Rotation type reflow soldering furnace and soldering method thereof

A reflow soldering furnace and rotary technology, applied in the direction of welding equipment, electric heating devices, auxiliary devices, etc., can solve the problems of affecting the heating and cooling temperature field, energy loss, and mutual influence of hot and cold air, so as to improve heat utilization efficiency, Save welding time and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

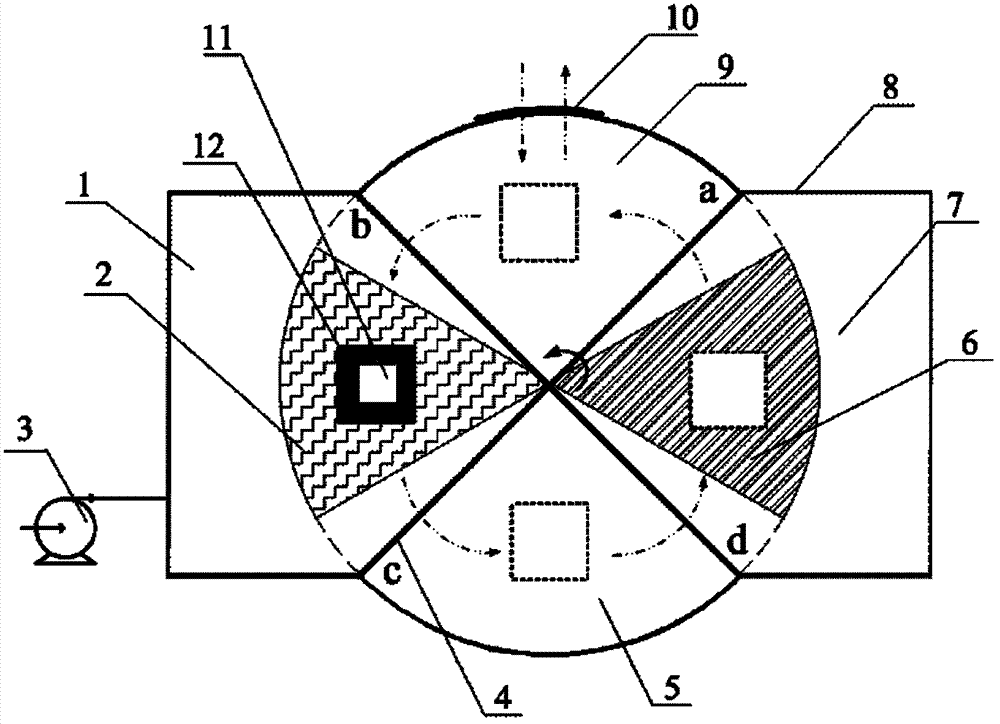

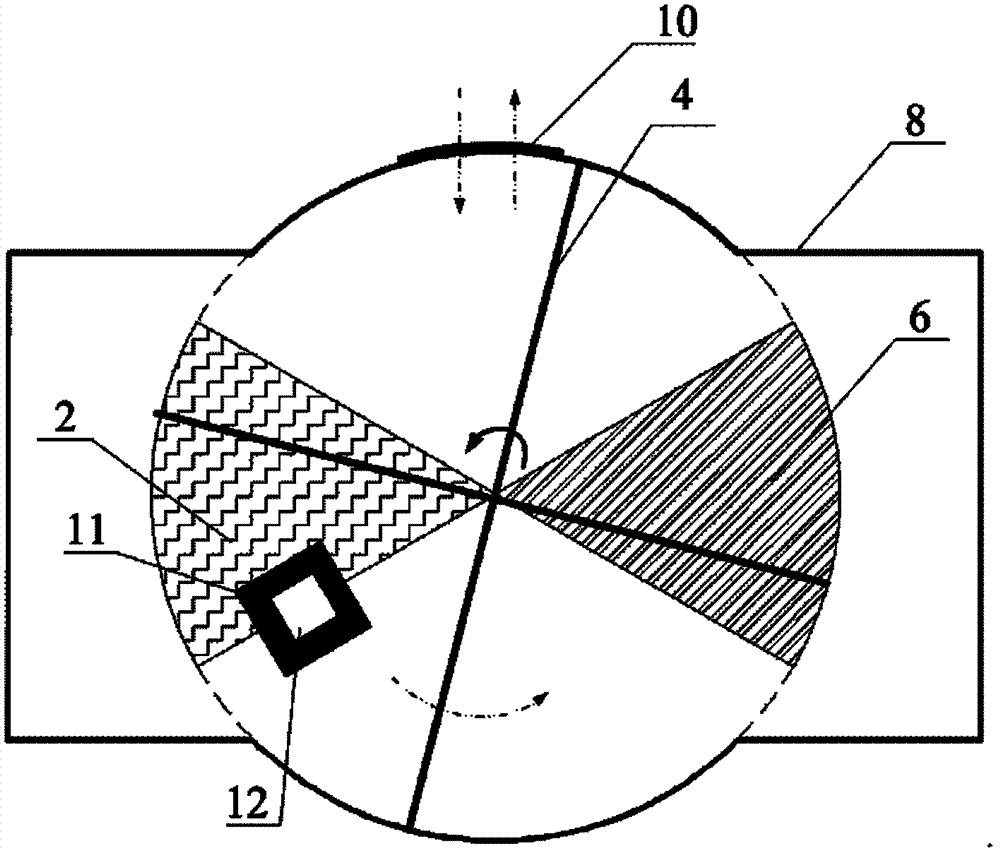

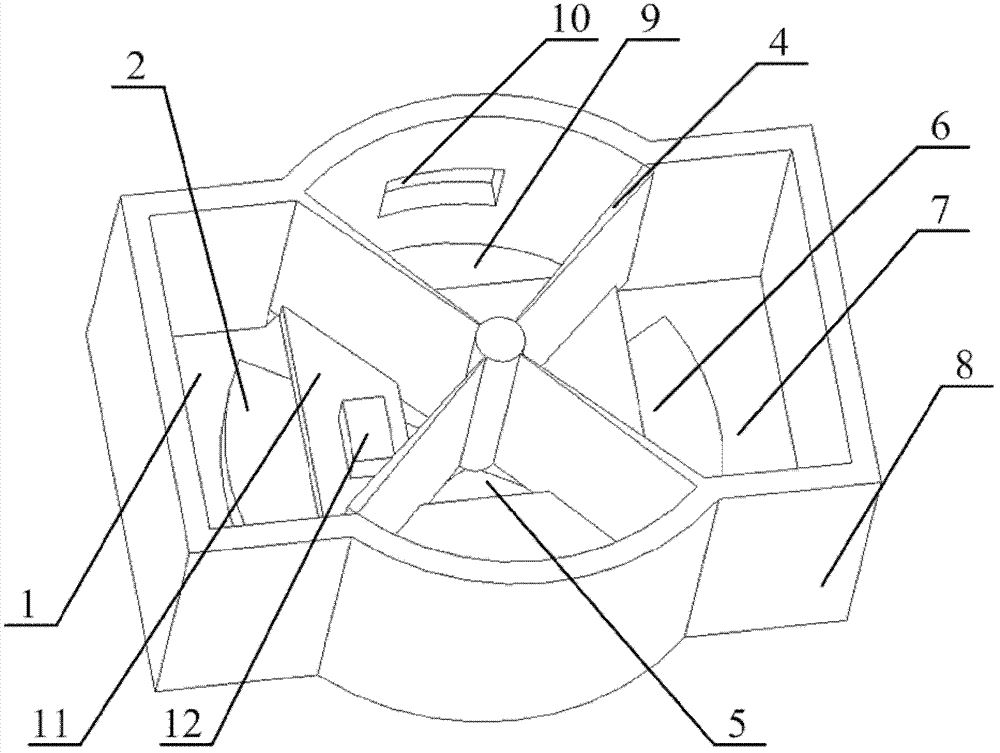

[0025] Further illustrate this embodiment below in conjunction with accompanying drawing:

[0026] figure 1 is a plan view of the main functional components of the rotary reflow soldering furnace according to the present embodiment, such as figure 1 As shown in , the present invention consists of hot plate 2, cold plate 6, impeller 4, tray 11, vacuum pump 3, furnace door 10, furnace body 8, object to be welded 12, temperature controller 14, rotation control device 15, tray position adjustment Device 16 etc. are formed. The material of the impeller 4 is made of rigid thermal insulation material, such as aluminum silicate ceramic material, which has better thermal insulation performance. The circular area at the bottom of the impeller 4 is divided into four fan-shaped areas with the same area and size with a fan-shaped angle of 90 degrees. And the blade of impeller 4 is vertically projected on the leaf length line segment of furnace bottom plane and the four dividing lines of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com