Automobile corrosion-resistant die-casting aluminum alloy and preparation method thereof

A technology for casting aluminum alloy and corrosion resistance, which is applied in the field of corrosion-resistant die-casting aluminum alloy for automobiles and its preparation, can solve the problems of poor mechanical properties and poor corrosion resistance, and achieves low production process cost, improved corrosion resistance, and improved corrosion resistance. Good extrusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

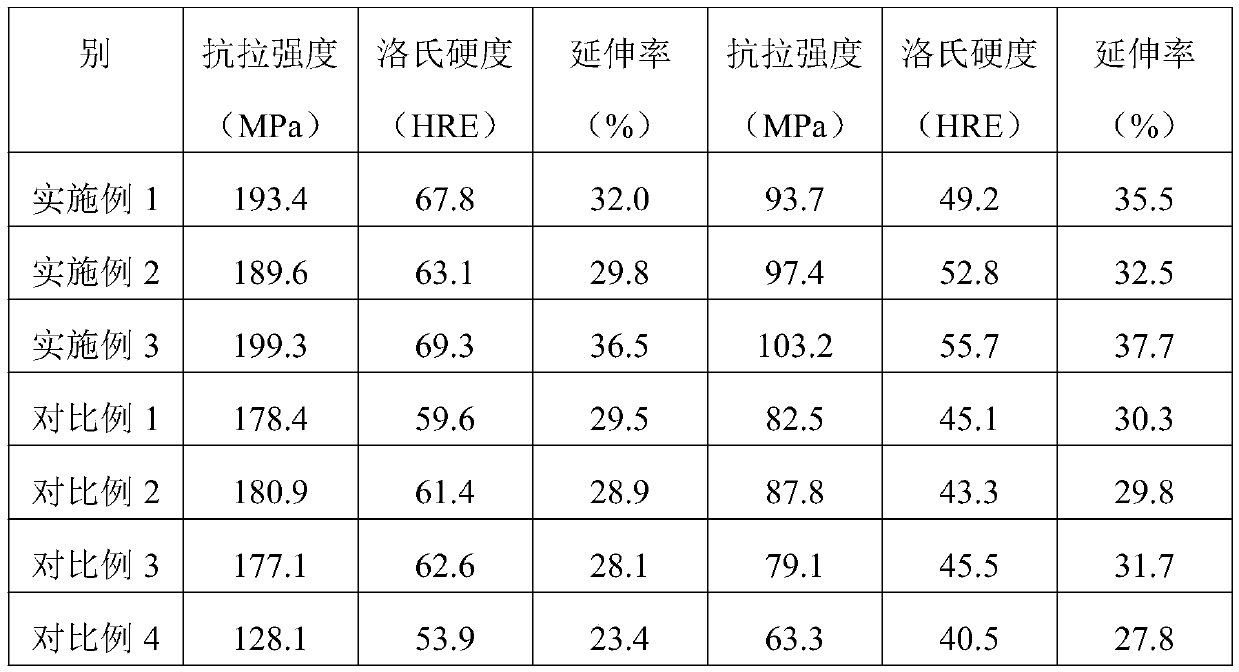

Embodiment 1

[0032] A corrosion-resistant die-casting aluminum alloy for automobiles, its components and the percentages of each component are: Si 6.5%, Mg 1.4%, Cu 0.8%, Sr 0.05%, Zn 0.4%, Mn 0.4%, Fe 0.2%, Y0.2%, Er 0.03%, the total amount of impurity elements of other metals and non-metals does not exceed 0.5%, and the rest is Al.

[0033] A method for preparing a corrosion-resistant die-casting aluminum alloy for automobiles, comprising the following steps:

[0034] S1: Melting: first add pure aluminum, pure magnesium, aluminum-silicon alloy into the melting furnace, heat to 735°C and stir to completely melt the alloy, then add electrolytic copper, aluminum-zinc alloy, iron-aluminum alloy and aluminum-manganese alloy, and continue to heat up To 770°C, after all the alloying elements are melted, the aluminum alloy melt is obtained, and the molten metal is stirred and shaken with a graphite rod, and the gas in the molten metal is discharged;

[0035]S2: Refining: adjust the temperature ...

Embodiment 2

[0041] A corrosion-resistant die-casting aluminum alloy for automobiles, its components and the percentages of each component are: Si 7.6%, Mg2.1%, Cu1.3%, Sr 0.11%, Zn 0.9%, Mn 0.8%, Fe 0.6%, Y 0.5%, Er 0.05%, the total amount of impurity elements of other metals and non-metals does not exceed 0.5%, and the rest is Al.

[0042] A method for preparing a corrosion-resistant die-casting aluminum alloy for automobiles, comprising the following steps:

[0043] S1: Melting: first add pure aluminum, pure magnesium, aluminum-silicon alloy into the melting furnace, heat to 750°C and stir to completely melt the alloy, then add electrolytic copper, aluminum-zinc alloy, iron-aluminum alloy and aluminum-manganese alloy, and continue to heat up To 810°C, after all the alloying elements are melted, the aluminum alloy melt is obtained, and the molten metal is stirred and shaken with a graphite rod, and the gas in the molten metal is discharged;

[0044] S2: Refining: adjust the temperature ...

Embodiment 3

[0050] A corrosion-resistant die-casting aluminum alloy for automobiles, its components and the percentages of each component are: Si 6.9%, Mg 1.7%, Cu 1.1%, Sr 0.07%, Zn 0.6%, Mn 0.6%, Fe 0.5%, Y0.3%, Er 0.04%, the total amount of impurity elements of other metals and non-metals does not exceed 0.5%, and the rest is Al.

[0051] A method for preparing a corrosion-resistant die-casting aluminum alloy for automobiles, comprising the following steps:

[0052] S1: Melting: first add pure aluminum, pure magnesium, aluminum-silicon alloy into the melting furnace, heat to 743°C and stir to completely melt the alloy, then add electrolytic copper, aluminum-zinc alloy, iron-aluminum alloy and aluminum-manganese alloy, and continue to heat up To 770-810°C, after all the alloying elements are melted, the aluminum alloy melt is obtained, and the molten metal is stirred and shaken with a graphite rod, and the gas in the molten metal is discharged;

[0053] S2: Refining: adjust the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com