Electric cookware with efficient heat dissipation function

A cooking utensil and high-efficiency technology are applied in the field of high-efficiency heat dissipation electric cooking utensils, which can solve the problems of increasing food cooking time, affecting food taste, heat waste, etc., and achieving the effects of improving heat utilization efficiency, improving texture and taste, and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

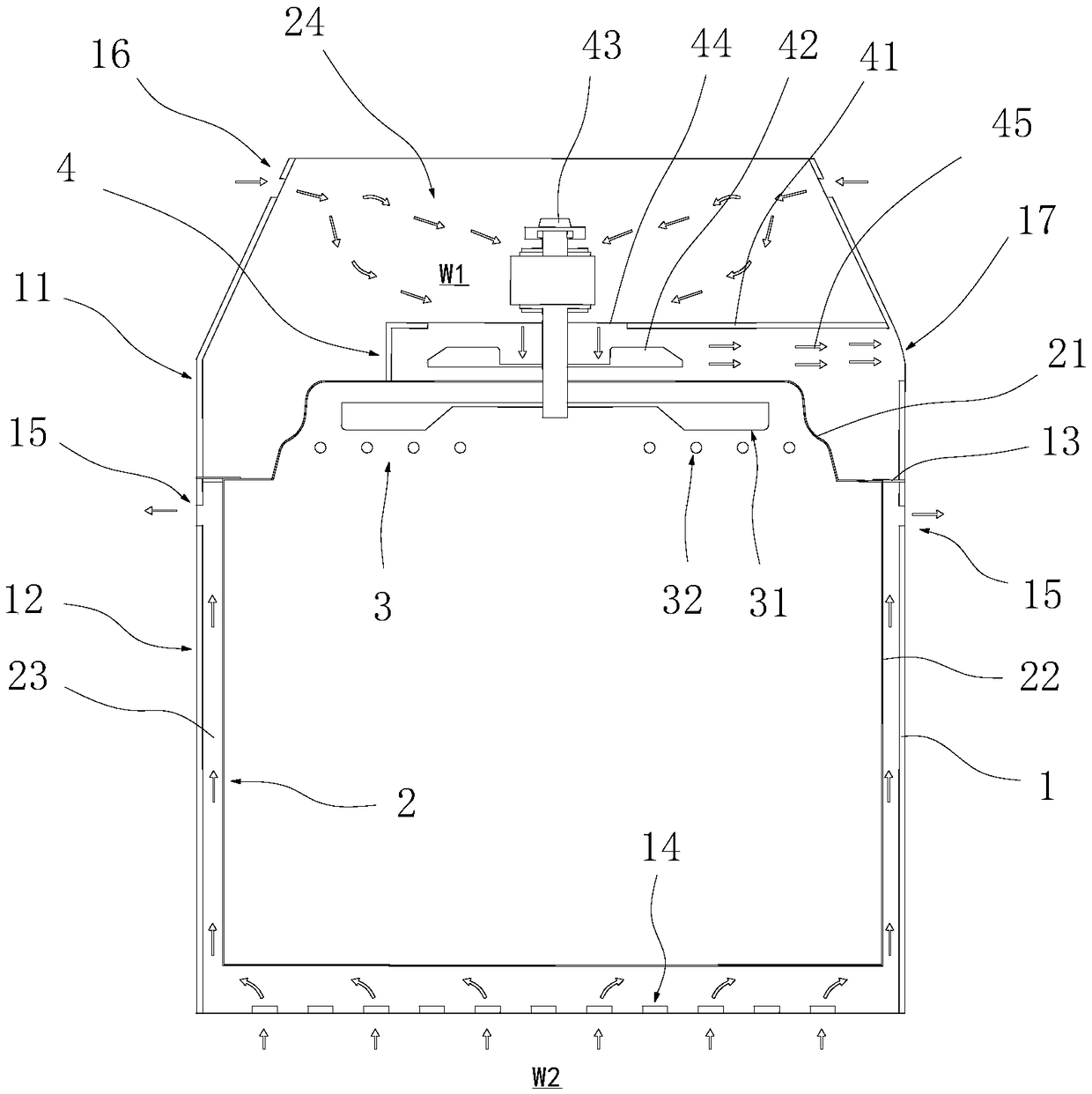

[0048] This embodiment provides a high-efficiency heat dissipation electric cooking appliance, such as figure 1 As shown, it includes a housing 1, a food preparation chamber 2, a heating device 3 and an air induction device 4.

[0049] Wherein, the shell 1 includes an upper shell 11, a lower shell 12 and a liner 13 arranged between the upper shell 11 and the lower shell 12, wherein the liner 13 connects the upper shell 11 and the lower shell 12 The space is isolated, and the gas between the upper casing 11 and the lower casing 12 is close to or not exchanged or circulated at all.

[0050] The food preparation chamber 2 is located at the inside of the lower casing 12, and the top of the food preparation chamber 2 is covered with a blast hood 21, and the heating device 3 is located in the blast hood 21, and the heating device 3 includes a blast wind wheel 31 and an electric heater. The tube 32, the electric heating tube 32 is arranged directly below the blast wheel 31, the blas...

Embodiment 2

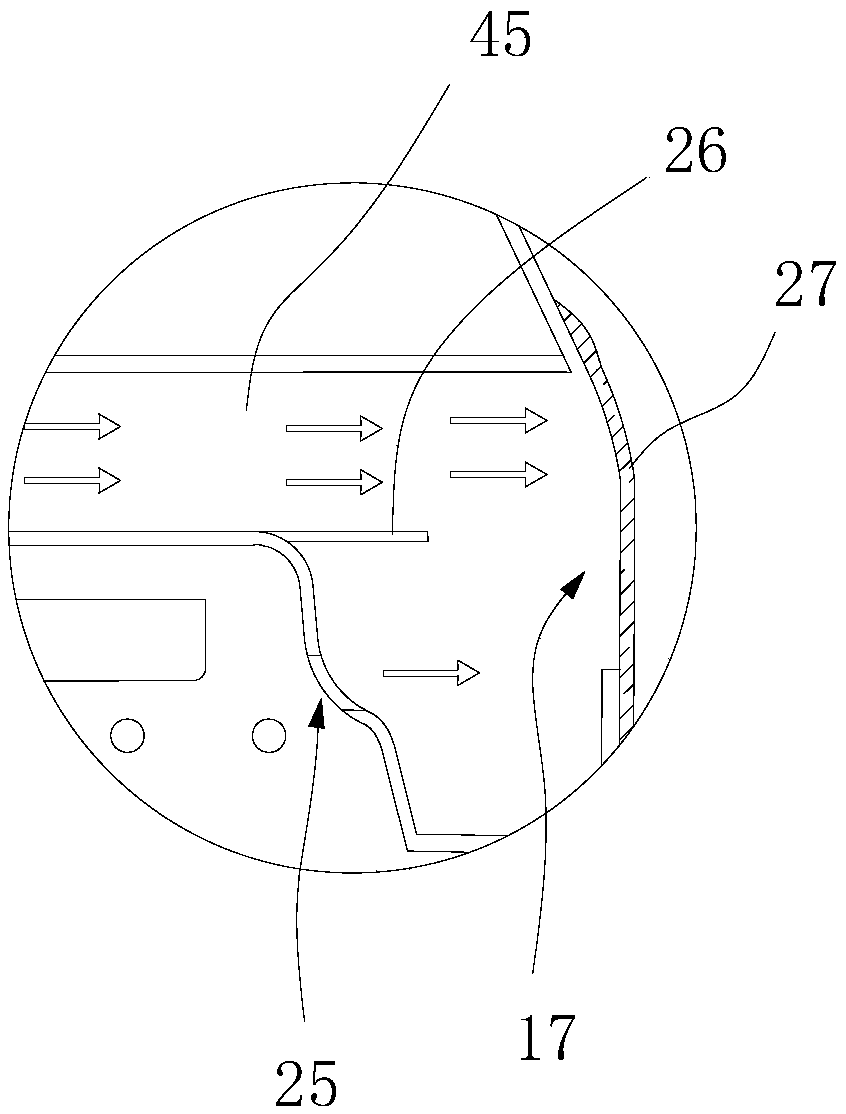

[0055] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the blower hood 21 of the food preparation chamber is provided with a water vapor outlet 25, and the water vapor outlet 25 is used to discharge excess water vapor during the food preparation process, so as to avoid the air pressure in the food preparation chamber rising during the process of heating the air to bake the food. High, water vapor condensation causes phenomena such as food surface softness; A dividing plate 26 is arranged between the water vapor outlet 25 and the air outlet 45 of the draft hood 41, and the upper air outlet completely covers the water vapor outlet 25 and the air outlet 45, and the two gases are respectively discharged from the upper air outlet 17, preferably, A grille cover 27 embedded in the upper casing is provided at the position of the upper air outlet.

Embodiment 3

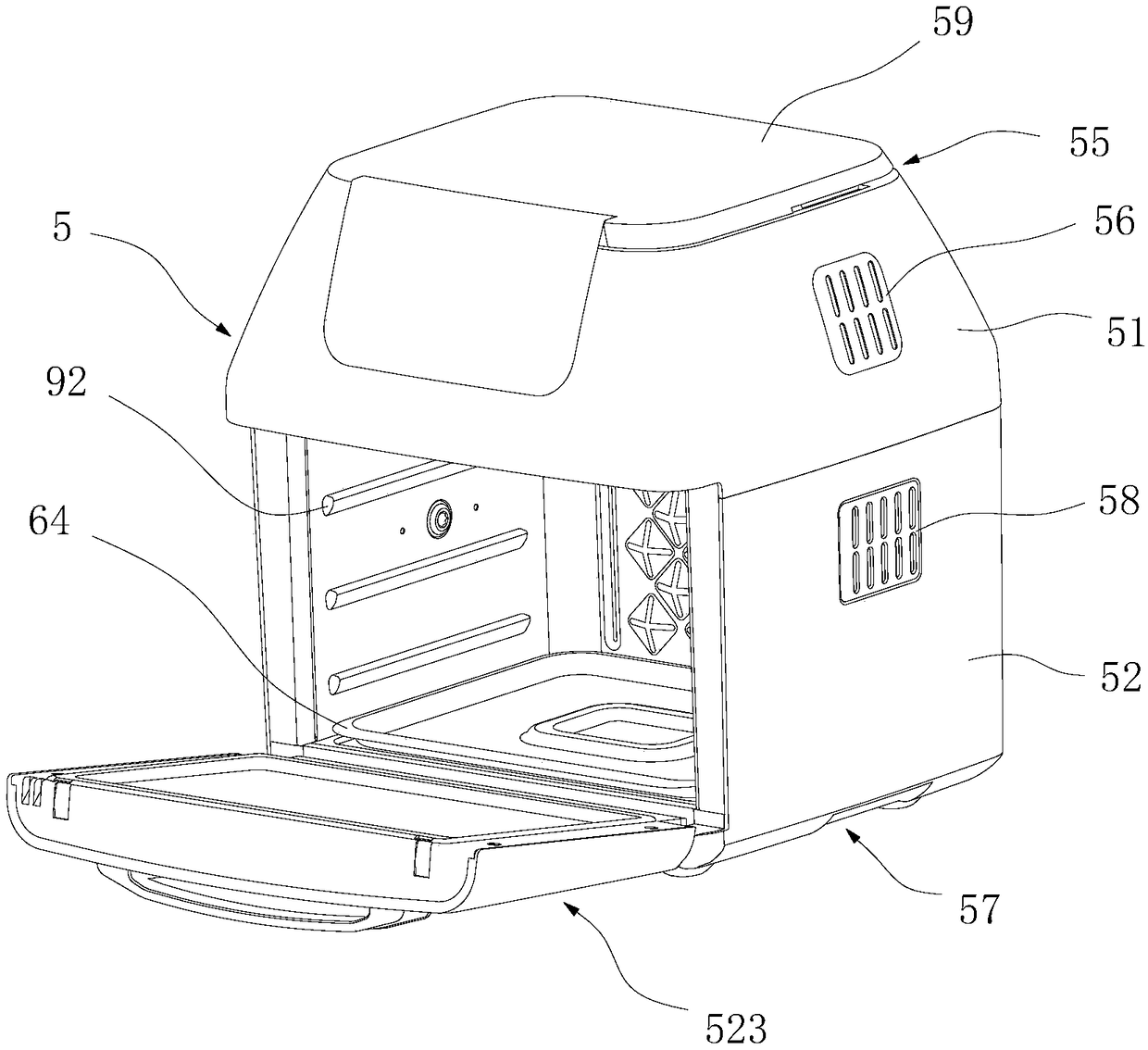

[0057] This embodiment provides an electric cooking appliance, such as image 3 As shown in -12, it uses a segmented heat dissipation structure to dissipate heat, specifically including a housing 5 , a food preparation chamber 6 , a heating device 7 , an air-inducing device 8 and a carrying device 9 .

[0058] Wherein, the casing 5 is a vertical structure, specifically comprising an upper casing 51, a lower casing 52 and a liner 53, wherein the liner 53 is arranged between the upper casing 51 and the lower casing 52, and the upper casing 51 It is separated from the lower case 52 , and the gas between the upper case 51 and the lower case 52 is close to or not exchanged or circulated at all.

[0059] The food preparation chamber 6 is located in the inside of the lower housing 52, and the food preparation chamber 6 top is covered with a blast hood 61, and the heating device 7 is located in the blast hood 61, and the heating device 7 includes a blast wind wheel 71 and an electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com