Method for increasing strength of ultra-thin glass

A technology of ultra-thin glass and strength, which is applied in the field of strengthening glass strength, which can solve the problems of ultra-thin glass being easily damaged and broken, and achieve the effects of increasing strength, simplifying the process, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

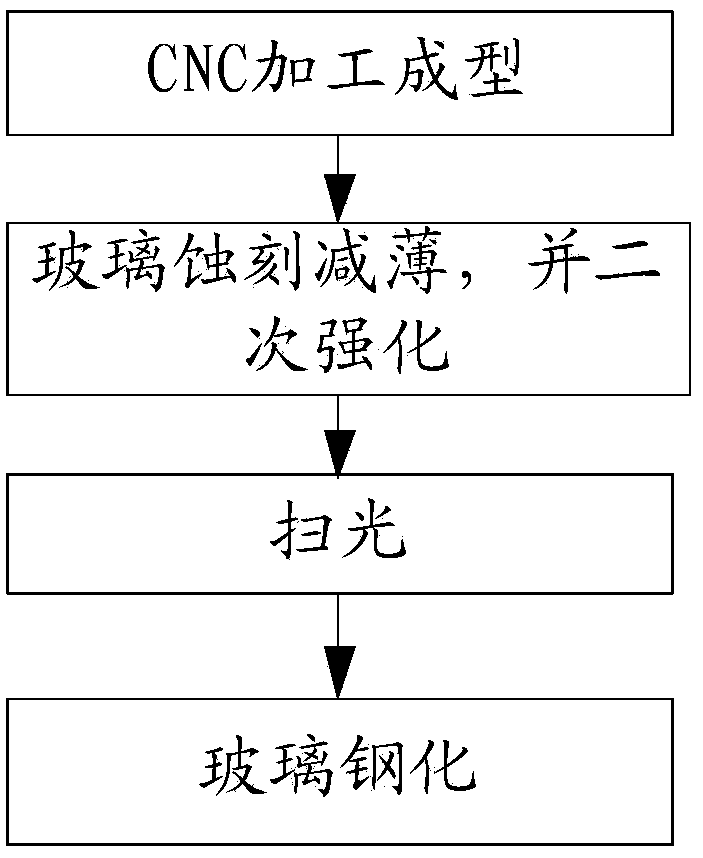

Image

Examples

specific Embodiment 1

[0021] Specific embodiment 1, comprising the following steps: Step A, carry out CNC processing and molding of the glass substrate, and cut into required size; Step B, put the processed glass substrate into an ultrasonic cleaning tank for the first cleaning, and the cleaning time is: 5 minutes, then put it into the etching tank and etch it with etchant, and then perform the second cleaning. The cleaning time is: 5 minutes, and finally dry it and strengthen it twice; The glass substrate is subjected to a light-sweeping treatment; step D, the glass substrate after the light-scanning is cleaned, and the glass substrate is soaked in a potassium nitrate tempering furnace at a temperature of 390° C. for 2.5 hours, and then cooled to room temperature within 1 hour.

specific Embodiment 2

[0022] The specific embodiment 2 includes the following steps: step A, carry out CNC processing and molding of the glass substrate, and cut it into the required size; step B, put the processed glass substrate into an ultrasonic cleaning tank for the first cleaning, and the cleaning time is: 3 minutes, then put it into the etching tank and etch it with an etchant, and then perform the second cleaning. The cleaning time is: 3 minutes, and finally dry it and strengthen it twice; The glass substrate is subjected to light-sweeping treatment; step D, clean the glass substrate after the light-scanning, and soak the glass substrate in a potassium nitrate tempering furnace at a temperature of 380° C. for 15 minutes, and then cool down to room temperature within 1 hour.

specific Embodiment 3

[0023] Specific embodiment three, comprising the following steps: step A, carry out CNC processing and molding of the glass substrate, and cut into required size; step B, put the processed glass substrate into an ultrasonic cleaning tank for the first cleaning, and the cleaning time is: 7 minutes, then put it into the etching tank and etch it with etchant, and then perform the second cleaning. The cleaning time is: 7 minutes, and finally dry it, and strengthen it twice; The glass substrate is subjected to light-sweeping treatment; step D, cleaning the glass substrate after the light-scanning, soaking the glass substrate in a potassium nitrate tempering furnace at a temperature of 400° C. for 1.5 hours, and then cooling down to room temperature within 1 hour.

[0024] It should be noted that the etchant is continuously supplied into the etching tank through a circulating pump, and the etchant is continuously supplied into the etching tank to ensure more sufficient and thorough e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com