Ejection-absorbing hybrid refrigerating and heat pump unit and operating method thereof

A technology of composite refrigeration and heat pump units, applied in refrigerators, refrigeration components, heat pumps, etc., can solve the problem of low comprehensive thermal performance of absorption units, high outlet temperature, and limited application of jet-absorption composite refrigeration and heat pump units. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

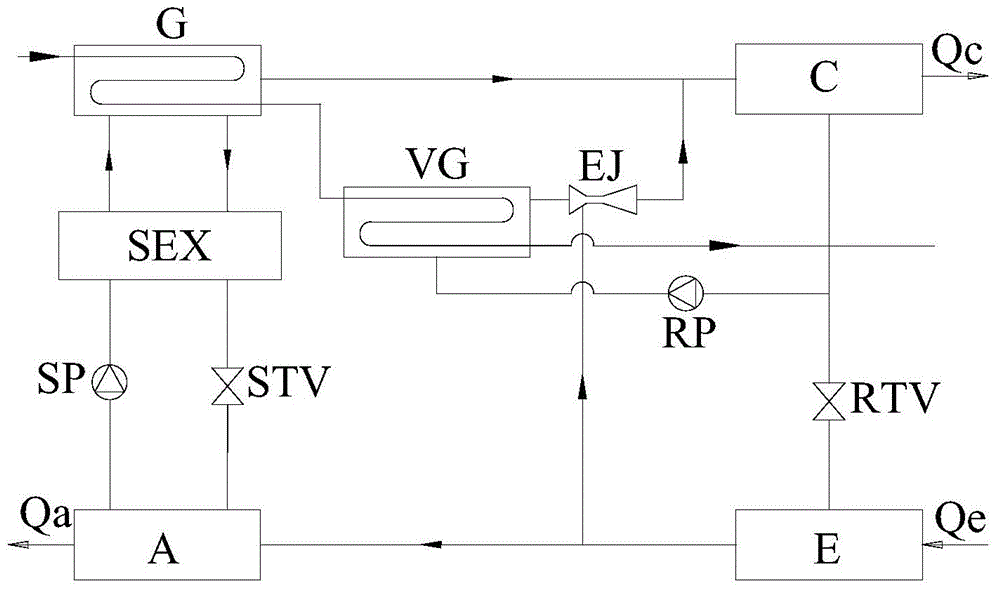

[0038] A jet-absorption compound refrigeration and heat pump unit, such as figure 1 As shown, including: generator G, condenser C, evaporator E, absorber A, solution heat exchanger SEX, solution pump SP, solution throttle valve STV, refrigerant throttle valve RTV, steam generator VG, gas Injector EJ;

[0039] Among them, the generator G is connected to the steam generator VG through the high-level heat source main pipeline, the steam outlet of the steam generator VG is connected to the working nozzle inlet of the gas injector EJ, and the outlet of the gas injector EJ is connected to the steam outlet of the generator G and the condensation The inlet of condenser C is connected, and the outlet of condenser C is divided into two routes: one is connected with the inlet of steam generator VG, and the other is connected with the inlet of evaporator E through refrigerant throttle valve RTV, and the outlet of evaporator E is divided into Two paths: one path is connected with the rece...

Embodiment 2

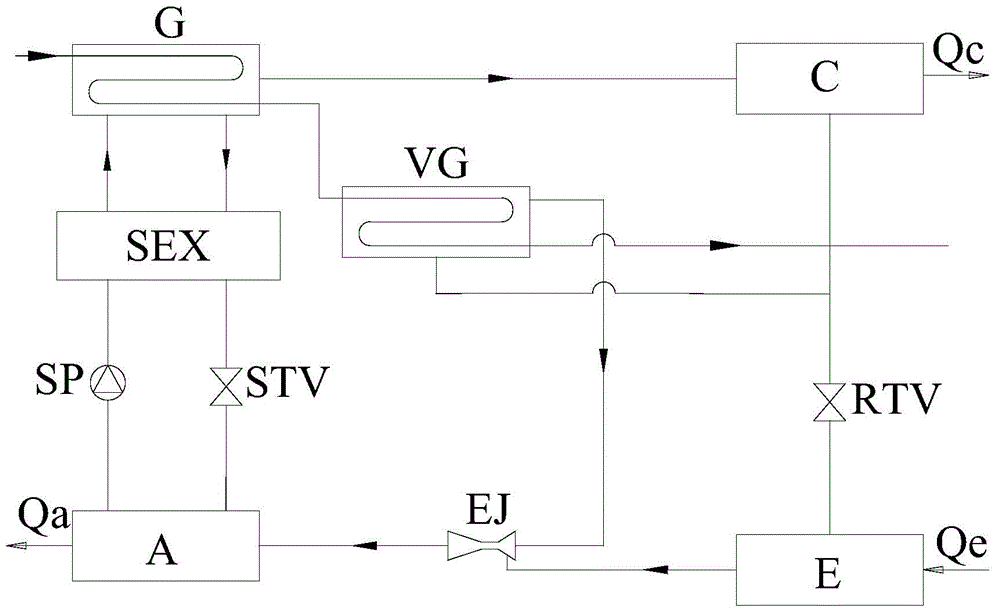

[0044] A jet-absorption compound refrigeration and heat pump unit, such as figure 2 As shown, including: generator G, condenser C, evaporator E, absorber A, solution heat exchanger SEX, solution pump SP, solution throttle valve STV, refrigerant throttle valve RTV, steam generator VG, gas Injector EJ;

[0045] Among them, the generator G is connected to the steam generator VG through the high-level heat source main pipeline, the steam outlet of the steam generator VG is connected to the working nozzle inlet of the gas injector EJ, and the outlet of the gas injector EJ is connected to the steam inlet of the absorber A, The dilute solution outlet of the absorber A is connected with the dilute solution inlet of the solution heat exchanger SEX through the solution pump SP, and the concentrated solution inlet of the absorber A is connected with the concentrated solution outlet of the solution heat exchanger SEX through the solution throttling valve STV, and the solution heat The d...

Embodiment 3

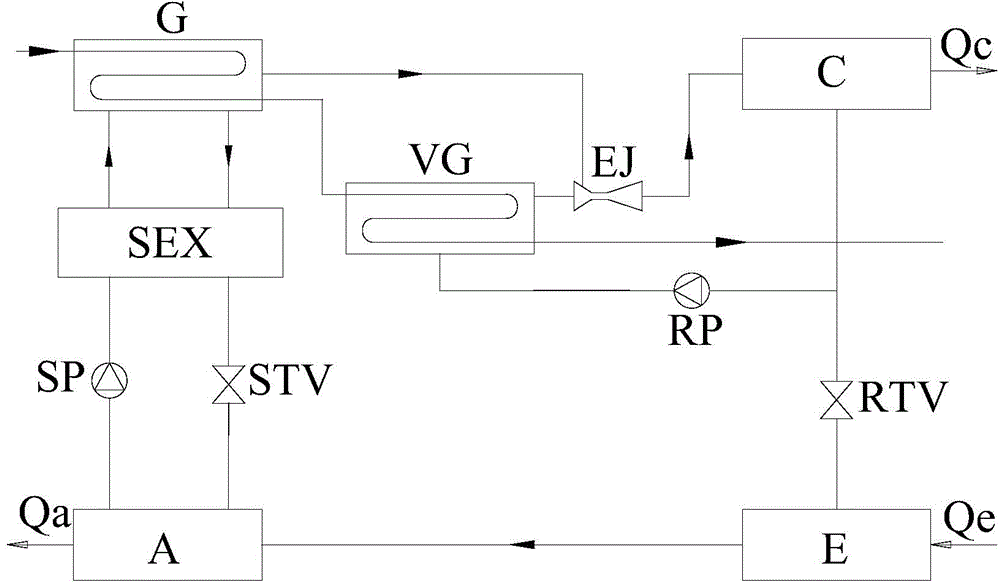

[0050] A jet-absorption compound refrigeration and heat pump unit, such as image 3 As shown, including: generator G, condenser C, evaporator E, absorber A, solution heat exchanger SEX, solution pump SP, solution throttle valve STV, refrigerant throttle valve RTV, steam generator VG, gas Injector EJ;

[0051] Among them, the generator G is connected to the steam generator VG through the high-level heat source main pipeline, the steam outlet of the steam generator VG is connected to the working nozzle inlet of the gas injector EJ, the outlet of the gas injector EJ is connected to the inlet of the condenser C, and the condensing The outlet of device C is divided into two routes: one is connected with the inlet of steam generator VG, and the other is connected with the inlet of evaporator E through refrigerant throttle valve RTV, and the outlet of evaporator E is connected with the steam inlet of absorber A, absorbing The dilute solution outlet of the absorber A is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com