High solid content coal tar suspended bed hydrogenation system and technology

A technology of coal tar and suspended bed, applied in the field of coal chemical industry, can solve problems such as troublesome recovery and recycling of high-efficiency homogeneous catalysts, waste of resources, and increased investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

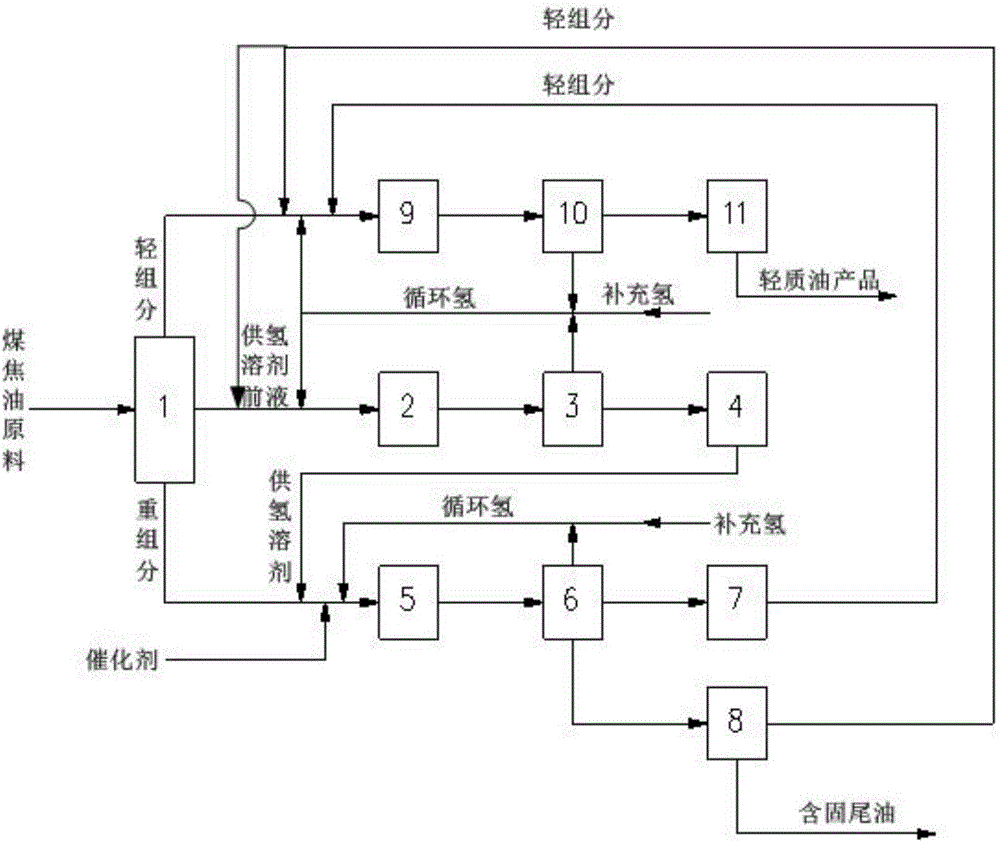

[0090] A coal tar suspended bed hydrogenation system, the system comprising:

[0091] A hydrogen supply unit for supplying hydrogen, including a hydrogen supply device;

[0092] Catalyst supply unit for supplying hydrogenation catalyst, including catalyst supply device;

[0093] The coal tar splitting unit is used to split the coal tar into a first light component, a hydrogen supply solvent precursor and a first heavy component; the boiling point of the first light component is less than 200°C, and the hydrogen supply solvent precursor has a boiling point of 200-450℃, the boiling point of the first heavy component is greater than 450℃; including the coal tar supply device and the first vacuum fractionation device 1, the first vacuum fractionation device 1 is provided with a feed inlet, a first light component outlet, and hydrogen supply The solvent front liquid outlet and the first heavy component outlet, and the outlet of the coal tar supply device is connected to the inlet of the ...

Embodiment 2

[0116] The coal tar suspension bed hydrogenation system and process described in Example 1 are used to prepare light oil products.

[0117] The properties of the raw coal tar are shown in Table 1.

[0118] Table 1 Properties of coal tar with high solid content

[0119] project Value Density (50℃), kg.m -3

1120 Kinematic viscosity (50℃), mm 2 / s

100.45 Moisture, wt%3 Solid impurities, wt%10 Element composition, wt%: C84.2 H7.8 O6.9 N0.8 S0.3

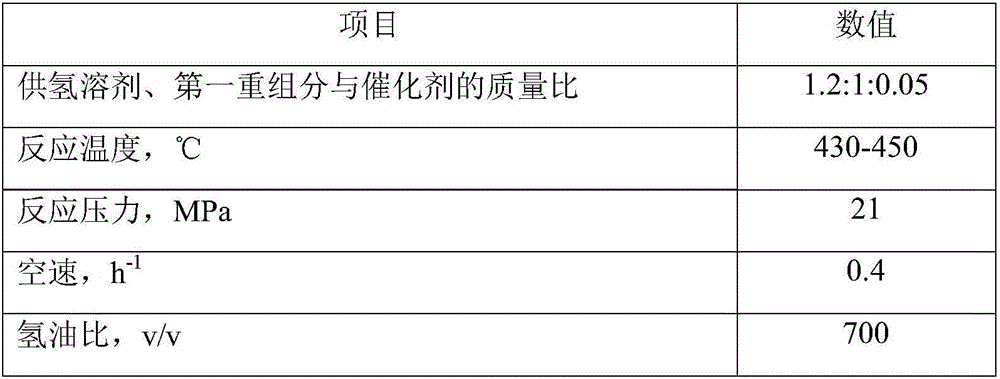

[0120] The process conditions used in the coal tar suspension bed hydrogenation process are shown in Table 2:

[0121] Table 2 Process conditions

[0122]

[0123]

[0124] The diameter of the catalyst is 10-50μm. The reaction temperature of the catalytic hydrogenation of the precursor liquid of the hydrogen supply solvent is 320-340°C and the pressure is 13MPa.

[0125] The reaction continued and stably proceeded for 720 hours, and the light oil yield was 75% determined by analysis, indicating that the invention can effectively carry out ...

Embodiment 3

[0127] The coal tar suspension bed hydrogenation system and process described in Example 1 are used to prepare light oil products.

[0128] The properties of the high solid content coal tar are the same as those of the raw material coal tar in Example 2.

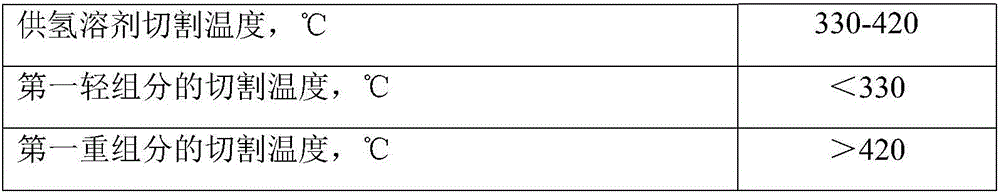

[0129] The process conditions used in the coal tar suspension bed hydrogenation process are shown in Table 3:

[0130] Table 3 Process conditions

[0131] project Value Mass ratio of hydrogen supply solvent, first heavy component and catalyst 0.5:1:0.01 Reaction temperature, ℃320-380 Reaction pressure, MPa10 Airspeed, h -1

0.2 Hydrogen to oil ratio, v / v500 Cutting temperature of hydrogen supply solvent, ℃200-450 Cutting temperature of the first light component, ℃ Cutting temperature of the first heavy component, ℃ >450

[0132] Among them, the diameter of the catalyst is 50-100 μm. The reaction temperature for the catalytic hydrogenation of the precursor liquid of the hydrogen supply solvent is 300-330°C and the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com