Wet etching system and method

A wet etching, wafer technology, applied in the direction of conveyor objects, electrical components, semiconductor/solid device manufacturing, etc., can solve the problem of increased etching difference between the top of the wafer and the bottom of the wafer, and reduce the wet The effect of different etching methods and improving the etching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

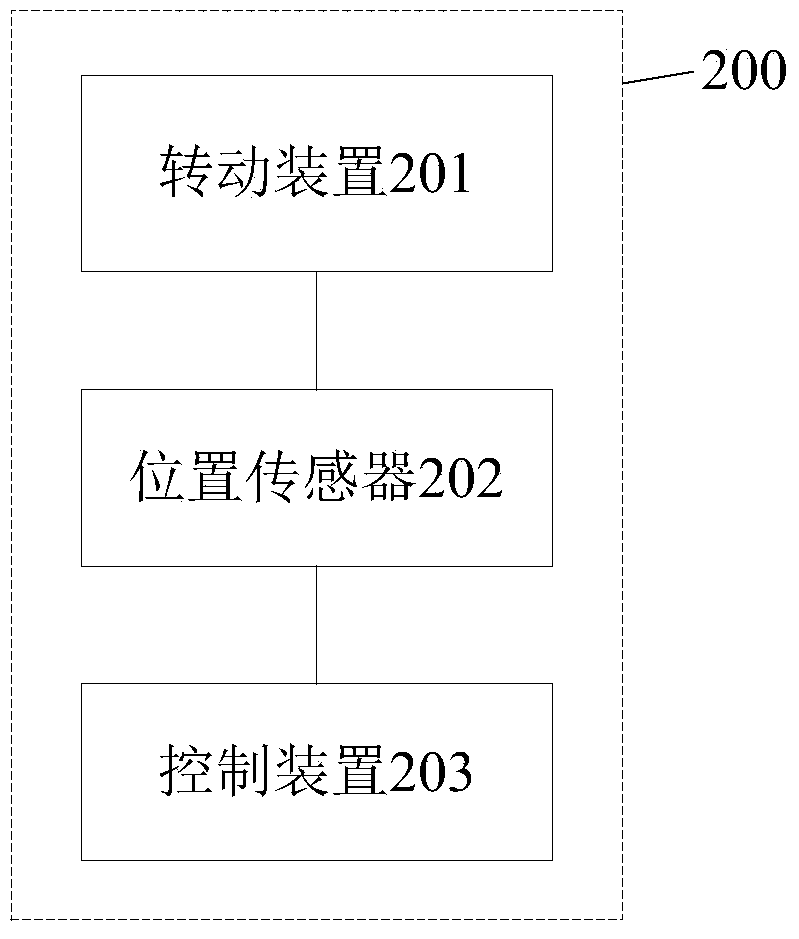

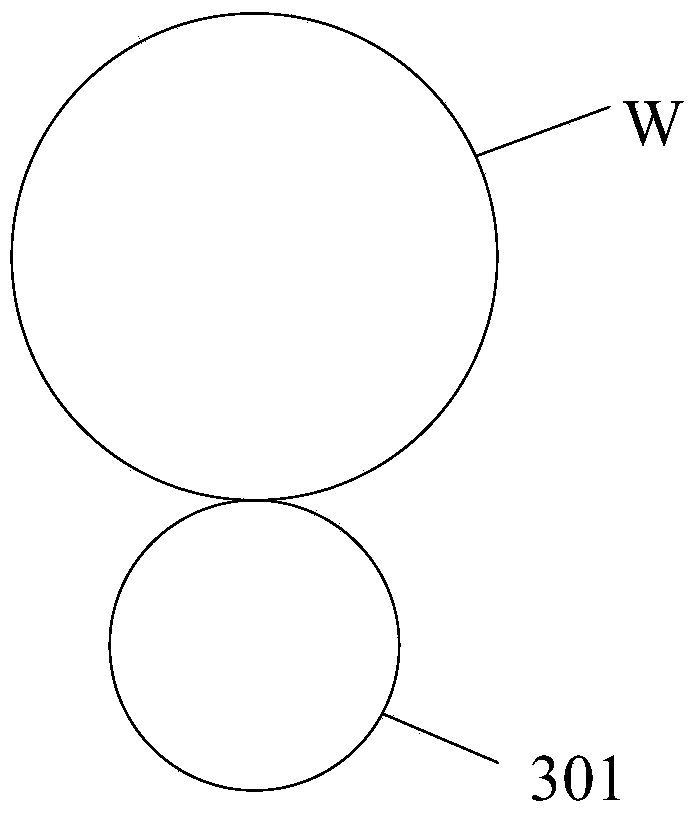

[0047] The following is attached Figure 2-4 As well as specific embodiments, the wet etching chemical solution tank of the present invention will be described in detail. in, figure 2 is a block diagram of the wet etching system of the present invention, image 3 It is a structural schematic diagram of a rotating device in a preferred embodiment of the present invention, Figure 4 It is a structural schematic diagram of a rotating device in another preferred embodiment of the present invention. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0048] see figure 2 , the wet etching system 200 of the present invention includes: a wafer card slot for carrying a plurality of wafers vertically placed in parallel; a chemical solution tank for performing a wet etching process; The card slot is placed in the chemical ...

Embodiment 2

[0060] The following is attached Figure 5 and specific embodiments, the wet etching method of the present invention will be described in detail. in, Figure 5 It is a schematic flow chart of the wet etching method according to Embodiment 2 of the present invention.

[0061] see Figure 5 , the wet etching method of the present invention, adopts above-mentioned wet etching system to operate, specifically comprises the following steps:

[0062] Step S01: the control device controls the manipulator to place the wafer slot carrying a plurality of wafers vertically placed in parallel into the liquid medicine tank;

[0063] Specifically, in a preferred embodiment of the present invention, the rotating device is fixed at the bottom of the liquid medicine tank. First, the existing method can be used to align all the wafers at the same position using the V-groove alignment device. ; Then, the wafer card slot is aligned with the wafer from below the wafer and stuck in the wafer car...

Embodiment 3

[0078] The following is attached Image 6 and specific embodiments, the wet etching method of the present invention will be further described in detail. in, Image 6 It is a schematic flowchart of the wet etching method according to the third embodiment of the present invention. In this embodiment, the rotating device includes: a transmission component and a driving component. The difference between the third embodiment and the second embodiment is that the wafer rotation process of the second embodiment is to rotate immediately after entering the chemical liquid tank; the wafer rotation process of the third embodiment is a wet etching process Afterwards, the wafer is spun before leaving the chemical bath.

[0079] Specifically, see Image 6 , the wet etching method in this embodiment includes the following steps:

[0080] Step A01: the control device controls the manipulator to place the wafer slot carrying multiple wafers placed vertically in parallel into the chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com