Production method of stearic acid

A production method and technology of stearic acid, applied in the field of oil deep processing, can solve the problems of unstable quality and high product price, and achieve the effects of low product price, stable product quality and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

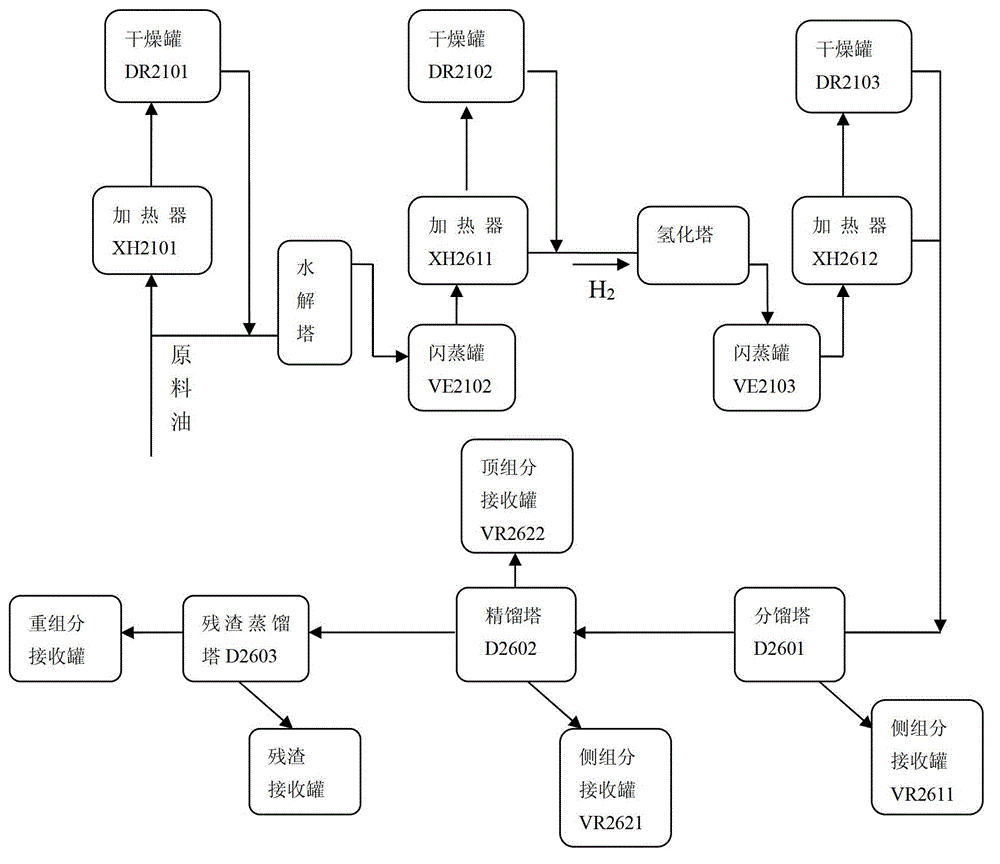

[0024] Such as figure 1 Shown, a kind of production method of stearic acid comprises the steps:

[0025] The raw material oil is refined palm stearin (RPS). The indicators of refined palm stearin are as follows: free fatty acid (calculated as palmitic acid) ≤ 0.2%, moisture and volatile matter ≤ 0.15%, iodine value ≤ 48gI 2 / 100g, color ≤3R, fatty acid content (C18:0+C18:1+C18:2) ≥36, melting point 50-56°C, saponification value 193-205mgKOH / g, unsaponifiable matter ≤1%.

[0026] In the drying tank DR2101, the raw material oil is dried and degassed. The pressure of the drying tank DR2101 is about 110mbar and the temperature is 105-110°C. Bring the Dryer DR2101 to a sufficient temperature.

[0027] The degassed and dehydrated raw oil is continuously sent to the bottom of the hydrolysis tower, the amount of water added is 60% of the mass of the raw oil, the reaction temperature of the hydrolysis is controlled at about 250°C, and the pressure of the hydrolysis is guaranteed to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com