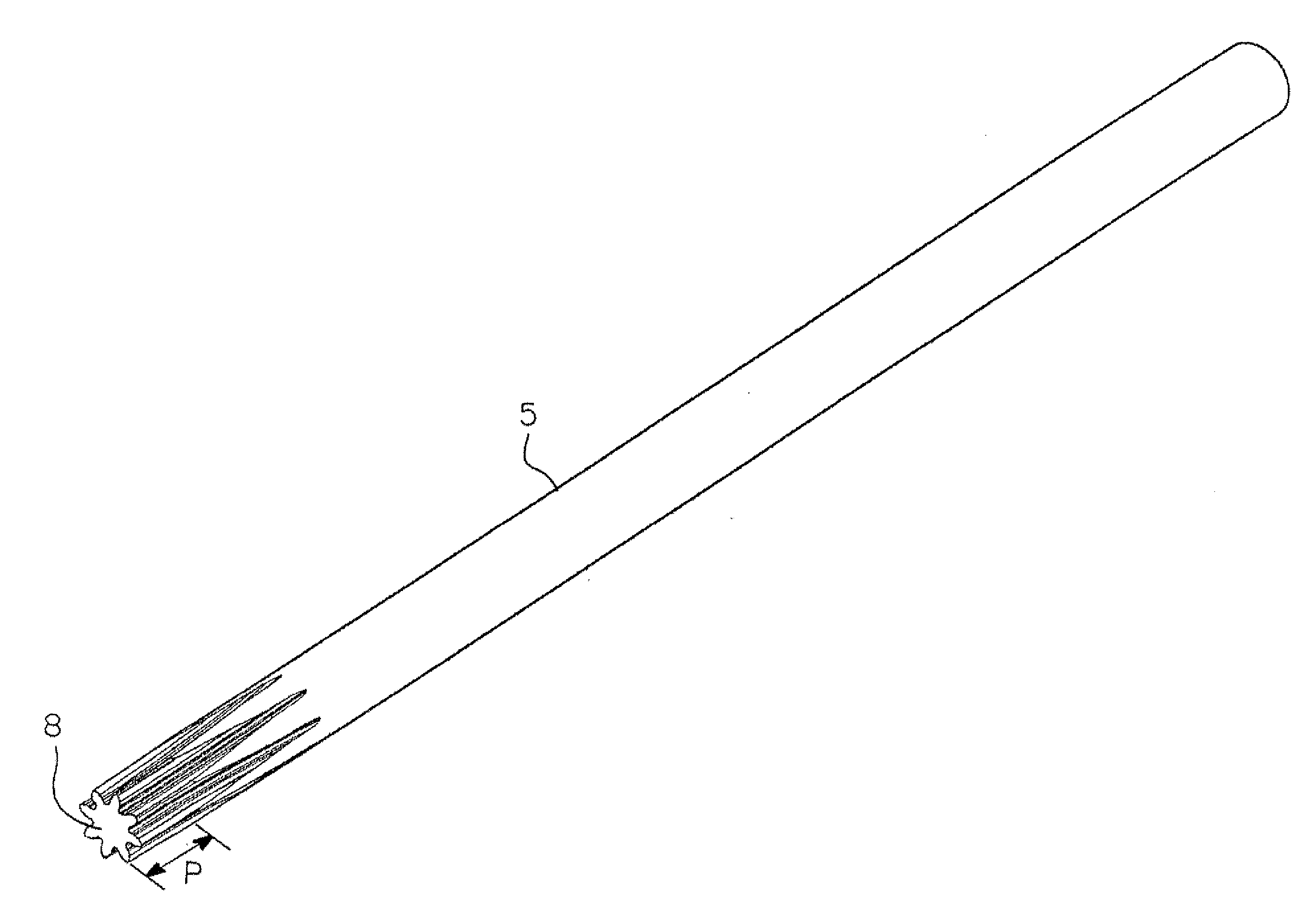

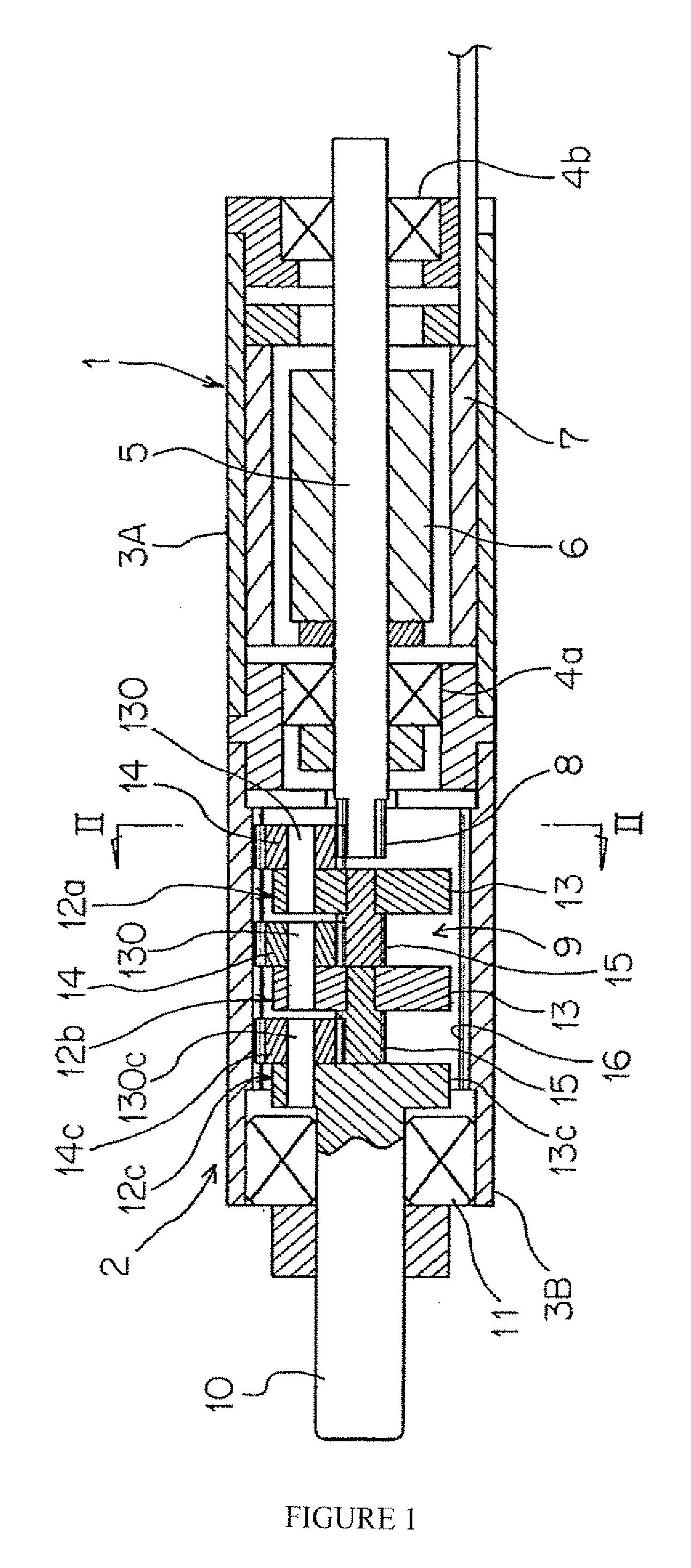

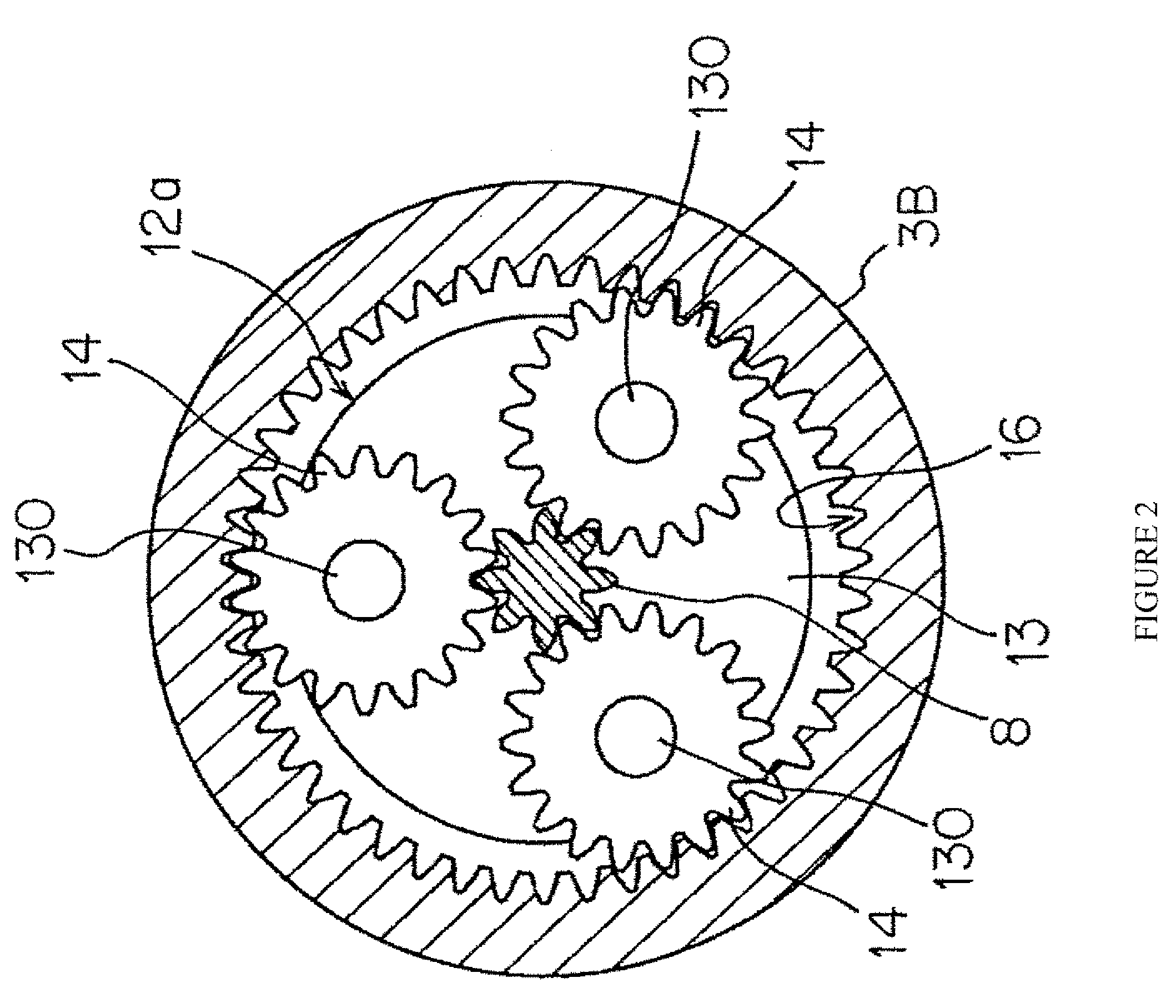

Motor shaft for micromotor, and micromotor

InactiveUS20090031839A1Increase the reduction ratioLow failure rateToothed gearingsMechanical energy handlingGear wheelReduction ratio

[Problems] A motor shaft for a micromotor where a high reduction ratio can be obtained by a speed-reduction gear mechanism and where high coaxiality between the motor shaft and a pinion can be achieved.[Means for Solving problems] The invention is based on the fact that, because a micromotor has a very small motor torque, even a pinion having a diameter smaller than that of a shaft has sufficient strength for the motor torque. Based on this, the motor shaft of the invention has a pinion integrally formed on the front end side of the shaft and the pinion has an outer diameter equal to or less than that of the shaft. Because the pinion can be sufficiently reduced in diameter, a high reduction ratio can be obtained by a speed-reduction gear mechanism. In addition, since the pinion can be integrally formed on the motor shaft, high coaxiality between the shaft and the pinion can be achieved.

Owner:NAMIKI PRECISION JEWEL CO LTD

Oxygen-bearing steel belt and production method thereof

The invention discloses an oxygen-bearing steel belt and a production method thereof and belongs to the technical field of metallurgy. The oxygen-bearing steel belt comprises, by mass, 0-0.008% of C, 0.15%-0.45% of Mn, 0-0.004% of Si, 0-0.006% of S, 0-0.020% of P, 0.001%-0.003% of Al, 0-0.0040% of N, 0-0.0050% of [O], and the balance iron and inevitable impurities. The production method comprises the specific steps of molten iron desulphurization, converter smelting, external refining, continuous casting, continuous casting slab heating, hot rolling and crimping; the production method is characterized in that the content of the [O] is controlled to be 0-0.0050% through the step of external refining. The oxygen-bearing steel belt produced through the production method is good in steel-aluminum compound property and wide in application range, the tensile strength is 315 MPa or higher, and the yield strength is 246 MPa or higher. According to the oxygen-bearing steel belt and the production method thereof, the production process cost is low, and the production stability is high.

Owner:TANGSHAN IRON & STEEL GROUP

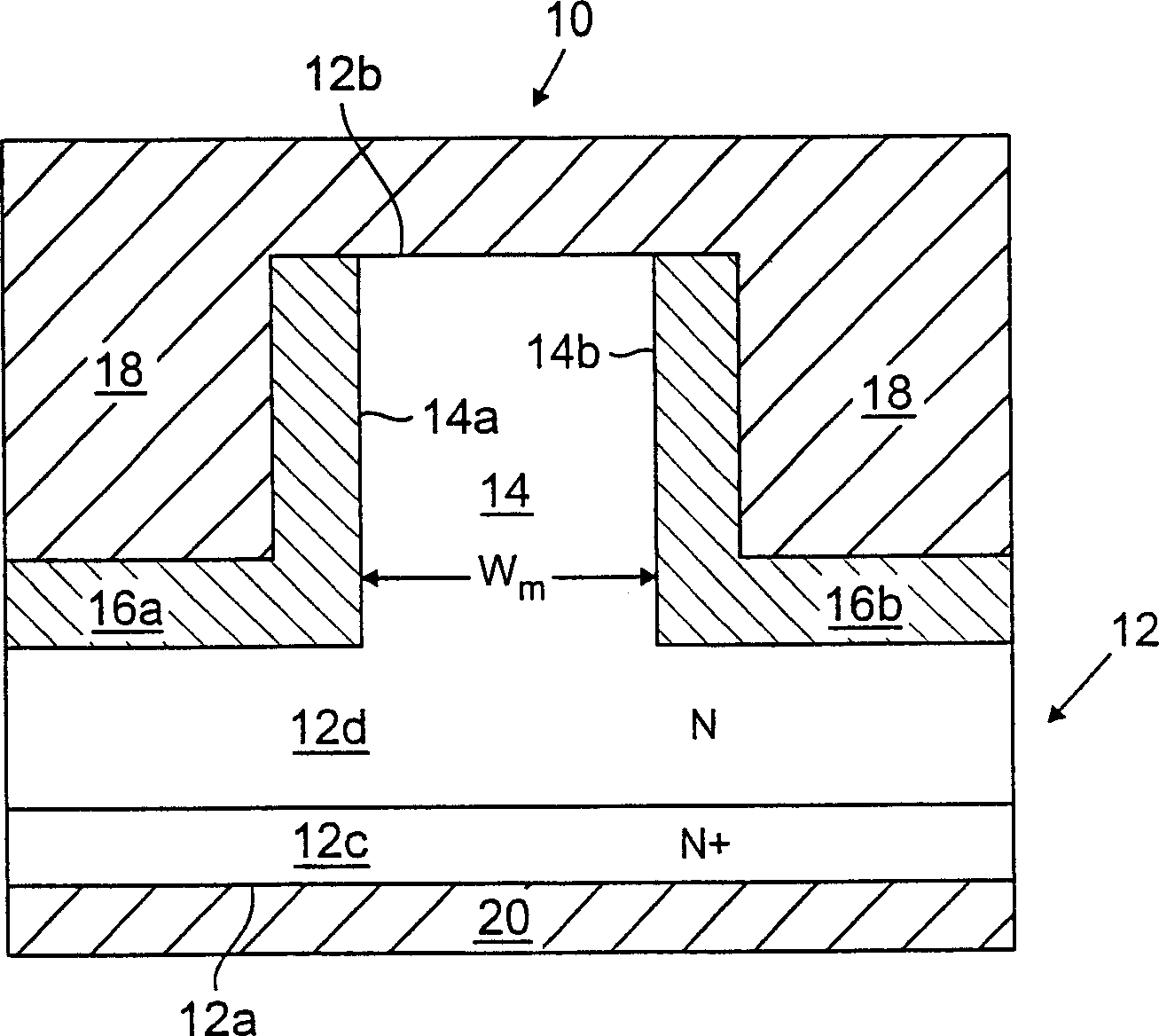

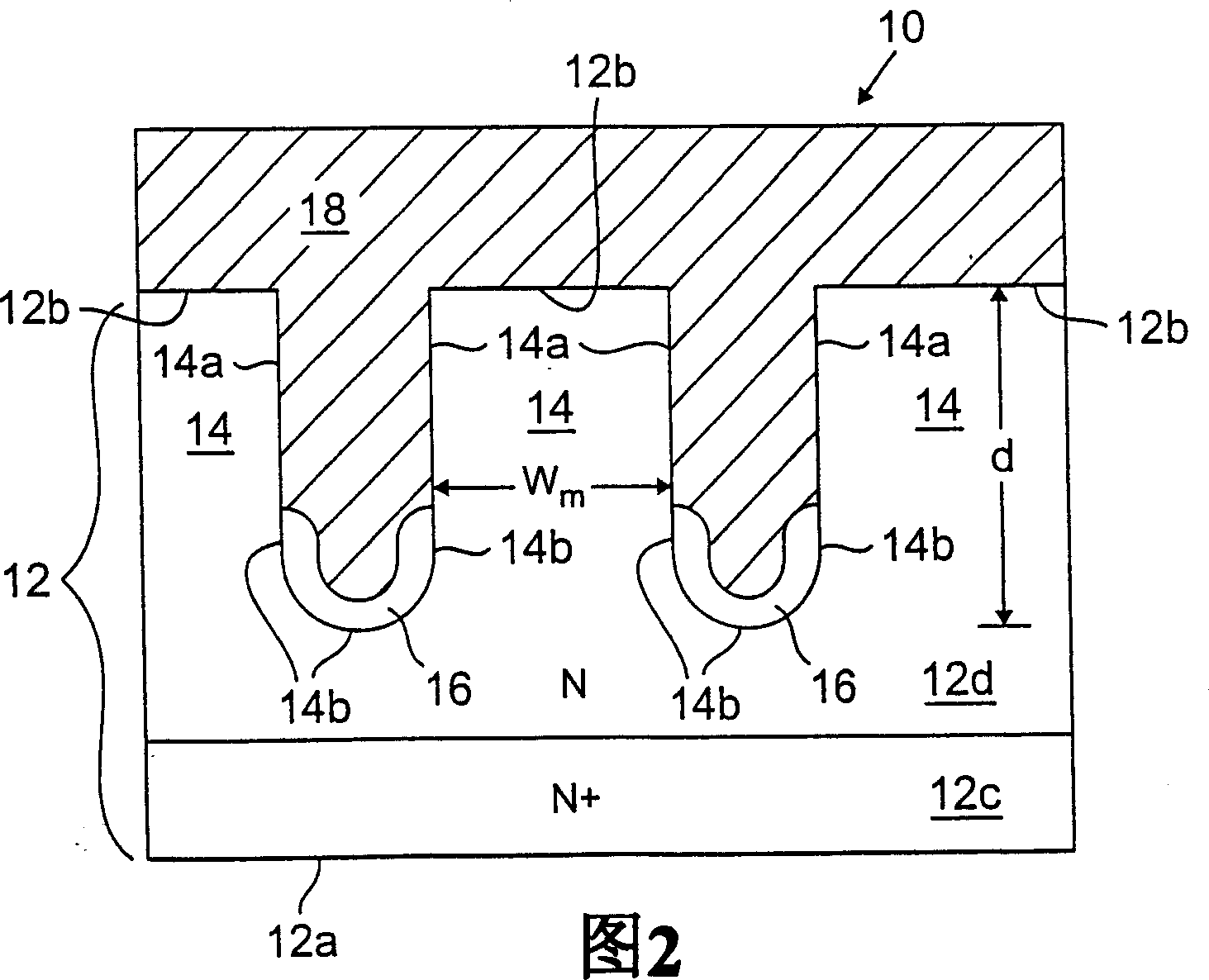

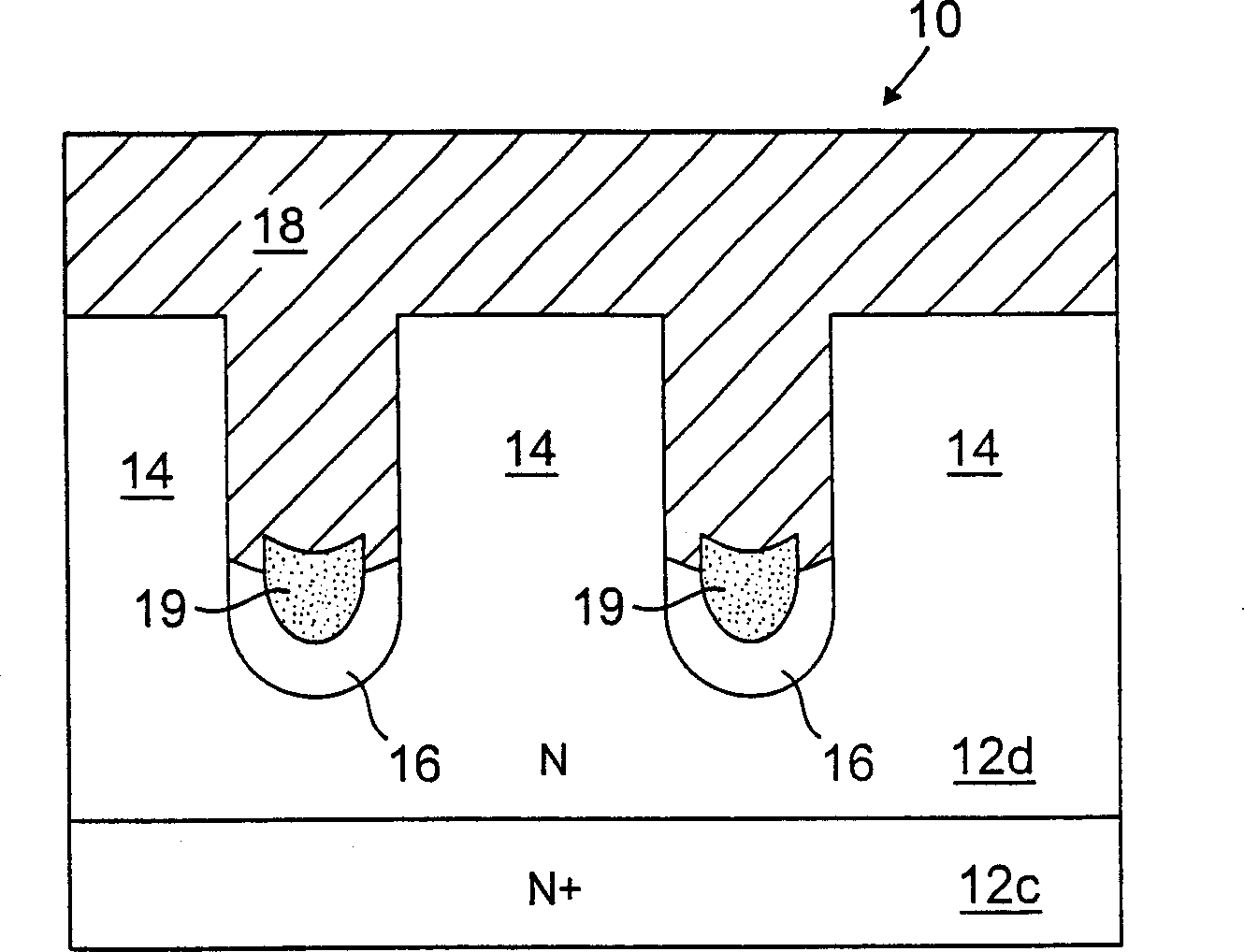

Trench Schottky rectifier

InactiveCN1498425AEasy to useReduce production process costsSemiconductor devicesSemiconductorRectifier

A Schottky rectifier is provided. The Schotttky rectifier comprises: (a) a semiconductor region having first and second opposing faces, with the semiconductor region comprising a cathode region of first conductivity type adjacent the first face and a drift region having a lower net doping concentration than that of the cathode region; (b) one or more trenches extending from the second face into the semiconductor region and defining one or more mesas within the semiconductor region; (c) an insulating region adjacent the semiconductor region in lower portions of the trench; (d) and an anode electrode that is (i) adjacent to and forms a Schottky rectifying contact with the semiconductor at the second face, (ii) adjacent to and forms a Schottky rectifying contact with the semiconductor region within upper portions of the trench and (iii) adjacent to the insulating region within the lower portions of the trench.

Owner:GEN SEMICON

Production method of high-cleanliness sulfur-containing and aluminum-containing steel

ActiveCN111235341ARaise the initial sulfur contentReduce production process costsManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses a production method of high-cleanliness sulfur-containing and aluminum-containing steel. The production method comprises the following steps: a top-bottom blowing combined converter is used for blowing, and molten steel is subjected to composite deoxidation, alloying and slagging in the tapping process; heating in the LF refining process, diffusing and deoxidizing of a slagsurface, and precipitating and deoxidizing of molten steel are performed, desulfurizing is not deliberate, the flow of ladle bottom blowing and stirring argon in the whole refining process is controlled, and calcium treatment and soft blowing are performed on the molten steel before the refining is finished; the molten steel is transferred to an RH station, a sulfur line is fed according to the residual sulfur content of the molten steel to a resulfurization target value of the molten steel, vacuum treatment is performed, and micro-calcium treatment denaturation is performed again after the molten steel is broken; and standing and soft blowing are performed on the molten steel; and an arc continuous casting machine performs protective casting. According to the method, the original sulfurcontent of the molten steel is improved, the refining process is not supplemented with slag materials for deliberate desulfurization, only molten steel diffusion and precipitation deoxidation are adopted, weak bottom blowing stirring and calcium treatment are adopted to promote inclusion removal, the sulfur line is fed before the molten steel enters the RH station, so that no component adjustmentis needed after the molten steel RH circulation, secondary pollution of the molten steel is avoided, and high cleanliness control of the molten steel is realized.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

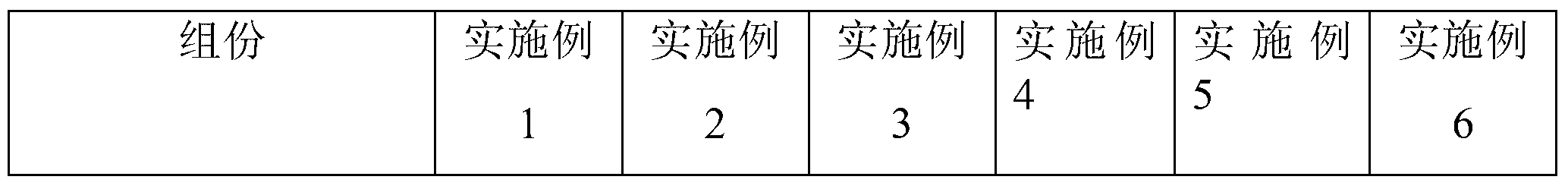

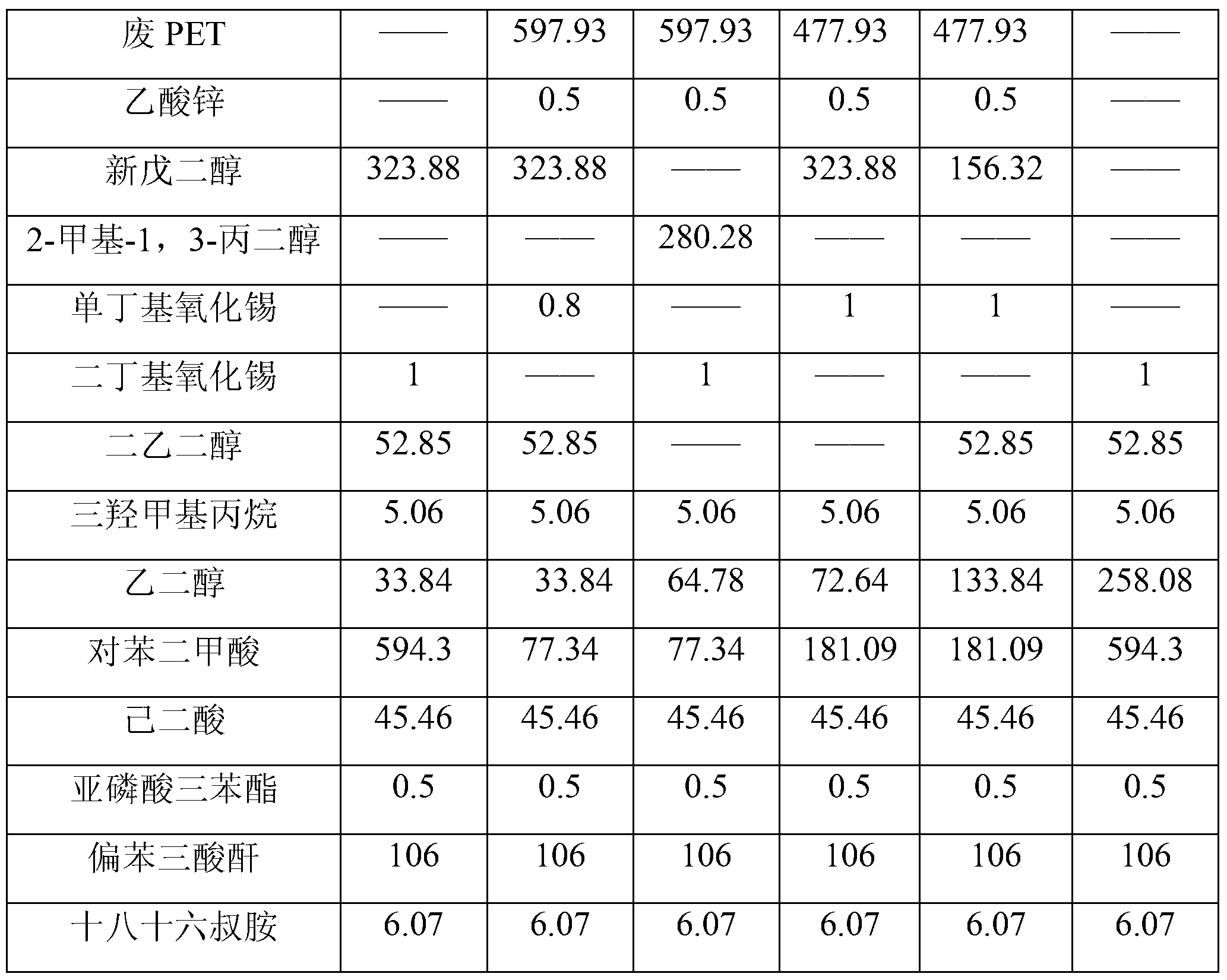

Preparation method of polyester resin for epoxy hybrid powder coating

InactiveCN103304792AAchieve recyclingReduce productionPowdery paintsEpoxy resin coatingsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a preparation method of polyester resin. The preparation method comprises the following steps of: (1) melting and mixing PET (Polyethylene Terephthalate) raw materials and dihydric alcohol to obtain a molten mixture, then adding the molten mixture into the molten dihydric alcohol, and carrying out ester exchange reaction in the existence of an ester exchange catalyst; and (2) adding polyhydric alcohol, polyatomic acid / acid anhydride and a stabilizer, carrying out esterification reaction under the action of an esterification catalyst, and then, adding trimellitic anhydride and octadecyl / hexadecyl tertiary amine to react while stirring to obtain the polyester resin. The polyester resin obtained according to the technical scheme disclosed by the invention not only has the characteristics of specific xanthochroia resistance, roasting resistance, salt mist resistance and the like of a powder coating produced through synthesizing high-quality polyester resin, but also has better luster and impact resistance and favorable leveling property, and can be used for reducing the generation of polyester wastes and environment pollution caused by esterified water generated by synthesizing purified terephthalic acid so as to be an environment-friendly technical scheme.

Owner:江苏宝田新材料股份有限公司

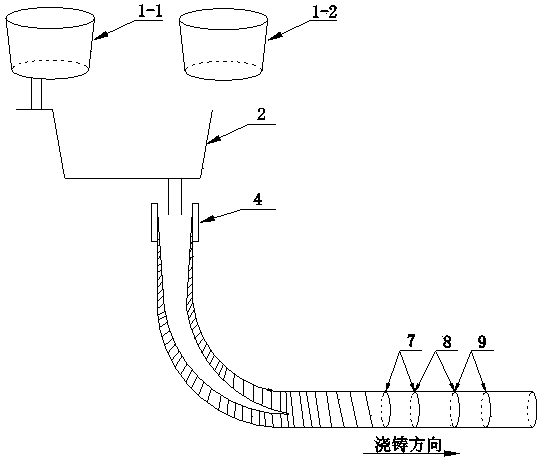

Continuous-casting big round billet dissimilar steel mixed casting production method

The invention discloses a continuous-casting big round billet dissimilar steel mixed casting production method. The method comprises the following steps that when molten steel of a prior melt is casted into a medium ladle, a certain amount of molten steel is left in a big ladle of the melt, and the casting speed is decreased; when the molten steel, left in the medium ladle, of the prior melt is decreased to a certain liquid level, casting is started on a big ladle of molten steel of a later melt, and a steel ladle covering agent in the medium ladle is replaced; after the big ladle of the latermelt is cast for a certain time, covering slag of a crystallizer is replaced; after the big ladle of the later melt is cast for 25 t, the liquid level of the medium ladle is kept, and the casting speed is increased; after the big ladle of the later melt is cast for 30 t, the liquid level of the medium ladle is slowly increased to the normal full liquid level, and then casting is conducted; and after the big ladle of the later melt is cast for 40 t, the casting speed is decreased to that corresponding to normal superheat degree, and then normal casting is conducted. According to the continuous-casting big round billet dissimilar steel mixed casting production method, when dissimilar steel is produced in the same medium ladle in a continuous casting manner, the thermal shutdown time can beshortened, the production efficiency of a continuous casting machine can be met, and the continuous casting billet yield can be increased.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Water-cooled shock absorber

ActiveCN104196945AAvoid carbonization or volume expansionReduce oil spillsSpringsShock absorbersVolume expansionEngineering

The invention discloses a water-cooled shock absorber. The water-cooled shock absorber comprises a shock absorber body and a water jacket which is arranged outside the shock absorber body, wherein a water inlet and a water outlet are formed in the water jacket. According to the water-cooled shock absorber, the water jacket allowing water flow to pass is arranged outside the cylindrical wall of the shock absorber body, heat of the high-temperature shock absorber body is transmitted to low-temperature water in the water jacket through heat transmission conducted when the low-temperature water flows through the water jacket, heat is taken away through the circulating flowing of the water, in this way, effective cooling of the shock absorber is achieved effectively, the shock absorber operates in a good working condition, carbonization of oil in the shock absorber or volume expansion of the shock absorber is avoided, the occurrence rate of accidents such as oil leakage is reduced, and the service life of the shock absorber is effectively prolonged.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

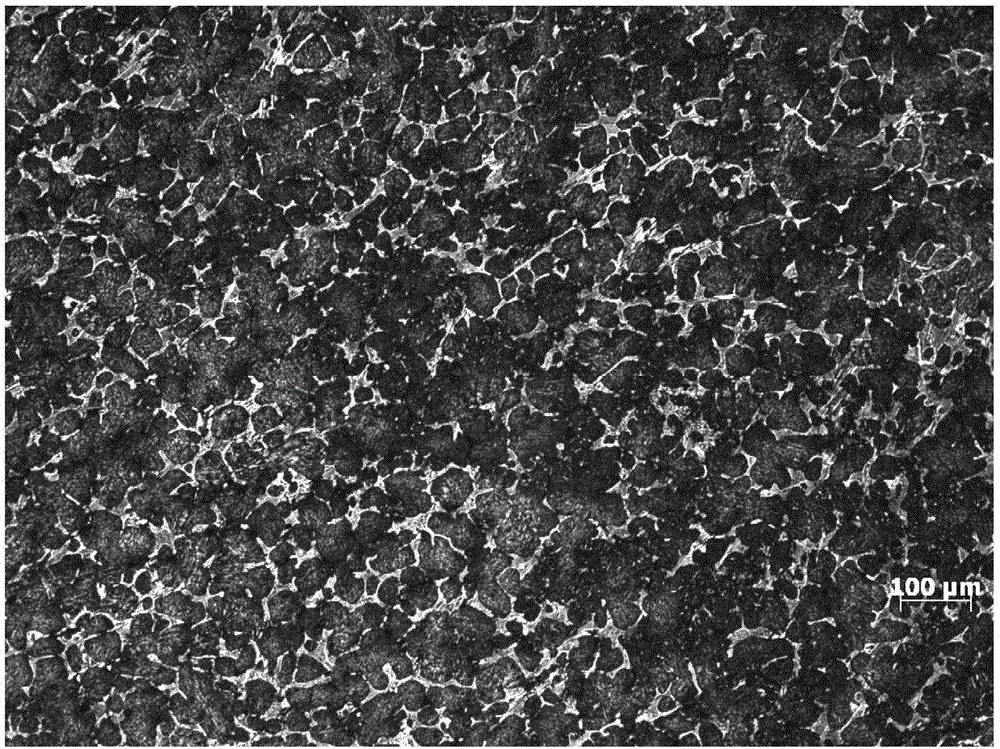

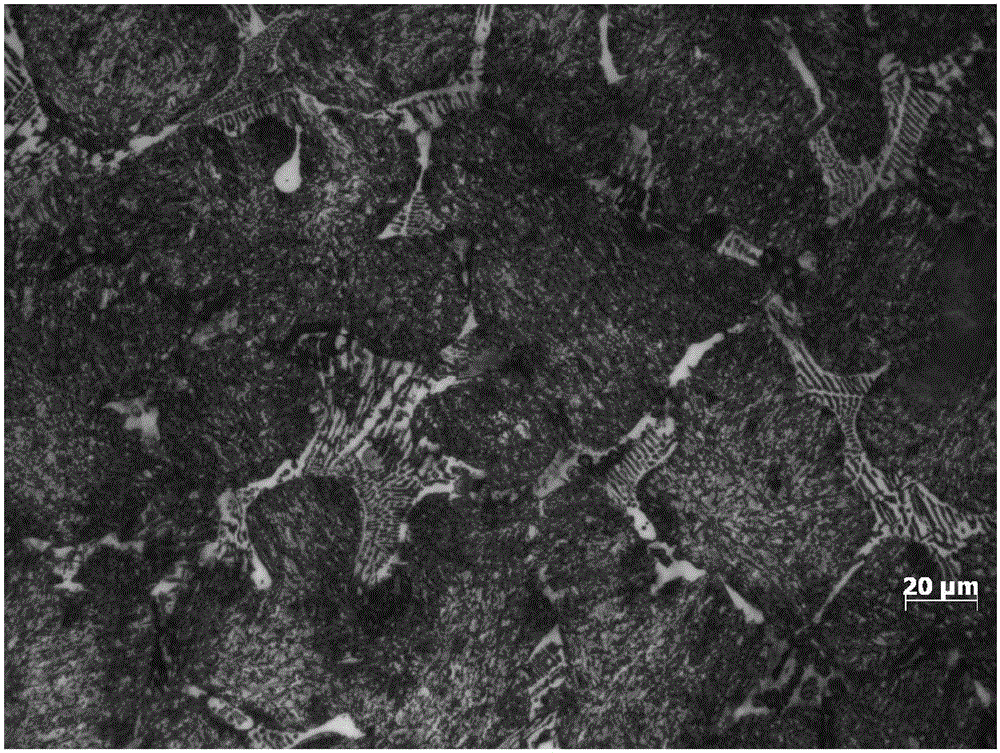

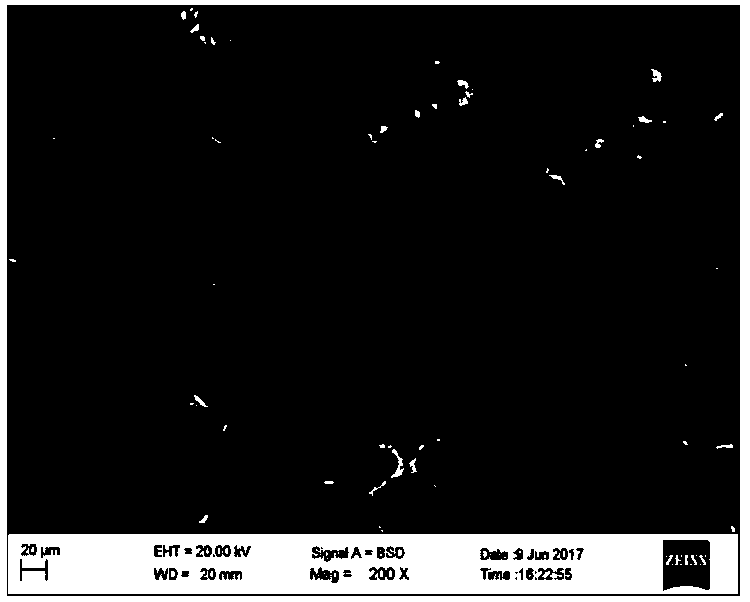

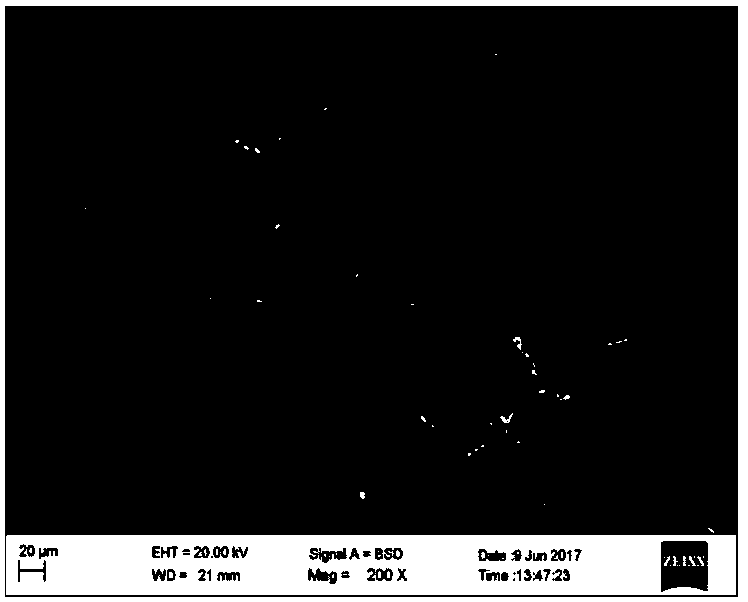

High-boron, iron-based and abrasion-resistant alloy material and production method thereof

InactiveCN105039859AReduce production process costsLow cost of metamorphic treatment technologyHeat treatingBoron

The invention relates to the field of abrasion resistant materials, in particular to a high-boron, iron-based and abrasion-resistant alloy material and a production method thereof. The high-boron, iron-based and abrasion-resistant alloy material is composed of, by mass, 0.4-0.5% of C, 2.0-2.5% of B, lower than or equal to 1.5% of Si, 0.8-1.5% of Mn, 0.6-0.8% of Cr, 0.1-0.3% of Mo, 0.5-1.0% of Ti, lower than or equal to 0.04% of S, lower than or equal to 0.04% of P and the balance Fe. By means of the production method, an electromagnetic stirrer is omitted, and the cost of the production process is low; the cost of the modification treatment technology is low, and the modification treatment method is simple. The defects that Fe2B in an existing high-boron and abrasion-resistant alloy material is of a net form, and the number of particles of the net form needs to be decreased by prolonging the reservation time of high temperature or adopting electromagnetic mixing in heat treatment are overcome. The roughness and performance reliability of the high-boron, iron-based and abrasion-resistant alloy material are improved, and the overall use performance is further improved.

Owner:曾松盛

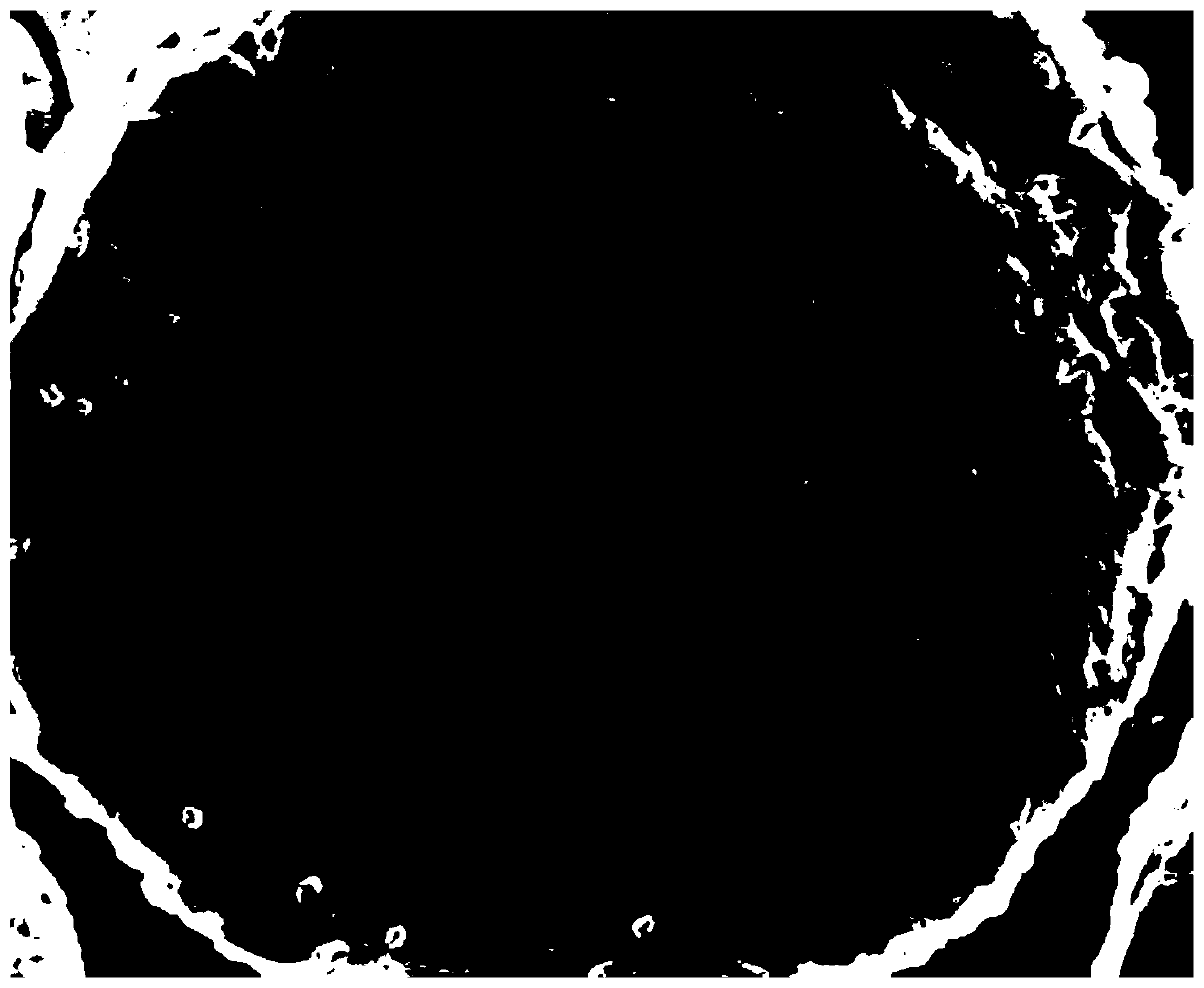

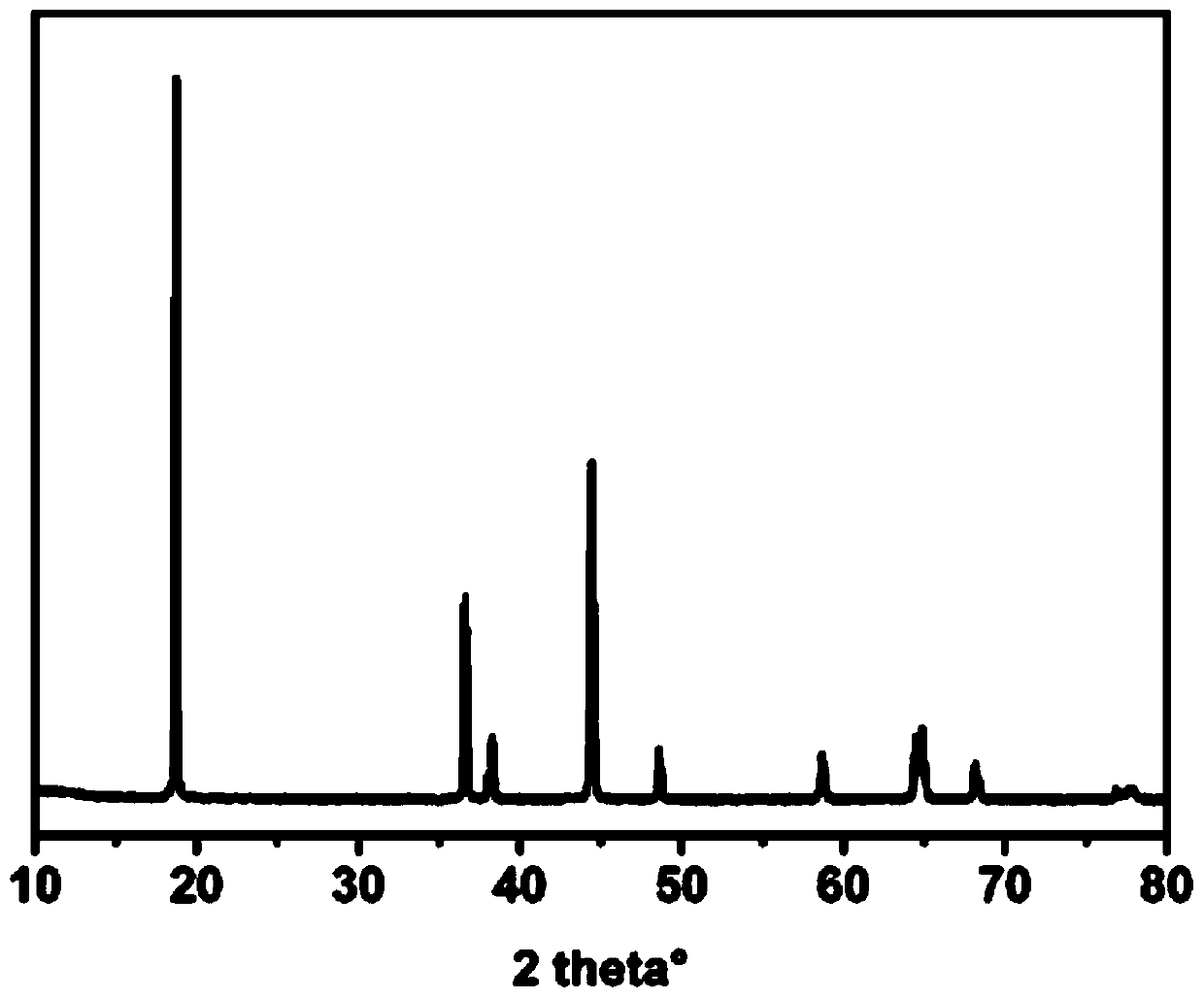

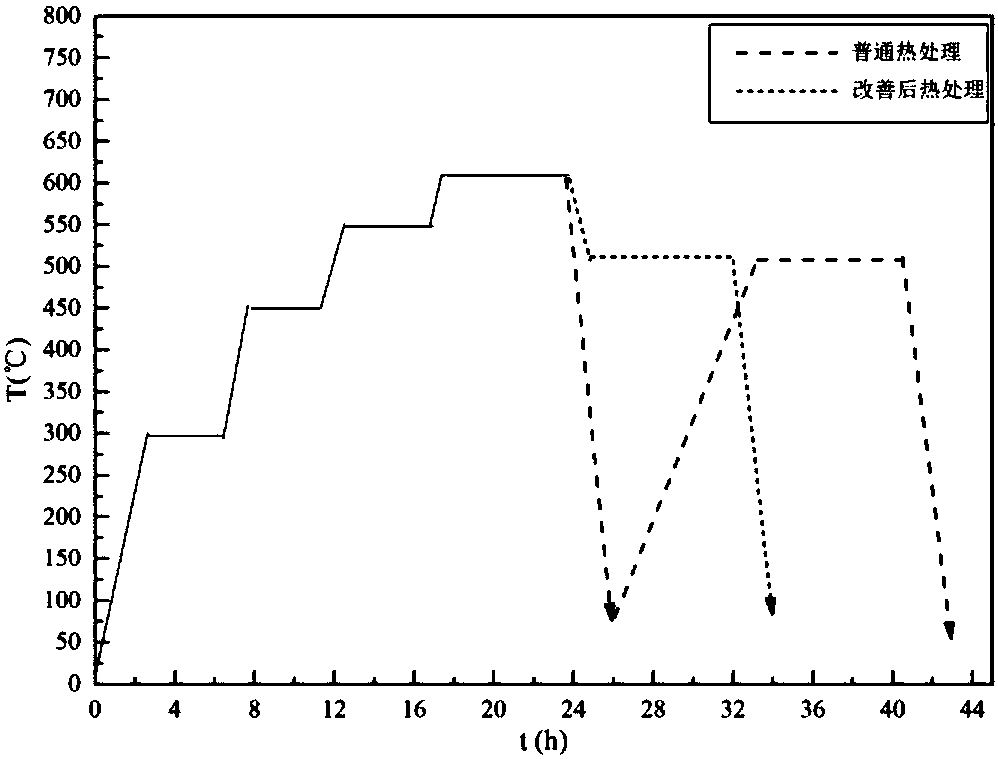

High-nickel positive electrode material with primary particles being directionally arranged, and preparation method for high-nickel positive electrode material

ActiveCN109713297AGood dispersionFacilitated releaseCell electrodesSecondary cellsLithiumThermal insulation

The preparation method comprises the following steps: (1) adding a high-nickel positive electrode material precursor, a lithium source and a dopant capable of reducing the surface energy of a crystalsurface 003 of a layered structure of the high-nickel positive electrode material into a mixing kettle, and performing stirring and uniform mixing to obtain a mixture; (2) putting the mixture obtainedat the step (1) into a muffle furnace for sintering, performing thermal insulation, cooling and screening to obtain the high-nickel positive electrode material with primary particles being directionally arranged, wherein the molecular formula of the high-nickel positive electrode material with primary particles being directionally arranged is LiNixMyO2, x is greater than or equal to 0.5 and lessthan 1, y is greater than or equal to 0 and less than 0.5, x + y is equal to 1, and M is one or more than one metal element. According to the invention, the growth orientation and shape of primary particle crystals are controlled by selecting a dopant capable of reducing the surface energy of a specific crystal face of the crystal, so that the high-nickel positive electrode material secondary particles with long circulation and high safety are obtained, wherein the primary particles in the high-nickel positive electrode material secondary particles are arranged in a radial manner and grow directionally.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

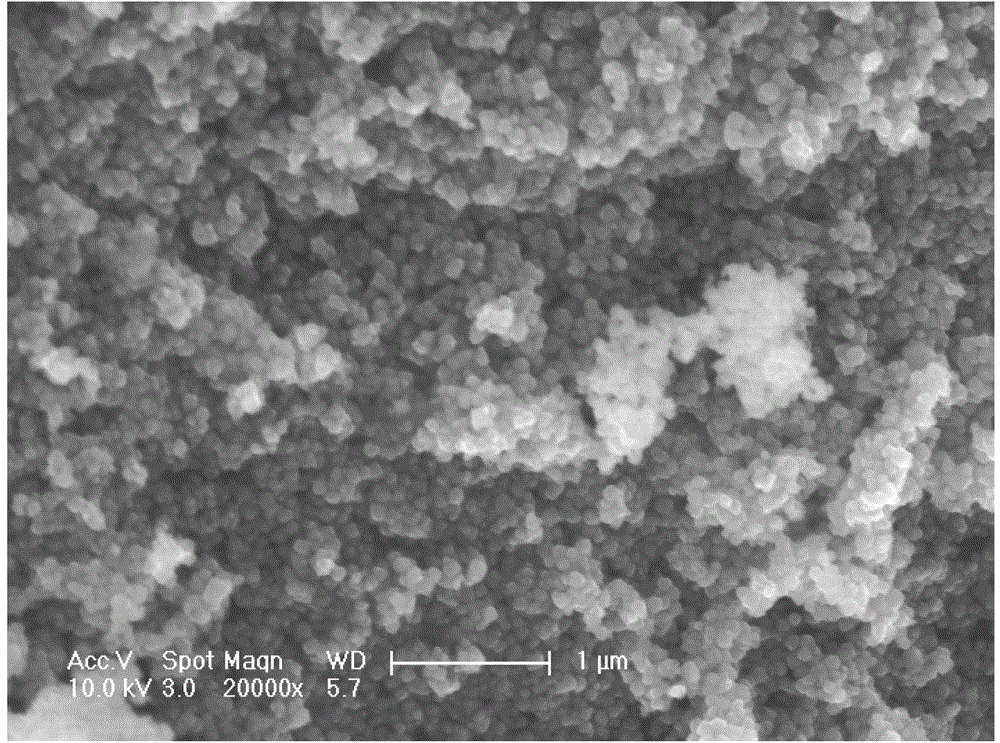

Carbon-coated lithium ion battery positive electrode material lithium iron phosphate and preparation method thereof

InactiveCN103441268ALow costLow process temperatureCell electrodesPhosphorus compoundsElectrical batteryLithium-ion battery

The invention relates to a preparation method for a carbon-coated lithium ion battery positive electrode material. The preparation method comprises the following steps: successively adding a carbon source dispersion liquid, a phosphorus source dispersion liquid, a lithium source dispersion liquid and a ferric iron source dispersion liquid into a solution of a dispersant or deionized water; fully mixing an obtained mixed liquid so as to obtain a uniformly dispersed solution or turbid liquid; drying the mixed liquid to obtain a precursor and then pre-decomposing and sintering the precursor so as to obtain the single-phase carbon-coated lithium ion battery positive electrode material lithium iron phosphate. According to the method, usage of the ferric iron source enables cost for raw materials to be substantially reduced; process temperature of the synthesized material is low, high-temperature processing time is short, a preparation period for the material is substantially shortened, and production cost is effectively reduced; there is no requirement for raw materials, so the source of the raw materials is broadened. The synthesized lithium iron phosphate has the advantages of a particle size of 60 to 550 nm, good particle dispersion, high conductivity, great specific capacity, a long cycle life, etc. and can meet needs of practical application of a lithium ion battery.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

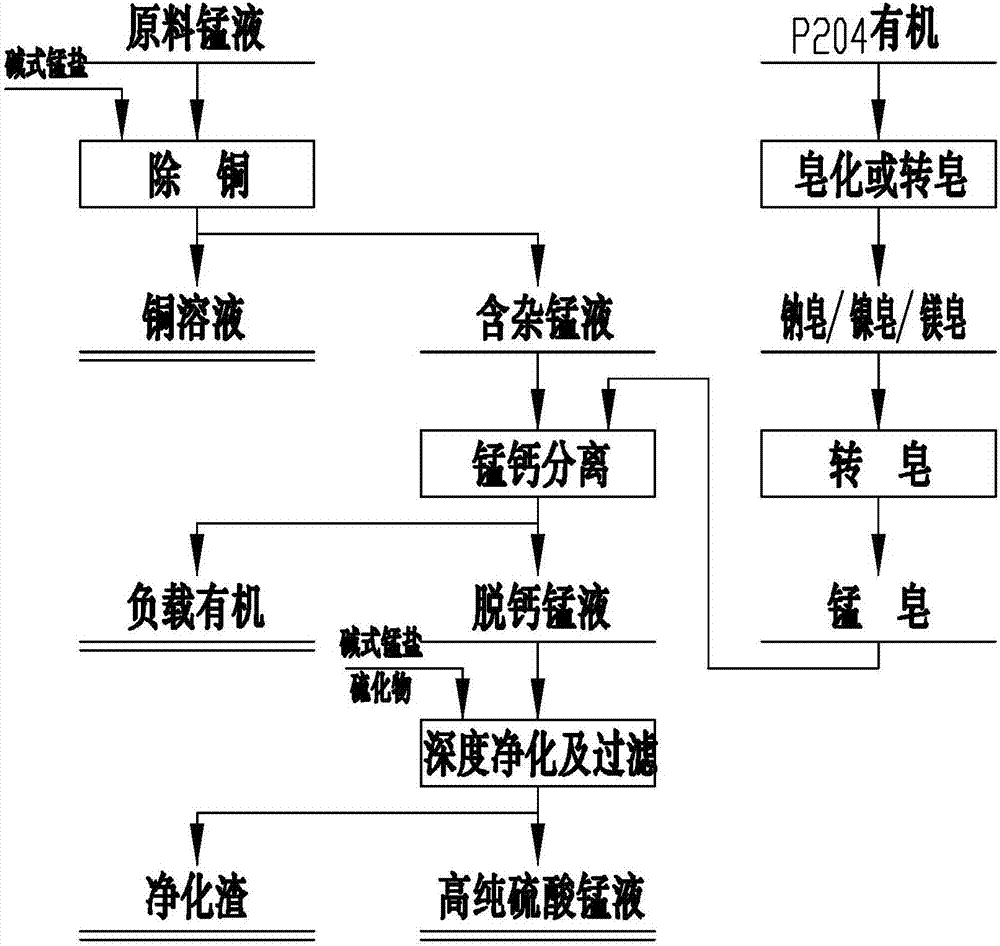

Method for preparing high-purity manganese sulfate solution with low cost

ActiveCN107416908AAchieve removalSimple preparation processManganese compounds preparationManganese sulfatesSulfateManganese

The invention discloses a method for preparing a high-purity manganese sulfate solution with low cost. The method comprises the following steps: (1) copper removal: obtaining copper-removed raw liquid manganese of which Cu is less than or equal to 0.2g / L; (2) pH value adjustment: adjusting the pH value of the copper-removed raw liquid manganese to be 1.5 to 5.0; (3) saponification: saponifying an extraction agent by using NaOH, Na2CO3, KOH, K2CO3 or ammonium hydroxide, so as to obtain sodium salt, potassium salt or ammonium salt containing the extraction agent; (4) manganese transforming saponification; (5) Mn and Ca extraction separation: making Ca in the raw liquid manganese enter an organic phase to be separated from Mn, and making all or most of Cu, Al, Zn and Cd enter the organic phase, so as to obtain extraction raffinate namely decalcified liquid manganese of which Ca is less than or equal to 5ppm; (6) deep purification: adding Na2S, NaHS, K2S, KHS or (NH4)2S into the decalcified liquid manganese, adjusting the pH value to be 4.0 to 6.0, and performing solid-liquid separation, so as to obtain a high-purity MnSO4 solution satisfying production of a positive precursor of a lithium ion battery.

Owner:广东芳源新材料集团股份有限公司 +1

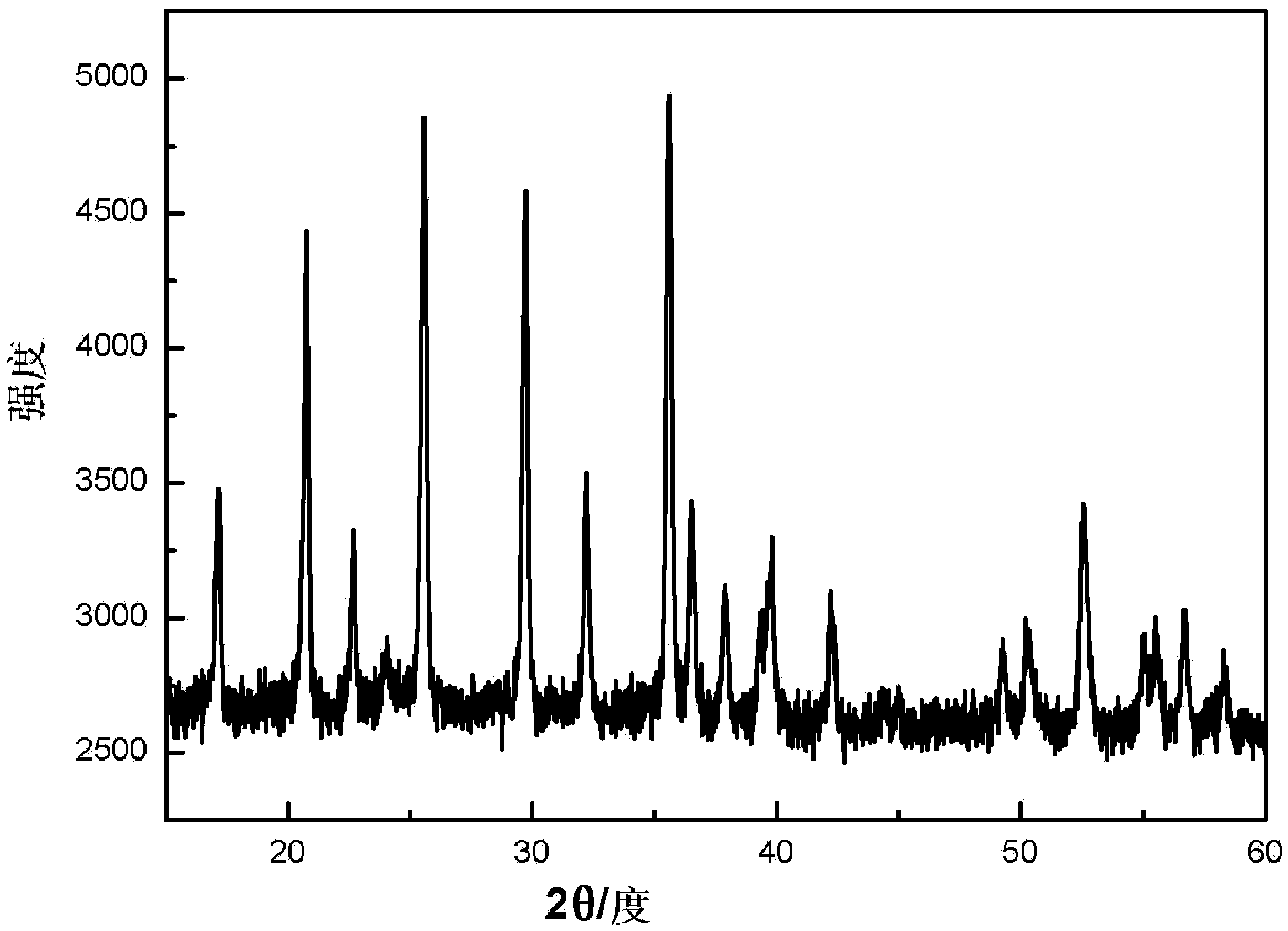

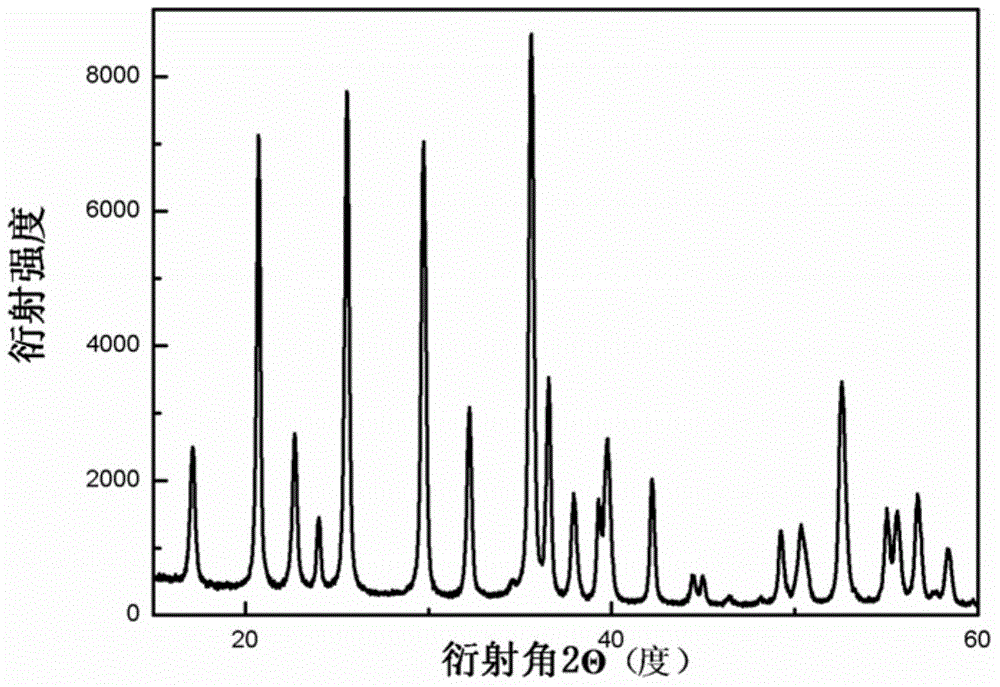

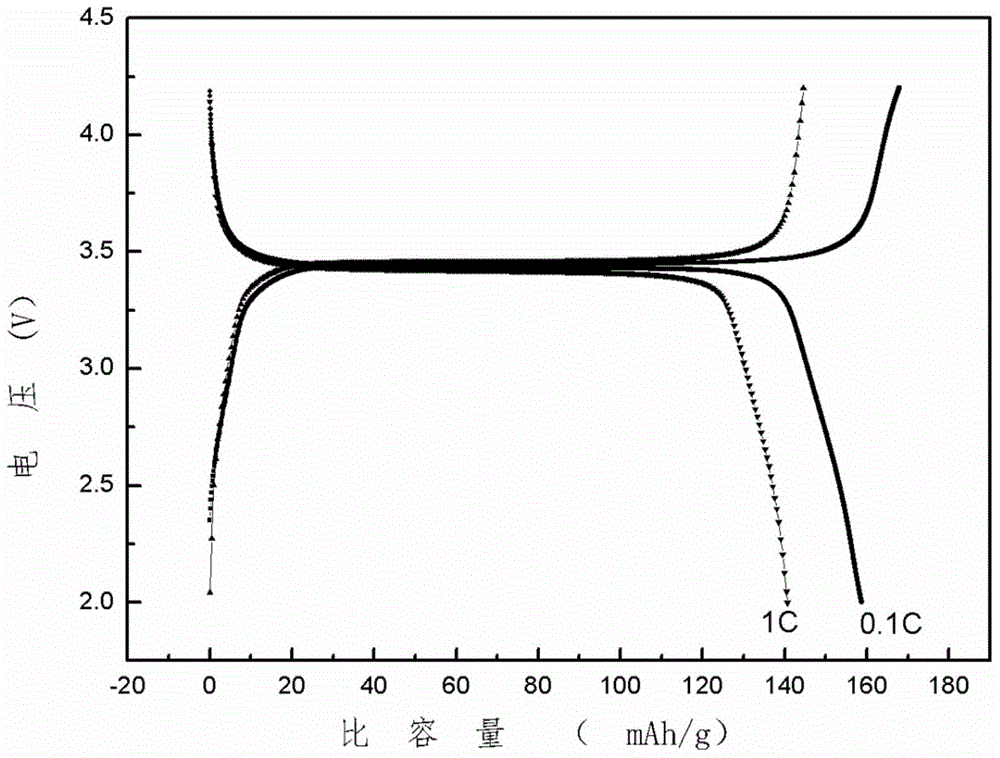

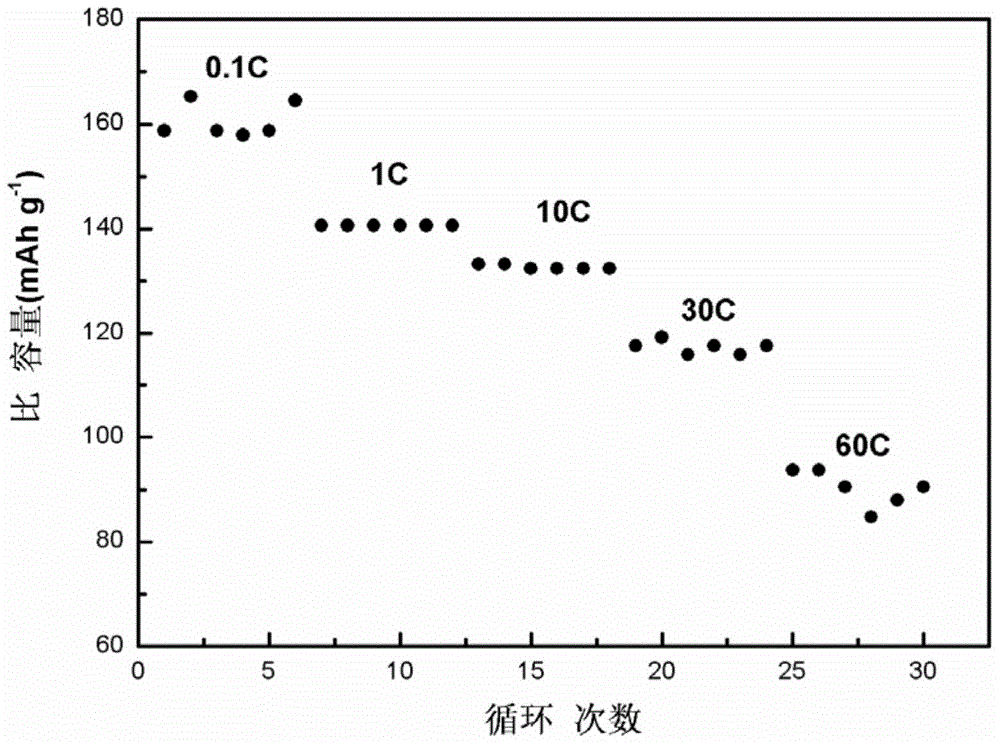

High rate LiFePO4/C positive electrode material and preparation method thereof

InactiveCN104638261AWide variety of sourcesLow process temperatureCell electrodesHigh rateLithium iron phosphate

The invention provides a high rate LiFePO4 / C positive electrode material and a preparation method thereof. The method comprises the following steps: uniformly mixing an aqueous solution of a phosphorus source, an aqueous solution of a lithium source and an aqueous solution of a divalent iron source with a dispersant and / or a surfactant; carrying out a hydrothermal reaction on the above obtained uniformly mixed solution at 120-250DEG C; separating out a precipitate from a material obtained after the hydrothermal reaction, washing the precipitate, and carrying out first stage drying on the precipitate; and uniformly mixing the obtained first stage dried solid with a carbon source, carrying out second stage drying, sintering the obtained solid, and cooling the sintered solid. The particle size of lithium iron phosphate (LiFePO4) synthesized through the method along b direction (the lithium ion diffusion direction) is 20-200nm, and the LiFePO4 / C positive electrode material has the advantages of small particle size and uniform distribution of particles, high phase purity, improvement of the diffusion performance and the electrochemical performances of lithium ions in the lithium iron phosphate material, high conductivity, large specific capacity and good cycle life.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Manufacturing method of non-woven dedusting filter material

The invention discloses a manufacturing method of a non-woven dedusting filter material, which has the advantages of enabling the filter material to be higher in intensity and lower in running resistance. The method comprises the following steps: A, polyester staple fiber is enabled to form opened cotton through the procedures of pre-opening, fine-opening, and cotton tank scutching; B, vaporific spraying humidification finishing is performed, by using a vaporific spraying humidification device, on the opened cotton made in the step A, then a carding machine is used for carding, the opened cotton is enabled to move parallelly and evenly and falls onto the surface of a lapping machine for lapping and pre-stabbing so as to form a fluffy and even nonwoven wadding making layer; C, after mixing bright polyester fiber and polyester staple fiber according to the weight ratio of 3 to 1, a mixed fibrous layer is formed through procedures of pre-opening, fine opening, cotton box scutching, carding, lapping and pre-stabbing in sequence.

Owner:JIANGSU FILTERTEX FILTER MATERIAL

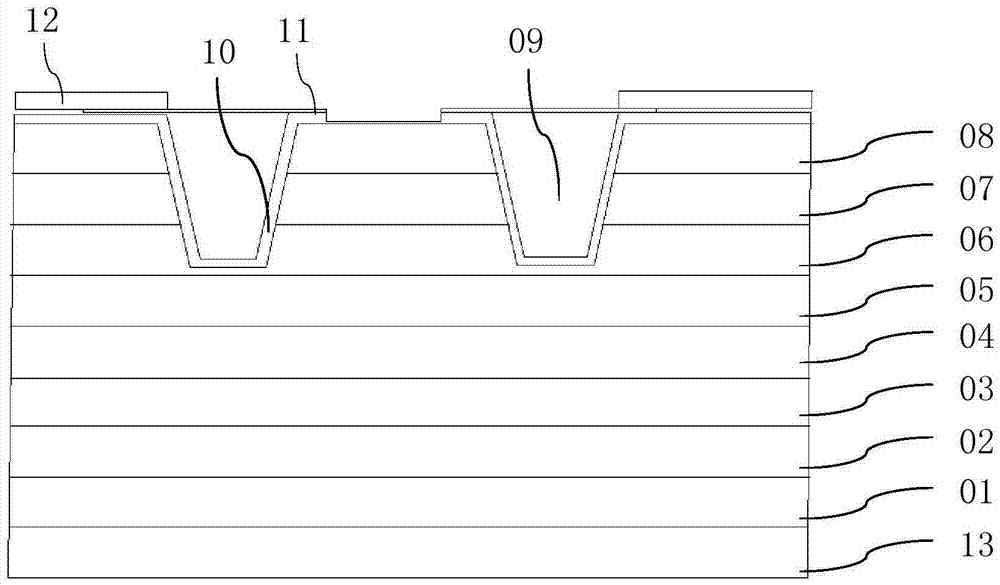

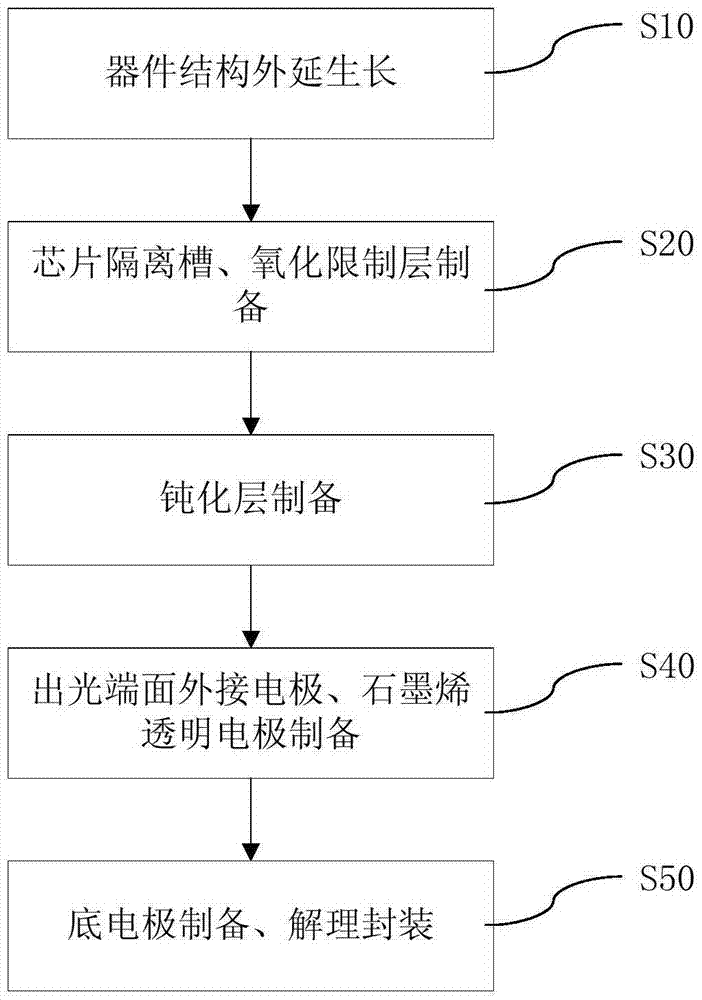

Surface emitting laser and preparation method thereof

InactiveCN106936069AImprove thermal conductivityImprove conductivityLaser detailsSemiconductor lasersOptoelectronicsContact layer

The invention discloses a surface emitting laser which sequentially comprises a bottom electrode, a substrate, a lower Bragg reflecting mirror, an active region, an oxidation confinement layer, an upper Bragg reflecting mirror, a contact layer and an external electrode from the bottom up. The surface emitting laser is characterized by further comprising isolation grooves, a passivation layer covering the surface of each isolation groove and a contact electrode connected between the contact layer and the external electrode, wherein the isolation groove extends downward from the surface of the contact layer, runs through the upper Bragg reflecting mirror and reaches the oxidation confinement layer, and the contact electrode is a graphene transparent electrode. According to the invention, a graphene material is adopted is prepare the graphene transparent electrode at a light emitting end face, the graphene transparent electrode forms a top electrode together with the external electrode at the light emitting end face so as to replace an existing annular metal electrode, injection of current is realized, and the working stability of the device can be improved. In addition, the graphene transparent electrode has the advantages of high thermal conductivity and electrical conductivity, high mechanical strength, extremely high transmittance and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

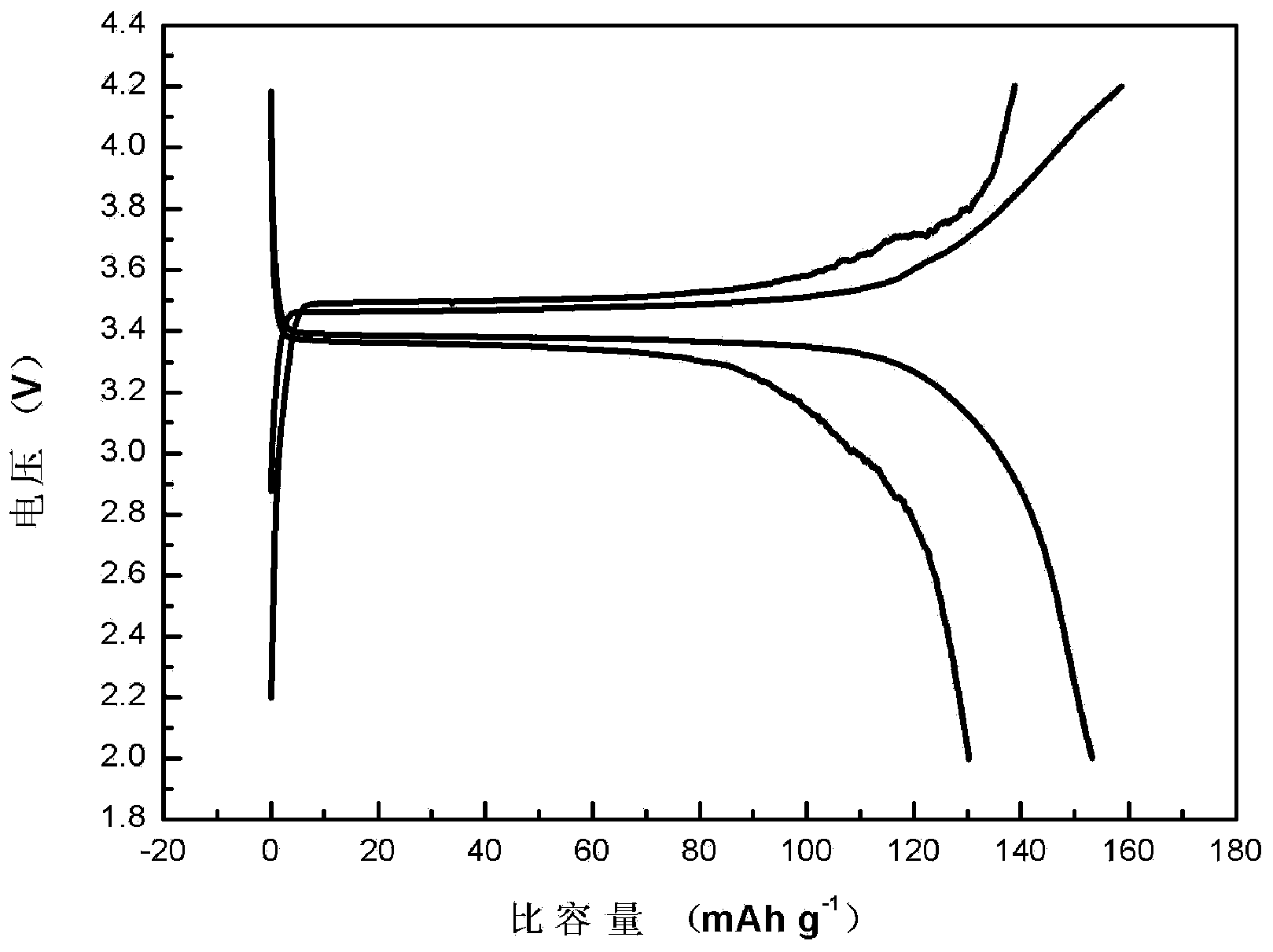

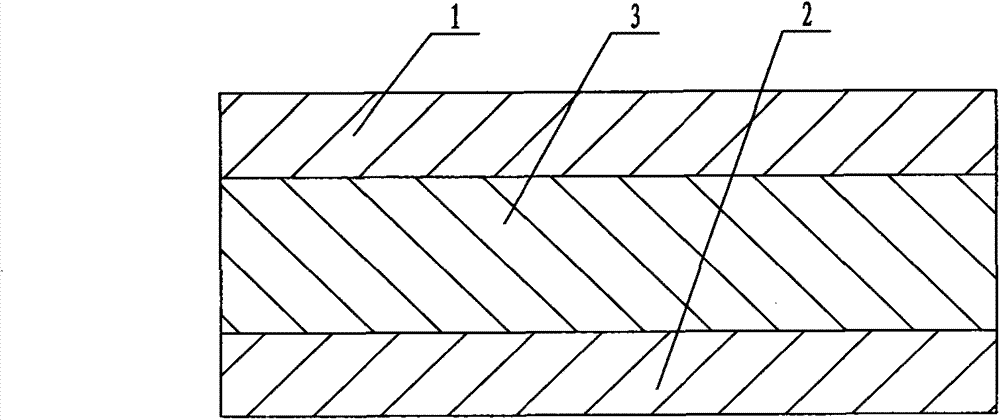

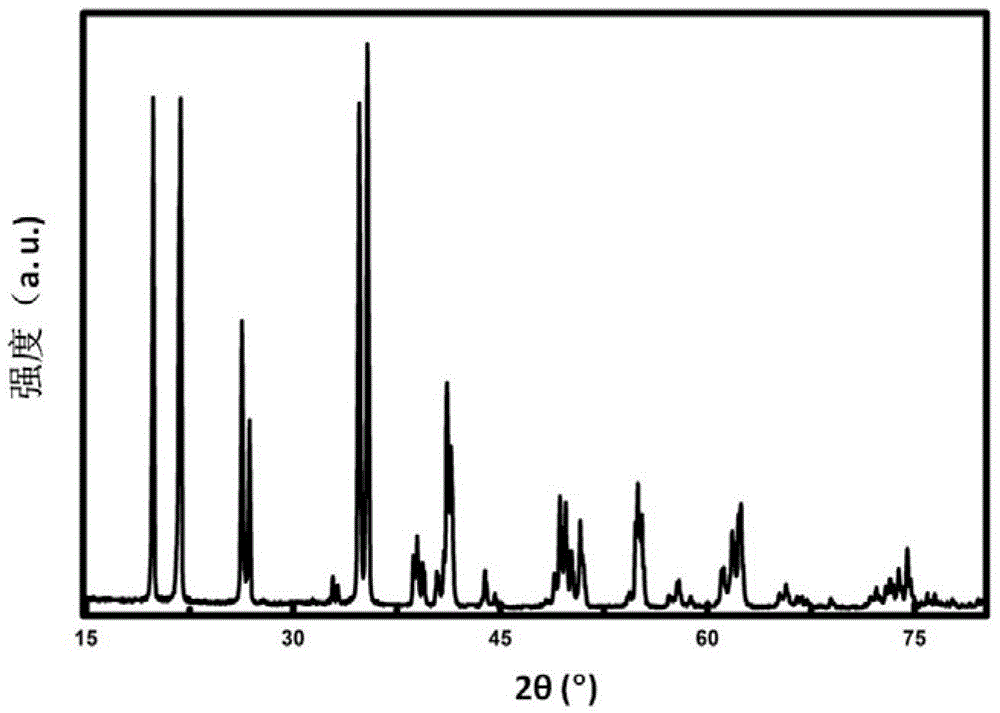

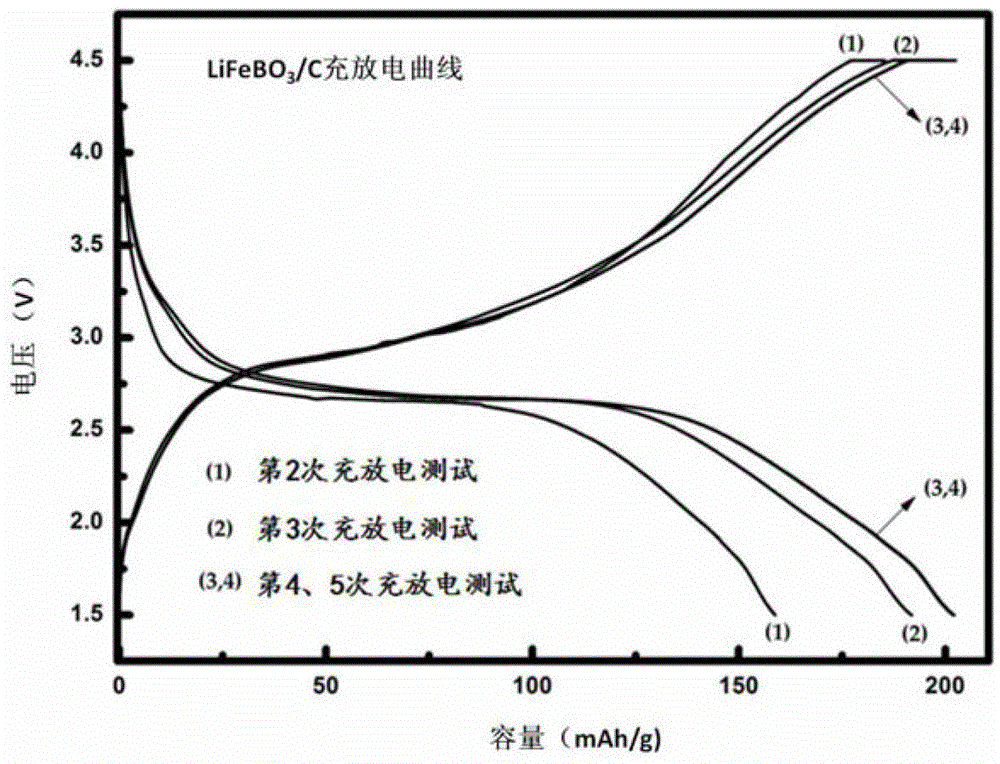

Lithium ferric borate block type electrode and preparation method thereof

ActiveCN104425799AIncrease contentIncrease energy densityPositive electrodesSodium-ion batteryElectrochemistry

The invention provides a lithium ferric borate block type electrode and a preparation method thereof. The preparation method of the lithium ion battery cathode comprises the following steps: (1), sequentially adding a lithium source water solution or suspension, a ferric iron source water solution or suspension and a boron source water solution or suspension in a carbon source water solution to obtain a mixed solution; (2) drying the mixed solution obtained in the step (1) to obtain a lithium ferric borate precursor; (3) mixing the lithium ferric borate precursor obtained in the step (2) with an organic matter to obtain a LiFeBO3 / C precursor; (4) forming the LiFeBO3 / C precursor obtained in the step (3) into a blocky shape to obtain a LiFeBO3 / C blocky type electrode precursor; and (5) calcining the LiFeBO3 / C block type electrode precursor obtained in the step (4) under the protection of an inert atmosphere. The lithium ion battery assembled by adopting the lithium ion battery cathode prepared according to the preparation method provided by the invention has excellent electrochemical performance.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing aluminum alloy component through powder metallurgy method

ActiveCN107829003ALow priceLow costTransportation and packagingMetal-working apparatusAl powderBinary alloy

The invention relates to a method for preparing an aluminum alloy component through a powder metallurgy method, and belongs to the technical field of preparing aluminum alloy components through the powder metallurgy method. According to the preparation method, after pure Al powder and three kinds of alloy element powder or binary alloy powder of Mg, Si and Cu are mixed uniformly according to a certain proportion, the aluminum alloy component is obtained through the processes of press forming, sintering, heat treatment, subsequent surface treatment and the like. According to the method, the pure aluminum powder is use as the main raw material, and an aluminum alloy system suitable for a pressing-sintering process is developed; and the sintering-heat treatment integrated production process is studied, the production process is simplified, the production efficiency is improved, and the production cost is reduced. The density of an aluminum alloy material prepared through the method is higher than 98%, the tensile strength of the aluminum alloy material is larger than 300 MPa, and the ductility of the aluminum alloy material is about 5%.

Owner:UNIV OF SCI & TECH BEIJING

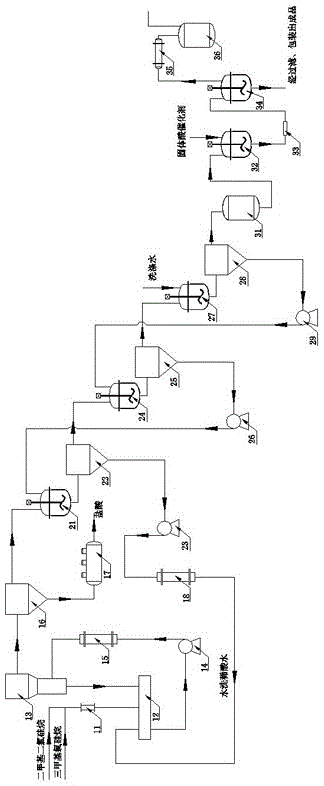

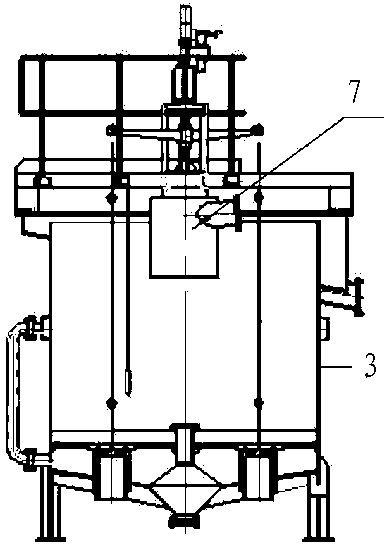

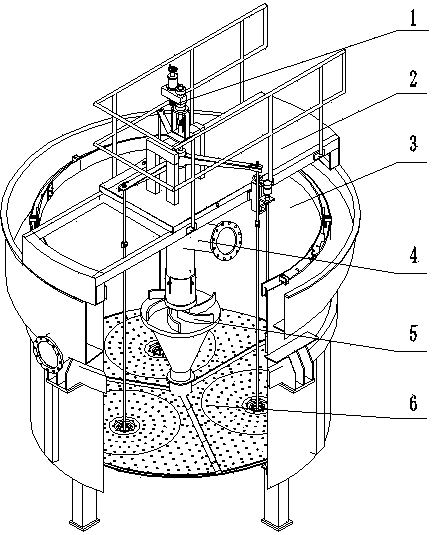

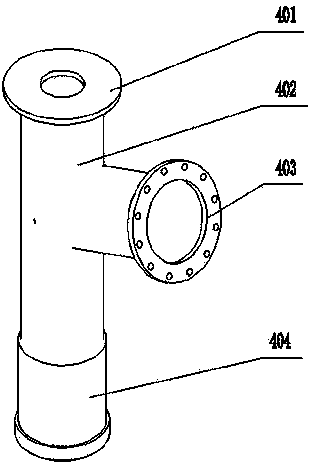

Continuous preparing technology for low-viscosity simethicone

The invention relates to a production technology for simethicone, in particular to a continuous preparing technology for low-viscosity simethicone. The continuous preparing technology comprises the following steps that hydrolysis is carried out, wherein trimethylchlorosilane and dimethyldichlorosilane are preliminarily mixed according to a mass ratio and then enter a tubular hydrolysis reactor to carry out a reaction; washing is carried out, wherein hydrolysate is washed to be neutral through three levels of washing step by step; telomerization is carried out, wherein under the condition that a catalyst is added, an equilibration reaction is carried out on siloxane; hydroxyl is removed, wherein a hydroxyl scavenging agent is added in the filtered simethicone to remove silicon hydroxyl remaining in silicon oil; low molecules are desorbed, wherein the low molecules are desorbed through an inert gas bubbling device, and the silicon oil with the low molecules desorbed is filtered and stored. The production technology has the advantages that the problems that washing acid water is large in discharging amount and contains much organic manner, and waste water is difficult to treat are solved, the product yield and the quality of the simethicone are improved, the low molecule desorbing time is shortened, cost is lower, and efficiency is higher.

Owner:TANGSHAN SANYOU SILICON IND

Coarse coal slime sorting machine

The invention belongs to the field of coal mine mechanical equipment and particularly relates to a coarse coal slime sorting machine, which comprises an electric actuating mechanism. The electric actuating mechanism is sequentially connected with an adjustable feeding device and a cyclone interference device of a pipe structure. The cyclone interference device is arranged in a water tank and comprises a plurality of arc-shaped plates. A movable casing can be in close contact with the arc-shaped pates on the cyclone interference device during field installation to guarantee materials to fully flow along the direction of the arc-shaped plates. The cyclone interference device in the coarse coal slime sorting machine enables the materials to forcibly form rotational flow under the effect of the arc-shaped plates on the cyclone interference device to enable the materials to be evenly scattered, so that the sorting effect can be improved by approximate 10 percent. The coarse coal slime sorting machine can still reach a better scattering effect under the situation that the materials flow naturally, the feeding pressure is not required to be increased and the construction cost and the production process cost are reduced.

Owner:苏州玛瑞麦精密机械有限公司

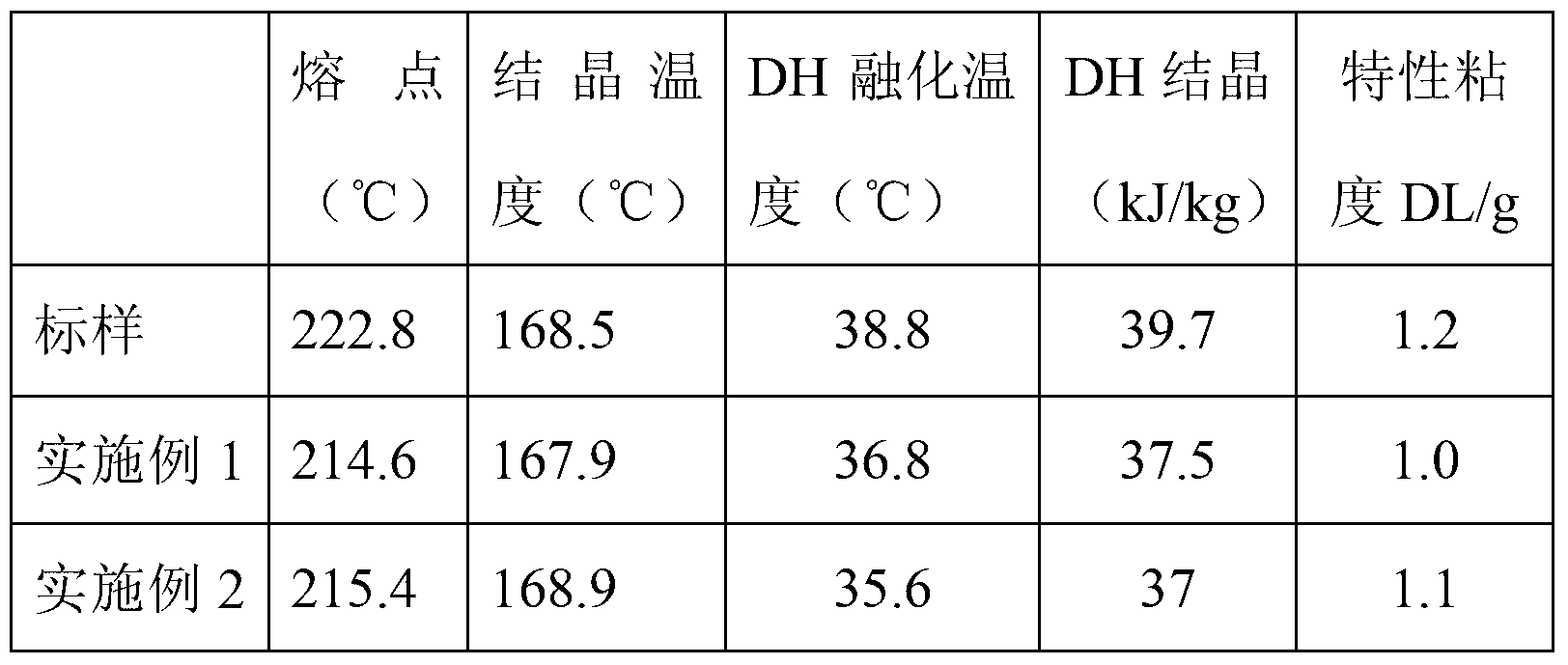

Preparation method of polybutylene terephthalate polyester resin

InactiveCN103304788AReduce productionImprove protectionPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a preparation method of polybutylene terephthalate polyester resin. The preparation method comprises the following steps of: (1) mixing PET (Polyethylene Terephthalate) raw materials, 1,4-butanediol and a catalyst to obtain a molten mixture, then continuously adding the molten mixture into an ester exchange reactor, and meanwhile, continuously adding the 1,4-butanediol to carry out ester exchange reaction to obtain a butylene terephthalate ester matter; and (2) simultaneously and continuously adding the butylene terephthalate ester matter and a stabilizer into a reaction kettle to carry out polymerization reaction to obtain the polybutylene terephthalate polyester resin when the viscosity of a product is larger than or equal to 0.50dL / g. According to the technical scheme disclosed by the invention, a great number of PET wastes with various shapes and performances can be used as raw materials for producing, so that the recycling of the waste PET is realized; and compared with a synthesis process in which purified terrephthalic acid is used, the preparation method can be used for greatly reducing the output of esterified wastewater in the synthesis process and is beneficial to the protection of the environment and the reduction of the environment-friendly cost.

Owner:江苏宝田新材料股份有限公司

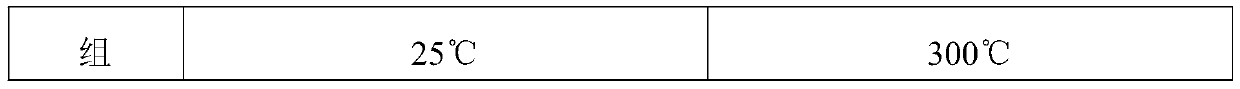

Automobile corrosion-resistant die-casting aluminum alloy and preparation method thereof

The invention discloses an automobile corrosion-resistant die-casting aluminum alloy and a preparation method thereof, and belongs to the field of aluminum alloy die-casting processing. The automobilecorrosion-resistant die-casting aluminum alloy comprises, by weight, 6.5%-7.6% of Si, 1.4%-2.1% of Mg, 0.8%-1.3% of Cu, 0.05%-0.11% of Sr, 0.4%-0.9%of Zn, 0.4%-0.8% of Mn, 0.2%-0.6% of Fe, 0.2%-0.5%of Y, 0.03%-0.05% of Er, less than or equal to 0.5% of other metals and non-metals, and the balance Al. The automobile corrosion-resistant die-casting aluminum alloy is prepared by the steps of melting, refining, standing, die casting, solid solution quenching treatment, aging treatment and the like. The aluminum alloy has the advantages that the corrosion resistance is greatly improved, the tensile property at high temperature is good, the toughness is high, and the extrusion resistance is good; and the preparation method is simple and feasible in process, and has the advantages of being highin safety and low in production process cost, and the produced aluminum alloy casting meets the use requirements of the workpiece needing to bear a large dynamic load.

Owner:广西平果铝合金精密铸件有限公司

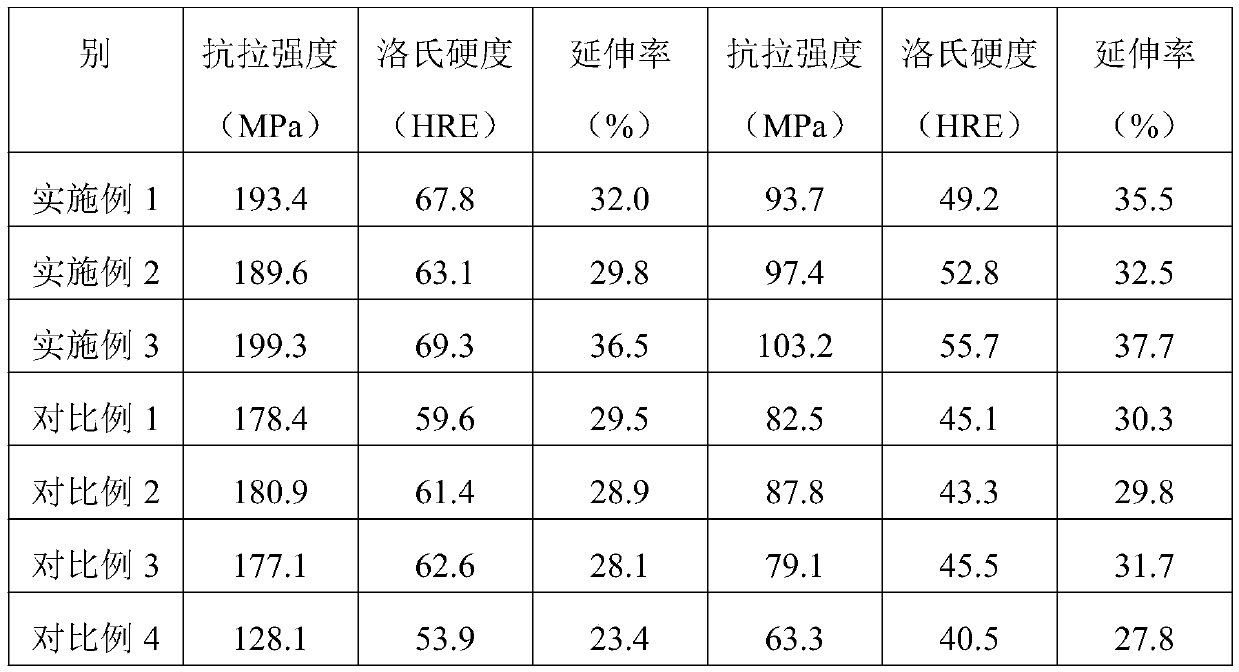

Production method of stearic acid

ActiveCN102942994AReduce production process costsReduce productionFatty acid hydrogenationFatty acids production/refiningDistillationReaction temperature

The invention relates to a production method of stearic acid, comprising the following steps: hydrolysis, hydrogenation, and distillation, wherein the hydrolysis step is characterized by selecting palm oil or other grease as raw oil, according to the weight ratio of the raw oil to water being 95-105:55-65, controlling the reaction temperature of hydrolysis to be 245-260 DEG C, and guaranteeing the pressure of hydrolysis to be 48-55bar. According to the invention, the production method disclosed herein has the advantages of low cost, high utilization rate of raw materials, stable product quality, and low product price, the competitiveness of the product in the market is raised, thus the product can be widely popularized in the market.

Owner:丰益油脂科技(天津)有限公司

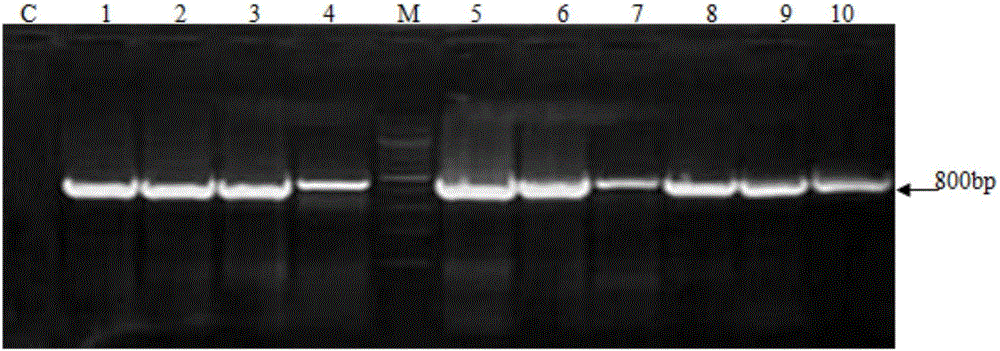

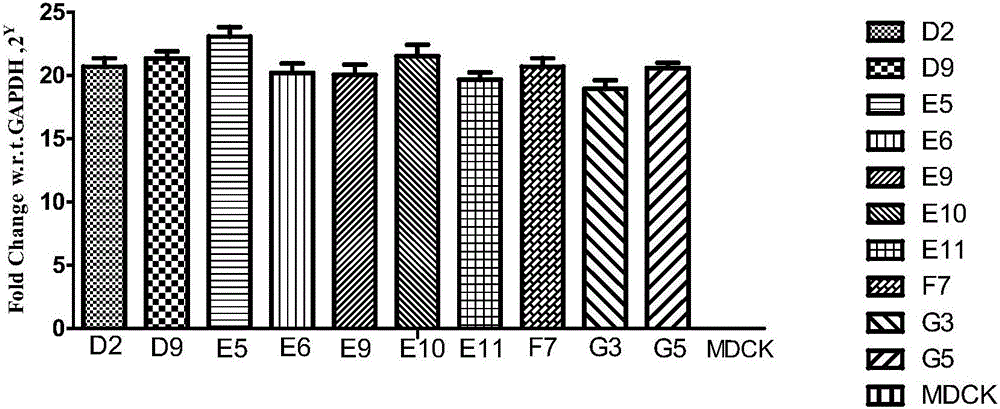

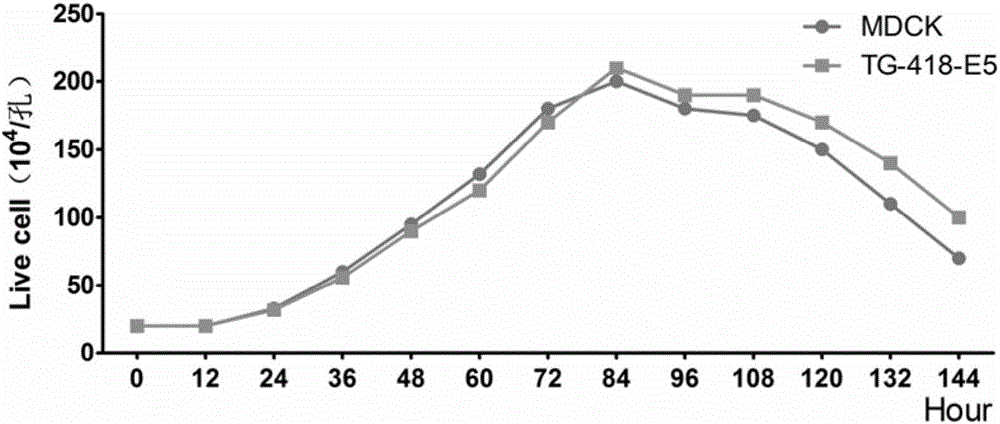

MDCK (Madin-Darby canine kidney) cell line capable of stably expressing human-derived TIGAR (TP53-induced glycolysis and apoptosis regulator) gene

ActiveCN106479983AImprove anti-apoptotic abilityReduce adhesionSsRNA viruses negative-senseCompound screeningCanine kidneyBiology

The invention belongs to the technical field of biology, and particularly relates to an MDCK (Madin-Darby canine kidney) cell line capable of stably expressing a human-derived TIGAR (TP53-induced glycolysis and apoptosis regulator) gene. The cell line is an MDCK cell line TG-418-E5 capable of stably expressing the human-derived TIGAR gene and contains a TIGAR coding gene sequence, and the preservation number of the cell line is CGMCC NO:12983. Through stable expression of the TIGAR gene in MDCK cells, anti-apoptosis capacity of the cells is improved, and the survival time of recombinant cells is prolonged. The method not only lays the foundation for research of application of MDCK serum-free fully-suspended culture in mass production of cell culture vaccines, but also increases breeding titer of avian influenza vaccine strains and saves the cost of a production process. Besides, the cell line TG-418-E5 has better application prospect in aspects of screening of anti-avian influenza virus drugs, screening of vaccine strains and production of the cell culture vaccines.

Owner:ZHONGCHONG XINNUO BIOTECH TAIZHOU CO LTD

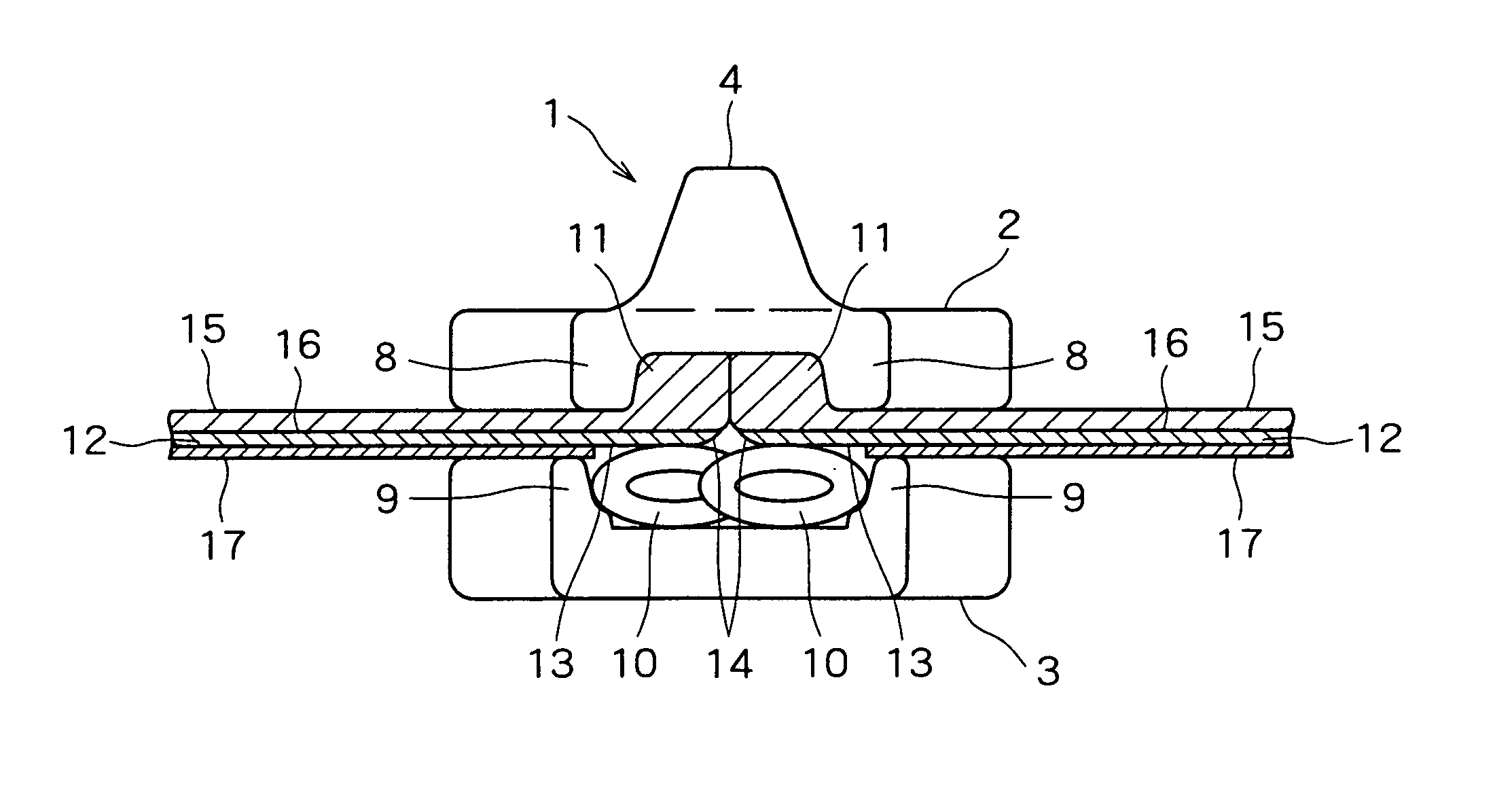

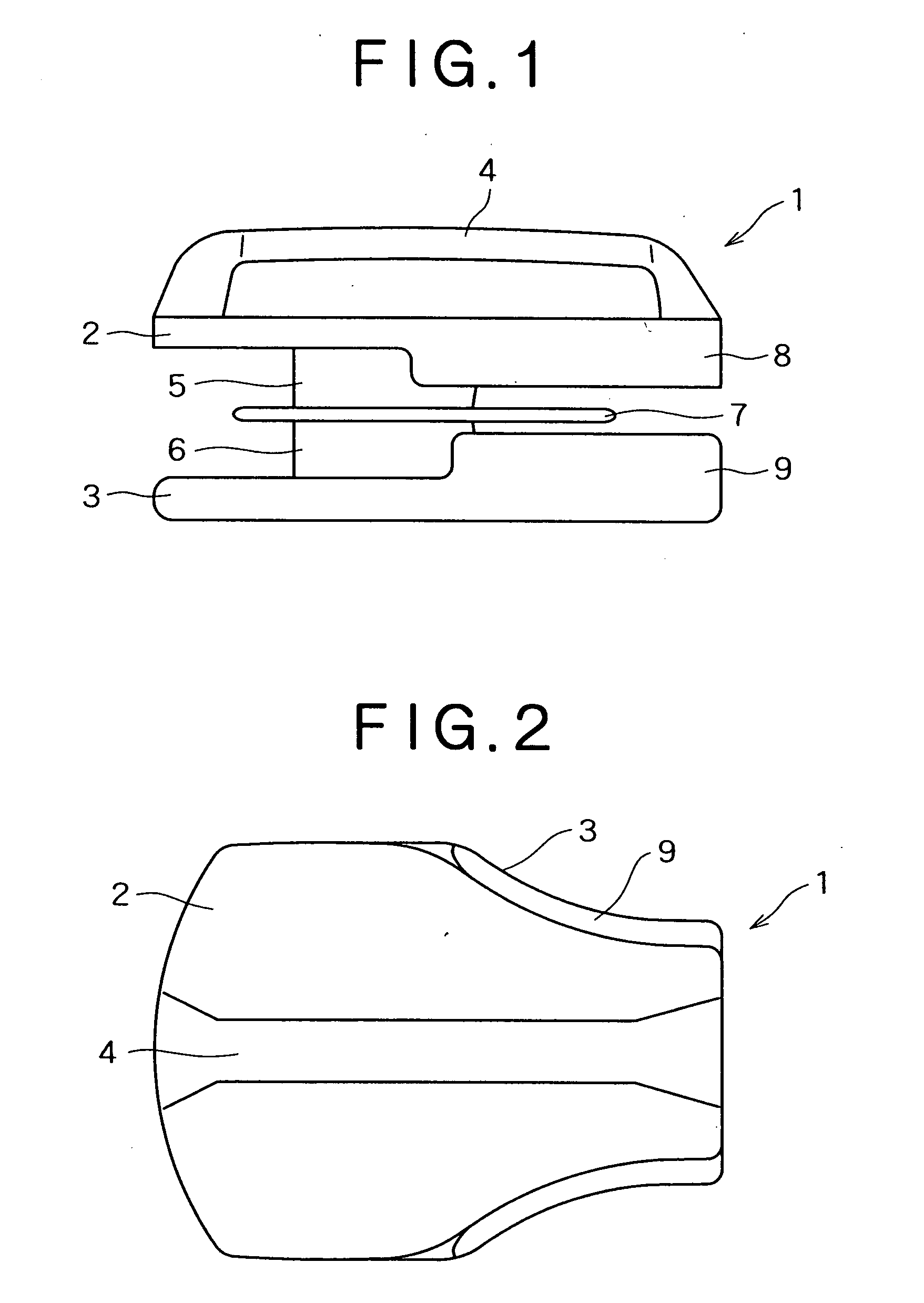

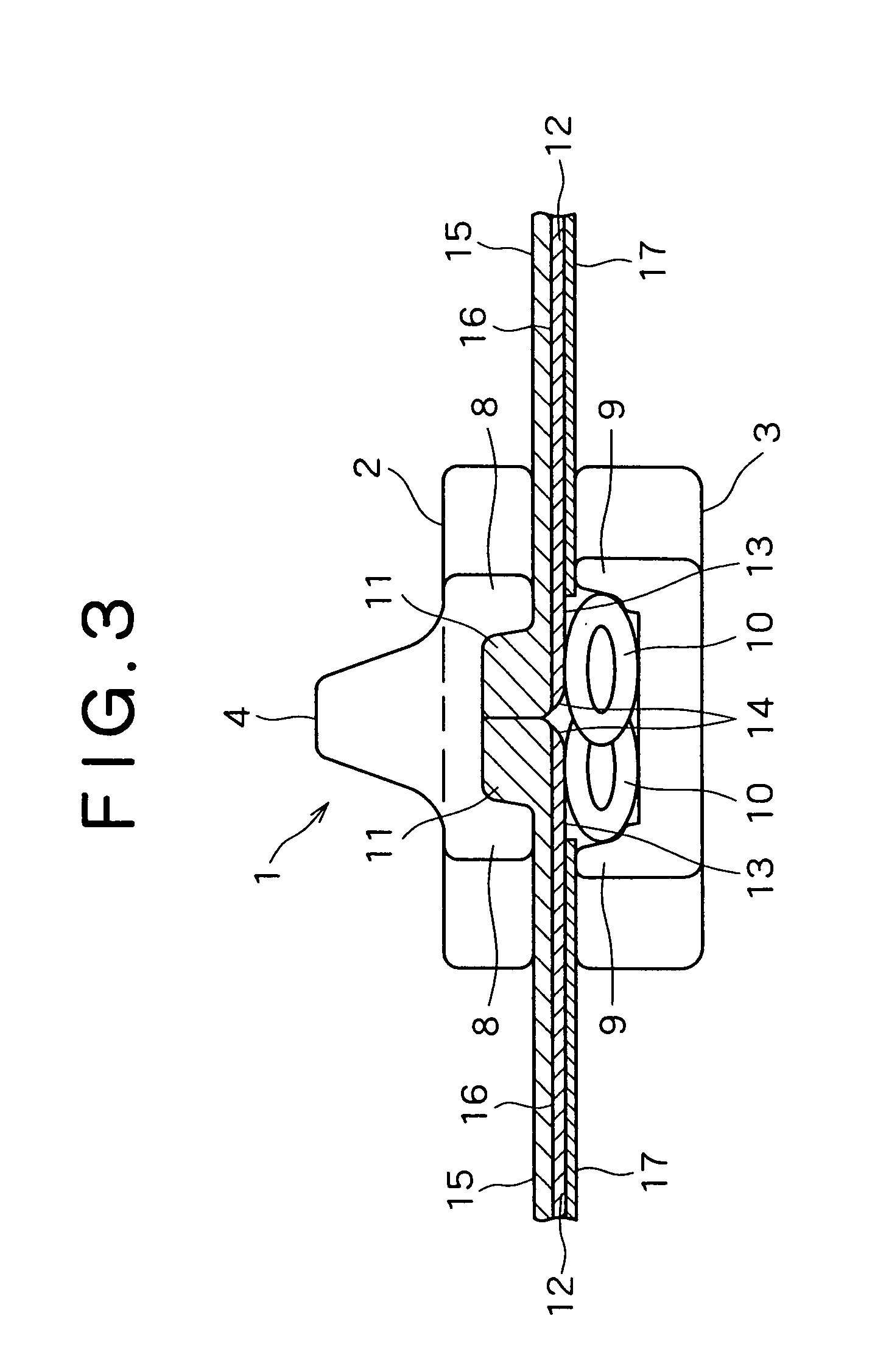

Slider for a fluid tight slide fastener

ActiveUS20080066270A1Reduce production process costsImprove product qualitySnap fastenersSlide fastenersFastenerEngineering

A slider 20 for a fluid tight slide fastener has upper and lower plates 21, 22 joined together by a guide post 23. A guide plate 24 is formed on the guide post 23 to cooperate with the upper and lower plates 21, 22 to guide the coupling elements and sealing lips of the slide fastener into engagement in conjunction with side flanges 27, 28 on the upper and lower plates 21, 22. The slider is integrally formed; such as by die casting or moulding. To facilitate moulding the guide plate 24 may be thickened at its leading end 32 and provided with a tapered edge, and connected to the upper plate 21 by a web 29 at its trailing end.

Owner:YKK CORP

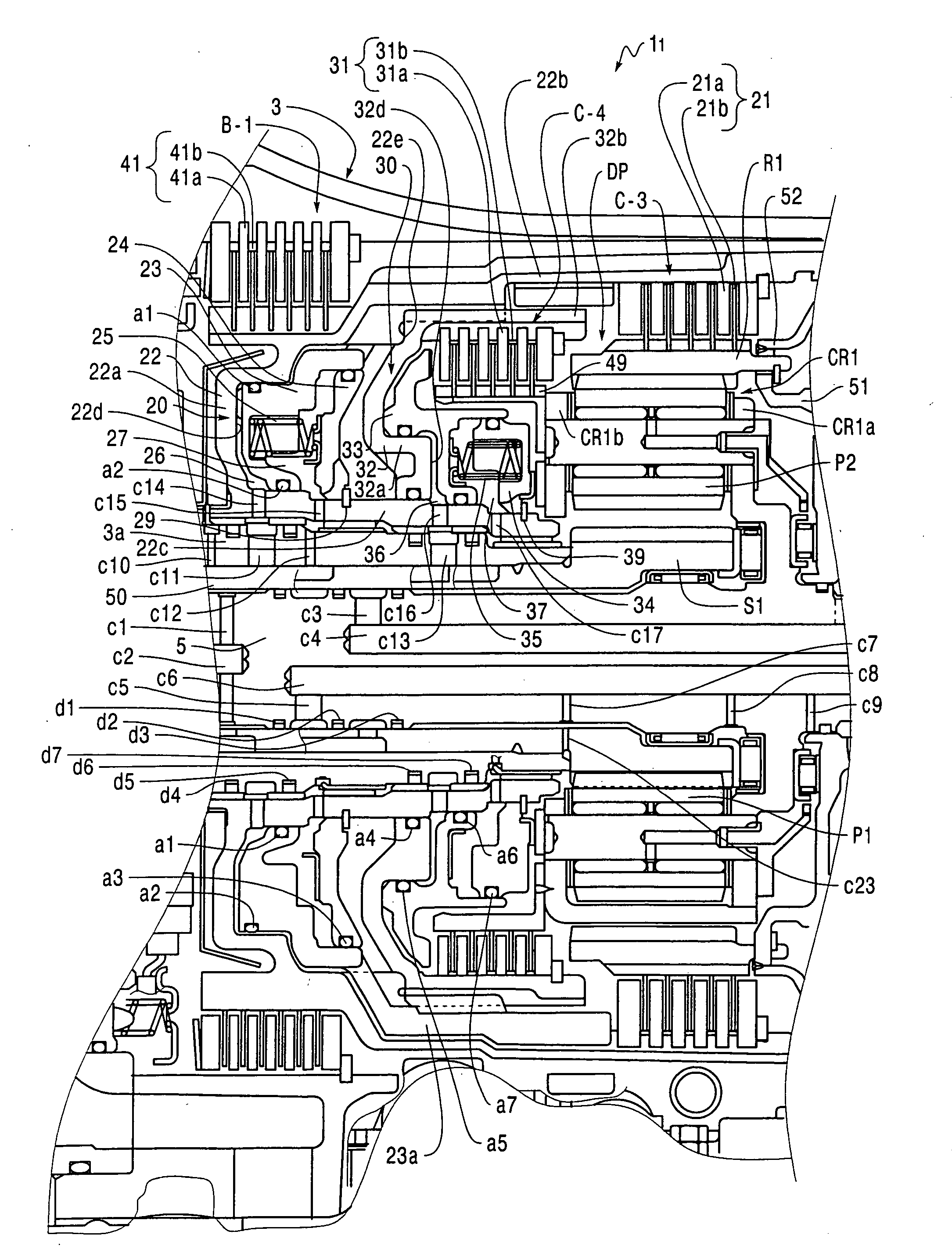

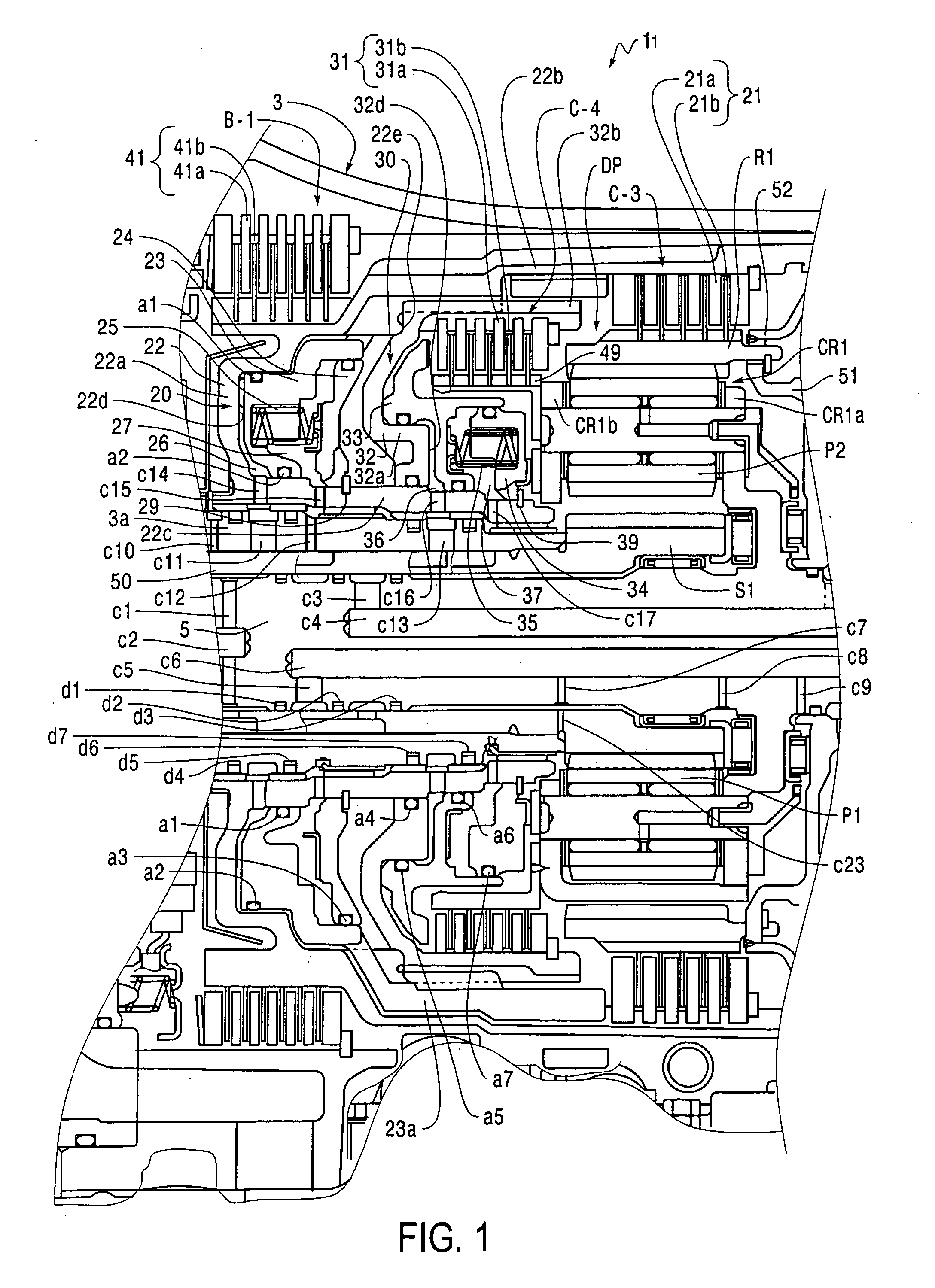

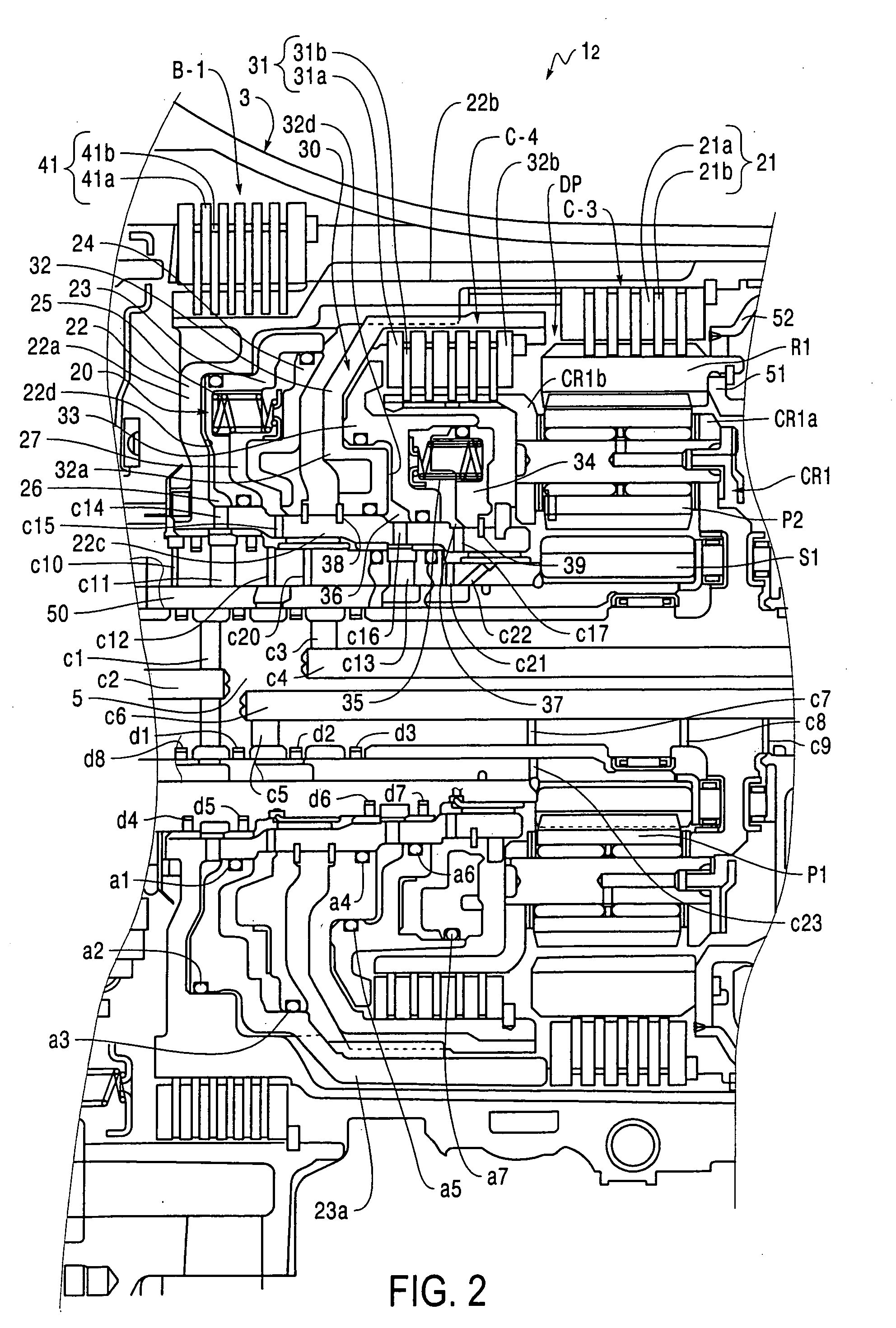

Clutch-purpose hydraulic servo

ActiveUS20070102257A1Improve usabilityLow production costMechanical actuated clutchesFluid actuated clutchesSpring forceEngineering

In a hydraulic servo for a clutch, a cancel plate is disposed on a second clutch drum that undergoes the same rotation as a second clutch drum provided with a cylinder portion, in such a fashion that the cancel plate is restricted from moving to a side opposite from a return spring in an axial direction. The first clutch drum is disposed, as a separate member, on the second clutch drum. A step portion of the second clutch drum prevents the first clutch drum from moving to a side opposite from the cancel plate. Due to the spring force of the return spring, the oil pressure in the cancel oil chamber and the oil pressure in the operating oil chamber, the force that presses the first clutch drum to the step portion is always greater than the force that presses the first clutch drum to the cancel plate side.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com