Preparation method of polybutylene terephthalate polyester resin

A technology of polybutylene terephthalate and ester polyester, which is applied in the field of preparation of polybutylene terephthalate polyester resin, and can solve the problems of poor quality stability, high rate of substandard products, and poor color of PBT and other issues, to achieve the effect of stable product quality, excellent product quality and small quality difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

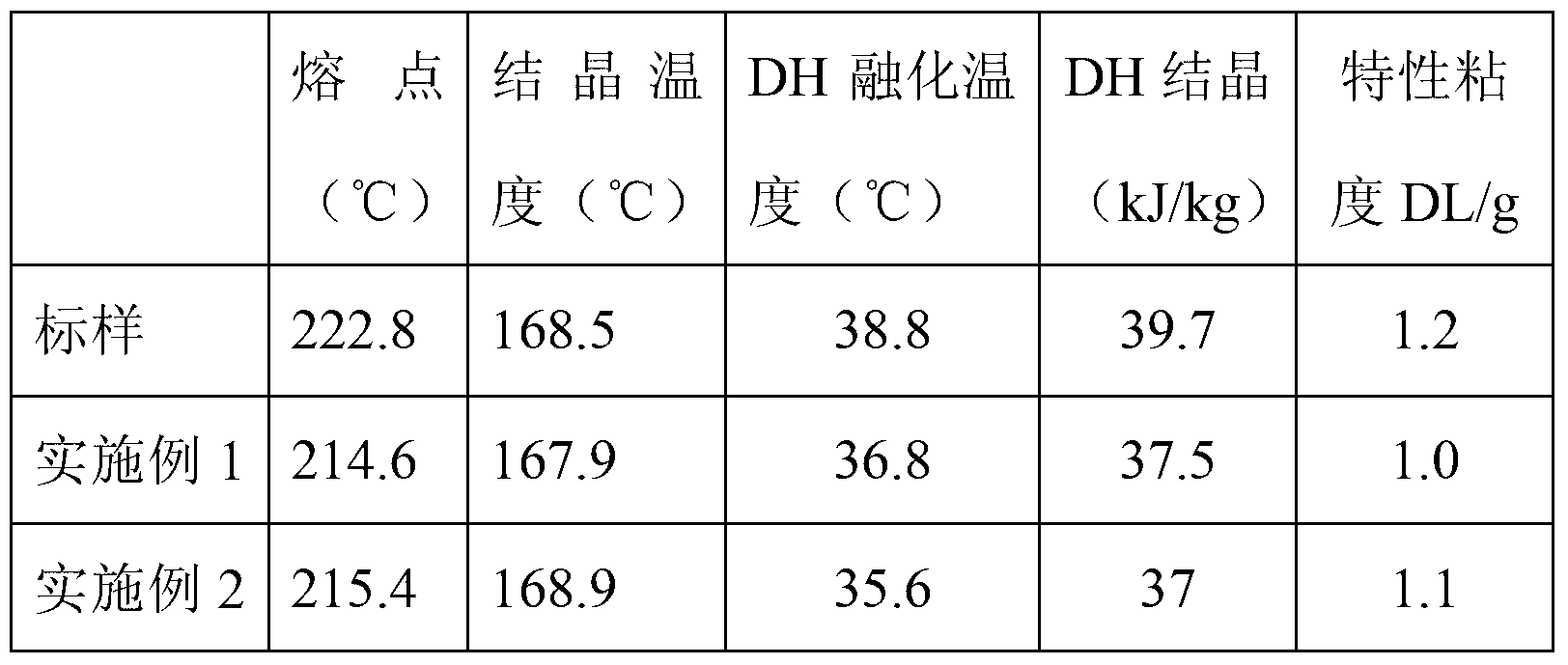

Embodiment 1

[0032] Nissan 120KG PBT Continuous Production Method

[0033] Feed the evenly mixed PET together with 1,4-butanediol and transesterification catalyst into a screw extruder. The mass ratio of PET is 0.3:1000; the temperature of the screw reaction zone is 200-300℃, the pressure of the reaction zone is 0.1Mpa-10Mpa, the screw speed is 10-60r / min, and the extruder is extruded at a constant speed of 5.515Kg / h. After being filtered by a 150-250 mesh melt filter, it is extruded into a 20-liter transesterification reactor. The transesterification reactor is equipped with a tube heat exchanger to ensure the heat exchange effect, and the extruded material is directly sent to the stirring paddle. At the lower end of the blade, the blades are propelled with 4 pieces of 210-degree twist. The wall of the reactor is equipped with a material drainage guide plate. After the material is directly sent to the lower end of the stirring blade, the blade stirs and presses the material downward, so t...

Embodiment 2

[0038] Continuous production method of 24 tons of PBT per day

[0039] The homogeneously mixed PET material raw material is fed into the screw extruder together with 1,4-butanediol and transesterification catalyst. The mass ratio of PET and 1,4-butanediol is 1:0.01-0.1. The zinc acetate catalyst and the The mass ratio of PET is 0.3:1000; the temperature of the screw reaction zone is 200~300℃, the pressure of the reaction zone is 0.1Mpa~10Mpa, the screw speed is 10~60r / min, and the extruded at a constant speed of 1103.00Kg / h, After being filtered by a 150-250 mesh melt filter, it is extruded into a 4,000-liter transesterification reactor. The transesterification reactor is equipped with a tube heat exchanger to ensure the heat exchange effect, and the extruded material is directly sent to the stirring paddle. At the lower end of the blade, the blades are propelled with 4 pieces of 210-degree twist. The wall of the reactor is equipped with a material drainage guide plate. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com