Printed circuit board alkaline etching solution suitable for electrolytic copper extraction

A technology of printed circuit board and etching solution, which is applied in the field of etching solution, can solve problems such as volatile ammonia gas, high ammonia water content, waste of resources, etc., and achieve the effects of reducing production costs, reducing environmental pollution, and reducing volatile loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

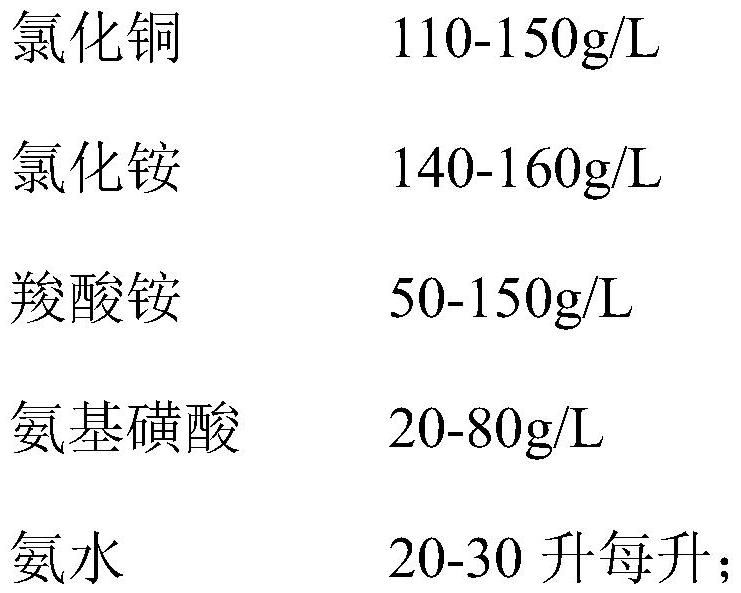

[0075] The printed circuit board alkaline etching solution suitable for electrolytic copper extraction of the present embodiment, each component of the alkaline etching solution and its content are:

[0076]

[0077] The pH is 8.3.

[0078] Use the process method of the printed circuit board alkaline etchant suitable for electrolytic copper extraction of the present embodiment to carry out the etching operation, and the process steps are:

[0079] 1) Pour the etching sub-liquid into the sub-liquid tank connected to the specific gravity meter in the automatic detection feeding control machine, set the temperature of the etching cylinder to 50°C, and set the pressure of the etching liquid nozzle of the etching machine to 2kg / cm 2 , start the etching operation, automatically detect the feeding control machine, automatically feed and replenish the components in the balance etching solution, so that the pH and specific gravity remain at the specified value;

[0080] 2) Take a 5...

Embodiment 2

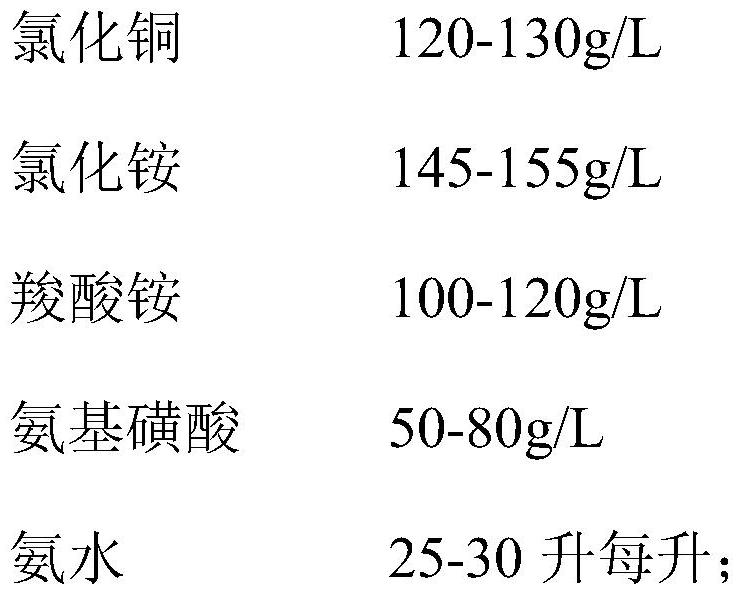

[0082] The printed circuit board alkaline etching solution suitable for electrolytic copper extraction of the present embodiment, each component of the alkaline etching solution and its content are:

[0083]

[0084] The pH is 8.3.

[0085] Use the process method of the printed circuit board alkaline etchant suitable for electrolytic copper extraction of the present embodiment to carry out the etching operation, and the process steps are:

[0086] 1) Pour the etching sub-liquid into the sub-liquid tank connected to the specific gravity meter in the automatic detection feeding control machine, set the temperature of the etching cylinder to 50°C, and set the pressure of the etching liquid nozzle of the etching machine to 2kg / cm 2 . Start the etching operation, and automatically detect the feeding control machine to automatically feed and replenish the components in the balance etching solution to keep the pH and specific gravity at the specified value.

[0087] 2) Take a 50...

Embodiment 3

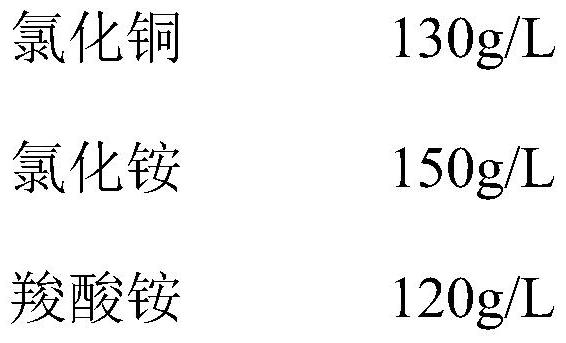

[0089] The printed circuit board alkaline etching solution suitable for electrolytic copper extraction of the present embodiment, each component of the alkaline etching solution and its content are:

[0090]

[0091] The pH is 8.2.

[0092] Use the process method of the printed circuit board alkaline etchant suitable for electrolytic copper extraction of the present embodiment to carry out the etching operation, and the process steps are:

[0093] 1) Pour the etching sub-liquid into the sub-liquid tank connected to the specific gravity meter in the automatic detection feeding control machine, set the temperature of the etching cylinder to 50°C, and set the pressure of the etching liquid nozzle of the etching machine to 2kg / cm 2 . Start the etching operation, and automatically detect the feeding control machine to automatically feed and replenish the components in the balance etching solution to keep the pH and specific gravity at the specified value.

[0094] 2) Take a 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com