Patents

Literature

45results about How to "Meet emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological aerated filter filtering material for treating sewage and preparation method thereof

InactiveCN101229946APromote growthImprove mass transfer efficiencySolid waste managementSustainable biological treatmentGypsumFilter material

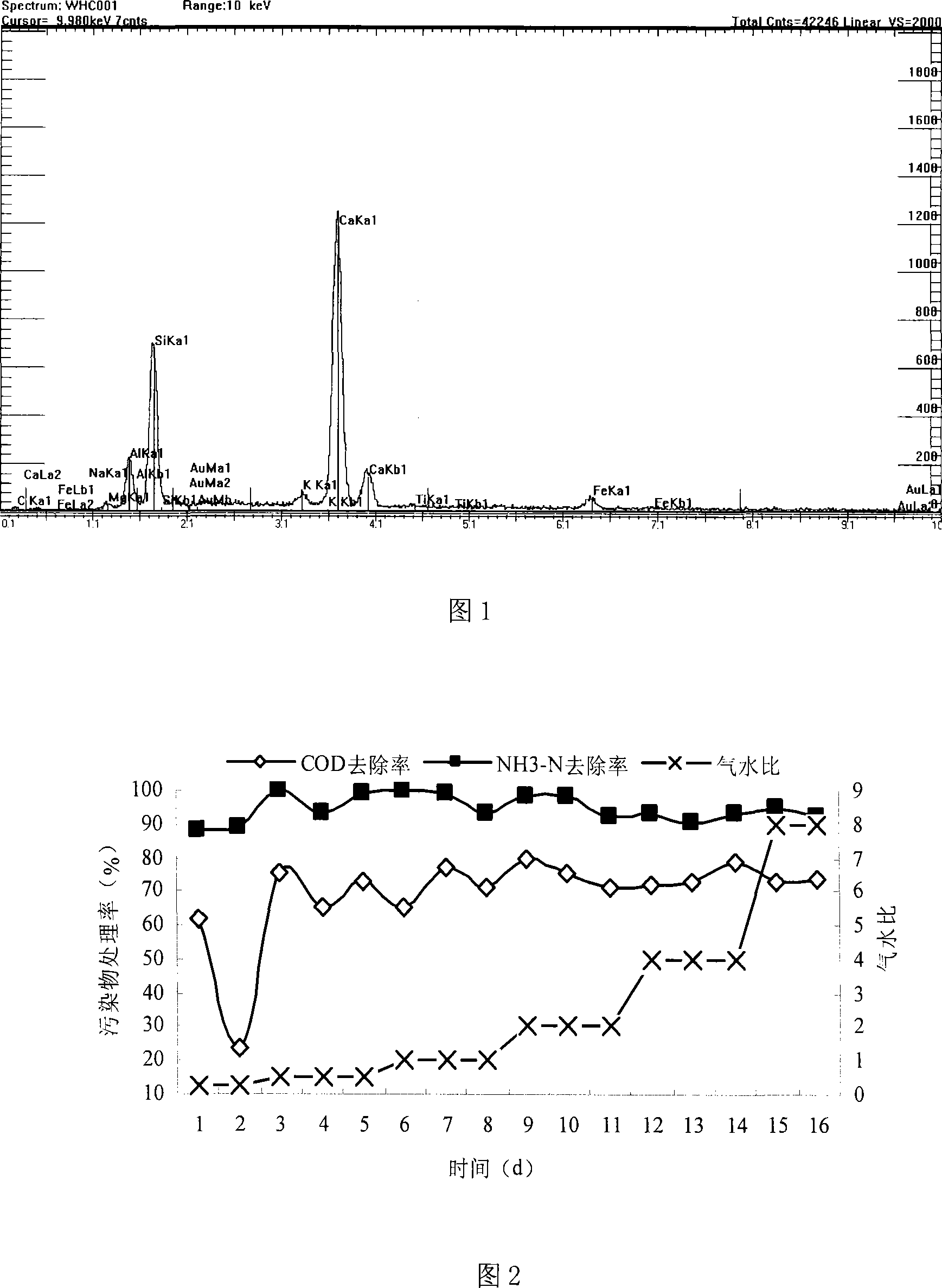

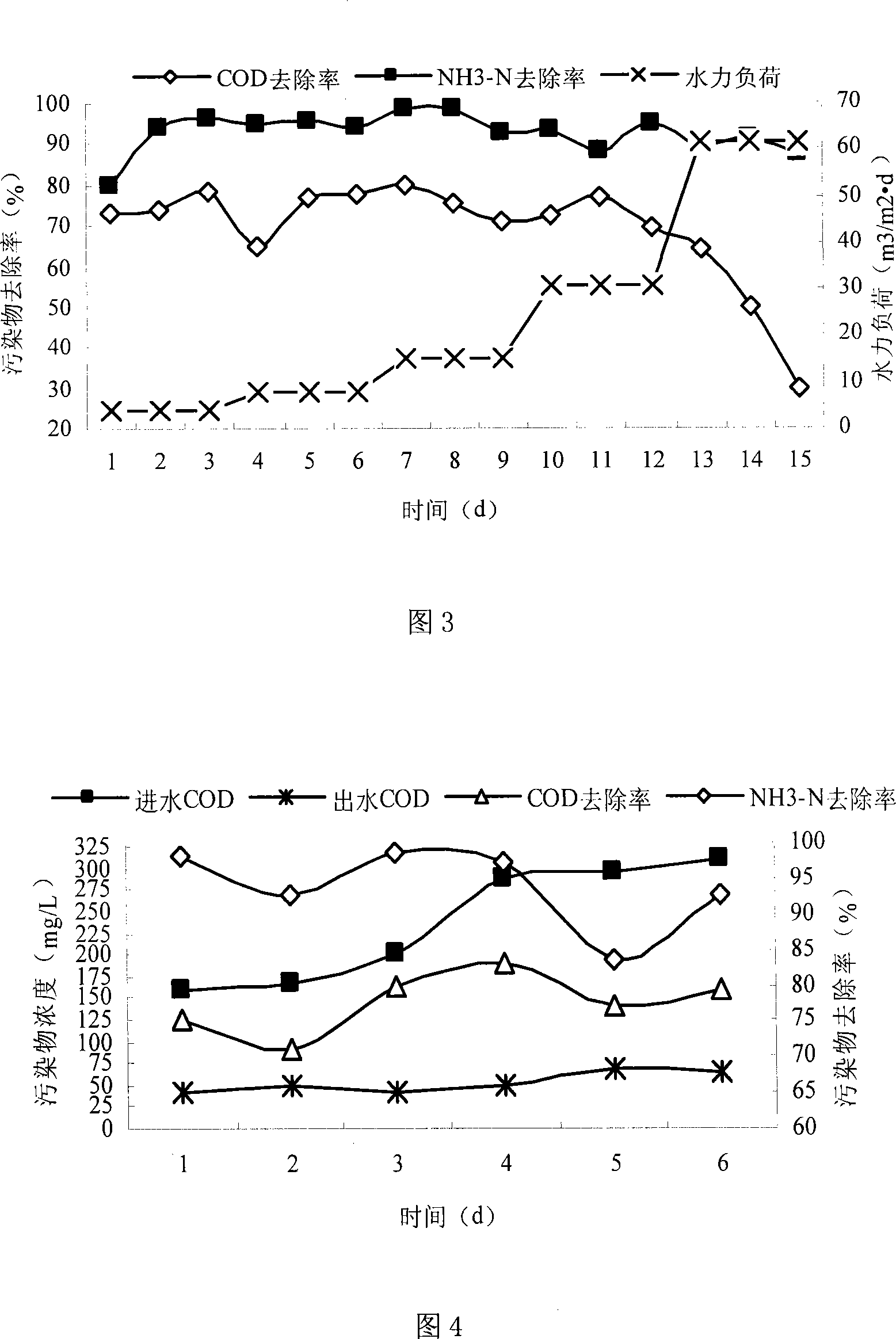

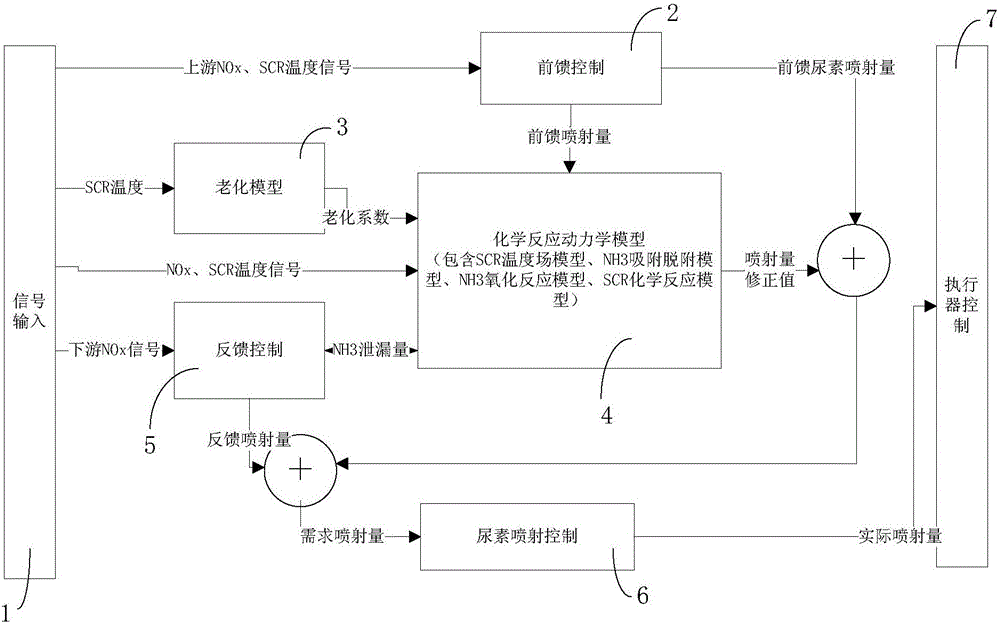

The invention essentially relates to a filter material for treating sewage, in particular to relate to a filtering material used in the sewage process technique of aeration biology filtering pool. The filtering material of sewage process of the aeration biology filtering pool is characterized in that the components of the raw material of the filtering material consists of by fly ash of 60 to 75 percent, portland cement of 10-20 percent, quick lime of 10-20 percent, gypsum 3-5 percent and degreasing aluminum powder of 0.06-0.08 percent. The preparation includes the following steps of pulping, stirring, pouring, cutting forming and ball milling. Under the optimal proportion of the air and water and the optimal water force load, the life sewage is treated by the aeration biology filtering pool with adding the fly ash to the gas concrete particle. When the average concentration of the water inlet is 176mg / L, the average removal rate of the CODis 75.3 percent, the average concentration of water inlet is 42.7mg / L, the average removal rate of the NH3-N is 96.4 percent, the average concentration of the water outlet is 0.87mg / L which meets the GB18918-2002 grade A standard of the sewage discharging.

Owner:LANZHOU UNIVERSITY

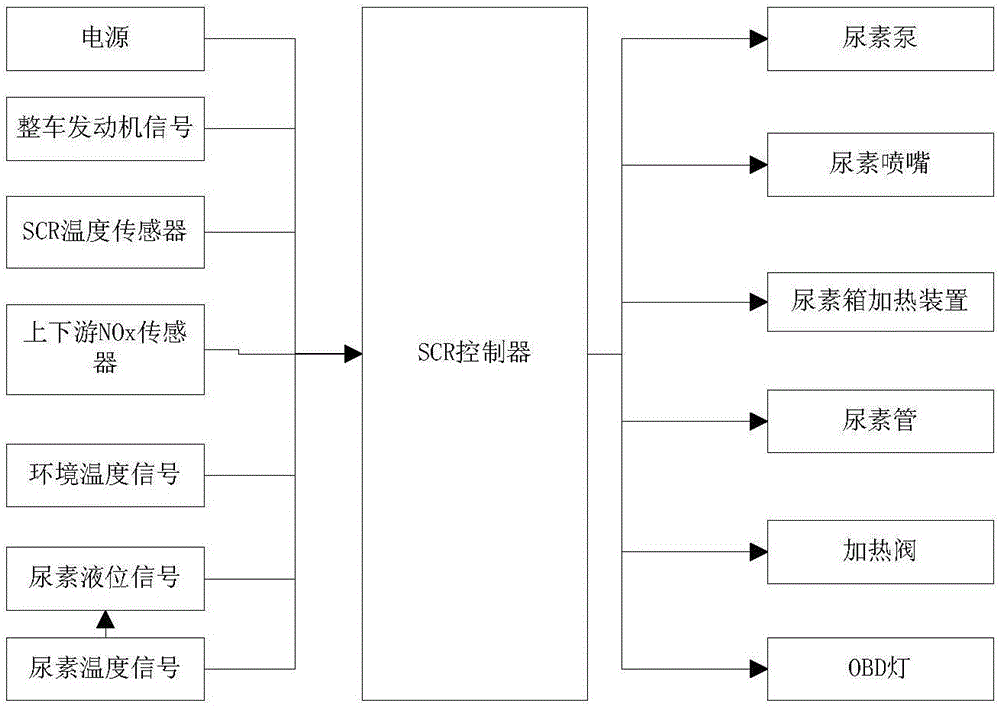

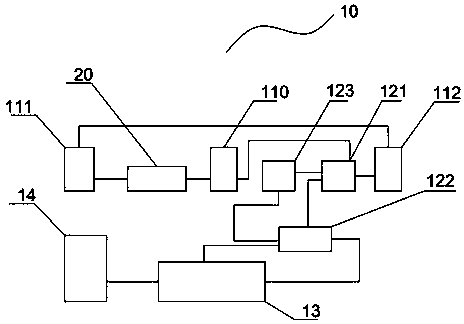

SCR system control device

ActiveCN106812577AAccurately Estimate Leakage ValuesAccurate estimateInternal combustion piston enginesExhaust apparatusControl systemEngineering

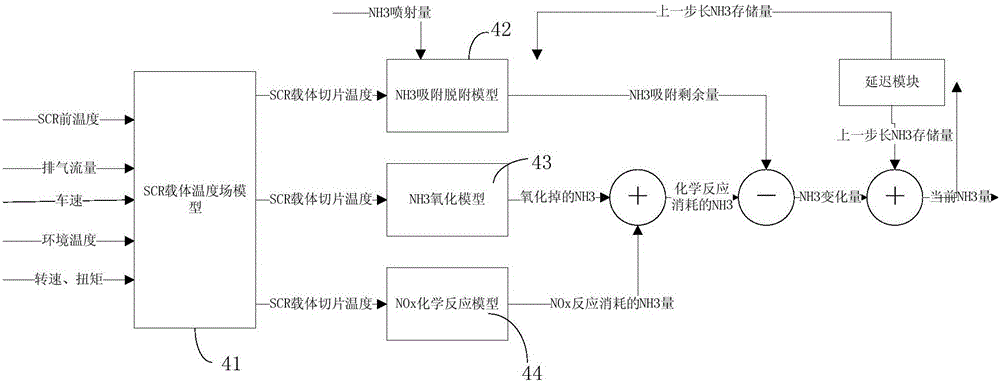

The invention relates to a SCR system control device. The device comprises a signal module, a feedforward control module, a feedback module, an urea jet control module and an actuator control module; the signal module is responsible for processing and detecting the signals from vehicles, engines, the SCR system sensor and external diagnostic apparatus; according to an upstream NOx concentration value, venting mass flow rate, SCR temperature and catalyst temperature efficiency MAP, the feedforward control module obtains the jetting amount of feedforward urea; the feedback module carries out PID control in real time based on the amount of NH3 leakage and figures out the jetting amount of feedforward urea; the urea jet control module obtains the total jetting quantity demand of urea based on the total jetting amount both of the feedforward urea and the feedback urea, and then outputs the amount of urea eventually required for the urea pump; the actuator control module drive the urea pump and the nozzle to eject urea. The device has the advantages that the precision of SCR control system is improved and the emission control of NOx from the national six emission regulations is met.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

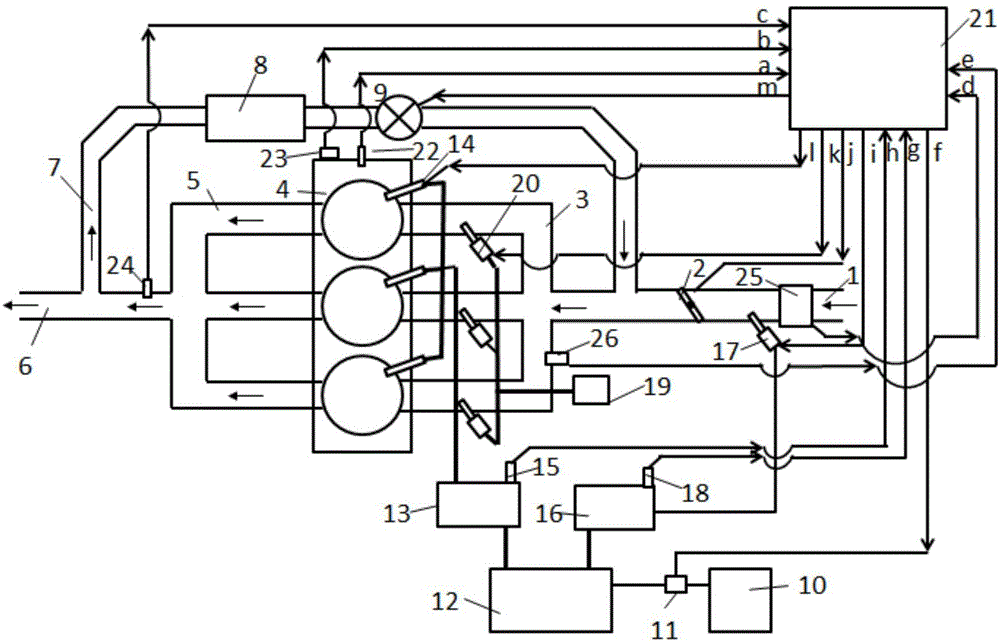

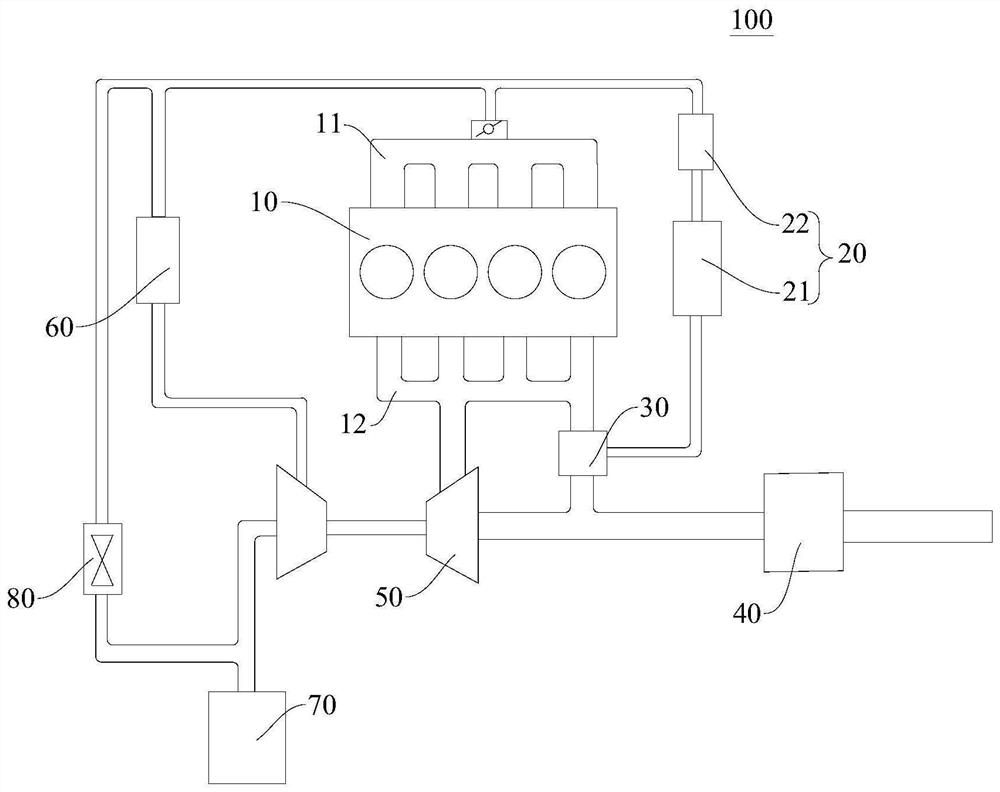

Hydrogen-doped inlet air and oxygen-enriched gasoline engine with EGR and combustion control method

ActiveCN105673199AEmission reductionEasy dischargeElectrical controlNon-fuel substance addition to fuelElectrolysisExhaust gas recirculation

The invention relates to a hydrogen-doped inlet air and oxygen-enriched gasoline engine with EGR and a combustion control method. The device mainly comprises a gasoline engine, an EGR cooler, an EGR valve, a water electrolysis device, a hydrogen storage, an oxygen storage, a pressure control device, a hydrogen injection device and an oxygen injection device. According to the hydrogen-doped inlet air and oxygen-enriched gasoline engine, in-cylinder combustion modes of four air inlet modes including inlet air doped with hydrogen and oxygen, small-scale exhaust gas recirculation and hydrogen doping, large-scale exhaust gas recirculation and hydrogen doping and oxygen enrichment are respectively adopted in a cold start and idling condition, a medium or small load condition, a large load condition and a full load condition of the engine, so that the effects that the thermal efficiency is obviously improved and the HC and CO discharge is reduced at the cold start and idling stage of the gasoline engine can be achieved; the pumping loss of the engine is greatly reduced in the medium or small load condition, and the oil consumption and NOx discharge are greatly reduced; the engine power is obviously increased within short time when a throttle valve is fully opened. The hydrogen-doped inlet air and oxygen-enriched gasoline engine has excellent overall properties such as low emission, low oil consumption and instantaneous high power output.

Owner:SHANGHAI JIAO TONG UNIV

Multilayer tube

ActiveUS8210213B2Reduce penetrationSoftness and ductility and impact resistanceSynthetic resin layered productsFlexible pipesElastomerPolyethylene terephthalate

A multilayer tube comprises at least the following three layers: an inner layer contactable with a fuel component, a barrier layer preventing the fuel component permeating, and an outermost layer. In the multilayer tube, the inner layer comprises a poly(butylene terephthalate) resin composition containing at least (A) a poly(butylene terephthalate) resin, the barrier layer comprises a polyester resin composition, and the outermost layer comprises a poly(butylene terephthalate) resin composition containing (A) a poly(butylene terephthalate) resin, (B) an elastomer component, (C) an aromatic polycarbodiimide compound, and (D) an antioxidant.

Owner:SUMITOMO RIKO CO LTD +1

Multilayer tube

ActiveUS20090246434A1Reduce penetrationSoftness and ductility and impact resistanceSynthetic resin layered productsFlexible pipesElastomerPolyethylene terephthalate

A multilayer tube comprises at least the following three layers: an inner layer contactable with a fuel component, a barrier layer preventing the fuel component permeating, and an outermost layer. In the multilayer tube, the inner layer comprises a poly(butylene terephthalate) resin composition containing at least (A) a poly(butylene terephthalate) resin, the barrier layer comprises a polyester resin composition, and the outermost layer comprises a poly(butylene terephthalate) resin composition containing (A) a poly(butylene terephthalate) resin, (B) an elastomer component, (C) an aromatic polycarbodiimide compound, and (D) an antioxidant.

Owner:SUMITOMO RIKO CO LTD +1

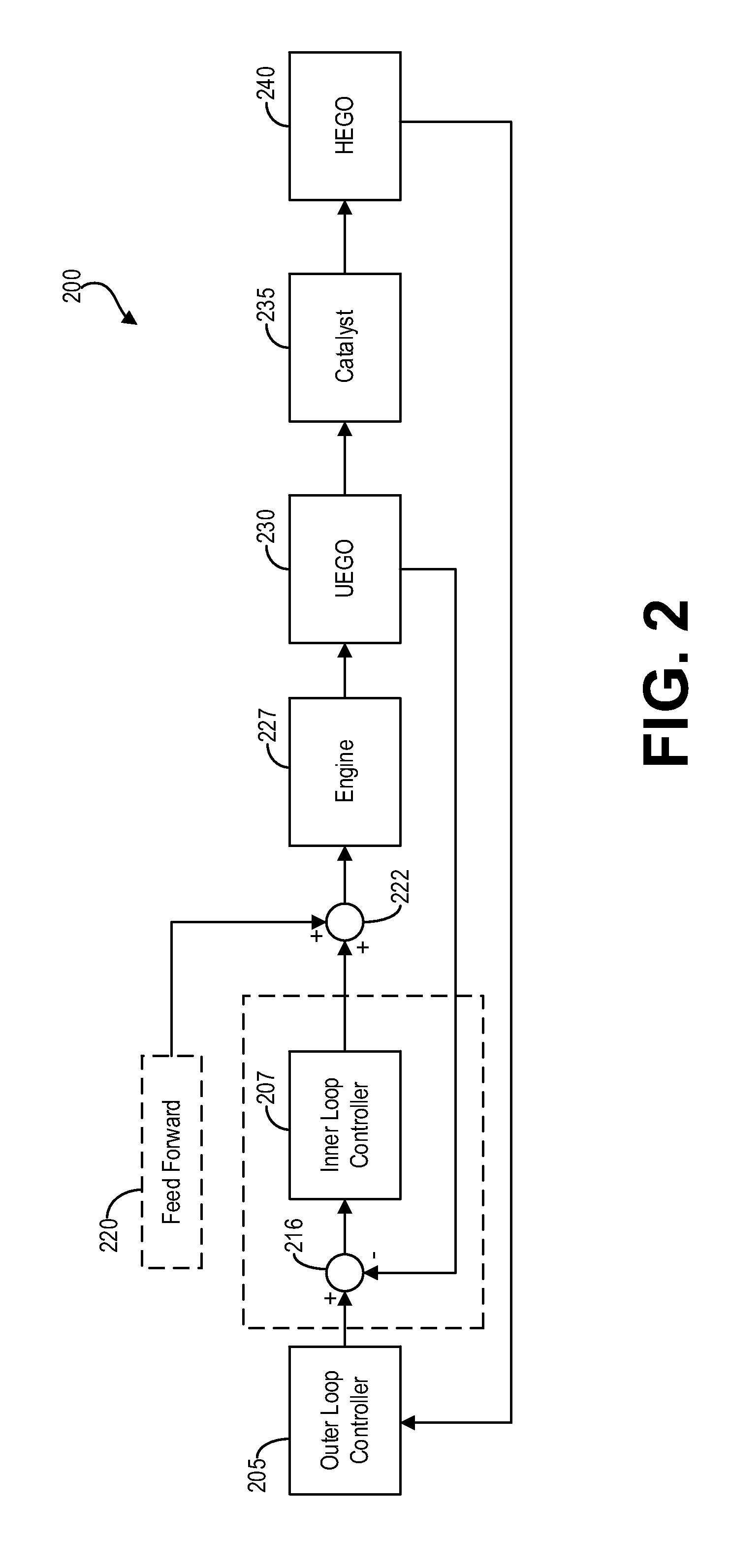

Identification and rejection of asymmetric faults

ActiveUS20150354485A1Increased riskEasy to controlAnalogue computers for vehiclesElectrical controlLoop controlControl system

Methods and systems are provided for identifying and rejecting asymmetric faults that cause engine emissions to be biased rich or lean. In one example, a method for an engine system comprises generating a UEGO sensor feedback set-point adjustment based on slower and faster time components within an outer loop of a catalyst control system; generating an inner-loop bias-offset correction from the slower time component; and indicating degradation of the engine system based on a comparison of the bias-offset correction to a degradation threshold. In this way, the total outer-loop control authority is increased while maintaining drivability and noise, vibration, and harshness (NVH) constraints and meeting emission standards in the presence of an air-to-fuel ratio biasing fault.

Owner:FORD GLOBAL TECH LLC

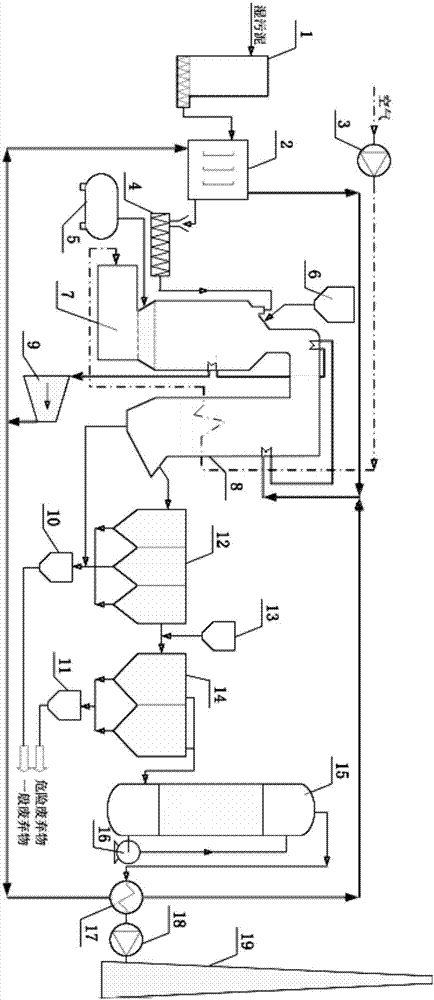

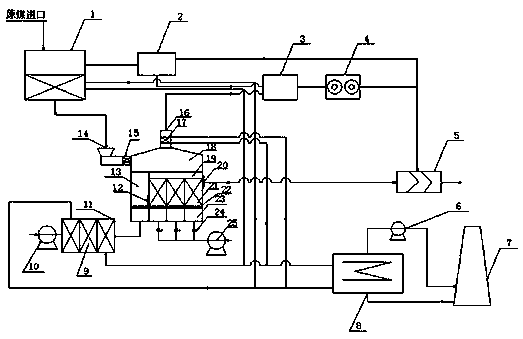

Self-maintaining incineration system for sludge and working method

InactiveCN107420915AImprove heat utilization efficiencyReduce the temperatureEmission preventionIncinerator apparatusExternal energySludge

The invention discloses a self-maintaining incineration system for sludge and a working method. The self-maintaining incineration system for the sludge comprises a storing and conveying system, a semi-desiccation system, an incineration and waste heat boiler system, a turbine power generation system, a flue gas treatment system and an ash slag treatment system; the semi-desiccation system comprises a sludge desiccation machine; the incineration and waste heat boiler system comprises an incinerator and a waste heat boiler; and the turbine power generation system comprises a turbine power generator and a steam circulating pipeline, wherein the steam circulating pipeline comprises closed-loop circulating pipelines which sequentially connect the turbine power generator, the sludge desiccation machine and the incineration and waste heat boiler system in series. The working method of the system comprises the steps that power generation is conducted through heat generated through incineration, and desiccation operation is conducted on the wet sludge through the semi-desiccation system. Therefore, the high heat utilization efficiency is achieved through cooperation of the whole desiccation, incineration and waste heat utilization system and the using method thereof, self-maintaining incineration of the sludge can be achieved without adding external energy, the yearly running time reaches 8,000 h, and outlet flue gas is exhausted in the manner of meeting the national standard.

Owner:张国闽

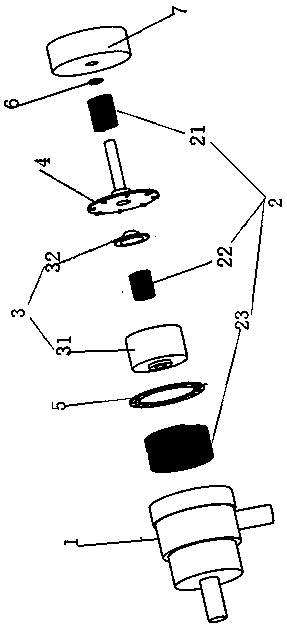

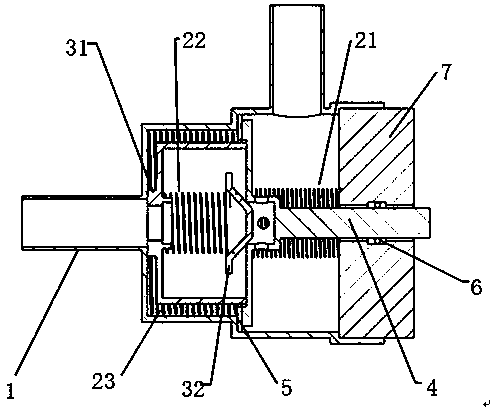

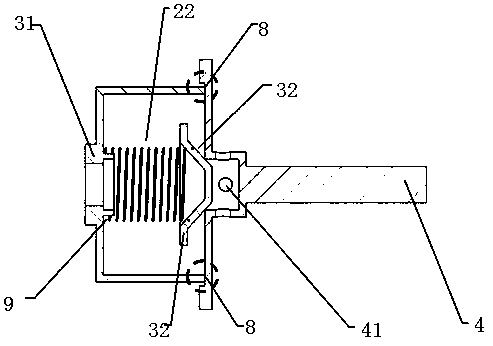

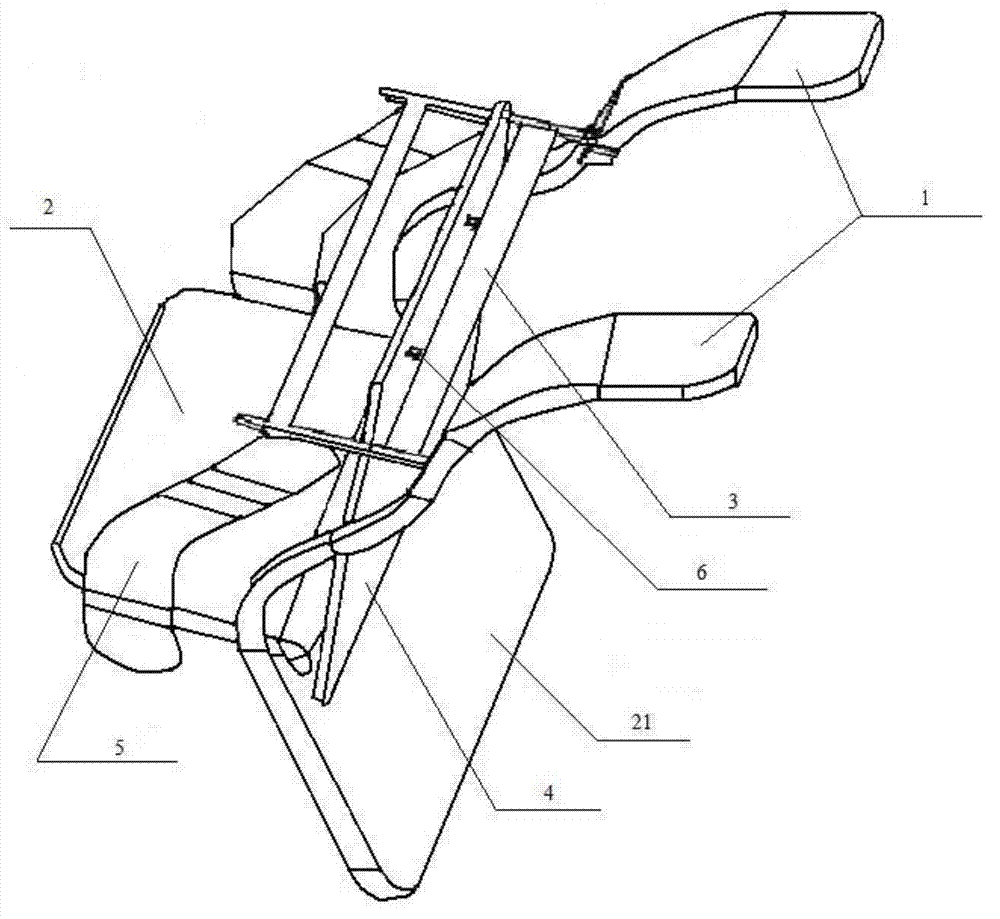

Novel automobile high-pressure-resistant oil tank isolation valve

PendingCN107606179AEmission reductionMeet emissionsOperating means/releasing devices for valvesNon-fuel substance addition to fuelIsolation valveFuel tank

The invention relates to a novel automobile high-pressure-resistant oil tank isolation valve. The novel automobile high-pressure-resistant oil tank isolation valve is characterized in that the oil tank isolation valve comprises an isolation valve body, a spring assembly, a valve core assembly, a supporting rod, a restrictor ring, a sealing ring and an electromagnetic valve; the spring assembly, the valve core assembly, the restrictor ring, the supporting rod and the sealing ring are all arranged in the isolation valve body; and the electromagnetic valve is arranged at the end of the isolationvalve body. According to the technical scheme, the novel automobile high-pressure-resistant oil tank isolation valve is simple and ingenious in structure, and the complex functions of high-pressure air exhausting, negative-pressure air supplementing, oil charging air exhausting and the like are achieved by means of a few of parts including plastic parts, springs, the electromagnetic valve, rubberparts and the like; by adjusting the diameter of a hole and the sizes of the springs, the requirements of different customers can be met; only one electromagnetic valve is adopted for the isolation valve of the structure, so that electric energy is saved; and the isolation valve of the structure is small in size and does not occupy the space of a chassis.

Owner:YAPP AUTOMOTIVE PARTS

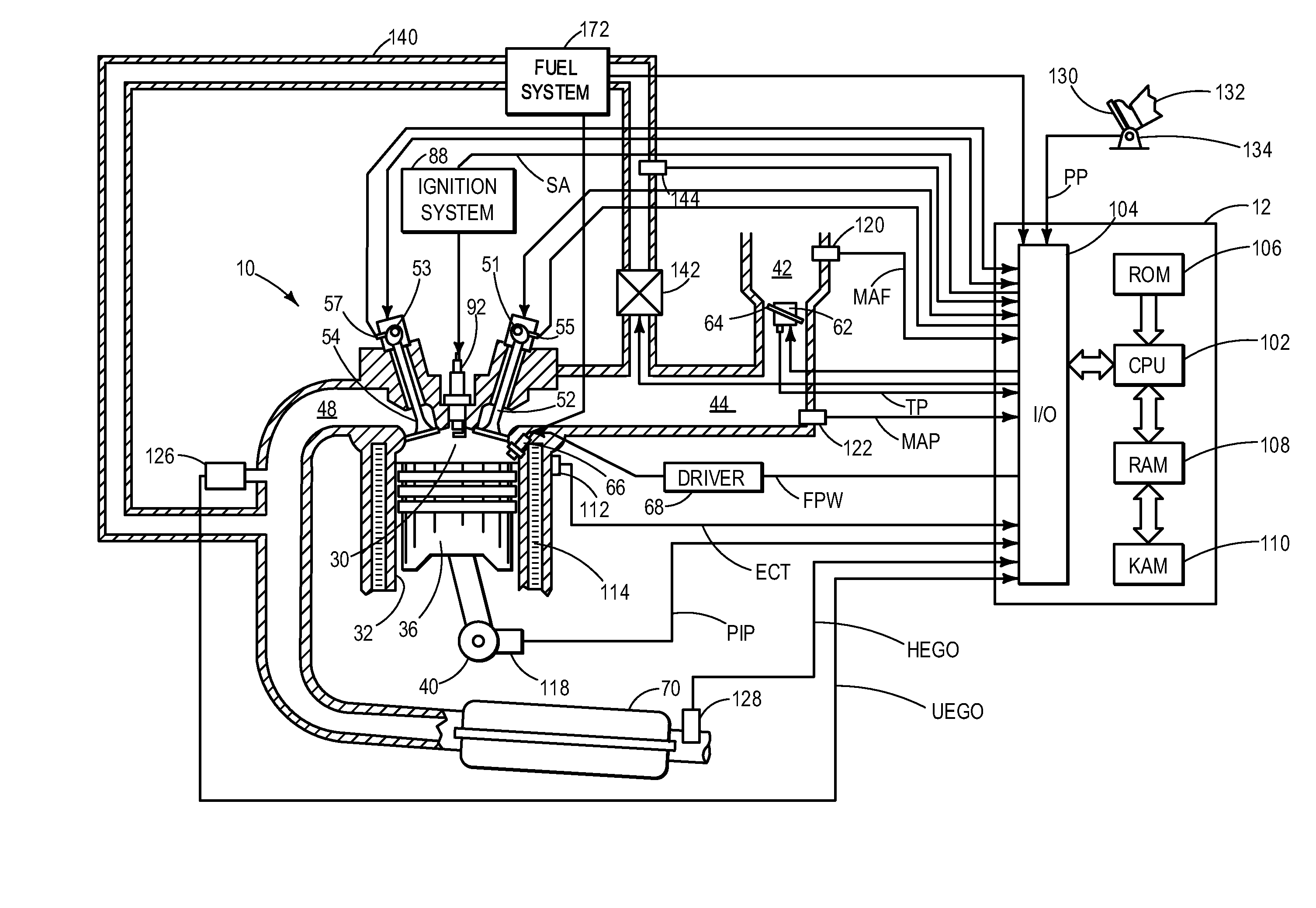

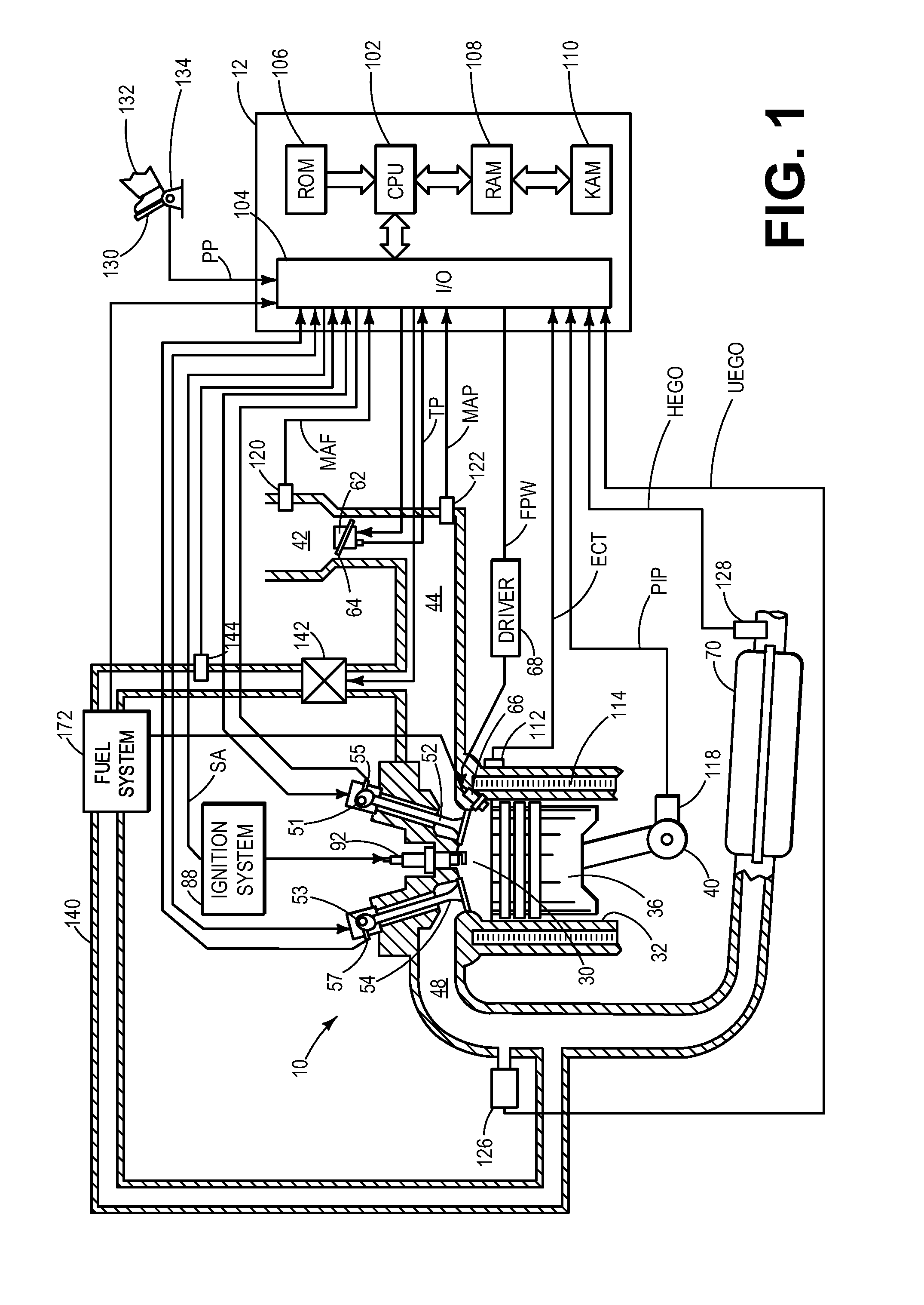

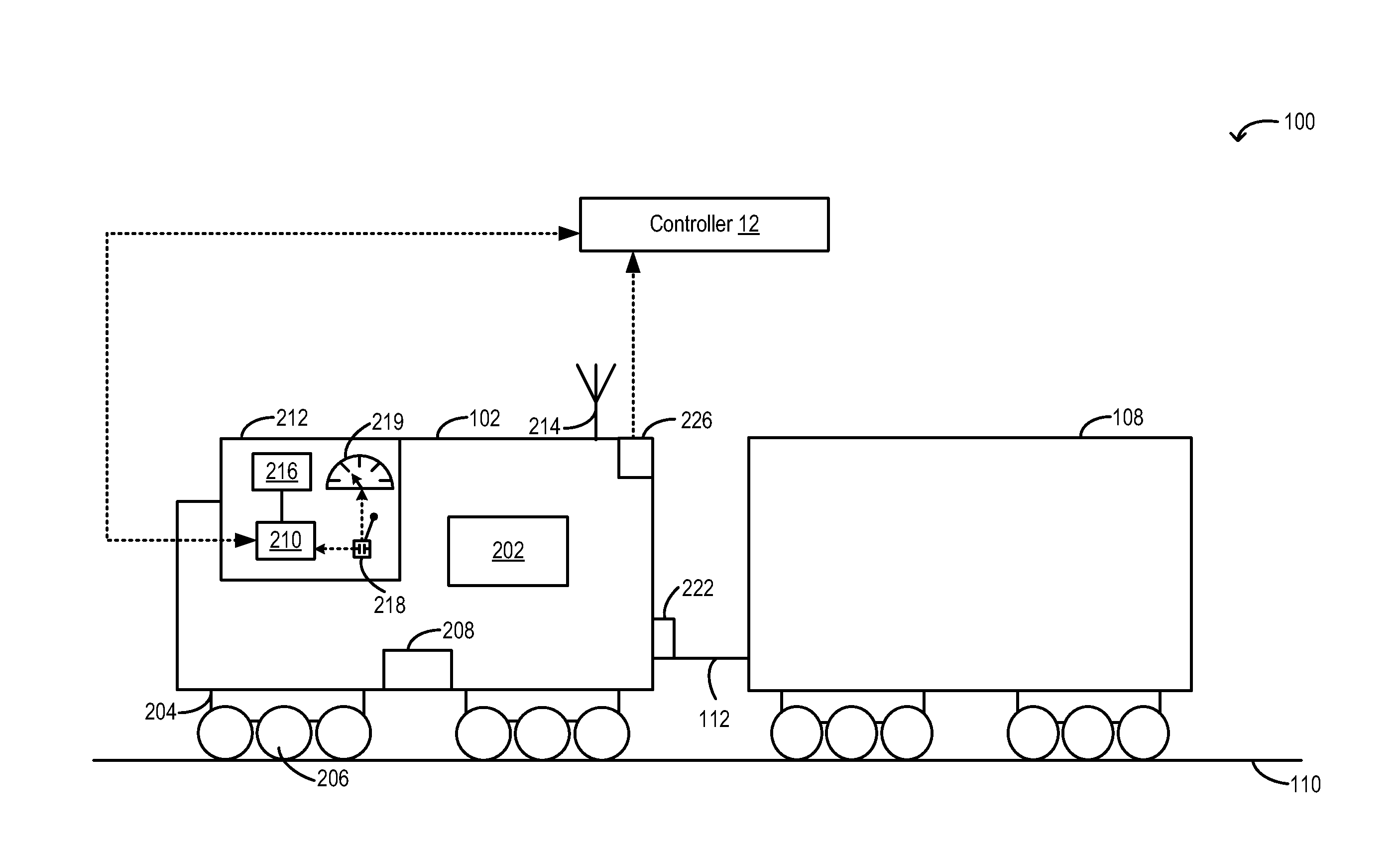

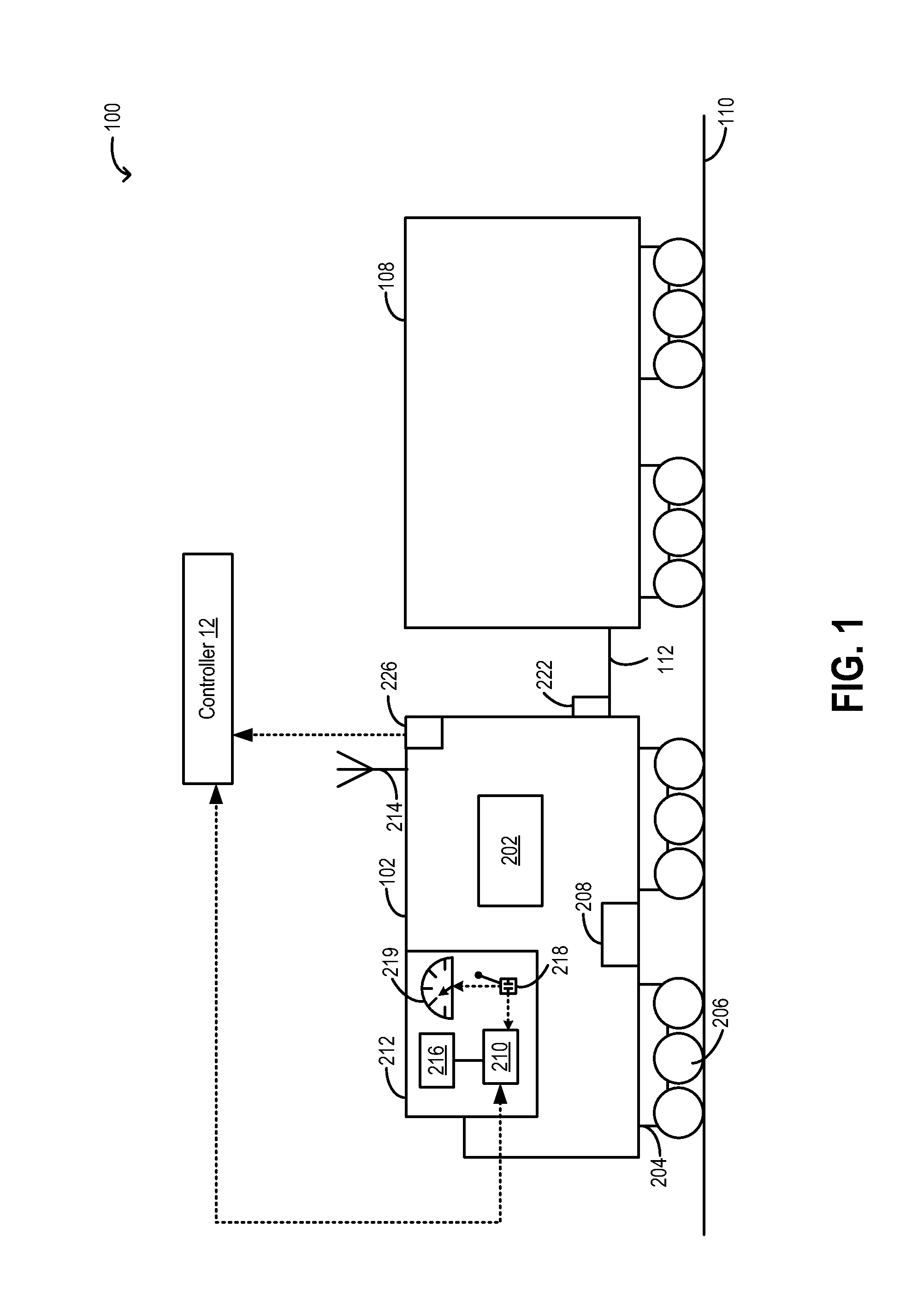

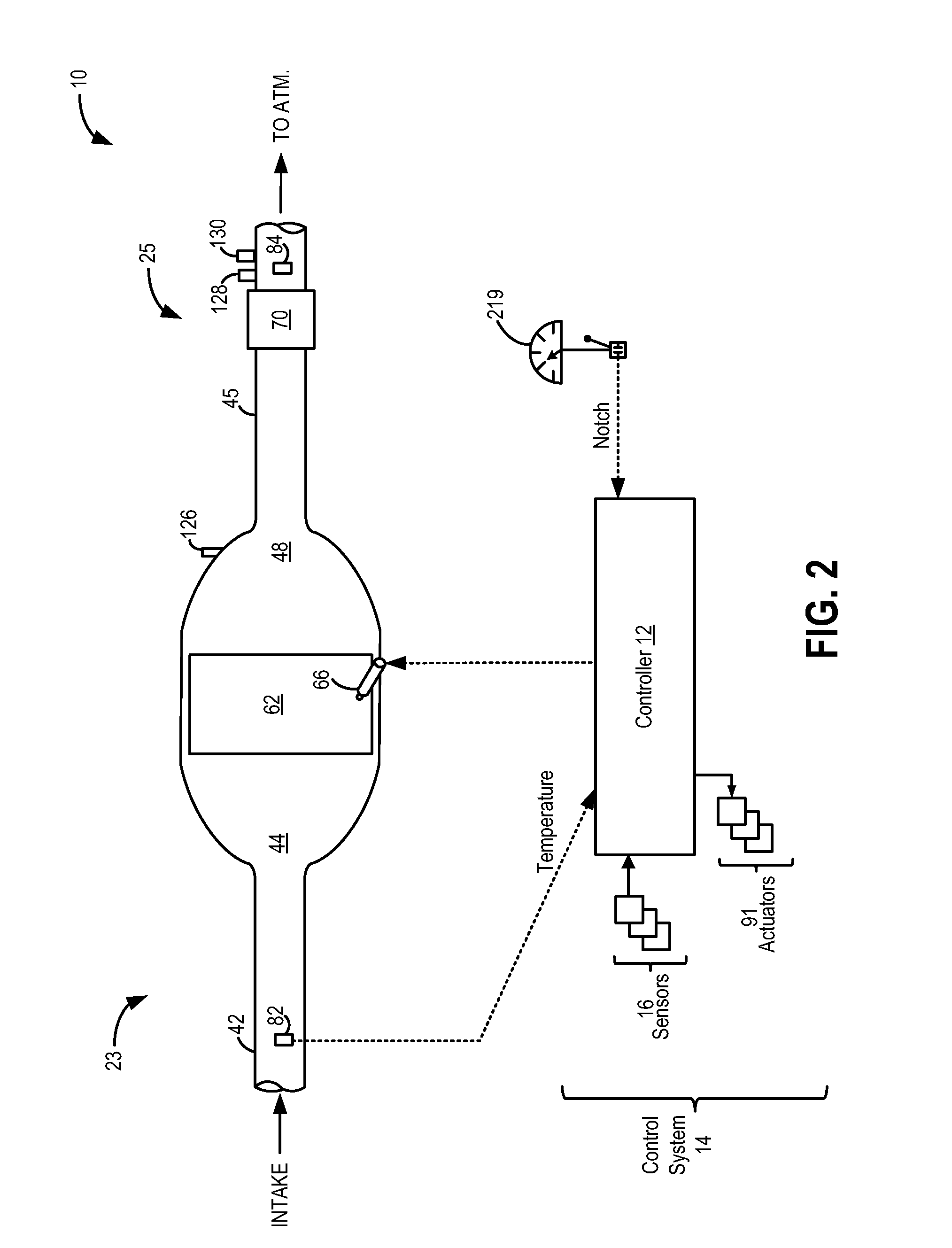

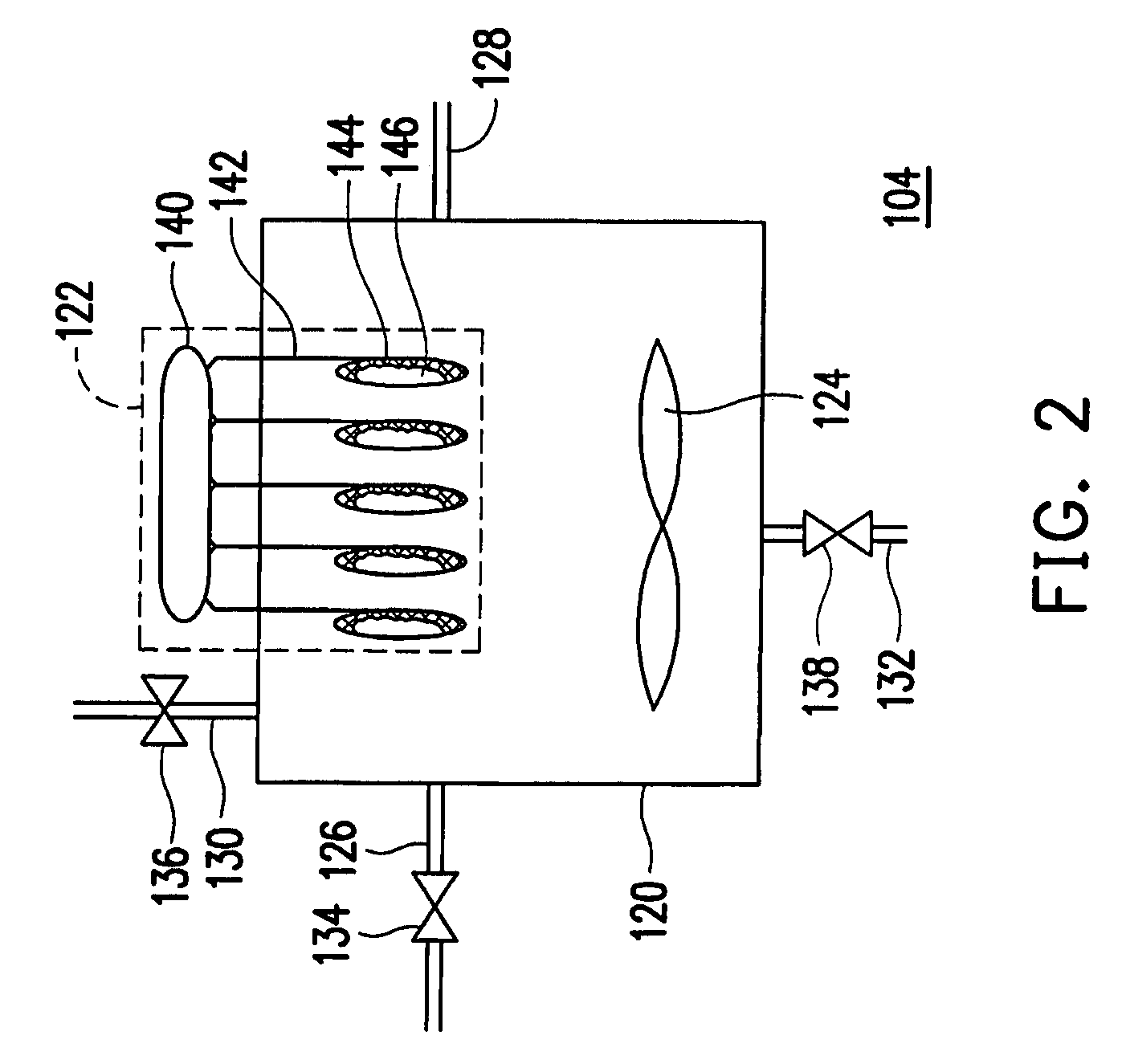

Method and system for engine emission control

ActiveUS20120123662A1Offset increased emissionEmission reductionAnalogue computers for vehiclesElectrical controlIncrease temperatureAutomotive engineering

Owner:GE GLOBAL SOURCING LLC

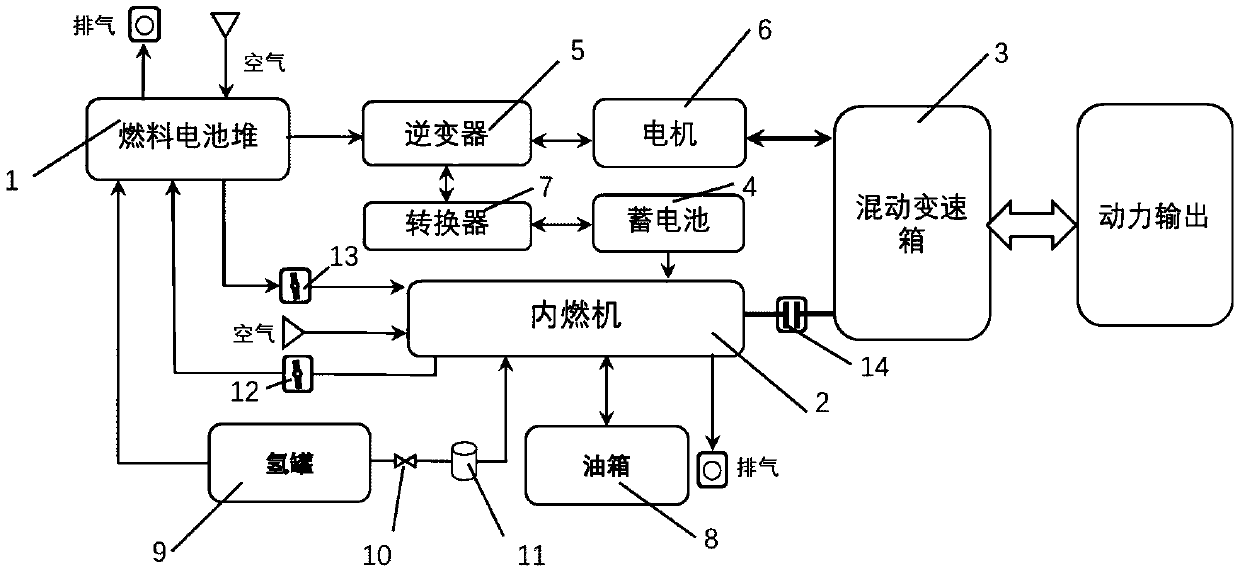

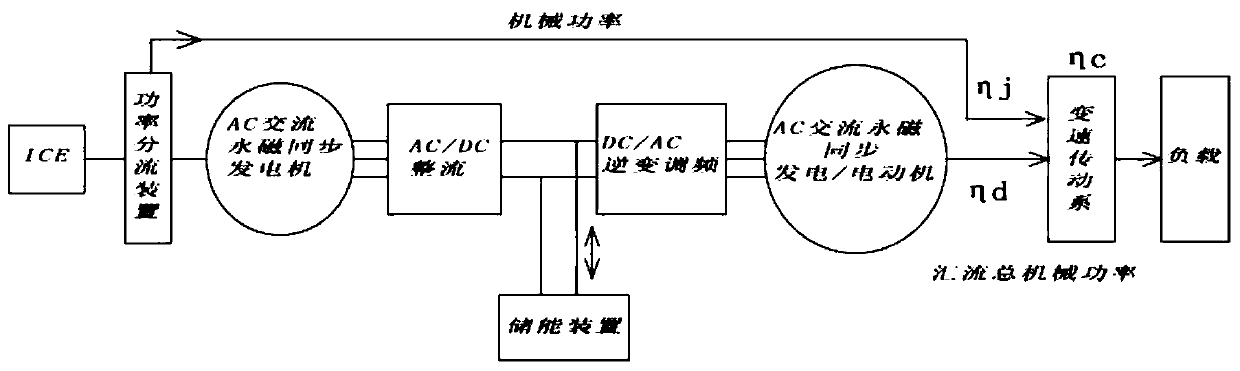

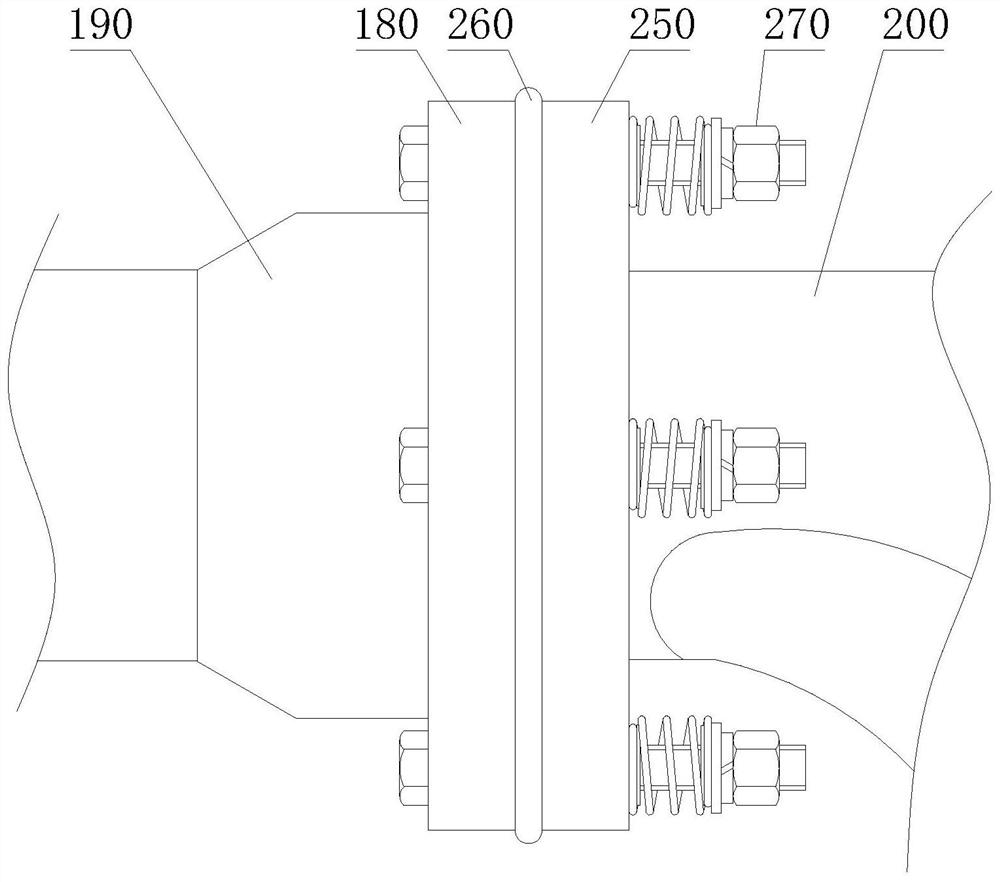

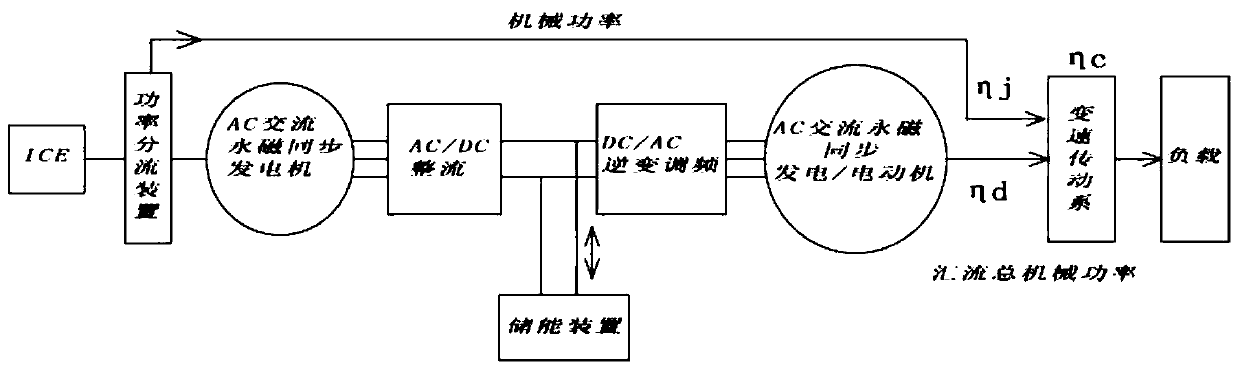

Hybrid power system and coupling operation method thereof

ActiveCN109823157ALow costGuaranteed uptimeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingCombustionElectric machine

The embodiment of the invention provides a hybrid power system and a coupling operation method thereof. The system comprises a fuel cell system, an internal combustion engine system, and a hybrid transmission, wherein the fuel cell system comprises a fuel cell stack, a storage battery, an inverter, a motor, a converter and a hydrogen tank, the internal combustion engine system comprises an internal combustion engine, a storage battery, a hydrogen tank, an oil tank and a clutch, the first input end of the hybrid transmission is connected with the motor, and the second input end of the hybrid transmission is connected with the torque output end of the internal combustion engine through the clutch. According to the hybrid power system and the coupling operation method thereof provided by theembodiment of the invention, when the hybrid power system works normally, the fuel cell system serves as a first power source, the internal combustion engine carries out power assistance according tothe working condition demand, and efficient and clean combustion of the internal combustion engine can be achieved by controlling the operation modes of the internal combustion engine under differentworking conditions. The fuel cell system can meet stricter emission and fuel consumption regulations, meanwhile the manufacturing cost of the fuel cell system is reduced by introducing the internal combustion engine system with low cost and reliable operation, and the hybrid power system has a good application prospect.

Owner:TSINGHUA UNIV

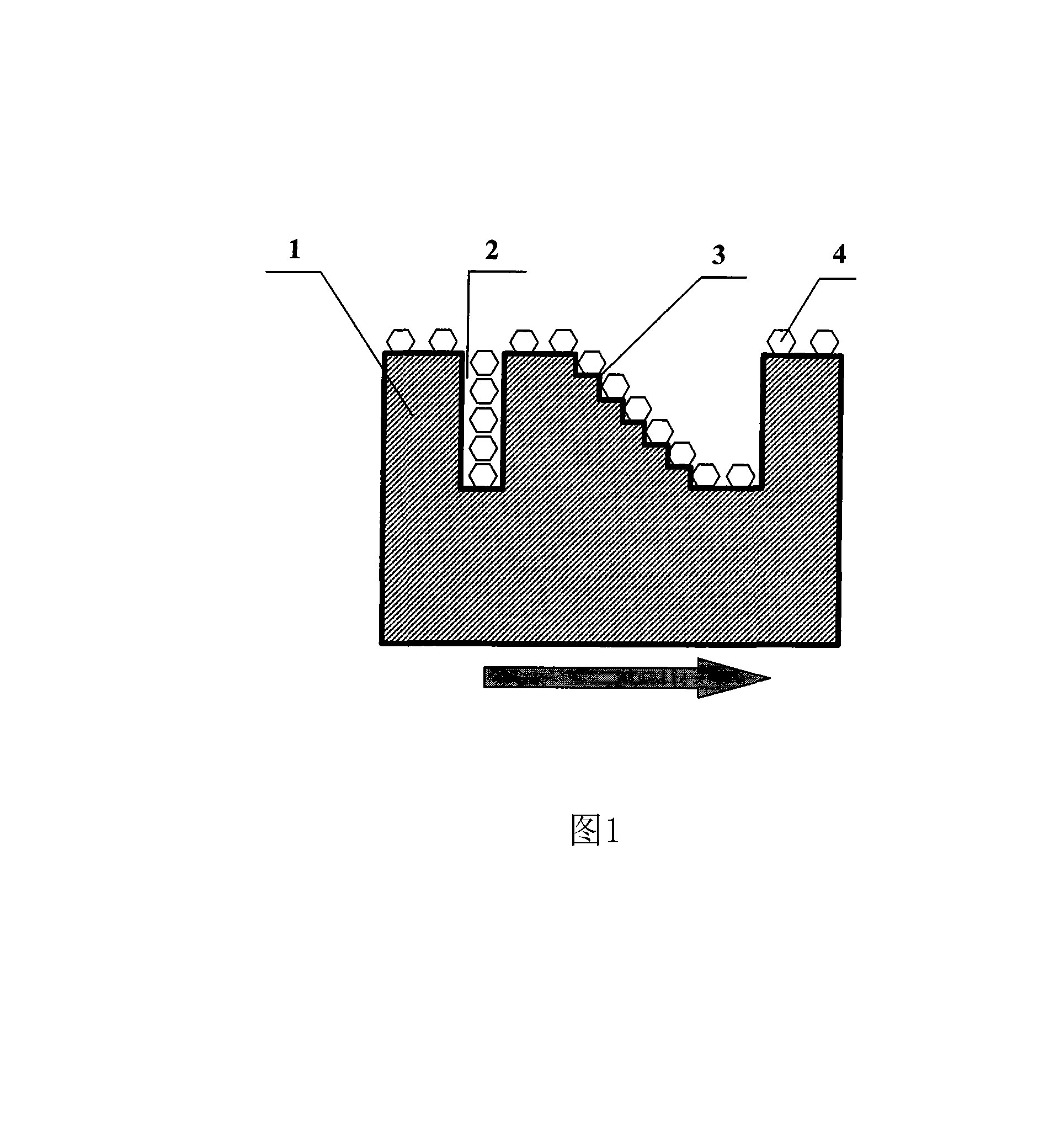

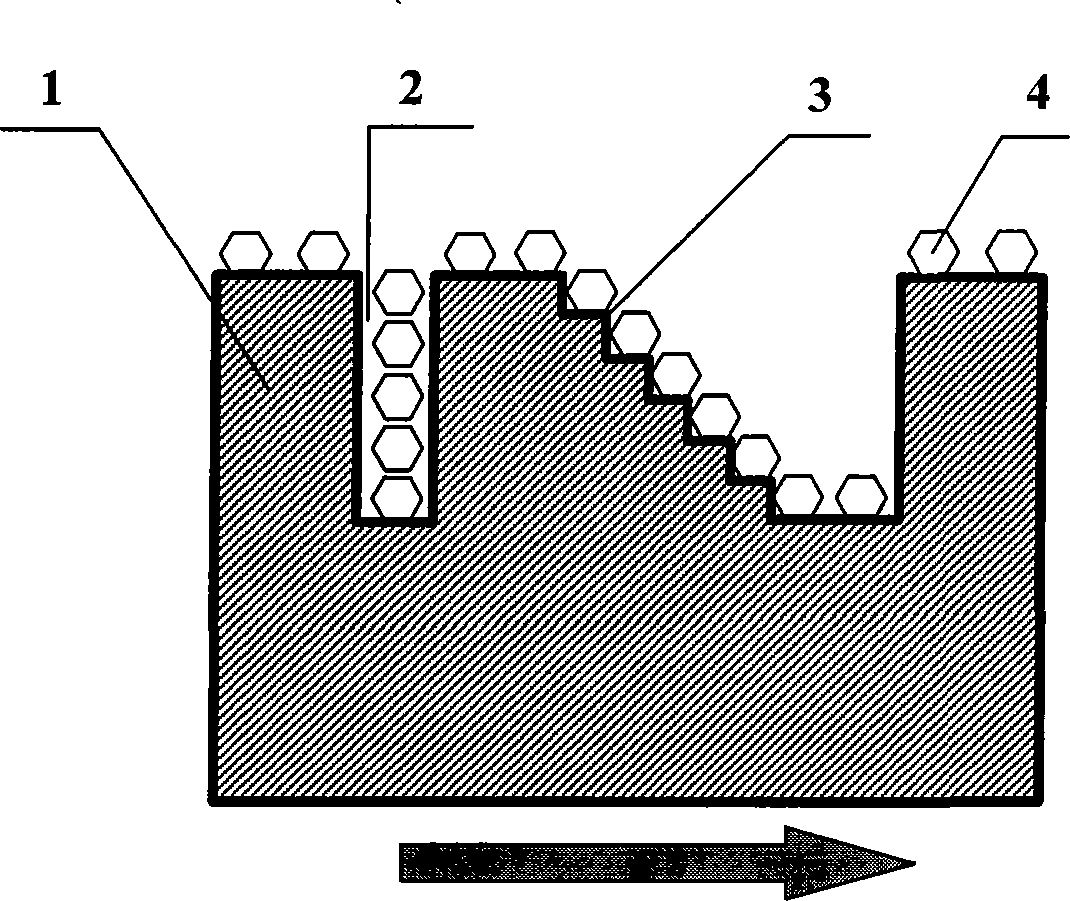

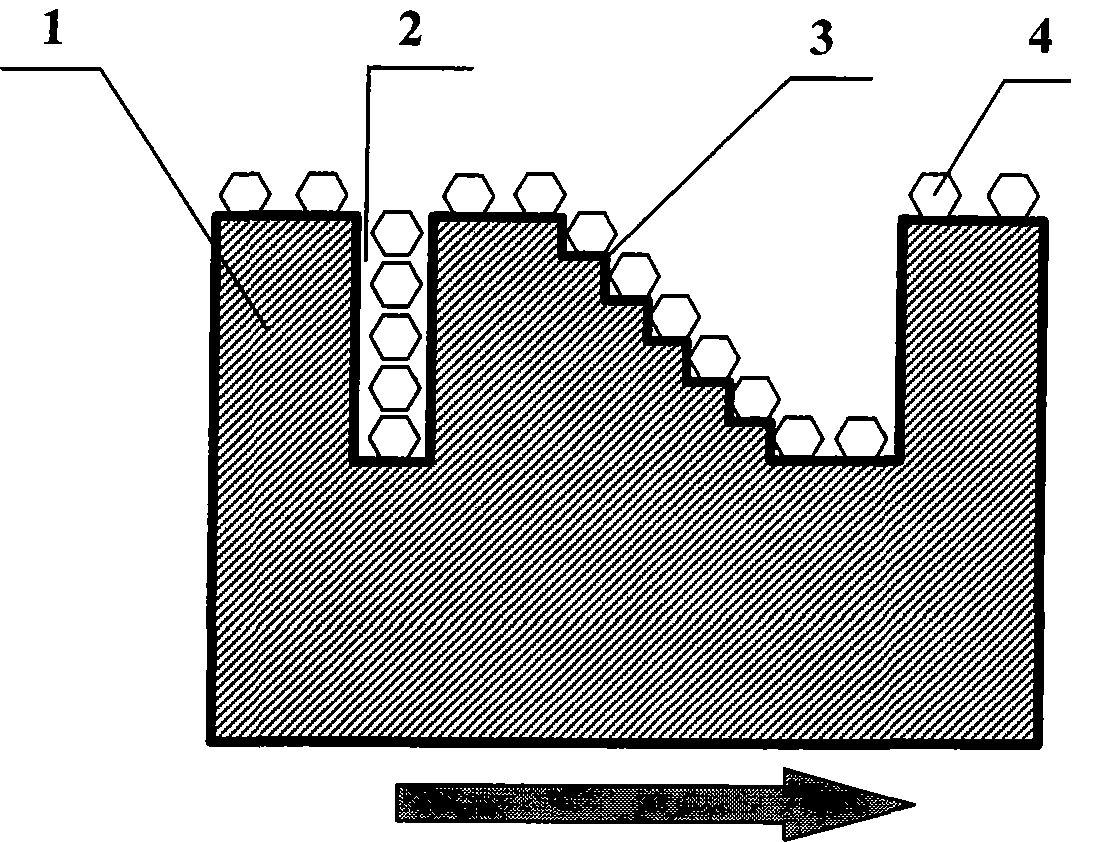

Diamond soldering appliance

InactiveCN101195257ASolution to short lifeMeet flowBonded abrasive wheelsStone-like material working toolsMaterials processingSoldering

The invention relates to the manufacturing field of hard brittle materials, in particular to a diamond brazing tool which is in the combining structure of joint and staircase-like steps. The invention comprises a bit, a saw blade and a grinding wheel, and is mainly used for the drilling, cutting, grinding and polishing of stone materials, concrete, glass, ceramics, crystal, hard alloy and the like materials. The matrix structure of the working area of the diamond brazing bit, the saw blade and the grinding wheel is designed to a combining structure of joint and staircase-like steps, diamond abrasive is brazed on the step surface and in the joint, and the diamond abrasive is put into use step by step when in the process of drilling, cutting, grinding and polishing, thereby the contact surface with the processing object is reduced, the grinding force is small and the cutting efficiency is high.

Owner:江苏华昌工具制造有限公司

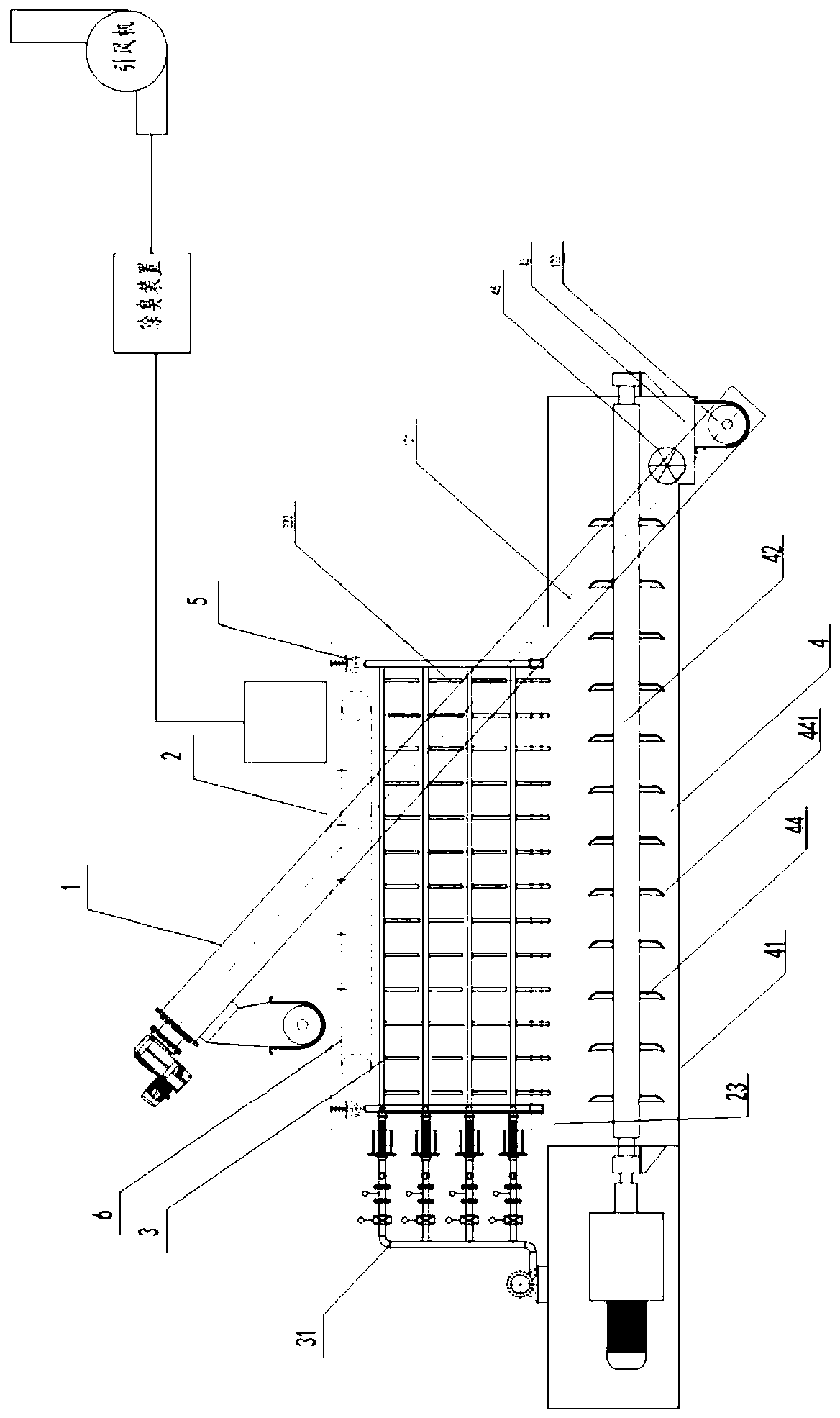

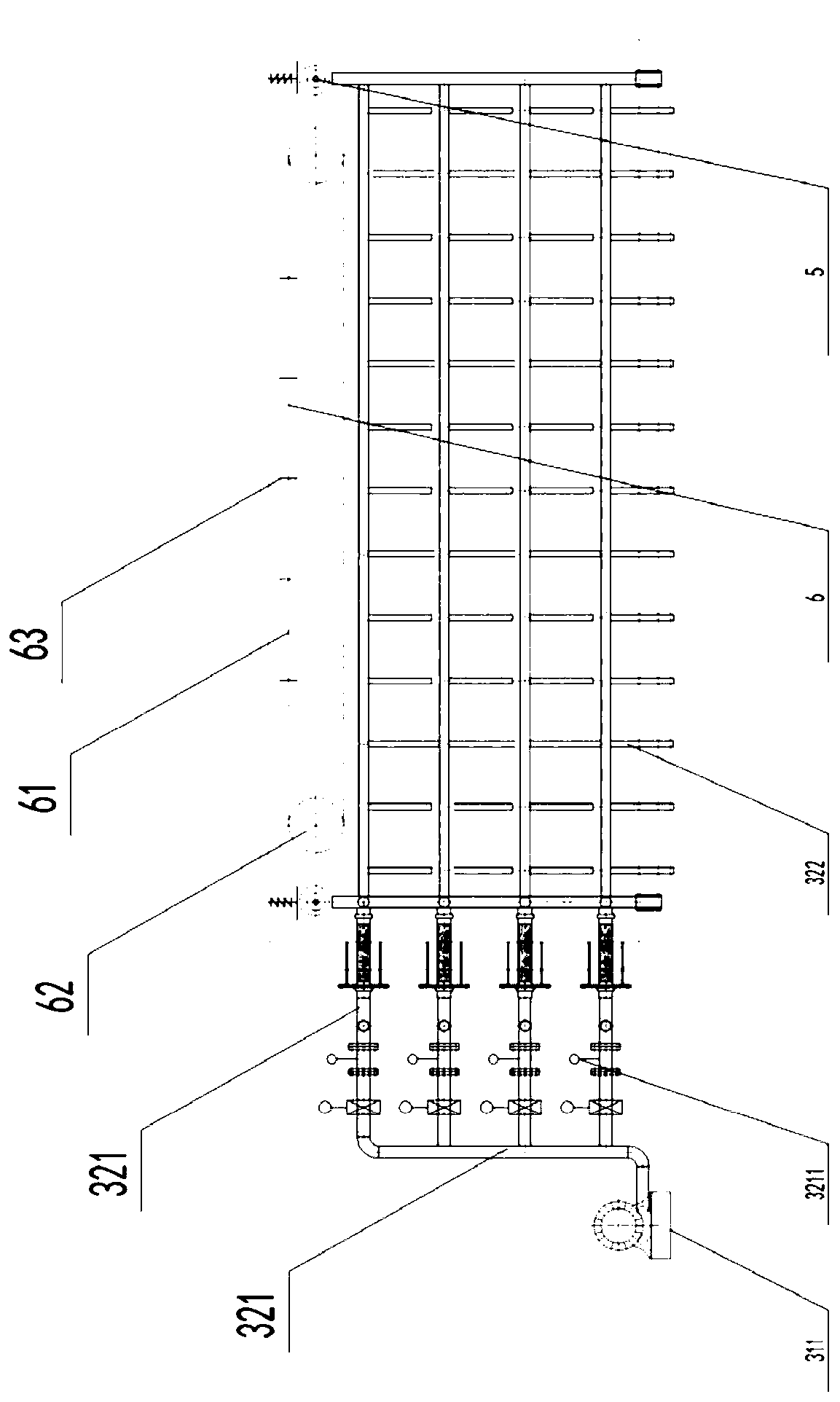

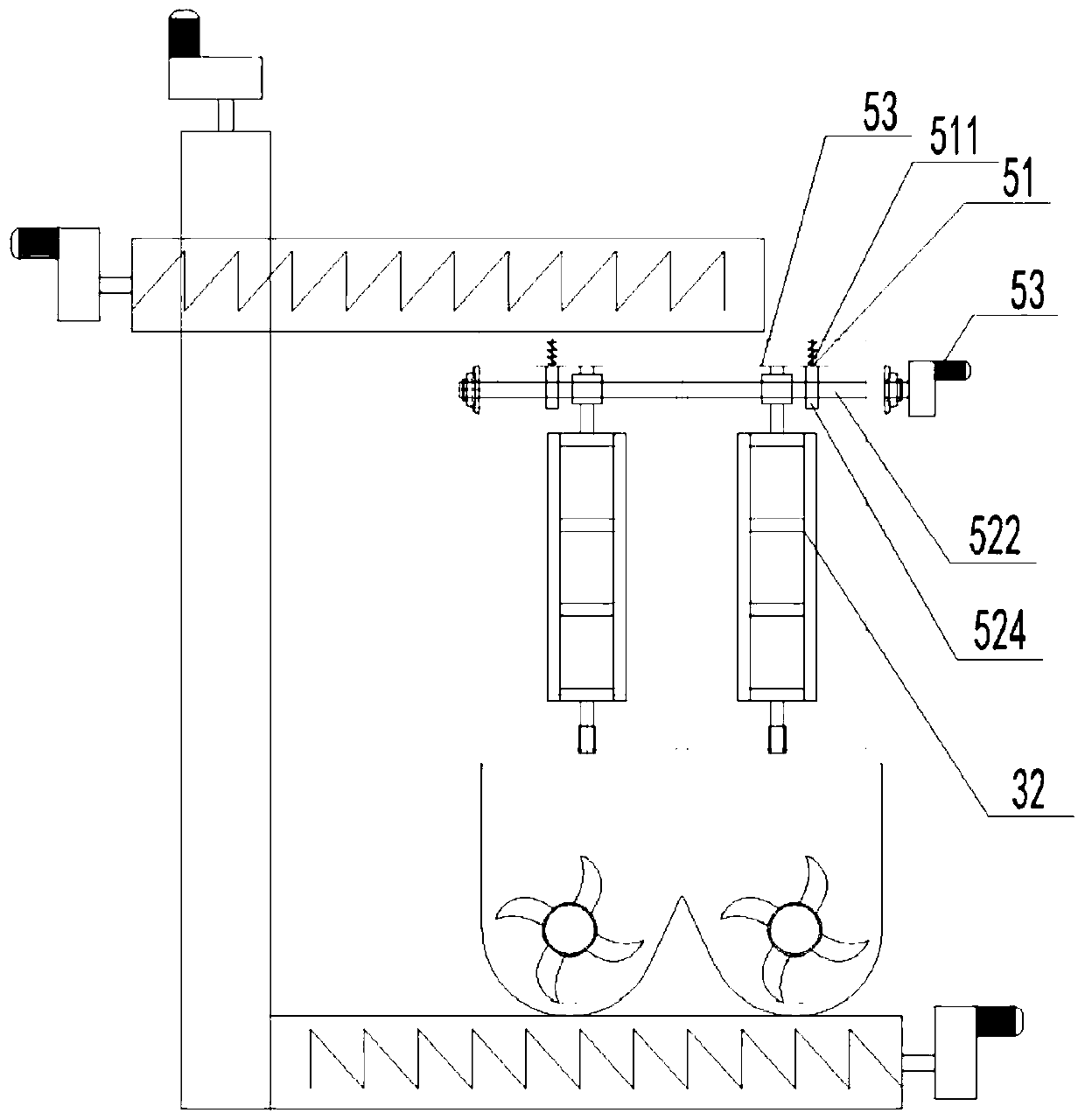

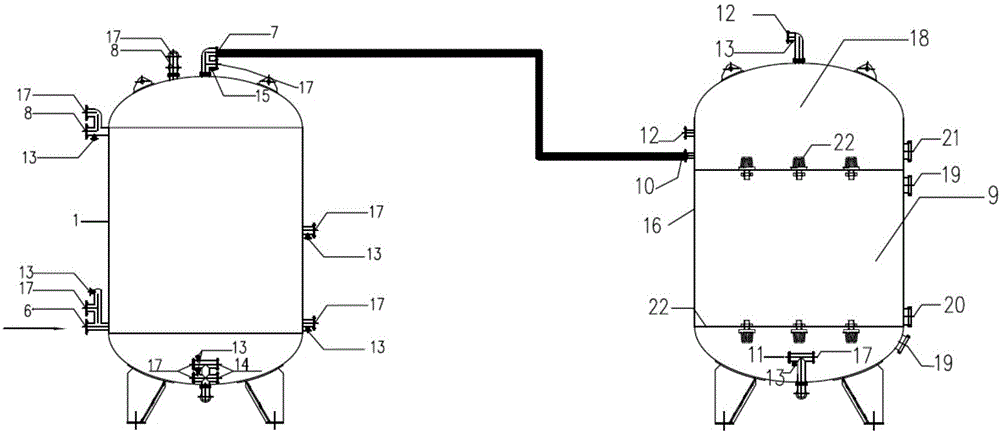

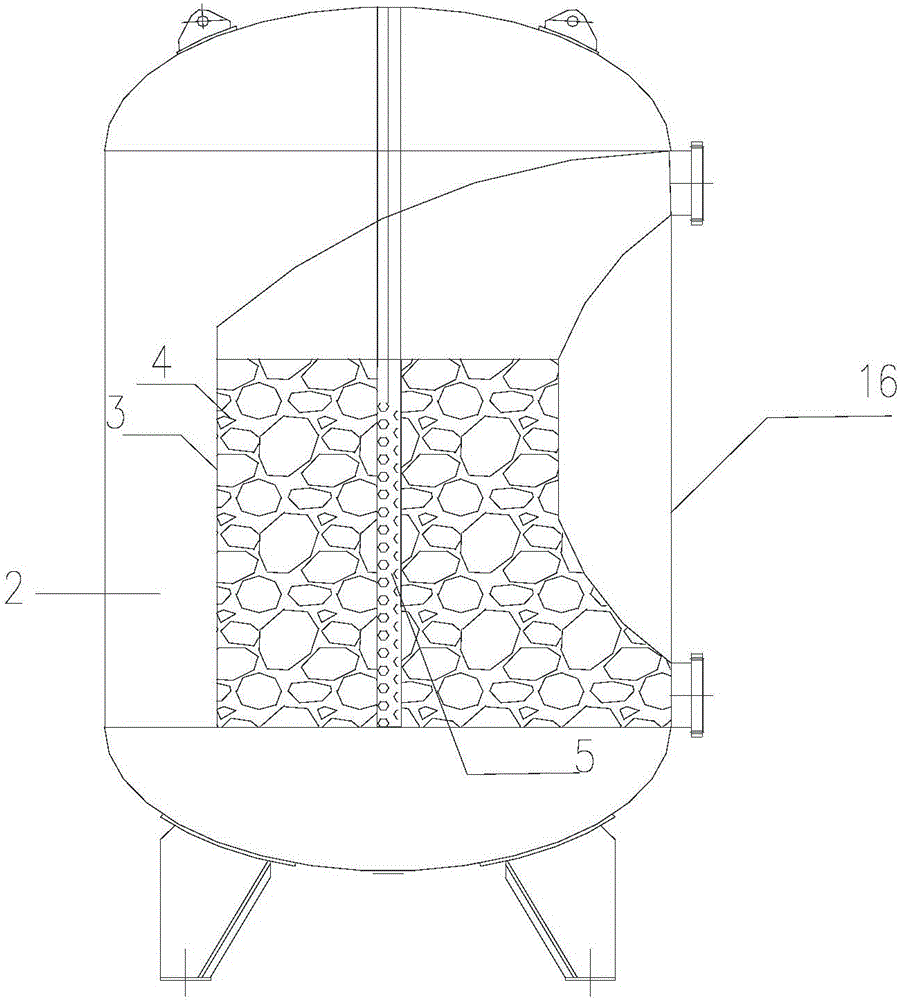

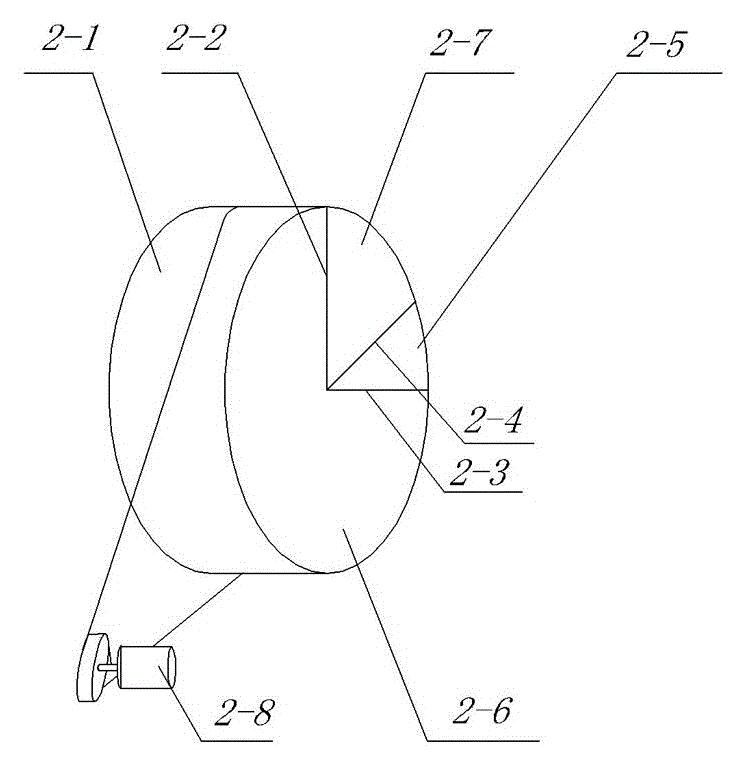

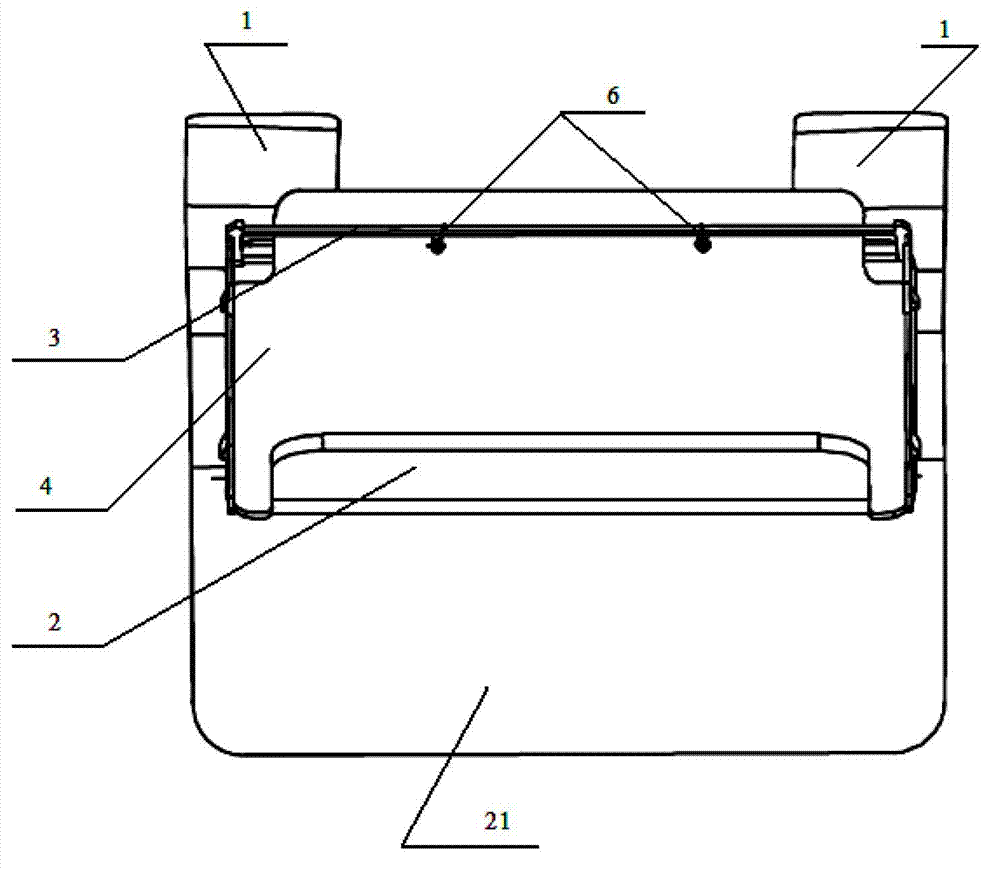

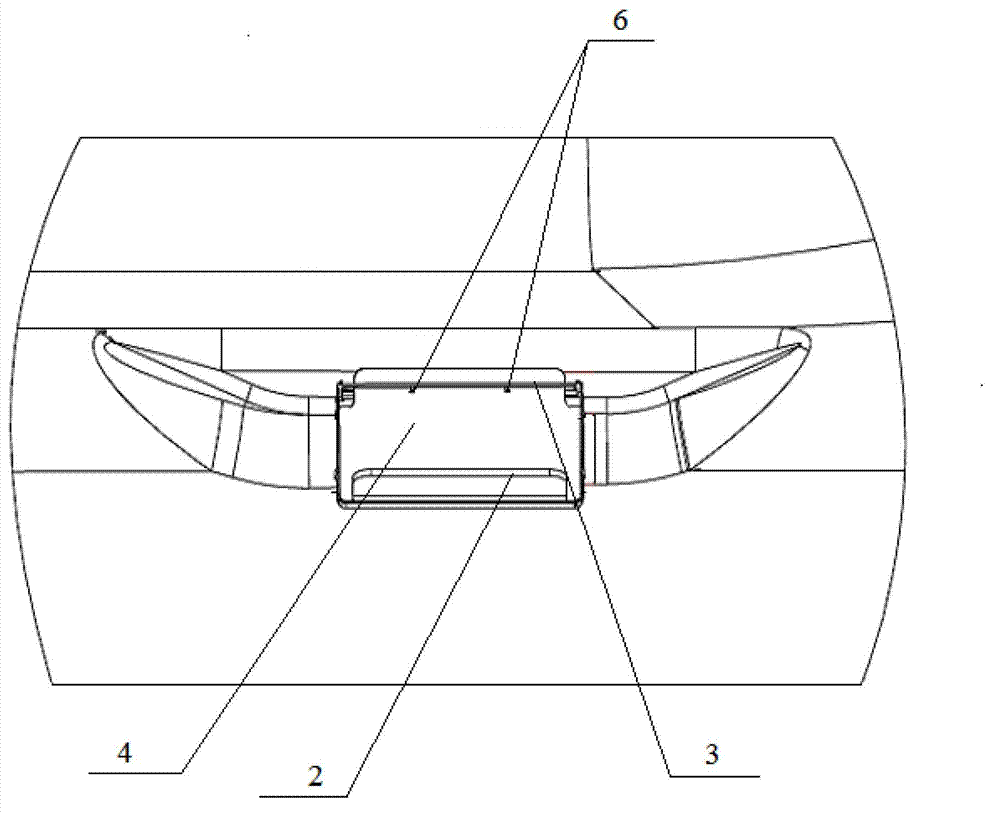

Sludge aerobic fermentation system

PendingCN109987809AEffective stirringEffective agitation for mixing and aerationGas treatmentDispersed particle filtrationSludgeOxygen

The invention discloses a sludge aerobic fermentation system. The sludge aerobic fermentation system comprises a feeding device, a fermentation tank, an aeration device and a discharging device; the feeding device conveys sludge to the upper end of the fermentation tank and feeds the sludge into the fermentation tank for fermentation, and after the sludge is fermented by oxygen provided by the aeration device, the fermented sludge is conveyed out of the fermentation tank. The aeration device comprises an air inlet pipe and a plurality of aeration units which are flexibly connected with the airinlet pipes, and the aeration units are distributed in the fermentation tank. The invention provides the sludge aerobic fermentation system which is convenient to install and transport and can effectively improve aerobic fermentation efficiency.

Owner:ZHEJIANG ZOKSEN ENVIRO ENERGY EQUIP

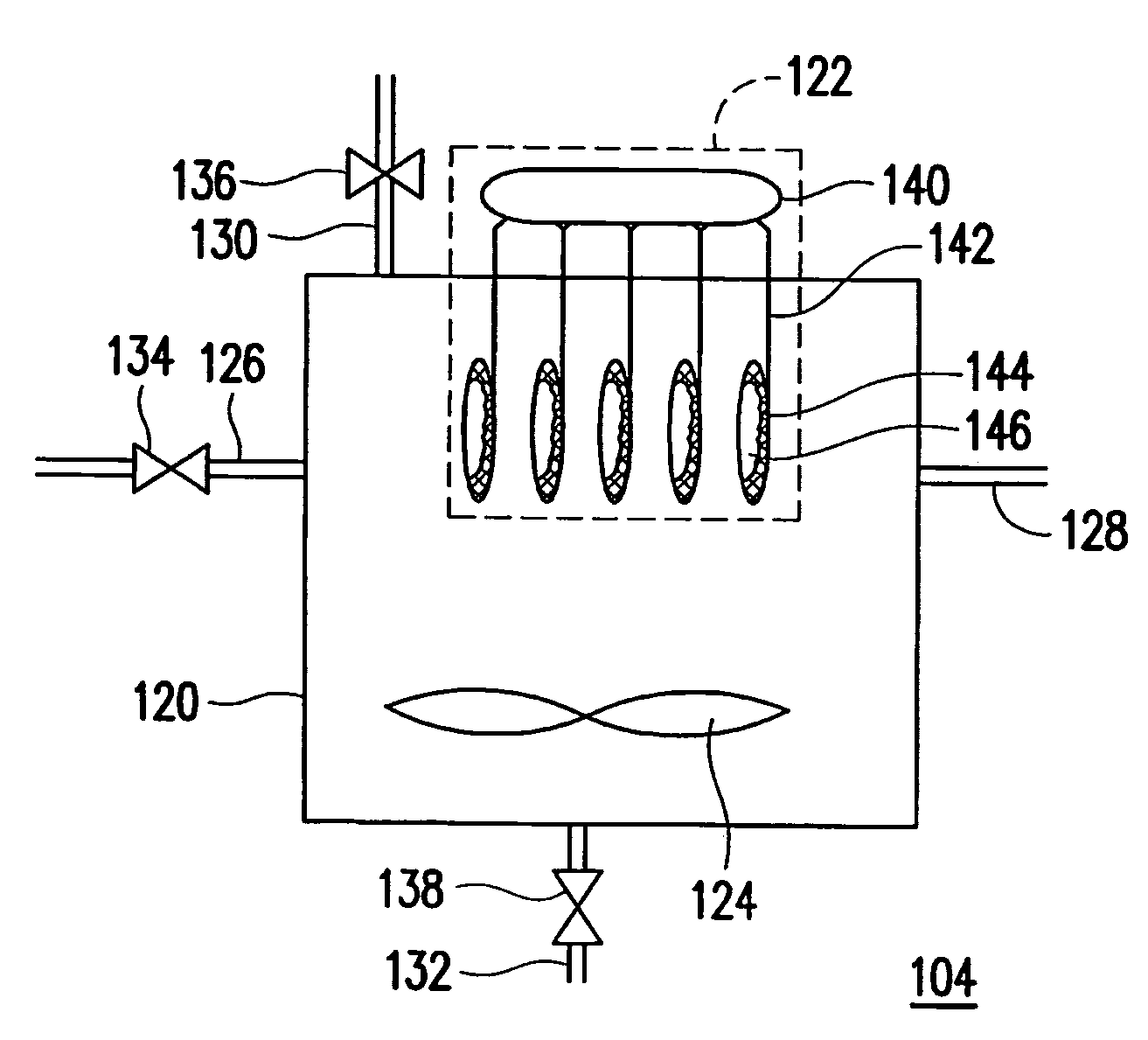

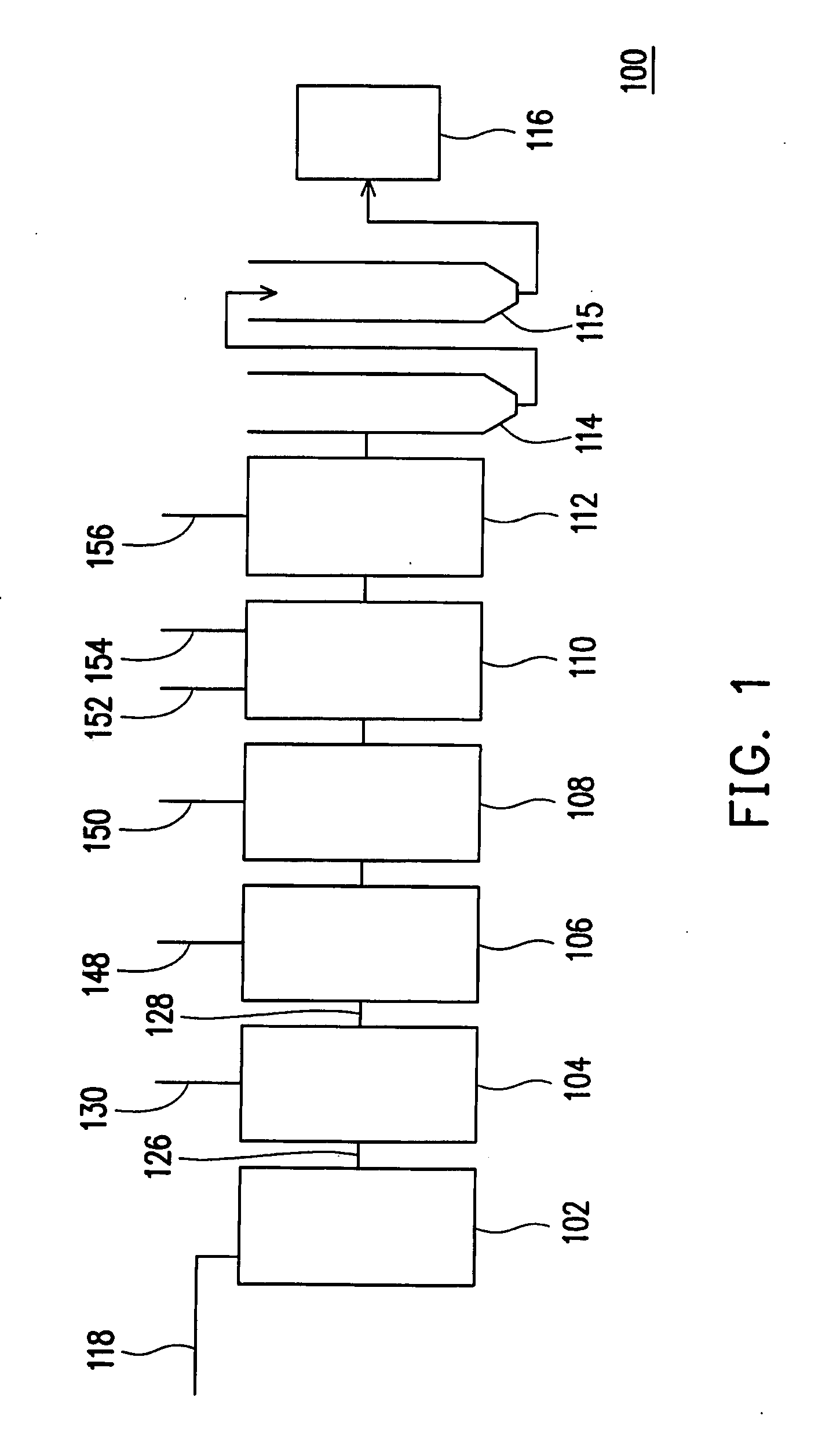

Method for treating fluoride-containing waste water and system of treating waste water

InactiveUS20090082607A1Low cost of treatmentReduces the deposition of dirtWater contaminantsWater/sewage treatmentCrystallizationChemistry

A method for treating fluoride-containing waste water is disclosed. The method includes, first, inducing fluoride-containing waste water and calcium compound into a crystallization reaction tank having a plurality of crystallizing webs so as to conduct a reaction between the fluoride-containing waste water and the calcium compound to form calcium fluoride crystals on the crystallizing webs; meanwhile, stirring the fluoride-containing waste water and the; then, discharging the fluoride-containing waste water out of the crystallization reaction tank for conducting a successive treating step.

Owner:POWERCHIP SEMICON CORP

Method for removing dust and oil from wastewater and dust and oil removing system

PendingCN106517556AEasy to cleanRaise the sintering temperatureTreatment involving filtrationMultistage water/sewage treatmentInlet valveSuspended matter

The invention discloses a method for removing dust and oil from coal-chemical engineering wastewater. The method comprises following steps: (1), dust removing: wastewater enters a water channel through a dust removing water inlet valve and rotates for 360 degrees in the water channel to flow upwards, pressure difference is formed, the wastewater enters a center water distributor through a grid and a dust removing filter material under the action of the pressure difference and then flows out from a dust removing water outlet valve, suspended solids are intercepted by the dust removing filter material, and the dust removing of the wastewater is completed; (2), oil removing: the wastewater after dust removing enters a tank through an oil removing water inlet valve and moves downwards under the action of gravity, lipophilic groups of the filter material absorb dispersed oil drops in the wastewater when the wastewater passes an oil removing particle membrane, oil is enabled to be demulsified on the oil removing particle membrane, a thin film is formed, water after oil removing continuously flows downwards and is discharged from an oil removing water outlet valve, oil molecules are intercepted and accumulated to form oil drops, the enriched oil drops are separated in a large oil drop form and float upwards to the top end of the tank, and oil removing is completed. The invention further discloses a dust and oil removing system implementing the method.

Owner:广东先能环保科技有限公司

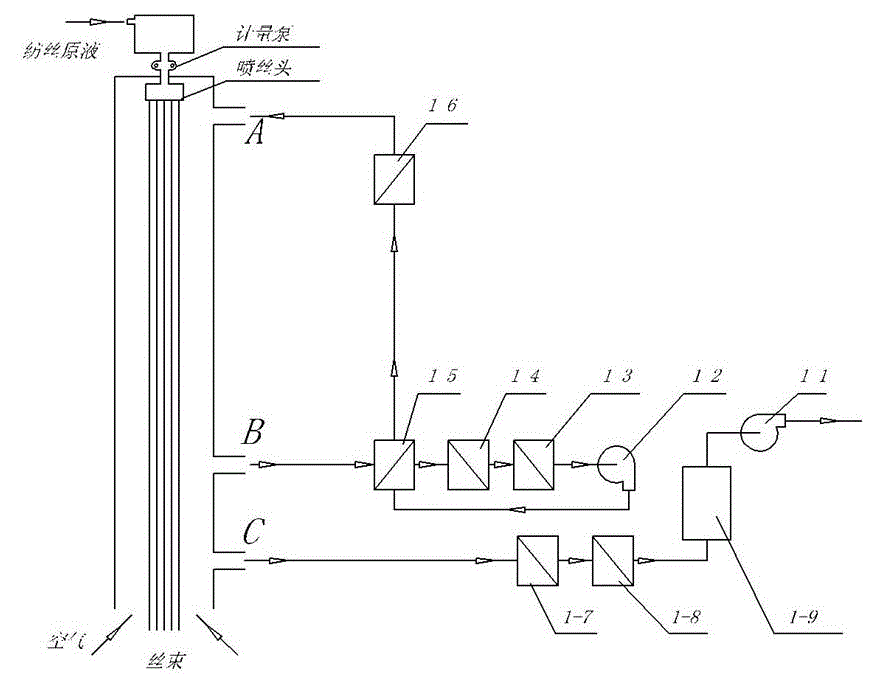

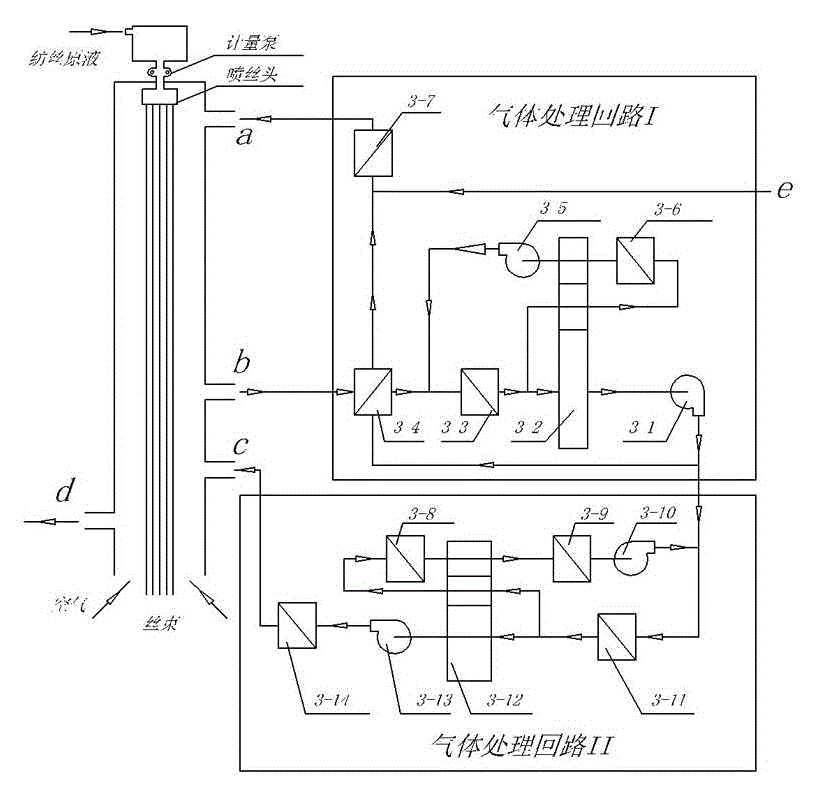

Dry spinning organic solvent recovery and air circulation process and its device

ActiveCN103757752BReduce recycling costsIncrease concentrationArtificial filament recoveryArtificial thread manufacturing machinesAir cycleThermodynamics

The invention relates to a process and a device for organic solvent recovery and air cycle use in dry spinning. A spinning shaft is sequentially provided with a high-temperature gas inlet, an organic solvent-containing gas exhaust port, a secondary high-temperature gas inlet and a cooling air exhaust port from top to bottom; a spinning shaft gas treatment system comprises a gas treatment loop I and a gas treatment loop II, the gas treatment loop I is used for recycling most of solvent from gas exhausted from the exhaust port, and the gas treatment loop II is used for further separating and recycling the organic solvent; a turning wheel is cooled and the regeneration treatment is realized due to the design of the pipeline and the own energy, the regenerated gas can be continuously used for the gas treatment system, and no gas is exhausted outside the system. The moisture content of circulating air and the recycled organic solvent is low, no organic solvent hydrolysis phenomenon occurs in the follow-up treatment, no low-temperature chilled water is required during solvent recovery, and zero emission in chemical fiber production is realized.

Owner:马军

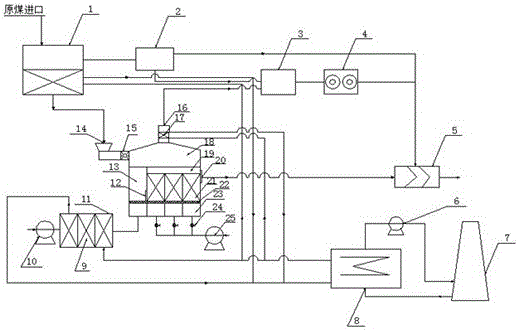

Clean and efficient gradient screening internal thermal fluidized bed coal moisture control process

InactiveCN105733635AWide adaptability to humidityReliable operation regulationCoke ovensScreening proceduresHeat carrier

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

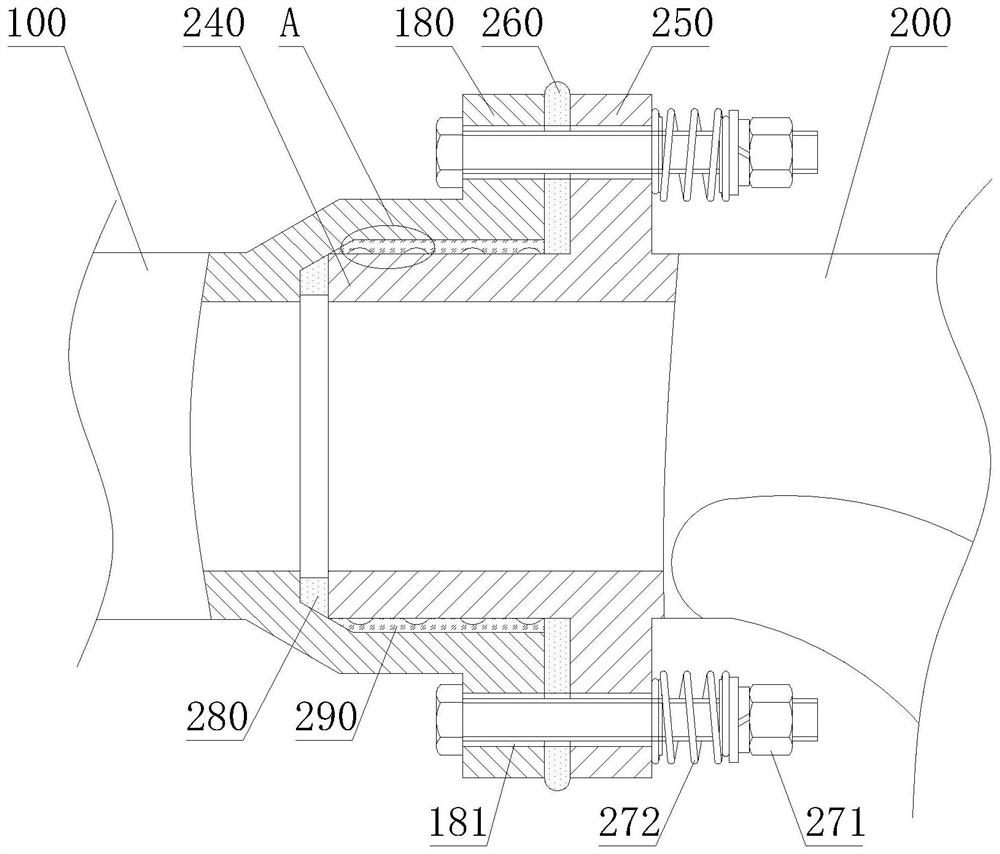

Leakage block

ActiveCN102963313AMeet emissionsImprove noiseEngine sealsVehicle sealing arrangementsHydraulic actionEngineering

The invention discloses a leakage block, which belongs to the technical field of automobiles. The leakage block structure comprises a fixing structure, a blocking pad and a suspended structure, wherein the leakage block is integrally fixed to a structure where a leakage hole is positioned by the fixing structure; and the blocking pad is arranged on the suspended structure and is vertically arranged by covering the leakage hole. When no liquid leaks from the leakage hole, the blocking pad has a sealing effect on the leakage hole; and when liquid flows out from the leakage hole, a gap is produced between the blocking pad and the outer edge of the leakage hole under the hydraulic action, so that the liquid is discharged from the gap. The leakage block guarantees the drainage function of the leakage hole and meanwhile can be used for sealing the leakage hole in case of no liquid discharge to solve the problem of air leakage of the leakage hole, so that the noise, vibration and harshness performance of the structure for mounting the leakage hole can be improved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Diamond soldering appliance

InactiveCN101195257BSolution to short lifeMeet flowBonded abrasive wheelsStone-like material working toolsMaterials processingSoldering

The invention relates to the manufacturing field of hard brittle materials, in particular to a diamond brazing tool which is in the combining structure of joint and staircase-like steps. The invention comprises a bit, a saw blade and a grinding wheel, and is mainly used for the drilling, cutting, grinding and polishing of stone materials, concrete, glass, ceramics, crystal, hard alloy and the like materials. The matrix structure of the working area of the diamond brazing bit, the saw blade and the grinding wheel is designed to a combining structure of joint and staircase-like steps, diamond abrasive is brazed on the step surface and in the joint, and the diamond abrasive is put into use step by step when in the process of drilling, cutting, grinding and polishing, thereby the contact surface with the processing object is reduced, the grinding force is small and the cutting efficiency is high.

Owner:江苏华昌工具制造有限公司

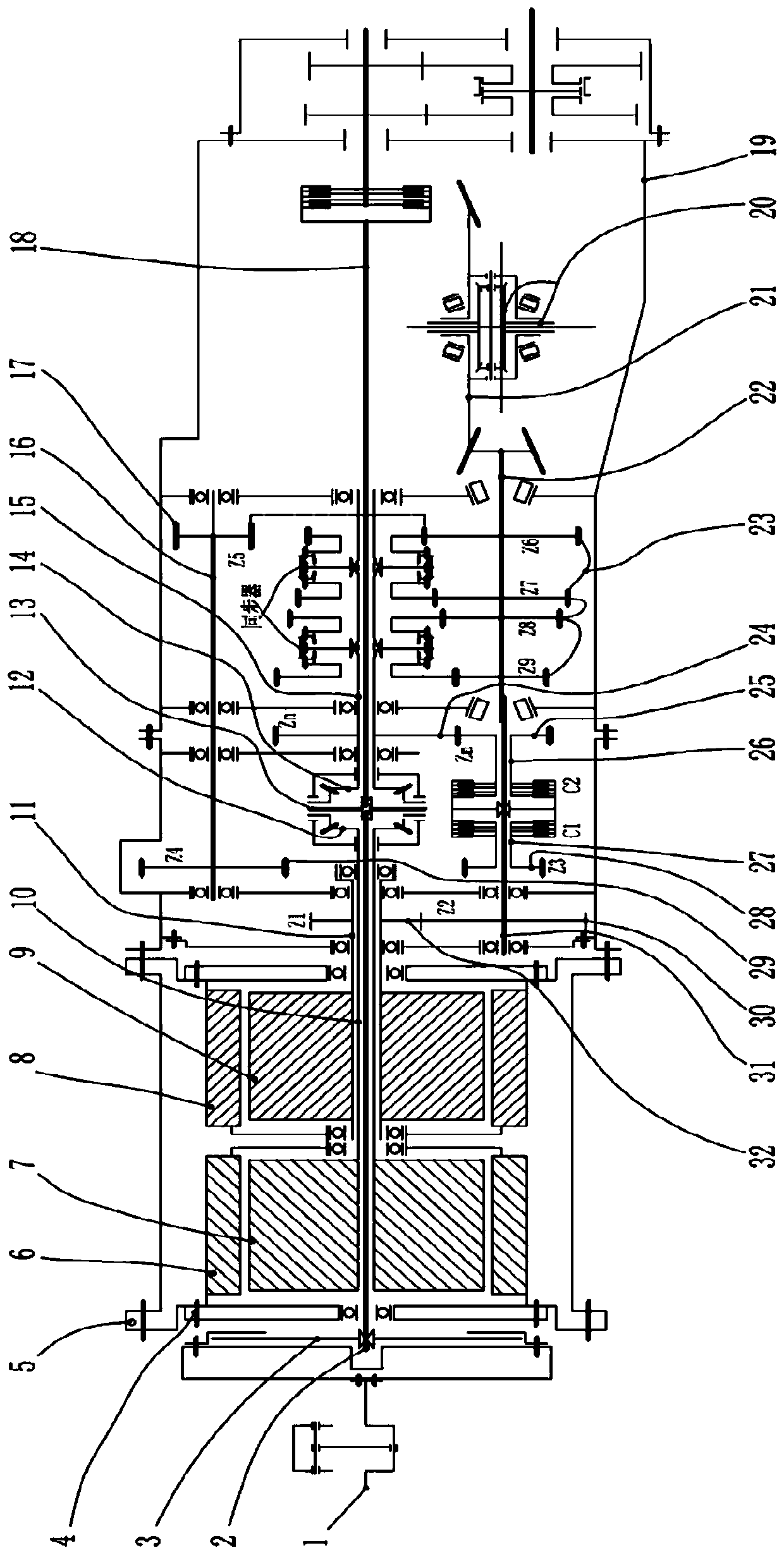

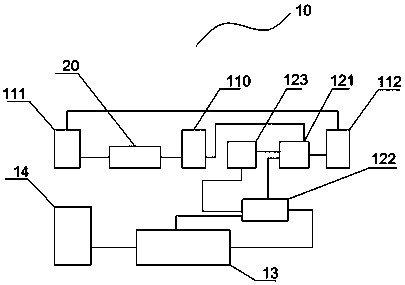

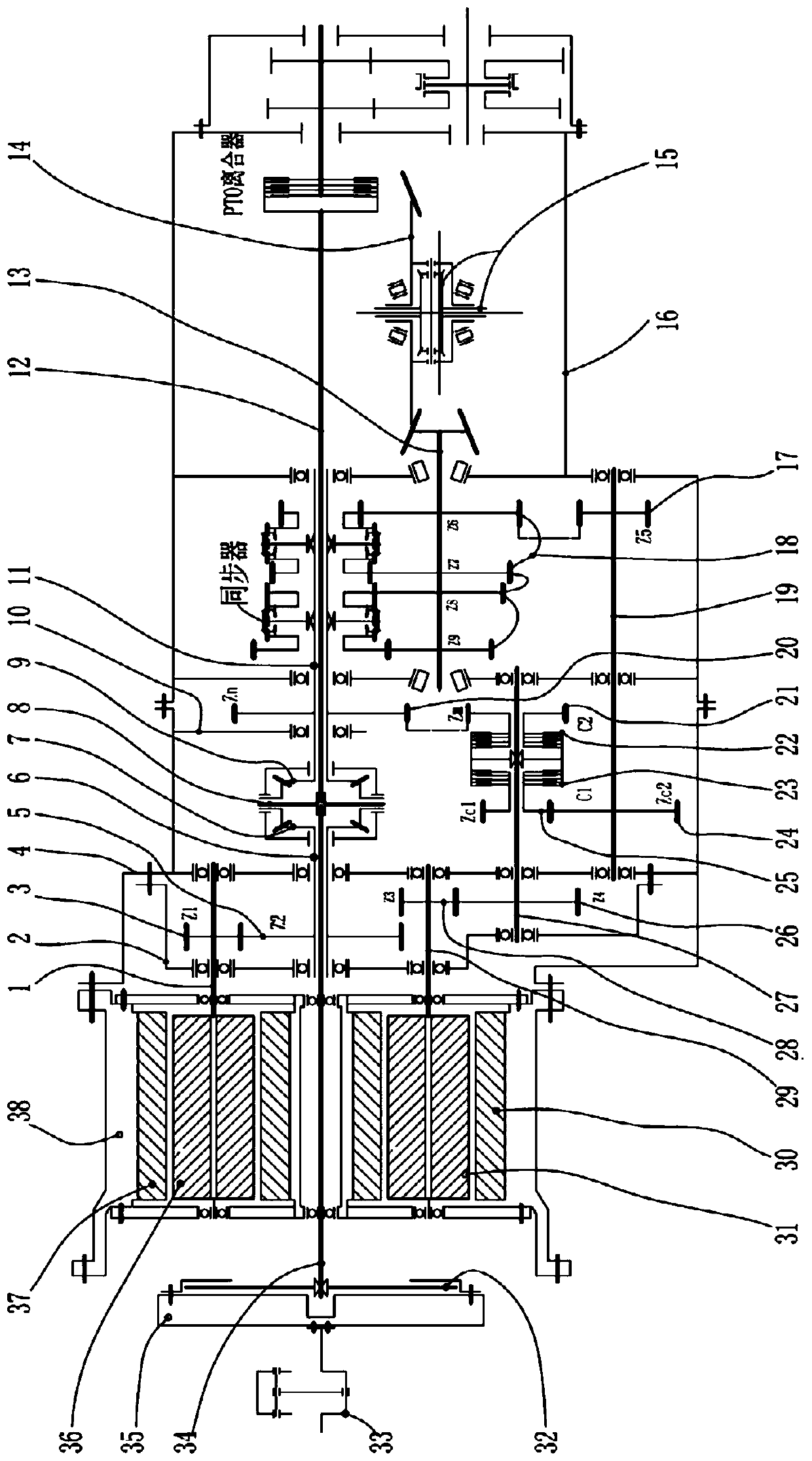

Stepless variable drive system for series dual-motor differential power dividing

PendingCN110303865AGuaranteed to workQuick responseElectric propulsion mountingControl devicesElectric machineElectric power system

The invention discloses a stepless variable drive system for series dual-motor differential power dividing. The system comprises an engine output / differential input shaft, a first motor, a second motor, a motor controller, a power dividing device, a clutch, a gearbox, an engine power output shaft and a storage battery; the first motor and the second motor are connected in series, power of an engine is transmitted to the first motor through the engine output / differential input shaft for power generation, and meanwhile, the engine output / differential input shaft outputs power outwards through the power dividing device, the clutch and the gearbox to form a first power path; the first motor supplies power to the second motor and the storage battery through the motor controller, and the secondmotor outputs power outwards through the power dividing device, the clutch and the gearbox to form a second power path. The stepless variable drive system has the two power paths of mechanical power and electric power.

Owner:GUANGXI YUCHAI MASCH CO LTD

Cyclic regeneration device for alkaline etching solution

The invention discloses a cyclic regeneration device for an alkaline etching solution. The cyclic regeneration device for the alkaline etching solution includes a circulating storage system, an extraction system and an electrolytic cell, and the circulating storage system, the extraction system and the electrolytic cell are sequentially connected; the circulating storage system comprises an etching waste liquid tank, a regenerating liquid tank and a regenerating liquid blending tank; the extraction system comprises a copper extraction separator and a stripping separator, and the copper extraction separator communicates with the etching waste liquid tank; and the stripping separator uses sulphuric acid to strip copper ions from the copper extraction separator to an sulphuric acid solution,and the stripped solution is conveyed to the electrolytic cell as an electrolyte. The cyclic regeneration device and method for the alkaline etching solution is adopted, the recycling and reuse of theetching waste liquid can be realized, and the utilization rate can reach 98% or above, thus the discharge of pollution waste from PCB enterprises is greatly reduced.

Owner:GUANGZHOU JICHI ENVIRONMENTAL TECH CO LTD

Recycling and regeneration method of alkaline etching liquid

InactiveCN109972140AImprove performanceRealize recyclingPhotography auxillary processesProcess efficiency improvementLiquid tankAlkaline etching

The invention discloses a recycling and regeneration method of an alkaline etching liquid. The recycling and regeneration method of the alkaline etching liquid includes the steps that S1, a regenerated etching liquid in a regenerated liquid tank is transported to an alkaline etching line (SES) for etching, and then a generated waste etching liquid is collected into an etching waste liquid tank; S2, the waste etching liquid is transported from the etching waste liquid tank to a copper extraction separator to separate and capture copper ions with a copper extractant; S3, after extraction is carried out, the waste etching liquid is separated from the extractant, and the waste etching liquid is collected into a regenerated liquid blending tank, the concentration of the waste etching liquid isblended and the blended waste etching liquid is re-transported to the regenerated liquid tank; and S4, the copper extractant is transported to a stripping separator, and the copper ions are subjectedto stripping and separated by a sulfuric acid solution to prepare the copper ions containing a copper solution to facilitate the treatment of the waste copper ions. By adopting the recycling and regeneration device and method of the alkaline etching liquid, the recycling and regeneration of the etching waste liquid is realized, the utilization rate can be above 98%, and thus the discharge of pollution waste from PCB enterprises is greatly reduced.

Owner:GUANGZHOU JICHI ENVIRONMENTAL TECH CO LTD

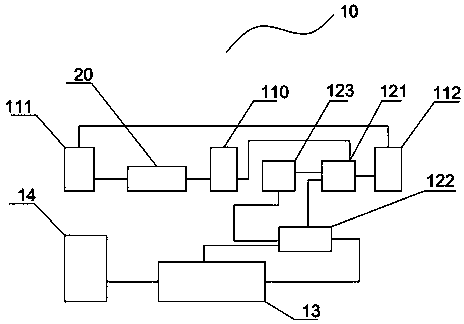

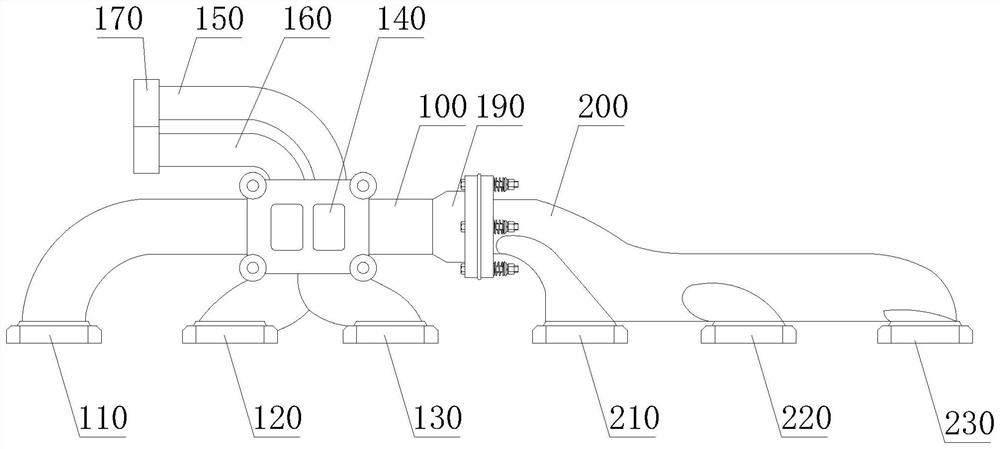

Double-channel exhaust pipe for taking gas from channel closest to supercharger through EGR

PendingCN113756926AMeet emissionsEven airflowExhaust apparatusExhaust gas recirculationThermodynamicsExhaust fumes

The invention provides a double-channel exhaust pipe for taking gas from a channel closest to supercharger through EGR, and belongs to the technical field of engine exhaust gas recirculation. The double-channel exhaust pipe for taking gas from the channel closest to the supercharger through EGR comprises a first exhaust manifold and a second exhaust manifold. A first air inlet, a second air inlet and a third air inlet are respectively formed in the bottom of the first exhaust manifold; and the top of the first exhaust manifold communicates with a first EGR gas taking pipe and a second EGR gas taking pipe. A double-channel EGR system connected with the first EGR gas taking pipe and the second EGR gas taking pipe is adopted at the top of the first exhaust manifold; in order to be matched with a double-channel EGR valve, the engine exhaust pipe is composed of a 1-3-cylinder exhaust manifold and a 4-6-cylinder exhaust manifold; and each cylinder exhaust manifold is provided with an EGR gas taking opening corresponding to an inlet of the double-channel EGR valve. The EGR gas taking opening is formed in the inlet position of the supercharger, so that gas flow is smoother.

Owner:GUANGXI YUCHAI MASCH CO LTD

Parallel dual-motor differential power dividing continuously variable transmission system

PendingCN110303861AGuaranteed to workQuick responseElectric propulsion mountingControl devicesElectricityTransmitted power

The invention discloses a parallel dual-motor differential power dividing continuously variable transmission system. The parallel dual-motor differential power dividing continuously variable transmission system is connected with an engine output shaft and comprises the engine output shaft, a first motor, a second motor, a motor controller, a differential mechanism, a clutch, a gearbox, a power output shaft and a storage battery; the first motor and the second motor are arranged in parallel, the engine output shaft transmits power of the engine to the first motor for generating electricity, meanwhile, the engine output shaft outputs power outwards to form a first power path through the differential mechanism, the clutch and the gearbox, the first motor supplies power to the second motor andthe storage battery through the motor controller, and the second motor outputs power outwards to form a second power path through the differential mechanism, the clutch and the gearbox. Accordingly,two power paths of mechanical power and electric power can be achieved.

Owner:GUANGXI YUCHAI MASCH CO LTD

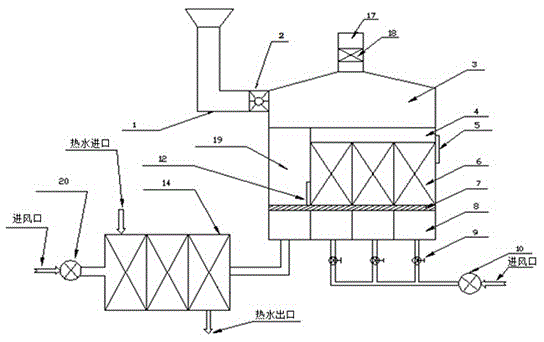

Device for coking coal stage drying step humidify regulating process

ActiveCN105647557AGuaranteed installation and maintenanceGuarantee normal productionDrying solid materials with heatCoke ovensAir preheaterProcess engineering

The invention discloses a device for a coking coal stage drying step humidify regulating process. The device comprises a first-stage humidify regulating process loop and a second-stage humidify regulating process loop, wherein the first-stage humidify regulating process loop comprises a first-stage fluidization air chamber (19), an air preheater (14) and a first fluidization fan (20), wherein no coiled pipe heating module is arranged in the first-stage fluidization air chamber (19), and a layer of bed materials with the thickness being 500 to 600mm is arranged at the bottom; the second-stage humidify regulating process loop comprises a second-stage fluidization air chamber (6) and a second fluidization fan (10); the second-stage fluidization air chamber (6) mainly consists of a plurality of humidify regulating modules; a coiled pipe heater is arranged in each humidify regulating module. The device has the advantages that the stage drying step humidify regulation is realized through two stages of humidify regulating process loops, so that the device has wide coal humidify applicability; the coal dust generation and elutriation can be orderly controlled; energy can be fed in a step way according to the technological process; the system operation regulation is reliable and flexible; the energy saving performance is high.

Owner:WUXI YIEN TECH

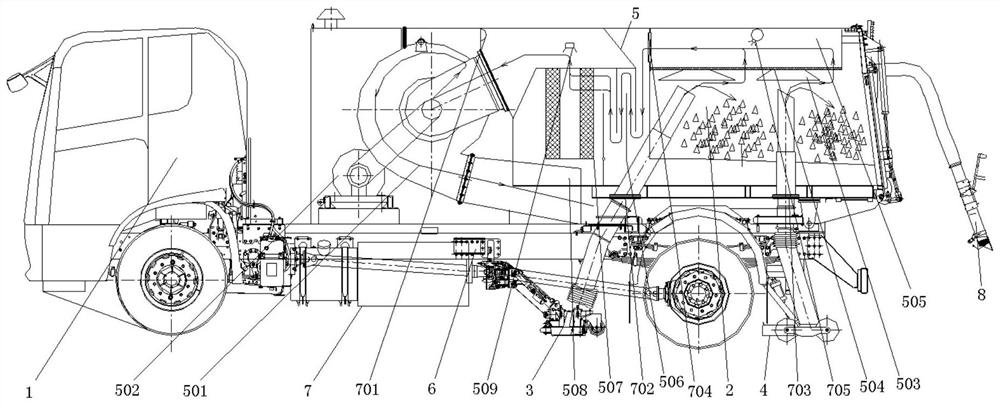

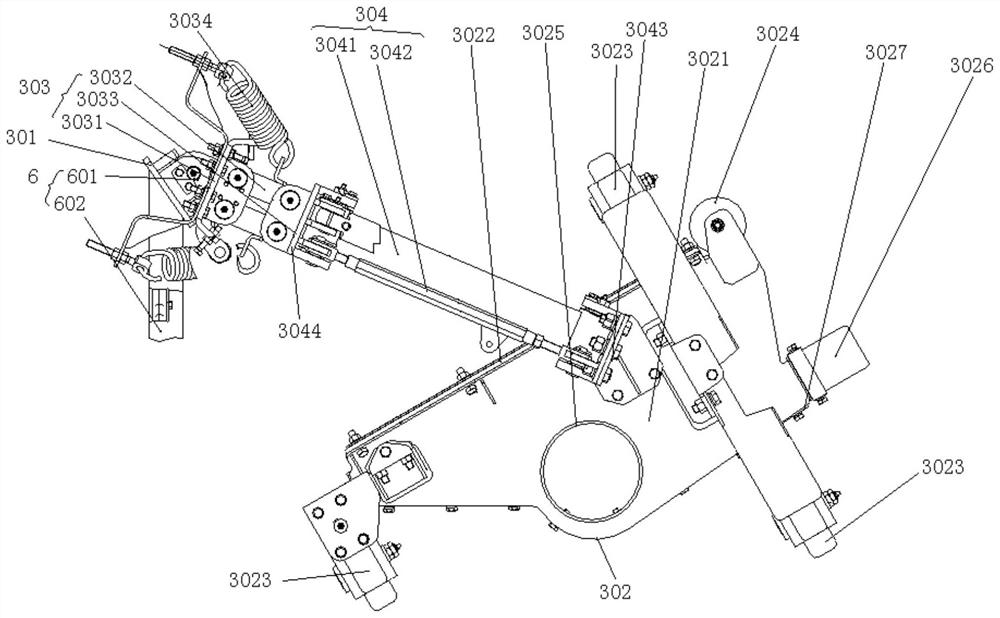

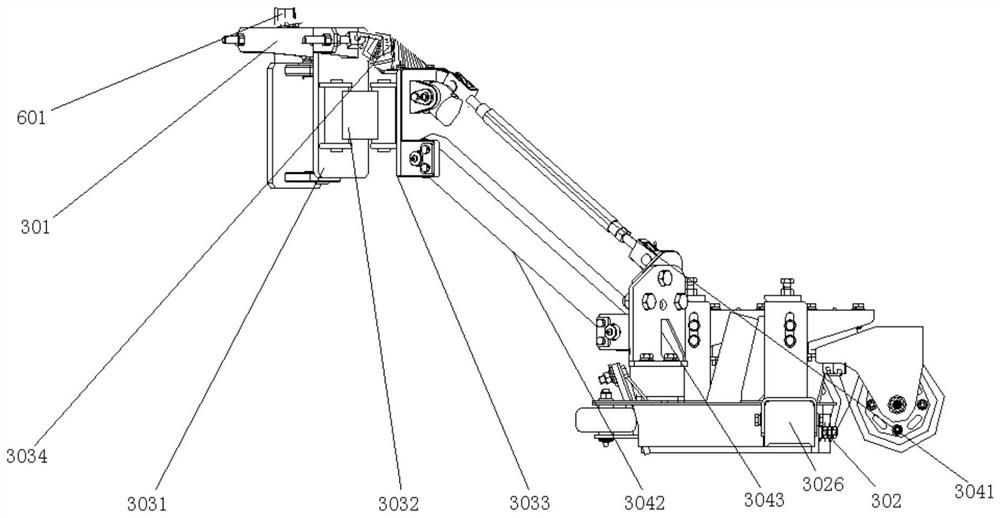

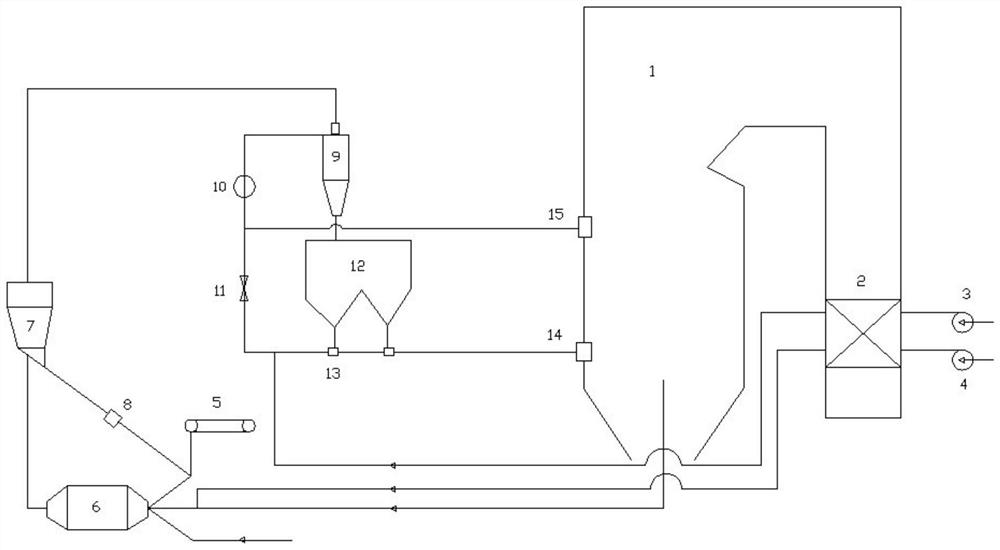

Dry type pure suction sweeper truck

The invention discloses a dry type pure suction sweeper truck which comprises a chassis and a dustbin body, the chassis is provided with side suction devices located on the two sides of the middle section of the chassis, a rear suction device located on the tail section of the chassis and a pneumatic conveying device located on the chassis. The pneumatic conveying device is positioned in an area between the vehicle head on the chassis and the dustbin; a multi-stage dry type dust removal device is arranged at the airflow input end of the pneumatic conveying device, and the pneumatic conveying device communicates with the inner cavity of the dustbin through the multi-stage dry type dust removal device so that vacuum negative pressure is formed in the inner cavity of the dustbin, and dust particles in the dustbin can are prevented from entering the atmosphere through the pneumatic conveying device; the side suction device and the rear suction and pickup device are independently arranged and communicate with the interior of the dustbin so as to suck and pick up garbage on the road surface through vacuum negative pressure in the dustbin. The road edge garbage can be effectively swept, operation flying dust can be effectively controlled, the content of solid particles in exhausted gas is small, and the environmental protection requirement can be met.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Process for generating power by coupling intermediate storage type pulverizing system with sludge drying incineration

InactiveCN112050243AKeep dryEmission reductionSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationBoiler furnaceSludge

The invention discloses a process for generating power by coupling an intermediate storage type coal pulverizing system with sludge drying incineration. The process utilizes the intermediate storage type coal pulverizing system, the intermediate storage type coal pulverizing system comprises a furnace smoke suction pipe and a steel ball coal mill, the steel ball coal mill uses sludge conveyed by apumping system, the furnace smoke suction pipe is used for sucking hot smoke at the bottom of a boiler hearth and sending the hot smoke into the steel ball coal mill for pre-drying of the sludge. According to the process, with addition of the furnace smoke suction pipe, the hot smoke at the bottom of the hearth is sucked to enter the steel ball coal mill, so that the drying capacity of the coal pulverizing system is improved, sludge can be fully dried by the hot smoke, moisture-carrying exhaust gas finally enters the hearth through a tertiary air nozzle, staged combustion is achieved, and NOxemission is reduced; and the hot smoke sucked by the furnace smoke suction pipe can form inert atmosphere in the coal pulverizing system, therefore, the adaptability of the coal pulverizing system tovolatile components mixed with the sludge is improved, and the explosion-proof risk is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

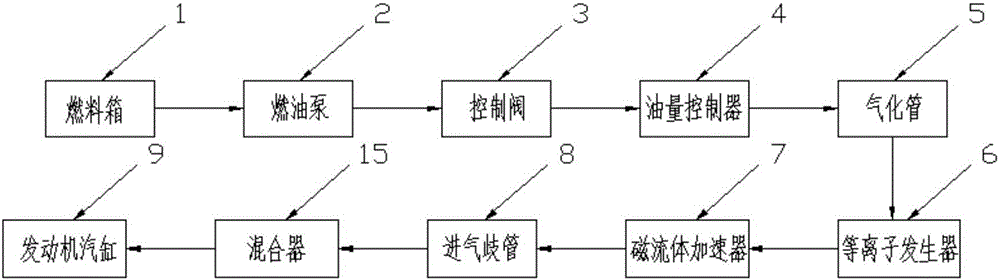

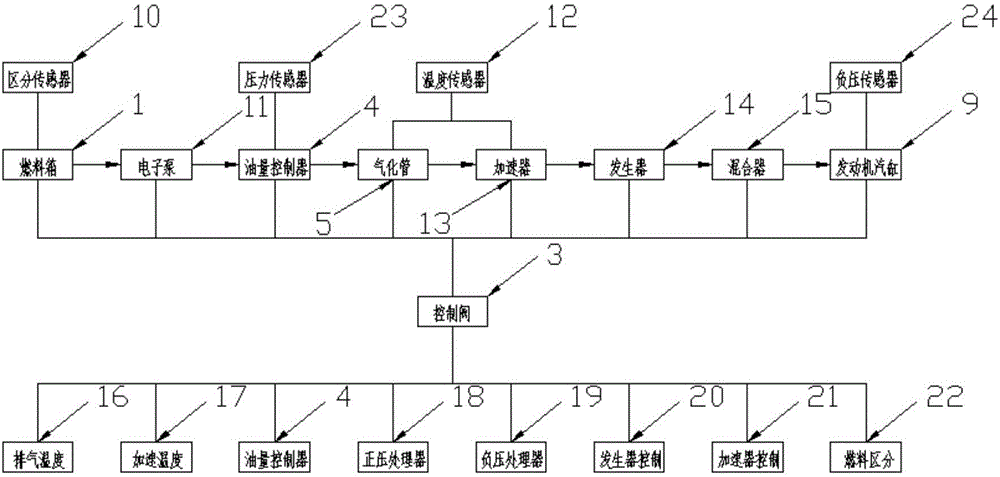

Engine suitable for various kinds of liquid fuel

InactiveCN106762125AMeet emissionsIncrease burn rateInternal combustion piston enginesExhaust apparatusPlasma generatorFuel tank

The invention relates to an engine suitable for various kinds of liquid fuel. The engine includes a fuel tank and a fuel pump which is connected to the fuel tank through a fuel pipe; the fuel pump is connected to a control valve through a line; the control valve is connected to a gasification pipe through a fuel quantity controller; the fuel pump is connected to the gasification pipe through a fuel pipe; the gasification pipe is externally connected to a plasma generator and an inlet manifold; the plasma generator is connected to a magnetic fluid accelerator; the plasma generator and the inlet manifold are connected to a mixer through pipelines; the mixer communicates with an engine cylinder; a signal input end of the control valve is connected to the fuel tank, the gasification pipe, the engine cylinder, an electronic pump, the fuel quantity controller, the accelerator, a generator, and the mixer; and a signal output end of the control valve is connected to the fuel quantity controller and an exhaust gas temperature detector. The technical problem petroleum resource shortage due to the fact that fuel engines are mainly dependent on petroleum fuel, and atmospheric pollution due to combustion of petroleum resources in the prior art can be solved.

Owner:佛山市快箭渔具科技有限公司

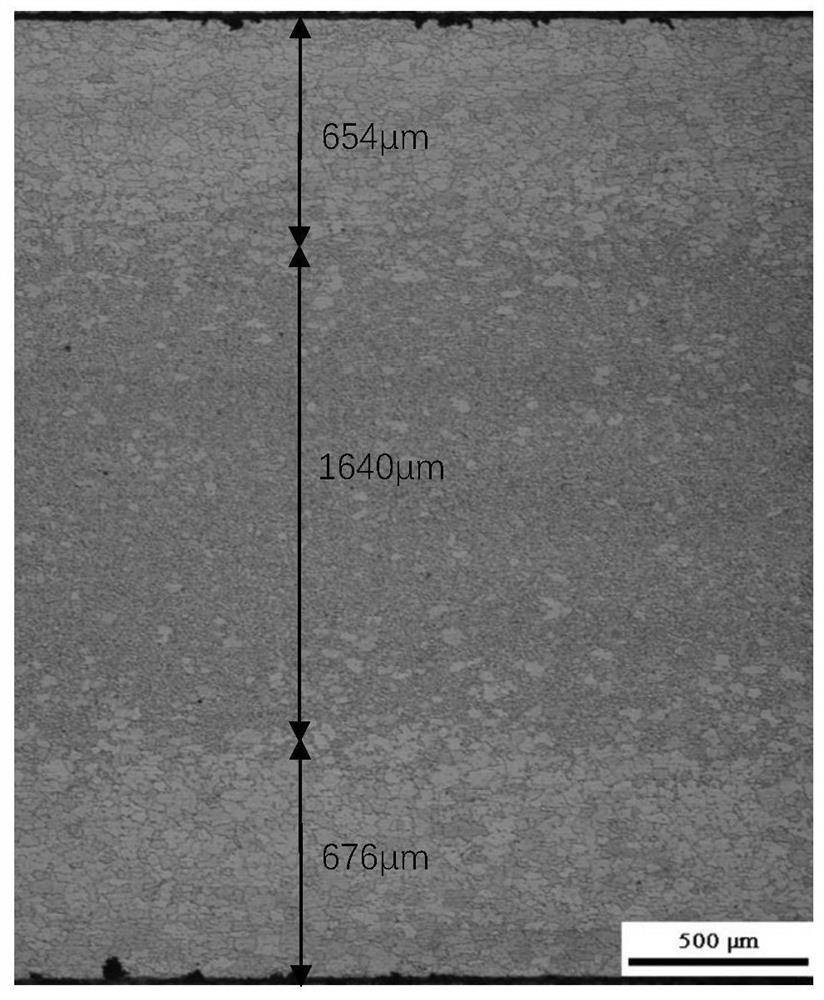

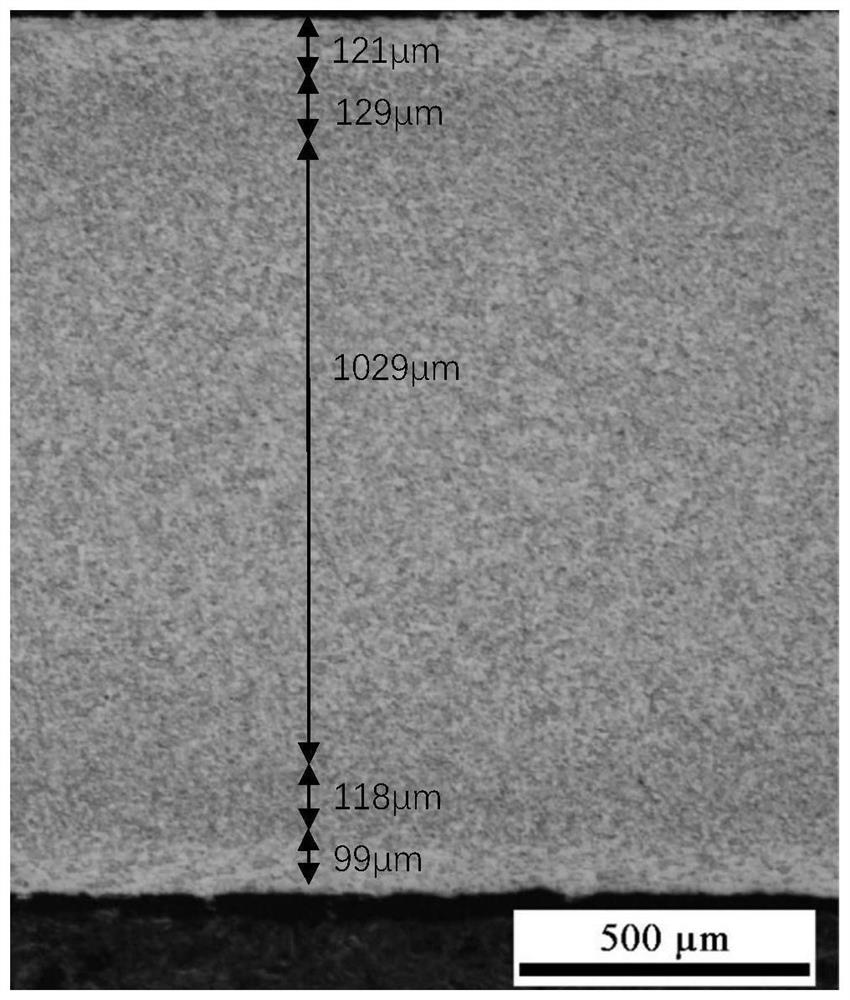

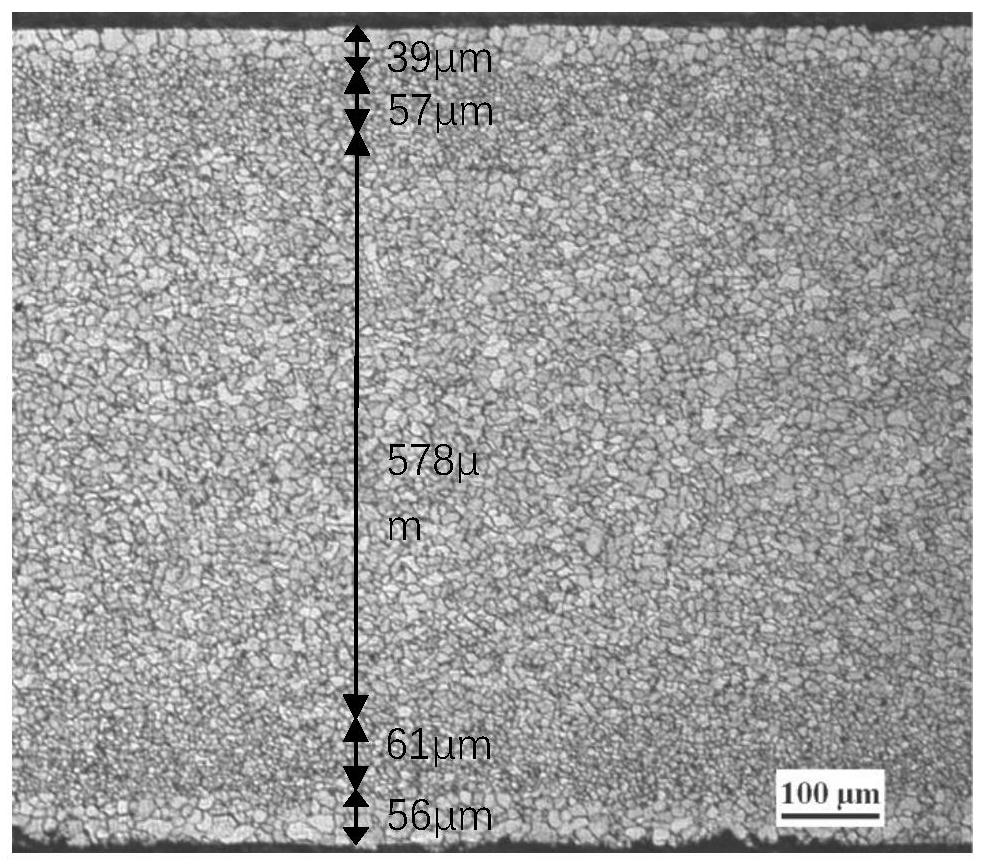

A kind of production method of low-carbon hot-rolled thin steel sheet with multi-layer structure

A method for producing a low-carbon hot-rolled thin steel plate with a multi-layered structure belongs to the technical field of metallurgy. The production process of the method is as follows: continuous casting into billets → soaking in the 1# heating furnace → rough rolling in the rough rolling group → heating in the 2# heating furnace → high-pressure water dephosphorization → finishing rolling in the finishing rolling group → cooling by the layer cooling device → coiling machine coil Pick. The low-carbon hot-rolled thin steel sheet with multi-layered structure obtained by this method is different from the composite steel plate obtained by the composite process such as explosion or hot rolling, and also different from the homogeneous steel plate obtained by the ordinary hot rolling process or cold rolling process. The low-carbon hot-rolled thin steel sheet produced by this method has very high edge ductility, low risk of edge cracking, and excellent performance, which can well meet the needs of downstream users. The method omits the cladding process of the clad steel plate, avoids the complex preparation process of the gradient material and the cracking of the homogeneous steel plate, and has the advantages of simplifying the process, reducing carbon emissions, high production efficiency, green environmental protection and low cost.

Owner:UNIV OF SCI & TECH BEIJING

Engine with EGR system, control method and vehicle

PendingCN114060182AFast ignitionMeet emissionsExhaust gas recirculationMachines/enginesAutomotive engineeringExhaust fumes

The invention discloses an engine with an EGR system, a control method and a vehicle, the engine comprises an engine body, wherein a plurality of air cylinders are arranged in the engine body, and the engine body is provided with an intake manifold and an exhaust manifold; an EGR assembly, wherein one end of the EGR assembly is communicated with the exhaust manifold; and a three-way valve and a catalyst, wherein an air inlet of the three-way valve communicates with the exhaust manifold, and a first air outlet and a second air outlet of the three-way valve communicate with the other end of the EGR assembly and the catalyst correspondingly so that waste gas in the exhaust manifold can selectively enter the catalyst or the EGR assembly. Therefore, the engine can be rapidly ignited, it is guaranteed that tail gas emission under the idling and starting working conditions meets the use requirements, the engine can operate in the low-temperature state, and after the temperature of the catalyst is high and the engine is switched to the medium-high-speed working condition, the EGR assembly is controlled to intervene in the working process of the engine, and the application range of the engine is widened.

Owner:深圳臻宇新能源动力科技有限公司

Clean and efficient cascade screening coal humidity control process with built-in thermal fluidized bed

InactiveCN105733635BWide adaptability to humidityReliable operation regulationCoke ovensHeat carrierHigh humidity

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com