Patents

Literature

80results about How to "Improve etch quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

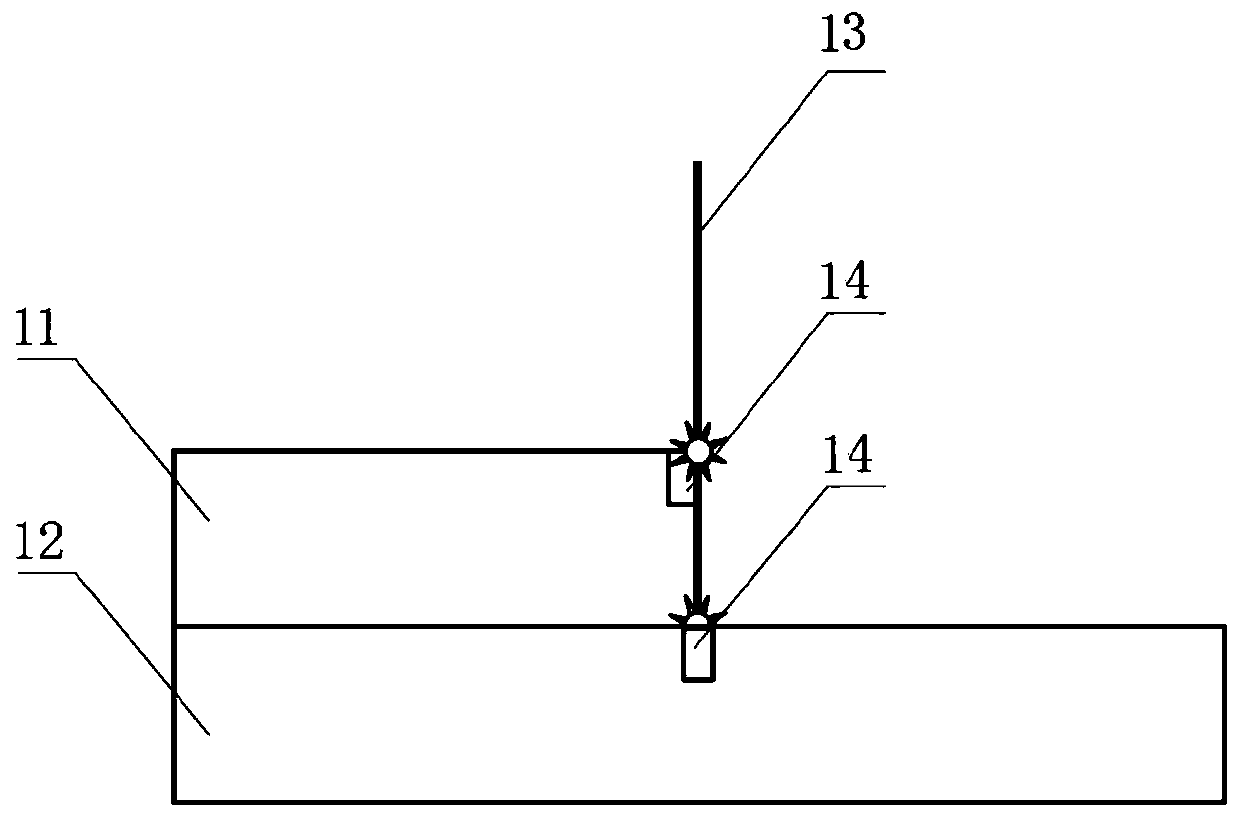

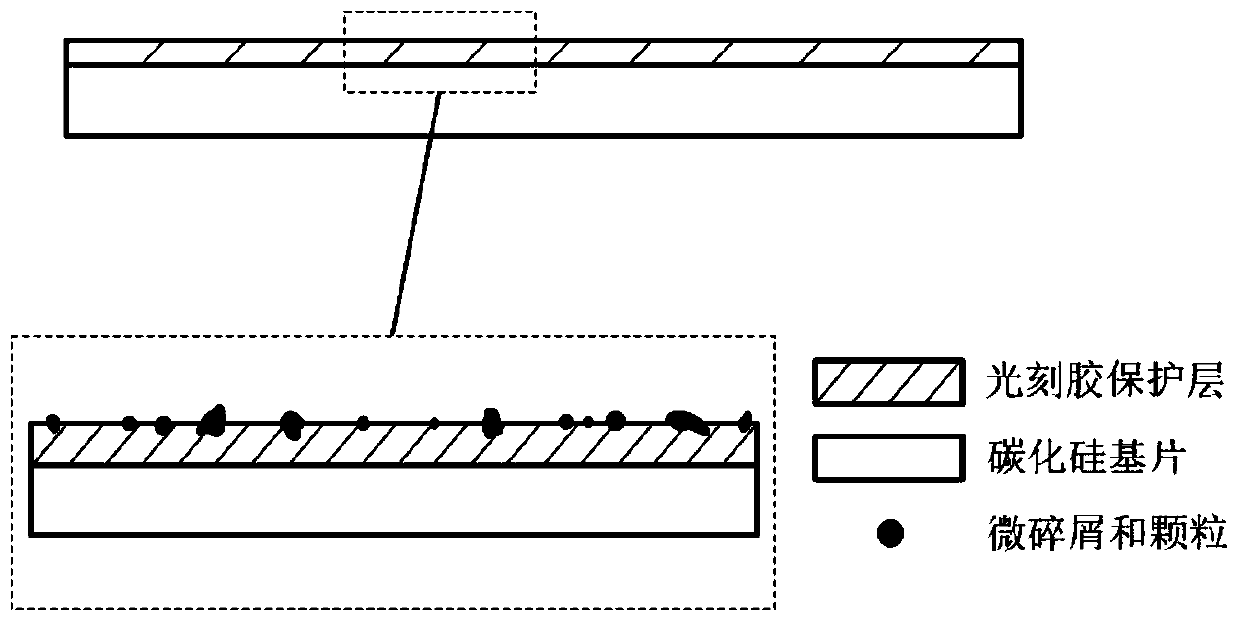

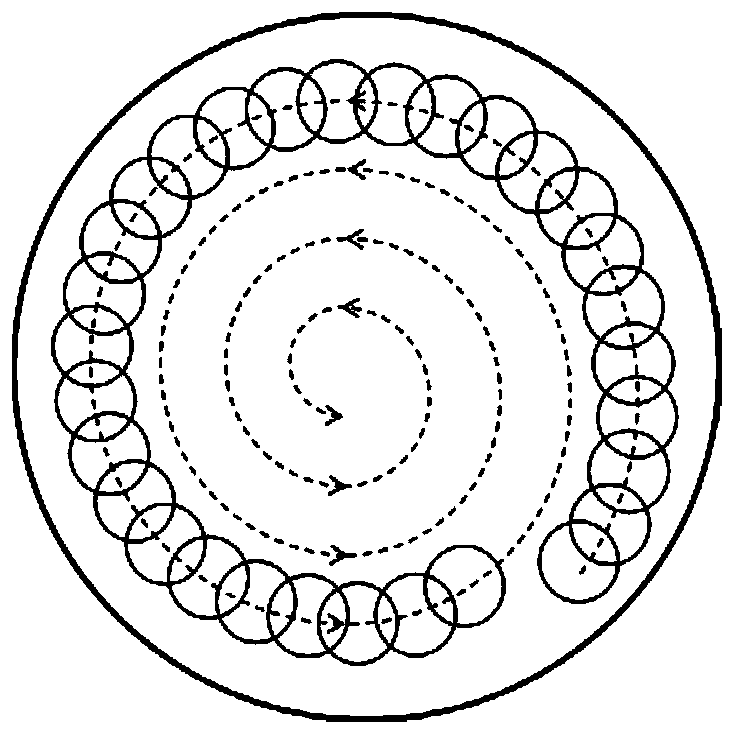

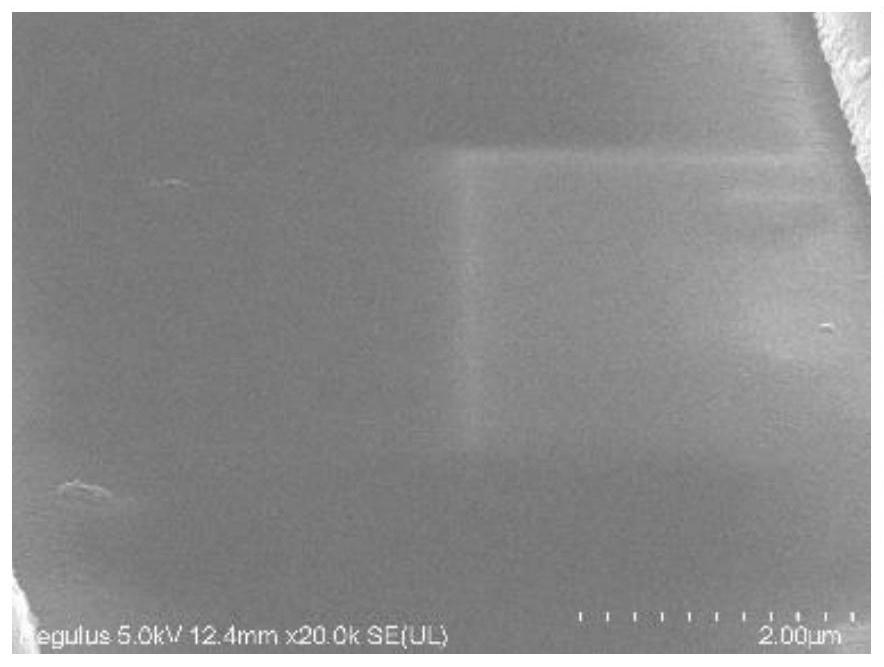

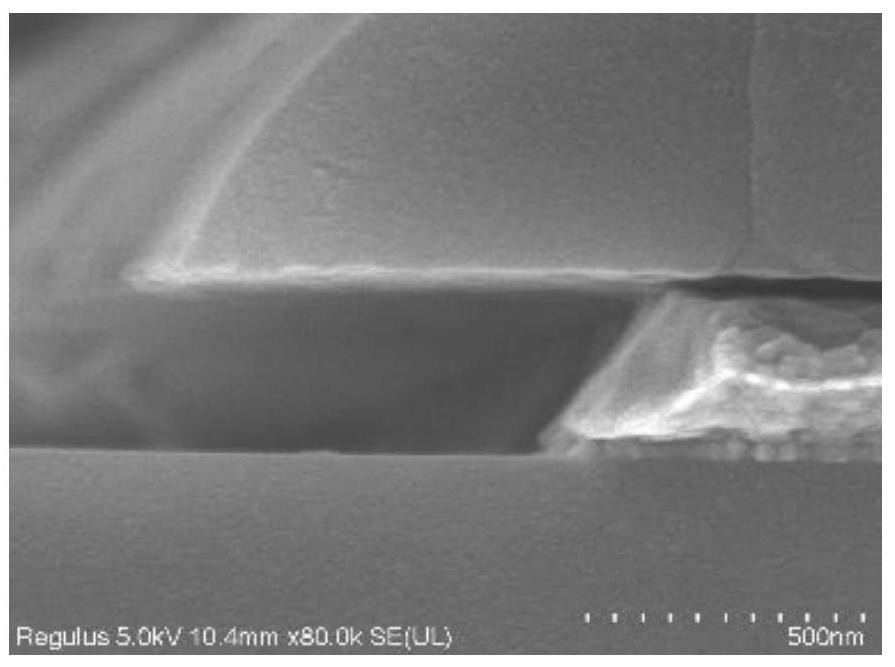

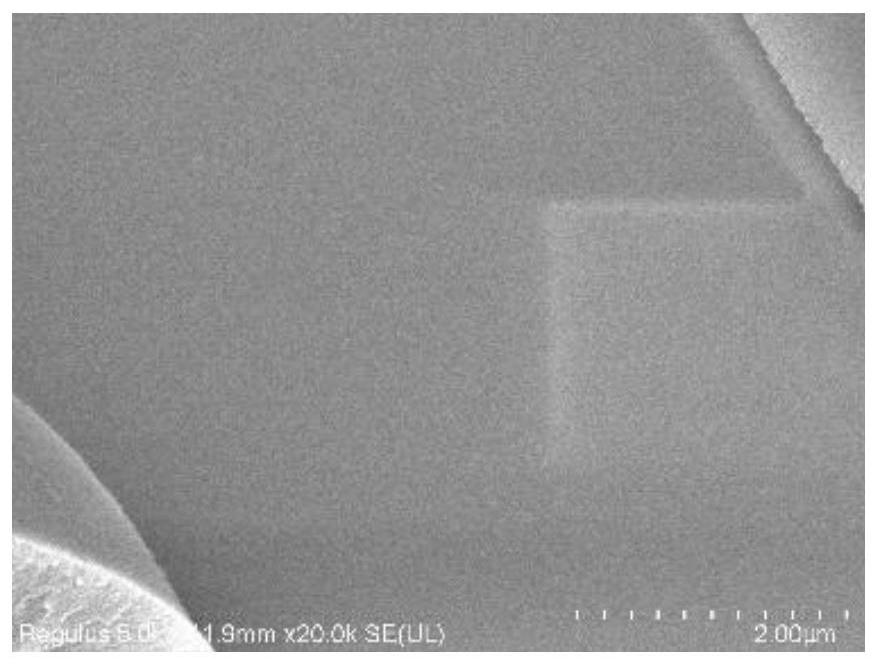

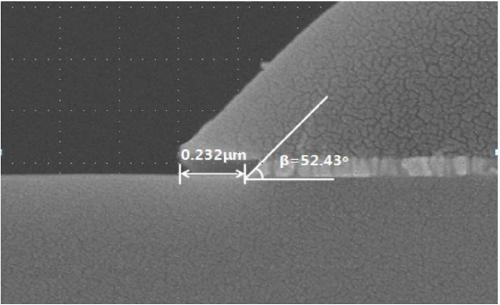

Femtosecond laser processing device and method for rapid deep etching of silicon carbide

ActiveCN110385521AFast etch qualityImprove etch qualityLaser beam welding apparatusLaser etchingLaser processing

The invention discloses a femtosecond laser processing device and method for rapid deep etching of silicon carbide. The femtosecond laser processing device mainly comprises a laser source module, a laser motion module, a shaping and focusing module, an auxiliary gas module and a laser etching module. According to the device and method, a focal plane is calibrated, a protection layer is prepared, an etching path is planned, layer-by-layer scanning etching is carried out according to parameter groups, and micro-chips are removed, so that deep etching of silicon carbide is realized. According tothe method, due to the fact that a femtosecond laser is used for processing silicon carbide, factors influencing the etching quality are controlled, namely, the laser energy density, the light spot overlapping rate and the line overlapping rate, and therefore silicon carbide is subjected to rapid and high-quality deep etching in a layer-by-layer scanning manner and a continuous feeding processingmanner according to the planned etching path.

Owner:XI AN JIAOTONG UNIV

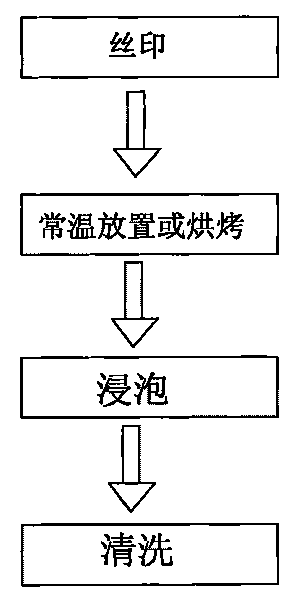

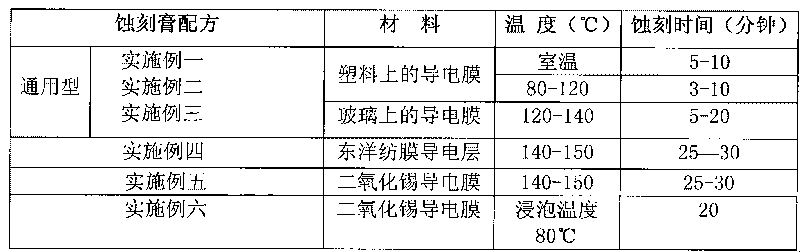

Etching plaster for metal and metal oxide transparent conducting layer and etching process

InactiveCN101717645AEliminate acid and alkali soaking processEliminate the soaking processSurface treatment compositionsEtchingDefoaming Agents

The invention discloses an etching plaster for metal and metal oxide transparent conducting layers and an etching process, in the invention, lagging production processes, such as the use of organic solvents, strong acid etching and strong alkaline cleaning and the like, are not used any longer, instead, the etching plaster and the etching process which do not pollute the environment are used. The etching plaster comprises the following components in parts by weight: 0.1-20 parts of salt substance, 2-50 parts of non-volatile acid, 10-30 parts of aqueous high molecular polymer, 0.1-10 parts of dilute wetting dispersant, 0.1-5 parts of defoamer, 10-40 parts of thickening agent, 0.1-10 parts of bacteriostat and 2-30 parts of water. The invention simplifies the process flow, cancels acid and alkali soaking and the use of organic solvents, lowers the environmental protection cost, improves the etching quality of products, and has the effects of high efficiency, energy saving and environmental protection. The invention is widely applied to the fields of electron, semiconductors, fine chemistry industry and the like.

Owner:张林

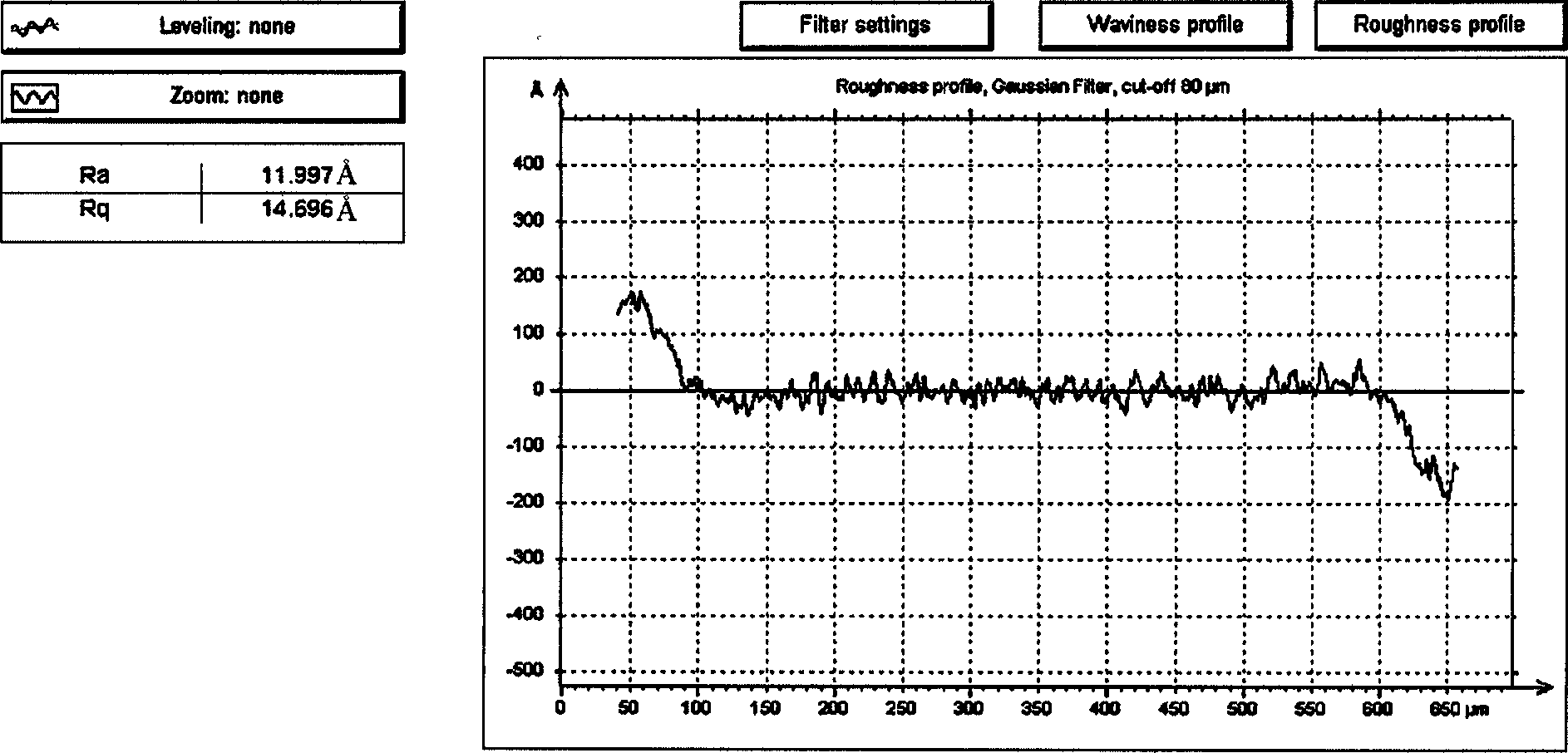

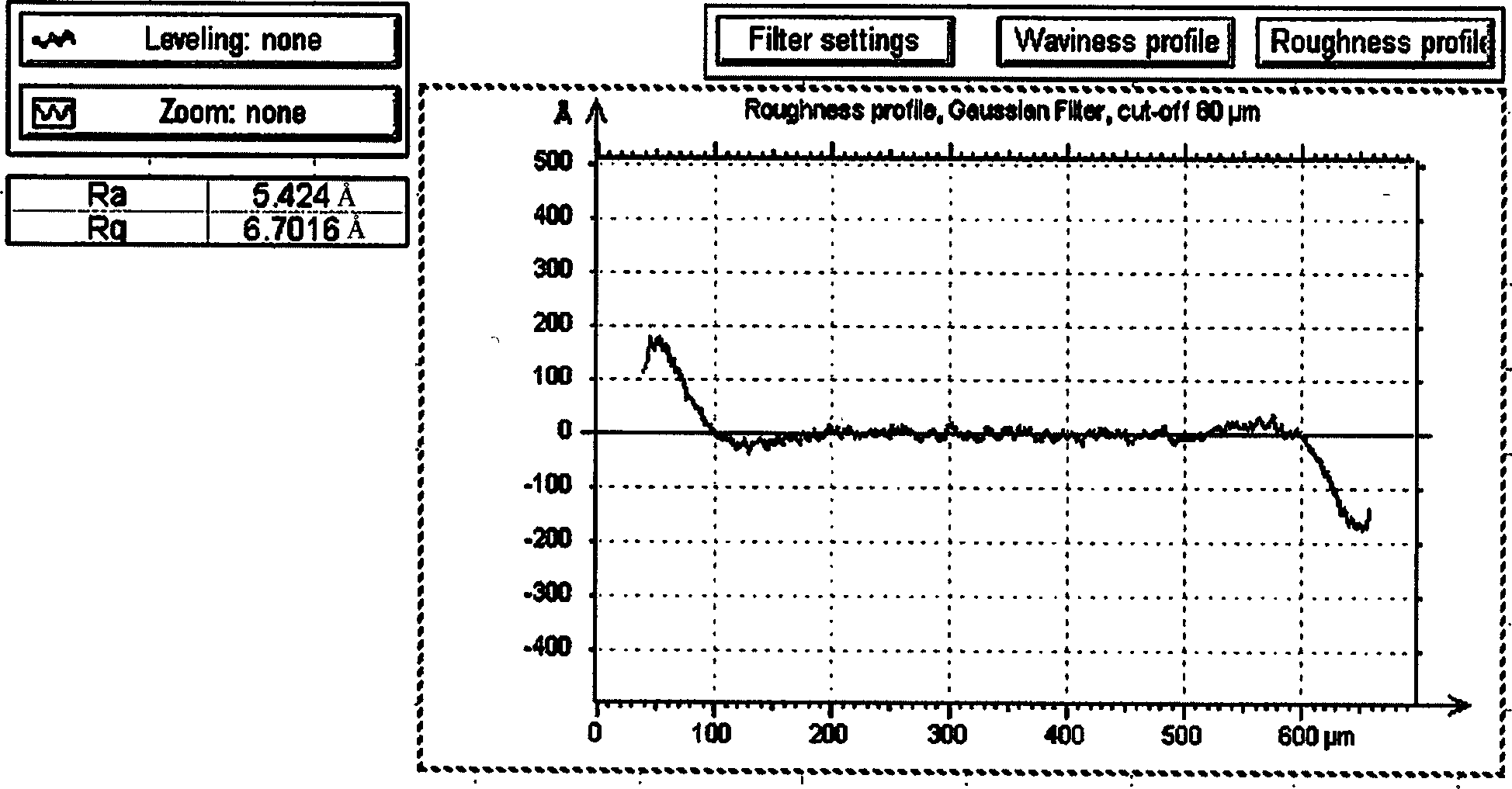

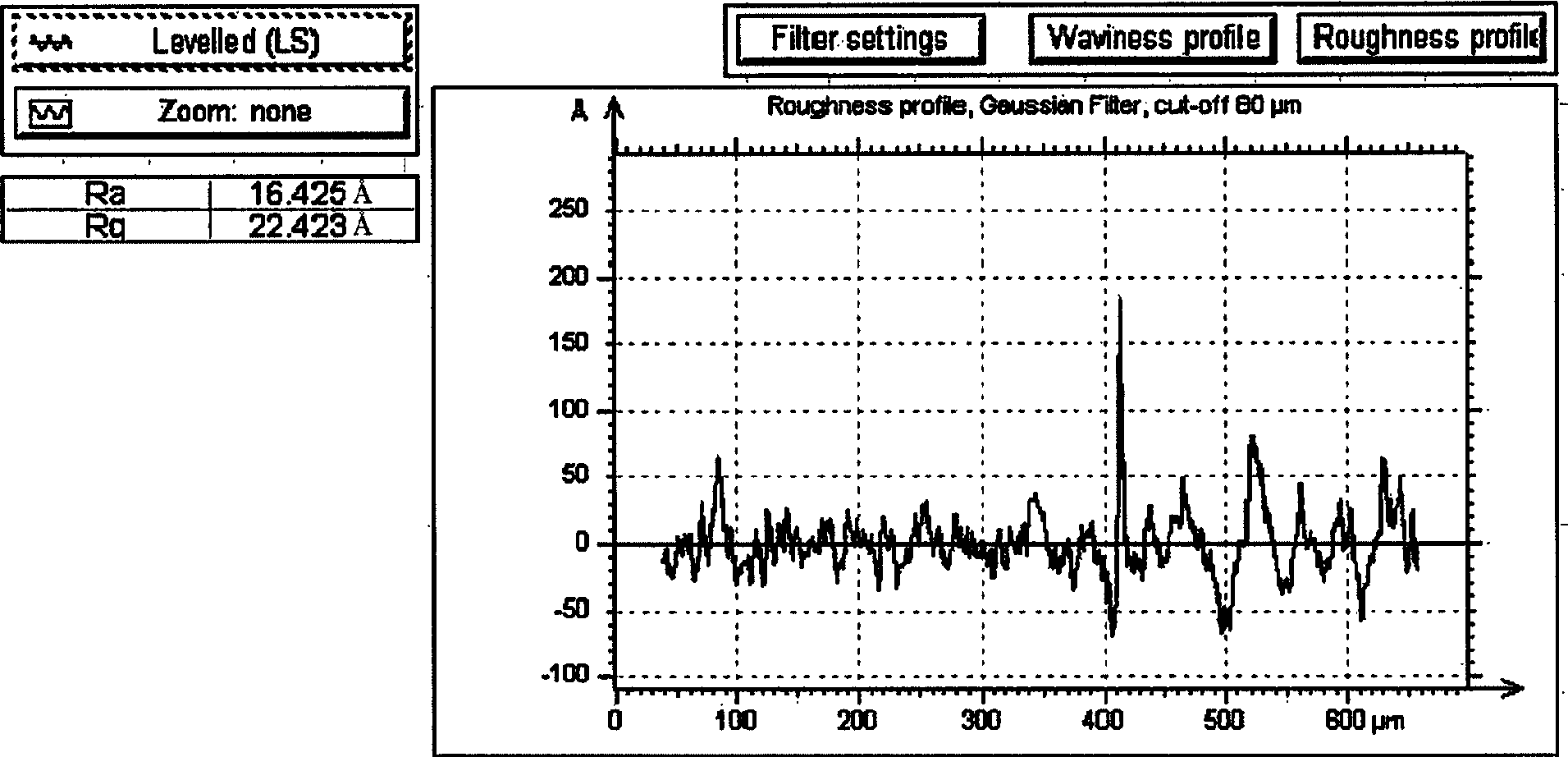

Etchant composition for glass of flat panel display

InactiveCN101481215AHigh transparencyQuality improvementSurface treatment compositionsNitrate saltsDisplay device

The invention relates to a glass etchant composition, more specifically, to a glass etchant composition forming a panel display. The glass etchant composition comprises 5-20 wt.% of HF; 10-50 wt.% of more than one inorganic acid selected from a group consisting of HSO, HPO, HCl, HCO, HNO and HClO; 0.5-10 wt.% of carboxylic acid; 0.01-5 wt.% of an inorganic nitrate salt as a first additive; and water residual. The glass etchant composition here provided brings high quality for transparency and surface roughness of glass processed, with stable etching capability, long service life and increased etching efficiency (etching sheet numbers).

Owner:EXAX INC

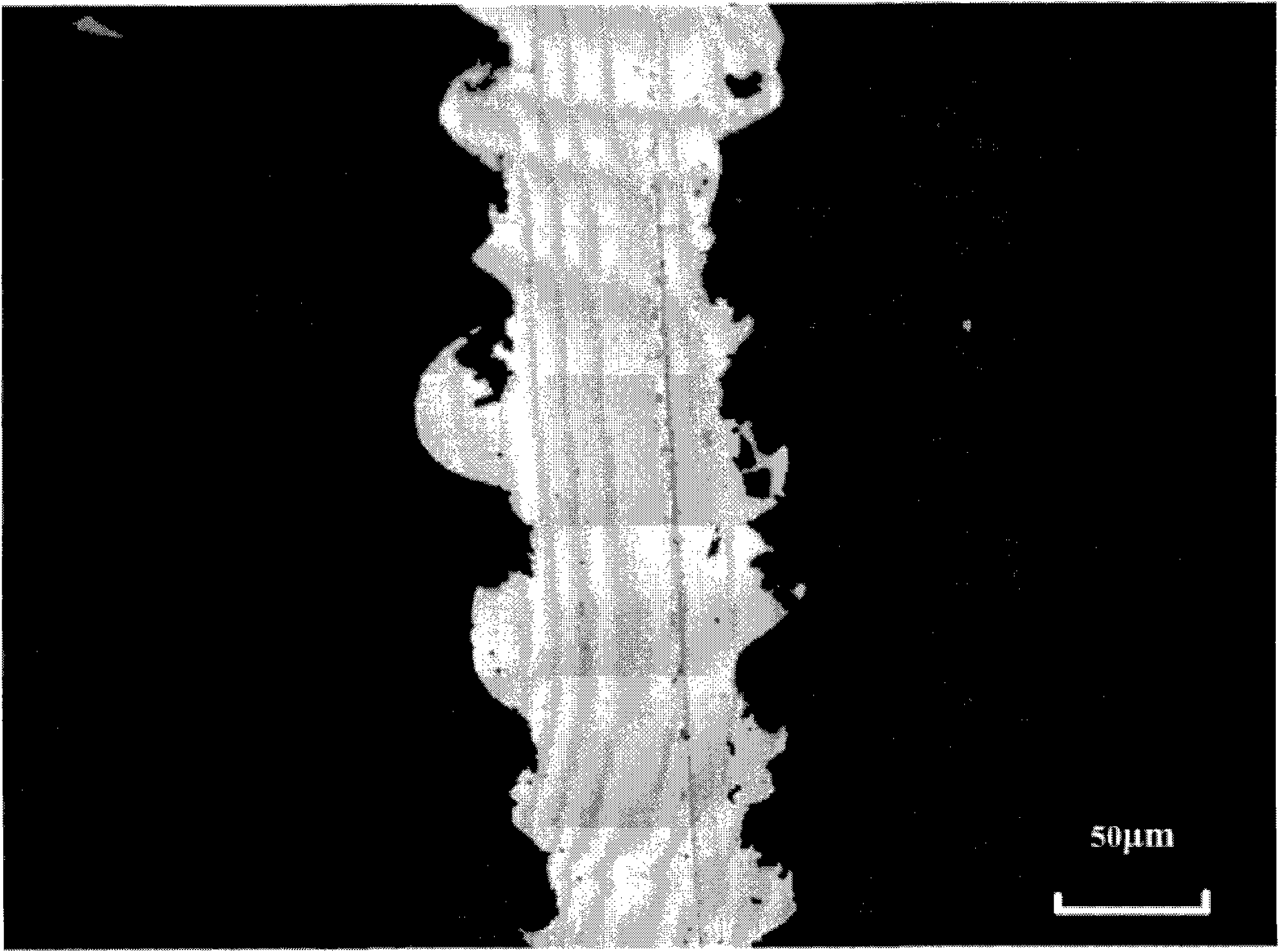

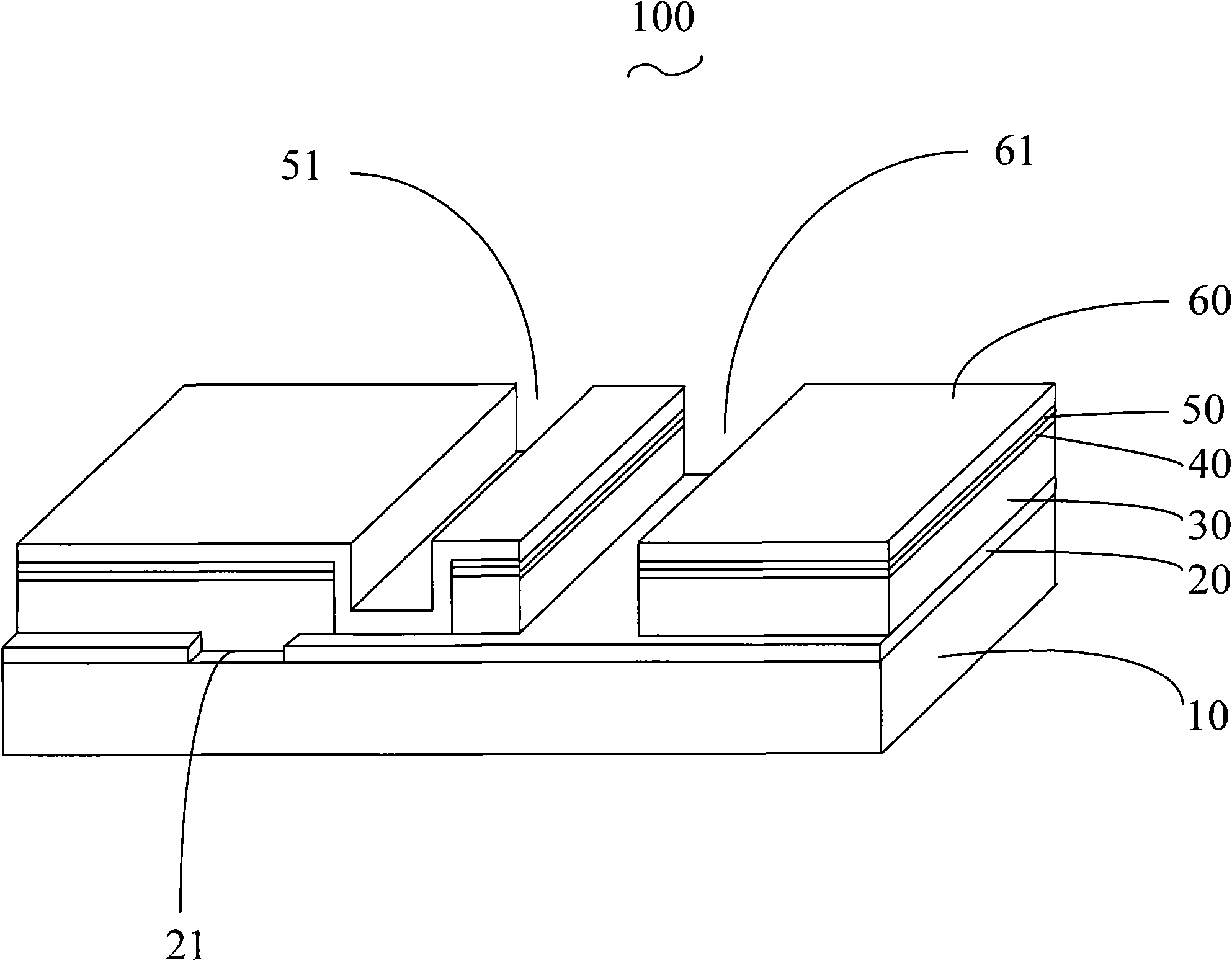

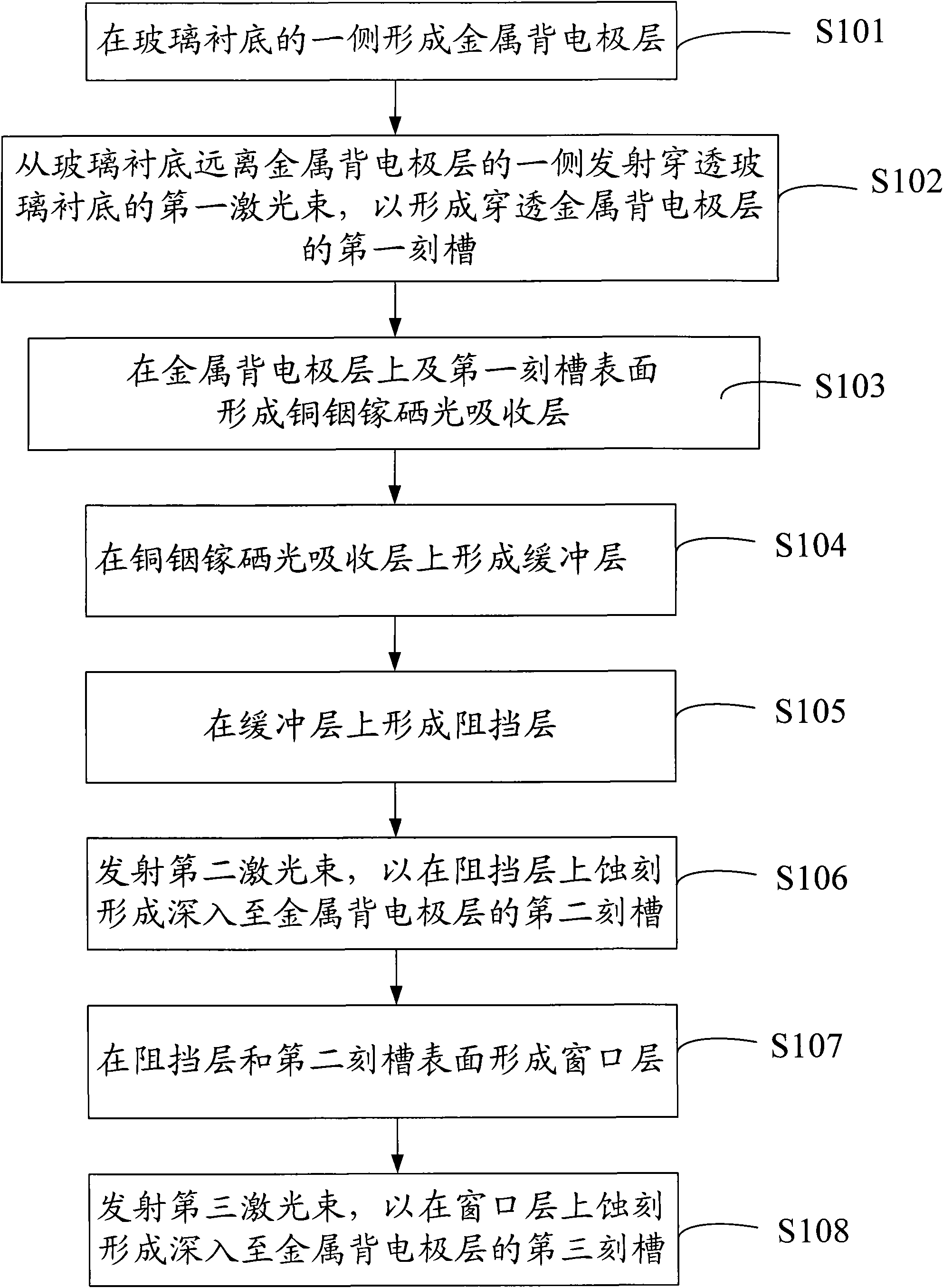

Method for preparing copper indium gallium selenide thin film battery

ActiveCN101980377AImprove insulation performanceNot easy to short circuitFinal product manufactureSemiconductor devicesIndiumCopper indium gallium selenide

The invention discloses a method for preparing a copper indium gallium selenide thin film battery, which comprises the following steps of: forming a metal back electrode layer on one side of a glass substrate; emitting a first laser beam penetrating the glass substrate from the side of the glass substrate away from the metal back electrode layer so as to form a first groove penetrating the metal back electrode layer; forming a copper indium gallium selenide light absorbing layer on the metal back electrode layer and the surface of the first groove; forming a buffer layer on the copper indium gallium selenide light absorbing layer; forming a barrier layer on the buffer layer; emitting a second laser beam to etch the barrier layer so as to form a second groove reaching the metal back electrode layer; forming a window layer on the barrier layer and the surface of the second groove; and emitting a third laser beam to etch the window layer so as to form a third groove reaching the metal back electrode layer. The copper indium gallium selenide thin film battery prepared by the method has the advantage of low possibility of generating short circuit.

Owner:珠海中科先进科技产业有限公司

Method for surface laser-etching of ceramic product

ActiveCN103302400AGood surface effectStrong ornamentalDecorative surface effectsLaser beam welding apparatusLaser etchingComputer programming

The invention discloses a method for surface laser-etching of a ceramic product. The method comprises the steps as follows: firstly, the ceramic product is preprocessed, the chromaticity, the glossiness and the roughness of the surface of the ceramic product are guaranteed to meet the design requirements; then laser etching is performed on the surface of the ceramic product, and patterns on the surface of the ceramic product are designed through computer programming; then laser carving is performed on the surface of the ceramic product by using a laser system; the patterns are controlled by a computer, so that three-dimensional concave-convex patterns are formed on the surface of the ceramic product. According to the method, the surface of the ceramic product is etched and processed with laser, high-temperature heat produced by laser beams instantly gasifies the surface of the ceramic product; the patterns are controlled by the computer, so that the concave-convex patterns having a three-dimensional effect are formed on the surface of the ceramic product. At the same time, the invention further provides the ceramic product subjected to surface laser etching processing with the method.

Owner:CHAOZHOU THREE CIRCLE GRP

Low line width and line space etching control method of thick copper plate

ActiveCN105163502AReduce consumptionAvoid scrappingConductive material chemical/electrolytical removalTinningCopper plating

The invention relates to a low line width and line space etching control method of a thick copper plate. The method comprises that cutting, boring and electroless copper plating are carried out on the thick copper plate, a dry film which does not cover holes is pasted to the thick copper plate after electroless copper plating, and exposure and development are carried out; after the developed thick copper plate is qualified in AOI scanning, patterned electro-coppering and electro-tinning are carried out, and first film removing, alkali etching and tin stripping are carried out successively; and when the thick copper plate after the first etching is qualified in AOI scanning, the dry film which does not cover the holes is pasted, exposure and development are carried out, patterned electro-coppering and electro-tinning are carried out after the cooper plate is qualified in AOI scanning, second film removing, alkali etching and tin stripping are carried out successively to obtain a circuit board, and a next procedure is moved to. The method can avoid board material waste caused by insufficient low line width and line space etching in integrated electroplating and etching of the board, etching burrs are reduced, the etching quality is improved, material consumption of the etching technology is reduced, and consumption of copper is reduced.

Owner:通元科技(惠州)有限公司

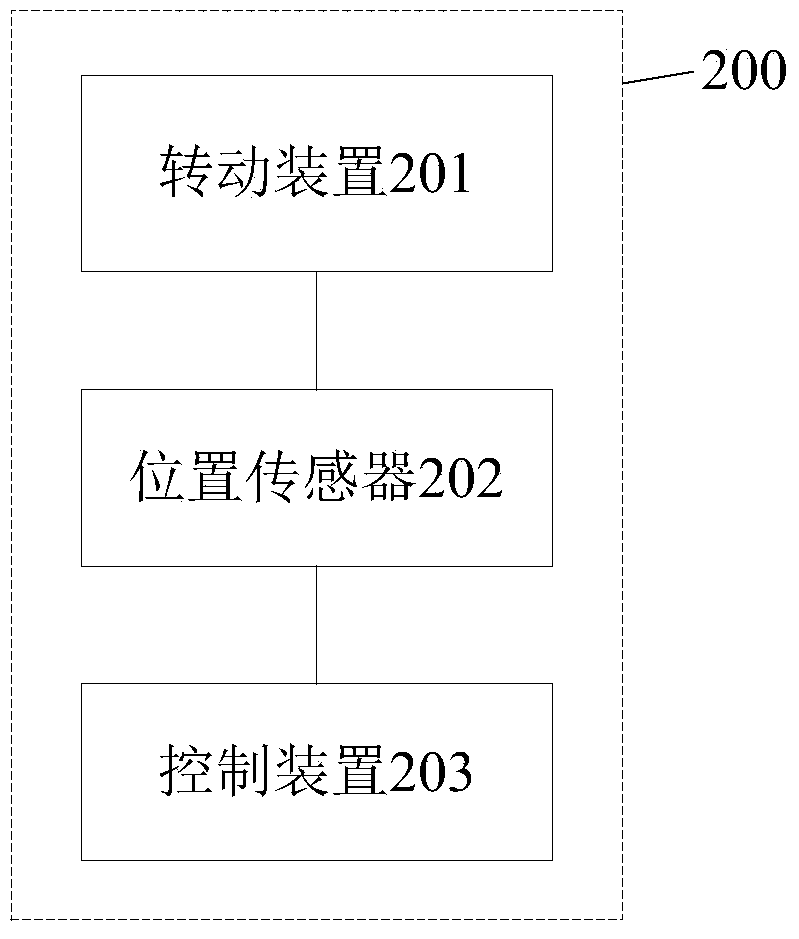

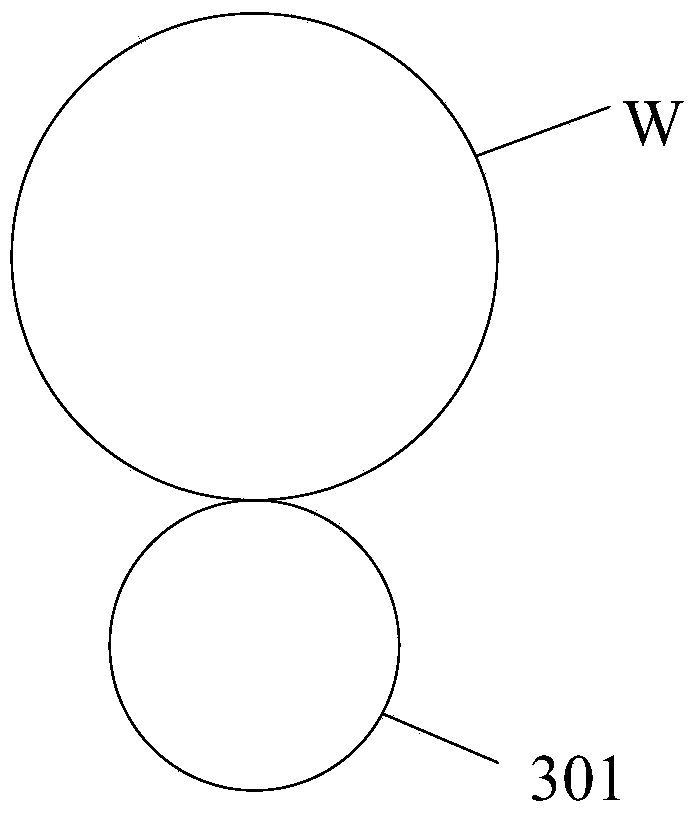

Wet etching system and method

ActiveCN103985660AMinimize Wet Etch VariationsImprove etch qualitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManipulatorEtching

The invention provides a wet etching system. The wet etching system comprises a wafer clamping groove, a solution groove, a manipulator, a control device, a position sensor and a rotating device. When the position sensor detects that wafers are completely immersed in a solution and / or the wafers make contact with the rotating device, a signal is sent to the control device, the control device controls the rotating device to rotate after receiving the signal sent by the position sensor, and the rotating device drives the edges of the wafers to rotate clockwise or counterclockwise; after the edges of the wafers rotate clockwise or counterclockwise by 180 degrees, the control device controls the rotating device to stop rotating. According to the wet etching system, all positions of the surfaces of the wafers can be immersed in the solution for the same time, and therefore the problem that in an existing wet etching method, an etching difference is large because the top and the bottom of a wafer are immersed in a solution for different times is solved, wet etching differences of the surfaces of the wafers are reduced, and etching quality and the quality of a device are improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

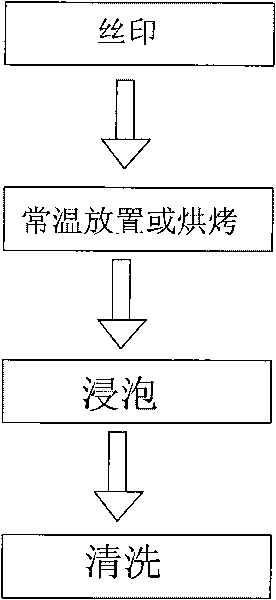

Surface chemical etching method of ceramic material product

The invention discloses a surface chemical etching method of a ceramic material product. The method comprises the steps that a ceramic material is pretreated, so that the chroma, glossiness and roughness of the surface of the ceramic material meet requirements; the surface of the pretreated ceramic material product is coated with a corrosion-resistant protective film, and soaked and etched in an acid solution; the etched ceramic material product is cleaned; the protective film is removed; and drying is performed. The method can achieve high-quality and high-efficiency surface etching on various hard ceramic materials; the etching quality is far better than the traditional technology; concave and convex are not limited; the depth is controllable; the third dimension is strong; the glossiness, roughness and chroma of the surface are controllable; various art fonts and any patterns can be etched; panels in different chroma can be etched; the operation is simple; and the generality is high. The invention further discloses the ceramic material product adopting the etching method for surface processing.

Owner:CHAOZHOU THREE CIRCLE GRP

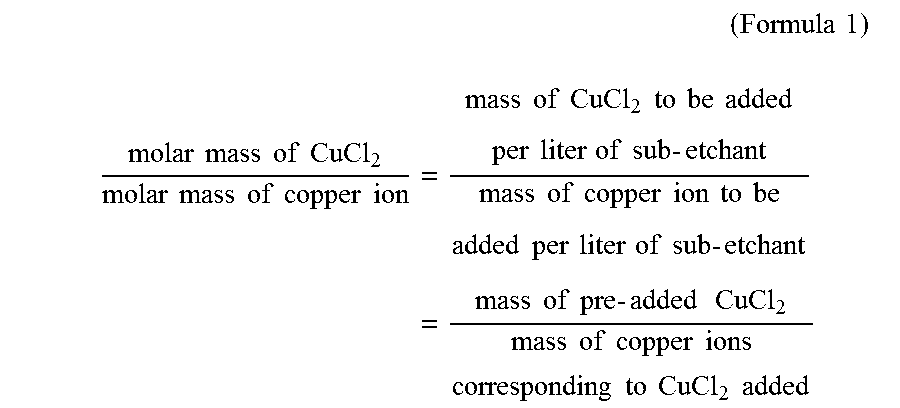

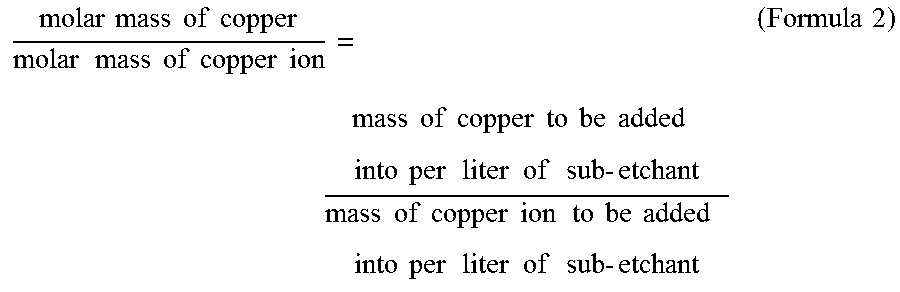

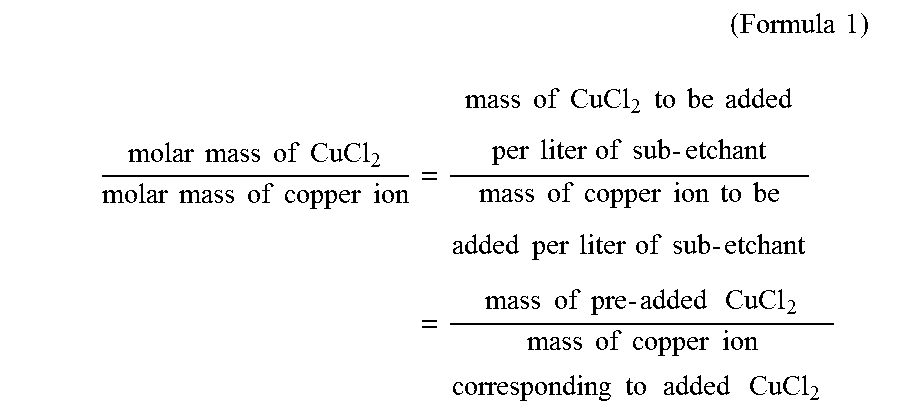

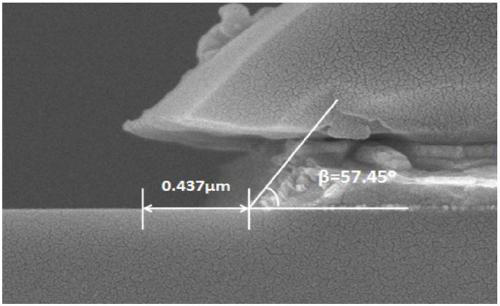

High-efficiency High-quality and Safe Alkaline Cupric Chloride Etchant for Printed Circuit Board

ActiveUS20150361341A1Reduce the amount requiredHigh-efficiency high-qualityInsulating layers/substrates workingCable/conductor manufactureCharge controlCarboxylic acid

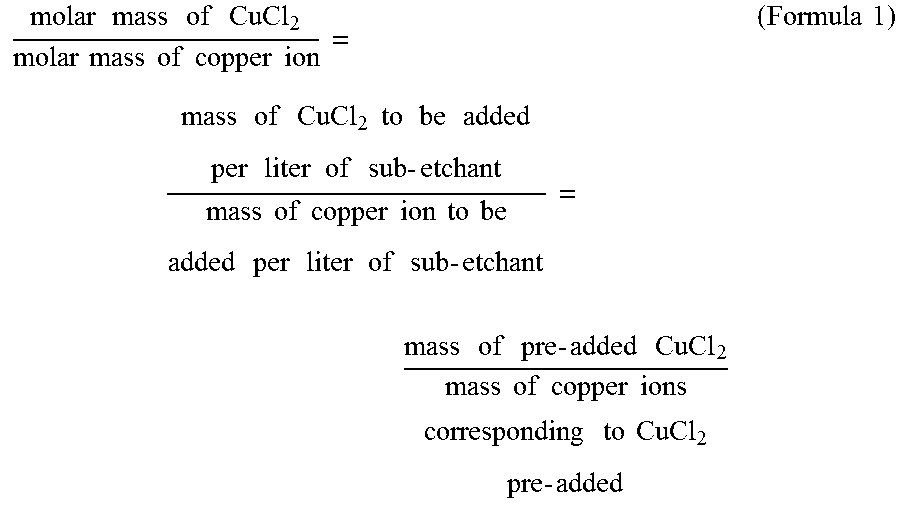

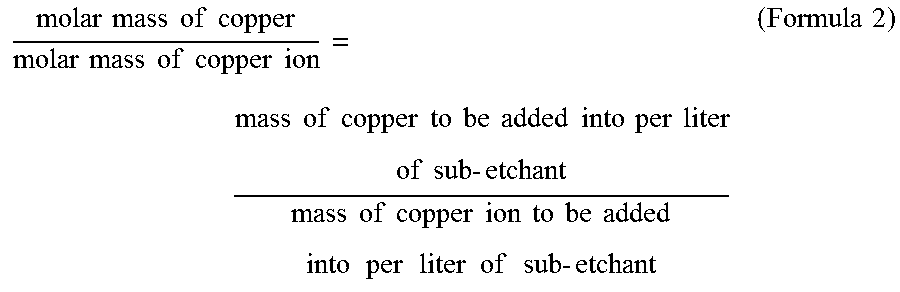

A high-efficiency high-quality and safe alkaline cupric chloride etchant for printed circuit board, which includes cupric chloride and a sub-etchant. The sub-etchant contains (in percentage by weight) 10%-30% NH4Cl; 0.0002%-25% carboxylic acid and / or ammonium carboxylate; 0.3%-25% ammonium hydroxide. The etchant is used in connection with an automatic detection and charging control during the etching process in order to keep the concentration of copper ions in the etchant no less than a set value.

Owner:YE TAO

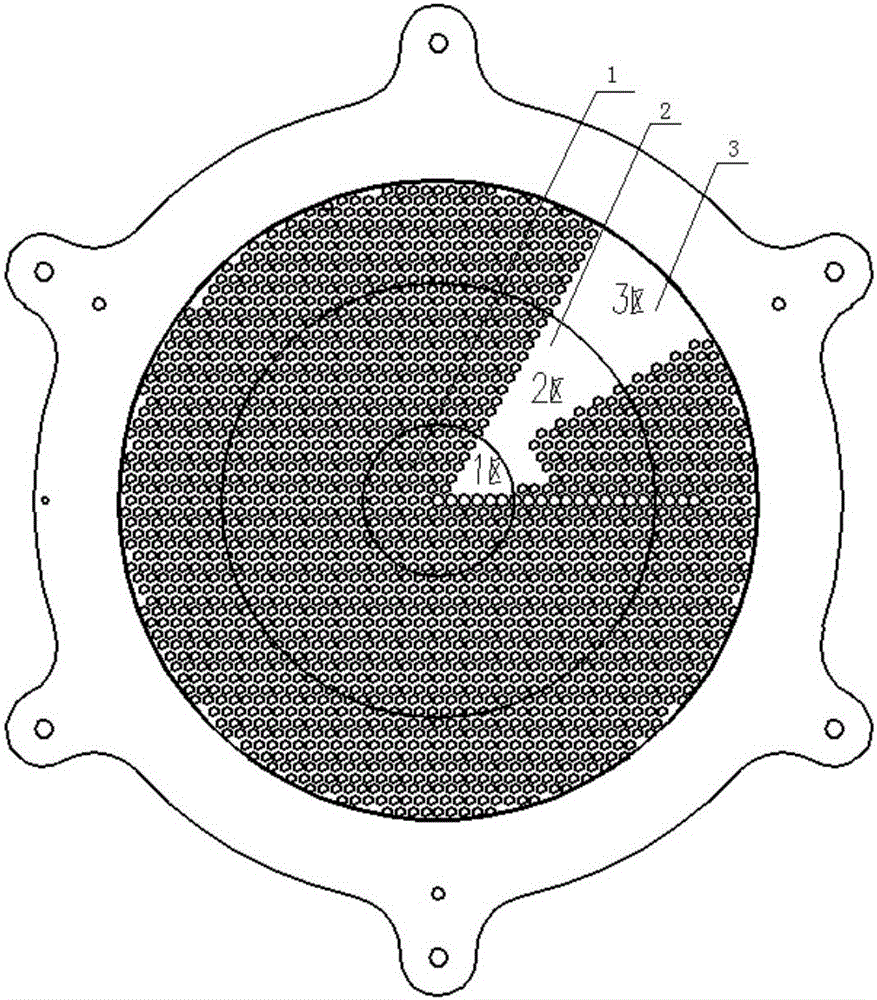

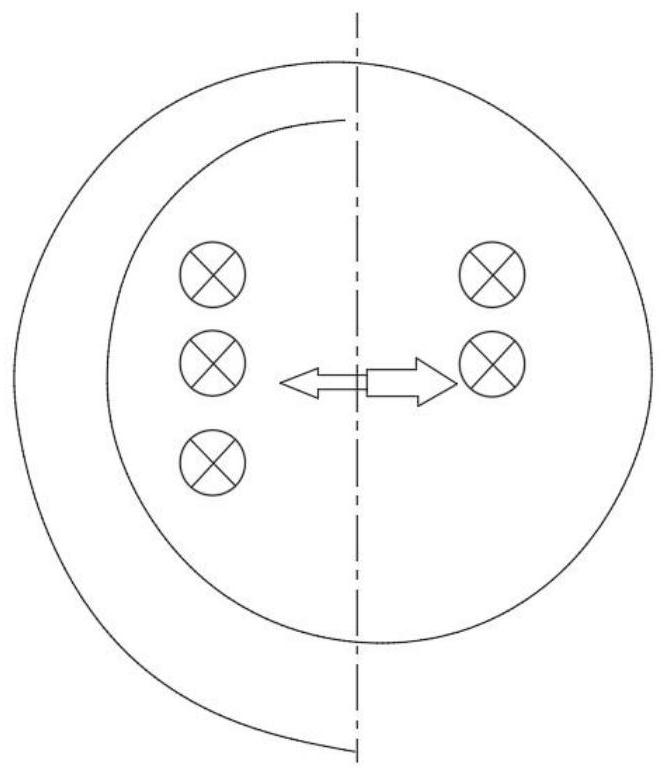

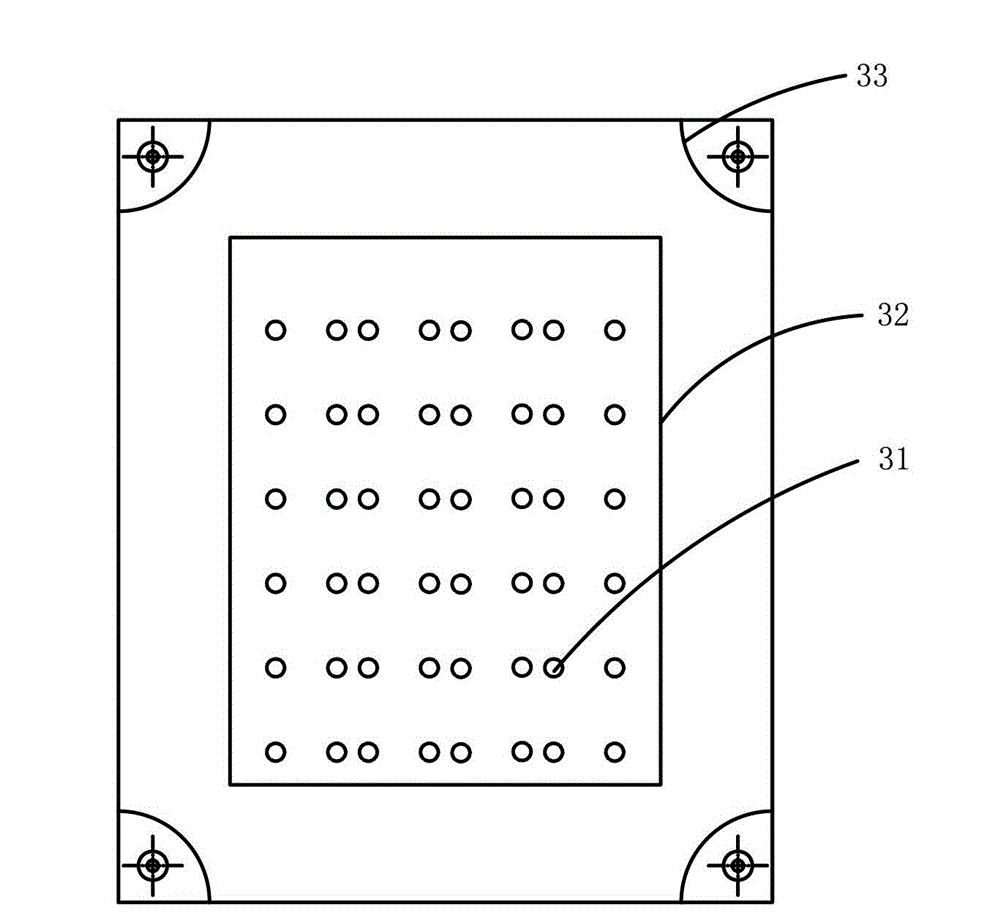

Small-caliber and variable-aperture grid assembly

InactiveCN105097407AGuarantee job stabilityReduce bombardment splashElectric discharge tubesCharge exchangeEngineering

The invention discloses a small-caliber and variable-aperture grid assembly. The target of prolonging the service life of an ion thruster is achieved by improving the beam extraction uniformity and prolonging the service life of the grid assembly. An accelerating grid in the grid assembly is uniform in diameter; an opening region of a screen grid is divided into a plurality of regions with different pore diameters; the pore diameters are sequentially increased progressively from small to large from the center region to the edge region, so that the beam extraction in the center region is suppressed and reduced; and the beam in the edge region is increased to improve the beam uniformity. Due to the reduction of the beam in the center region, charge exchange ions in the region can be effectively reduced, so that sputtering corrosion to the region of the grid assembly caused by the charge exchange ions is reduced, and the service life of the grid assembly is prolonged.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

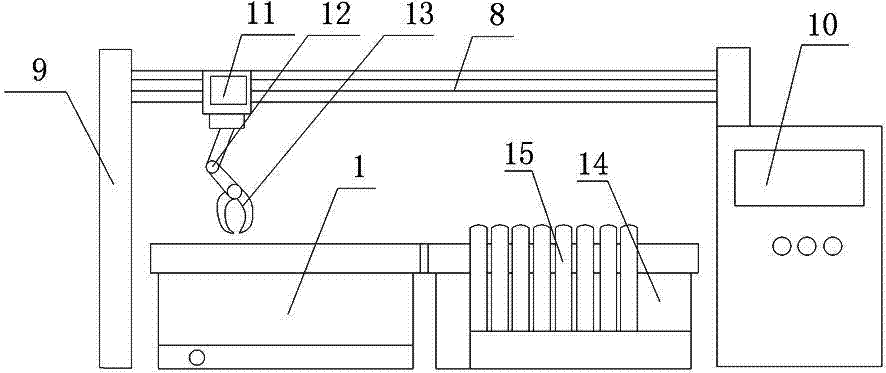

Automatic etching and cleaning device for PCB

InactiveCN104853526AReduce labor intensityGuaranteed cleaning qualityConductive pattern polishing/cleaningRobotic controlEtching

The invention discloses an automatic etching and cleaning device for a PCB, and the device comprises an etching tank, a cleaning tank, a grabbing mechanism, a cross bar, a support, and a control box. The grabbing mechanism comprises a mechanical arm controller, a mechanical arm, and a mechanical hand. The etching tank is provided with an etching agent tube, and the inlet of the etching agent tube is connected with an etching pump. The outlet of the etching agent tube is located in the etching tank, and the etching pump is connected with an etching auxiliary tank. The interior of a detection apparatus is provided with an aerometer and a probe. A side wall of the etching tank is provided with a controller, and two side walls of the cleaning tank are respectively provided with a plurality of tap water pipes. The outlets of the plurality of tap water pipes are located in the cleaning tank, and are sequentially provided with a plurality of high-pressure spraying heads from the top to the bottom. The bottom of the cleaning tank is provided with a tapered tank, and the bottom of the tapered tank is provided with a water outlet pipe. The beneficial effects of the invention are that the device is high in automation degree, is good in etching quality, and is good in cleaning quality.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Method for etching anode of printed circuit board

InactiveCN101660192AFast dissolutionHigh speedConductive material chemical/electrolytical removalCurrent meterEtching

The invention discloses a method for etching an anode of a printed circuit board, which comprises the following steps: (1) micro-etching, cleaning and drying the surface of a workpiece; (2) preparinga paintable and anticorrosive shielding pattern on the surface of the workpiece; (3) etching with etching liquid; and (4) performing finishing on the surface of the workpiece, wherein the step (3) comprises the following steps: injecting the etching liquid in an etching bath; connecting the printed circuit board with an anode of a pulse power source, and then putting the connected two serving as an anode into the etching liquid; connecting inert metal with a cathode of the pulse power source, and then putting the connected two serving as a cathode into the etching liquid; and serially connecting an ammeter in the circuit. The etching method has the advantages of quick etching, high etching quality, big etching coefficient, and even etching lines.

Owner:杨合生

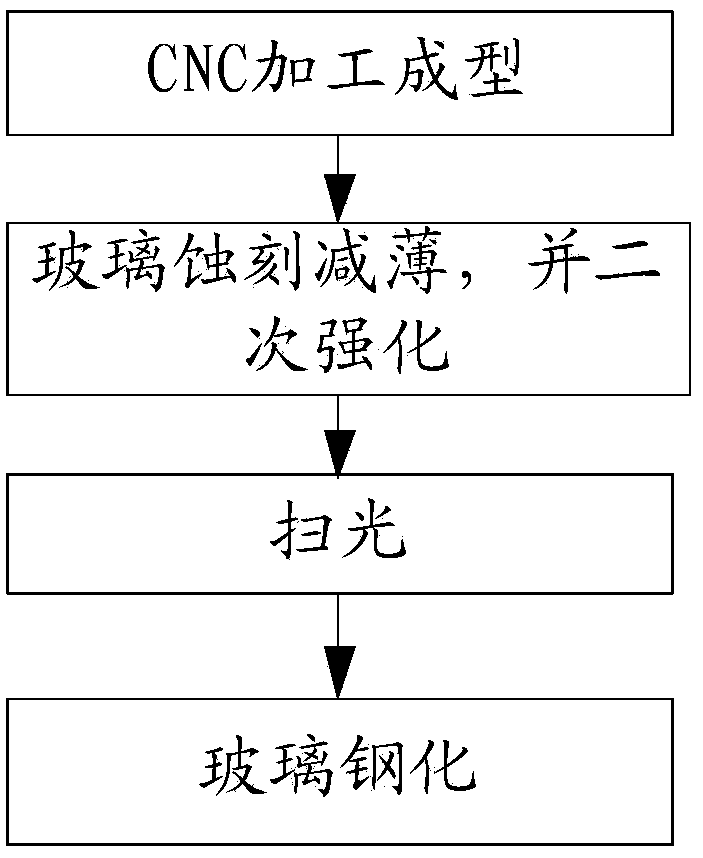

Method for increasing strength of ultra-thin glass

The invention relates to a method for increasing the strength of ultra-thin glass. The method comprises the following steps: step A, carrying out CNC (Computer Numerical Control) processing molding ona glass substrate; step B, etching and thinning the processed glass substrate, and carrying out secondary reinforcement; step C, carrying out light sweeping treatment on the reinforced glass substrate through a glass light sweeping machine; step D, tempering the glass substrate after light sweeping. According to the technical scheme disclosed by the invention, the strength of the ultra-thin glassof which the thickness range is 0.10 to 0.33 mm can be increased, the requirement of existing mobile phone cover plate and a protective piece on strength can be met, and accident breakage during a dropping process of a mobile phone, a tablet PC (Personal Computer) and the like can be reduced, so that electronic products can be protected.

Owner:YONGZHOU FUXING ELECTRONICS SCI & TECH

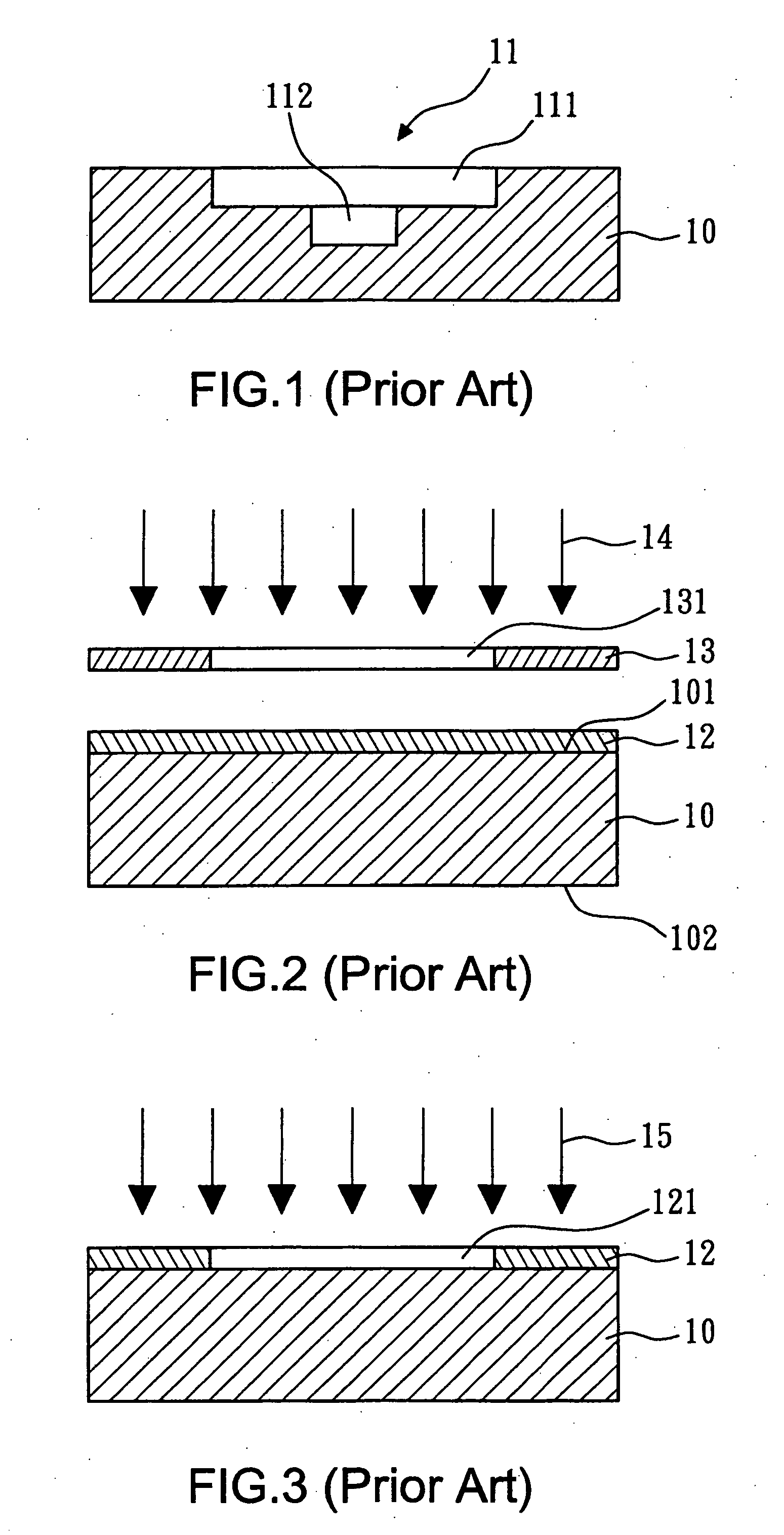

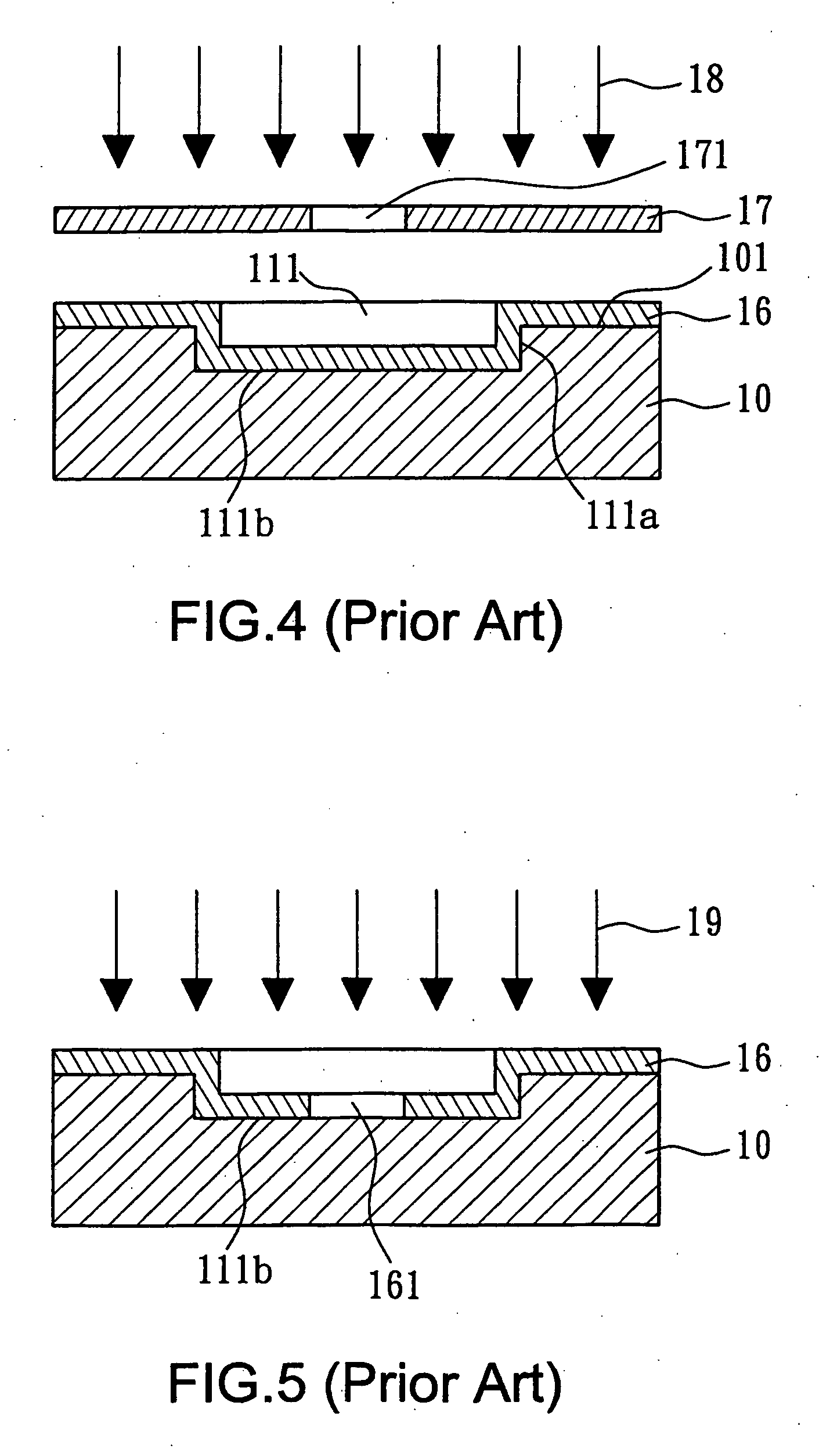

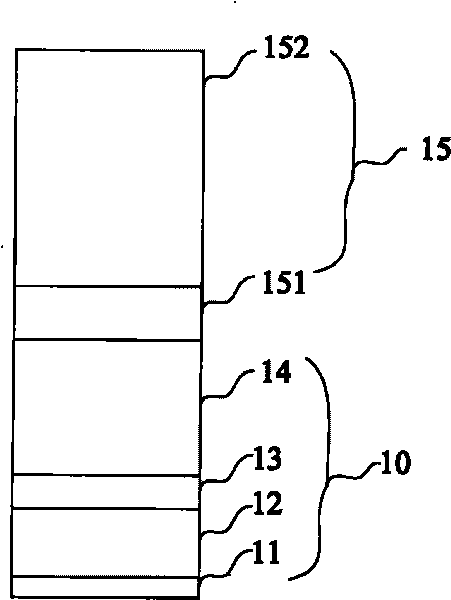

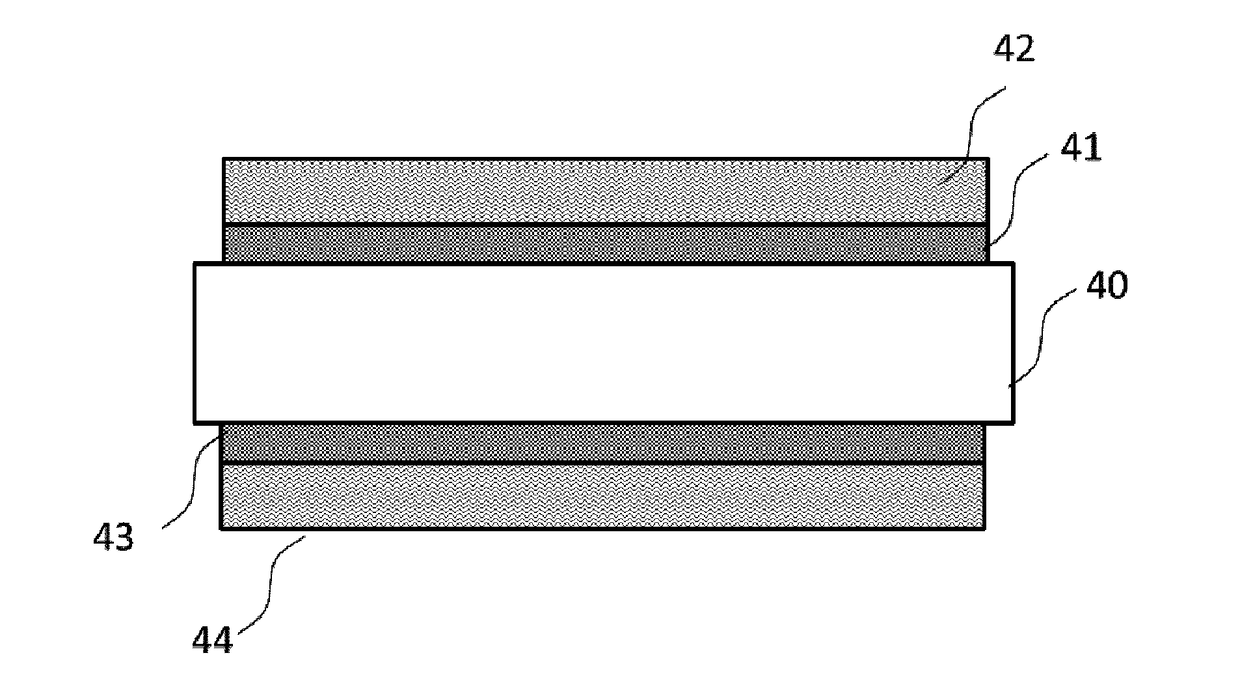

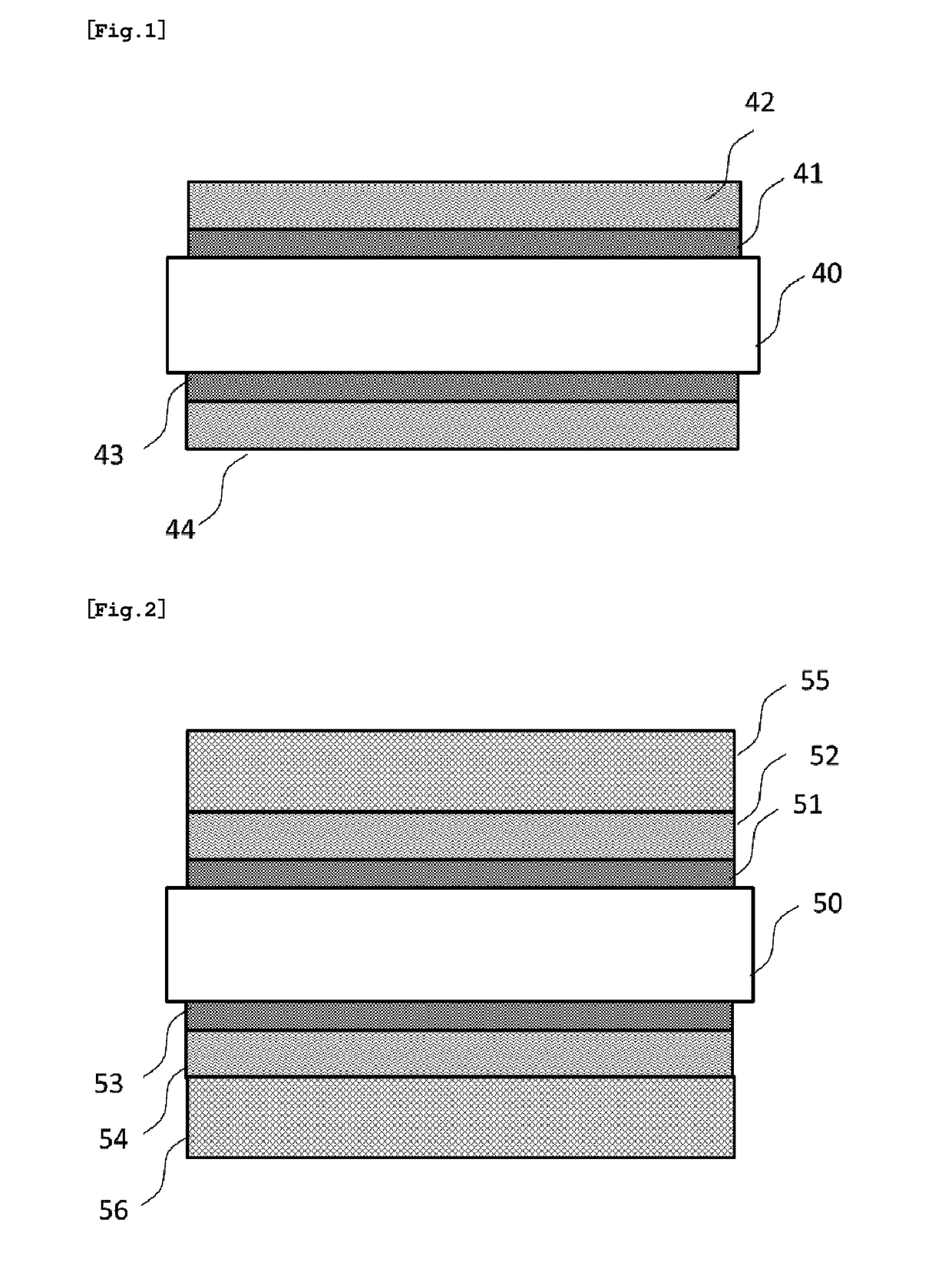

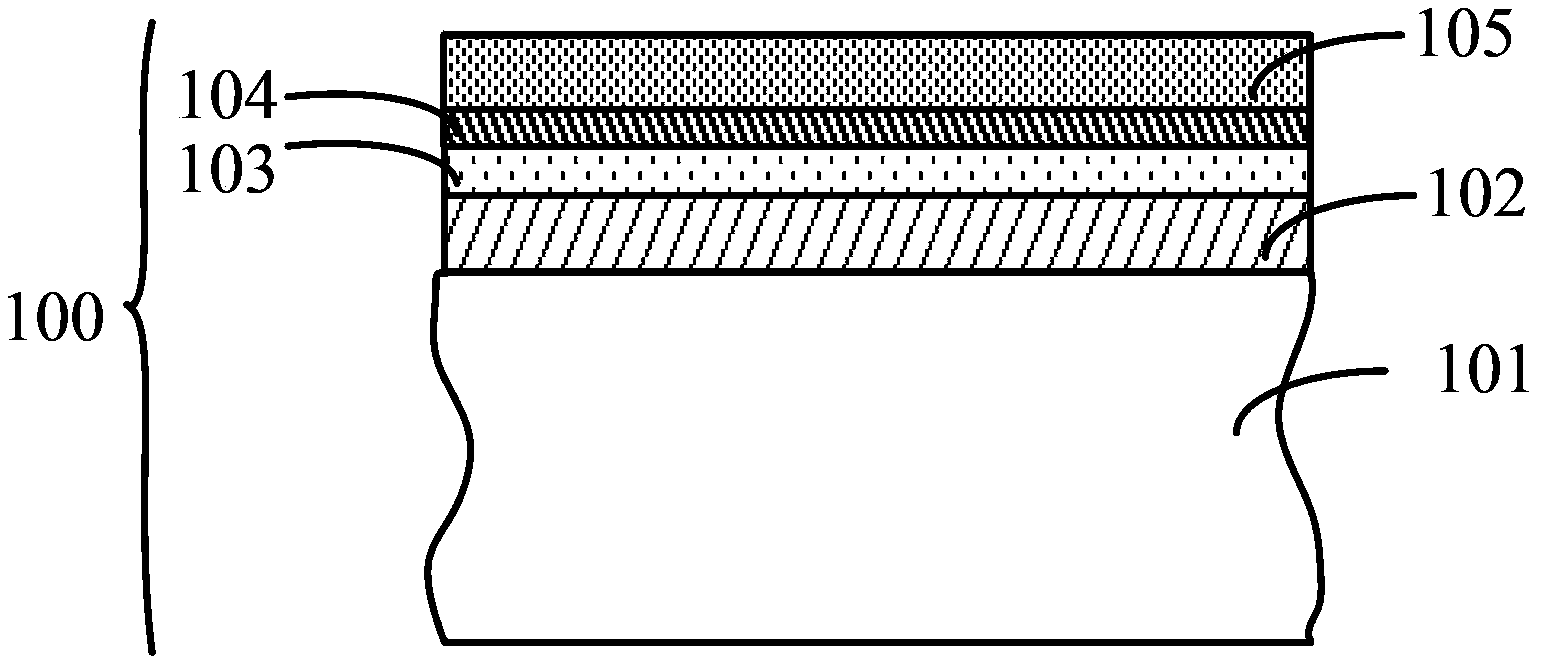

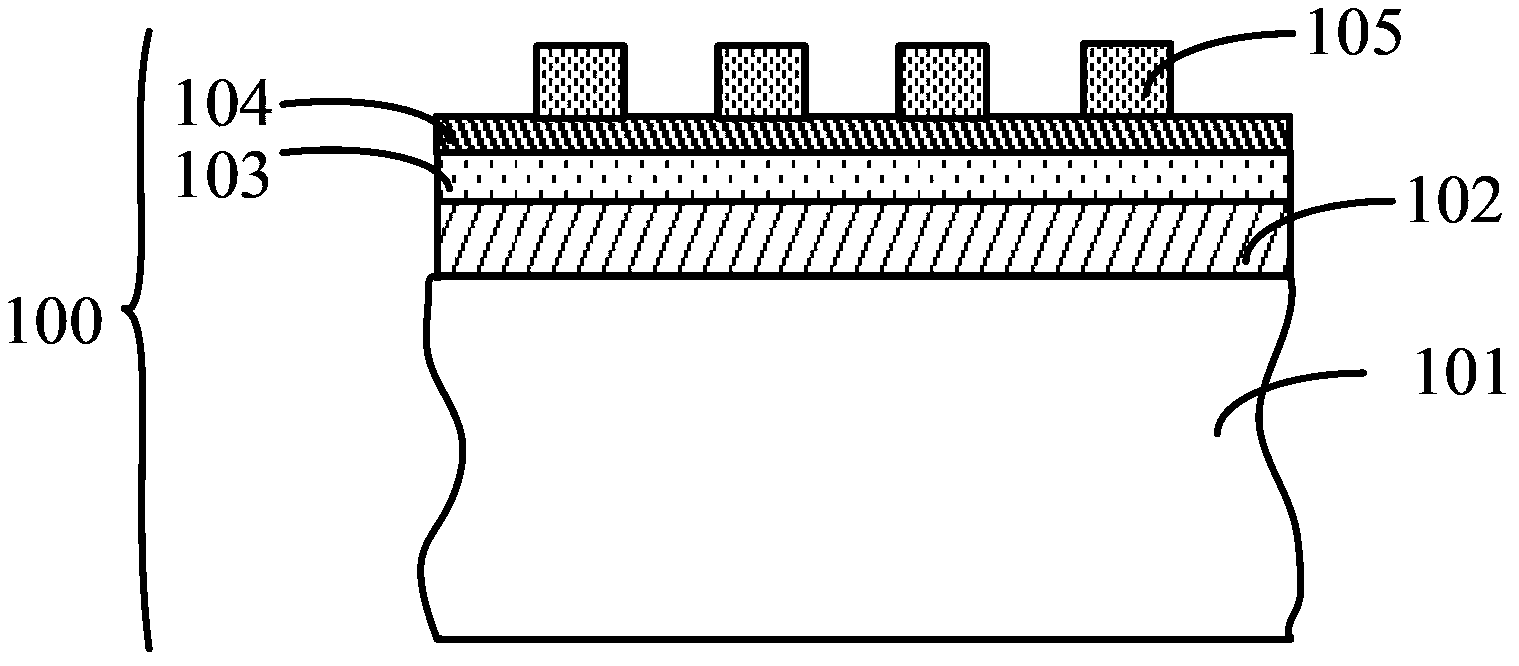

Multi-layer photoresist and method for making the same and method for etching a substrate

InactiveUS20070042287A1Improve etch qualityImprove efficiencyDiffusion transfer processes3-dimensional image productionResistPhotoresist

The present invention relates to a multi-layer photoresist and the method for making the same and method for etching a substrate. The multi-layer photoresist comprises a plurality of photoresist layers, wherein the photoresist layers have different photoreceptive areas. Therefore, the multi-layer photoresist itself has different light transmitting effects. Thus, a substrate is etched to form a 3D structure by utilizing the multi-layer photoresist directly. The conventional process of applying the photoresist for a second time is not necessary, and naturally the disadvantage that the conventional second photoresist layer is not easily controlled is eliminated, thus the etching quality is improved and the efficiency is high.

Owner:CHI LIN TECH CO LTD

Copper etching liquid composition as well as preparation method and application thereof

Owner:江苏和达电子科技有限公司 +1

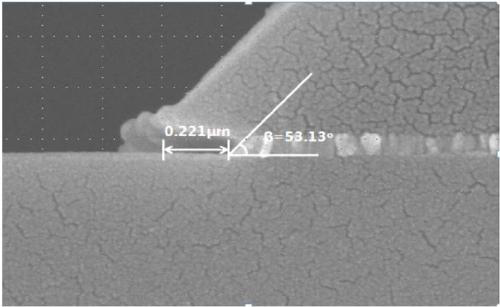

High-Efficiency and High-Quality Acidic Cupric Chloride Etchant for Printed Circuit Board

ActiveUS20150361342A1Ensure safetyMeet emissionsInsulating layers/substrates workingSurface treatment compositionsHydrogenPhysical chemistry

A high-efficiency and high-quality acidic cupric chloride etchant for printed circuit board, which contains cupric chloride, a sub-etchant and an oxidant, where the sub-etchant includes (in percentage by weight) 1%-36.5% of Hcl; 0.01%-45% of one or more compounds selected from FeCl3, FeCl2, Fe, FeO and Fe2O3. The etchant is used in connection with an automatic detection and charging control during the etching process to ensure the concentration of copper ions, the concentration of dissociated hydrogen ions and the oxidation-reduction potential in the solution arriving at set numerical values.

Owner:YE TAO

Dry film hole masking method for PTH long slotted hole

PendingCN110996537AImprove masking performanceMeet the masking requirements of dry filmConductive material chemical/electrolytical removalNon-metallic protective coating applicationAcid etchingPunching

The invention belongs to the technical field of manufacturing of printed circuit boards. The invention provides a dry film hole masking method for a PTH long slotted hole. The dry film hole masking method comprises the following steps of pressing of a conventional multilayer board, outer layer drilling, CNC groove milling, board electroplating and grinding, copper deposition, VCP primary copper plating, line board grinding, dry film pasting, LDI exposure, development, line inspection, acid etching and inspection. In the CNC groove milling process, cold punching plates are additionally arrangedon the upper face and the lower face of the PCB, and the burr height is controlled. According to the method, the dry film mask hole quality of the 4.0*50.0 mm PTH long groove can be stably and efficiently ensured, so that the processing requirement of acid etching is met.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

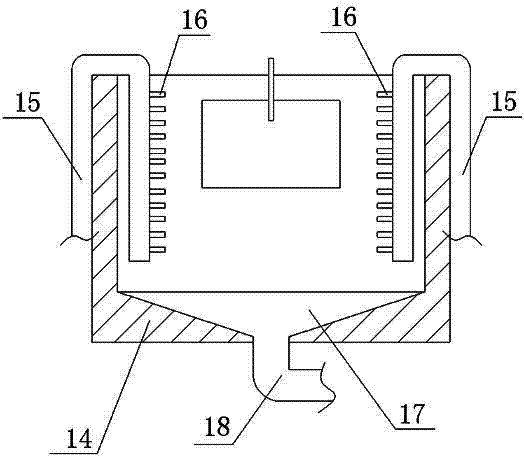

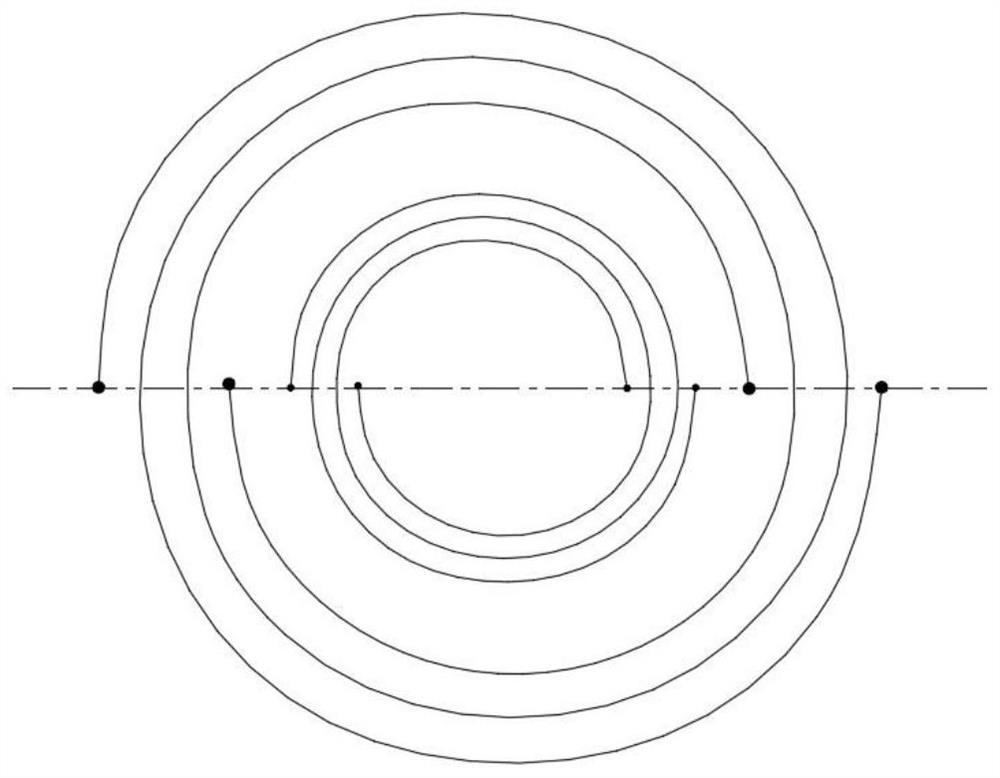

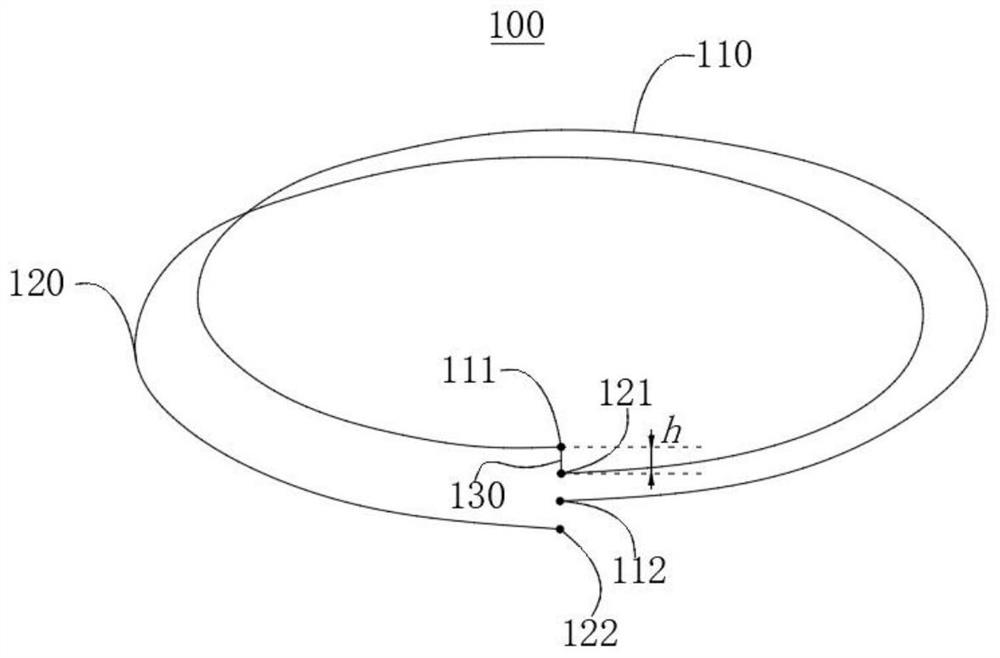

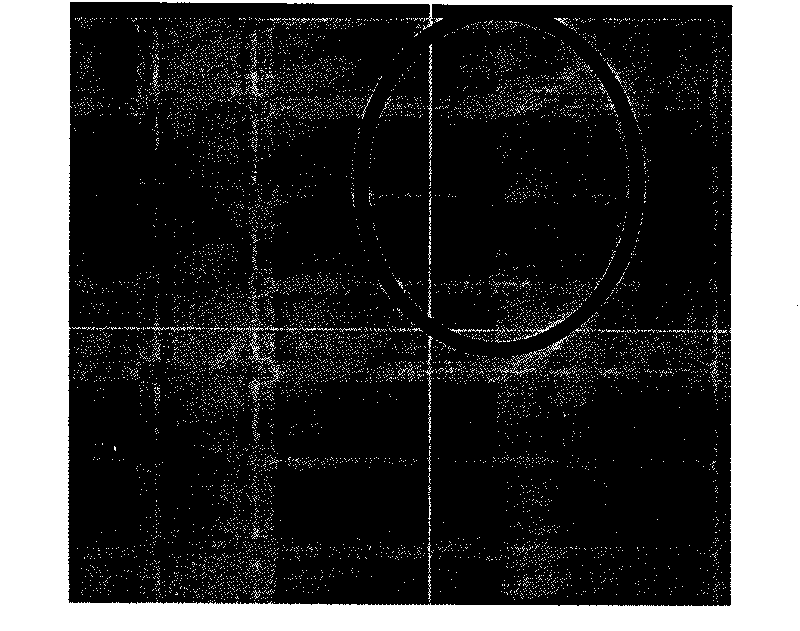

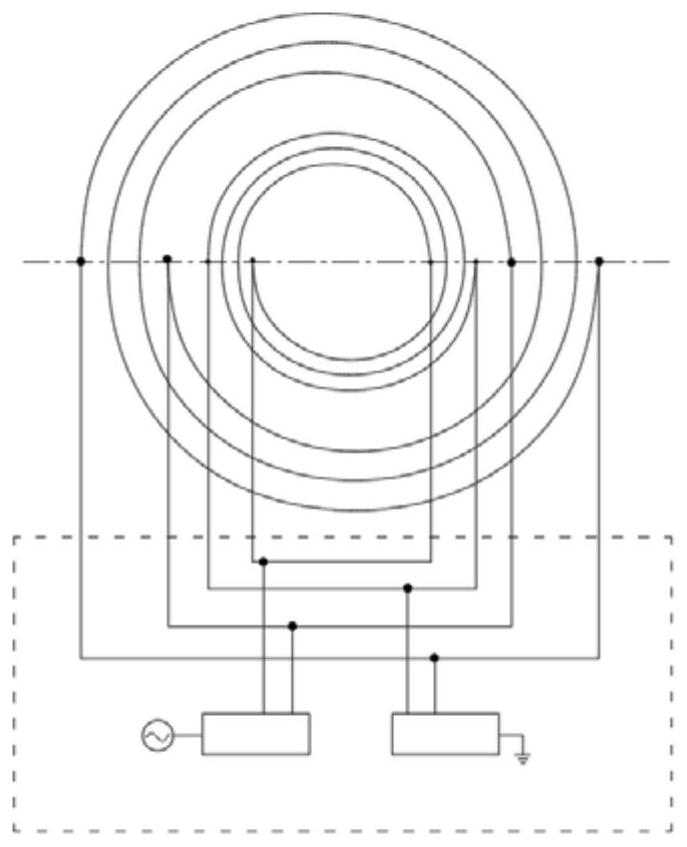

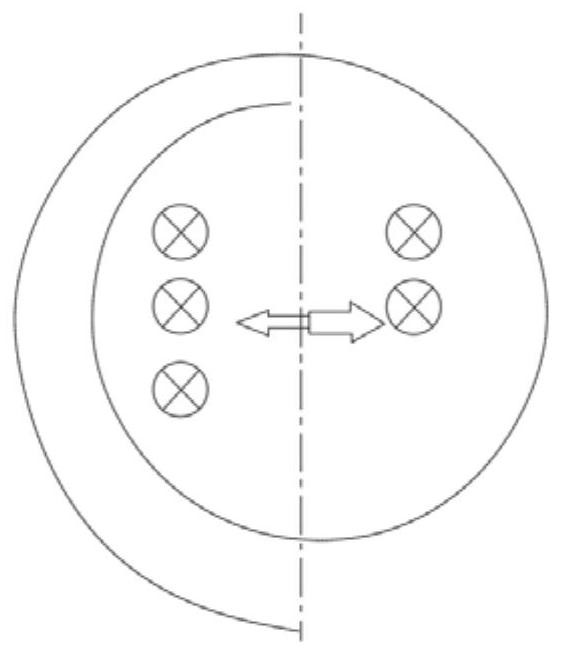

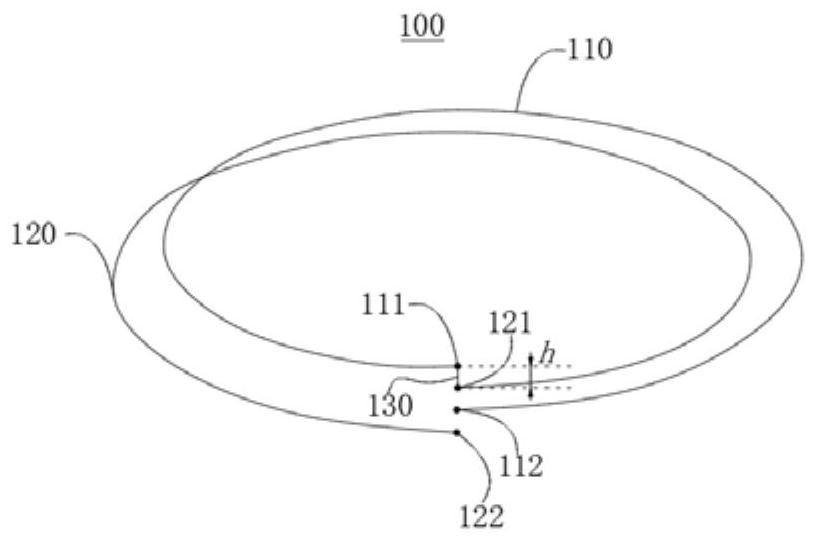

Coil structure and semiconductor processing equipment

InactiveCN111785605AImprove etch qualityImprove etching efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical connectionEngineering

The invention relates to the technical field of semiconductors, in particular to a coil structure. The coil structure comprises at least one coil assembly. The coil assembly comprises a first coil anda second coil, wherein the first coil and the second coil are wound to form an annular area, the first end of the first coil and the first end of the second coil are both gradually close to an innerring of the annular area, and the second end of the first coil and the second end of the second coil are both gradually close to an outer ring of the annular area; the first end of the first coil is electrically connected with the first end of the second coil, or the second end of the first coil is electrically connected with the second end of the second coil; the first coil forms a first projection on a plane perpendicular to the axial direction of the coil structure, the second coil forms a second projection on a plane perpendicular to the axial direction of the coil structure, and the firstprojection and the second projection are in mirror symmetry. The coil structure can produce uniform plasmas, and the etching quality and the etching efficiency of a semiconductor are effectively improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

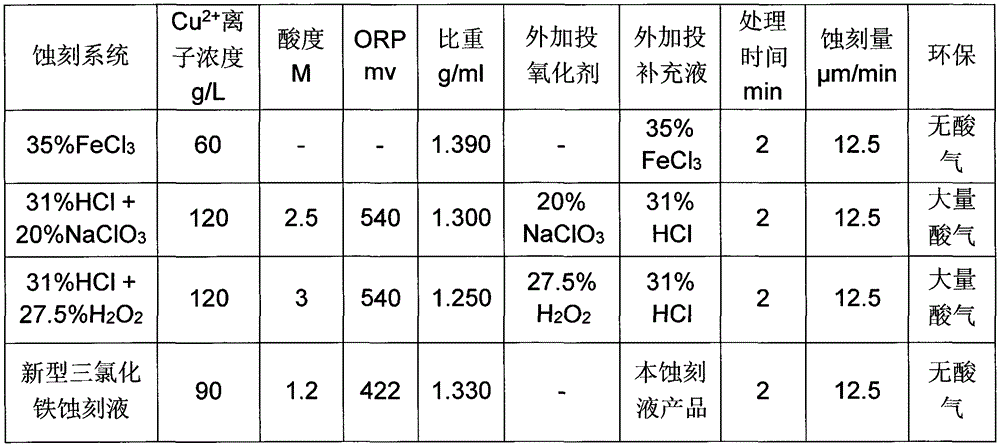

Novel ferric trichloride etching solution

InactiveCN105887088AEnvironmental Process ImprovementImprove liquidityCopper chlorideOxidizing agent

A novel ferric trichloride etching solution of the invention is a novel monad liquid etching technical product based on a traditional [ferric trichloride + hydrochloric acid] etching system and with acidic copper chloride etching as the leading factor. By combining advantages of two copper etching oxidants ferric trichloride and copper chloride, etching rate is stabilized and etching quality is enhanced. Production cost is reduced, and the environmental protection problem generated by an acidic copper chloride and oxidizing agent etching technology widely applied nowadays is overcome.

Owner:叶涛

Chemical thinning method of alkali-free boroaluminosilicate glass

The invention relates to a chemical thinning method of alkali-free boroaluminosilicate glass. The chemical thinning method comprises the following steps: step 1, preparing thinning etching liquid; step 2, performing visual examination on alkali-free borosilicate glass; step 3, performing sealing treatment on the periphery of the alkali-free borosilicate glass; step 4, cleaning the alkali-free borosilicate glass; step 5, putting the alkali-free borosilicate glass into the prepared etching liquid groove for performing etching; and step 6, cleaning, drying and measuring the etched alkali-free borosilicate glass. The chemical thinning method has the following advantages: the chemical thinning method improves the etching quality of the alkali-free boroaluminosilicate glass, the etching qualityis good, the glass with the thickness of 0.8mm can be thinned to 0.4mm, even lower than 0.4mm, the thinning time is short, the thinning yield is high, the glass surface etching effect is good, the method is applicable to large-scale production in factories, and the etching liquid for thinning is easy to prepare.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

A molybdenum-aluminum common etching solution and an etching method

In order to overcome the problems of low etching efficiency and high cost of an M3 layer and an LS layer in the existing LTPS technology, the invention provides a molybdenum-aluminum common etching solution, which comprises phosphoric acid, nitric acid, acetic acid, an additive and water, wherein based on the total weight of the etching solution, the content of the phosphoric acid is 55-65wt%, thecontent of the nitric acid is 3-5wt%, the content of the acetic acid is 12-18wt%, and the content of the additive is 2.5-4.0wt%, and the balance being water. The additive comprises a metal salt, an inorganic ammonium salt and an auxiliary agent. In the etching solution, the content of inorganic ammonium salt is 0.1-0.3wt%. The auxiliary agent is selected from one or more of 4-hydroxybenzene sulfonic acid, diethyl triamine pentaacetic acid and phytic acid. Meanwhile, the invention also provides an etching method by adopting the etching solution. The molybdenum-aluminum common etching solutionprovided by the invention can be used for etching M3 layers and LS layers at the same time, so that the process is simplified, the efficiency is improved, and the cost is reduced.

Owner:SHENZHEN CAPCHEM TECH CO LTD

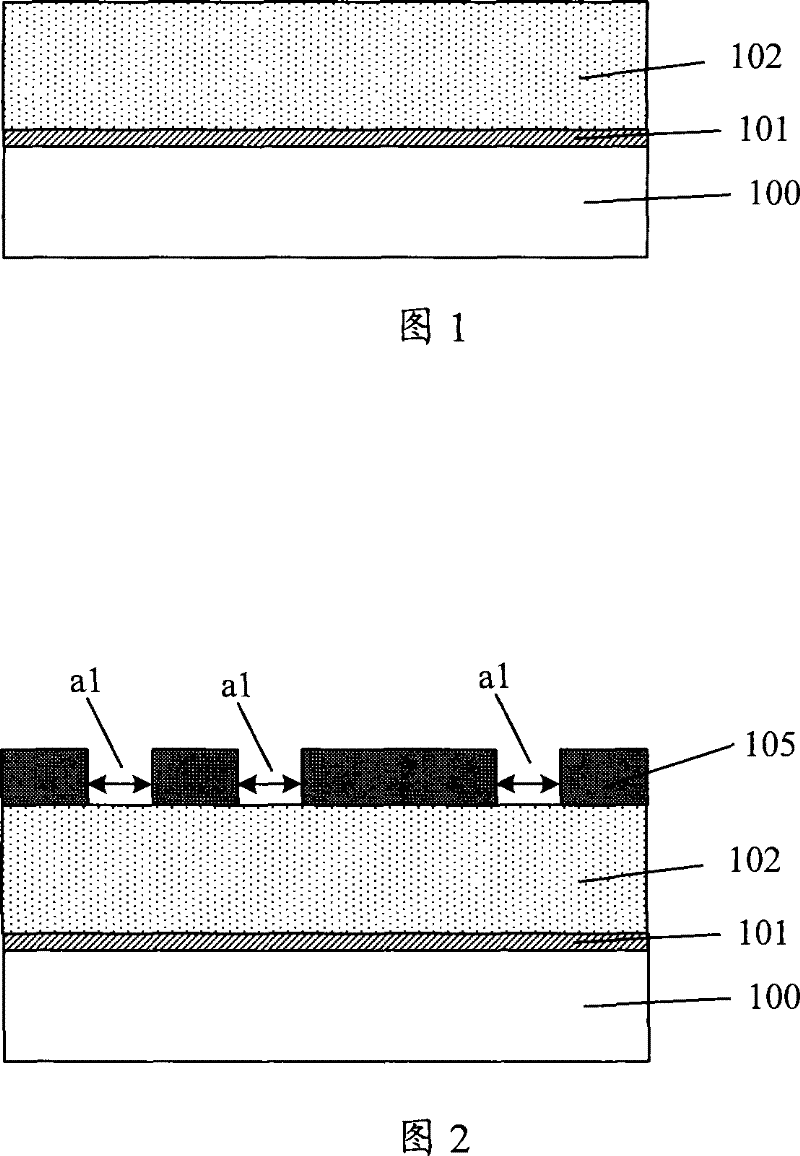

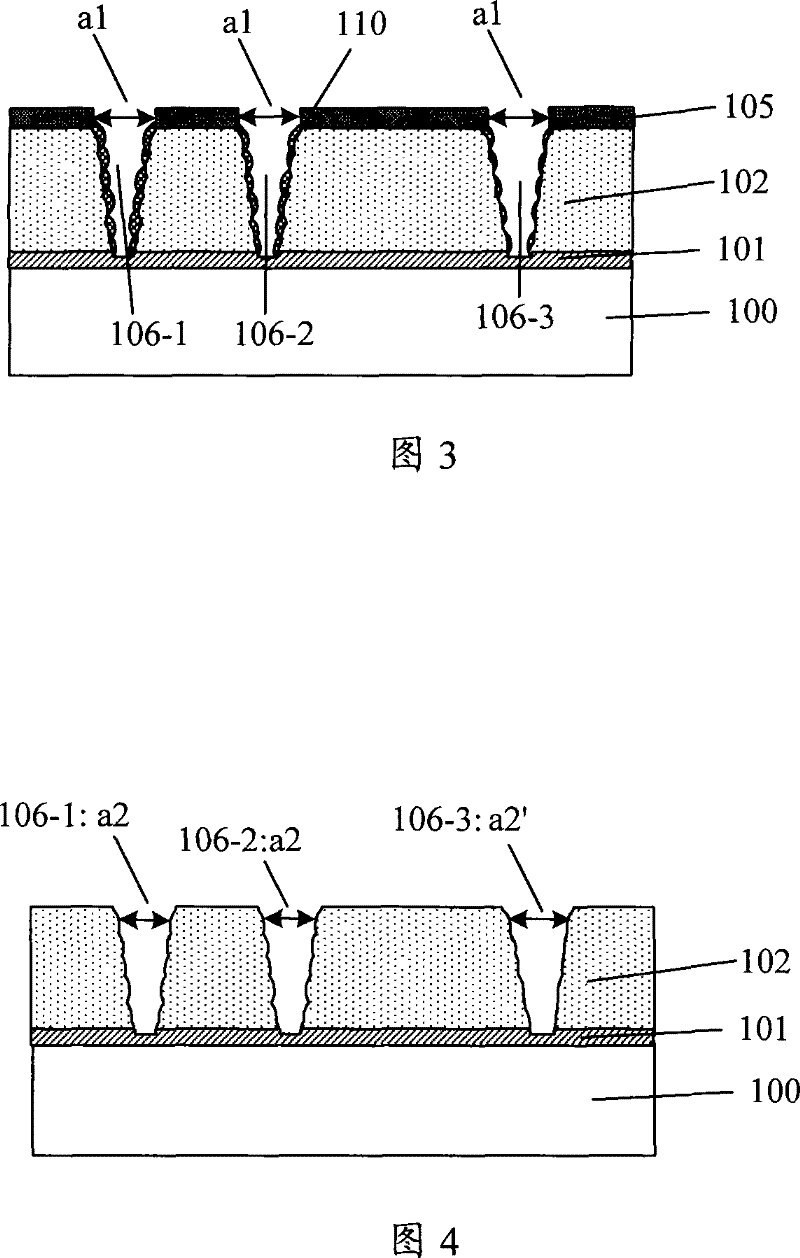

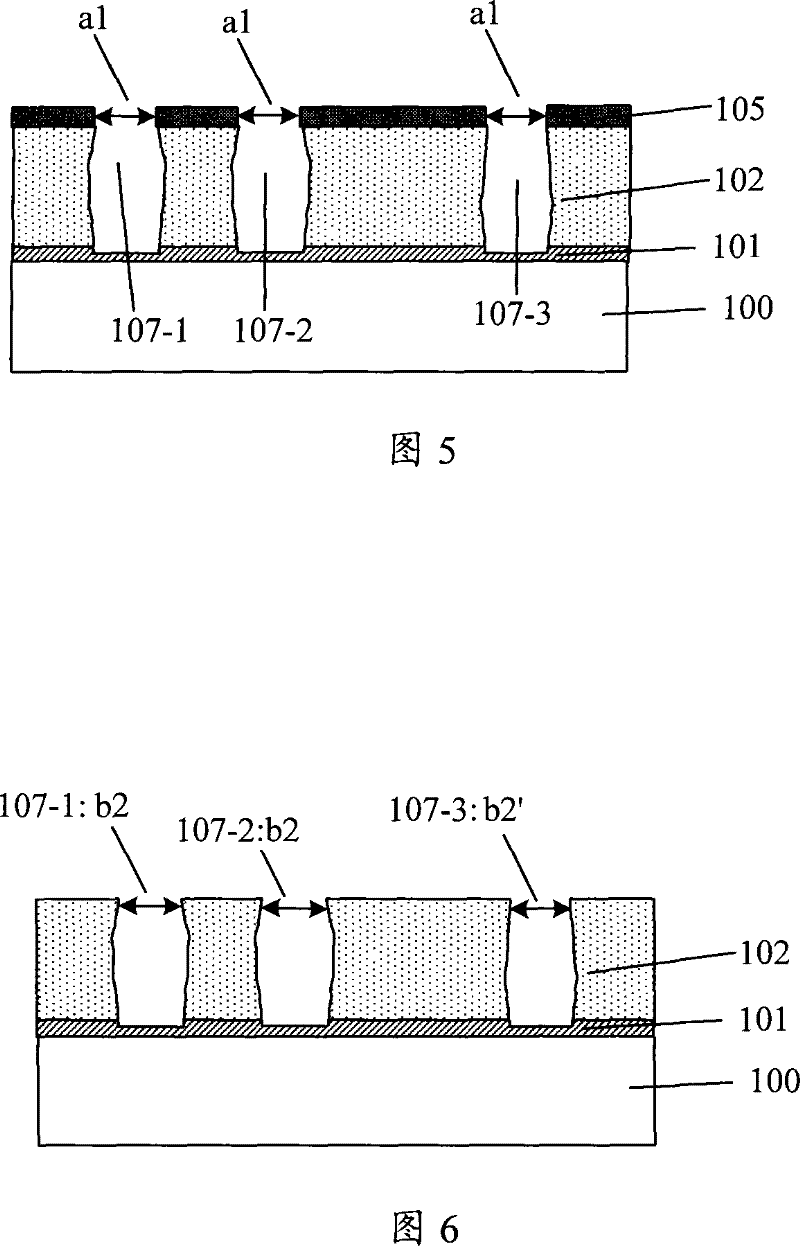

Etching method

InactiveCN101740328AReduce thicknessImprove etch qualitySemiconductor/solid-state device manufacturingSemiconductor devicesMask layerPhysics

The invention provides an etching method for improving etching quality. The method comprises the steps of: providing a substrate; forming a shielding layer, a bottom anti-reflection layer and a photoresist layer on the substrate in sequence to form a mask layer; patterning the mask layer; and etching the substrate on the basis of the patterned mask layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

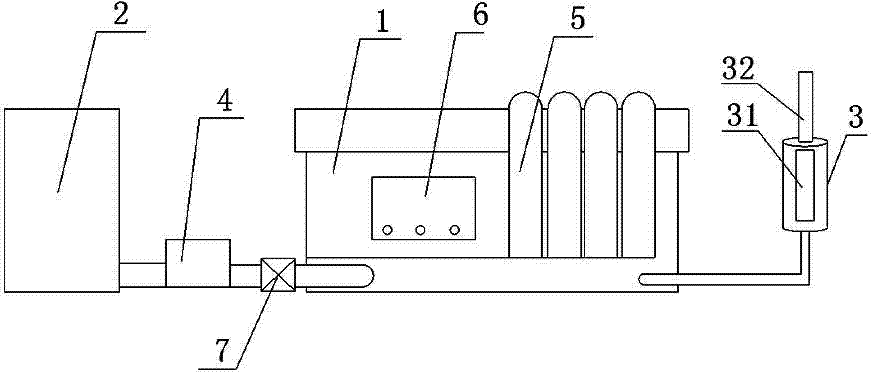

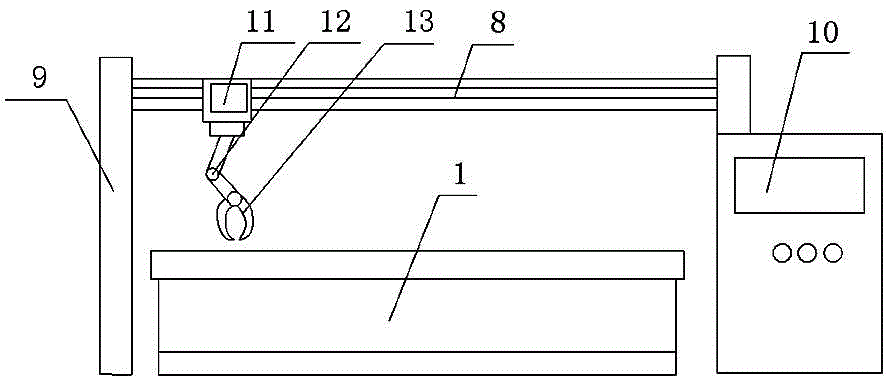

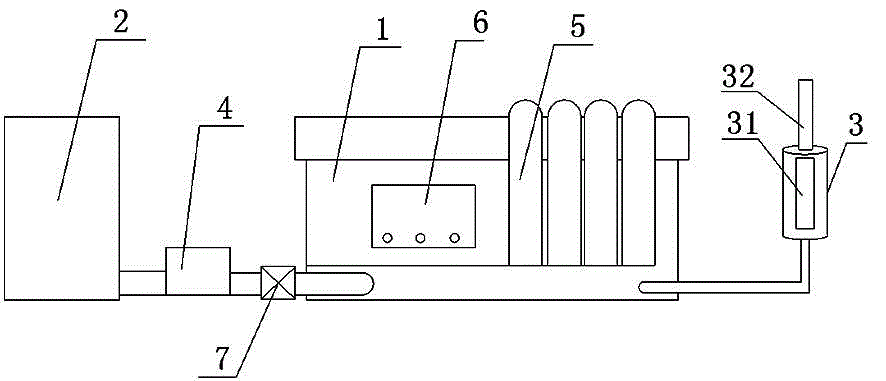

Full-automatic etching device

The invention discloses a full-automatic etching device which comprises an etching groove (1), a grabbing mechanism, a cross rod (8), a support (9) and a control box (10). The grabbing mechanism comprises a manipulator controller (11), a mechanical arm (12) and a manipulator (13), the manipulator controller (11) and the mechanical arm (12) are connected movably, the manipulator controller (11) is movably mounted on the cross rod (8), an etching agent pipe (5) and a detection device (3) are mounted on the etching groove (1), an inlet of the etching agent pipe (5) is connected with an etching pump (4) while an outlet of the same is positioned in the etching groove (1), the etching pump (4) is connected with an auxiliary etching groove (2), a gravimeter (31) and a probe (32) are arranged in the detection device (3), and a controller (6) is arranged on the side wall of the etching groove (1). The full-automatic etching device has the advantages of high automation level, high etching quality and low labor intensity.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

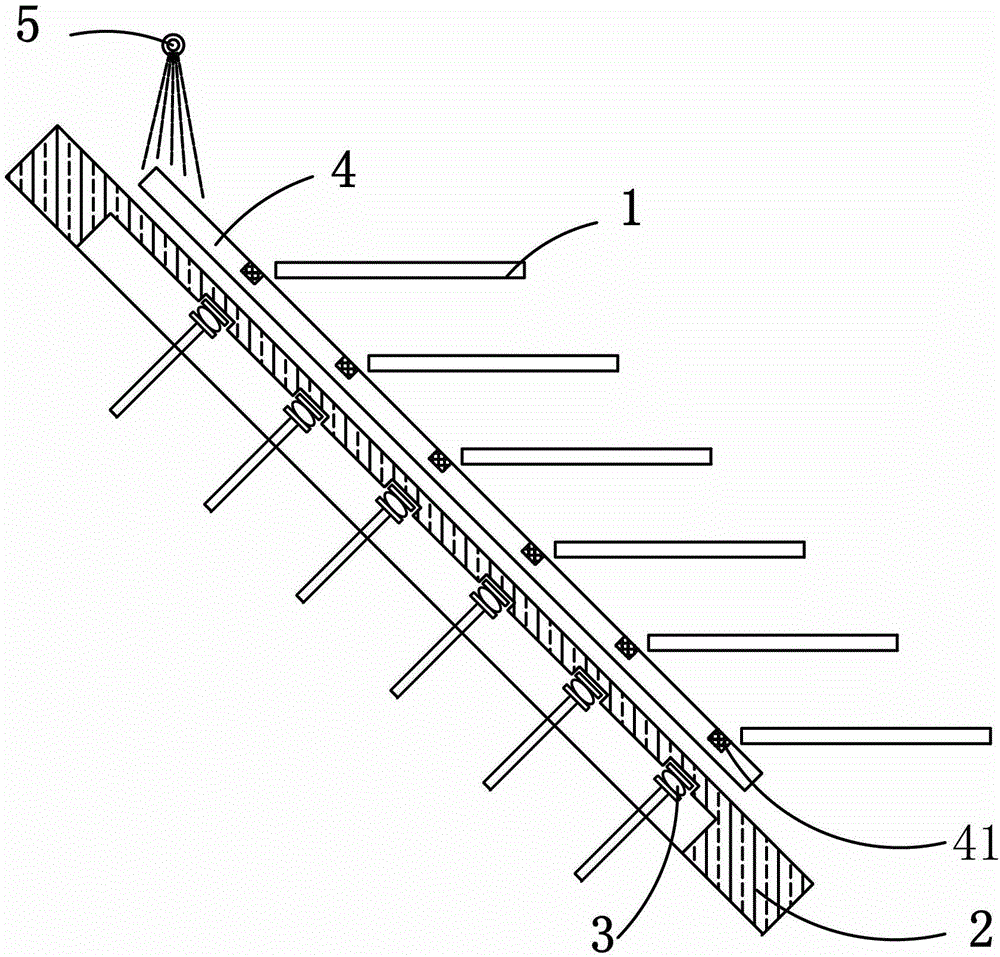

OLED (Organic Light Emitting Diode) panel thinning device and application method thereof

The invention discloses an OLED (Organic Light Emitting Diode) panel thinning device which comprises an etching liquid spraying system as well as nitrogen ejection tubes, quartz baffles and constant temperature heaters, wherein an inclined angle is formed between the nitrogen ejection tubes and the upper surface of an OLED panel and the nitrogen ejection tubes are not contacted with the OLED panel; one nitrogen ejection tube is arranged in the position of each preserved electrode testing hole in the OLED panel; the quartz baffles are arranged on the back side of the OLED panel in parallel; mounting holes of which the positions correspond to the positions of the preserved electrode testing holes in the OLED panel are formed in one sides opposite to the OLED panel, in the quartz baffles; the constant temperature heaters are arranged inside the mounting grooves; a spraying tube of the etching liquid spraying system is positioned above the OLED panel and is not contacted with the OLED panel. The invention further discloses an application method of the OLED panel thinning device. The OLED panel thinning device is simple in structure, no impurities are introduced in the application process, the misjudgement on whether the OLED panel is qualified or not is avoided, the operation is simple and convenient, and the application is convenient.

Owner:SICHUAN CCO DISPLAY TECH

Etching method and dual damascene structure forming method

ActiveCN101459074BEvenly distributedSmall apertureSemiconductor/solid-state device manufacturingEtchingDielectric layer

The invention discloses an etching method, which includes steps of providing a substrate equipped with a dielectric layer, defining etching patterns on the dielectric layer, utilizing a first etching gas to carry out first etching to the dielectric layer, and utilizing a second etching gas to carry out second etching to the dielectric layer, wherein polymer generated by the second etching gas is less than that generated by the first etching gas. The invention further discloses a corresponding method of forming a corresponding dual damascene structure, and poor uniformity in the existing etching method can be improved by adopting the etching method and the method of forming a corresponding dual damascene structure, thereby increasing the formed quality of etched patterns and the dual damascene structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

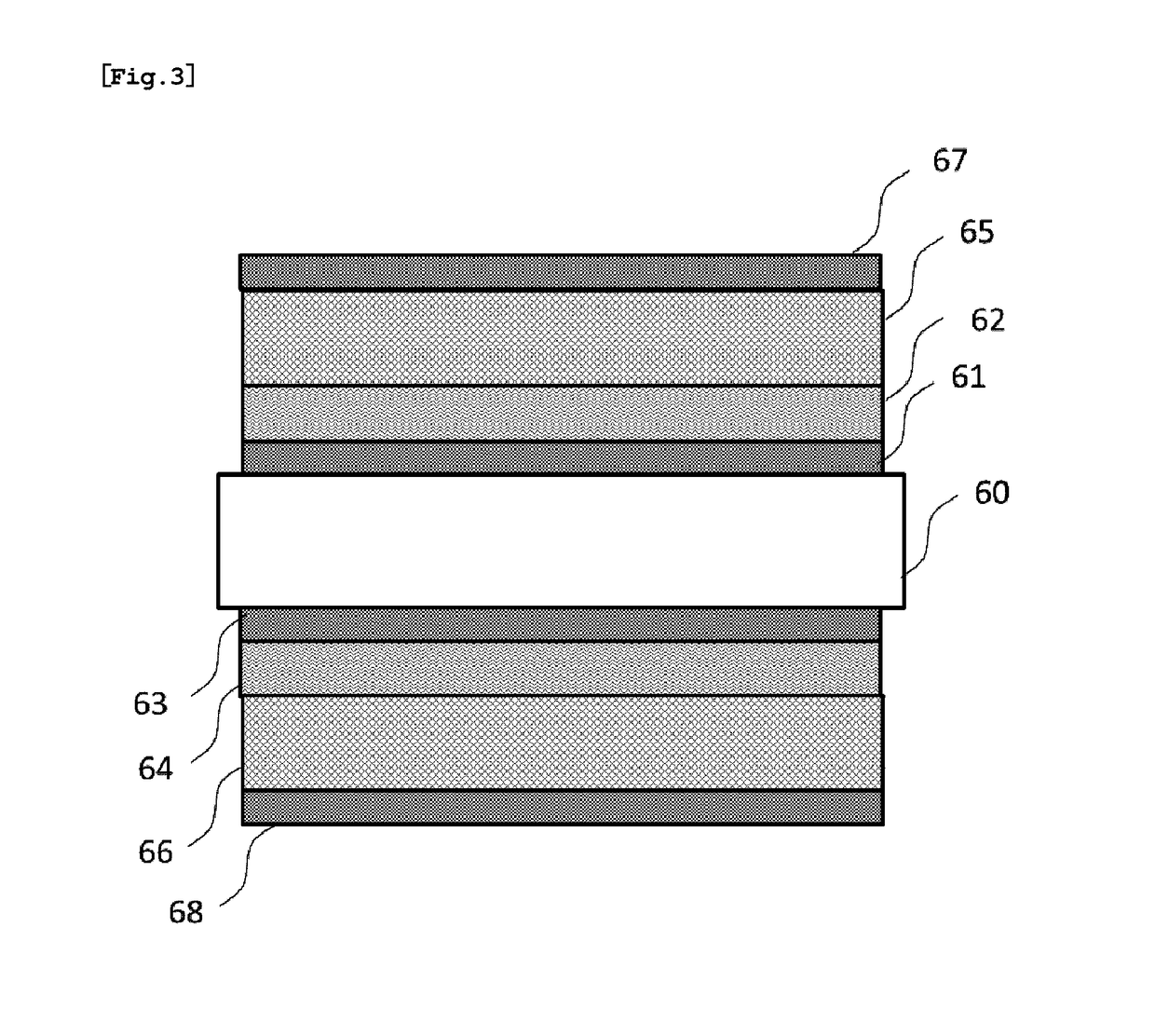

Laminate film and electrode substrate film, and method of manufacturing the same

ActiveUS20170226624A1Avoid problemsReduce the amount requiredCircuit optical detailsSemiconductor/solid-state device detailsHydrogenReactive gas

[Object] Provided are a laminate film and an electrode substrate film with excellent etching quality, in which a circuit pattern formed by etching processing is less visible under highly bright illumination, and a method of manufacturing the same.[Solving Means] A laminate film includes a transparent substrate 60 formed of a resin film and a layered film provided on at least one surface of the transparent substrate. The layered film includes metal absorption layers 61 and 63 as a first layer and metal layers (62, 65), (64, 66) as a second layer, counted from the transparent substrate side. The metal absorption layers are formed by a reactive sputtering method which uses a metal target made of Ni alone or an alloy containing two or more elements selected from Ni, Ti, Al, V, W, Ta, Si, Cr, Ag, Mo, and Cu, and a reactive gas containing oxygen. The reactive gas contains hydrogen.

Owner:SUMITOMO METAL MINING CO LTD

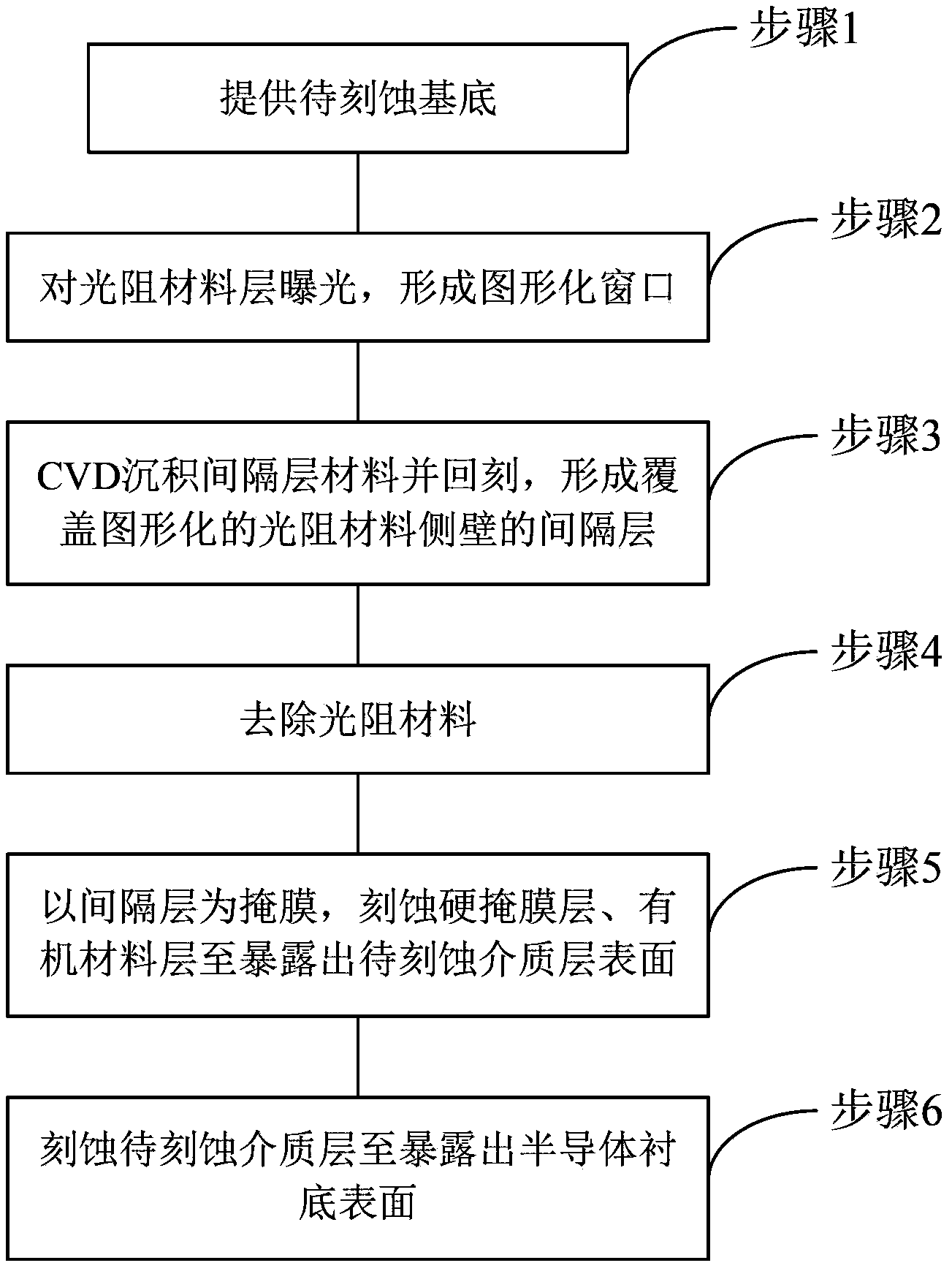

Spacing layer double-exposure etching method

ActiveCN104299899AShape correctionImprove etch qualitySemiconductor/solid-state device manufacturingSemiconductorIon

The invention relates to the technical field of semiconductors, and discloses a spacing layer double-exposure etching method. Before etching of an organic material layer and a semiconductor substrate, etching is performed on a spacing layer by adopting etching gas which contains CF4, Ar and Xe and is easy to form positive ion gas so that correction of the shape of the spacing layer is realized. Thickness of the spacing layer is reduced, and the shape of the spacing layer is corrected into a symmetrical or approximately symmetrical structure so that problems of uneven etching rate and over-etching caused by the spacing layer can be avoided. Meanwhile, the spacing layer is thinned via etching so that stress between the spacing layer and the organic material layer is reduced to some extent, and thus line edge roughness of the etching structure is improved and etching quality of the semiconductor substrate is enhanced.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

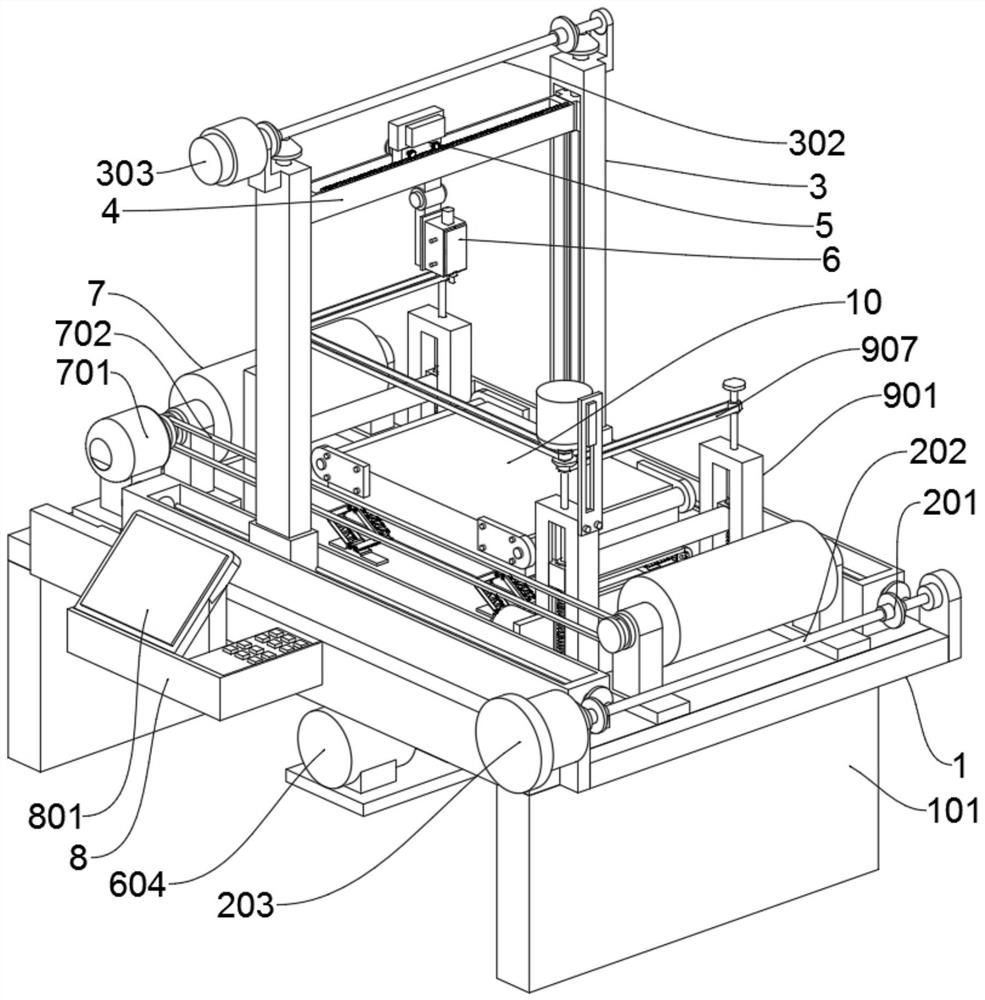

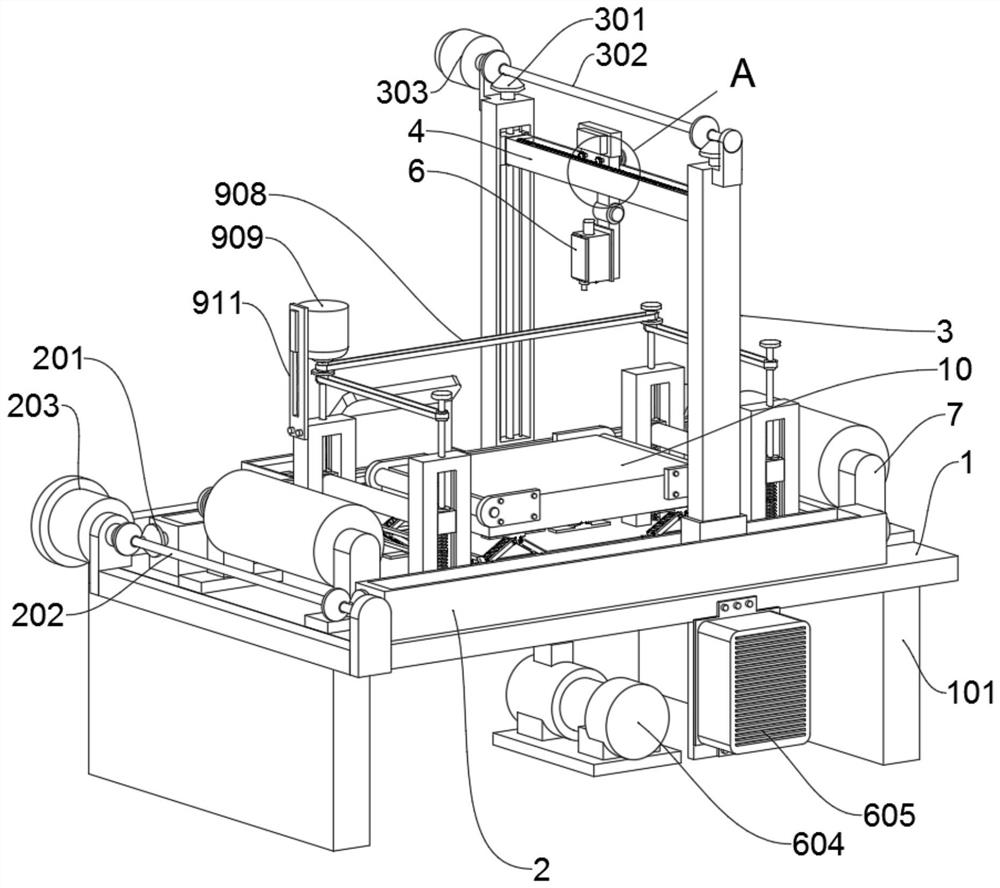

High-speed laser etching device for PET film

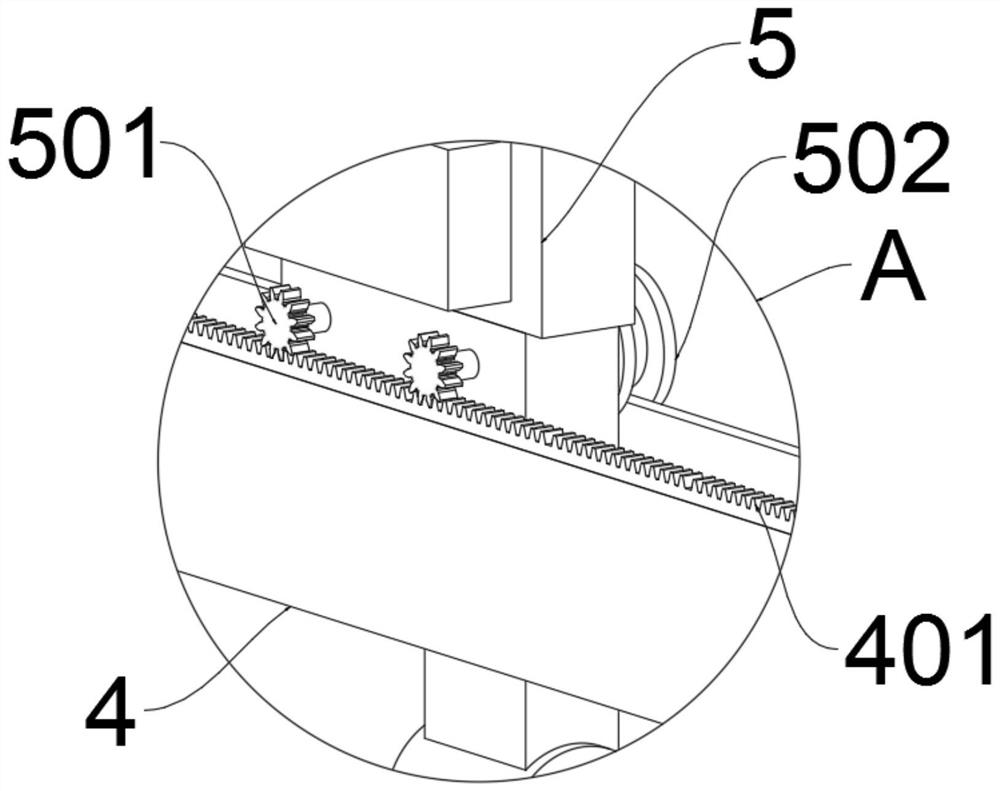

PendingCN113084356AFast laser etchingReduce frictionPrinted circuitsMetal working apparatusLaser etchingMotor drive

The invention discloses a high-speed laser etching device for a PET film, relates to the technical field of film etching, and solves the problem that an existing device cannot maintain the high etching quality while rapid laser etching is conducted on the PET film. The high-speed laser etching device for the PET film comprises a workbench. The bottom of the workbench is fixedly connected with base plates, and the two base plates are arranged. The top of the workbench is fixedly connected with transverse reciprocating lead screws, and the two transverse reciprocating lead screws are arranged. Bevel gear sets A are arranged on the right sides of the transverse reciprocating lead screws in a coaxial connection mode, and a connecting rod A is arranged on bevel gears in the bevel gear sets A in a coaxial connection mode. A stepping motor drives a bearing roller wound with the PET film to operate in a stepping manner, tensioning rollers extrude the top of the film, and therefore the film can keep the good stability in the transmission process, and the PET film can be subjected to rapid laser etching while the high etching quality is kept.

Owner:莱西市亨元产业互联网中心

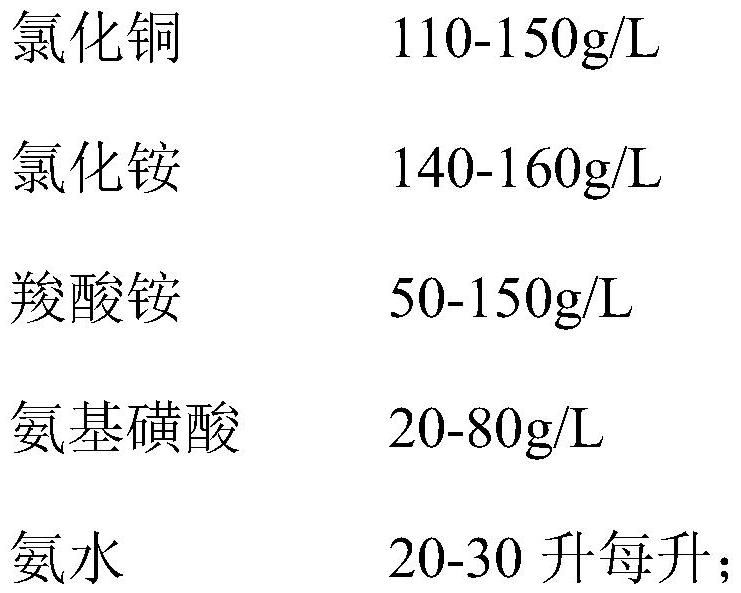

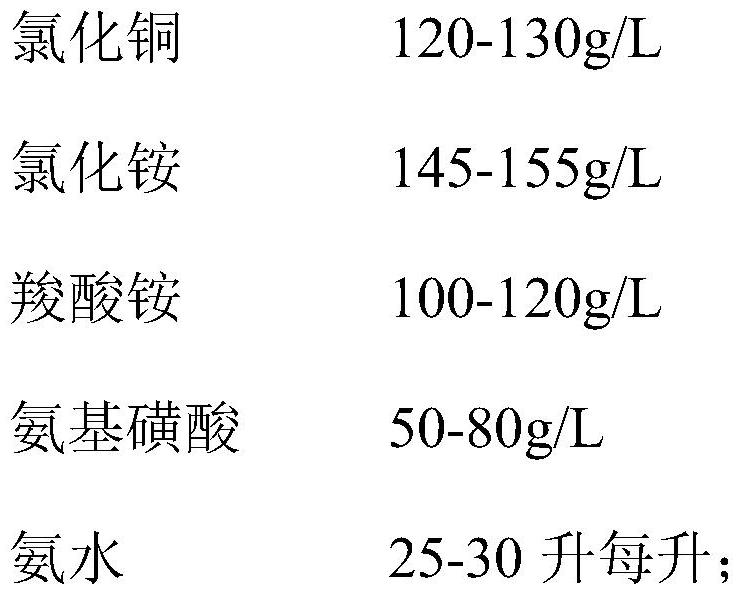

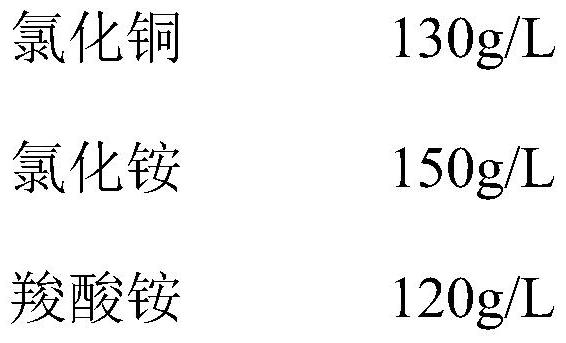

Printed circuit board alkaline etching solution suitable for electrolytic copper extraction

InactiveCN112064030AFast regenerationEtching speed is fastPhotography auxillary processesProcess efficiency improvementElectrolysisCopper chloride

The invention relates to the technical field of etching solutions, in particular to a printed circuit board alkaline etching solution suitable for electrolytic copper extraction. The alkaline etchingsolution comprises 110-150 g / L of copper chloride, 140-160 g / L of ammonium chloride, 50-150 g / L of ammonium carboxylate, 20-80 g / L of sulfamic acid and 20-30 liters of ammonia water per liter of etching solution, wherein the pH is 7.8-8.8. The printed circuit board alkaline etching solution suitable for electrolytic copper extraction contains the sulfamic acid, so that sulfamic acid chlorine can be formed during electrolysis and used as an oxidation regenerant to regenerate the etching solution on line, and the etching capacity of the etching solution is greatly improved.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

Coil structure and plasma processing equipment

PendingCN113838736ARadial size increases or gradually decreasesImprove etch qualityElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical connectionEngineering

The invention relates to the technical field of semiconductors, in particular to a coil structure which comprises at least one coil assembly. The coil assembly comprises a first coil and a second coil, the first coil and the second coil are wound to form an annular area, the first end of the first coil and the first end of the second coil are gradually close to an inner ring of the annular area, and the second end of the first coil and the second end of the second coil are gradually close to an outer ring of the annular area; the first end of the first coil is electrically connected with the first end of the second coil; and the first coil forms a first projection on a plane perpendicular to the axial direction of the coil structure, the second coil forms a second projection on the plane perpendicular to the axial direction of the coil structure, and the first projection and the second projection are in mirror symmetry. The coil structure can generate electromagnetic fields which are symmetrically distributed left and right, so that plasma which is uniformly distributed is formed, and the etching quality and the etching efficiency of a semiconductor are effectively improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com