Etching method and dual damascene structure forming method

A technology of etching gas and etching time, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as uniformity and poor consistency, achieve uniform polymer distribution, improve uniformity, and improve etching quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

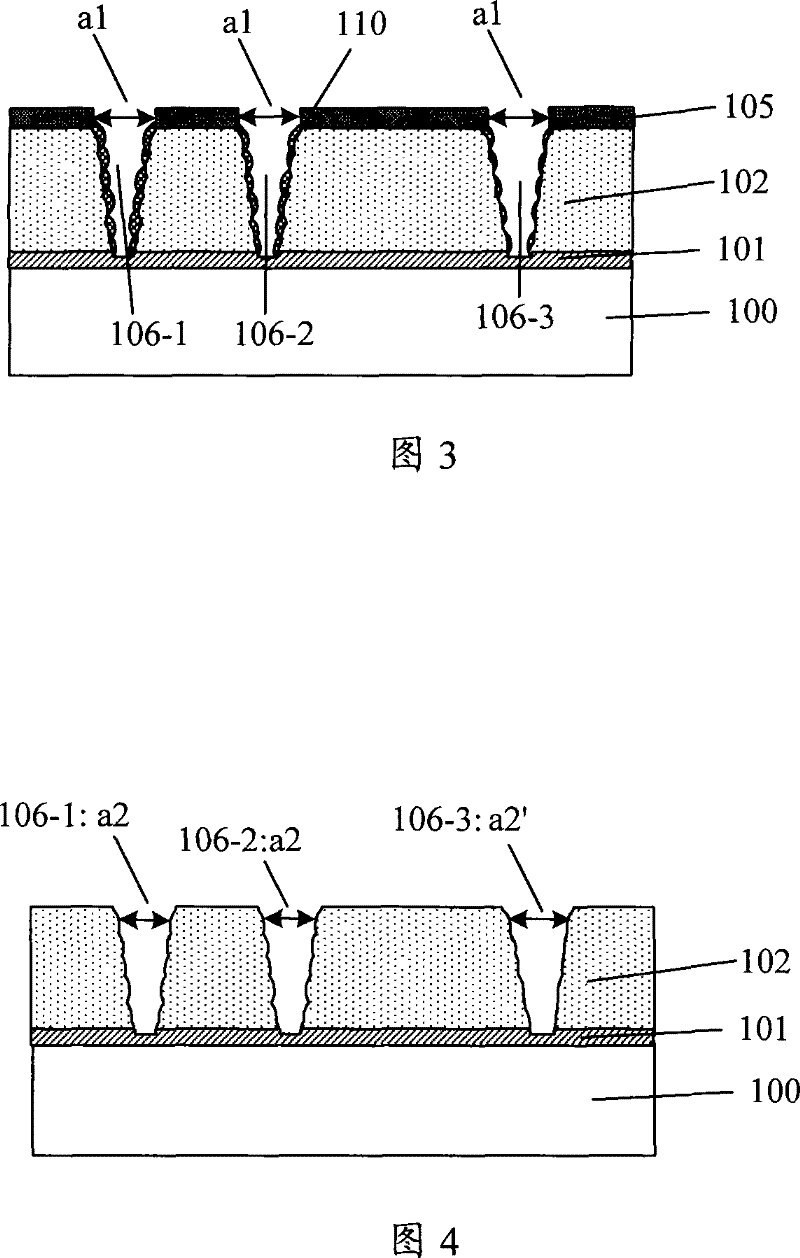

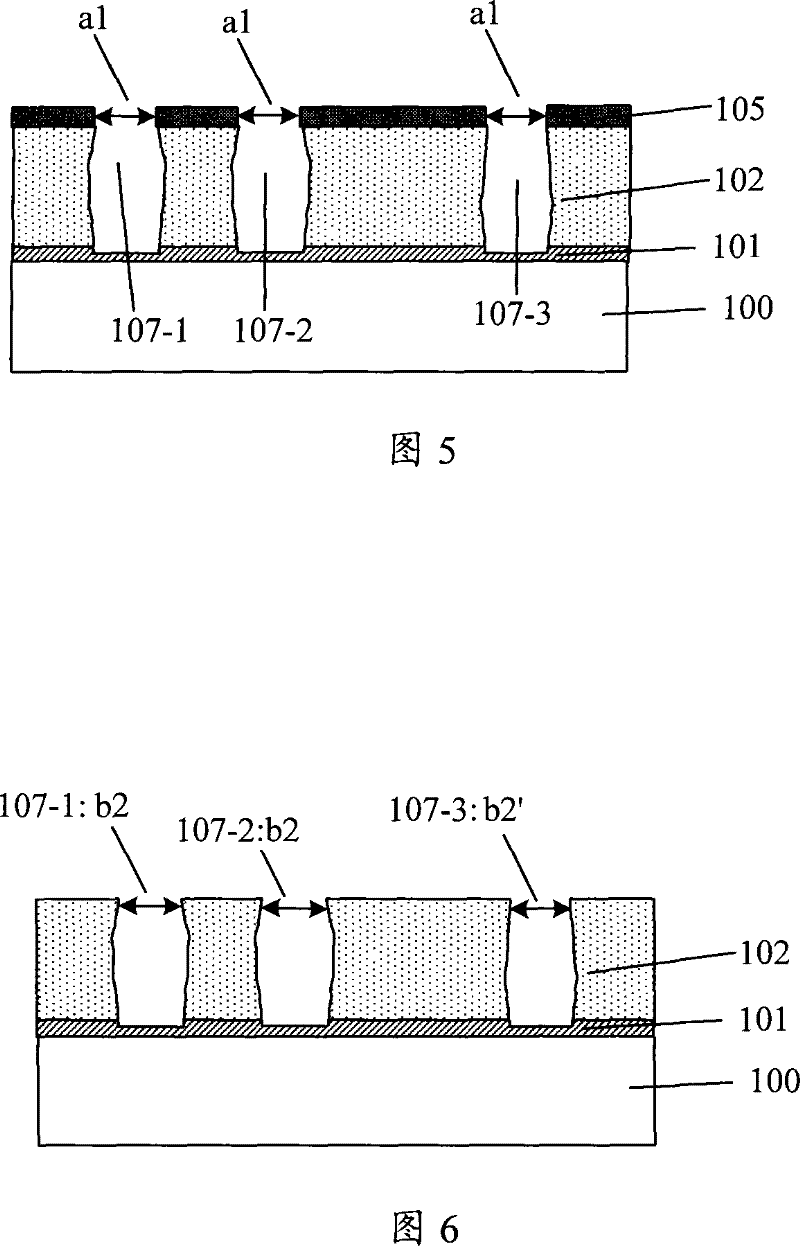

[0085] In this embodiment, through holes (or contact holes) are formed in the dielectric layer by using the etching method of the present invention.

[0086] Figure 7 It is a flow chart of the etching method in the first embodiment of the present invention, Figure 8 to Figure 12 In order to illustrate the device cross-sectional view of the etching method of the first embodiment of the present invention, below in conjunction with Figure 7 to Figure 12 The first embodiment of the present invention will be described in detail.

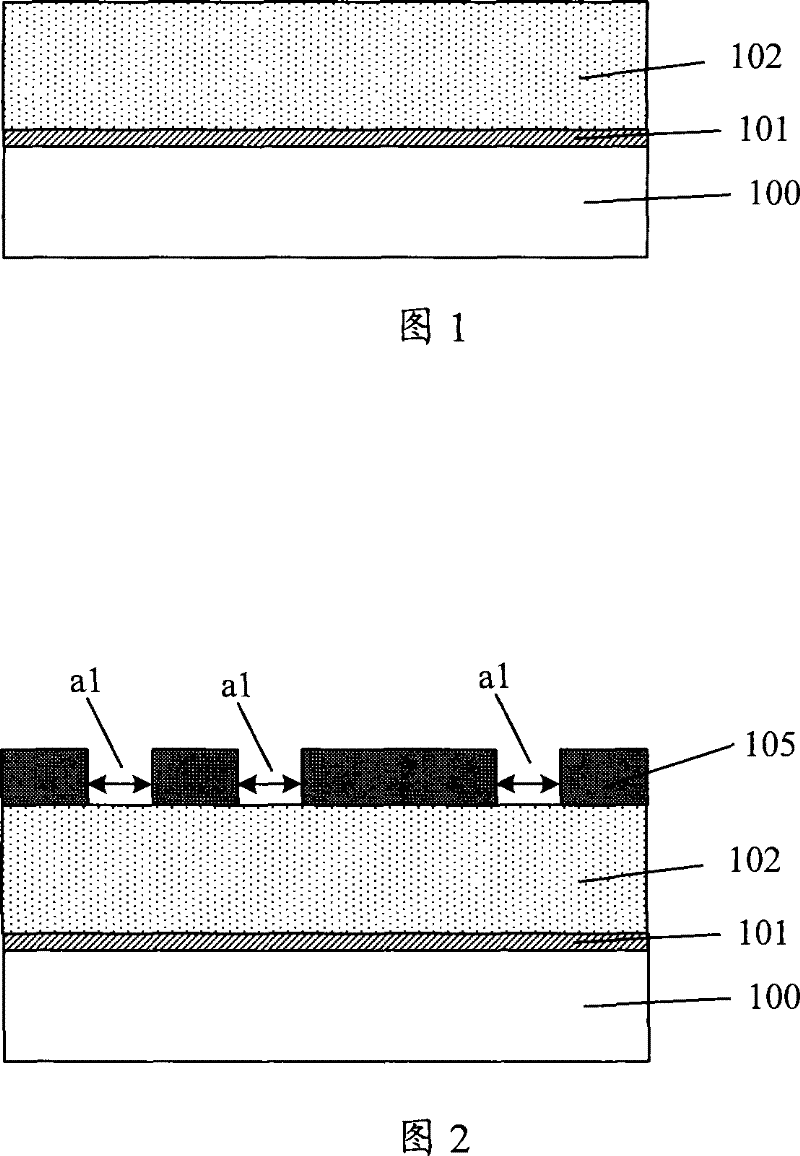

[0087] Step 701: Provide a substrate with a dielectric layer on the substrate.

[0088] The substrate in this embodiment may be a substrate on which metal-oxide-semiconductor transistors have been formed, or a substrate on which an underlying metal wiring structure has been formed (not shown in the figure).

[0089] In addition, in order to improve the uniformity and consistency of the etching pattern in terms of etching depth, usually an etching st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com