Etching method

A technology of shielding layer and substrate, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as PR pattern error, etching failure, and reduced etching quality, so as to reduce the possibility of etching failure , Improve the etching success rate and improve the etching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

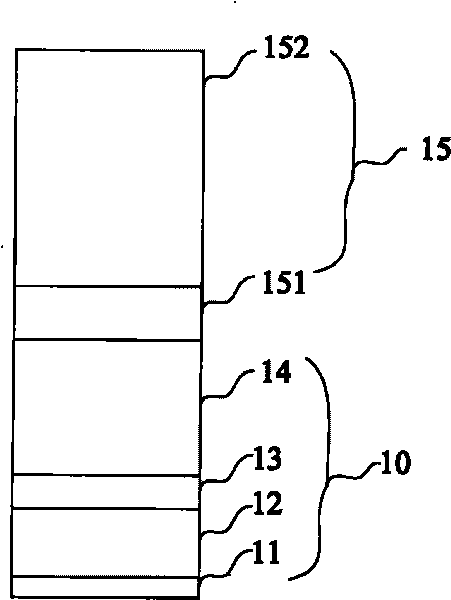

[0027] In view of the problems mentioned in the background technology, the embodiment of the present invention proposes to form a mask layer composed of a shielding layer, a BARC layer and a PR layer on the substrate, and then etch based on the mask layer. Since the mask layer includes the above three layers, it can allow a larger process margin (margin), for example, the thickness of the PR layer can be allowed to have a larger selection range, so even to avoid PR peeling and PR scum, reduce the PR layer Thickness, also can not produce the problem of excessive etching in the prior art, expose BARC, damage the polysilicon layer that does not need to be etched away, cause the edge damage of the manufactured control gate, improve the etching quality.

[0028] Based on the above idea, the embodiment of the present invention proposes the following design method to solve the above problems existing in the existing etching scheme.

[0029] Figure 5 It is a flowchart of an etching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com