Self-maintaining incineration system for sludge and working method

A self-sustaining incineration and sludge technology, applied in the field of pollutant treatment, can solve the problems of increasing dust removal and flue gas purification load, reducing boiler efficiency, reducing furnace temperature and ash softening point, etc., achieving high heat utilization efficiency and meeting national standards The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

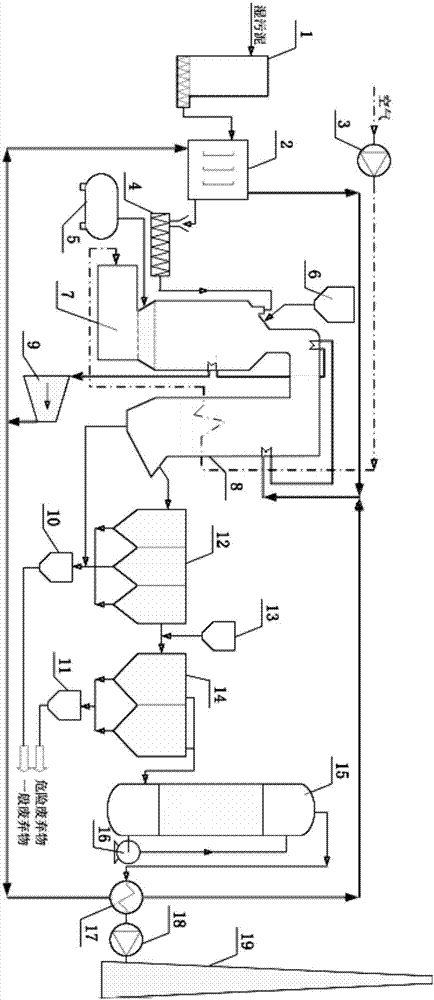

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] as attached figure 1 The sludge self-sustaining incineration system shown includes storage and transportation system, semi-drying system, incineration and waste heat boiler system, steam turbine power generation system, flue gas treatment system, ash treatment system and flue gas discharge system from front to back. In the accompanying drawings, solid arrows with solid lines indicate steam pipelines, hollow arrows with dotted lines indicate air pipelines, and hollow arrows with solid lines indicate material pipelines.

[0030] The storage and delivery system includes a wet sludge storage bin 1 and a screw conveyor at the bottom of the wet sludge storage bin 1; the screw conveyor gradually pushes the wet sludge in the wet sludge storage bin 1 to the semi-drying system .

[0031] The semi-drying system includes a sludge dryer 2 and a second screw conveyor 4. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com