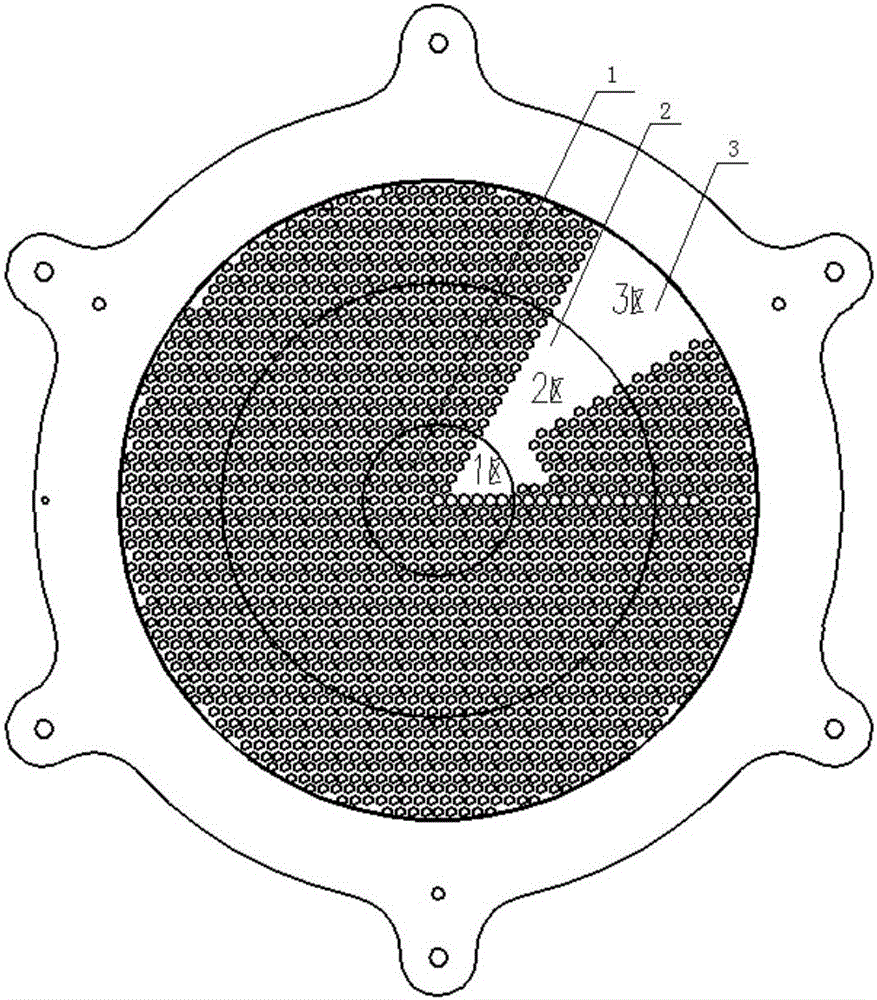

Small-caliber and variable-aperture grid assembly

A variable aperture and grid technology, applied to electrical components, discharge tubes, circuits, etc., can solve problems such as shortened lifespan, achieve the effects of improving lifespan, improving uniformity and stability, and prolonging lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0011] In view of the problems raised by the background technology, if the density of the extracted beam current in the center area of the grid assembly is reduced and the density of the extracted beam current in the edge area is increased, the bombardment and sputtering of the exchanged charge ions to the central area of the accelerating grid can be reduced, solving the problem of Ions are too concentrated on the bombardment and sputtering of the central area of the accelerating grid, so as to achieve the purpose of prolonging its life. Therefore, reducing the extracted beam current density in the central area of the grid assembly and increasing the extracted beam current density in the edge area is one of the effective ways to prolong the life of the grid assembly.

[0012] Therefore, the present invention designs a variable aperture grid assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com