Etching plaster for metal and metal oxide transparent conducting layer and etching process

A transparent conductive layer and oxide technology, applied in the field of etching paste, can solve the problems of complex process, pollute the environment, accelerate equipment aging, etc., and achieve the effect of simplifying the process flow, improving the etching quality, and reducing the cost of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

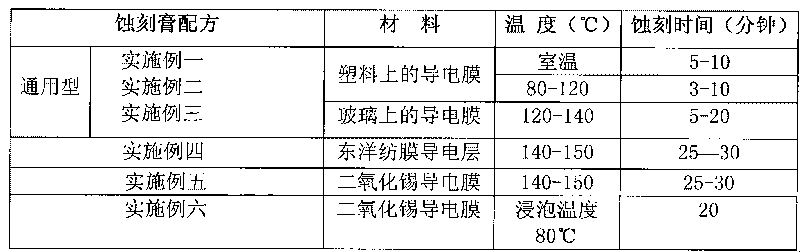

Embodiment 1

[0032] The formula of etching paste of the present invention is: by weight, it is made up of the following components:

[0033] Take 0.1 part of ferric chloride;

[0034] Take 2 parts of sulfuric acid and oxalic acid;

[0035] Take 10 parts of water-based polyurethane, polyvinyl alcohol, and water-soluble epoxy resin;

[0036] 0.1 part of castor oil sulfuric acid compound and polyphosphate;

[0037] The defoamer is 0.1 part of SN-D468 defoamer produced by San Nopco in Japan;

[0038] Thickeners are colloidal silicon and methyl cellulose to take 10 parts;

[0039] The bacteriostatic agent is 0.1 part of TS-802 bactericidal and algicide;

[0040] The amount of water is 30 parts; the etching paste is prepared by mixing the above-mentioned raw materials.

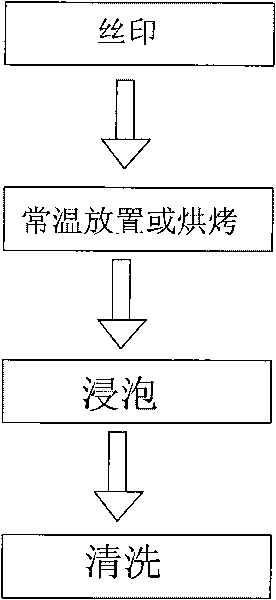

[0041] The etching process of the present invention for the etching paste of the metal and metal oxide transparent conductive layers is:

[0042] like figure 1 As shown, the etching paste was printed on indium tin oxide I...

Embodiment 2

[0044] The formula of etching paste of the present invention is: by weight, it is made up of the following components:

[0045] Take 20 parts of ferrous chloride;

[0046] Take 50 parts of sulfuric acid and pyrosulfuric acid;

[0047] Take 30 parts of water-soluble alkyd resin, polyethylene glycol and modified starch;

[0048] Take 10 parts of polyphosphate, silicate and polyacrylic acid derivatives;

[0049] The antifoaming agent is Bevaloid691 antifoaming agent produced by Bew-aloid in the United Kingdom, and take 5 copies;

[0050] Thickeners are carboxymethyl cellulose and hydroxymethyl cellulose, take 40 parts;

[0051] The bacteriostatic agent is 10 copies of SJ-304 bactericidal and algicide;

[0052] The amount of water is 2 parts; the etching paste is prepared by mixing the above-mentioned raw materials.

[0053] The etching process of the present invention for the etching paste of the metal and metal oxide transparent conductive layers is:

[0054] The etching p...

Embodiment 3

[0056]The formula of etching paste of the present invention is: by weight, it is made up of the following components:

[0057] Take 10 parts of copper chloride;

[0058] Take 25 parts of sulfonic acid and carboxylic acid;

[0059] 20 parts of modified cellulose ether, water-soluble oil, rosin modified resin and gum arabic;

[0060] 5 parts of silicate, polyacrylic acid derivatives and polyoxyethylene glycol alkyl ester;

[0061] The antifoaming agent is Bevaloid691 antifoaming agent produced by Bew-aloid in the United Kingdom, and take 3 copies;

[0062] The thickener is polyacrylic acid, organic bentonite and inorganic bentonite to take 25 parts;

[0063] The bacteriostatic agent is 5 copies of 2.4.5.6-tetrachloroisophthalic acid;

[0064] The amount of water is 20 parts; the etching paste is prepared by mixing the above-mentioned raw materials.

[0065] The difference between this embodiment and the second embodiment is that the material is a conductive film on glass, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com