Patents

Literature

573results about How to "Reduce environmental costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

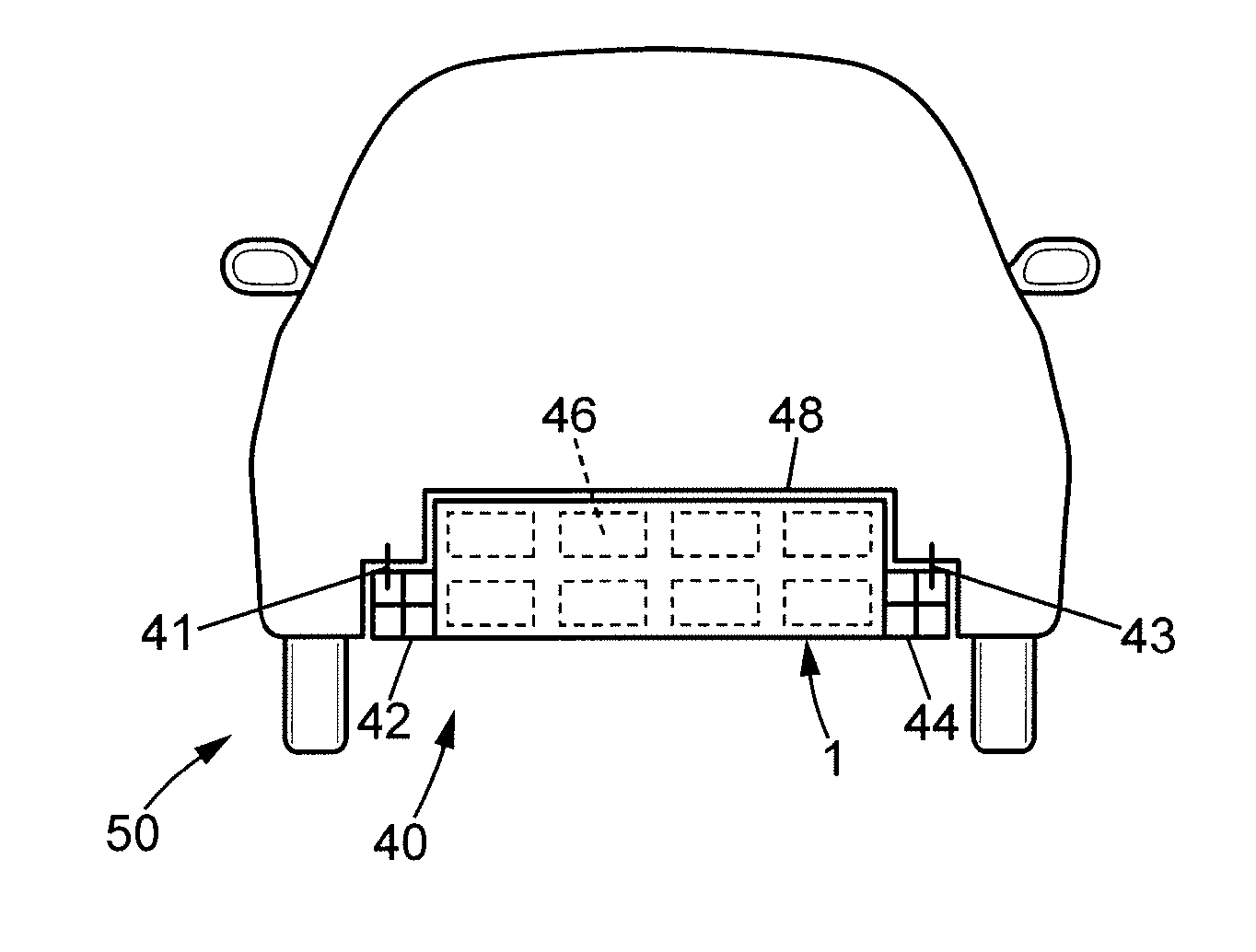

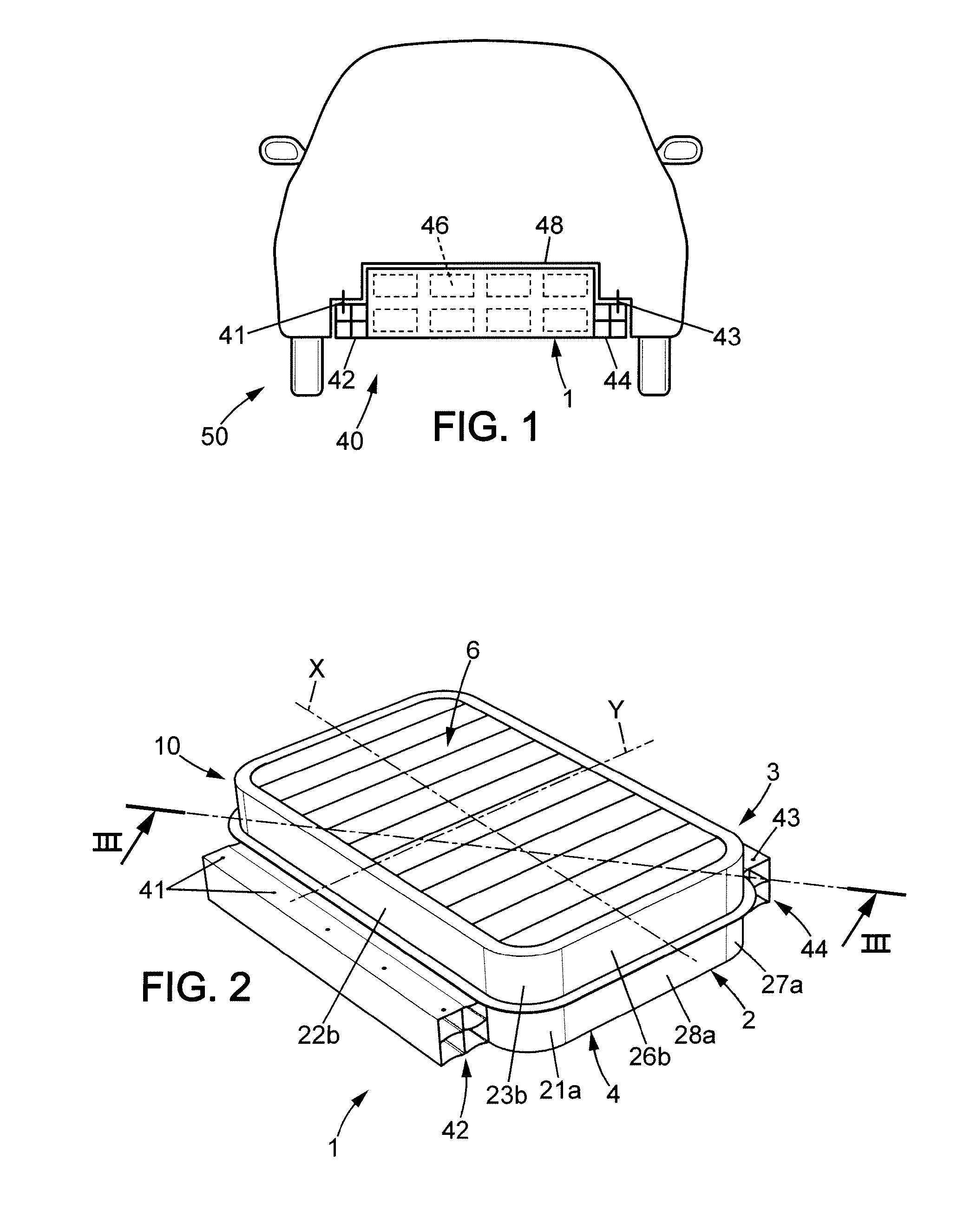

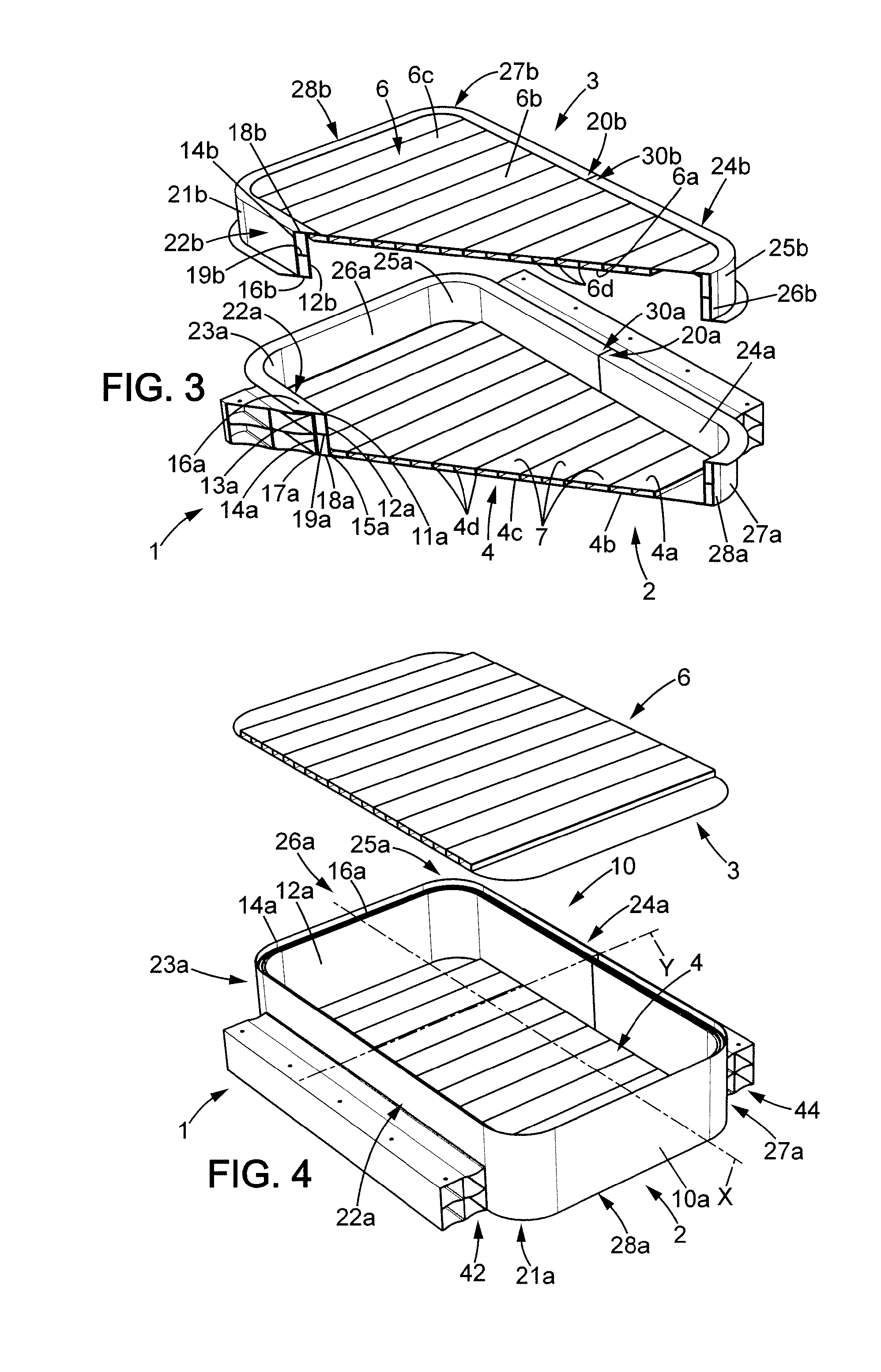

Battery Tray for Vehicle and Method for Producing the Battery Tray

InactiveUS20120223113A1Avoid deformationLarge deformationCharging stationsElectric propulsion mountingEngineeringElectrical battery

Owner:BENTELER ALUMINUM SYST FRANCE

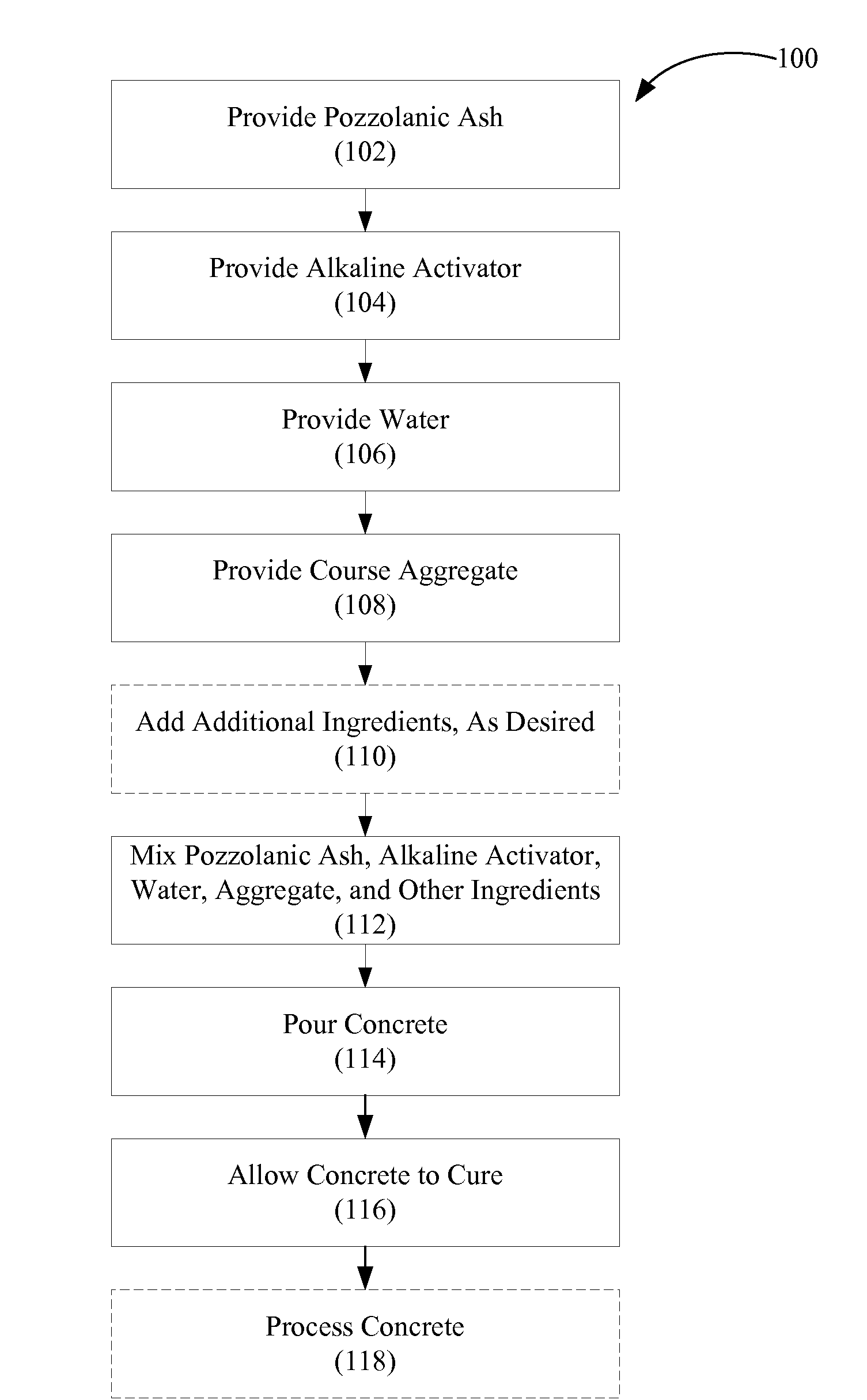

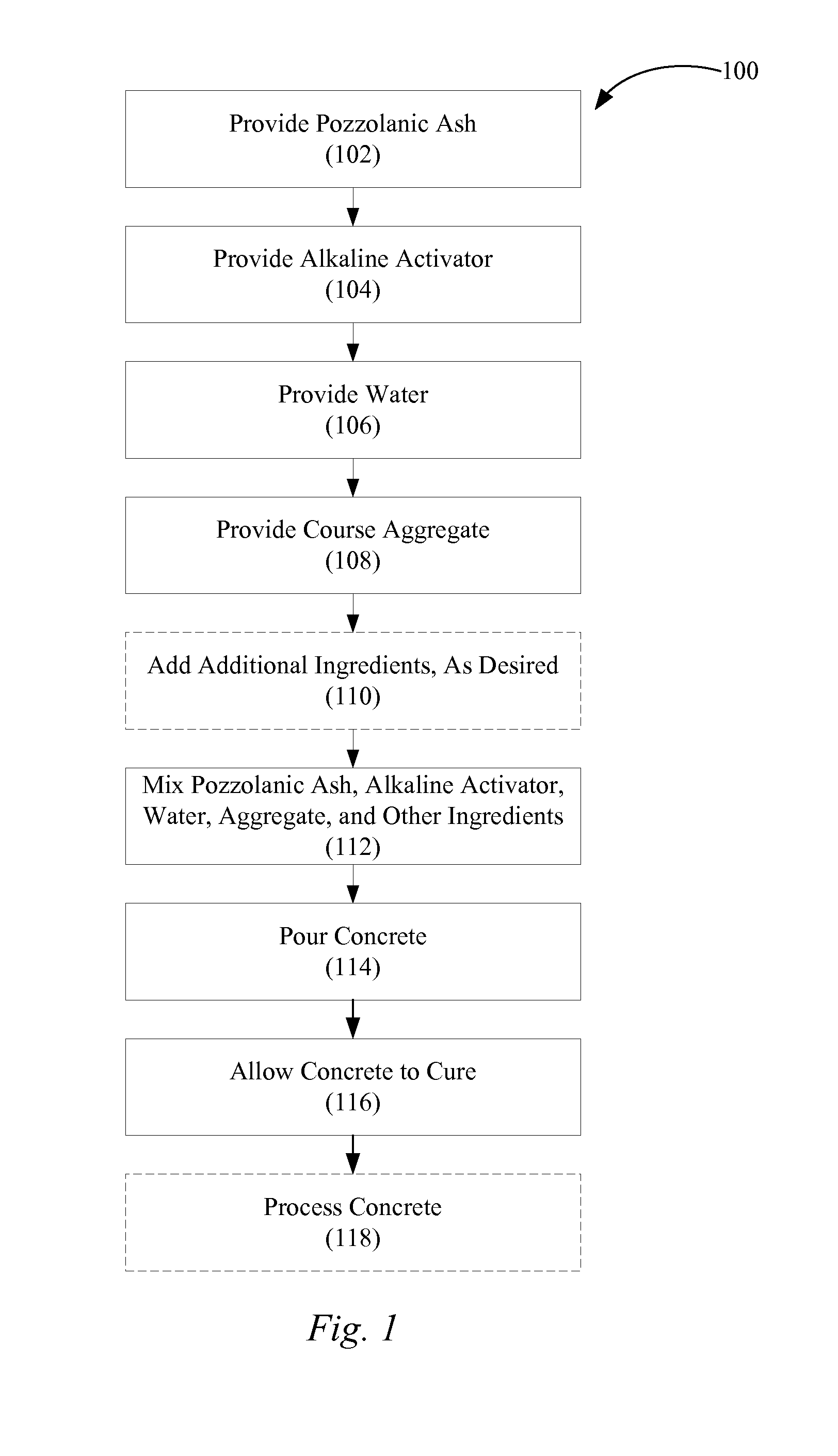

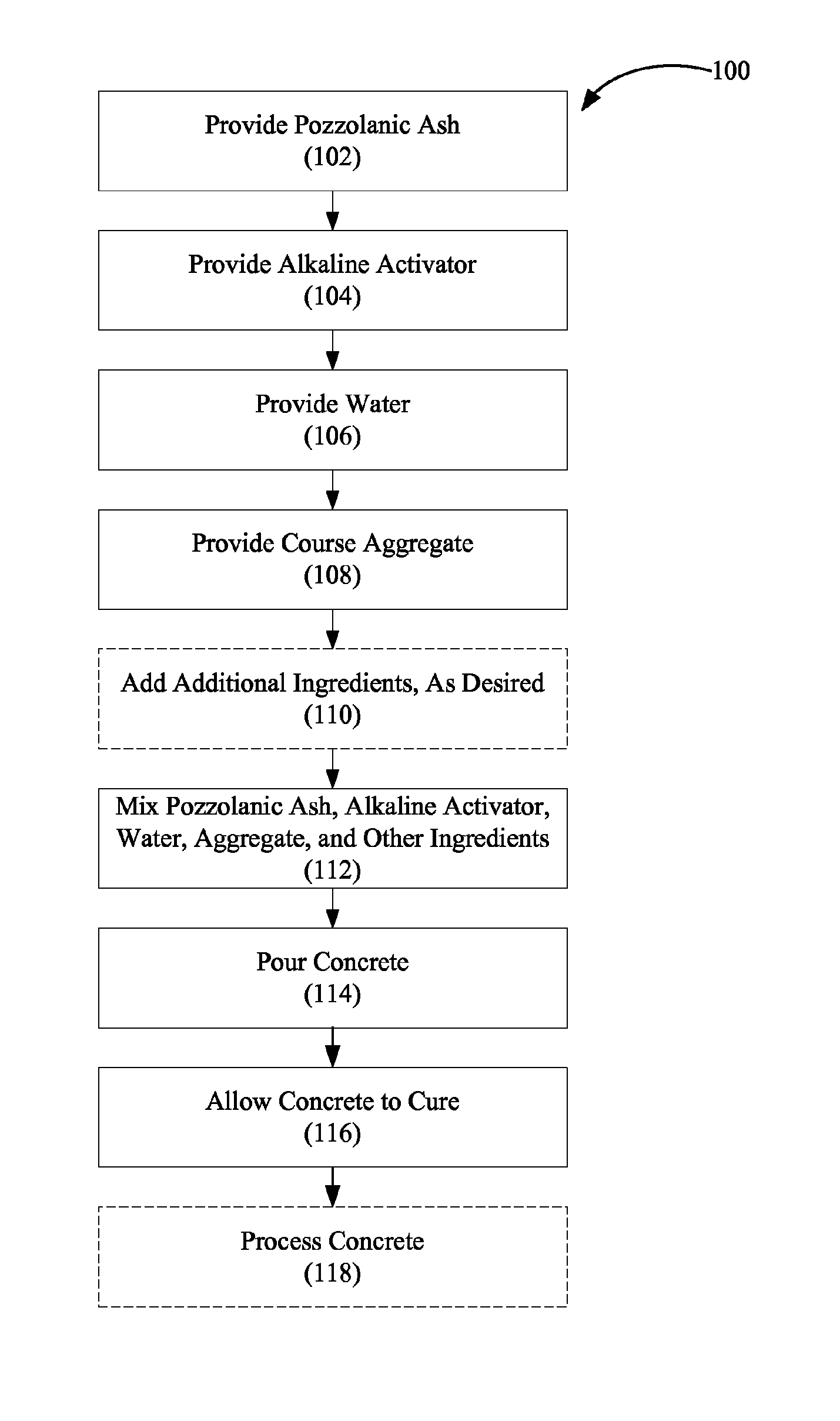

Previous concrete comprising a geopolymerized pozzolanic ash binder

ActiveUS20100058957A1Low costImprove performanceSolid waste managementCement productionAluminateCombustion

A process for making a pervious concrete comprising a geopolymerized pozzolanic ash. Generally, the process includes mixing a solid aggregate and a geopolymerized pozzolanic ash binder together to form a pervious concrete mixture. Some examples of suitable aggregates comprise recycled carpet, recycled cement, and aggregates of coal-combustion byproducts. The geopolymerized pozzolanic ash binder is made by combining a pozzolanic ash, such as fly ash, with a sufficient amount of an alkaline activator and water to initiate a geopolymerization reaction. The activator solution may contain an alkali metal hydroxide, carbonate, silicate, aluminate, or mixtures thereof. In some aspects, the final concrete forms a solid mass in the form of pavement or a pre-cast concrete shape. The solid mass of concrete may have a void content of between about 5% and about 35%.

Owner:CERAMTEC

Fire retardant composition

InactiveUS20100069488A1Improve flame retardant performanceEfficient and reasonably safe to manufactureFireproof paintsOrganic active ingredientsCross-linkActive agent

A composition can embrace a fire retardant can be combined with a fluoropolymer, which can be a coating, for example, a paint, especially a latex paint, or which can be an organic solvent based coating, for example, a paint. The fire retardant can be an ammonium phosphate containing fire retardant, which can be combined with a fluoropolymer, a penetrating barrier, borate-containing formulation having resistance to water damage with protective properties coming from materials used in food packaging and cosmetics, and / or a medium-to-long chain polar carboxyl substance to make a composition. Also, a composition can embrace a fire retardant formulation having a cross-linked component, which composition may be a coating, for example, a paint or stain, especially a latex paint. The cross-linked component may be a base of the paint or stain, say, a vinyl acetate base of the fire retardant latex paint. At least one other active agent, for example, a mold inhibitor and / or an insecticide, may be included. The composition can be used by contacting it with a substrate, which beneficially is otherwise flammable. The composition or its residue may be found in combination with the substrate.

Owner:NO BURN INVESTMENTS

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

Process for producing methane by dry-type fermentation of stalks

InactiveCN101338325ALess investmentReduce operating costsBio-organic fraction processingClimate change adaptationSlagSlurry

The invention provides a technique for producing biogas by utilizing stalk dry fermentation which includes the steps: I, cracking the stalks into 2 to 8mm by a cracking machine; II, transmitting the cracked stalks into a pre-treatment pool, adding hot water of 40 to 53 DEG C and a stalk fermentation agent in the pre-treatment pool to carry out pre-treatment; the cracked stalks and the biogas slurry refluxed by the anaerobic digester of the pre-treatment pool are mixed according to a proportion of 2 to 1; after stirring, the solid content rate of the stalk liquid is 20 to 35 percent; III, using a mud pump to equally transmit the stalk liquid to the top part of the anaerobic digester with a fermentation temperature of 40 to 53 DEG C; IV, the biogas generated by fermentation is purified to be clean fuel by gas-liquid separation. The technique can lead the stalks of 1.5kg to generate the biogas of 1m<3> (the content of methane is larger or equal to 55 percent); the degrading rate is more than 90 percent. The technique of the invention can continuously feed and discharge; the biogas slurry can be repeatedly used; only biogas slag is discharged; the biogas slag is manufactured into organic fertilizer by processing and can not cause any pollution to the environment.

Owner:HENAN FUCHENG ECOLOGICAL ENERGY TECH

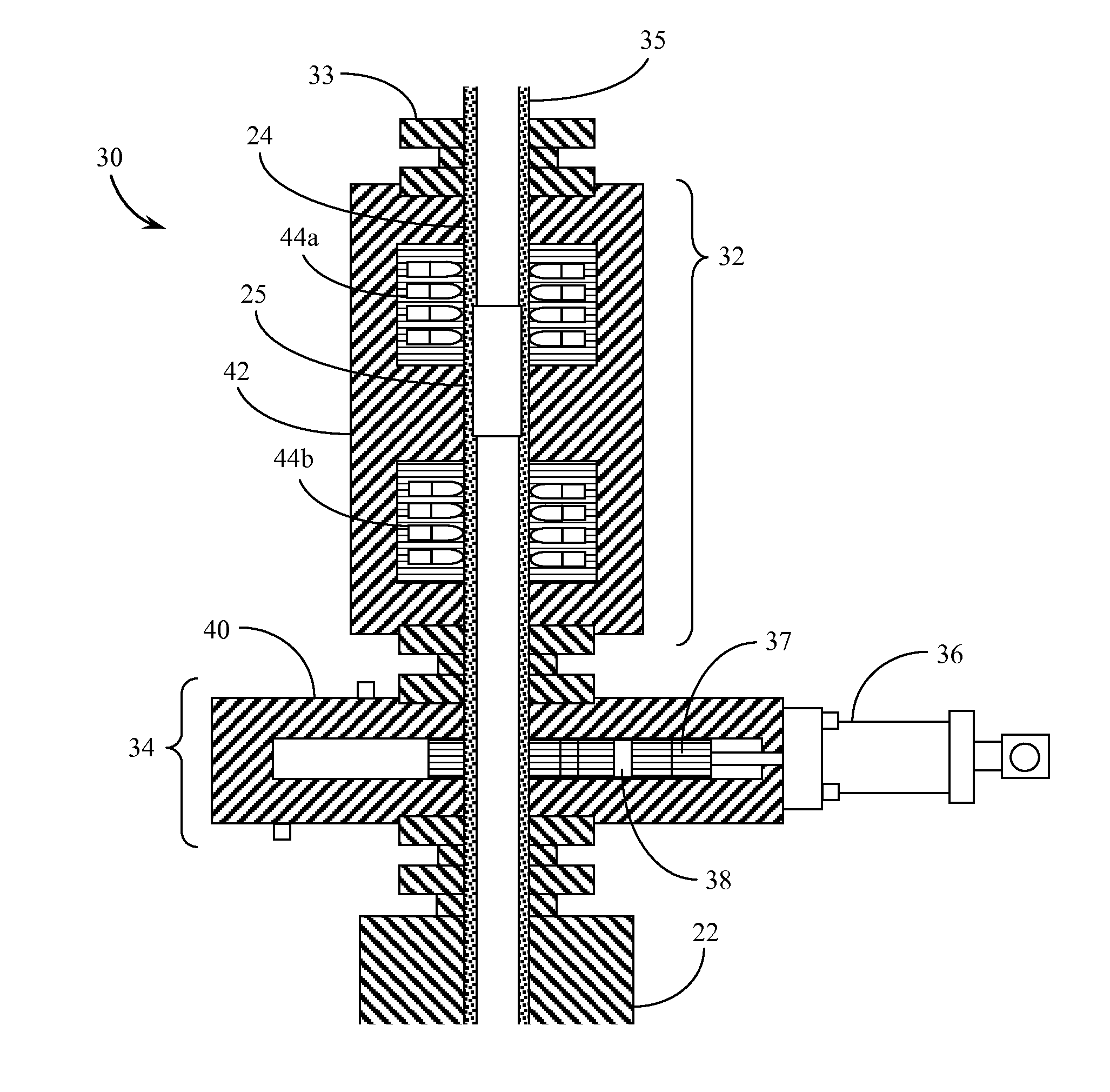

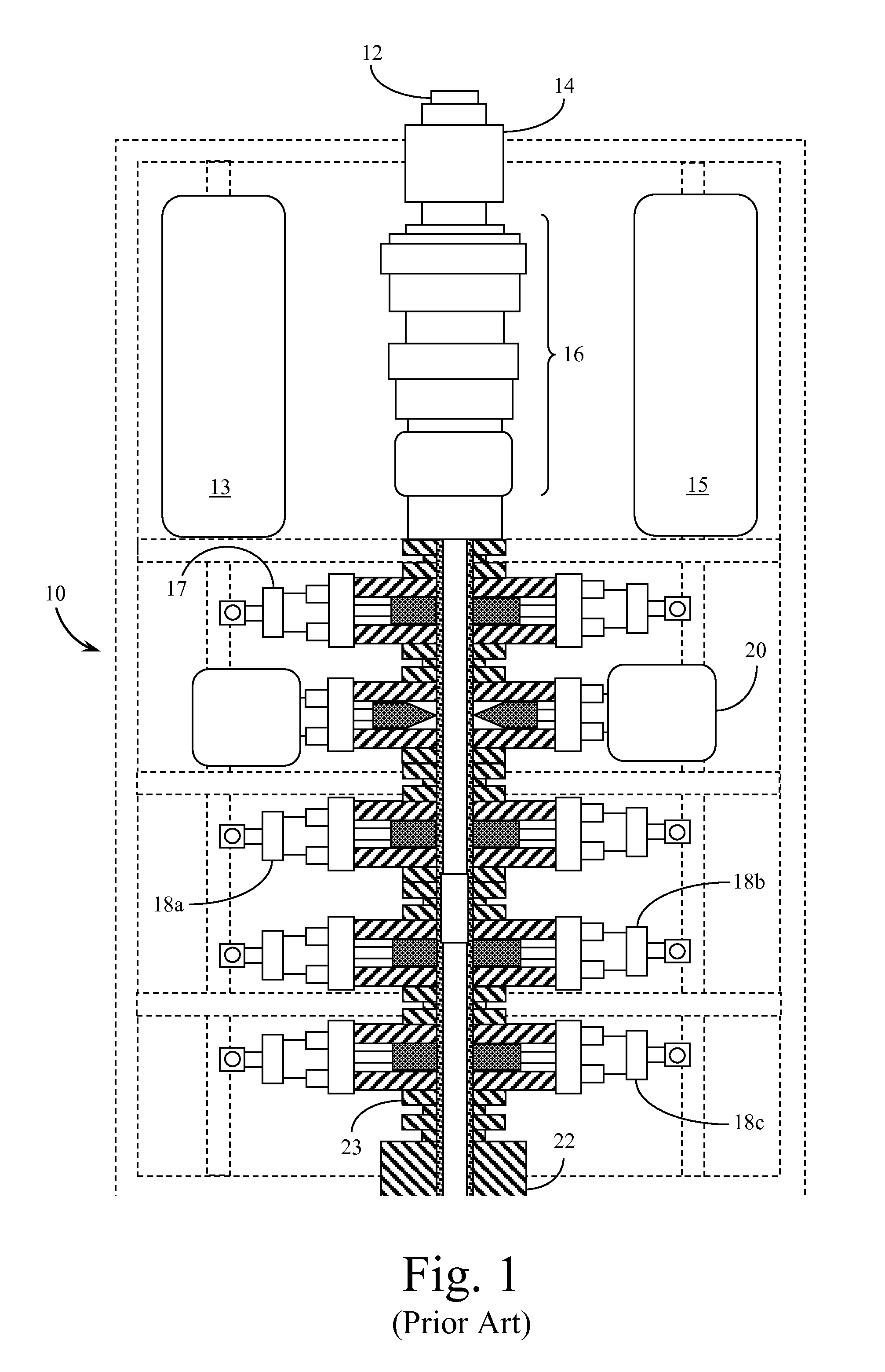

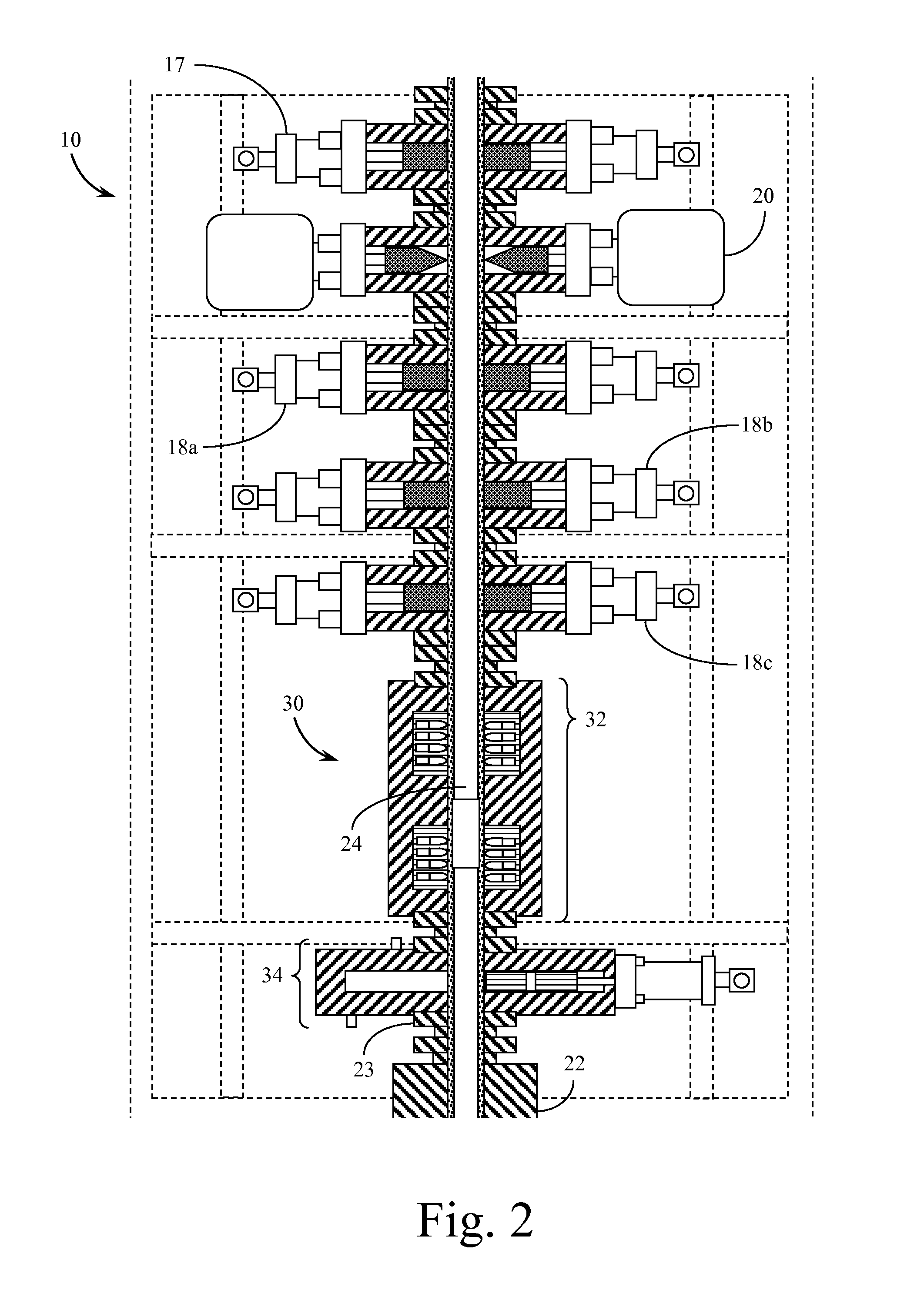

Blowout Container

InactiveUS20130126153A1Cost-effective and neededCost effective and needed safe guardFluid removalSealing/packingEngineeringBiological activation

A system for containing and recovering from the blowout of an oil or gas well. The blowout containment (BOC) system is operable in place of, or as a failsafe alternative to, standard blowout preventer (BOP) systems. The BOC system includes a hydraulically operated gate valve positioned over the well at the wellhead. The gate valve includes a check valve operable when the gate valve is closed. The BOC system further includes at least one shearing assembly positioned over the gate valve. The shearing assembly orients explosive charges into the well flow path. An activation trigger detonates the explosive charges to clear the well flow path of obstructions to permit the gate valve to close. Operation of the BOC system is preferably monitored and controlled from a remote location apart from the rig associated with the well.

Owner:BAKER DWIGHT

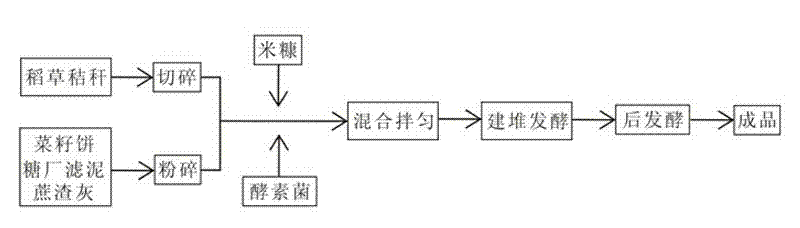

Organic fertilizer or bio-mixed organic fertilizer special for rice and preparing method thereof

ActiveCN102503611ARestore fertilityReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationChaffRapeseed

The invention discloses an organic fertilizer or a bio-mixed organic fertilizer special for rice and a preparing method thereof. The organic fertilizer or the bio-mixed organic fertilizer special for rice is prepared by composting and fermenting raw materials (dry basis) according to the following weight percentage: 10%-20% of straw stalks, 25%-30% of rice chaff (bran), 25%-35% of rapeseed cakes (dregs), 5%-20% of sugar refinery filtered mud, 5%-10% of bagasse ash and 0.1% of ferment bacterial fertilizer. The organic fertilizer or the bio-mixed organic fertilizer is good in fertilizer effect and environment-friendly, can lead nutritional components absorbed by rice, rape and sugarcanes from the soil to return to the land so as to restore soil fertility, leads circular economy to be developed, use quantity of fertilizers and pesticides are reduced, green and organic agricultural products are produced, production cost and environment cost are reduced, food safety is improved, environment is protected, and modern agriculture and green agriculture development are promoted.

Owner:广西宾阳县华彦新材料科技有限公司

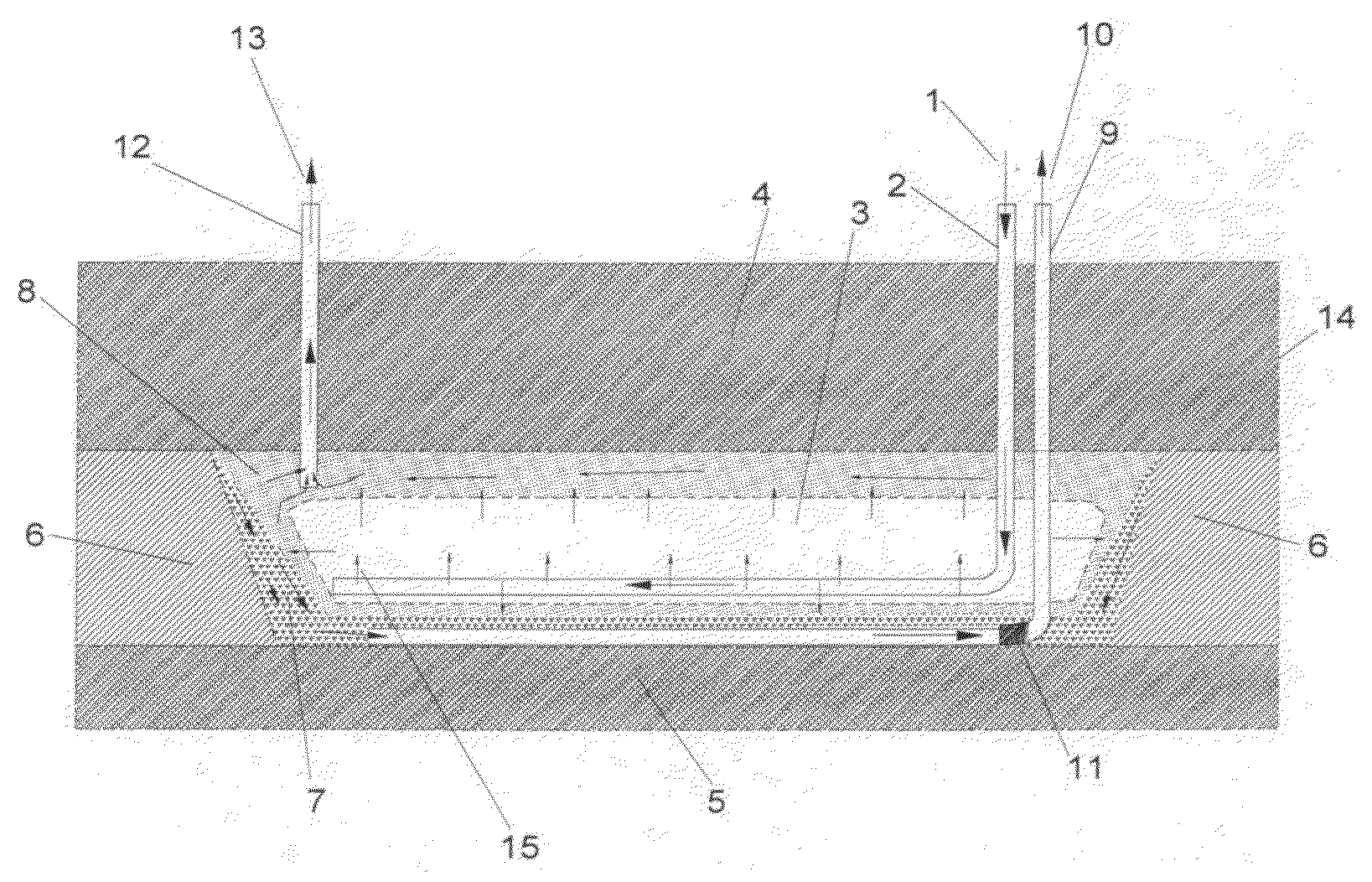

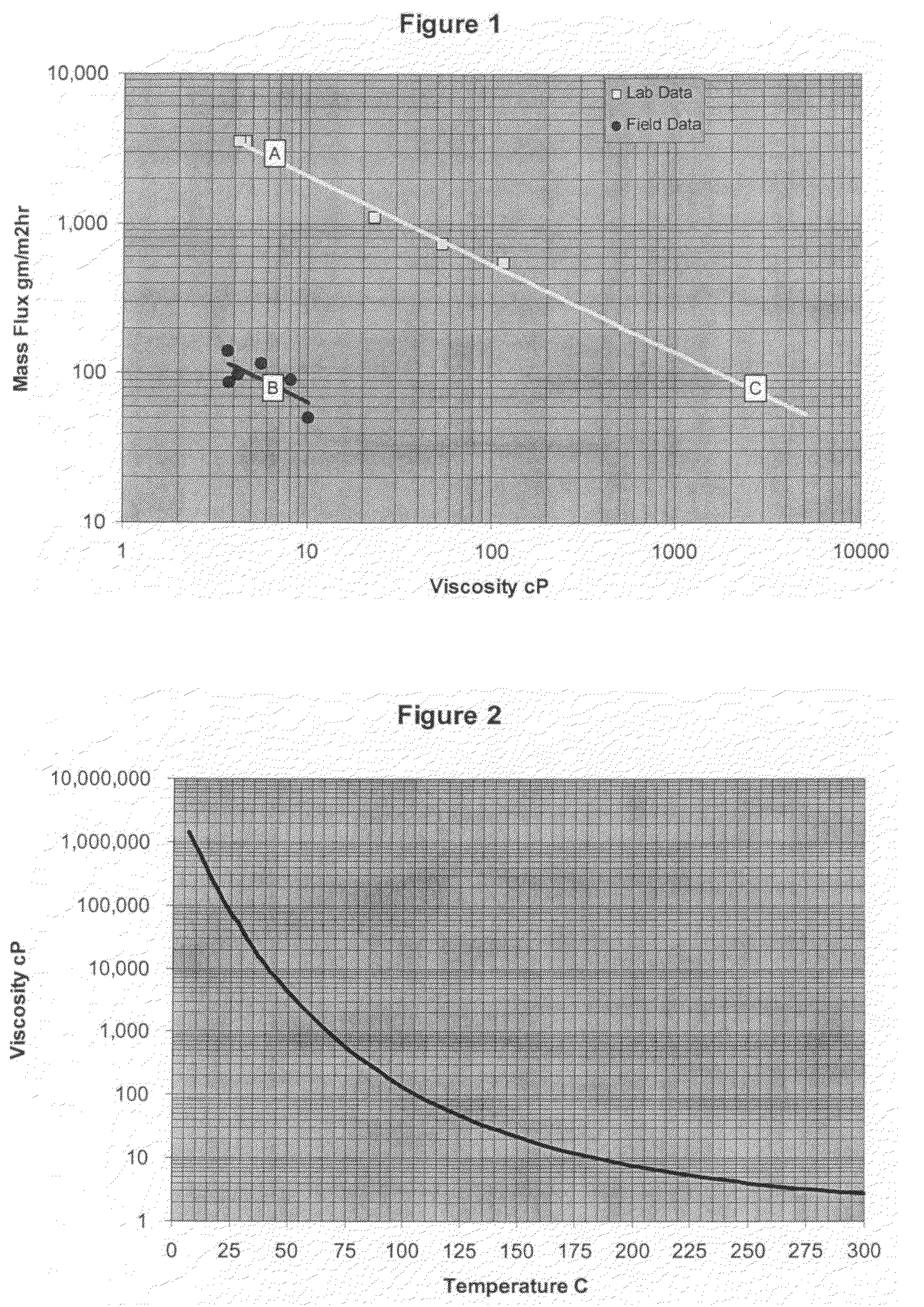

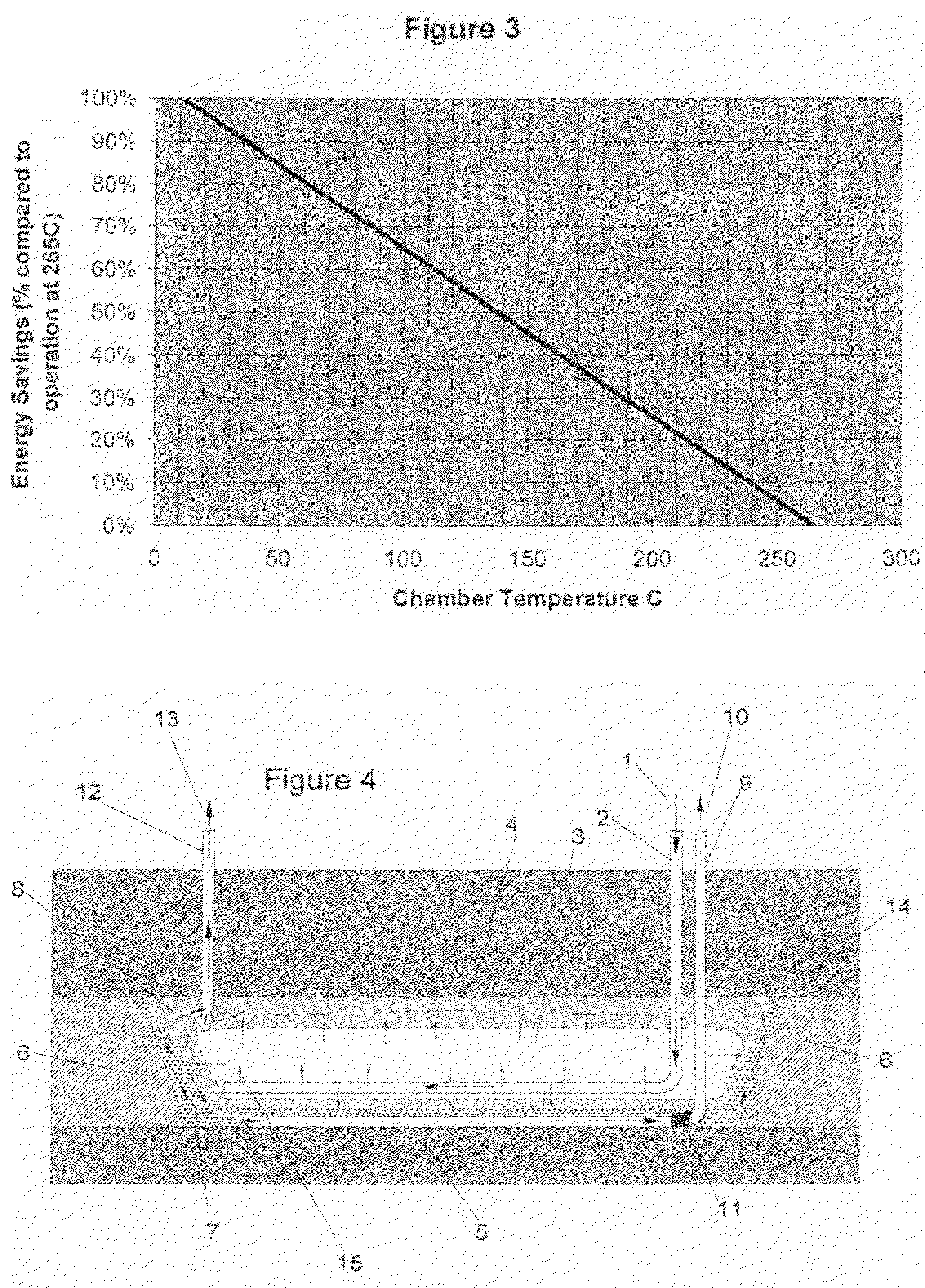

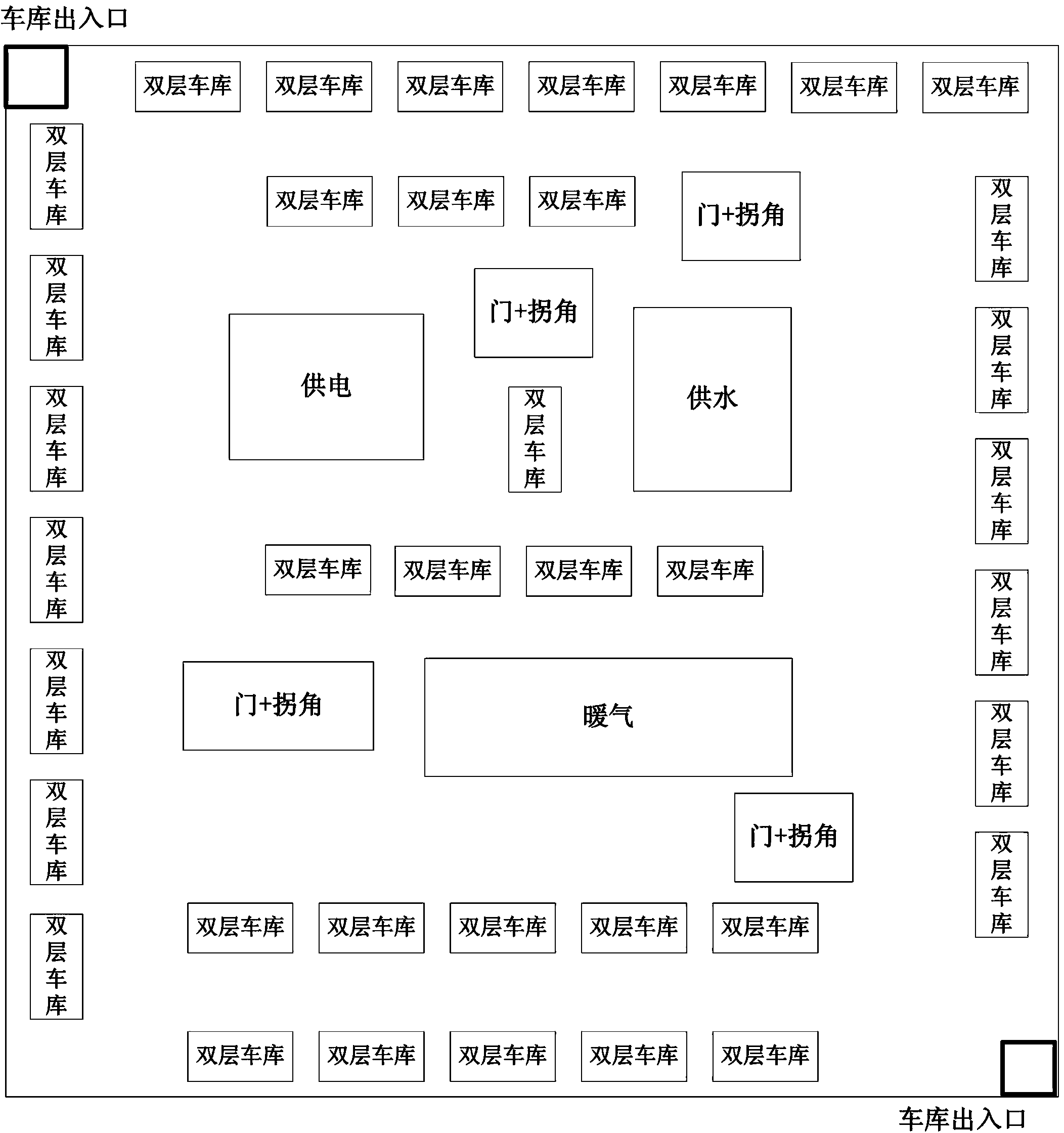

Methods and apparatuses for sagd hydrocarbon production

InactiveUS20100163229A1Improve energy efficiencyLow costFluid removalHydrogen compoundsInjection well

A process for recovering hydrocarbons from an in situ formation. The process includes the steps of injecting steam though an injection well into an underground extraction chamber having a hydrocarbon extraction interface, warming the hydrocarbons at the extraction interface to cause the hydrocarbons to flow downwardly by gravity drainage and to release dissolved hydrocarbon gases and moving the hydrocarbon gases from the extraction interface to improve heat transfer from said steam to said interface. The last step is to recover liquids such as hydrocarbons and water through a production well. The invention provides adding a buoyancy modifying agent to the steam to cause the hydrocarbon gases to accumulate in the well in a preferred location. The preferred location is at the top of the chamber where the gases protect the top of the chamber from being extracted to the point of breakthrough.

Owner:NENNIGER JOHN

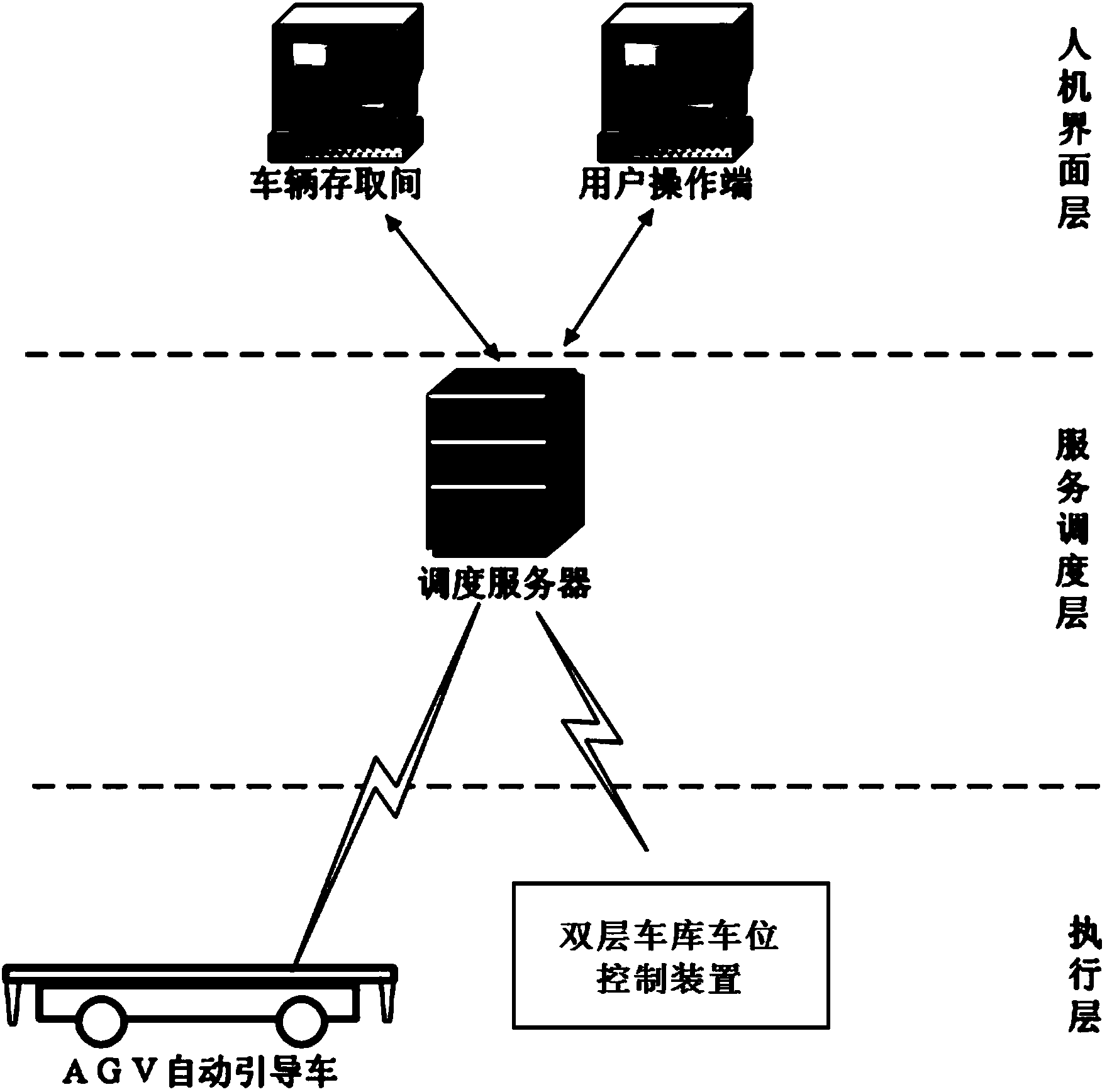

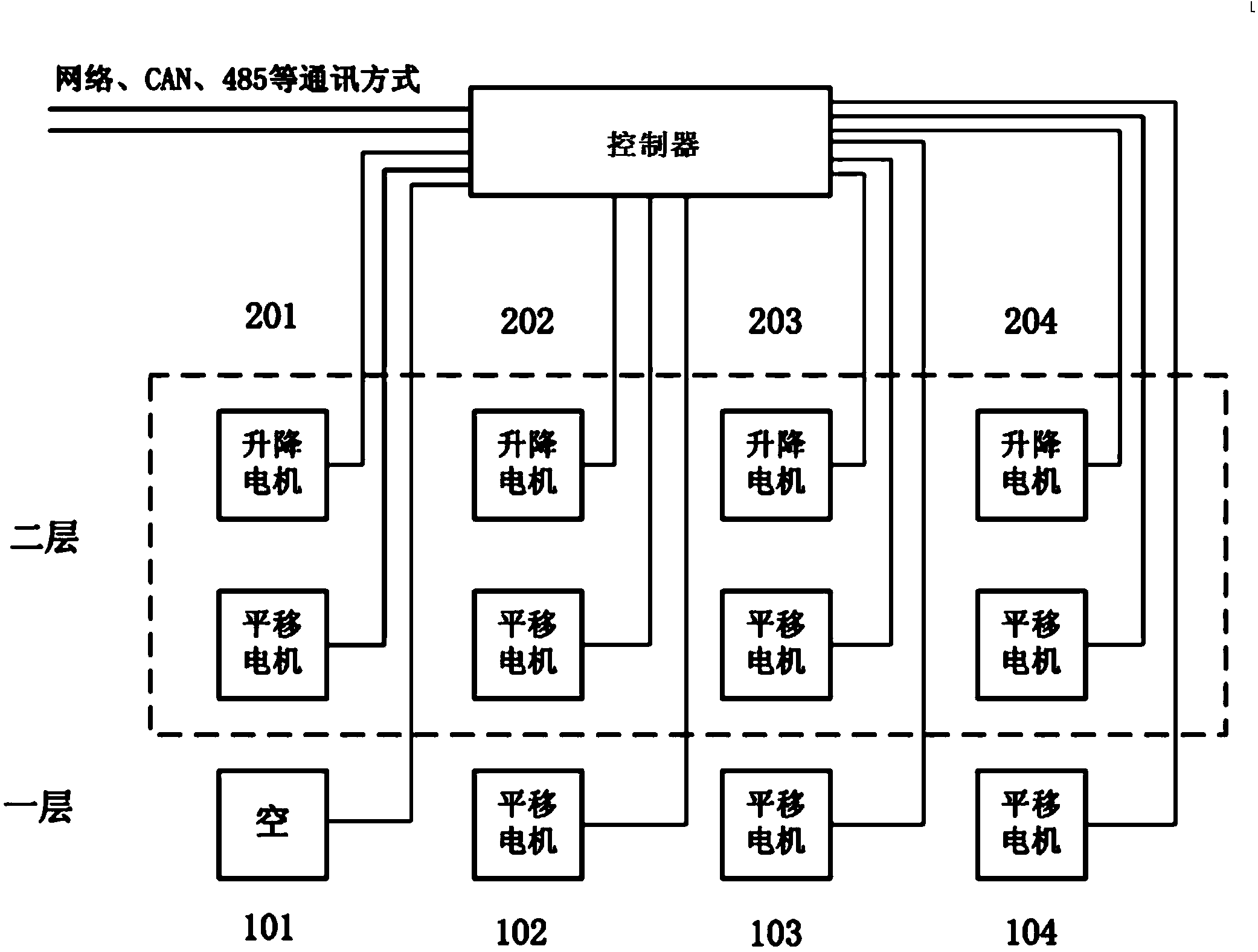

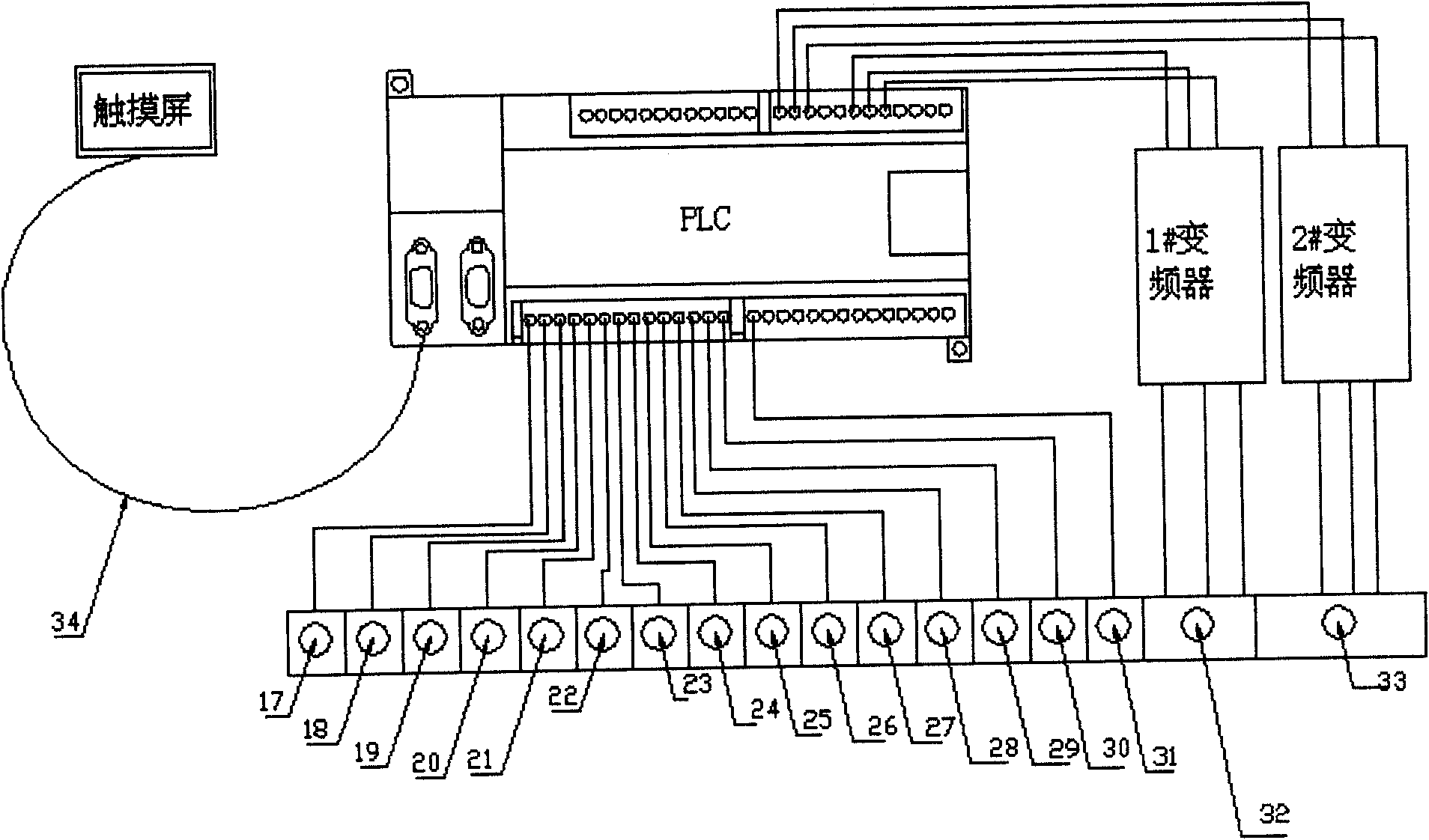

Intelligent control system and method based on combination of mechanical three-dimensional parking lot and AGV

InactiveCN103592926AEasy accessReduce pickup timeElectric/hybrid propulsionTotal factory controlWired communicationMovement control

The invention relates to an intelligent control system and method based on combination of a mechanical three-dimensional parking lot and an AGV. The system comprises a dispatching server, the AGV, a double-layer garage carport control device and vehicle guidance marks laid on a driving channel in the mechanical three-dimensional parking lot. The dispatching server is connected with the double-layer garage carport control device in a wired communication mode to achieve a function of vertical and horizontal movement control of double-layer garage carports; and the dispatching server is connected with the AGV in a wireless communication mode. According to the intelligent control system and method based on combination of the mechanical three-dimensional parking lot and the AGV, by the relay matching of the double-layer garage carport control device and the AGV, a convenient vehicle storage and taking function is achieved under the control of the dispatching server, not only is vehicle taking time effectively shortened for car owners, but also indoor exhaust pollution caused by the fact that the car owners drive vehicles in the parking lot for a long time to look for the carports can be avoided fundamentally, and the environmental protection cost is reduced.

Owner:SHENZHEN PUZHILIANKE ROBOT TECH CO LTD

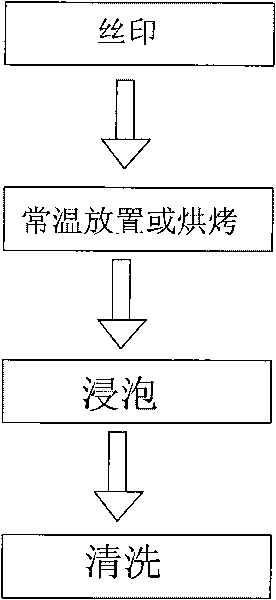

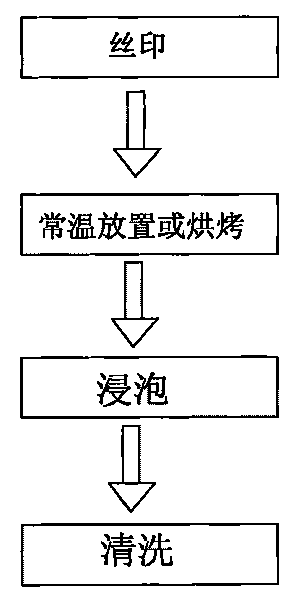

Etching plaster for metal and metal oxide transparent conducting layer and etching process

InactiveCN101717645AEliminate acid and alkali soaking processEliminate the soaking processSurface treatment compositionsEtchingDefoaming Agents

The invention discloses an etching plaster for metal and metal oxide transparent conducting layers and an etching process, in the invention, lagging production processes, such as the use of organic solvents, strong acid etching and strong alkaline cleaning and the like, are not used any longer, instead, the etching plaster and the etching process which do not pollute the environment are used. The etching plaster comprises the following components in parts by weight: 0.1-20 parts of salt substance, 2-50 parts of non-volatile acid, 10-30 parts of aqueous high molecular polymer, 0.1-10 parts of dilute wetting dispersant, 0.1-5 parts of defoamer, 10-40 parts of thickening agent, 0.1-10 parts of bacteriostat and 2-30 parts of water. The invention simplifies the process flow, cancels acid and alkali soaking and the use of organic solvents, lowers the environmental protection cost, improves the etching quality of products, and has the effects of high efficiency, energy saving and environmental protection. The invention is widely applied to the fields of electron, semiconductors, fine chemistry industry and the like.

Owner:张林

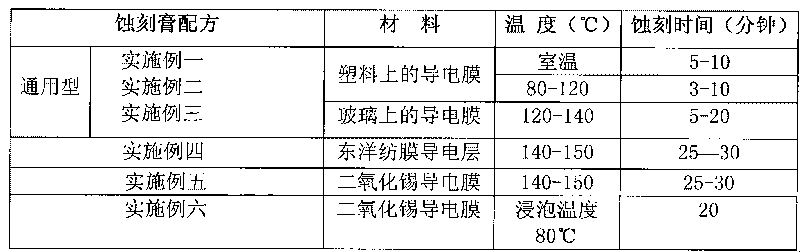

Mineral processing technology by utilizing grade difference of potassium feldspar

The invention relates to a mineral processing technology by utilizing the grade difference of potassium feldspar. The mineral processing technology comprises the following steps that (1), potassium feldspar raw ore is mined and sorted in a separated mode according to the three classes of low-grade potassium feldspar ore, medium-grade potassium feldspar ore and high-grade potassium feldspar ore; (2), the mineral processing processes of crushing, washing, grinding for grading, desliming, and magnetic separation for deep iron removal are carried out on the low-grade potassium feldspar ore; (3), the mineral processing processes of crushing, washing, grinding for grading, desliming, flotation for mica removal and iron removal, flotation for separating feldspar from quartz, and magnetic separation for deep iron removal are carried out on the medium-grade potassium feldspar ore; (4), the mineral processing processes of crushing, washing, grinding for grading, desliming, magnetic separation for deep iron removal, wet superfine grinding and screening are carried out on the high-grade potassium feldspar ore. The different mineral processing technical schemes are adopted for the potassium feldspar ore of different grades, and the purposes of being free of environmental pollution, simplifying the production processes and efficiently developing and utilizing resources are achieved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

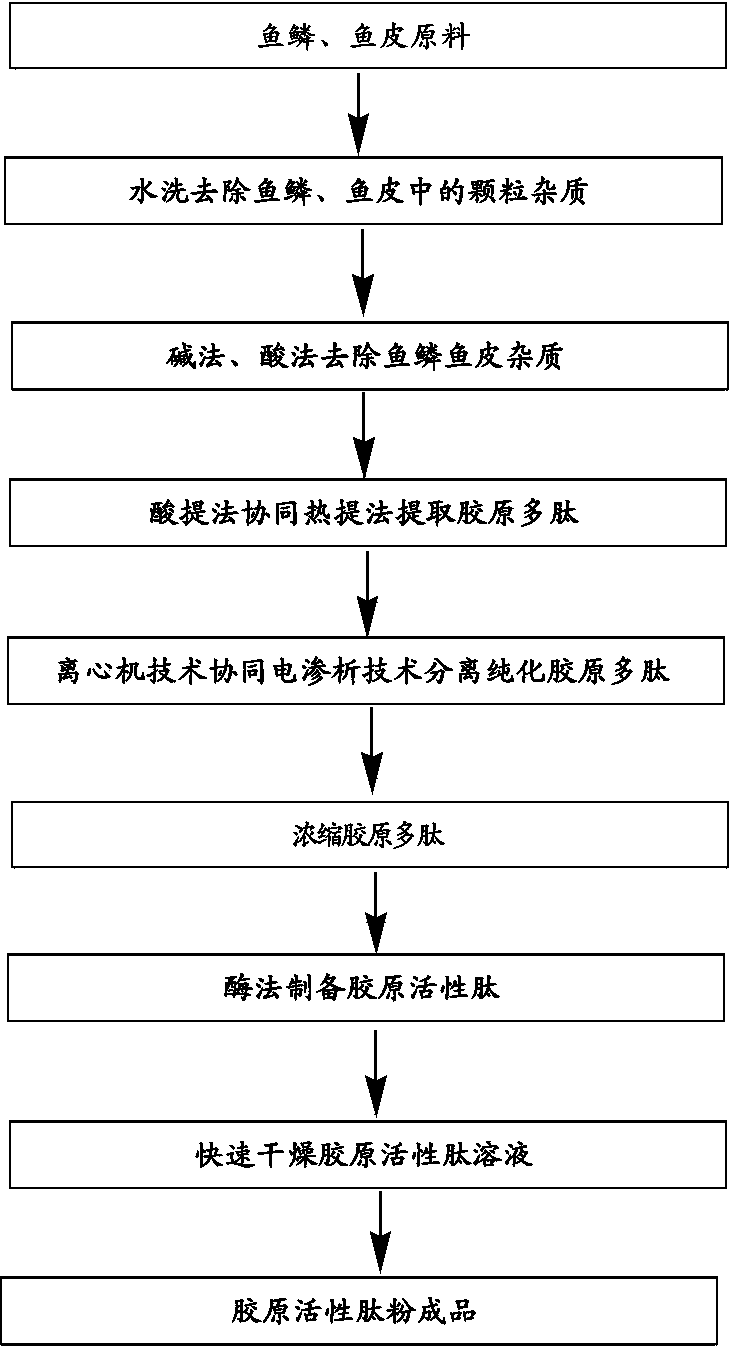

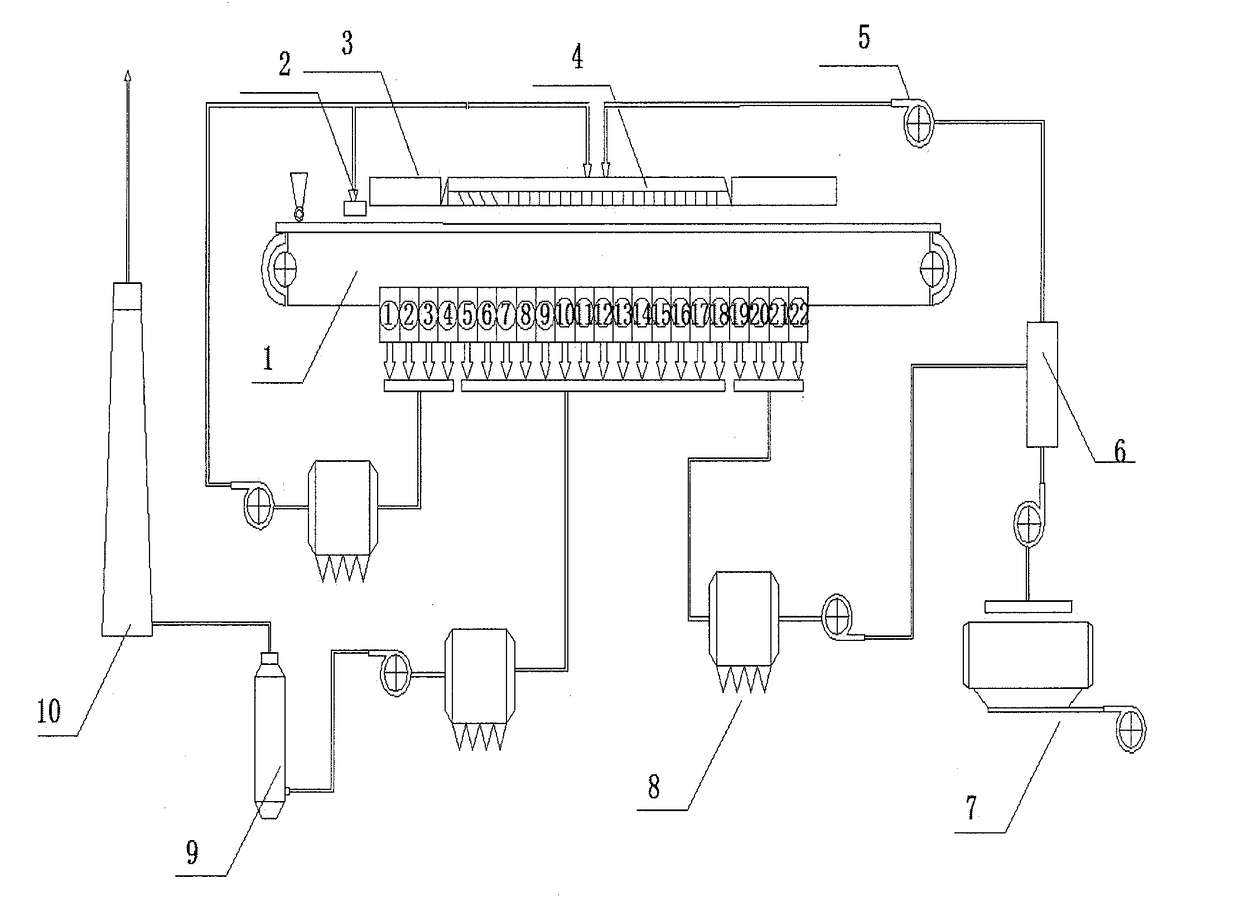

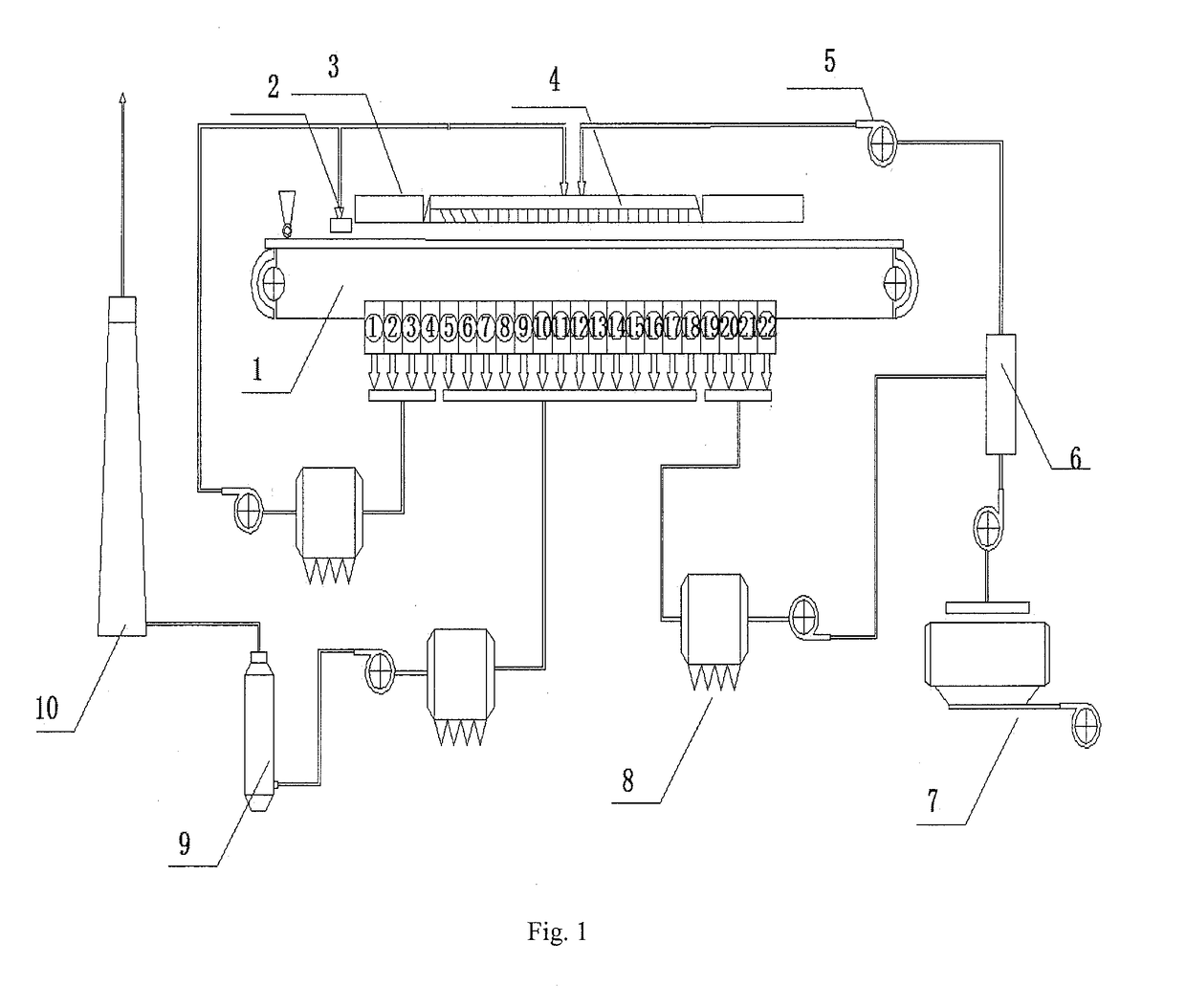

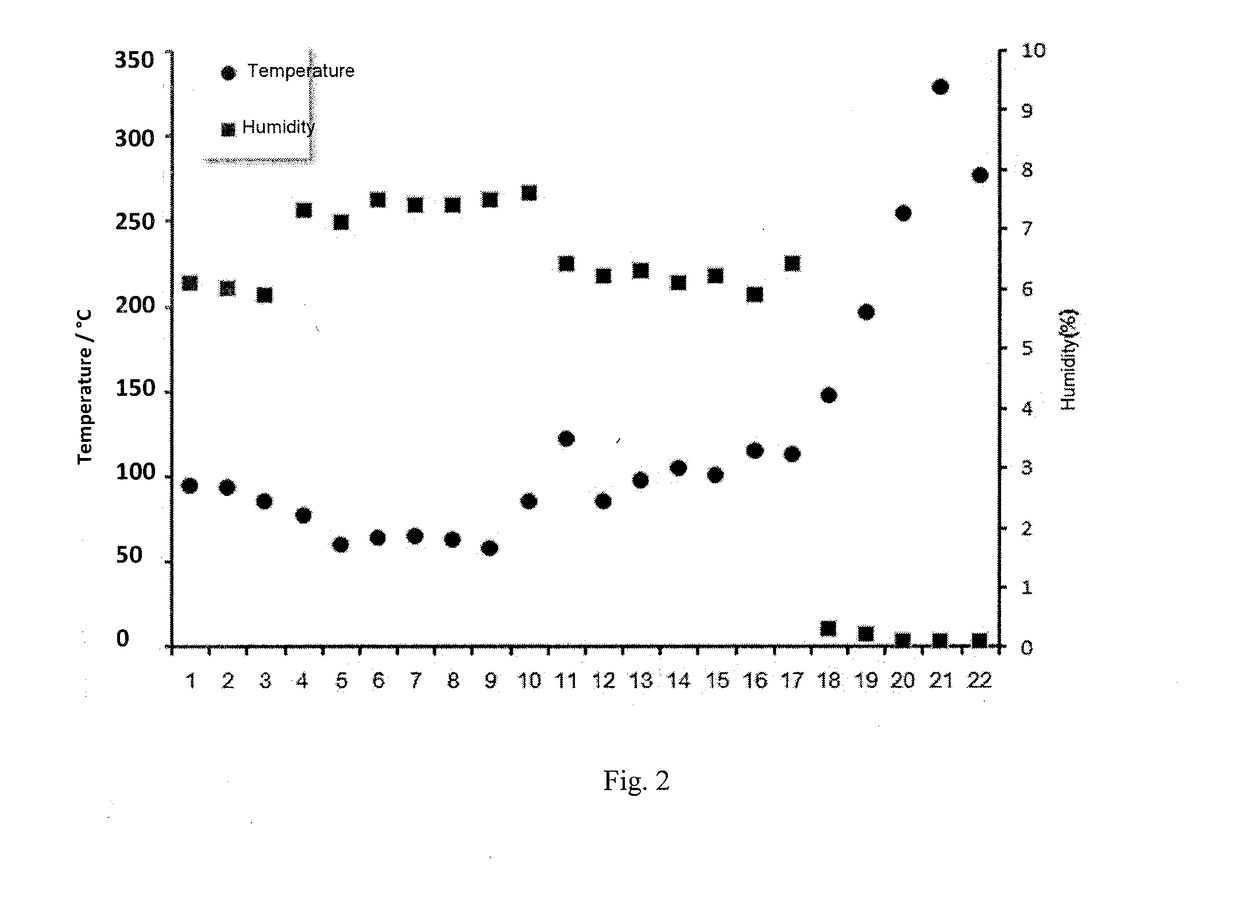

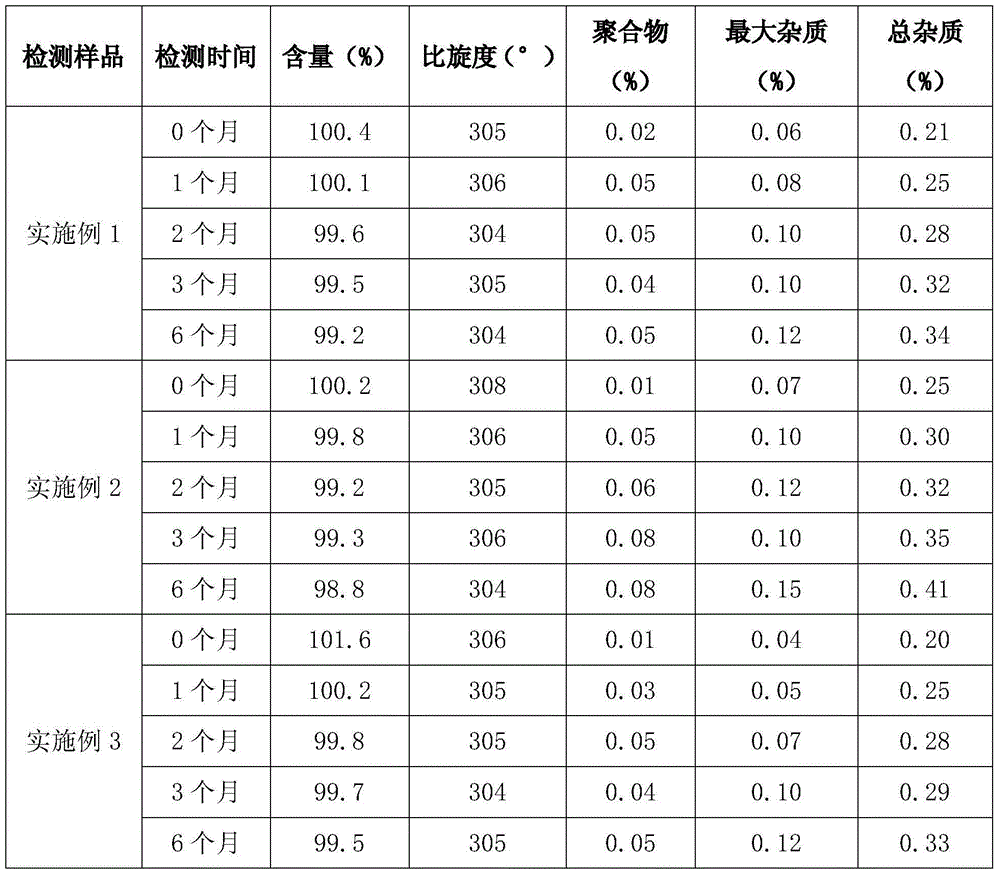

Fish scale and fish skin collagen active peptide manufacturing technology

InactiveCN103352066AImprove extraction efficiencyReduce production cost and environmental protection costFermentationEngineeringElectrodialysis

The invention discloses a fish scale and fish skin collagen active peptide manufacturing technology and belongs to the field of biotechnology. The manufacturing technology comprises the following steps: (1), pre-processing fish scale and fish skin; (2), extracting collagen polypeptide through a method of combining acid extraction method and a heat extraction method, with the extraction yield over 95%; (3), purifying collagen polypeptide extract; (4), concentrating collagen polypeptide solution; (5), preparing collagen bioactive peptide solution through an enzymic method; (6), drying the solution to obtain a finished product of collagen bioactive peptide powder with the total nitrogen content higher than 14% and the relative molecular mass smaller than 10kD. In the technology, marine fish residual wastes are fully utilized, wastes are changed into valuable, and a new way of developing and utilizing sea residual wastes with high values is developed; a separation technology system integrating a centrifugal machine technology and an electrodialysis technology is established, and the purpose of separating excess acid and collagen bioactive peptide and recycling recovered acid is realized, so that the manufacturing cost and the cost of environmental protection are reduced remarkably; the produced collagen bioactive peptide is high in total nitrogen content, high in security, high in biological activity and low in average relative molecular mass.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

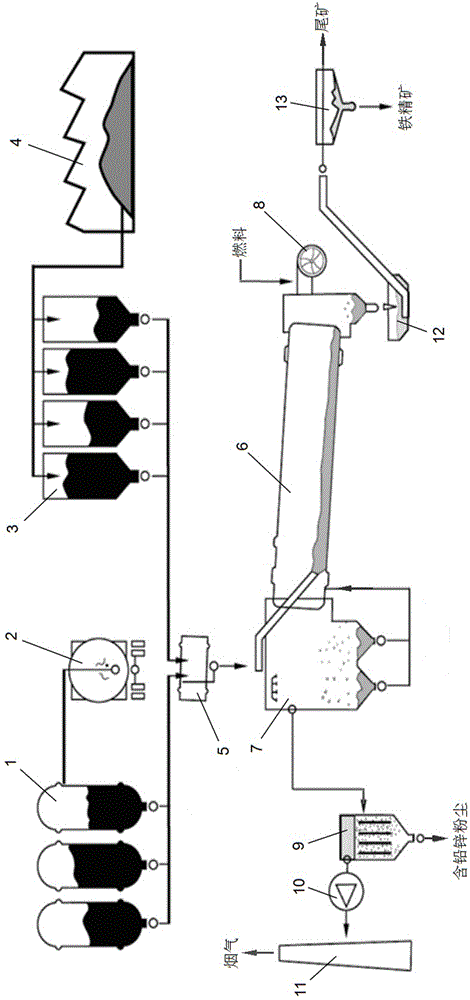

Process and system for waste heat grading cyclic utilization and pollutant emission reduction of sintering flue gas

InactiveUS20170108275A1Reduce loadReduce environmental costsGas treatmentDispersed particle separationLow oxygenMaterials science

The present invention provides a process and system for waste heat grading cyclic utilization and pollutant emission reduction of sintering flue gas, in which the sintering flue gas is divided into low-temperature, high-oxygen, low-humidity section sintering flue gas; middle-temperature, low-oxygen, high-humidity section sintering flue gas; and high-temperature, high-oxygen, low-humidity section sintering flue gas according to the emission characteristics of temperature, oxygen content and humidity of the flue gas. The low-temperature, high-oxygen, low-humidity section sintering flue gas is led into the sintering machine for hot air ignition and hot air sintering; the middle-temperature, low-oxygen, high-humidity section sintering flue gas is subjected to dust removal and desulfurization treatments; the high-temperature, high-oxygen, low-humidity section sintering flue gas is mixed with exhaust gas of a cooler and then is led into the sintering machine for hot air sintering. The present invention can conduct grading utilization to the flue gas and recycle low-temperature sensible heat in flue gas, making the carbon monoxide left in the sintering flue gas burn again and thus saving energy consumption in the sintering process, on the premise that the quality and yield of the sintered ores are ensured. The present invention can also conduct cyclic utilization to the flue gas and thereby reduce pollutant emissions and the total emissions of sintering flue gas per unit of the sintered ores. Thus, the present invention has a very high value on energy saving and emission reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

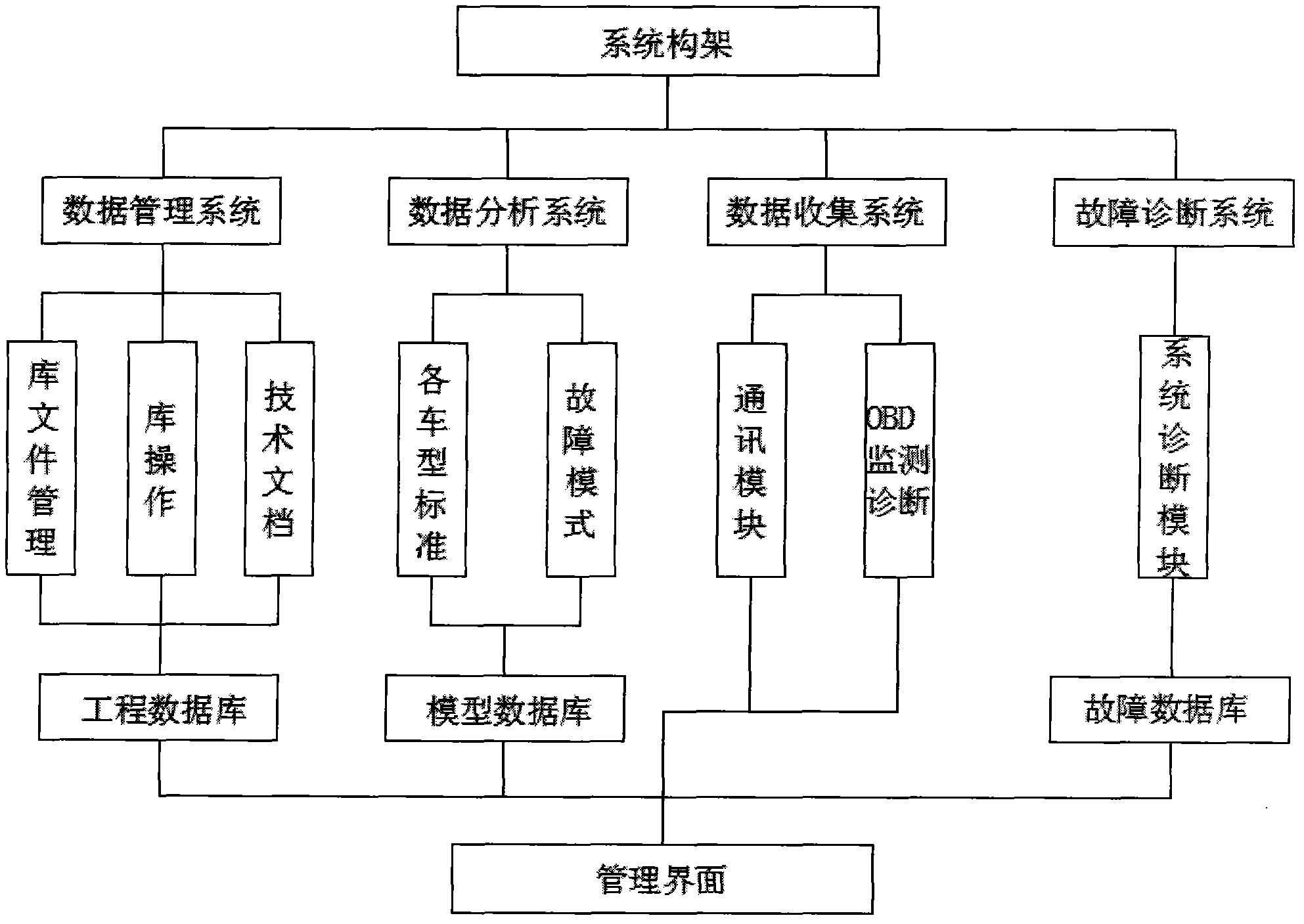

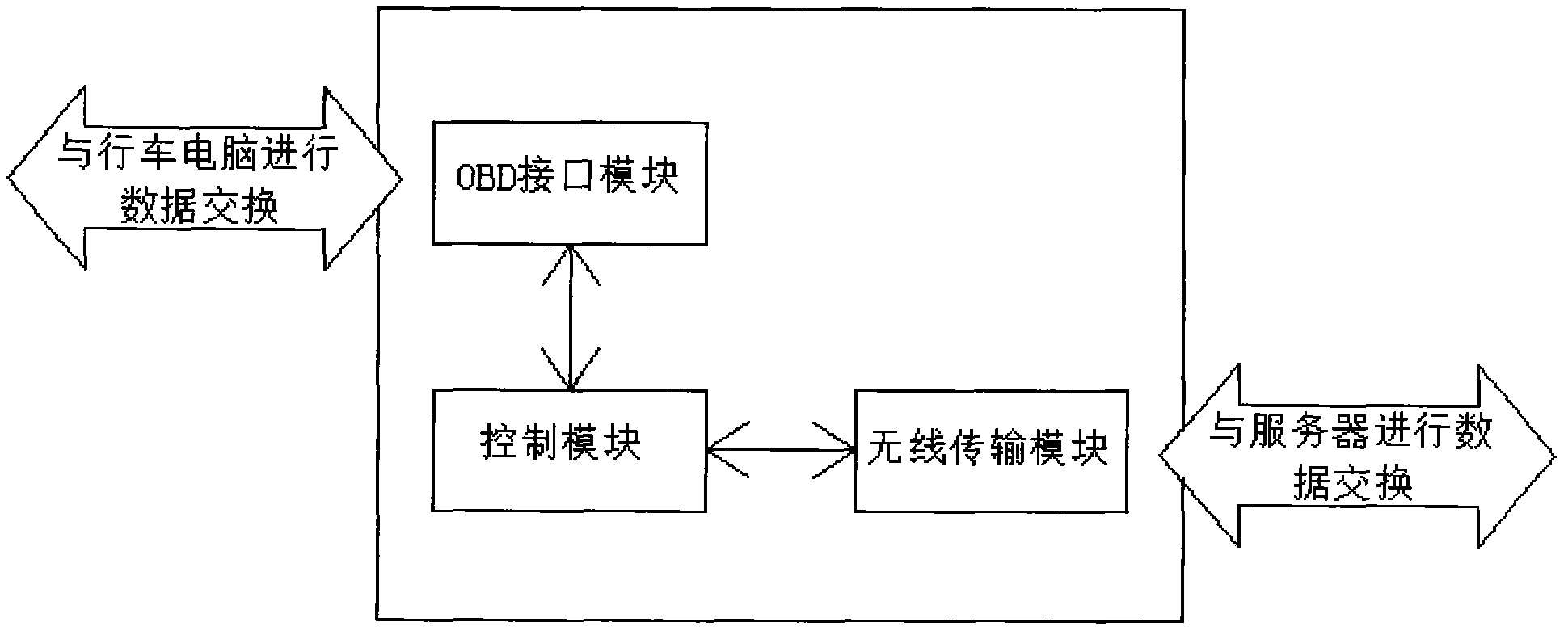

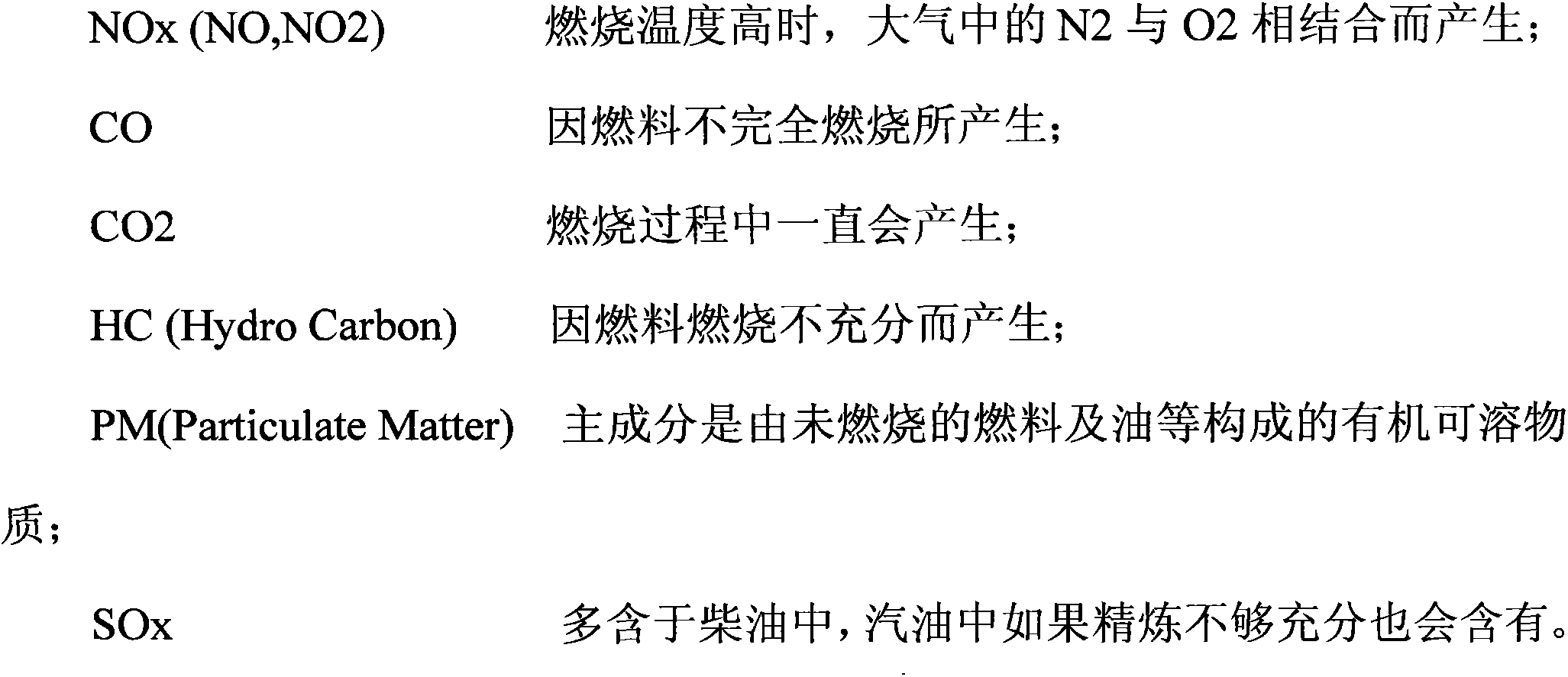

Monitoring system and method for the pollutants produced by automobile exhaust emissions in the air pollutants

InactiveCN104074580AEmission complianceEasy to track in timeInternal combustion piston enginesExhaust apparatusProper timeAtmospheric pollution

The invention discloses a monitoring system and method for the pollutants produced by automobile exhaust emissions in the air pollutants. The standard emission database of all automobile types is established, OBD monitoring and diagnosis devices are mounted on all automobiles for transmitting automobile emission data, and a remote-control data monitoring center monitors automobile exhaust by analyzing the automobile data and notifies a driver the emission is excessive. Compared with the prior art, the method and system has the advantages that the automobile exhaust emission situation is analyzed through the engine data during driving, the automobile exhaust emission can be monitored in real time, emission of the automobiles with the OBD monitoring and diagnosis devices are monitored for 7*24 hours in an uninterrupted manner, emission data can be counted, automobiles with abnormal emission can be found and necessarily controlled in proper time, the automobile owner can be contacted timely to repair the automobiles according to the problems, and the atmosphere pollution caused by automobile abnormity can be prevented.

Owner:孙磊

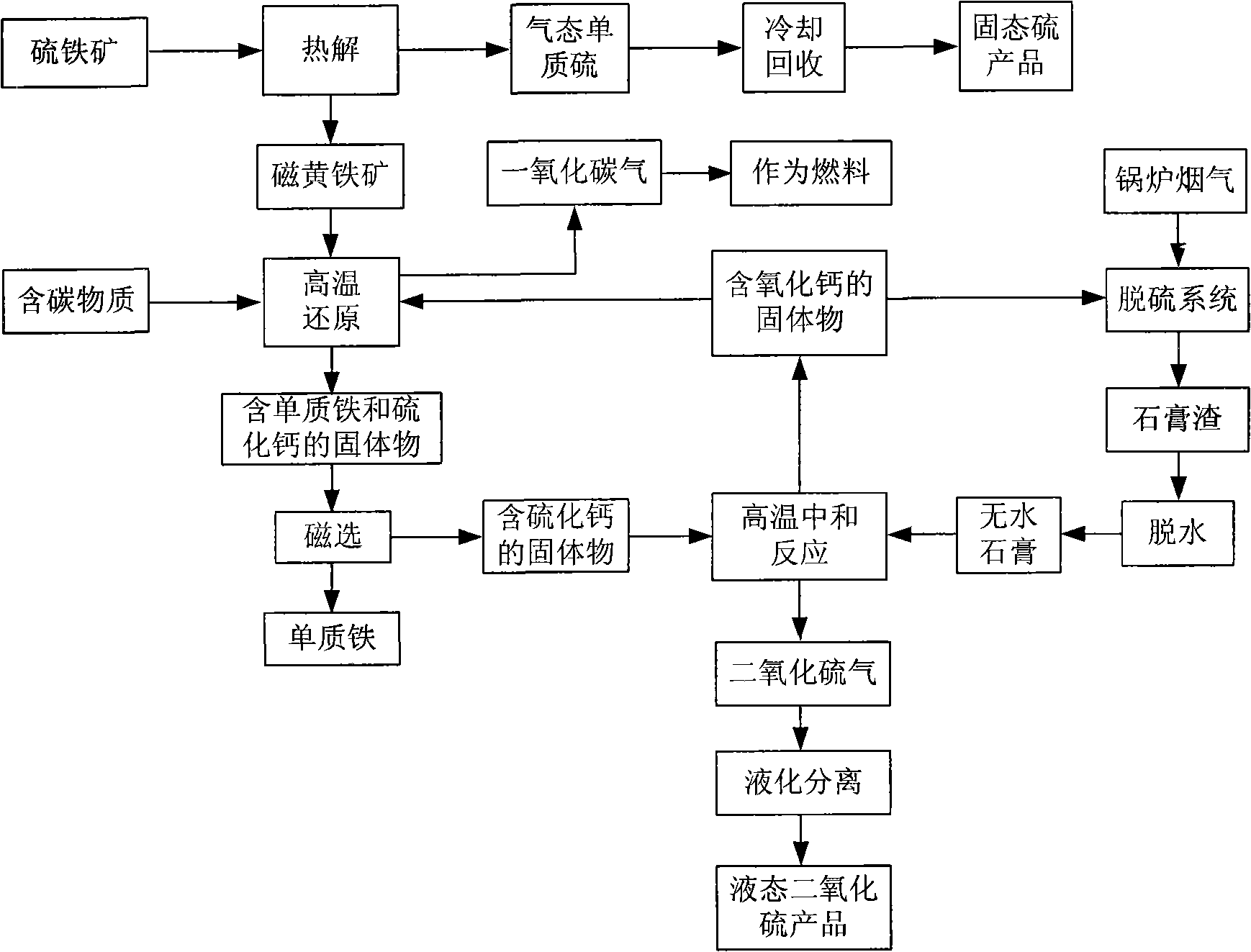

Method for utilizing comprehensive resource of sulfur-containing solid waste

InactiveCN101570341ATo promote metabolismSave resourcesDispersed particle separationSulfur compoundsSulfur containingPollution

The invention discloses a method for utilizing comprehensive resource of sulfur-containing solid waste, which comprises the following steps: (1) pyrolyzing sulfurous iron ore to obtain pyrrhotite and an elemental sulfur product; (2) mixing the pyrrhotite, a carbon-containing substance and a calcium-containing substance to carry out reduction reaction under a high temperature to obtain a solid mixture of elemental iron and calcium sulfide; (3) magnetically separating the solid mixture, and separating and recovering the solid mixture to obtain the elemental iron; (4) mixing and heating the solid containing the calcium sulfide and dehydrated gypsum to obtain tail gas containing SO2 and solid containing calcium oxide; and (5) separating the tail gas containing the SO2 through liquefying to obtain a liquid SO2 product, and using the solid containing the calcium oxide as the calcium-containing substance to participate in the reaction of the step (2) and as flue gas desulfurizing agent for cyclically utilization. The method solves the problems of occupied floor due to the stacking of desulfurization gypsum and coal washing sulfurous iron ore, environment pollution and potential safety hazard, makes full use of calcium, sulfur and iron resources rich in the wastes, and can realize recycling economy and clean production.

Owner:HUAZHONG UNIV OF SCI & TECH

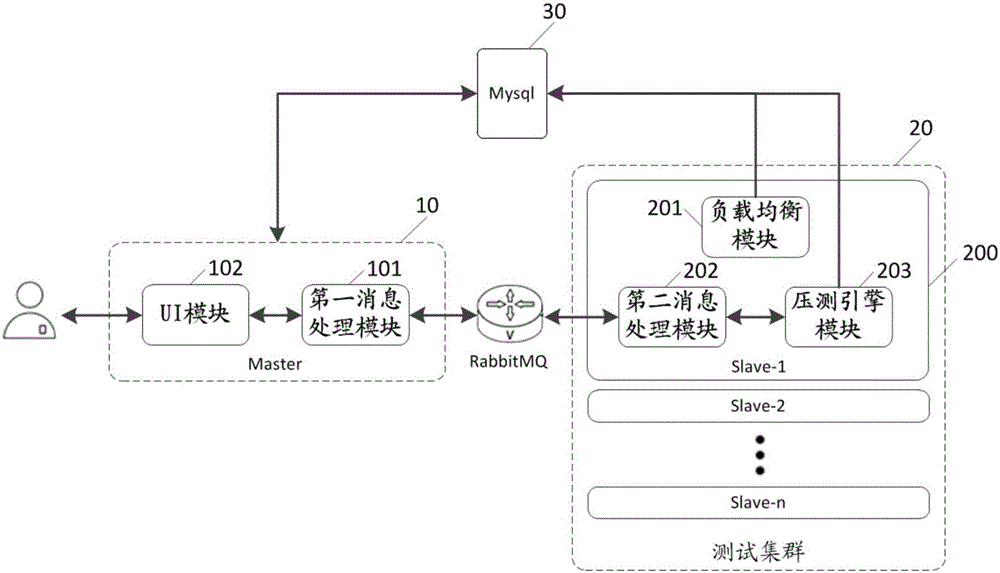

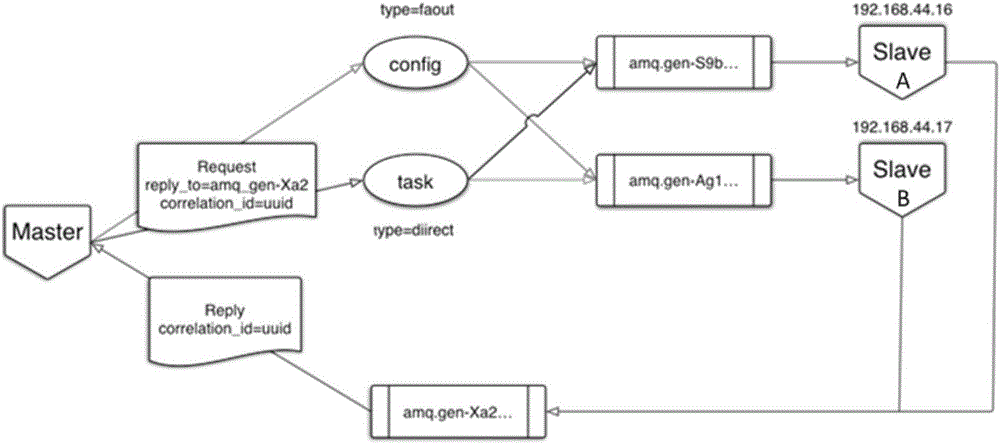

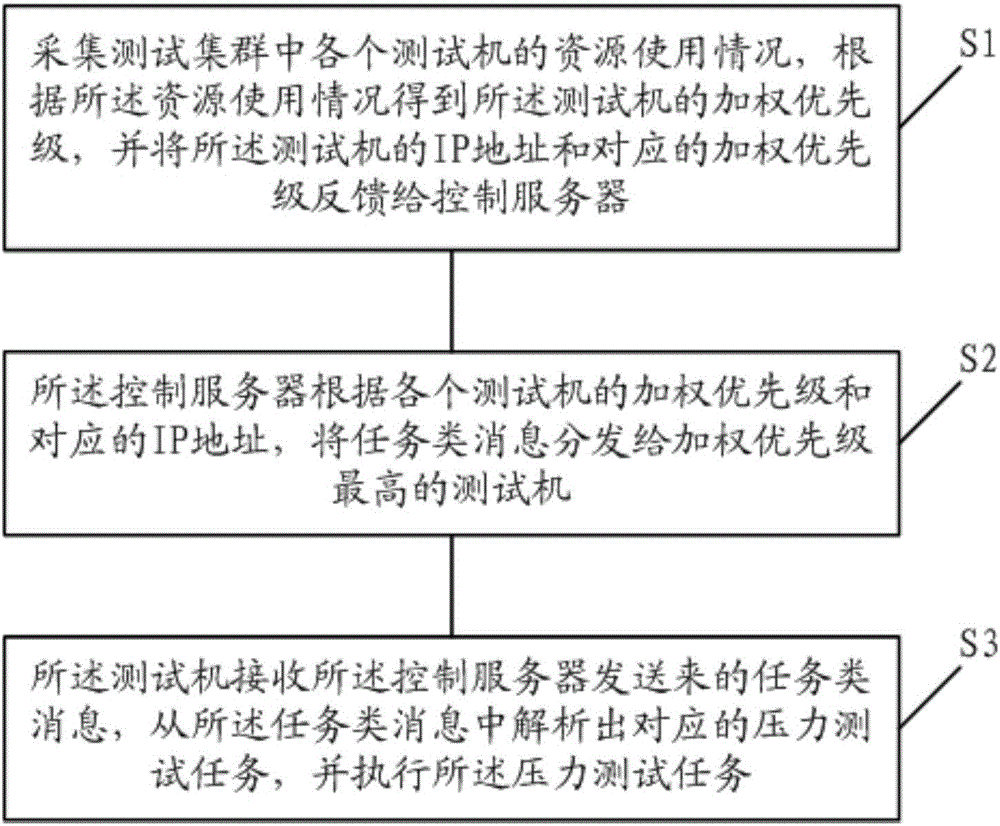

Distributed pressure test method and system

InactiveCN106649088AImprove pressure measurement efficiencyImprove resource utilizationResource allocationSoftware testing/debuggingTest efficiencyIp address

The invention discloses a distributed pressure test method and system. The system comprises a control server and a test cluster consisting of at least two test machines, wherein each test machine comprises a load balance module, which is used for acquiring a resource usage state of the test machine and obtaining a weighted priority of the test machine according to the resource usage state; the control server comprises a first message processing module, which is used for distributing a task type message to the test machine with the highest weighted priority according to the weighted priorities of all the test machines and corresponding IP addresses; each test machine further comprises a second message processing module and a pressure test engine module; the second message processing module is used for receiving the task type message sent by the control server and analyzing a corresponding pressure test task from the task type message; and the pressure test engine module is used for executing the pressure test task. By adopting the method and the system, the pressure test efficiency can be improved and the load balance of the pressure test is realized.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Organic fertilizer prepared by waste phosphate tailing powder and preparation method thereof

The invention discloses organic fertilizer prepared by waste phosphate tailing powder, which comprises the following raw materials by weight: 20-35 parts of phosphate tailing powder, 20-40 parts of crop straw powder, and 20-40 parts of soy sauce residues. The preparation method comprises the following steps: well mixing the crop straw powder and the soy sauce residues according to the weight ratios, adding water with a material-water ratio of 1:2-1:3, inoculating 4-5% of aspergillusniger, 2-3% of lactobacillus, 3-4% of acetobacter, and 4-6% of bacillus megaterium, performing fermentation at 28-32 DEG C for 3-5 days; adding 15-20% of water, performing fermentation at 50-65 DEG C for 10-15 days; drying, and packaging. The organic fertilizer of the invention has comprehensive nutrition, and lasting fertilizer efficiency, can improve the physical and chemical properties and biological activity of soil, and has low production cost.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

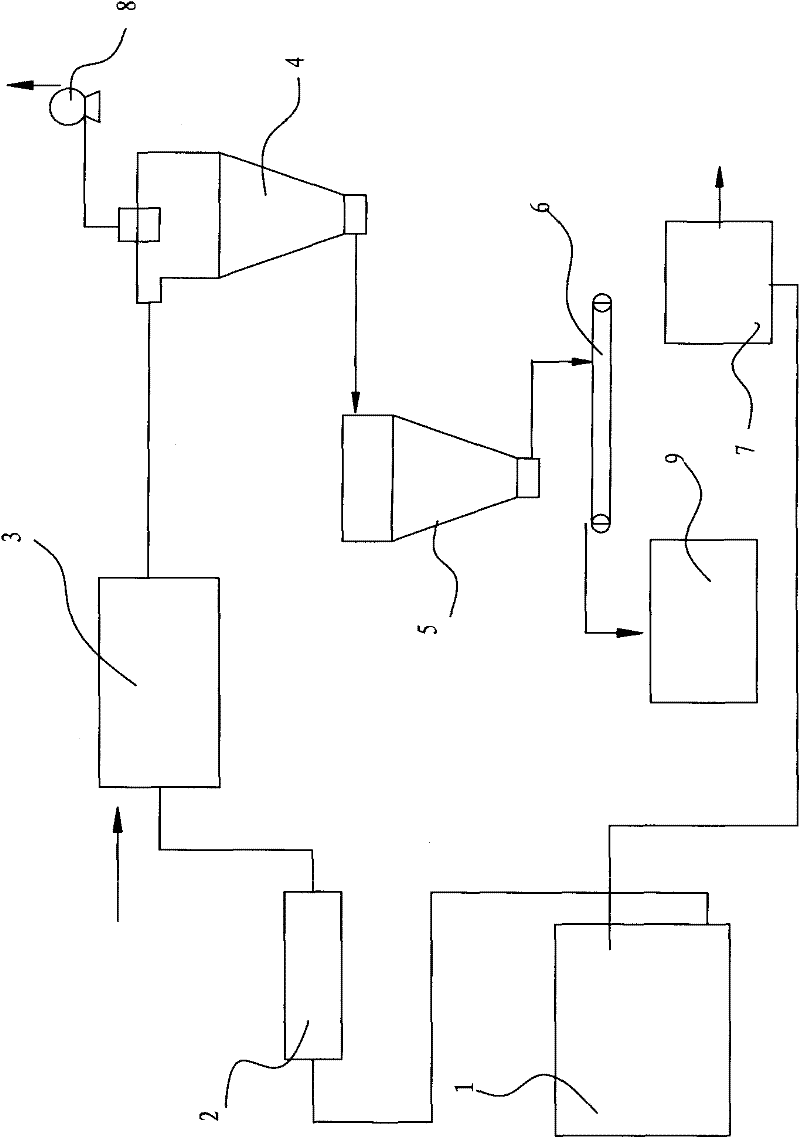

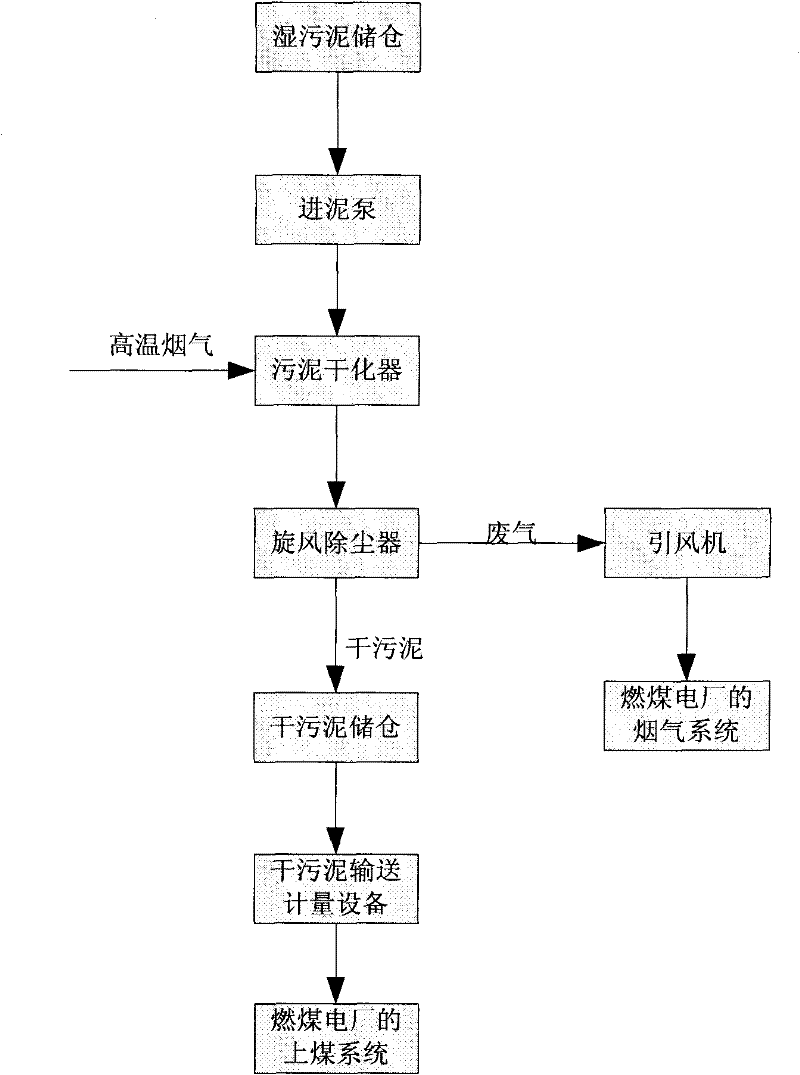

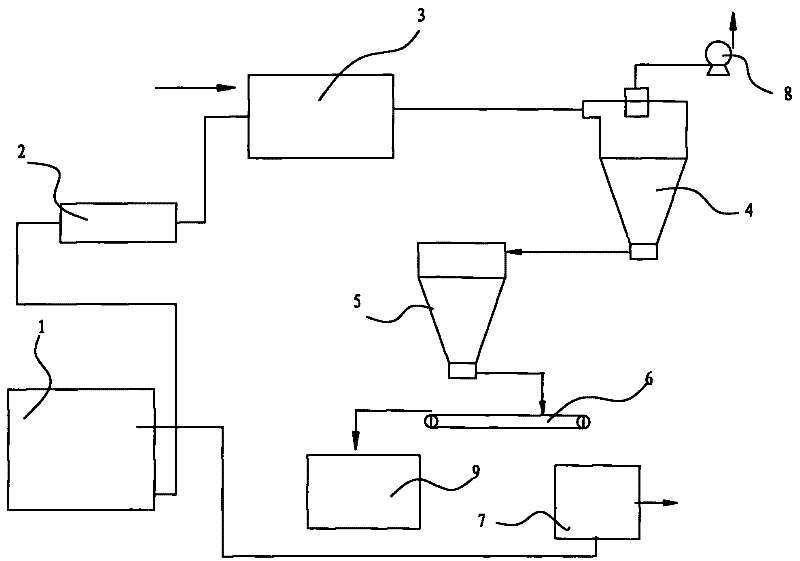

Sludge treatment and disposal system and method

ActiveCN102211845AReduce drying costsReduce environmental costsSludge treatment by de-watering/drying/thickeningIncinerator apparatusCyclonic spray scrubberDewatered sludge

The invention discloses a sludge treatment and disposal system, which is used for conveying dewatered sludge discharged by a sludge plant to a coal fired power plant to be combusted in a blended way after the dewatered sludge is dried. The sludge treatment and disposal system comprises a wet sludge storage bin, a sludge dryer, a sludge feeding pump, a cyclone dust collector, a dried sludge storage bin, dried sludge conveying equipment and a draught fan. The sludge feeding pump is respectively connected with the wet sludge storage bin and the sludge dryer. The cyclone dust collector is communicated with the sludge dryer so as to perform gas-solid separation on dried sludge and waste gas of the dryer. The dried sludge storage bin is connected with the cyclone dust collector so as to receivethe separated dried sludge. The dried sludge conveying equipment is connected with the dried sludge storage bin and used for conveying the dried sludge to a coaling system of the coal fired power plant. The draught fan is connected with a waste gas hole of the cyclone dust collector. According to the sludge treatment and disposal system disclosed by the invention, the sludge treatment and disposal cost can be effectively reduced; vast high-quality resources can be saved; and a way of using waste to treat waste is realized. The invention further discloses a sludge treatment and disposal method.

Owner:国能朗新明环保科技有限公司

Pervious concrete comprising a geopolymerized pozzolanic ash binder

InactiveUS8038789B2Low costImprove performanceSolid waste managementCement productionAluminateRoad surface

Owner:CERAMTEC

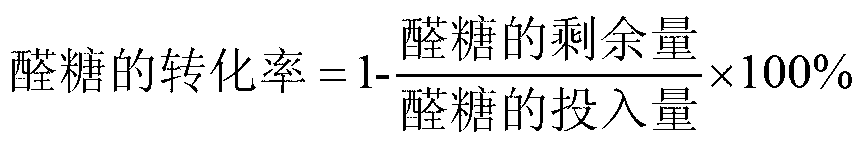

Method for preparing ketose by utilizing aldose

ActiveCN103288887AMild reaction conditionsHigh activitySugar derivativesCarbonyl group formation/introductionSolventChemistry

The invention discloses a method for preparing ketose by utilizing aldose. The method for preparing ketose by utilizing aldose comprises the following steps of: in an organic solvent, carrying out isomerization reaction on aldose under the catalytic action of a molecular sieve based catalyst to obtain glucoside; and carrying out in-situ hydrolysis on the glucoside under the catalytic action of water and the molecular sieve based catalyst to obtain ketose. The invention provides a method for producing ketose by taking low-cost and high-efficiency aldose as a raw material. The method for preparing ketose by utilizing aldose has the advantages that reaction conditions are mild, activity is high, and recovery rates of the catalyst and the solvent are high; the amount of byproducts is low, and yield of a target product is 81%; a molecular sieve and alcohol are respectively taken as the catalyst and the solvent, and economic and environmental costs are low; a heterogeneous catalysis system is adopted, products and the catalyst can be easily separated, aftertreatment is simple, and industrialization is easy to realize.

Owner:PEKING UNIV

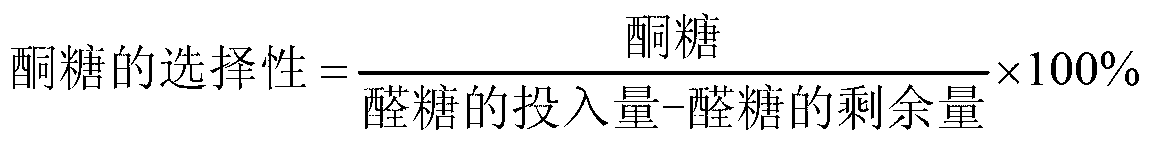

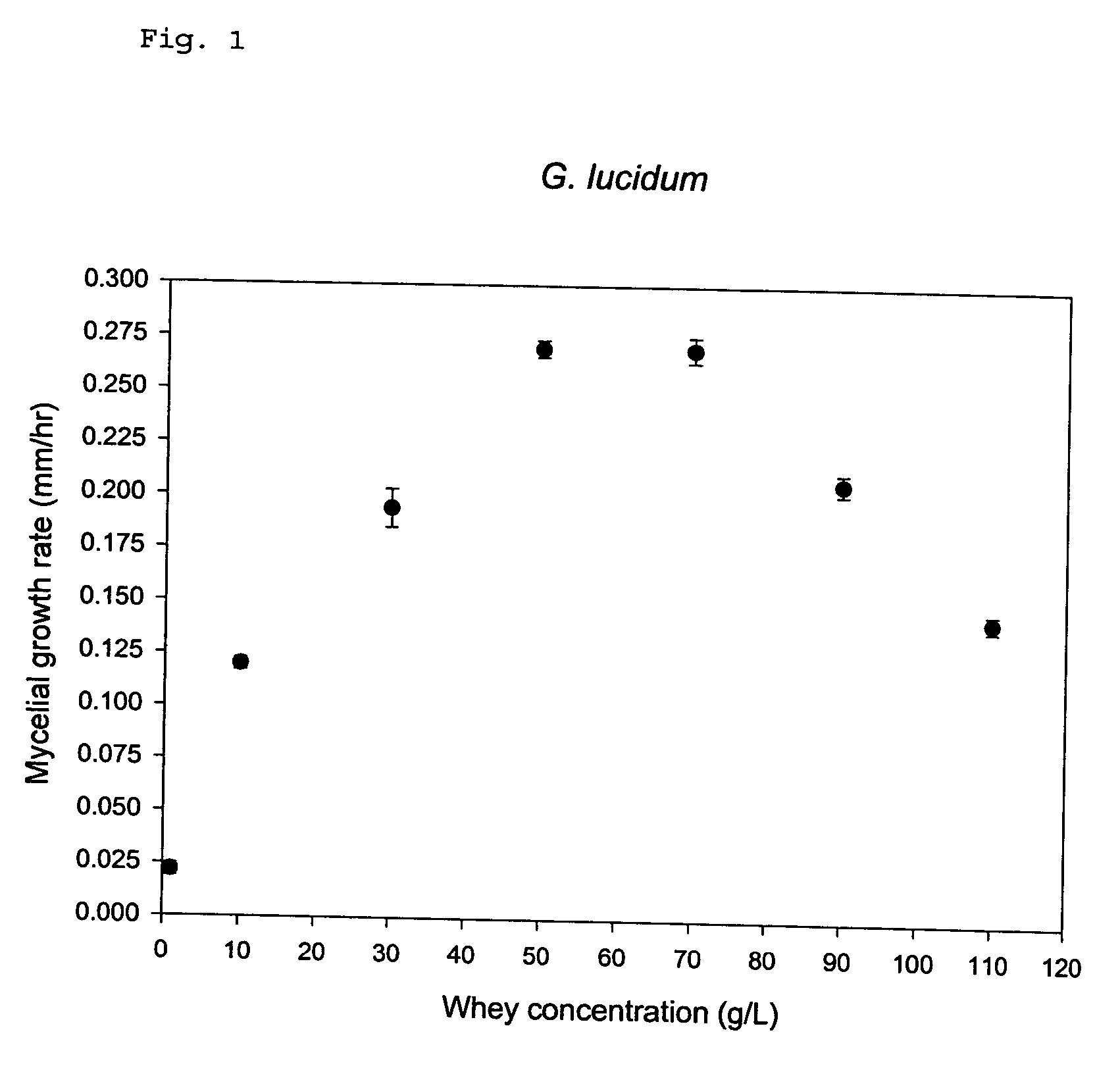

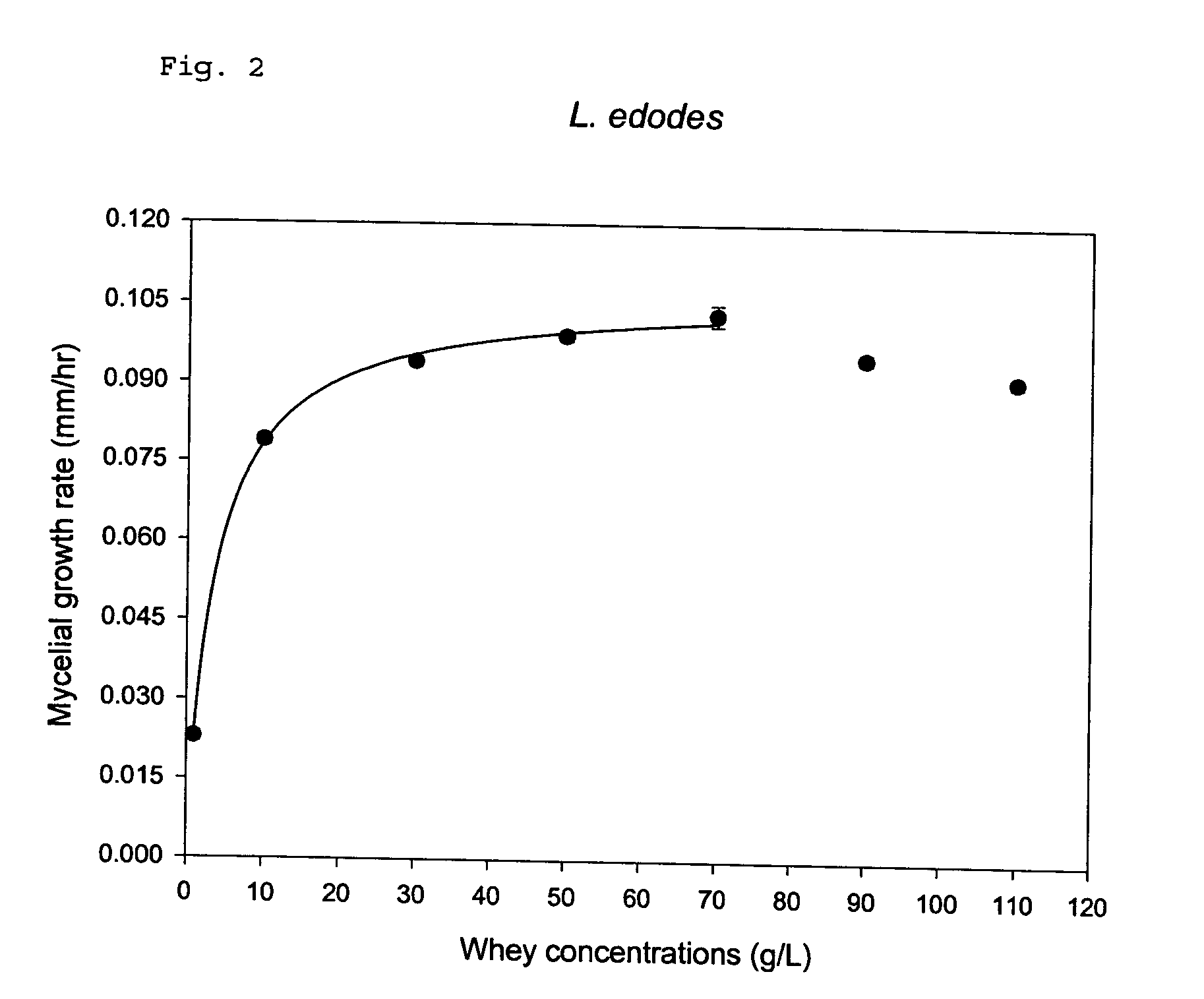

Biotreatment of cheese-processing wastewater by cultivating mushroom mycelia

InactiveUS20040035047A1Effective treatmentReduce environmental costsWhey manufactureCultivating equipmentsResource recoverySludge

Disclosed herein is a biological method for aerobically treating whey using mushroom mycelia wherein the whey can be biologically treated at a disposal rate comparable to conventional methods. According to the method, since environmentally unfriendly sludge is not discharged, post-treatment operations in connection with the disposal of sludge can be simplified. Therefore, the method can lower environmental costs and further enables the economical cultivation of mushroom mycelia. Furthermore, the method has an advantage in terms of resource recycling.

Owner:ENVITECH +1

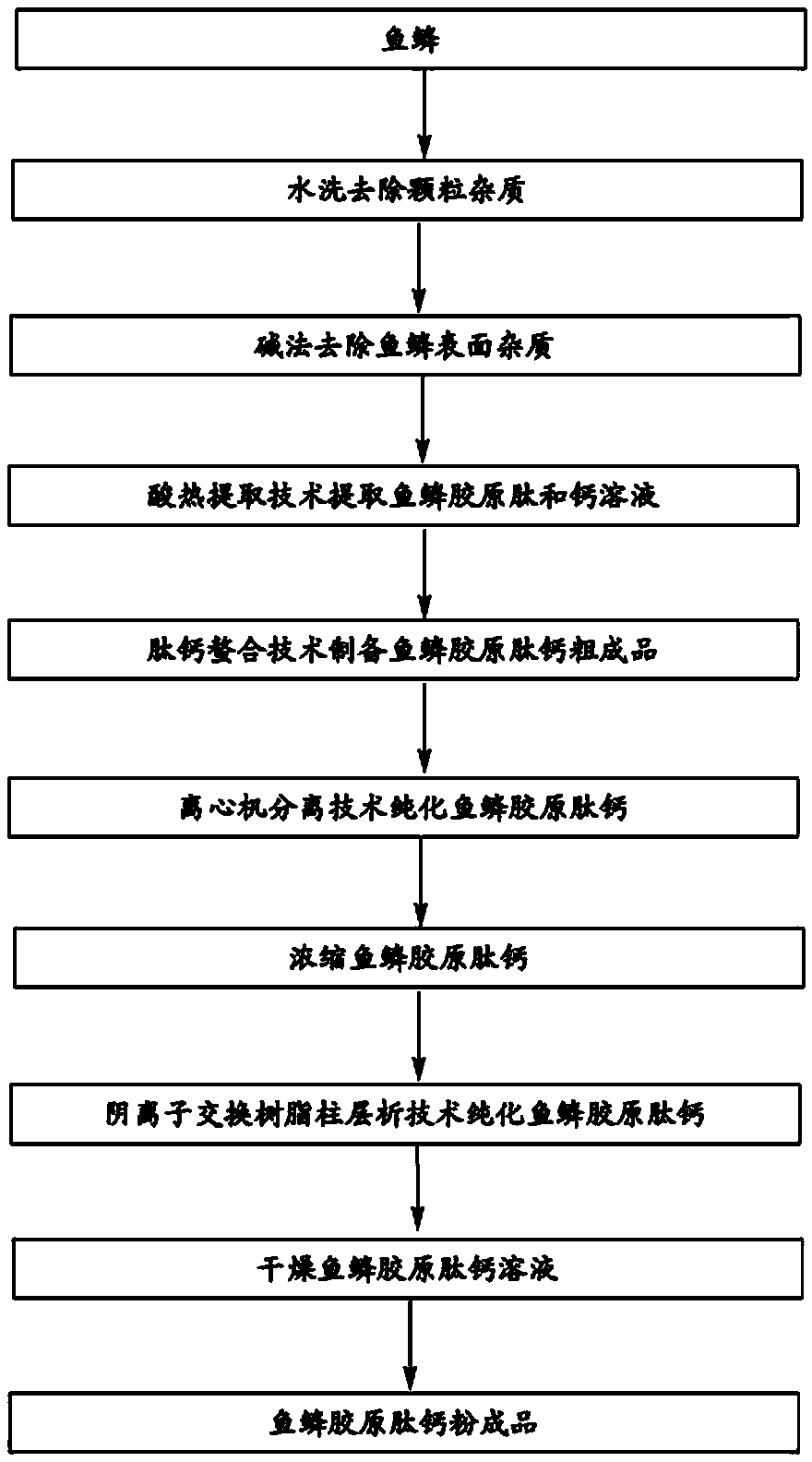

Production process for fish scale collagen peptide calcium

InactiveCN103462018AReduce manufacturing costImprove technical levelFood preparationPeptideColumn chromatography

The invention discloses a production process for fish scale collagen peptide calcium, and belongs to the technical field of biology. The production process comprises the following steps: (1) pretreating fish scale; (2) extracting fish scale collagen peptide and a calcium solution by an acid heat extraction technology; (3) preparing crude finished fish scale collagen peptide calcium by a peptide calcium chelating technology; (4) removing solid impurities by a centrifuge separation technology; (5) concentrating the fish scale collagen peptide calcium; (6) purifying the fish scale collagen peptide calcium by an anion exchange resin column chromatography technology to obtain a fish scale collagen peptide calcium solution; (7) drying the solution to obtain finished fish scale collagen peptide powder with the calcium content of greater than 1 percent and the protein content of greater than 85 percent. According to the process, fish scrap, namely fish scale, serves as a raw material; an exogenous calcium salt is not added; a separation and purification technology system integrated with the centrifuge separation technology and the anion exchange resin column chromatography technology is established, an organic solvent is not required to be used, the produced fish scale collagen peptide calcium product has high calcium content, high bioavailability and high safety; both the peptide and the calcium can be supplemented, so that the fish scale collagen peptide calcium has a great market prospect.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

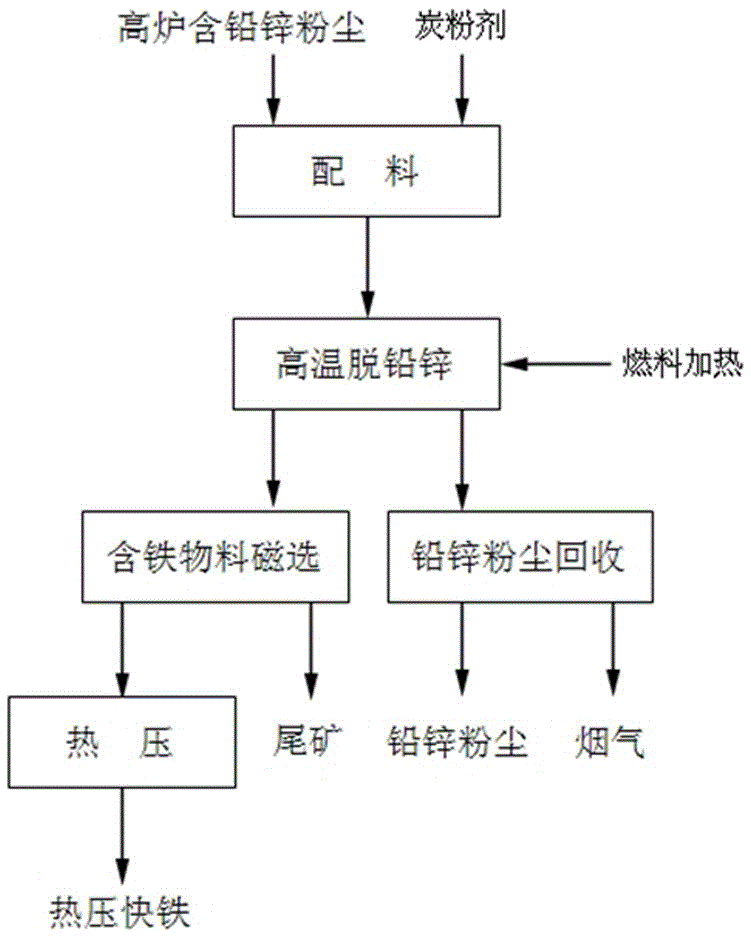

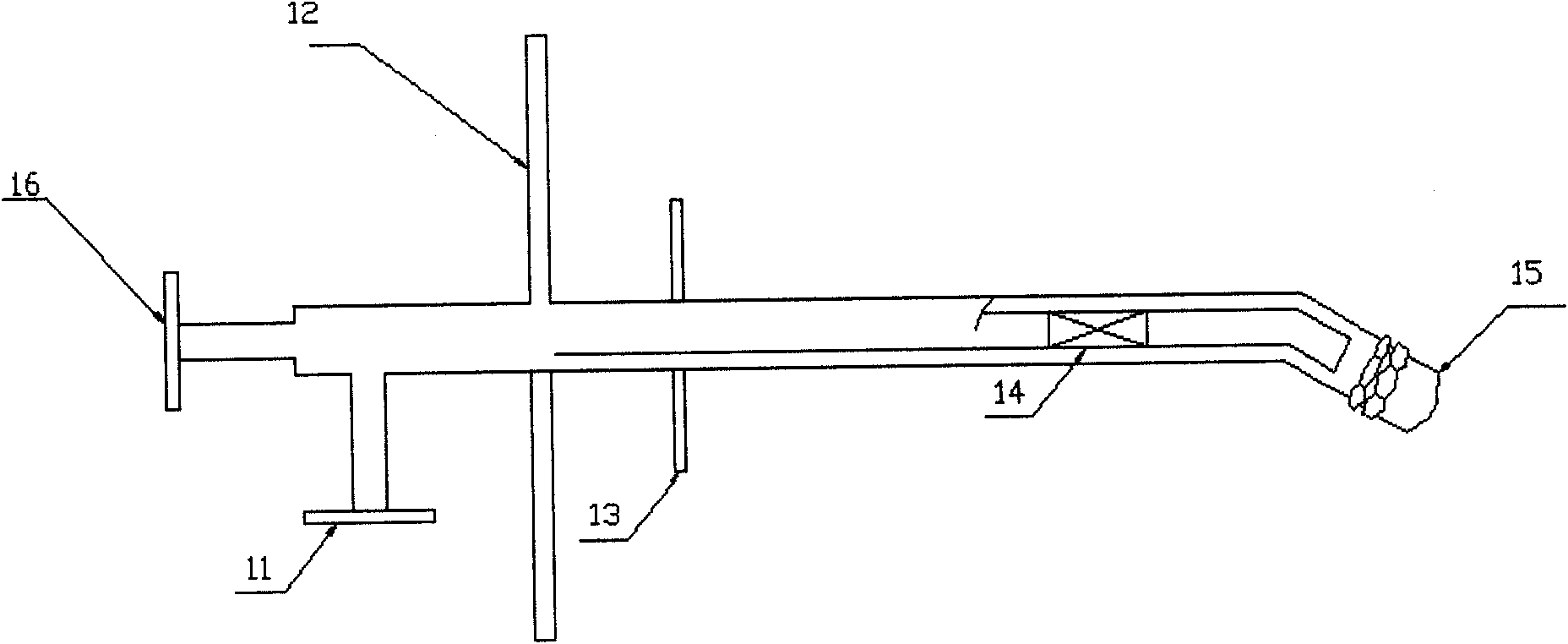

Method for comprehensively recycling lead and zinc containing blast furnace dust

ActiveCN105483371AComplete restorationAvoid secondary pollutionProcess efficiency improvementZincCyclonic spray scrubber

The invention discloses a method for comprehensively recycling lead and zinc containing blast furnace dust and belongs to the technical field of iron and steel smelting. The method comprises the following steps: the step of batching: evenly mixing reclaimed lead and zinc containing blast furnace dust and a carbon powder agent according to the weight ratio of 10 to 1-3 to prepare pellets; the step of removing lead and zinc at a high temperature: adding the pellets into a rotary kiln from a kiln tail, spraying fuel from a kiln head to heat the pellets to reach the temperature of 900 to 1300 DEG C and smelting for 30 to 50 min, after smelting, discharging an obtained lead and zinc removed iron containing material from the kiln head and cooling to reach a normal temperature, and discharging dust and gas from the kiln tail; the step of lead and zinc dust recycling: collecting and sending the gas and the dust discharged from the kiln tail of the rotary kiln into a cyclone dust collector to obtain lead and zinc containing dust through catching, and externally discharging residual smoke; and the step of magnetic separation of an iron containing material: carrying out magnetic separation on the lead and zinc removed iron containing material so as to obtain iron ore concentrate and tailings. The method provided by the invention is characterized in that the process is simple, more than 90 percent of lead and zinc in the lead and zinc containing blast furnace dust can be effectively removed, iron containing dust, lead and zinc can be comprehensively recycled, and energy conservation and emission reduction can be achieved.

Owner:红河钢铁有限公司

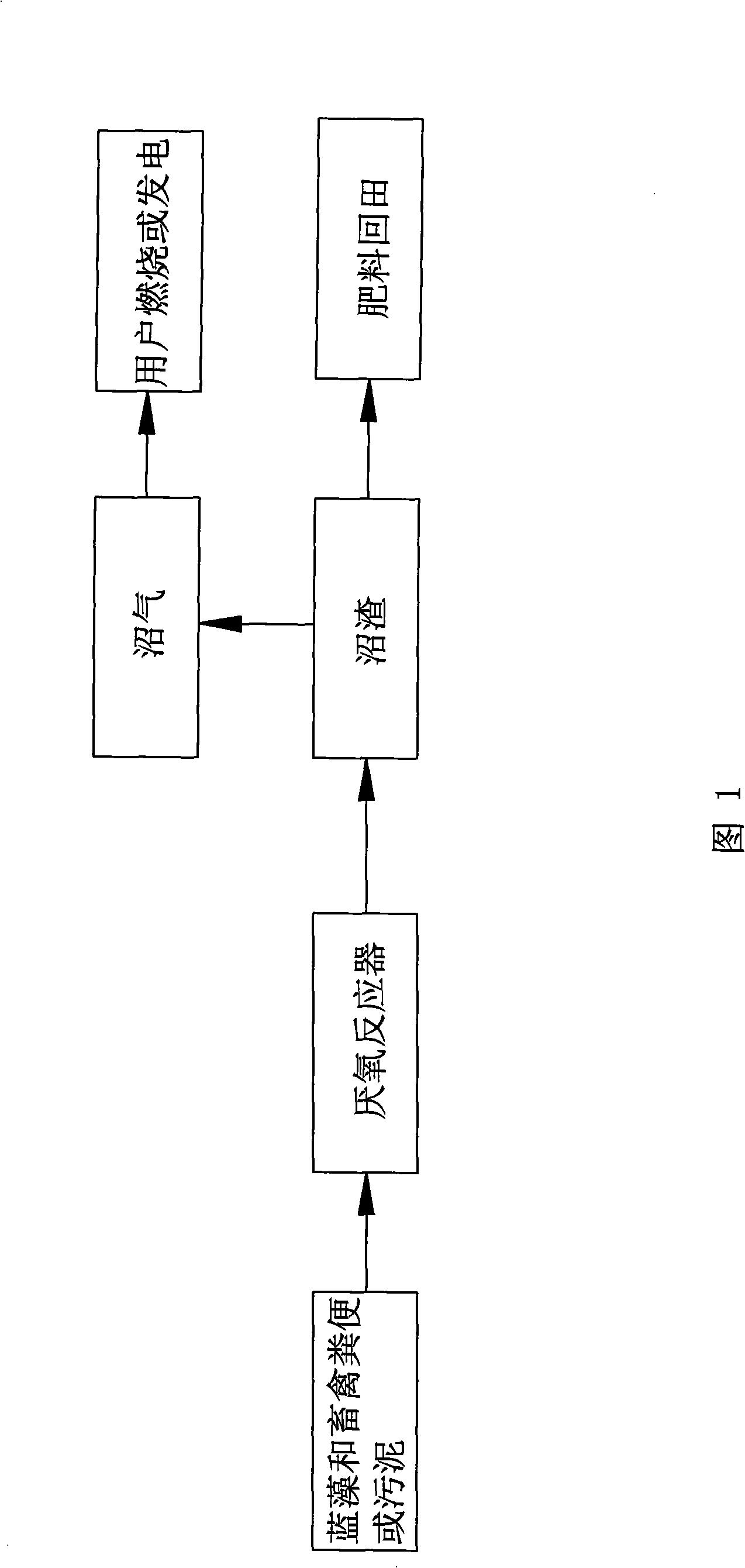

Improved blue algae treatment utilization method

InactiveCN101255075ABe harmlessDo resourcesBio-organic fraction processingWaste based fuelPhylum CyanobacteriaAutomatic control

This invention is an improved method for dealing with cyanobacteria, which can realize a harmless and resourceful treatment of cyanobacteria with automatic control, low operation cost, no secondary pollution and easy management. The method is characterized in that cyanobacteria and animal manure or sludge and other biomass can be used together as the fermentation material to obtain biogas through anaerobic digestion and the biogas is used to generate power or is burned for a direct use, and the biogas residue and biogas slurry are recovered to field or the biogas residue can be developed into feeds or organic fertilizers.

Owner:WUXI MASHENG ENVIRONMENT ENERGY TECH CO LTD

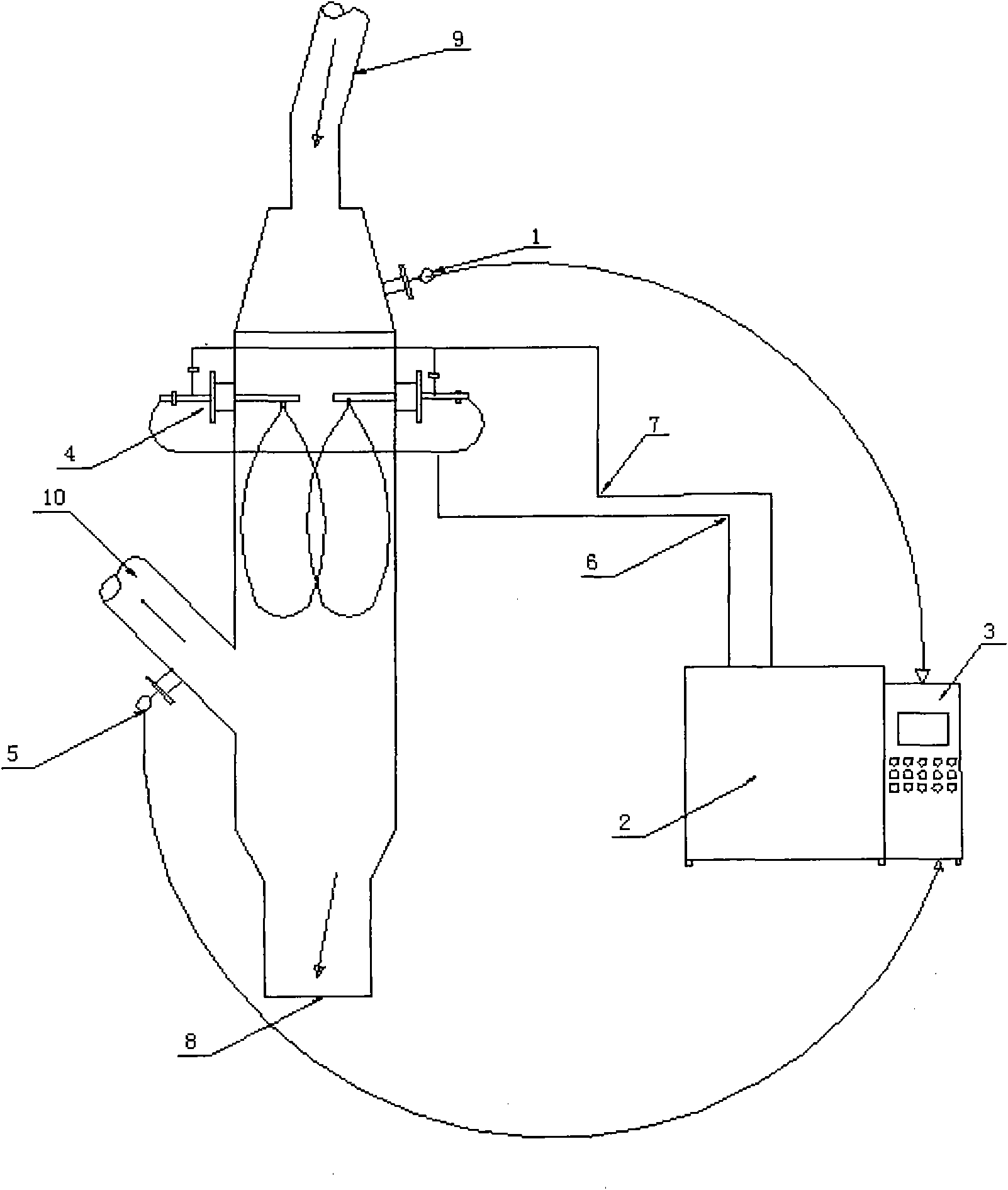

Quenching and tempering device for cooling high-temperature fume

InactiveCN101596389AEmission reductionReduce energy consumptionAuxillary pretreatmentEfficient regulation technologiesFrequency changerAir pump

The invention discloses a quenching and tempering device for cooling high-temperature fume, comprising a two-fluid electrical appliance controller, a water path and an air path arranged between a high-temperature fume inlet and a high-temperature fume outlet. The device of the invention is characterized in that a low pressure pump is arranged in the air path, a low pressure air path is combined into a water pipeline before a spray gun, two transducers are arranged to adjust the pressure and flow of a water pump and an air pump, the nozzle bore diameter is phi 6-7mm, and the spray particle diameter is smaller than 300 micrometers; a temperature sensor is respectively arranged at a wetting tower inlet and the fume outlet, and the outlet temperature is controller to 130-150 DEG C; an operation program is controlled to calculate the temperature difference of the fume inlet temperature and the fume outlet temperature, tower volume and spray fall height; two transducers are used for controlling the water pump and the air pump to automatically adjust operation power when low air pressure is 0.4-0.6MPa, and air flow quantity and water flow quantity are 5-25T / H. the particle diameter of sprayed water spray is small and even, which can better realize precise control to temperature and reduces atomization particle residence time and wet bottom danger. The dust removal device designed by the invention increases fume density and volume, lowers speed and improves dust removal function. In particular, the spray granularity is small, which can obviously control temperature and humidity, lower discharge Dioxin and furan mixed in dust and reduce environment protection cost.

Owner:SHENYANG XINCHENG TECH

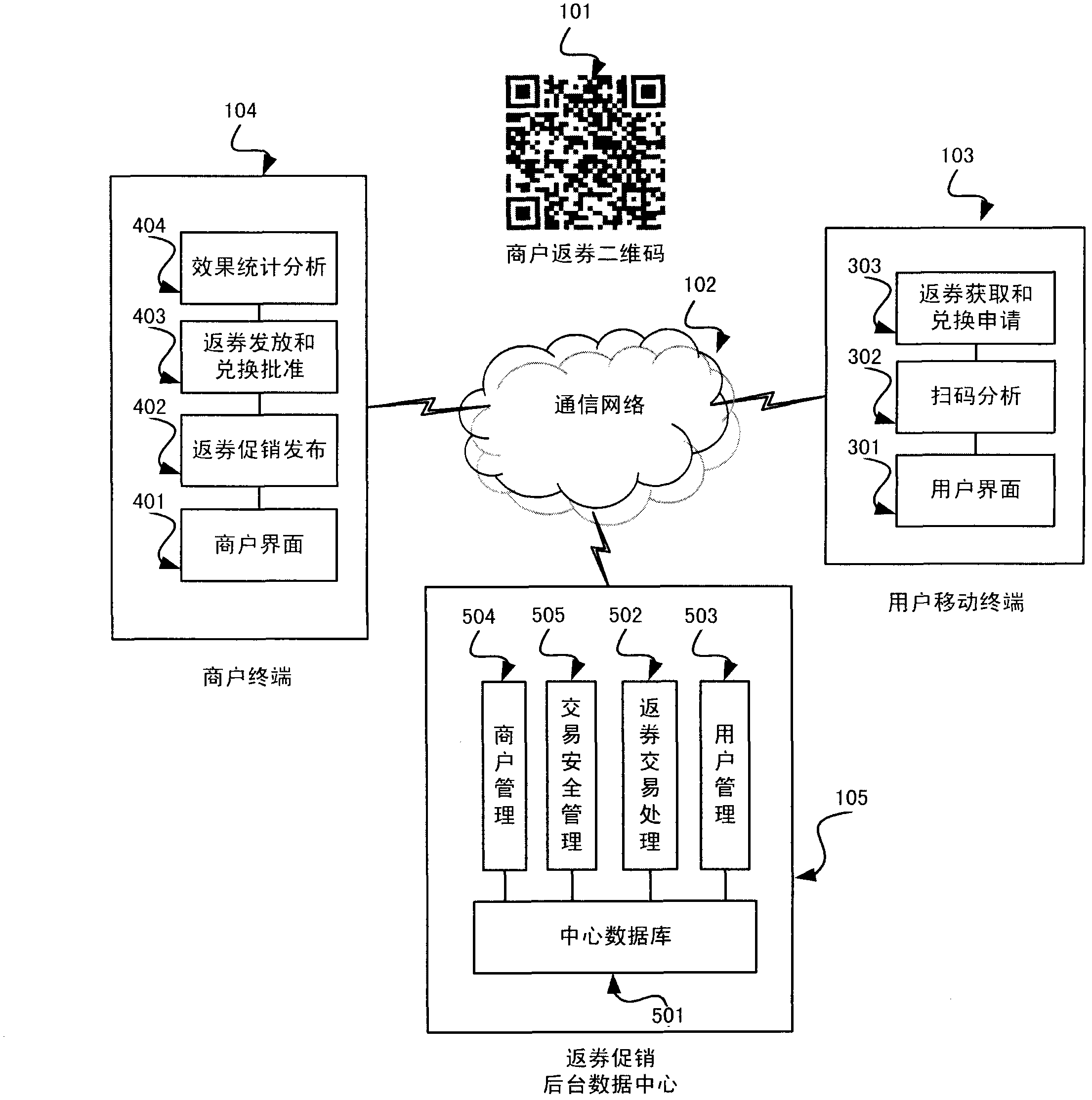

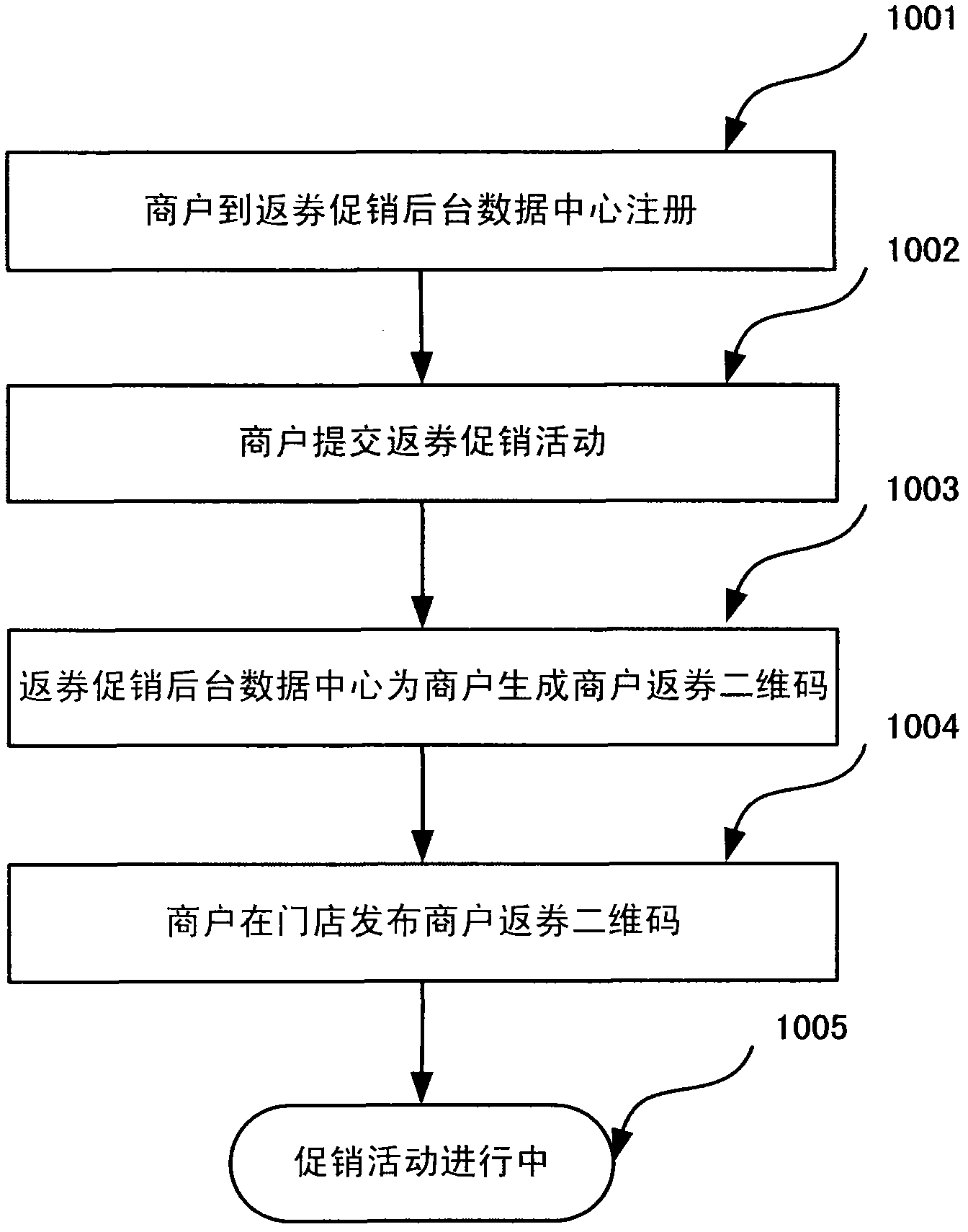

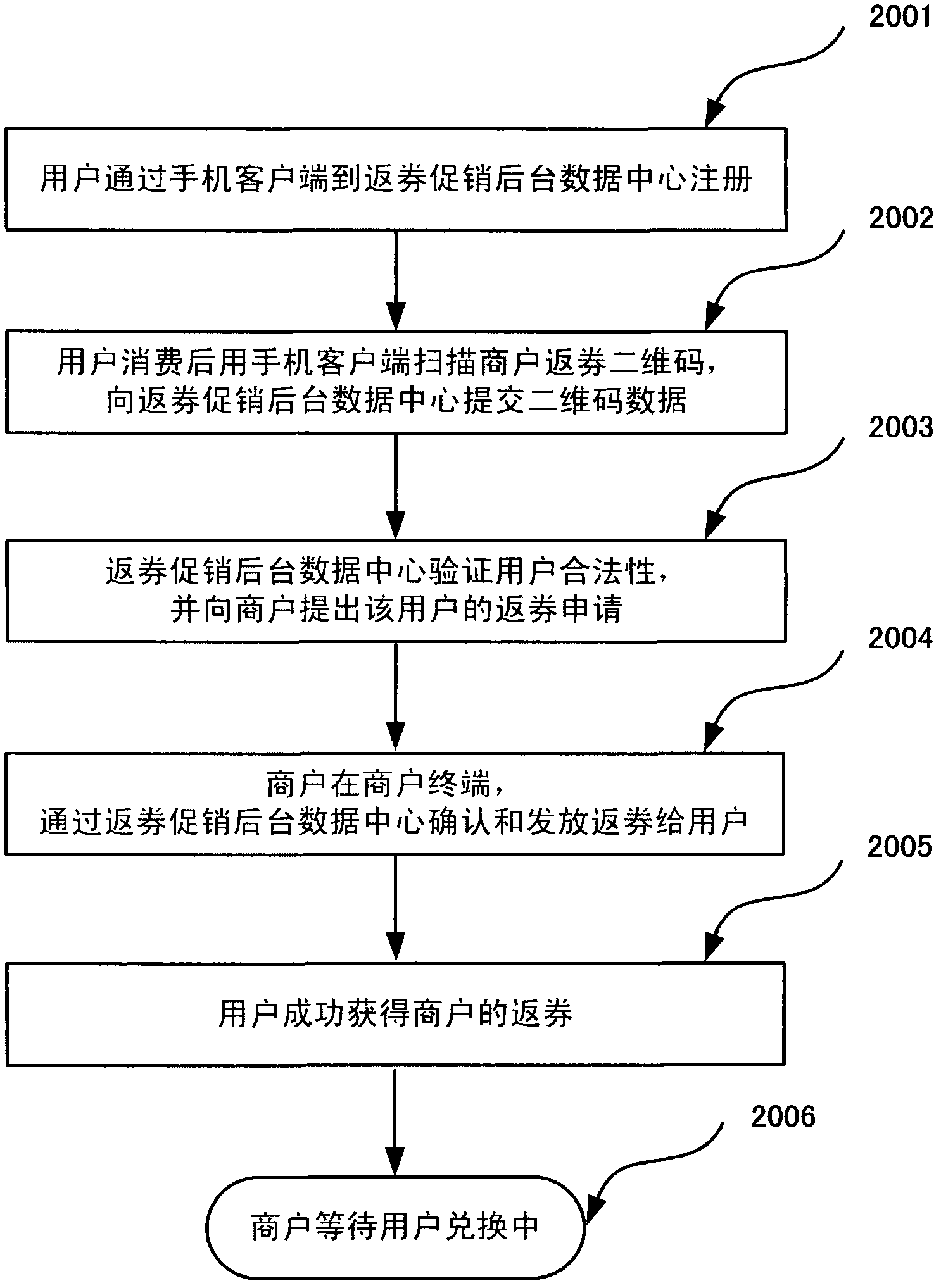

System and method for retail coupon promotion by adopting mobile terminal

The invention provides a system and a method for retail coupon promotion by adopting a mobile terminal. The system comprises a coupon promotion backstage data center, a merchant coupon two-dimensional code, a merchant terminal, a user mobile terminal and a communication network, wherein a merchant registers with the merchant terminal, releases information of a promotional activity to the coupon promotion backstage data center, and obtains the merchant coupon two-dimensional code; a user uses the mobile terminal to shoot the merchant coupon two-dimensional code and connects the mobile terminal to the backstage data center for verification, then the merchant terminal confirms the verification and thus the coupon application is successfully completed; and when redeeming the coupon, the user operates the mobile terminal to shoot the merchant coupon two-dimensional code and connects the mobile terminal to the backstage data center for verification, then the merchant terminal confirms the verification and thus the coupon redeeming is completed. The system provided by the invention is reliable, effective and low in cost.

Owner:北京普罗信科技有限公司

Denitrification and VOC removing catalyst

ActiveCN106238067ALarge specific surface areaHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationInterference resistanceActive component

The invention relates to a denitrification and VOC removing catalyst, and belongs to the field of environmental protection catalysts. According to the present invention, the Mo-V-W / TiO2-Al2O3 system is formed among various components of the catalyst, such that the functions of denitrification and VOC removing can be concurrently achieved under the effect of the active components such as Mo, V and W and the carrier TiO2-Al2O3, the structure of the tail gas filtration discharging equipment can be effectively simplified, and the environmental protection cost can be reduced; and the denitrification and VOC removing catalyst has the high dust interference resistance, and can provide the maximum filtration performance on the basis of no requirement of the frequent stopping-dust cleaning, such that the catalyst has advantages of uniform aging speed, strong filtration ability, and long service life.

Owner:山东海润环保科技有限公司

Technology for preparing amoxicillin by straight-through method

The invention discloses a technology for preparing amoxicillin by a straight-through method. The technology takes a penicillin degreasing fluid as a starting raw material; 6-APA (6-amino penicillanic acid) crystallization, suction filtration, washing and drying steps are saved; the amoxicillin can be prepared without obtaining solid 6-APA via separation; and the prepared amoxicillin meets a requirement of a medicinal standard. The technology saves an operation procedure, reduces the labor intensity of production personnel, lowers the production cost, reduces environmental protection pressure, avoids contact between the production personnel and 6-APA dry powder, and reduces anaphylaxis.

Owner:石药集团中诺药业(石家庄)有限公司

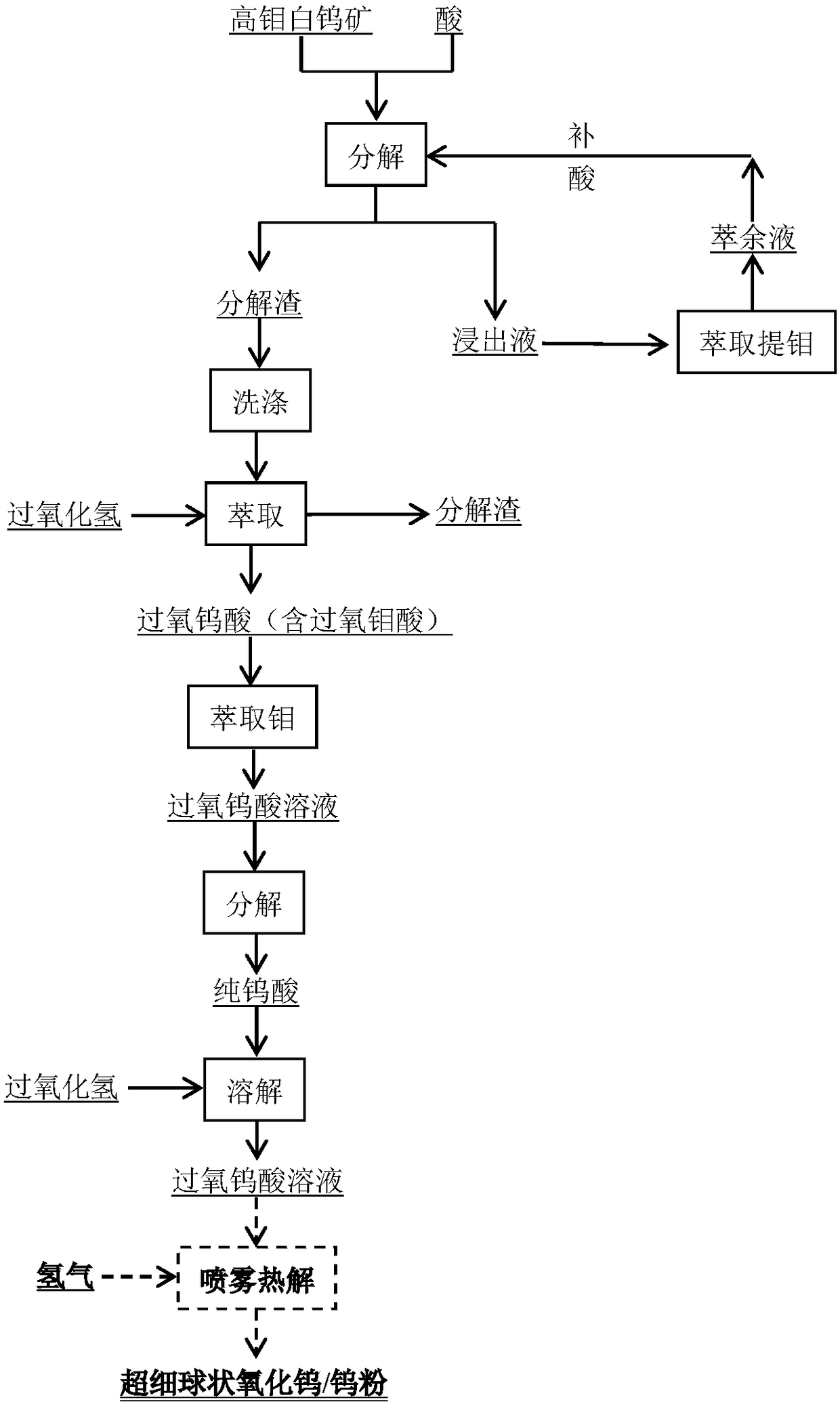

Method for extracting tungsten and molybdenum through acid decomposition of high-molybdenum scheelite

ActiveCN108425010AReduce break down costReduce manufacturing costProcess efficiency improvementDecompositionUltrasonic spray pyrolysis

The invention relates to a method for extracting tungsten and molybdenum through acid decomposition of high-molybdenum scheelite. The method comprises the following steps: leaching the high-molybdenumscheelite with an acid solution, and extracting a leachate to extract molybdenum; extracting a leaching residue with hydrogen peroxide to obtain a solution containing peroxotungstic acid and peroxymolybdic acid, and heating or introducing SO2 to obtain tungstic acid and a solution containing the peroxomolybdic acid; extracting the tungstic acid with hydrogen peroxide, and heating or introducing SO2 to obtain tungstic acid and a solution containing the peroxomolybdic acid; repeating for several times till pure tungstic acid is obtained; preparing tungsten trioxide or tungsten powder from the pure tungstic acid; and heating or introducing SO2 into the solution containing the peroxomolybdic acid, dissolving obtained molybdic acid in a hydrogen peroxide solution to prepare a peroxomolybdic acid solution, and performing ultrasonic spraying pyrolysis to prepare molybdenum trioxide powder or molybdenum powder. By the method, the separation effect is good and the operation process is simple and easy to control, so that the method is easy to popularize and apply industrially.

Owner:CENT SOUTH UNIV

Method for producing microbial agent by using filter mud of sugar mills through fermentation

InactiveCN102924133ASimple processLow costBio-organic fraction processingOrganic fertilisersBiosphereMicrobial agent

The invention provides a method for producing a microbial agent by using filter mud of sugar mills through fermentation, belonging to the field of the production technology of the microbial agents. The method can produce the high quality microbial agent and treat the pollutions caused by the industrial waste filter mud of the sugar mills at the same time, and also can achieve the circulating economic benefits for the sugar industries. The method comprises the steps of mixing the filter mud of the sugar mills, weathered coal of the humic acid or grass carbon and dried straw to obtain a mixture, controlling the water content of the mixture to 33%-70%, adding the microbial agent into the mixture at a mass ratio of 2% of the microbial agent to the mixture, rapidly stirring to form a homogeneous mixture, loading into a sealing bag, and carrying out anaerobic fermentation for 10 days at a room temperature of the south of China to obtain the microbial agent with an effective living bacteria number being greater than or equal to 300 million / g (higher than the national standard of 200 million / g). According to the invention, the method has the advantages of low cost, simple operation and high product quality, achieves the effective resource utilization through converting the filter mud of the sugar mill into a treasure, solves the problem of the environmental pollution and saves high environmental protection cost for the sugar industries, and brings good economic benefits at the same time, which can form a closed biosphere of the sugar production; and the biosphere creates circulating economic benefits, and brings rich rewards to the sugar industries and the sugarcane farmers.

Owner:王天喜 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com