Patents

Literature

50results about How to "Good vaporization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

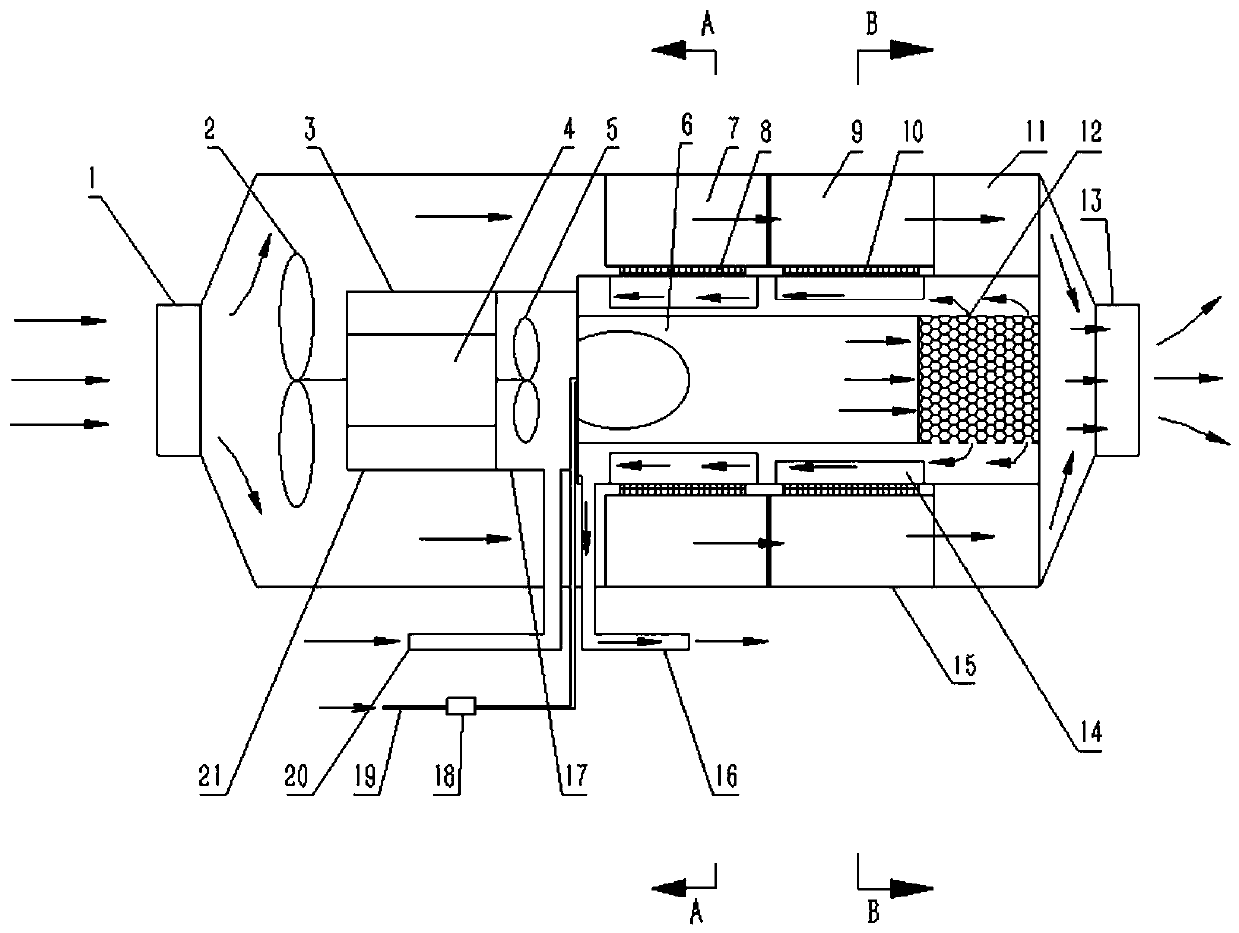

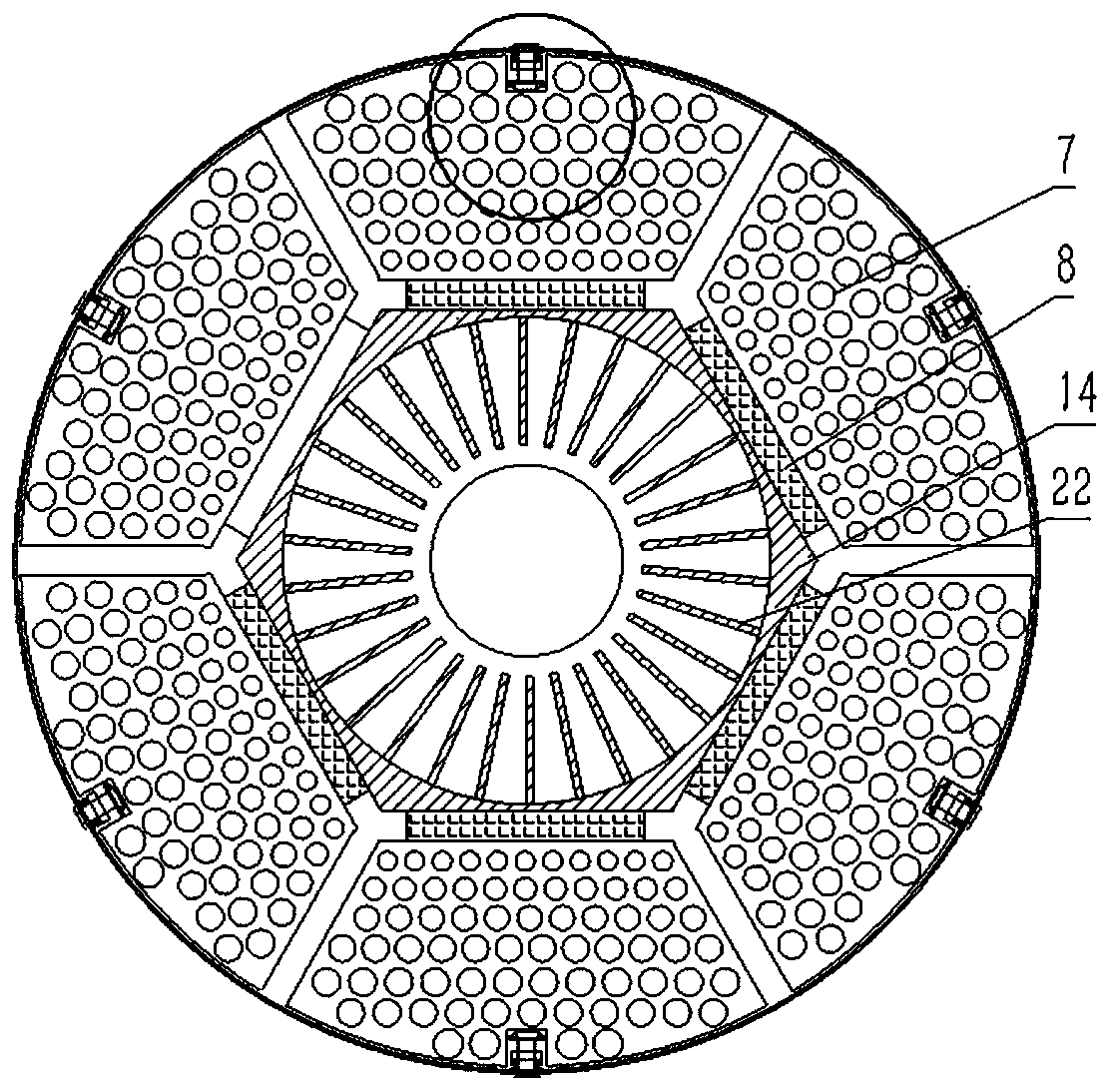

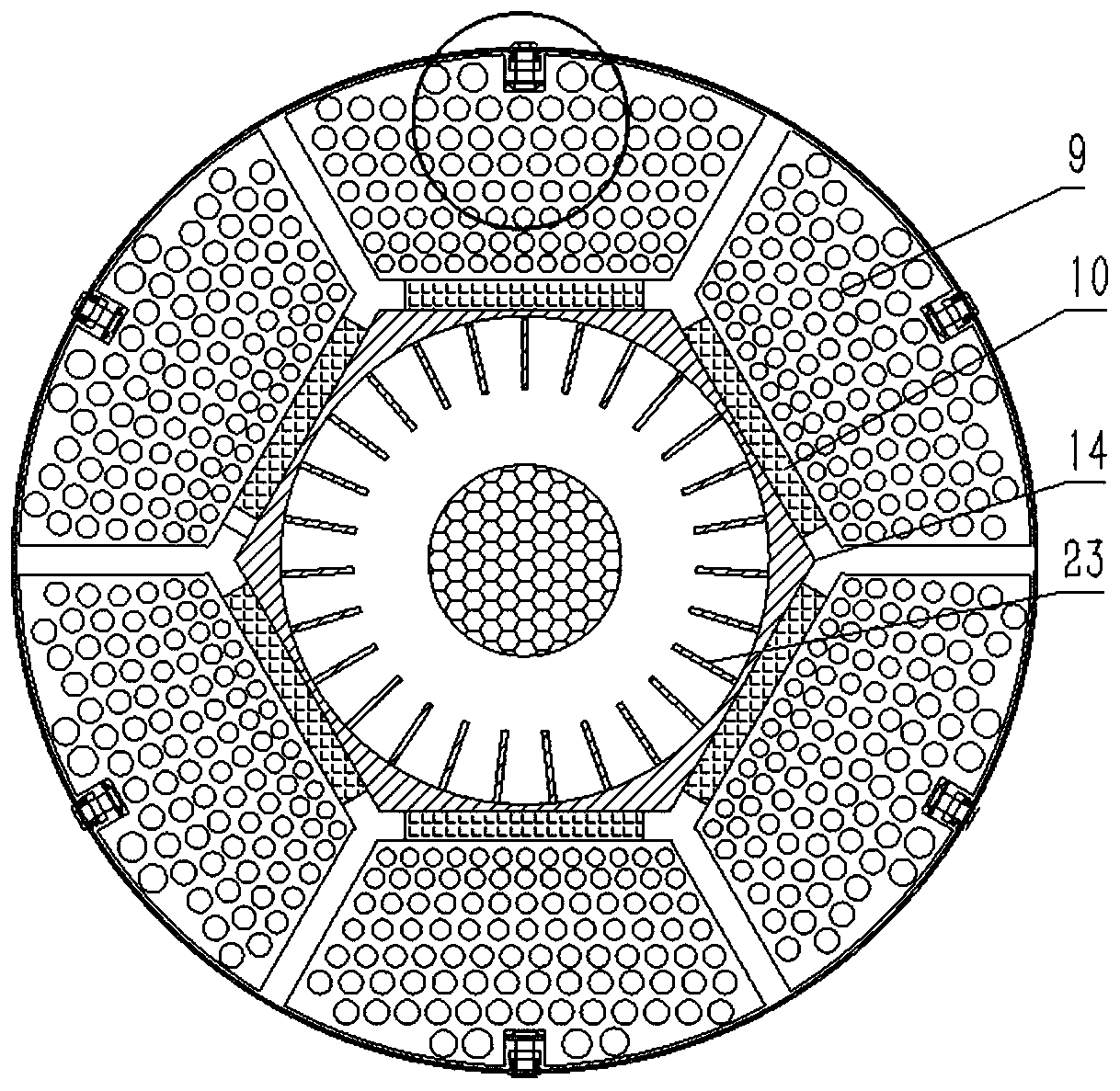

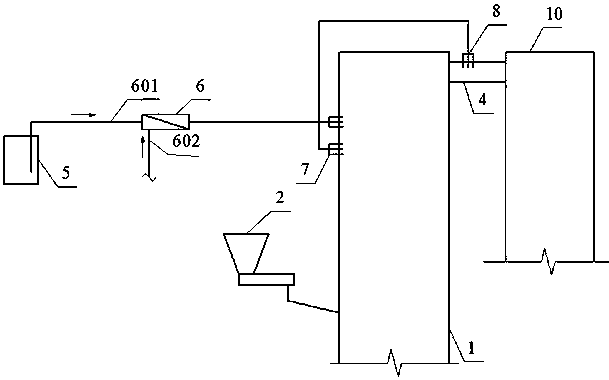

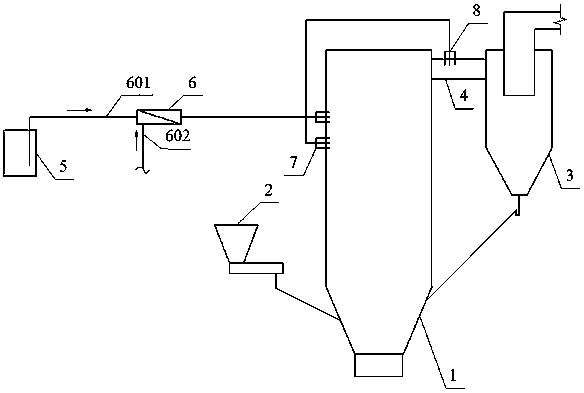

Method for heightening two-stage roasting arsenic collecting efficiency and special equipment

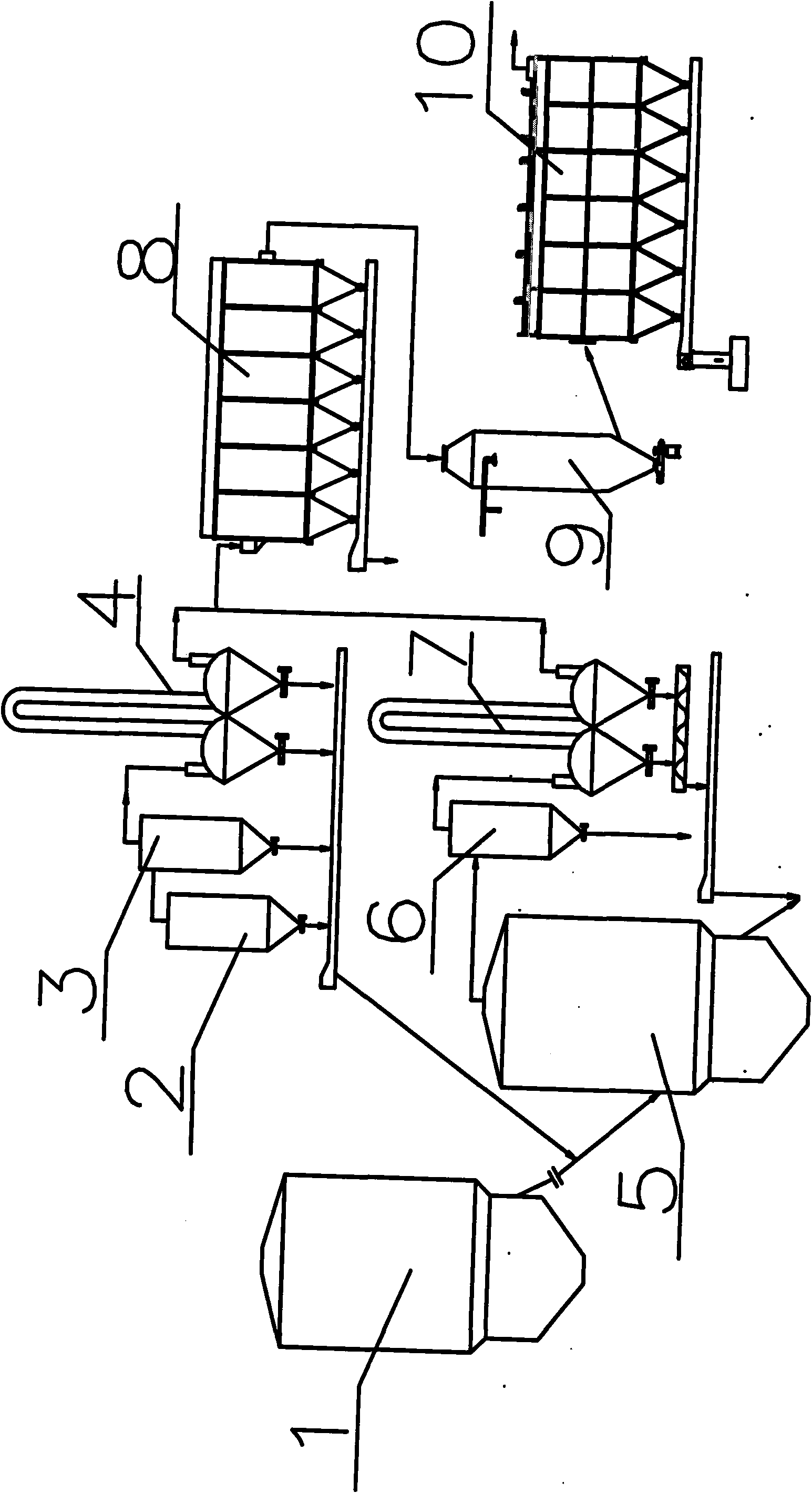

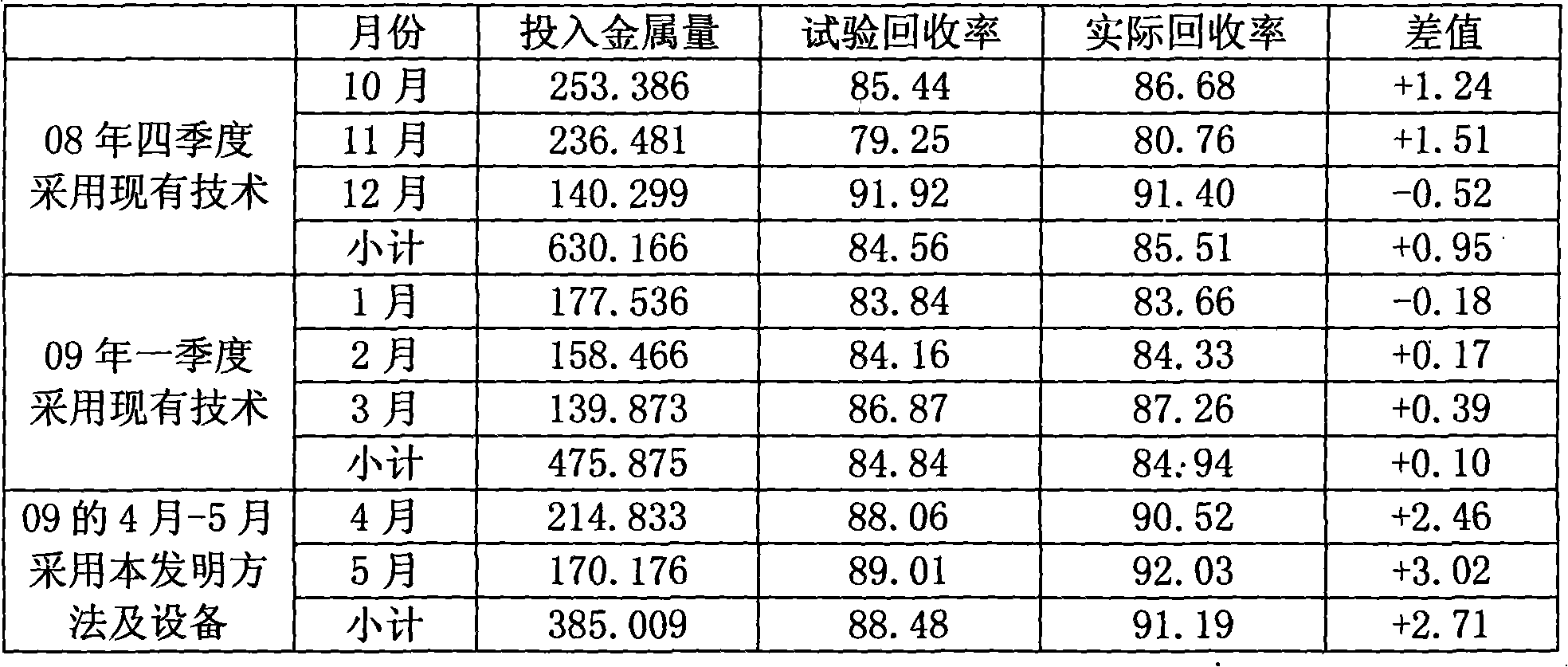

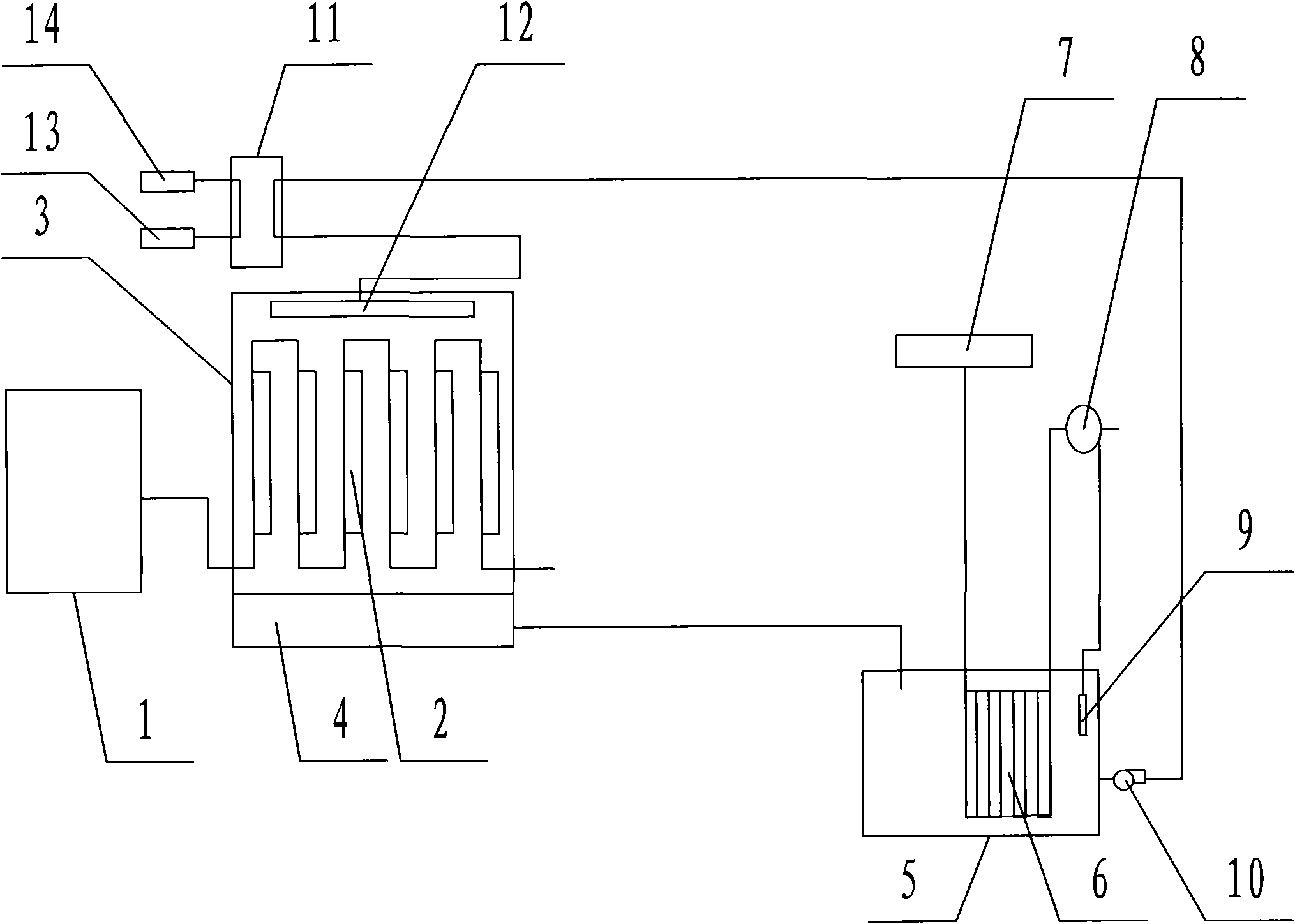

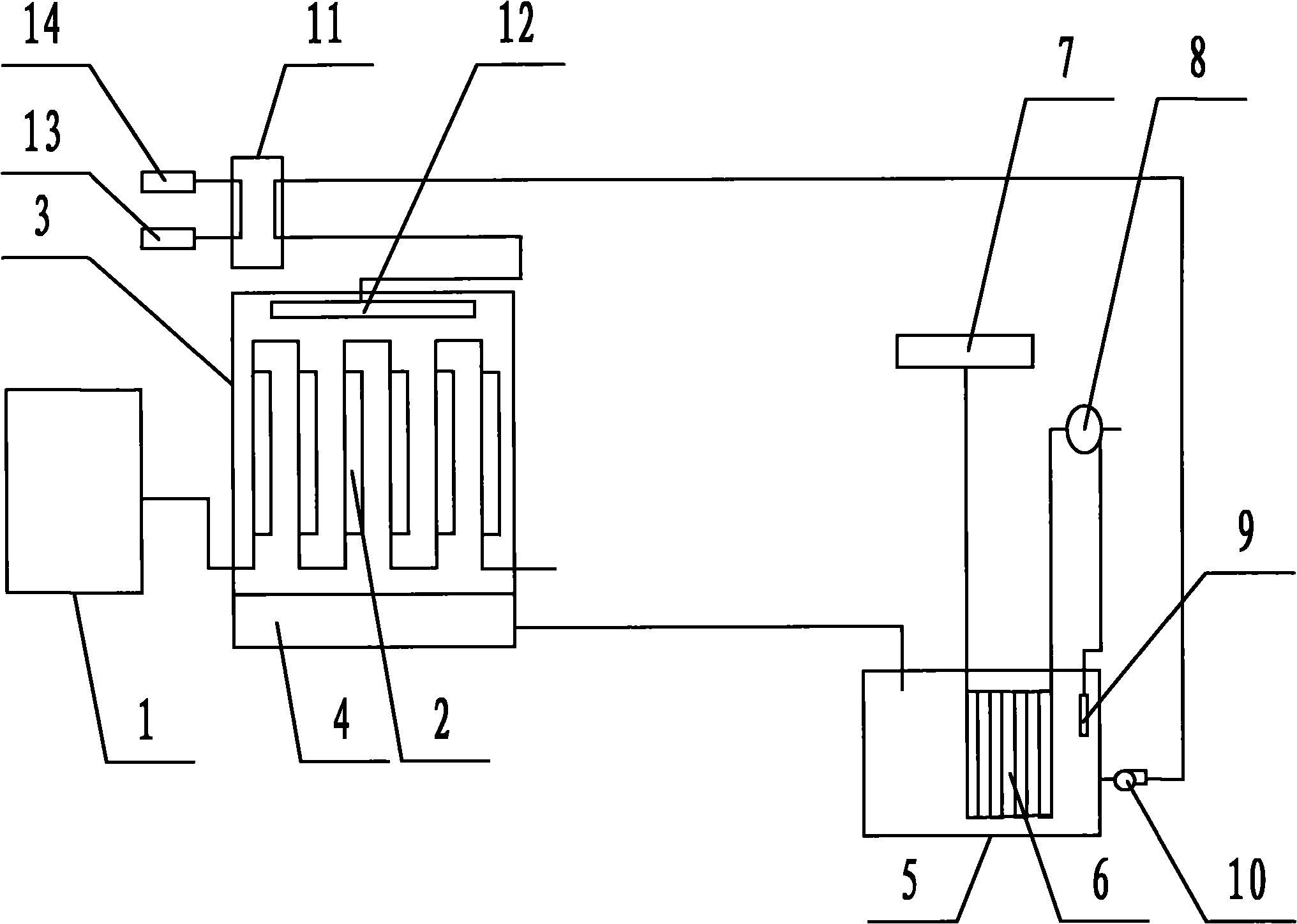

The invention discloses a method for heightening two-stage roasting arsenic collecting efficiency and special equipment. The method comprises the following steps: furnace gas, which is generated by one-stage roasting, is dedusted by means of reducing temperature through a two-stage whirlwind furnace cooler, and is again dedusted by means of removing electricity with furnace gas which is generated by two-stage roasting and be dedusted by means of reducing temperature through a one-stage whirlwind furnace cooler; the temperature of the dedusted furnace gas is reduced through a quench tower, and the arsenic of the dedusted furnace is recycled through a cloth bag arsenic collector; the remaining furnace gas is used for producing aid; and the dust and roasting slag, which are collected by the furnace cooler by means of the one-stage roasting, are put into the two-stage roasting. The equipment comprises a one-stage roasting furnace (1) and a two-stage roasting furnace (5). The equipment is characterized in that the one-stage roasting furnace (1) is connected with the two whirlwind devices and the furnace cooler by means of sealing in sequence; the bottom end of the one-stage roasting furnace (1) is communicated with the two-stage roasting furnace (5); the two-stage roasting furnace (5) is connected with one of the whirlwind devices and the furnace cooler by means of sealing in sequence; the bottom of the two-stage roasting furnace (5) is connected with a water quenching system; and the furnace cooler is communicated with an electric deduster (8), a cold collecting tower (9) and a cloth bag arsenic collecting device (10) in sequence. The invention has high arsenic collecting efficiency, does not frequently stop vehicles to clean the cloth bag, and increases productivity effect.

Owner:SHANDONG HUMON SMELTING

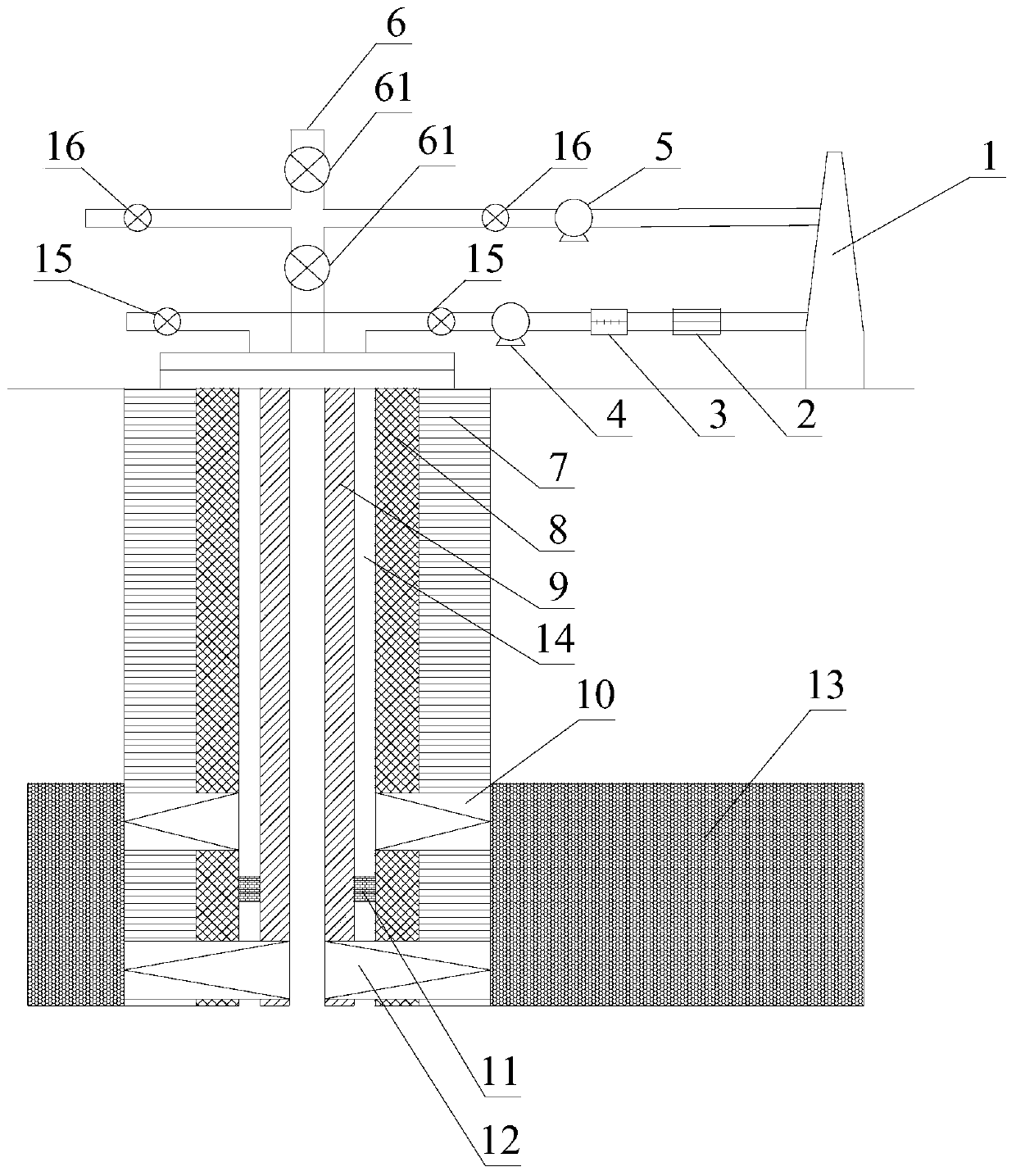

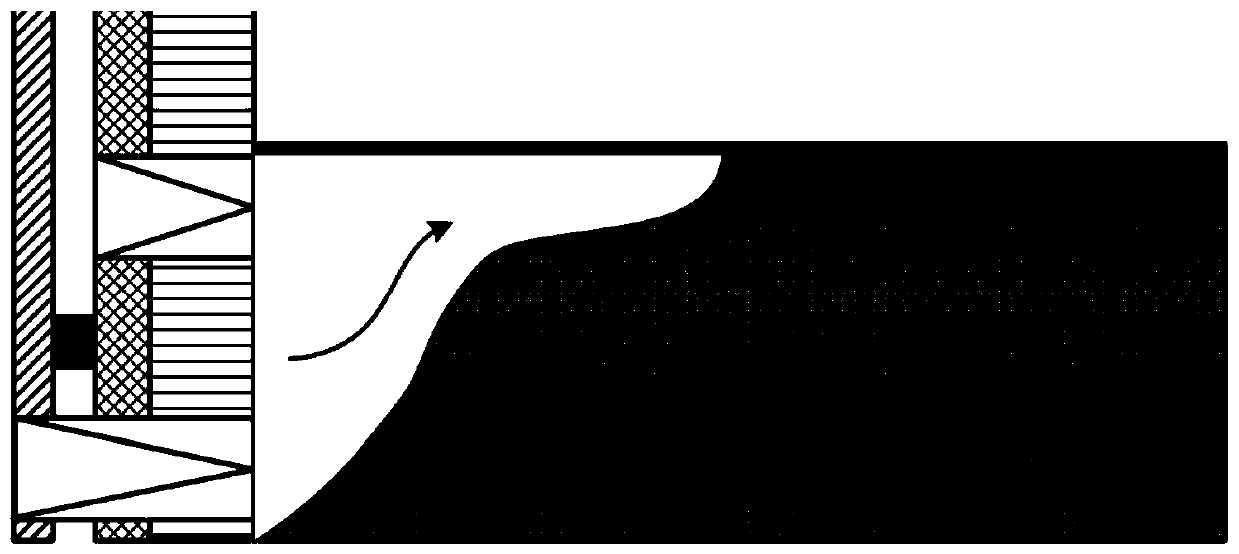

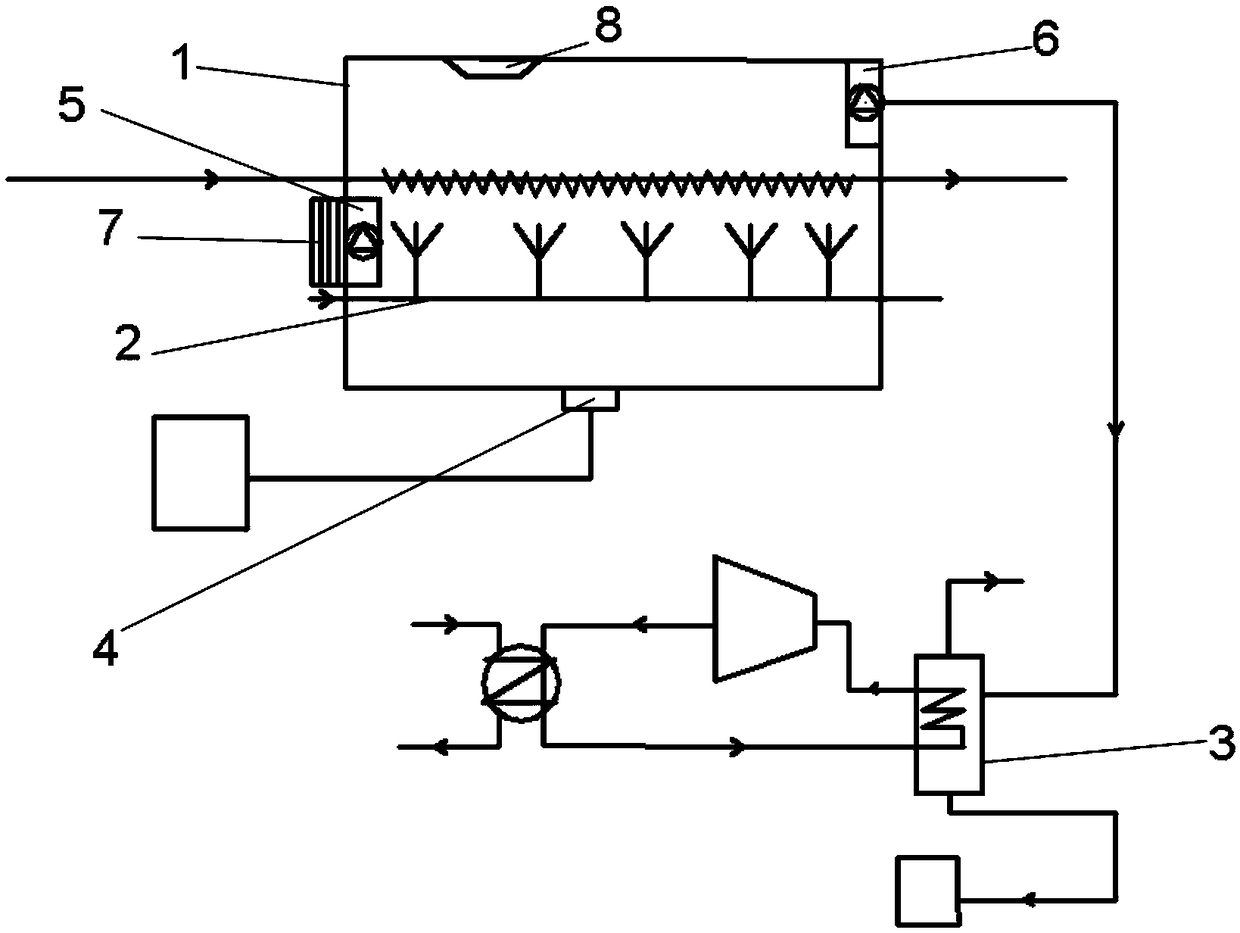

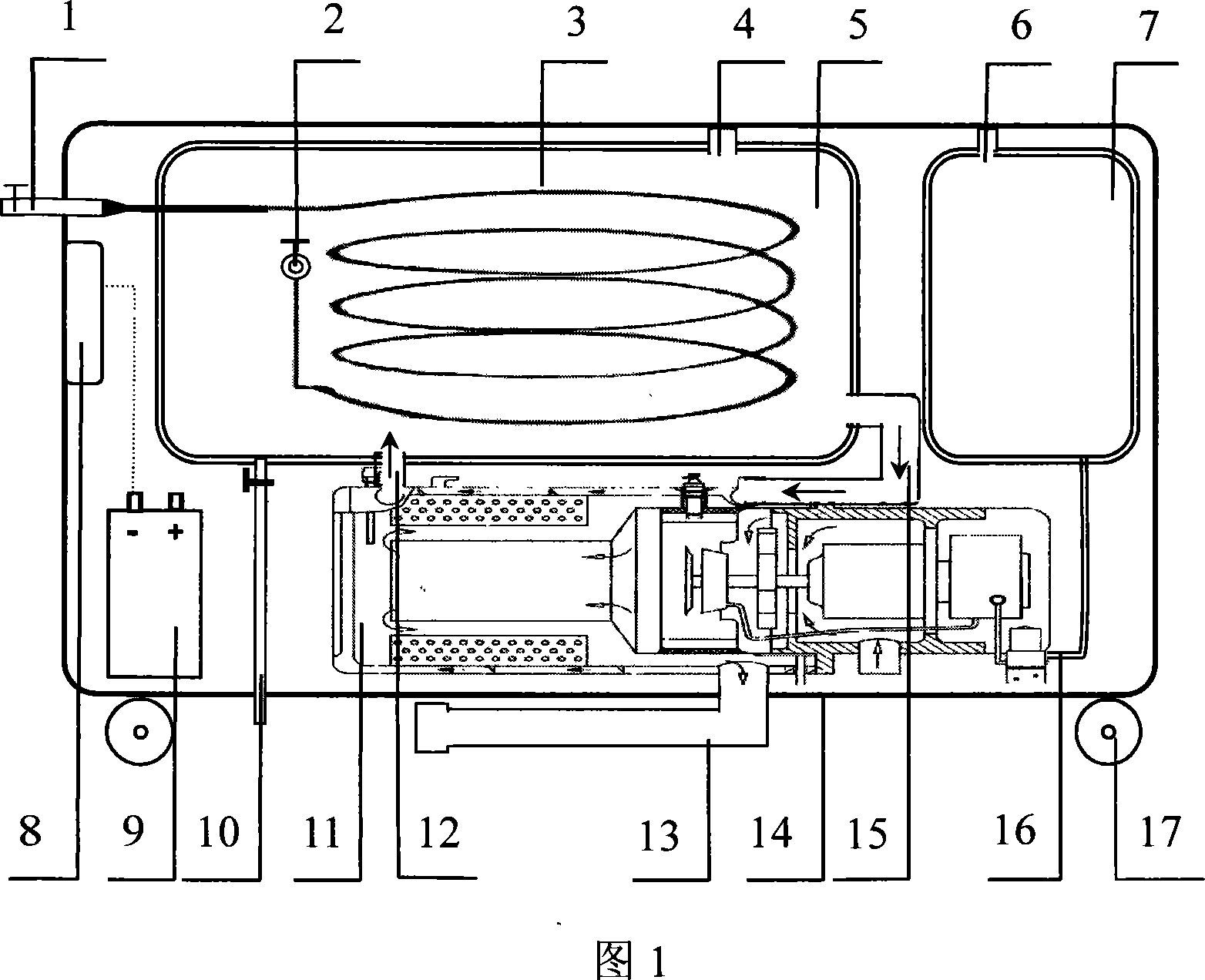

Hot nitrogen assisted heavy oil reservoir steam huff and puff oil production system and method

The invention relates to the technical field of heavy oil thermal production, and discloses a hot nitrogen assisted heavy oil reservoir steam huff and puff oil production system and method. The systemcomprises a steam generating device, a membrane separating device, a Christmas tree, a cementing cement ring, a bushing, an oil pipe and a packer; the oil pipe is arranged in the bushing in a sleevedmode, and an oil jacket annular region is formed between the oil pipe and the bushing; the bushing is arranged in the cementing cement ring in a sleeved mode, and the outer side of the bushing is tightly connected with the inner side of the cementing cement ring; one ends of the bushing and the oil pipe are fixedly connected with the Christmas tree, and the other ends of the bushing and the oil pipe are inserted into an oil layer; a bushing perforation layer section is formed at the position, close to the top of the oil layer, of the bushing, an oil pipe perforation layer section is arrangedat the position, close to the bottom of the oil layer, of the oil pipe, and the packer is arranged in the oil jacket annular region between the two perforation layer sections; steam produced by the steam generating device is injected into the oil pipe through the Christmas tree; and oxygen and nitrogen from the membrane separating unit are separately injected into the oil jacket annular region through the steam generating device and through the Christmas tree. The system increases the thermal efficiency of the steam and increases the recovery efficiency of heavy oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

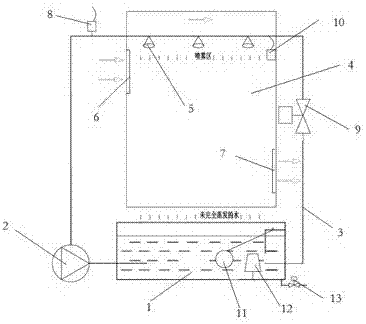

Liquid nitrogen vaporization cold recycling device

ActiveCN102012141AGood vaporization effectLow costDomestic cooling apparatusLighting and heating apparatusWater storage tankVaporization

The invention relates to a liquid nitrogen vaporization cold recycling device, which comprises a liquid nitrogen storage tank, wherein the liquid nitrogen storage tank is connected with a vaporizer; a protective cover is arranged at the periphery of the vaporizer; a collecting tank is arranged at the bottom of the protective cover and is connected with a water inlet of a water storage tank through a pipeline; a temperature regulating device is arranged inside the water storage tank; a water outlet of the water storage tank is connected with a first water inlet of a heat exchanger through the pipeline and a water pump; a first water outlet of the heat exchanger is connected with a nozzle; the nozzle is arranged above the vaporizer; a second water inlet of the heat exchanger is connected with a water return pipeline for technological cooling water; and a second water outlet of the heat exchanger is connected with a water inlet pipeline for the technological cooling water. The invention provides a liquid nitrogen vaporization cold recycling device capable of optimizing the vaporization effect of the liquid nitrogen and obtaining the technological cooling water without an industrial water chiller.

Owner:苏州潞能能源科技有限公司

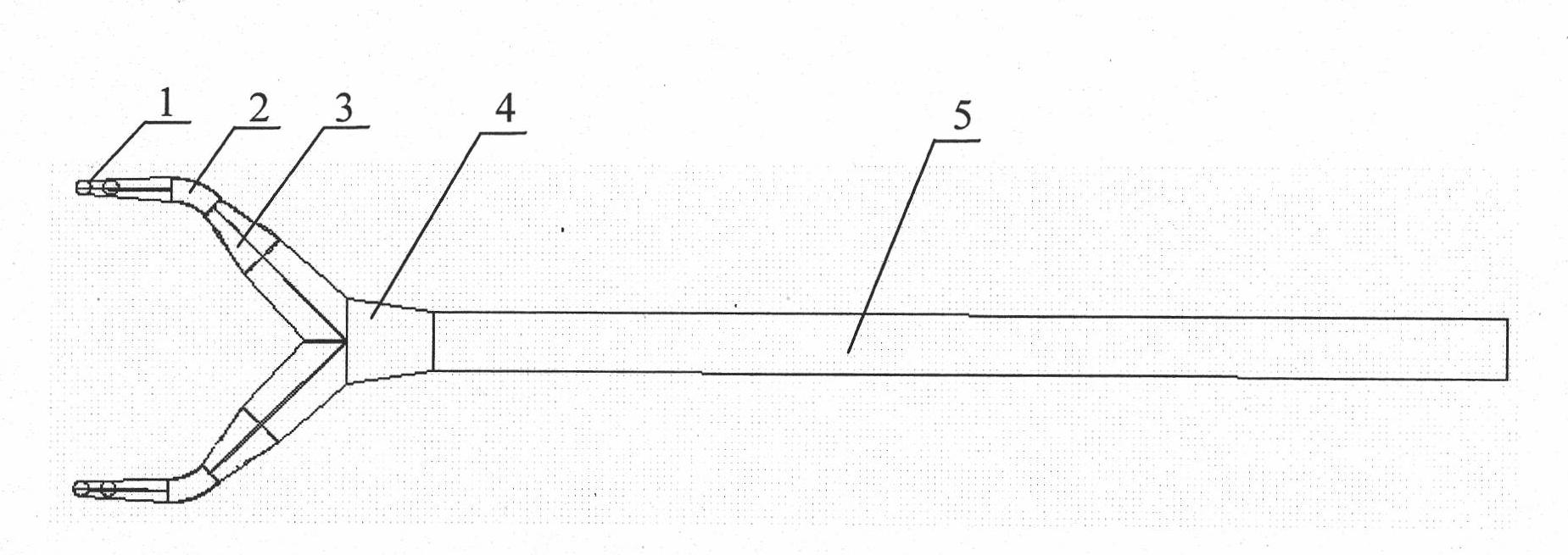

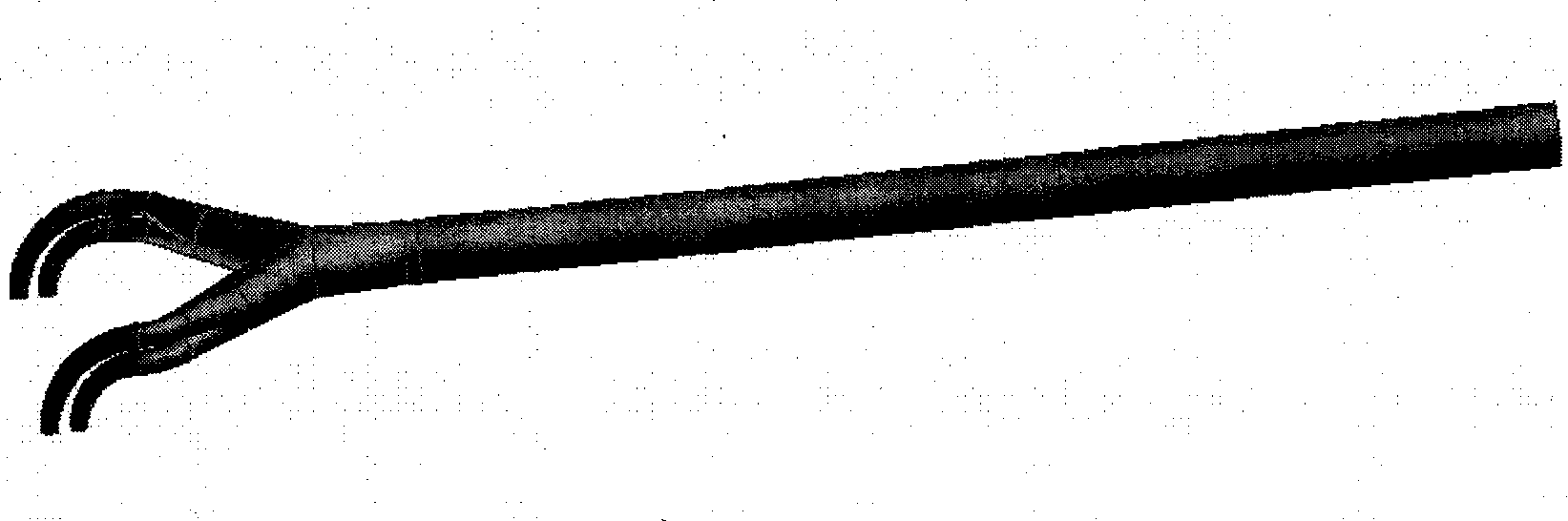

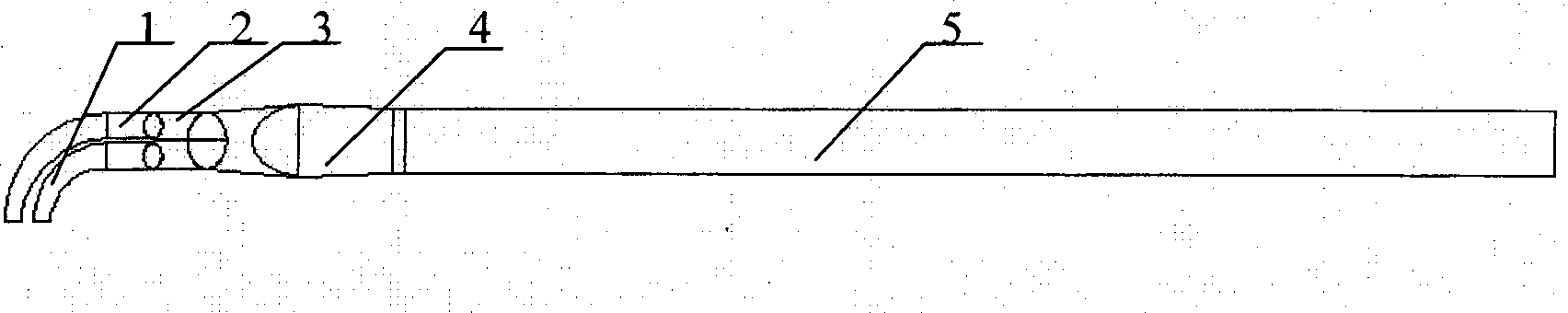

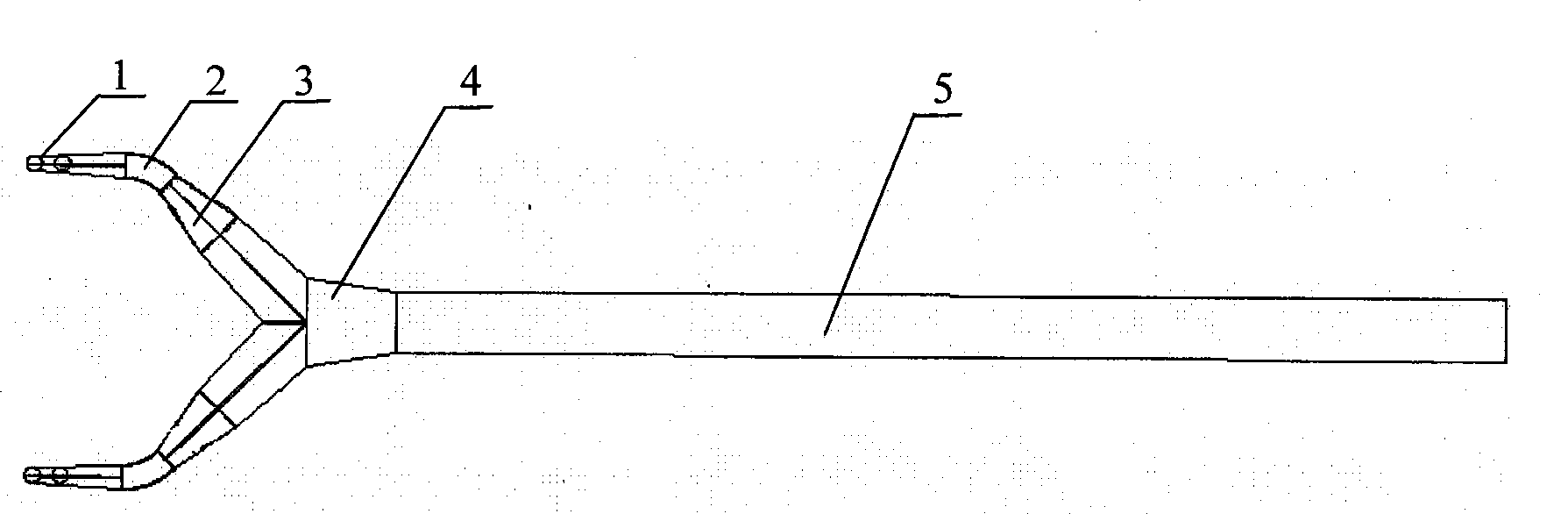

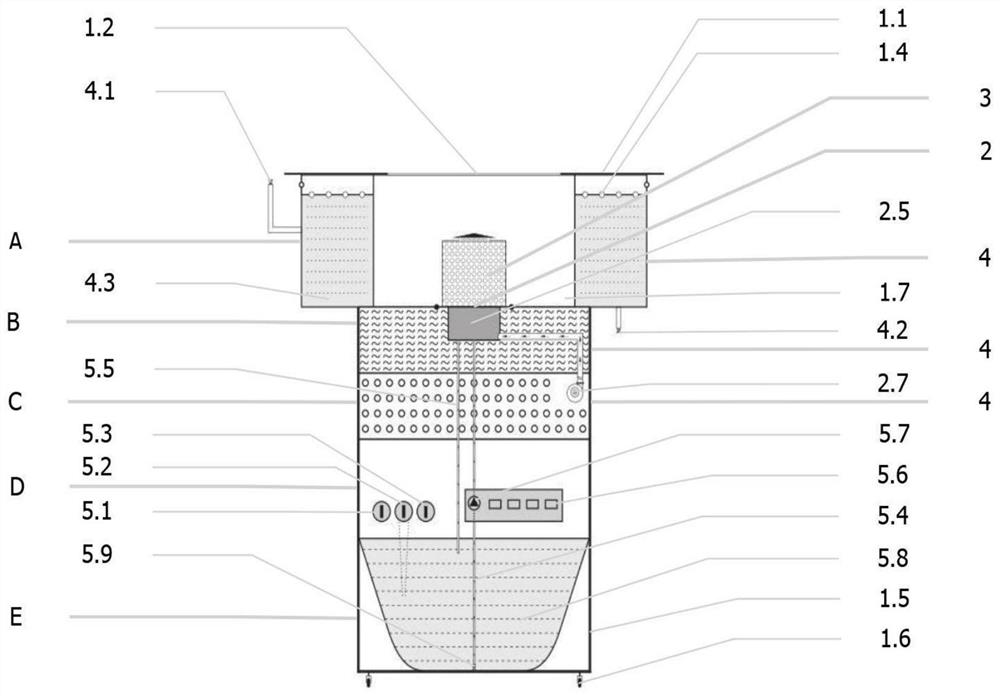

Low dropout decompression transfer line

ActiveCN101532594BSmall pressure dropGood vaporization effectDistillation separationRigid pipesLow speedPetroleum

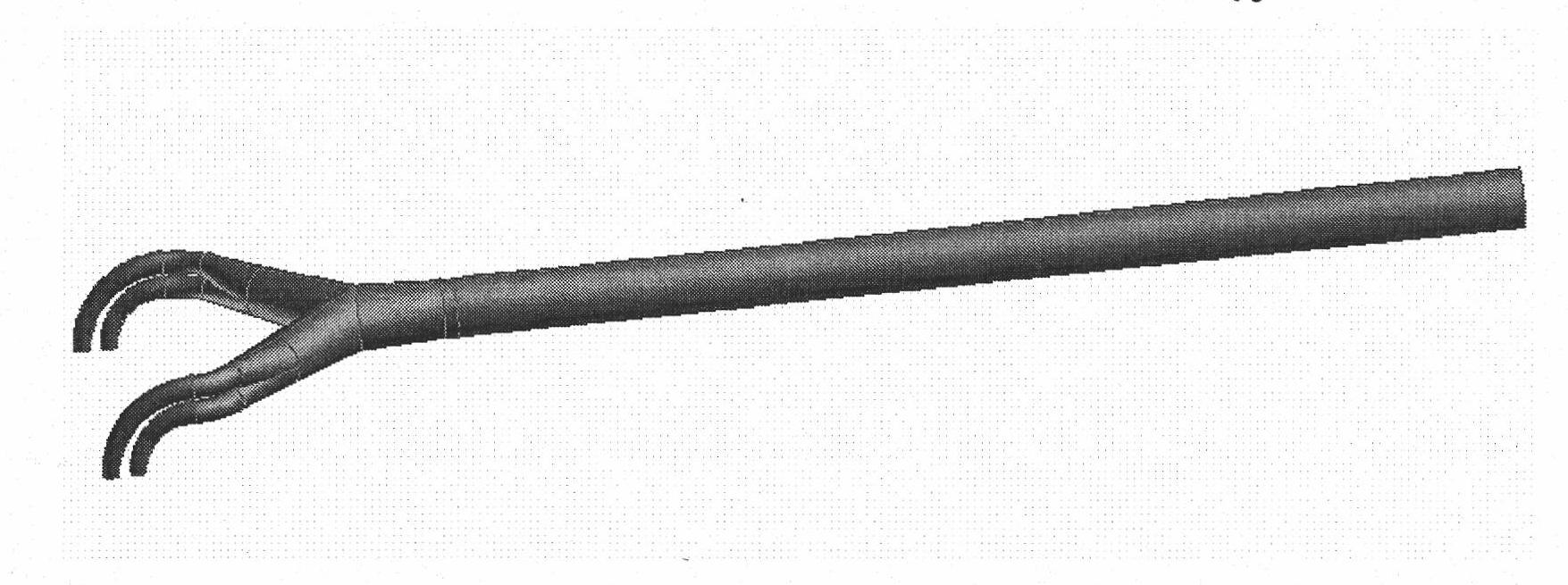

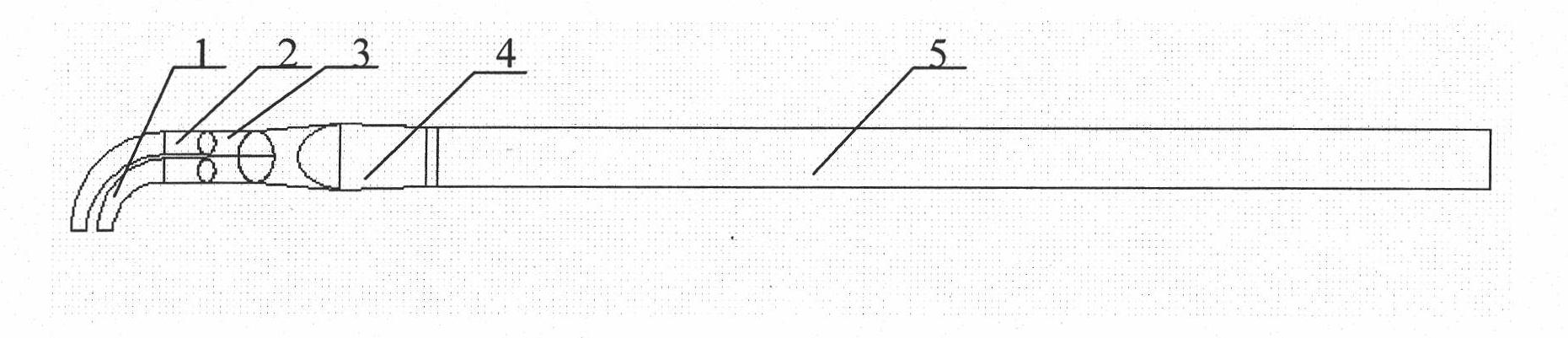

A low dropout decompression transfer line of the invention is used in a pipeline between a vacuum furnace and a vacuum tower of an atmosphere and vacuum distillation unit in the process of oil refining and in other devices for transporting oil products with high temperature and low pressure. The low dropout decompression transfer line comprises a 90 degree extend elbow, a 30-60 degree elbow, a transition section and a low speed section; wherein, the transition section adopts a structure of progressive hole enlargement, the 90 degree extend elbow is one with the curvature radius being 3-6 times of the diameter of a bent pipe, and the transition section is structured in the way that a trousers-shaped straight tee (3) with 15-30 degree of included angle is connected with a Y-shaped straight tee (4) in the shape of trousers with 45-90 degree of included angle. The invention adopts the principle of pipe diameter extending and smooth processing at joints, reduces resistance loss in the process of flowing and pressure drop of the transfer line and optimizes vaporization effect of the oil products, thus improving distillate yield and generating appreciable economic benefits.

Owner:TIANJIN UNIV

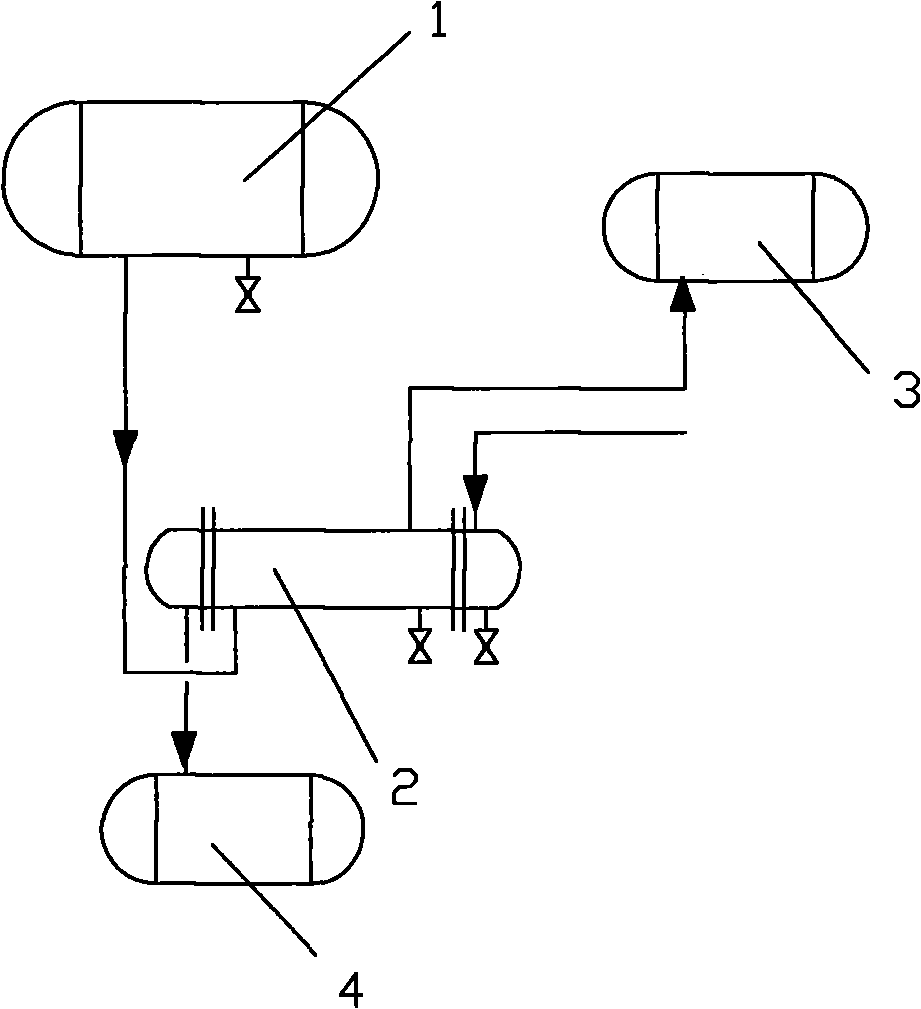

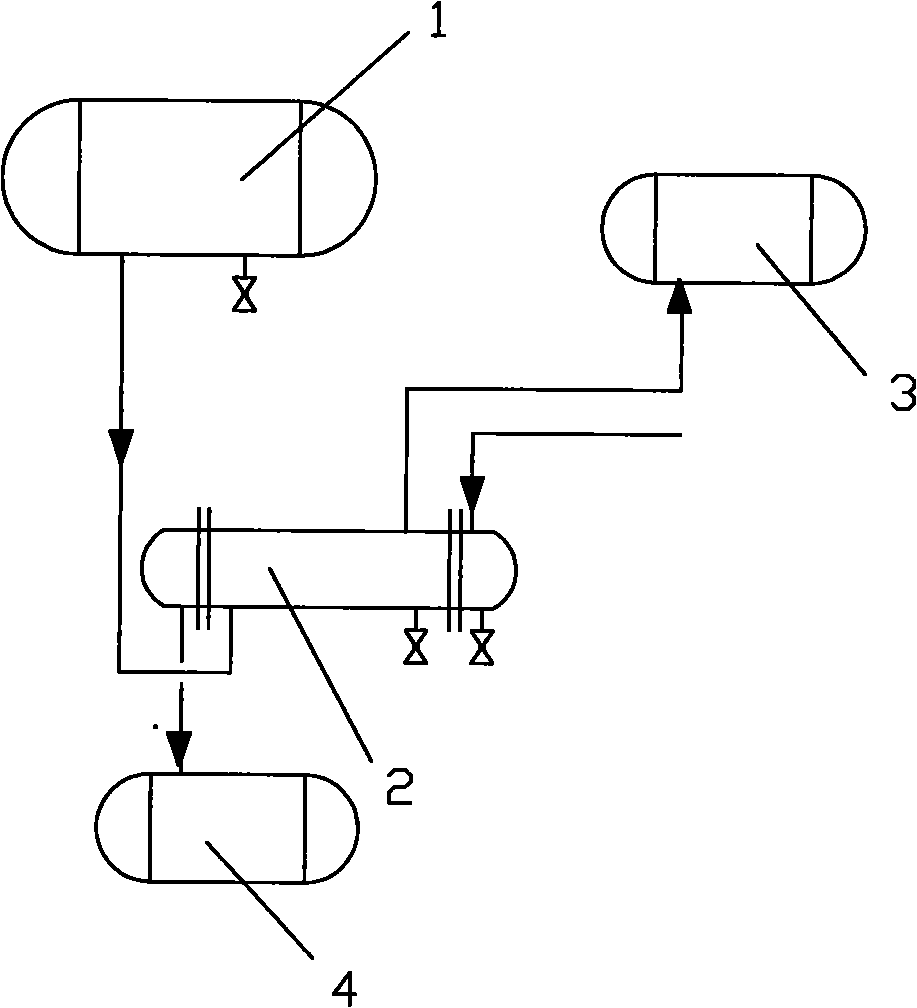

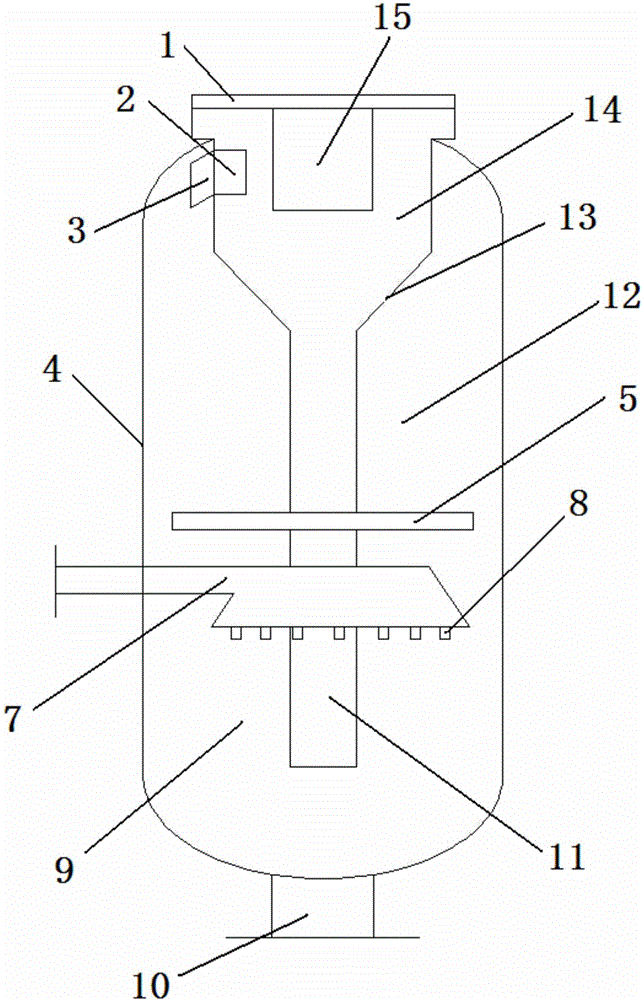

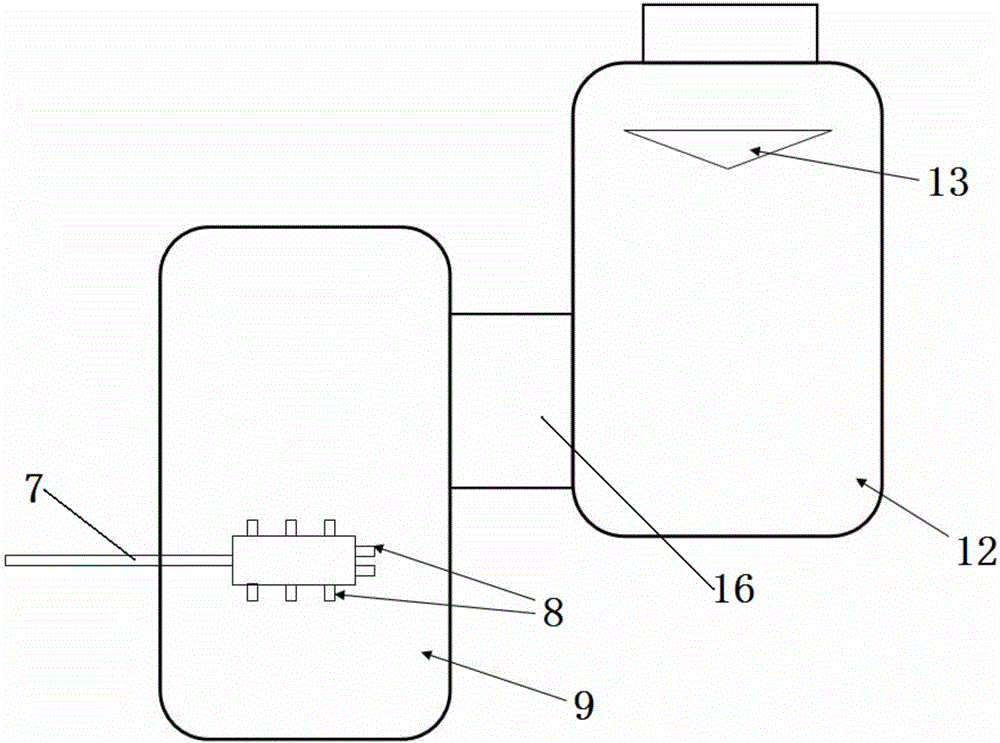

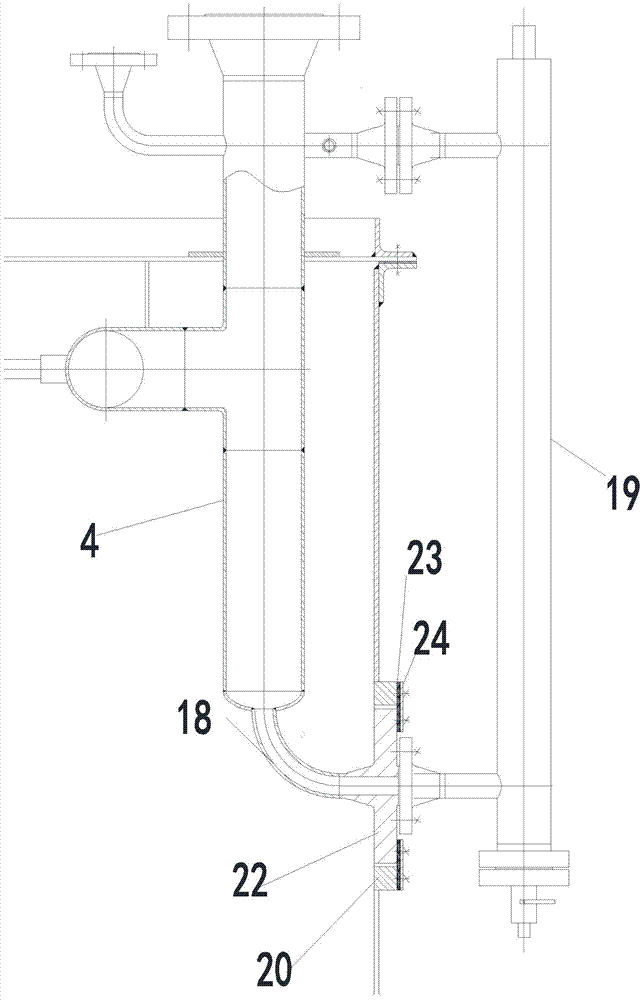

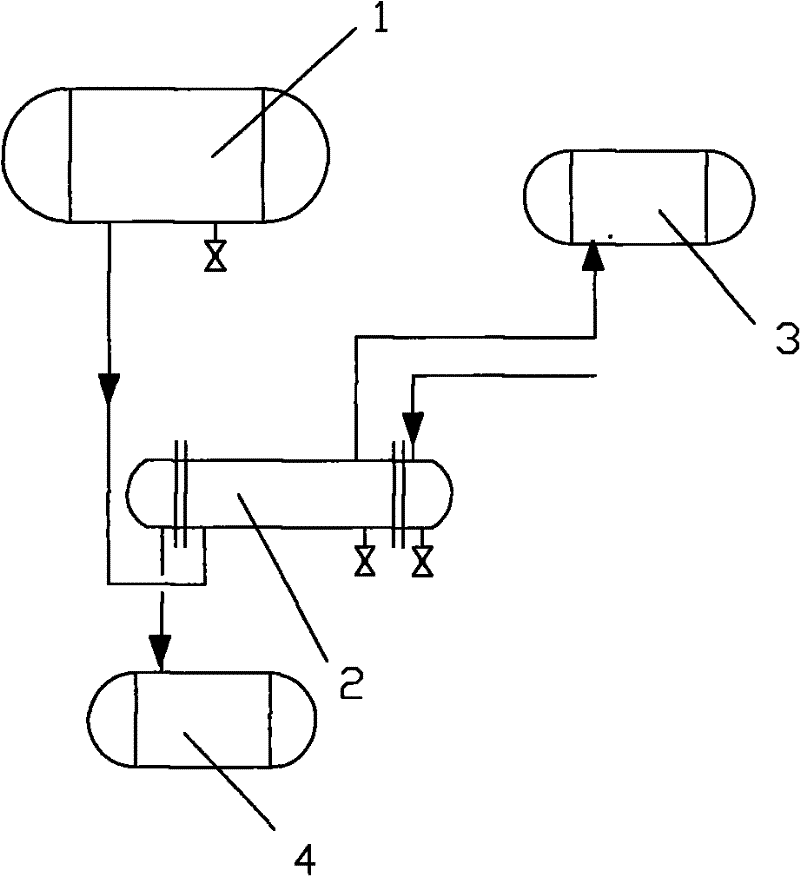

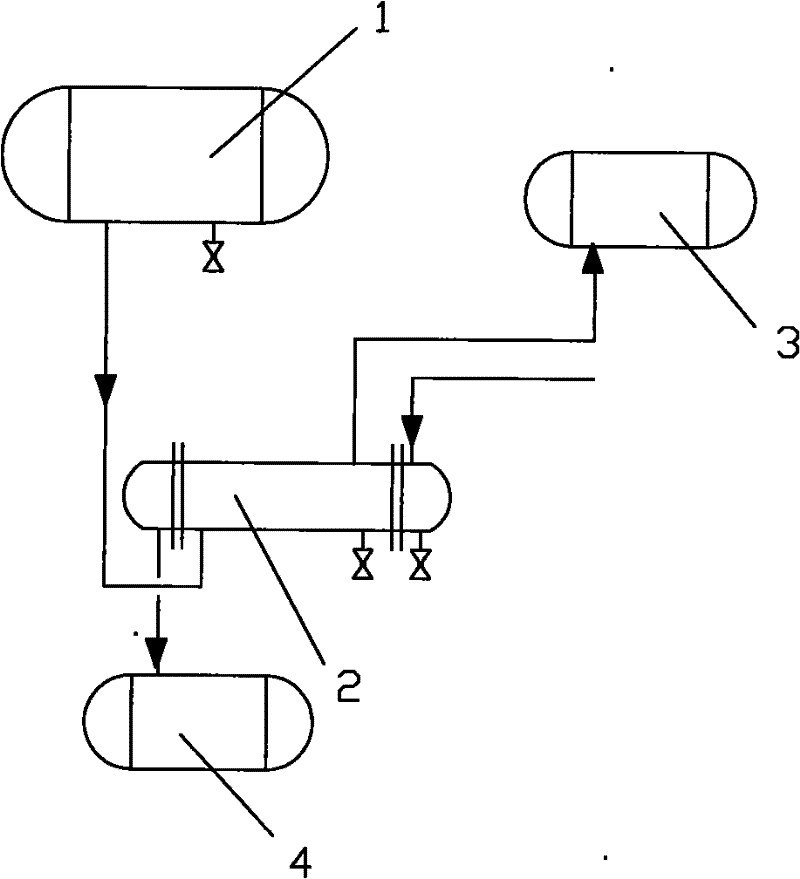

Method and device for vaporizing hydrogen chloride in tail gas in polycrystalline silicon production

ActiveCN102039082AGood vaporization effectImprove the effect of energy saving and consumption reductionDispersed particle separationTowerHydrogen chloride

The invention discloses a method and a device for vaporizing hydrogen chloride in tail gas in polycrystalline silicon production. The method is characterized in that: low-temperature hydrogen chloride liquid separated from the top of a hydrogen chloride separating tower exchanges heat with high-temperature chlorosilane liquid output from the bottom of the hydrogen chloride separating tower through heat exchange equipment, so that the low-temperature hydrogen chloride liquid absorbs the heat and is completely vaporized, the temperature of high-temperature chlorosilane is reduced, and chlorosilane serving as low-temperature absorption liquid enters an absorption tower to continuously absorb the hydrogen chloride in the tail gas. The device comprises a hydrogen chloride condensation storage tank, a heat exchanger and a demister, wherein a chlorosilane storage tank is arranged below the heat exchanger and connected with the heat exchanger. Heat quantity and cold quantity in a tail gas recovery system are mutually converted, so that energy is fully utilized and saved.

Owner:XINTE ENERGY

Low dropout decompression transfer line

ActiveCN101532594ASmall pressure dropGood vaporization effectDistillation separationRigid pipesLow speedPetroleum

A low dropout decompression transfer line of the invention is used in a pipeline between a vacuum furnace and a vacuum tower of an atmosphere and vacuum distillation unit in the process of oil refining and in other devices for transporting oil products with high temperature and low pressure. The low dropout decompression transfer line comprises a 90 degree extend elbow, a 30-60 degree elbow, a transition section and a low speed section; wherein, the transition section adopts a structure of progressive hole enlargement, the 90 degree extend elbow is one with the curvature radius being 3-6 times of the diameter of a bent pipe, and the transition section is structured in the way that a trousers-shaped straight tee (3) with 15-30 degree of included angle is connected with a Y-shaped straight tee (4) in the shape of trousers with 45-90 degree of included angle. The invention adopts the principle of pipe diameter extending and smooth processing at joints, reduces resistance loss in the process of flowing and pressure drop of the transfer line and optimizes vaporization effect of the oil products, thus improving distillate yield and generating appreciable economic benefits.

Owner:TIANJIN UNIV

Fine atomization flash tank

InactiveCN105727583AGood vaporization effectIncrease surface areaFlash distillationVaporizationFlash evaporation

The invention provides a fine atomization flash tank, which comprises an atomizing chamber and a vaporizing chamber, wherein the atomizing chamber is communicated with the vaporizing chamber; a feeding pipe of the fine atomization flash tank is arranged in the atomizing chamber and is provided with a plurality of atomization nozzles; a gas-liquid separator of the fine atomization flash tank is arranged on the vaporizing chamber; the inside of a tank body of the fine atomization flash tank is partitioned into two communicated chambers which are partitioned by a partition plate; the vaporizing chamber is arranged at the upper part of the partition plate; and the atomizing chamber is arranged at the lower part of the partition plate; or two tank bodies are taken as the atomizing chamber and the vaporizing chamber respectively and are communicated through a communicating channel. When the flash tank works, a material can be sprayed into the tank body through the atomization nozzles in a form of disperse droplets; the disperse droplets suspend in a space in the tank body; the surface area is large; vaporization is carried out on the surfaces of all droplets under the condition of low pressure in the tank body; a hydrostatic effect is avoided; the liquid vaporization effect is relatively good; and the defects that a traditional flash tank has the hydrostatic effect and is small in flash evaporation and vaporization surface area are overcome.

Owner:GUANGXI UNIV

Semiconductor temperature difference power generation parking heater

PendingCN110588289ATake advantage ofImprove utilization efficiencyAir-treating devicesVehicle heating/cooling devicesThermal energyCombustion chamber

The invention discloses a semiconductor temperature difference power generation parking heater. The semiconductor temperature difference power generation parking heater comprises a shell with a chimney, a combustion chamber with a flue gas outlet is arranged in the shell, a combustor is arranged in the combustion chamber, the exterior of the front end of the combustor is provided with a combustion-supporting air static pressure cavity, the back end of the combustor is provided with an air outlet hole, and the air outlet hole communicates with the interior of the combustion chamber through ceramic foam; and the side wall of the end, close to the combustor, of the combustion chamber is provided with a flue gas outlet, the flue gas outlet is connected with the chimney, a flue gas channel is formed between the inner wall of the combustion chamber and the combustor, and flue gas passes through the flue gas channel between the inner wall of the combustion chamber and the combustor, passes through the flue gas outlet and then is exhausted from the chimney. According to the semiconductor temperature difference power generation parking heater, both heat energy and electric energy are supplied, full utilization of fuel is achieved, the utilization efficiency is improved, and the semiconductor temperature difference power generation parking heater is widely used for warming of vehicles such as long-distance trucks and passenger cars.

Owner:江西卓超科技有限公司

Material cooling device

PendingCN109028751AEfficient use ofAvoid wastingDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention provides a recycling cooling device, and relates to the technical field of cooling. The device comprises a box body allowing a material to pass through, a cooling system for cooling thematerial is arranged in the box body, after heat exchange of a cooling medium, the cooling medium is vaporized to be guided to a refrigeration system through a pipeline, the refrigeration system is used for condensing the vaporized cooling medium, through adding of the refrigeration system, the vaporized cooling medium is liquidated and collected and then used, resource waste is avoided, cost is saved, and the higher practical value is achieved.

Owner:TIANJIN BOHAI PETROCHEM CO LTD

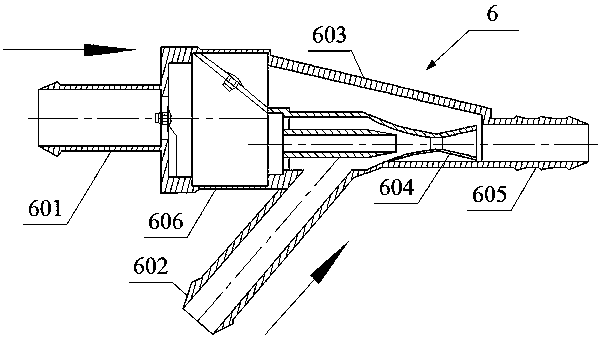

SNCR denitrification system and denitrification method

InactiveCN109999646AAvoid affecting combustionIncrease contact areaGas treatmentLighting and heating apparatusFlue gasVaporization

The invention discloses an SNCR denitrification system and a denitrification method. The SNCR denitrification system comprises a first nozzle group arranged in the middle-upper part of a furnace hearth and / or a second nozzle group arranged on the connection flue, and an ammonia liquid tank and a mixing vaporizer. The mixing vaporizer comprises an ammonia liquid pipe, a steam pipe, a venturi mixingpipe and a vaporizing pipe. A three-way structure is formed between the ammonia liquid pipe, the steam pipe and the vaporizing pipe. The nozzle adopts a sleeve structure, including a denitrifying agent inner tube and a cooling sleeve, and the front end of the denitrifying agent inner tube is provided with a venturi atomizing tube and a nozzle is arranged at the outlet end of the venturi atomizingtube. A steam with pressure is introduced into the mixing vaporizer through a steam pipe, and a negative pressure is formed when that steam passes through the venturi vaporization pipe, so that a denitrifying agent in the ammonia liquid tank is sucked into the venturi vaporization pipe from the ammonia liquid pipe under the negative pressure; the denitrifying agent and steam are mixed and heat isexchanged in the venturi vaporizing pipe, so that the denitrifying agent is vaporized. The denitrifying agent steam is sent from the vaporizing pipe to the spray pipe and sprayed into the flue gas toremove NOx from the flue gas. The invention has the advantages of good ammonia liquid mixing and atomizing effect, high denitrification efficiency and the like.

Owner:贾新华

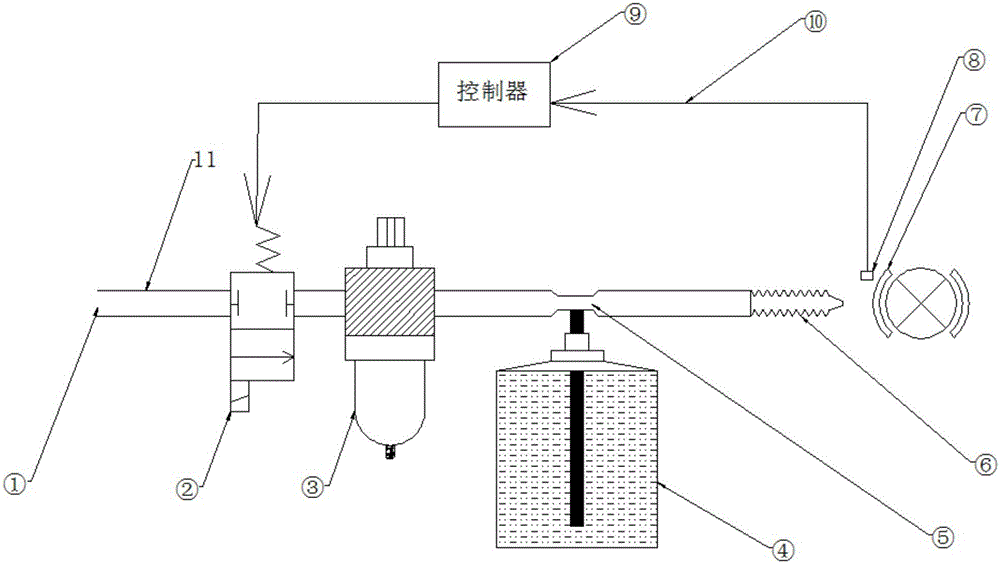

Heavy-duty commercial vehicle brake micro liquid cooling device and control method thereof

PendingCN106627524AImprove cooling effectGood vaporization effectBrake coolingBrake safety systemsControl systemDifferential pressure

The invention discloses a heavy-duty commercial vehicle brake micro liquid cooling device and a control method thereof. The device comprises a high-pressure gas pipeline, a liquid tank and a control system. One end of the high-pressure gas pipeline is connected with a high-pressure gas inlet, and a nozzle is arranged at the other end of the high-pressure gas pipeline and is close to a brake. A venturi is arranged on the high-pressure gas pipeline and communicates with a fine tube extending into the liquid tank. The control system controls high-pressure gas to enter the venturi along the high-pressure gas pipeline, differential pressure is formed between the venturi and the liquid tank, liquid in the liquid tank enters the venturi along the fine tube under the action of the differential pressure, and the liquid is sprayed to the brake along with the high-pressure gas from the nozzle after being atomized under the contraction action of the nozzle. Through the device and the control method thereof, the temperature of the vehicle brake is not increased, thus the hot water subsidence phenomenon does not occur when the heavy-duty commercial vehicle brake brakes for a long time.

Owner:CHANGAN UNIV

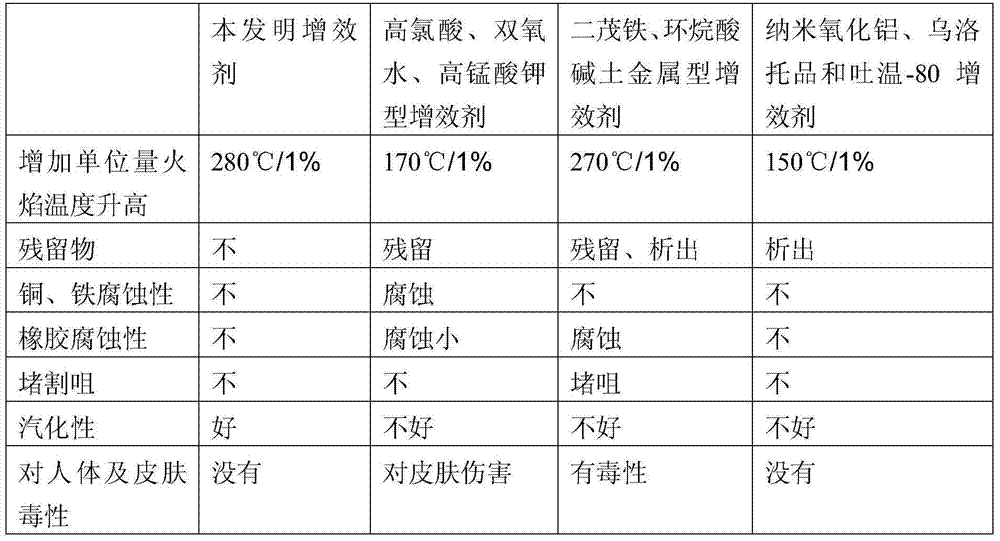

Industrial natural gas synergist and preparation method thereof

The invention discloses an industrial natural gas synergist. The industrial natural gas synergist is prepared by the following steps: sequentially adding the following chemical raw materials into a tank in parts by weight: 8-9 parts of di-tert-butyl peroxide butane, 7-8 parts of menthane hydroperoxide, 3-5 parts of cyclohexane peroxide, 1 part of isooctyl nitrate and 3-4 parts of C5-C9 straight-chain paraffins, slowly stirring the raw materials for 15 to 25 minutes, standing for 8 to 15 minutes, and then, putting the mixture in a wrappage to obtain a finished product. The industrial natural gas synergist is used with natural gas according to a ratio of synergist to natural gas of (1-3): 10 in parts by weight. The industrial natural gas synergist disclosed by the invention can regulate the combustion speed in the combustion process of natural gas and can remove smoke. In an oxygen-fuel combustion process, the flame temperature is higher than 3200 DEG C. The industrial natural gas synergist has good intermiscibility with natural gas and has good evaporability while having no residue or precipitation.

Owner:黄诚 +1

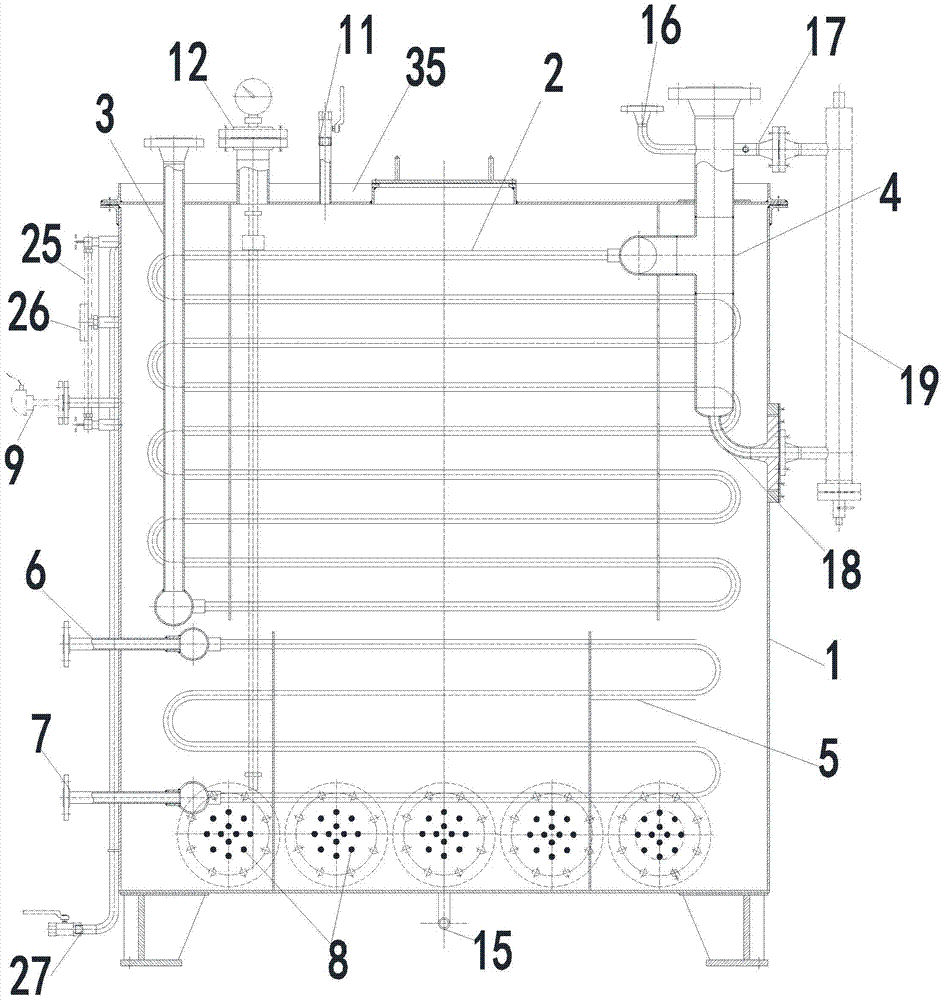

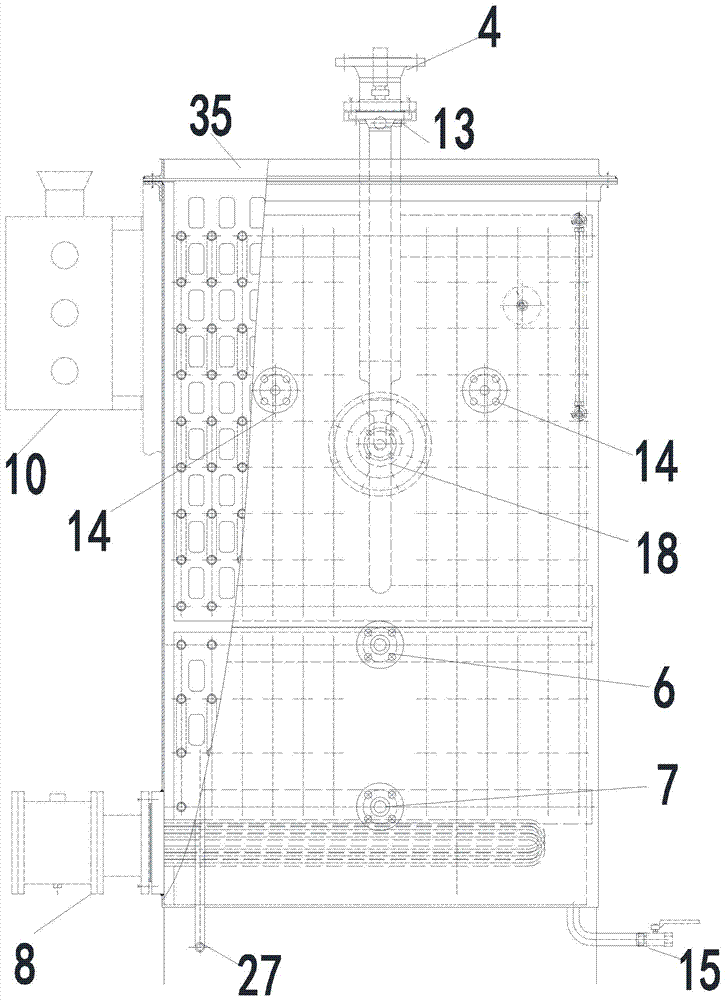

Ultra-high purity gas heat exchanger and implementation method thereof

The invention discloses an ultra-high purity gas heat exchanger and an implementation method thereof. The ultra-high purity gas heat exchanger comprises a shell filled with water inside, a left heat exchange pipe supporting and fixing plate, a right heat exchange pipe supporting and fixing plate, an ammonia circulation coil component, a feed pipe, a discharge pipe, a hot-water circulation coil component, a plurality of plug-in electric heaters and a thermalcouple. A hot-water inlet is formed in the upper end of the hot-water circulation coil component, a hot-water outlet is formed in the lower end of the hot-water circulation coil component, the thermalcouple is connected with a PID (piping and instruments diagram) controller in an explosion-proof tank on the outer surface of the shell, and the PID controller is connected with the plug-in electric heaters. The invention further discloses an implementation method of the Ultra-high purity gas heat exchanger. The ultra-high purity gas heat exchanger and the implementation method thereof have the advantages of simple structure, low cost and capability of being operated for a long time in succession, evaporation is quite stable, electrical heating and hot water of waste heat are combined for heating, energy conservation and environment protection are achieved and the like.

Owner:ZHEJIANG KIN SHINE TECH

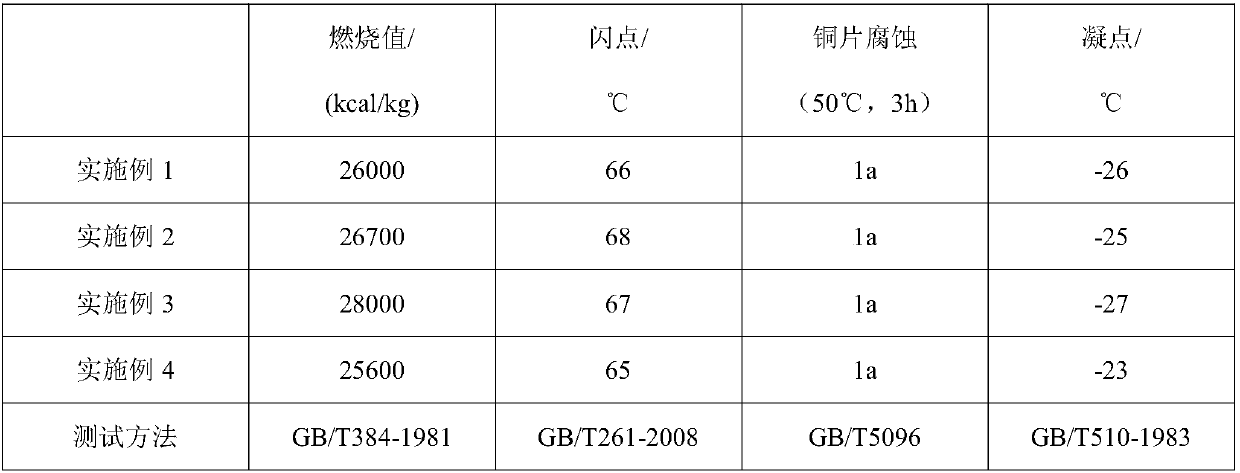

Alcohol-based fuel with high calorific value and preparation method thereof

ActiveCN107892957AHigh calorific valueEliminate odorLiquid carbonaceous fuelsFuel additivesLiquid fuelOctanol

The invention specifically relates to an alcohol-based liquid fuel with high calorific value and a preparation method thereof. The alcohol-based liquid fuel comprises the following raw materials by weight: 85 to 90 parts of methanol, 10 to 15 parts of C12 fuel oil, 5 to 10 parts of octanol, 15 to 20 parts of methylal, 1 to 4 parts of a deodorant and 10 to 15 parts of an additive. The additive comprises the following raw materials by weight: 5 to 10 parts of ethanol, 3 to 5 parts of glyceryl triacetate, 4 to 7 parts of a cationic fluorocarbon surfactant, 3 to 5 parts of ferrocene, 10 to 15 parts of a hydrocarbon compound, 10 to 15 parts of a combustion improver, 3 to 5 parts of a stabilizing agent and 3 to 5 parts of an antidetonant. According to the invention, the components of the alcohol-based liquid fuel with high calorific value cooperate with each other, so the alcohol-based liquid fuel is thorough in combustion, high in combustion heat value and free of carbon deposition, and hasgood intersolubility with gasoline, good corrosion resistance, good vaporability and good positive additivity.

Owner:临沂星火知识产权服务有限公司

Evaporation cool evaporation water amount control device and control method

InactiveCN107975898AImprove atomization effectImprove evaporation efficiencyMechanical apparatusLighting and heating apparatusWater storageSpray nozzle

The invention discloses an evaporation cool evaporation water amount control device and control method. The control device includes a water storage box, a spray water pump, a pipeline, a heat insulation chamber and a nozzle. The heat insulation chamber is provided with an air inlet and an air outlet. The two ends of the pipeline are both located in the water storage box. The spray water pump is arranged in the pipeline. The nozzle is arranged in the pipeline located in the heat insulation chamber. The pipeline is connected with a water pressure sensor and a regulating valve. The heat insulation chamber is internally provided with a temperature and humidity sensor. The control method is that according to the water pressure in the pipeline and the humidity in the heat insulation chamber, theopening of the regulating valve is controlled, so that the purpose of controlling the spray water amount from the nozzle is achieved. By means of the evaporation cool evaporation water amount controldevice and control method, increasing of the contact area between water and air is achieved by the size and amount of water spray particles, water droplets are prompted to be better integrated with air, the evaporation water amount is effectively controlled, and meanwhile, the water evaporation effect is further improved, and evaporation cooling efficiency is improved.

Owner:YIMIKANG TECH GRP CO LTD

Alcohol-based vaporization combustion furnace

PendingCN109945245ASolve the technical problem that heating is not affectedBurn completelyBurnersDomestic stoves or rangesElectricityAlcohol

The invention discloses an alcohol-based vaporization combustion furnace which comprises a combustion cavity, a sound elimination cavity, an electric heater and a vaporization cavity. The sound elimination cavity is arranged around the combustion cavity and is provided with an inlet communicating with fuel oil. The electric heater is arranged around the sound elimination cavity and is electricallyconnected with a power supply. The vaporization cavity is arranged around the electric heater and communicates with the sound elimination cavity and an alcohol-based furnace end correspondingly through pipelines.

Owner:邓光勇 +1

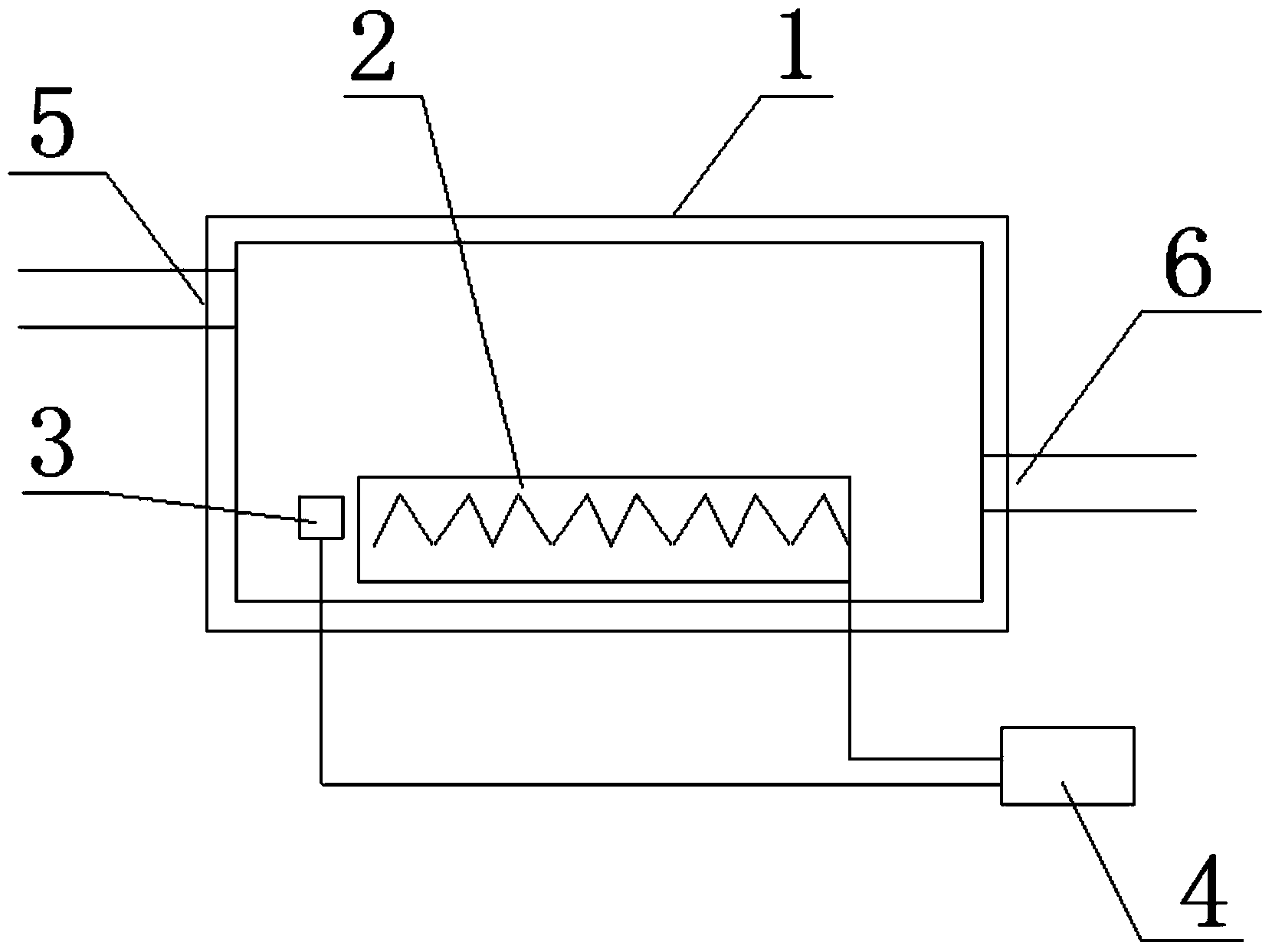

Gasoline vaporization device

InactiveCN104047774ASpeed up vaporizationStable vaporization effectMachines/enginesThermal treatment of fuelCombustionGasoline

The invention relates to a gasoline vaporization device, which comprises a vaporization box, a heater, a temperature sensor and a temperature controller, wherein the heater is arranged at the bottom in the vaporization box, and is fixedly connected with the bottom of the vaporization box; the temperature sensor is arranged in the vaporization box; the temperature controller is connected with the temperature sensor and the heater respectively through lines. Compared with the prior art, the gasoline vaporization device has the advantages of simple structure, wide application range, high petroleum vaporization efficiency and stability and sufficient combustion of gasoline, and the aim of saving gasoline is fulfilled.

Owner:韩志先

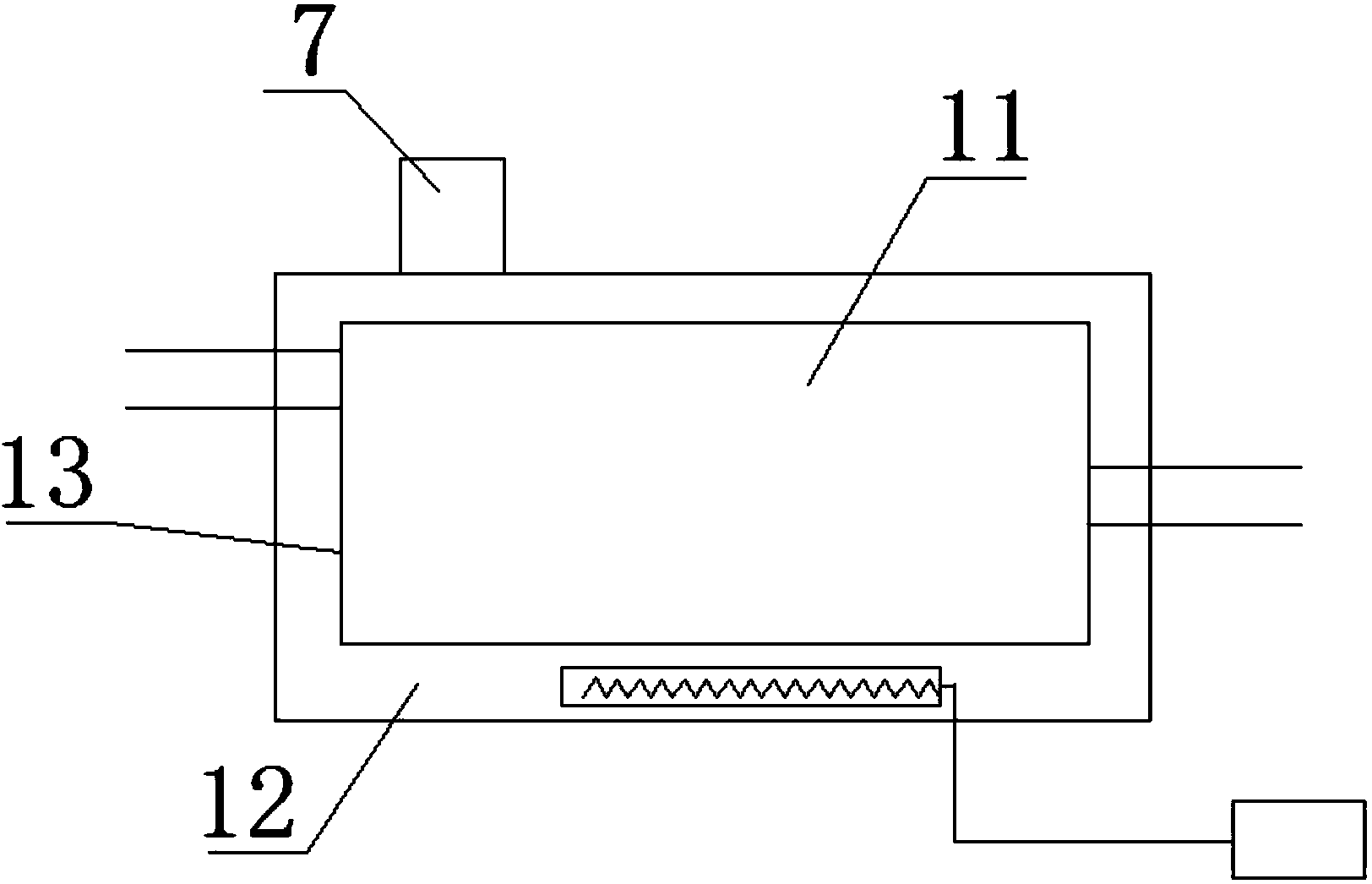

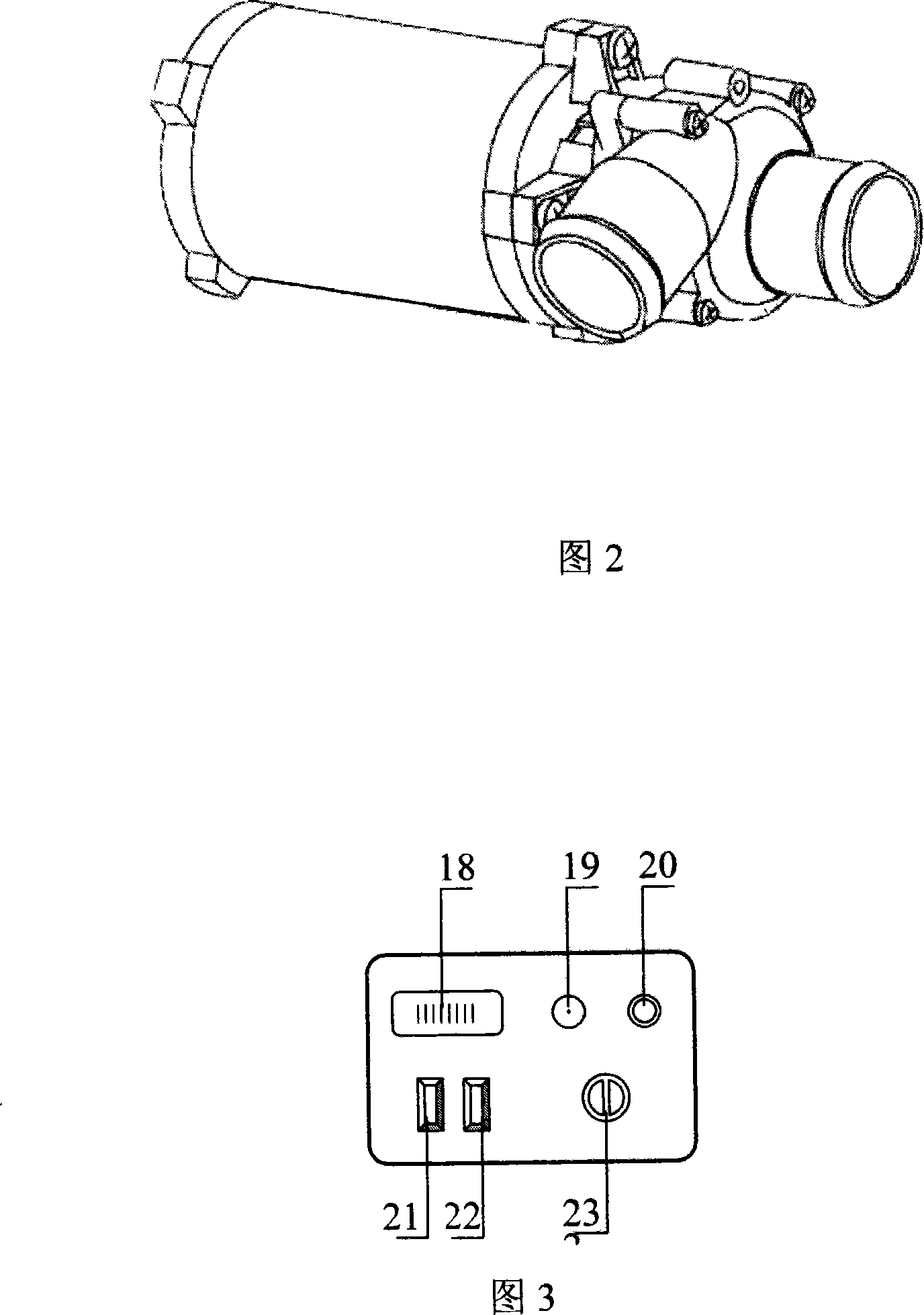

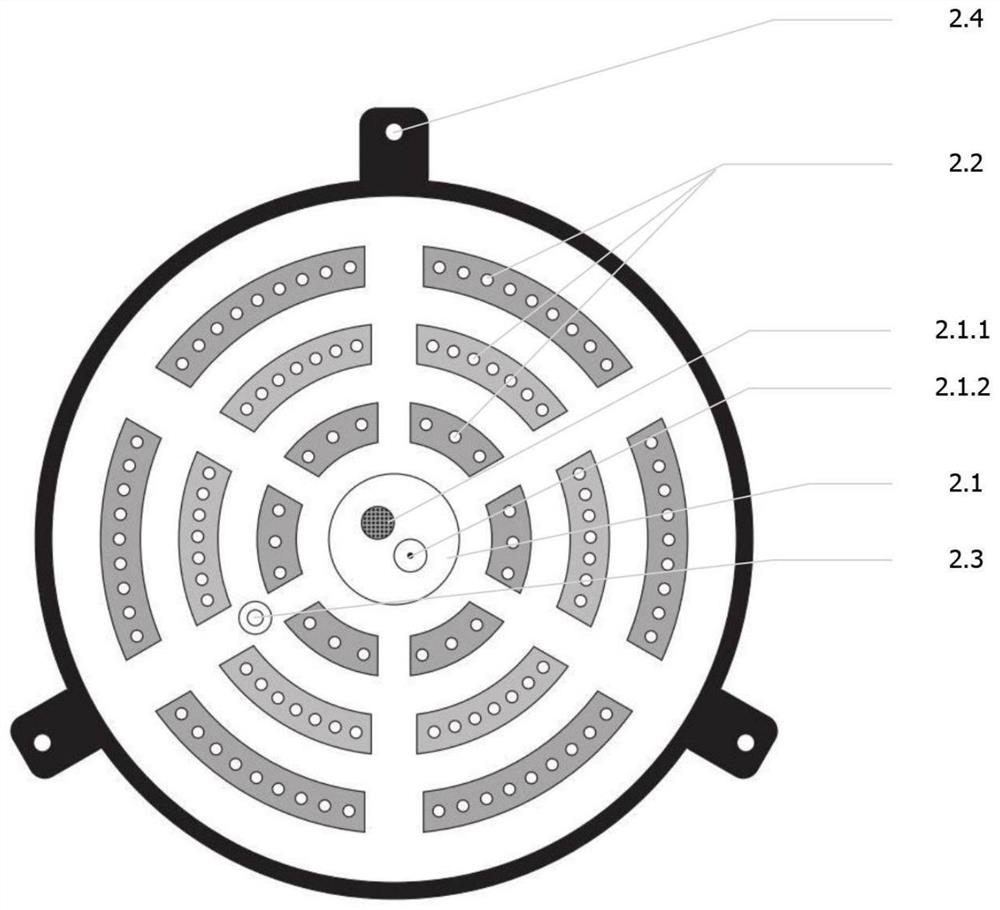

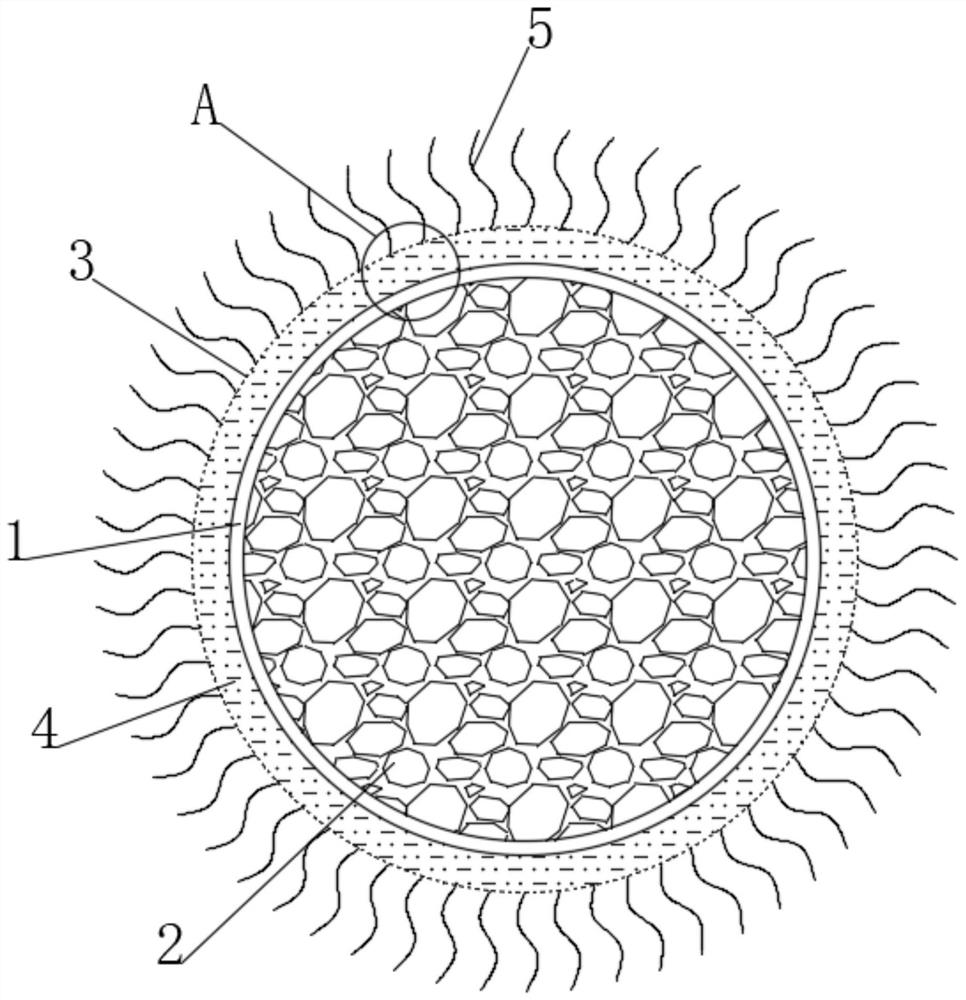

Fumigation medicament vaporization administration device

The invention relates to a fumigant vaporization dosage device which is provided with a heater (11). The heater (11) is communicated with a water tank (5) through a water inlet pipe (15) and a water outlet pipe (12). The water inlet pipe (15) is connected with the heater through a water pump. A drain pipe (10) is arranged on the water tank (5), and a twist coiled pipe (3) is arranged in the water tank (5). The air outlet (1) of the twist coiled pipe (3) is connected with a dosage pipe through a valve, and a air outlet (2) is connected with a steel cylinder through a valve. Comparing with prior technology, the invention has the advantages of quick heating speed, good vaporization effect, strong temperature controllability, good heat preservation effect and that the invention does not be limited by site conditions. The invention is simple and convenient to operate, is safe and reliable, and has a strong practicability and a good application effect.

Owner:李广仁

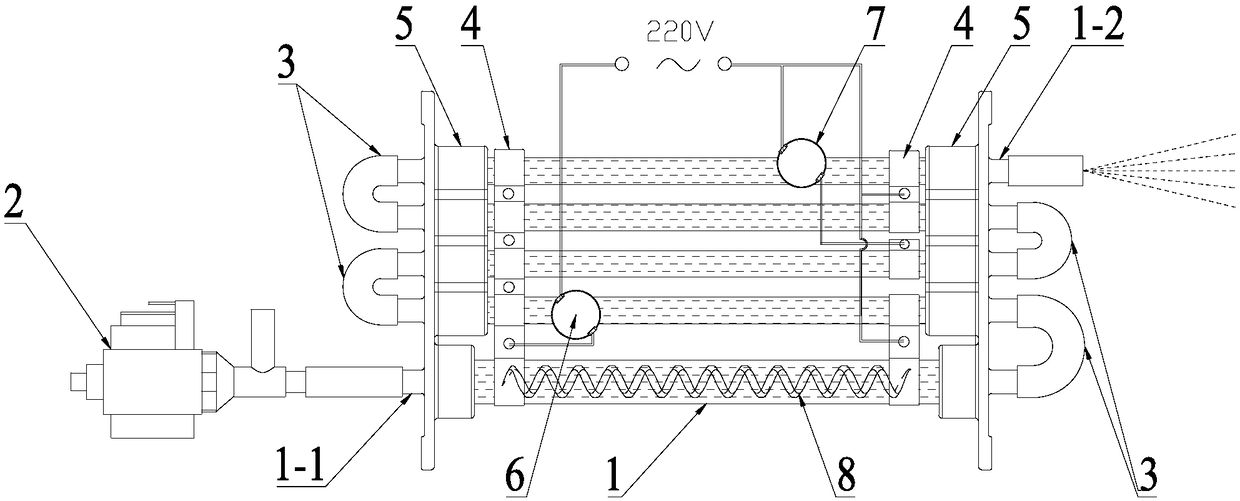

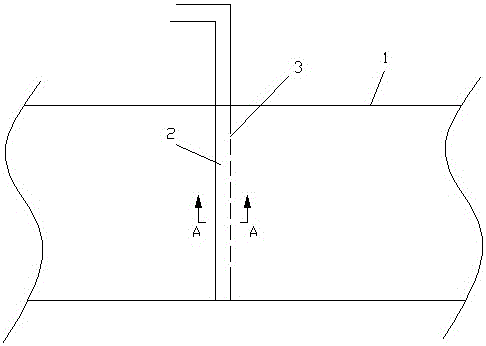

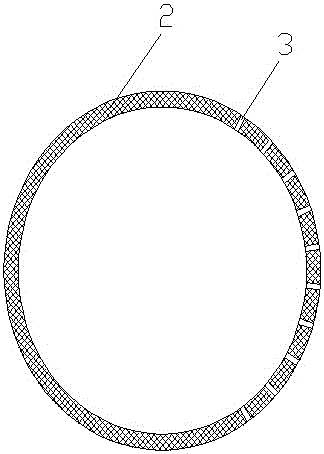

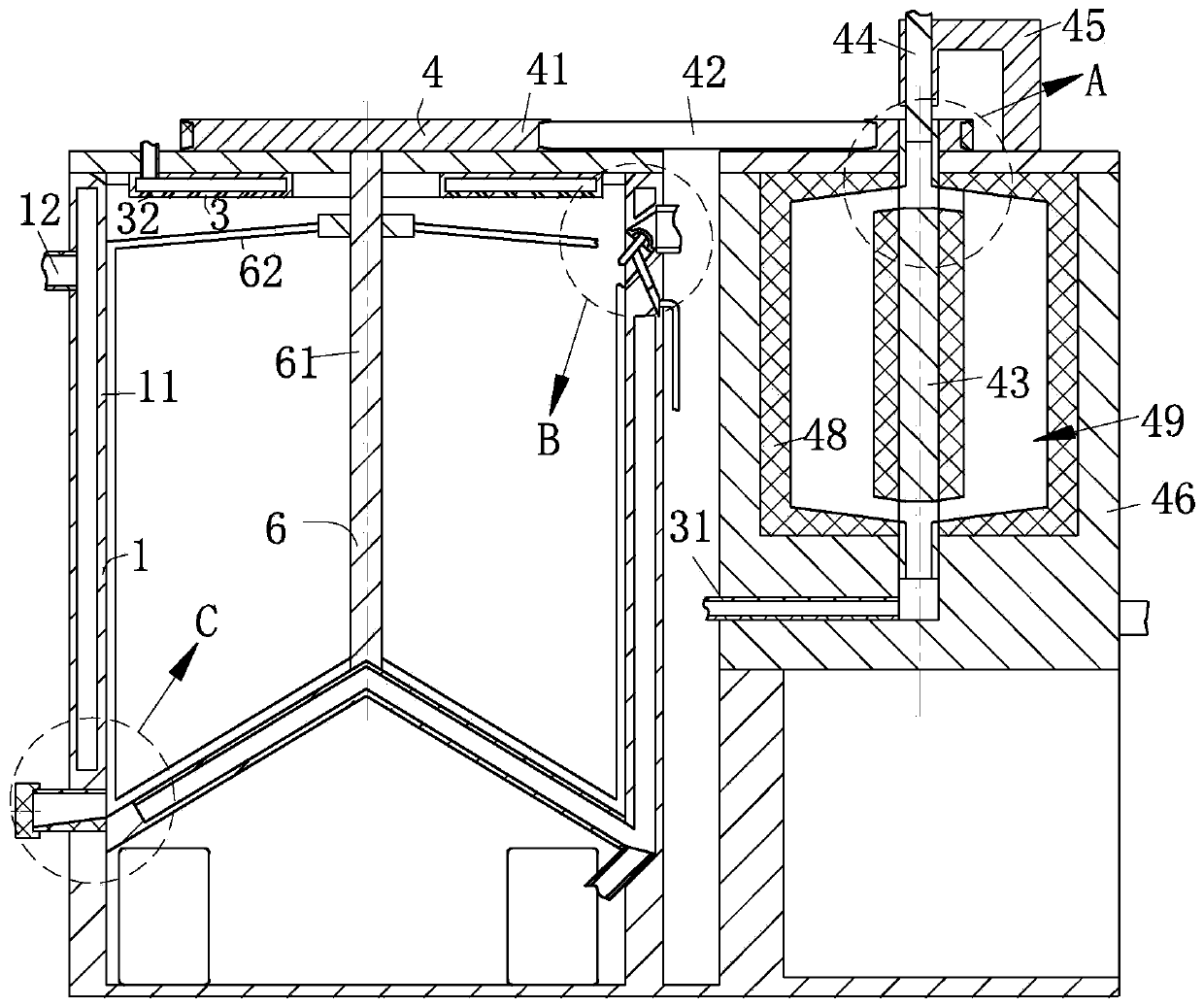

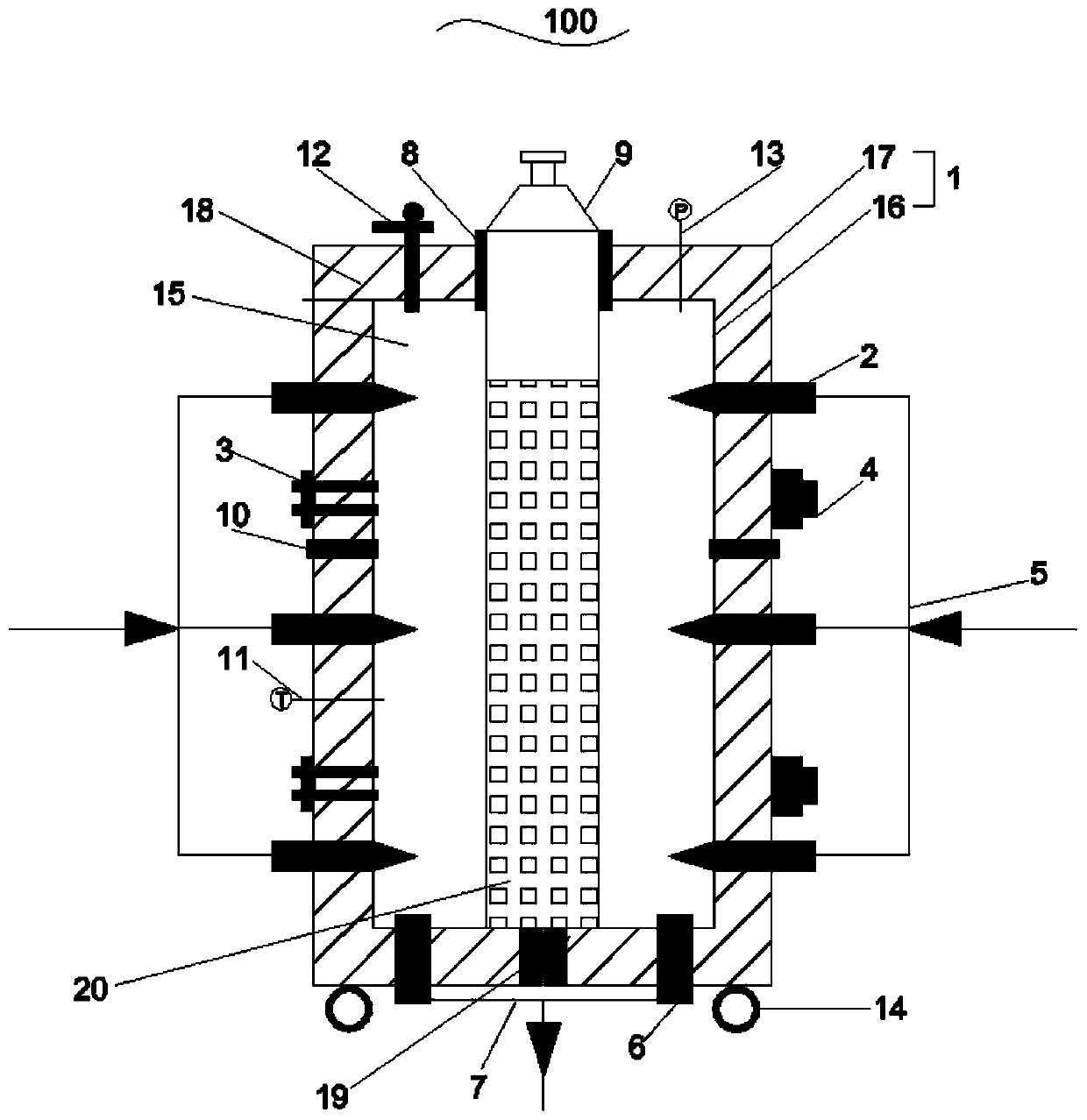

Instantaneous heating type steam generating device

PendingCN108826255AHigh trafficGood vaporization effectSteam generation heating methodsEngineeringHeat pipe

The invention discloses an instantaneous heating type steam generating device. The instantaneous heating type steam producing device includes multiple heating pipes (1), a water pump (2) and a first temperature controller (6). The multiple heating pipes (1) are arranged side by side, a water inlet (1-1) is formed in the first heating pipe (1), an air outlet (1-2) is formed in the last heating pipe(1), each adjacent heating pipe (1) communicates through a connecting pipe (3), and two ends of each heating pipe (1) are connected through an energizing fixed electrode (4). The water out end of thewater pump (2) is connected to the water inlet (1-1). The first temperature controller (6) is used for controlling the on and off of heating circuits of the heating pipes (1), and the heating circuitof the heating pipes (1) are at least two ways. The instantaneous heating type steam generating device has a high heat utilization rate, steam can be generated without pre-heating, and scale removalis not required in the use process.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

Gas odorization device

InactiveCN105972438ASimple and reasonable structureGood vaporization effectPipeline systemsPlunger pumpGas pipeline

The invention discloses a gas odorizing device, comprising: a medicament storage tank, a gas pipeline, a diaphragm plunger pump, a medicament output pipe, a flow meter and a single-chip microcomputer control device. The end of the medicament output pipe is connected with a dosing pipe. The dosing pipe is located inside the gas pipeline, and the lower end is closed. The dosing pipe includes a dosing pipe body and a plurality of micropores on the dosing pipe body, and the plurality of micropores are distributed on one side of the dosing pipe. , and the outlet direction of the micropores is along the gas flow direction, and the distribution angle of the micropores on the circumference is 120°~130°. Through the above method, the structure of the present invention is simple and reasonable, and the vaporization effect of the dosing pipe is good, so that the medicine and the gas are well mixed.

Owner:无锡欧洛普科技有限公司

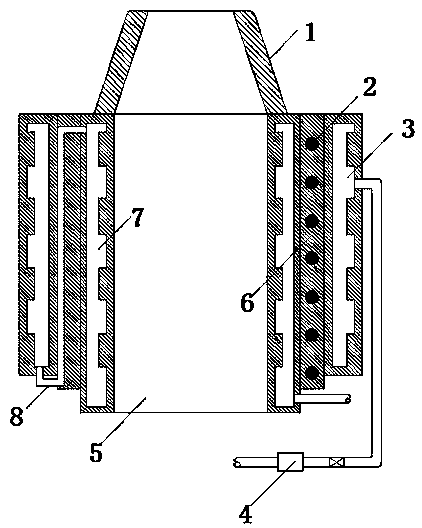

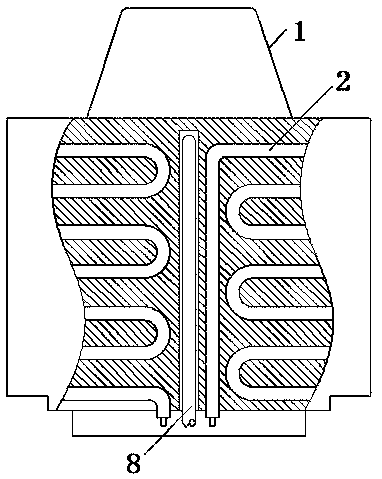

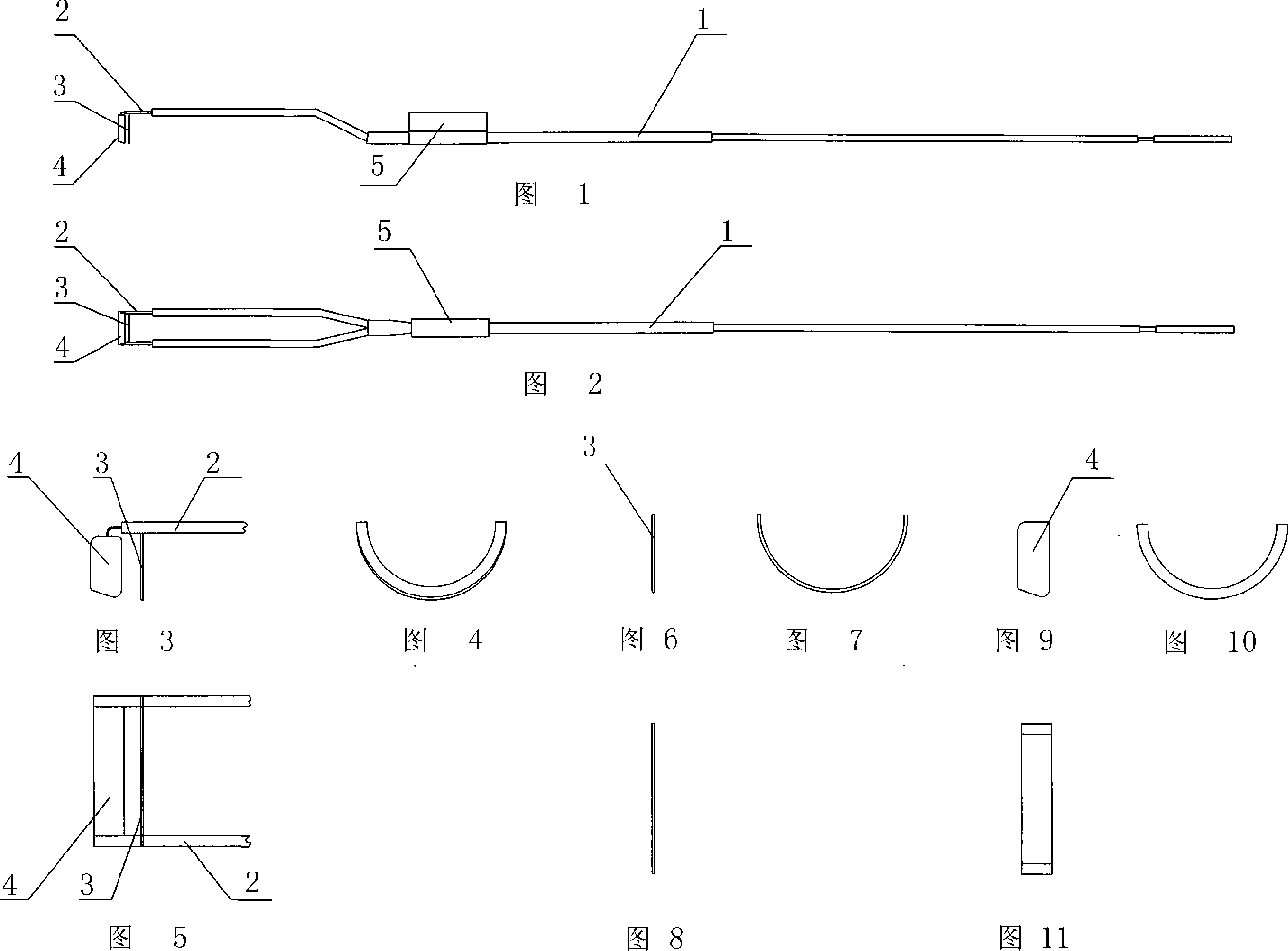

Combination type electric cutting knife of prostate

InactiveCN101081175AImprove cutting effectGood vaporization effectIncision instrumentsSurgical instruments for heatingElectricitySurgical operation

The present invention relates to medical equipment, and is especially one kind of combined electric knife for prostate. The combined electric knife is superior to available one, which consists of one knife bar, one knife head and one knife, and has two knifes, including one arc linear knife with excellent cutting performance and one plate vaporizing knife with excellent vaporizing performance. The combined electric knife has raised performance, and capacity of facilitating surgical operation and raising operation quality.

Owner:王璠

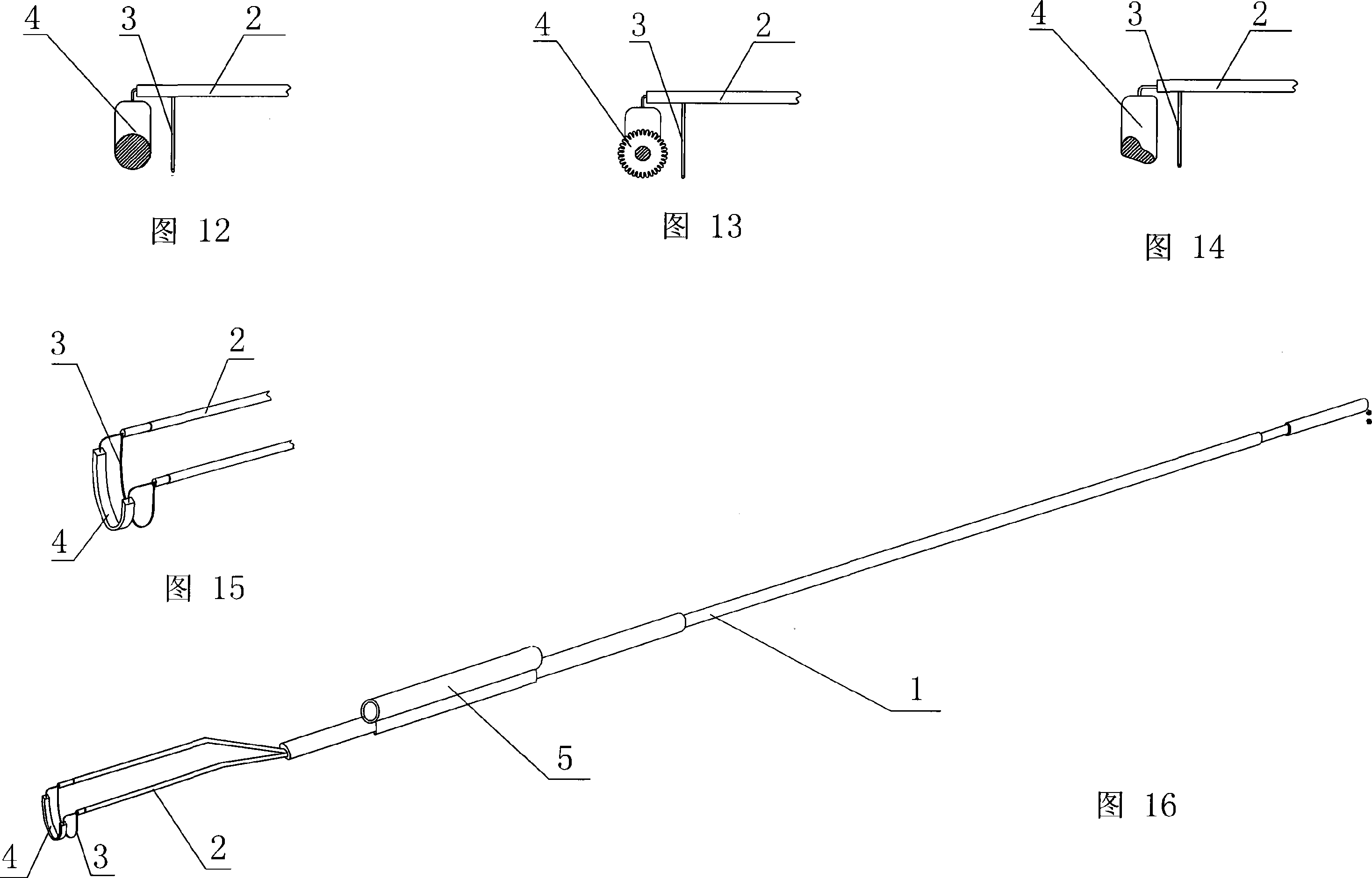

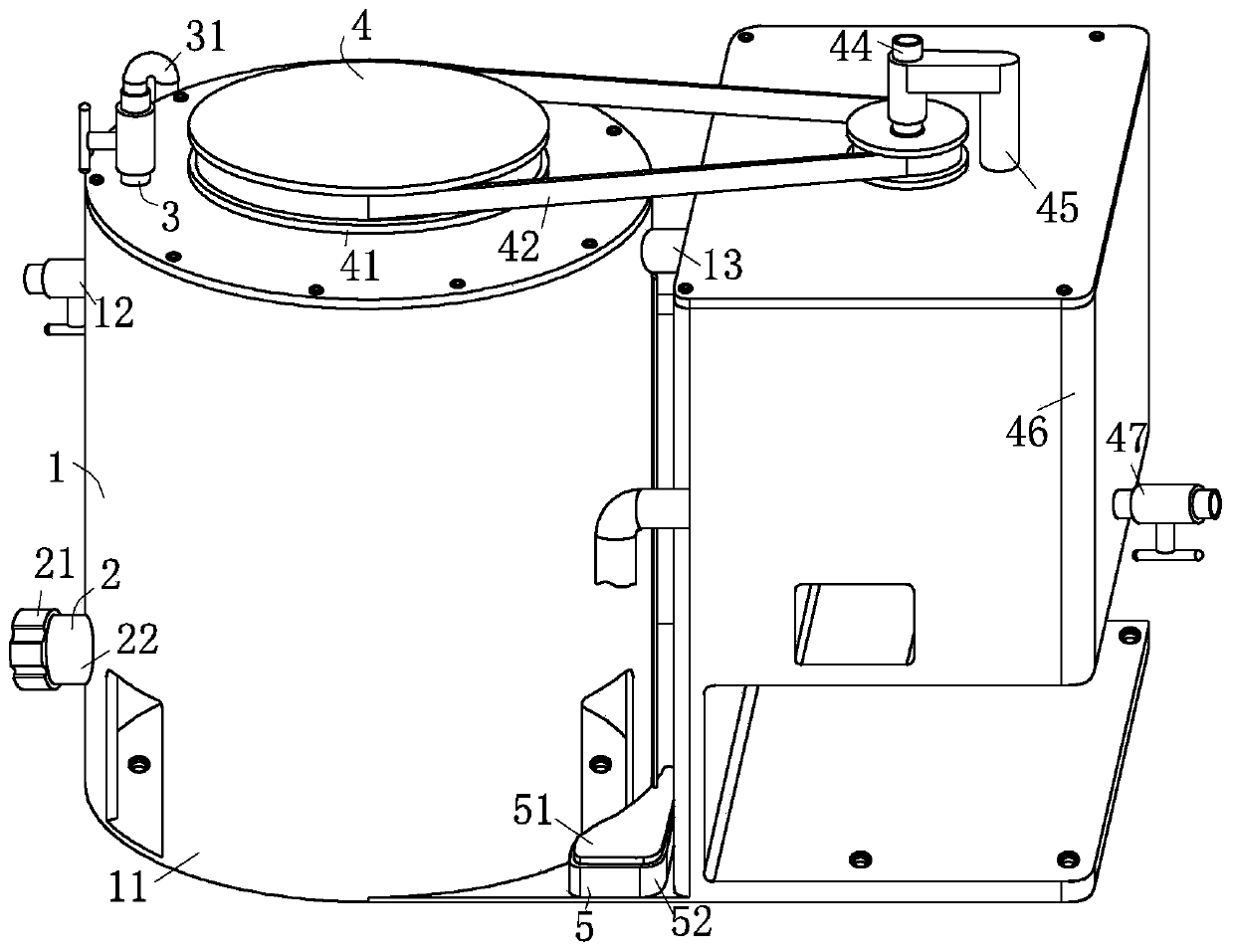

Multifunctional high-efficiency and energy-saving alcohol-based biofuel vaporization stove

PendingCN112303683AVersatileEasy to operateLiquid heating fuelLighting and heating apparatusThermodynamicsBiofuel

The invention discloses a multifunctional high-efficiency and energy-saving alcohol-based biofuel vaporization stove. The multifunctional high-efficiency and energy-saving alcohol-based biofuel vaporization stove is composed of five layers and four functional systems, namely a stove cooking range and functional use layer A, a fiber heat insulation layer B, an air isolation and air inlet layer C, acontrol panel layer D, an alcohol-based fuel storage tank layer E, a stove main body structure 1, a stove cooking range and inlet system 2, a stove vaporizing chamber and fire gathering ring system 3, a stove cooling, heat insulation and hot water supply system 4, and a stove ignition control and fuel supply system 5. The multifunctional high-efficiency and energy-saving alcohol-based biofuel vaporization stove integrates the six functions of heating, cooking, humidifying, barbecuing, hot pot and hot water, and is complete in function, high-efficiency and energy-saving, clean and environment-friendly, safe and reliable, beautiful and practical, and convenient to operate. The stove is safer to use and more stable and reliable in performance, and therefore the multifunctional high-efficiency and energy-saving alcohol-based biofuel vaporization stove has wider market application prospects.

Owner:LANZHOU YINENG BIOTECHNOLOGY CO LTD +1

Heavy metal sewage treatment and reutilization device

InactiveCN110776031AImprove evaporation effectPromote aggregationDispersed particle filtrationSpecific water treatment objectivesSewageSewage treatment

The invention relates to the field of heavy metal sewage treatment and reutilization devices, in particular to a heavy metal sewage treatment and reutilization device. The device comprises an evaporation structure, a discharging structure, an atomization structure, a cooling structure, a first cleaning structure and a second cleaning structure, wherein the cooling structure is connected to the evaporation structure to convert kinetic energy of vaporization of the evaporation structure into kinetic energy of the cooling structure, meanwhile, the cooling structure absorbs waste heat while liquefying vaporized sewage so as to preheat sewage not subjected to evaporation treatment, the later evaporation vaporization efficiency of the sewage is higher, the utilization efficiency of the waste heat is improved greatly, meanwhile, the liquefying effect of vaporized sewage is better, the second cleaning structure is driven by vapor to rotate in the evaporation structure, bonding of heavy metal particles to the inner side wall of the evaporation structure is avoided, and the evaporation and heat exchange effects are better; and by arrangement of the first cleaning structure, the heavy metal particles can be effectively prevented from entering the cooling structure, and the treatment quality of the heavy metal particles is improved.

Owner:朱正直

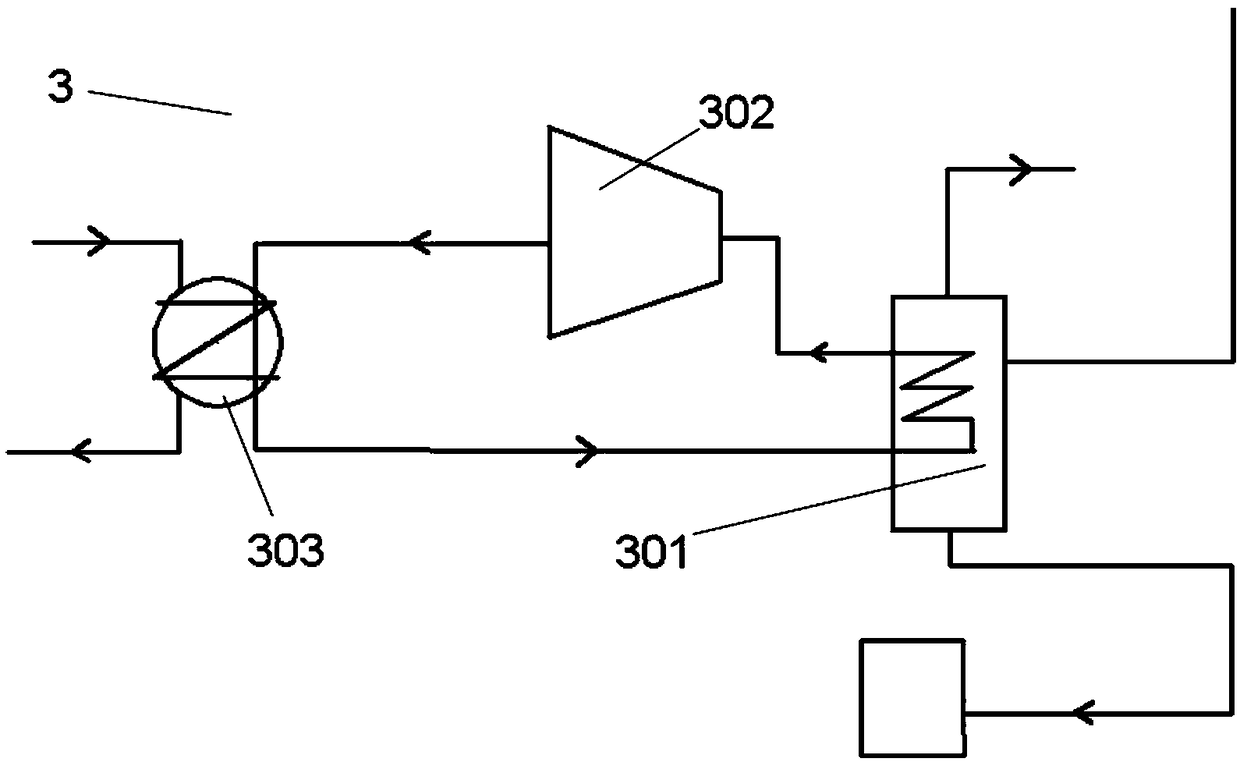

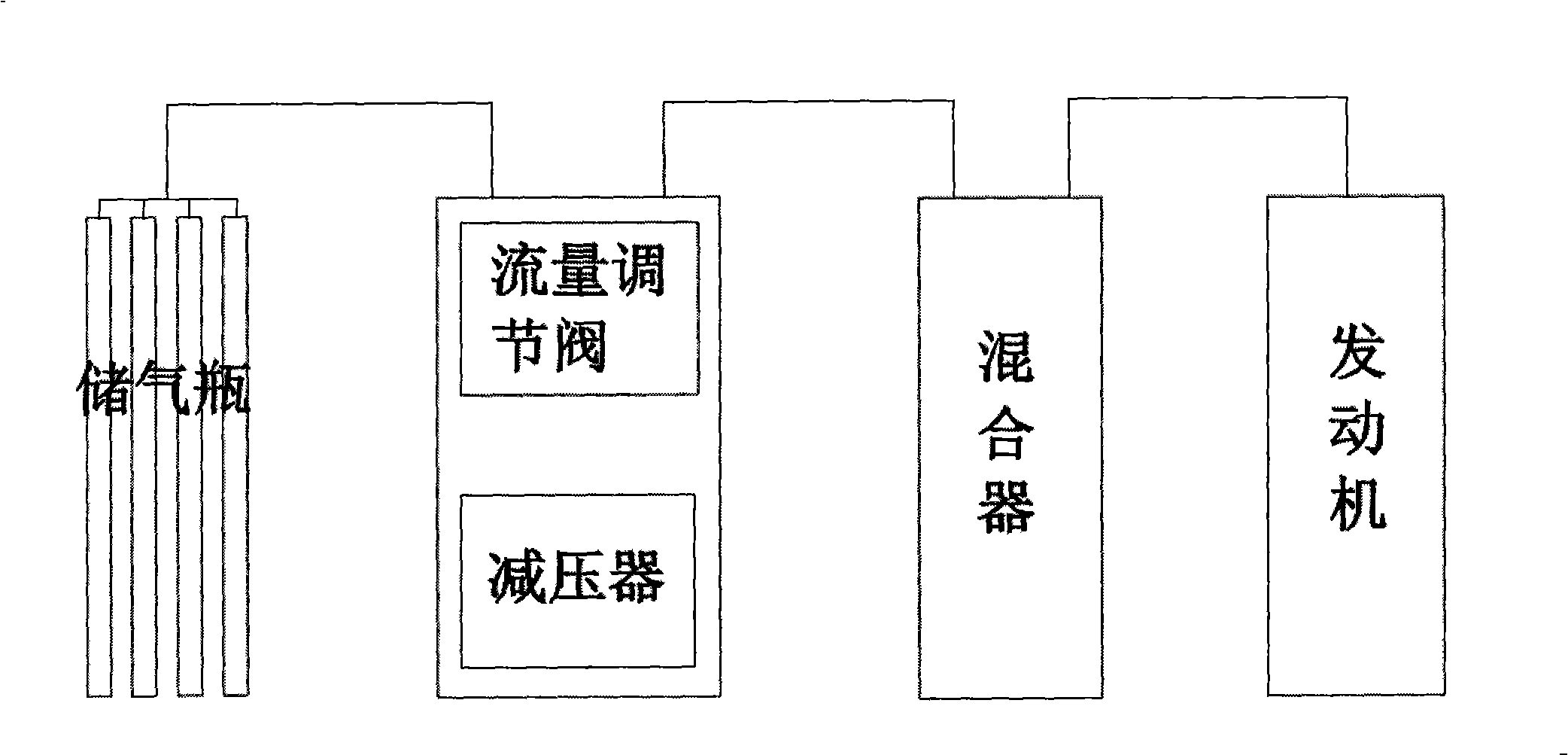

Pressure control gas system

InactiveCN101275517AGood gas vaporization effectCylinder air intake evenlyInternal combustion piston enginesFuel supply apparatusProcess engineeringFlammable gas

The invention relates to a pressure-controlled gas system, comprising a gas storage bottle, a pressure regulating system connected with the gas storage bottle, a gas supply system connected with the pressure regulating system and a gas engine connected with the gas supply system, characterized in that the pressure regulating system includes a flow regulating valve and a reducer for reducing the pressure of a flammable gas, the reducer is an electromagnetic reducing valve, the gas supply system is provided with mixers for mixing gas and air into a flammable gas, the mixers are arranged on the air inlet branch pipelines of cylinders.

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD +1

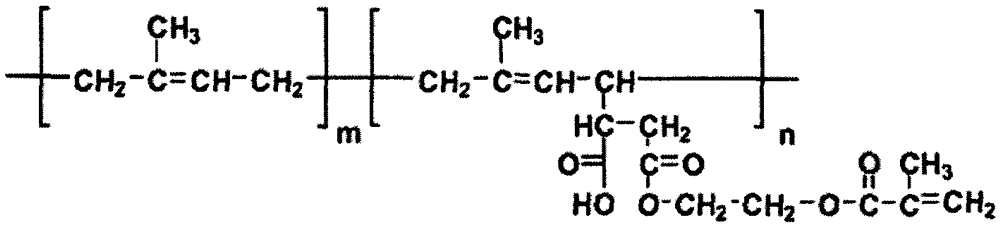

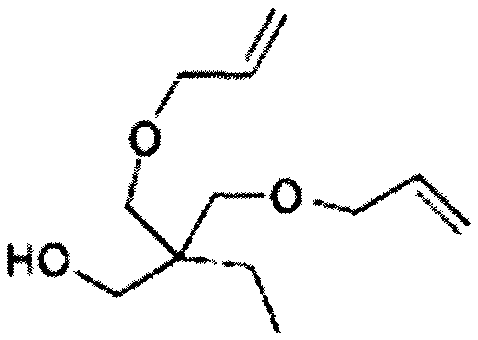

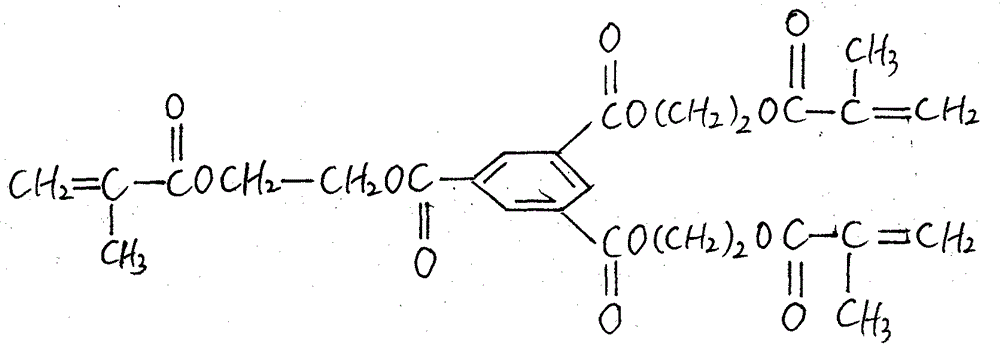

UV adhesive for 3D printing mold casting molding, and uses thereof

ActiveCN105400436AImprove toughnessGood vaporization effectAdditive manufacturing apparatusNon-macromolecular adhesive additivesContinuous lightPolyolefin

The present invention discloses a UV adhesive for 3D printing mold casting molding, and uses thereof, wherein the adhesive comprises, by weight, 25-80% of a polyolefin UV oligomer, 10-50% of a polylol acrylate monomer, 1-10% of a photoinitiator, and 1-15% of an oxygen barrier agent. According to the present invention, with the application of the adhesive in jewelry manufacture and tooth mold casting, the adhesive can completely vaporize at a low temperature (600-700 DEG C) after the adhesive is subjected to light curing, the residual ash does not exist, and the precise and smooth mold cavity can be formed; and the adhesive can be used for 3D projection printing adopting a mercury lamp or 405 nm LED lamp as a light source, and can further meet the continuous light high-speed 3D printing.

Owner:SHENZHEN SAPIENCE TECH CO LTD

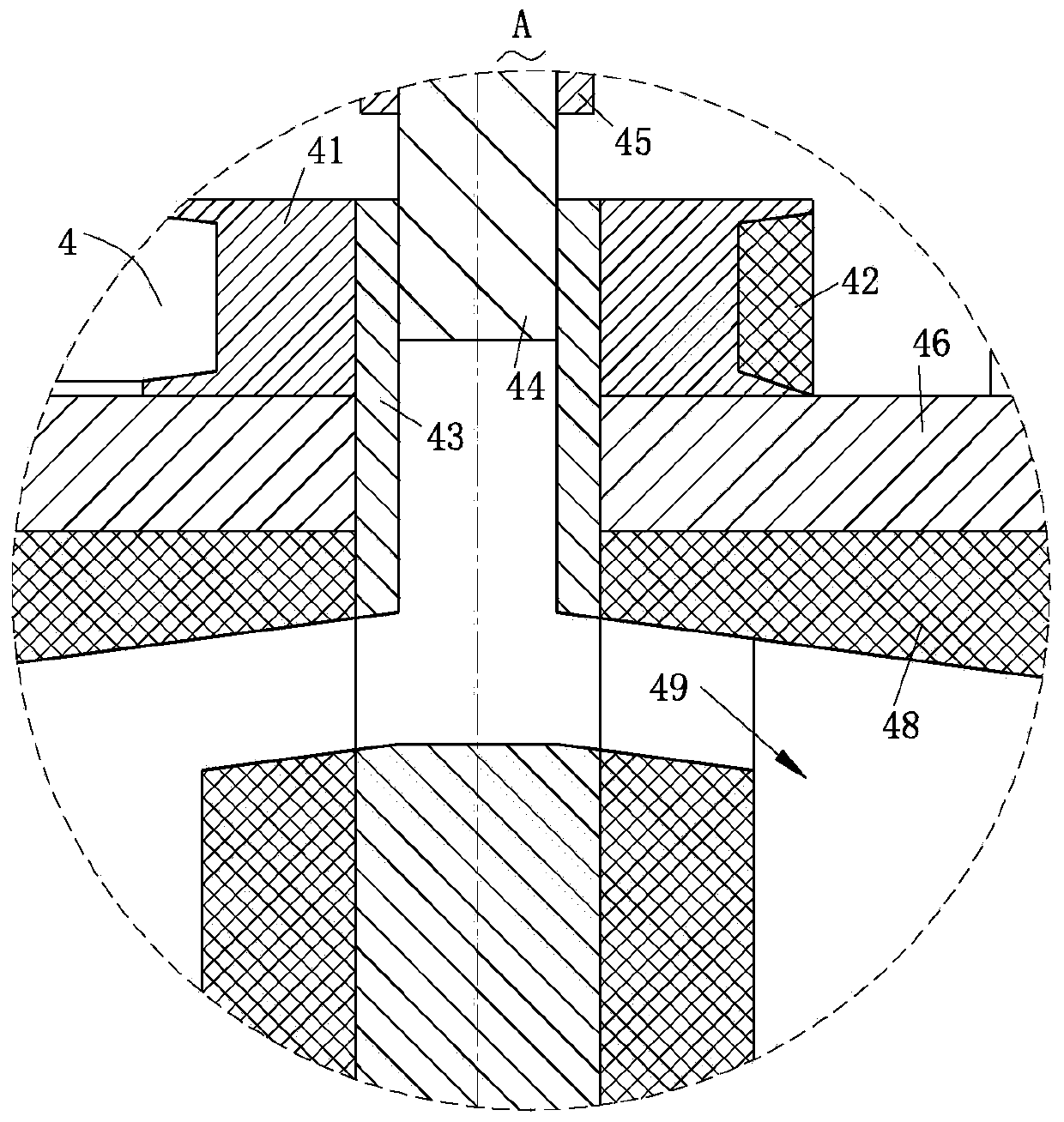

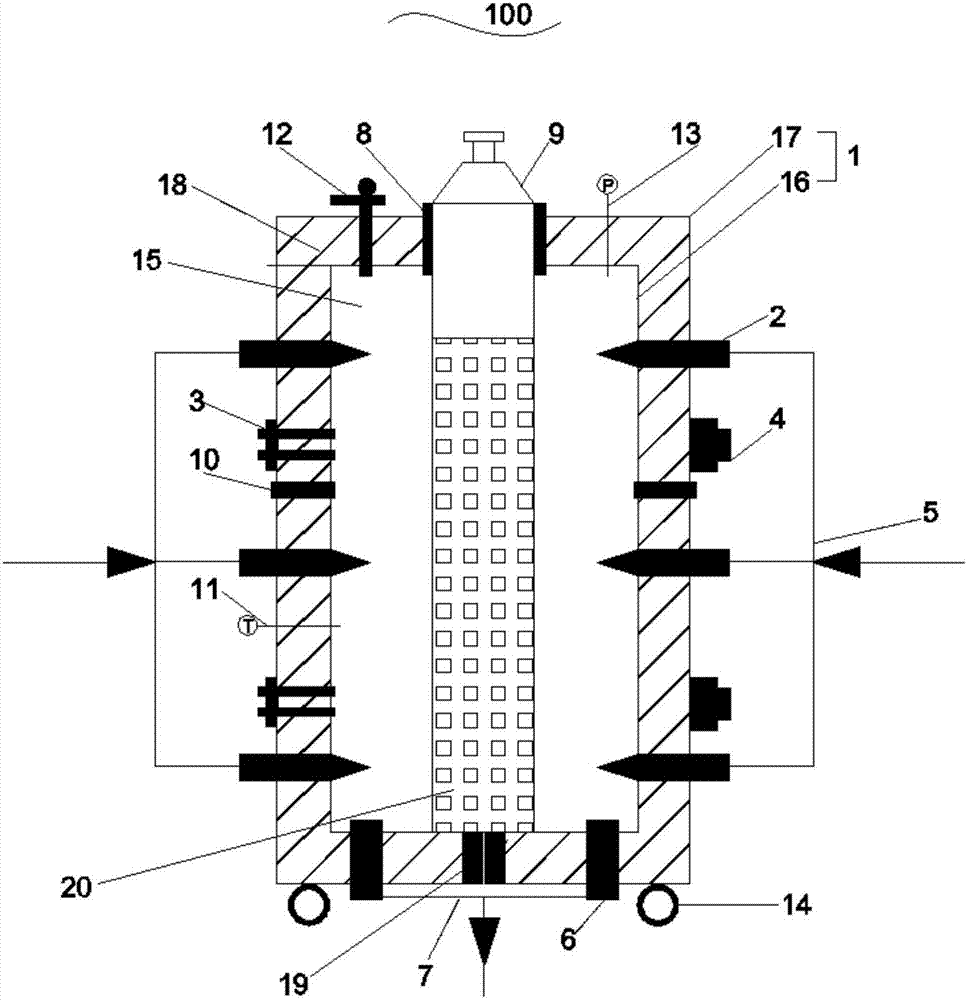

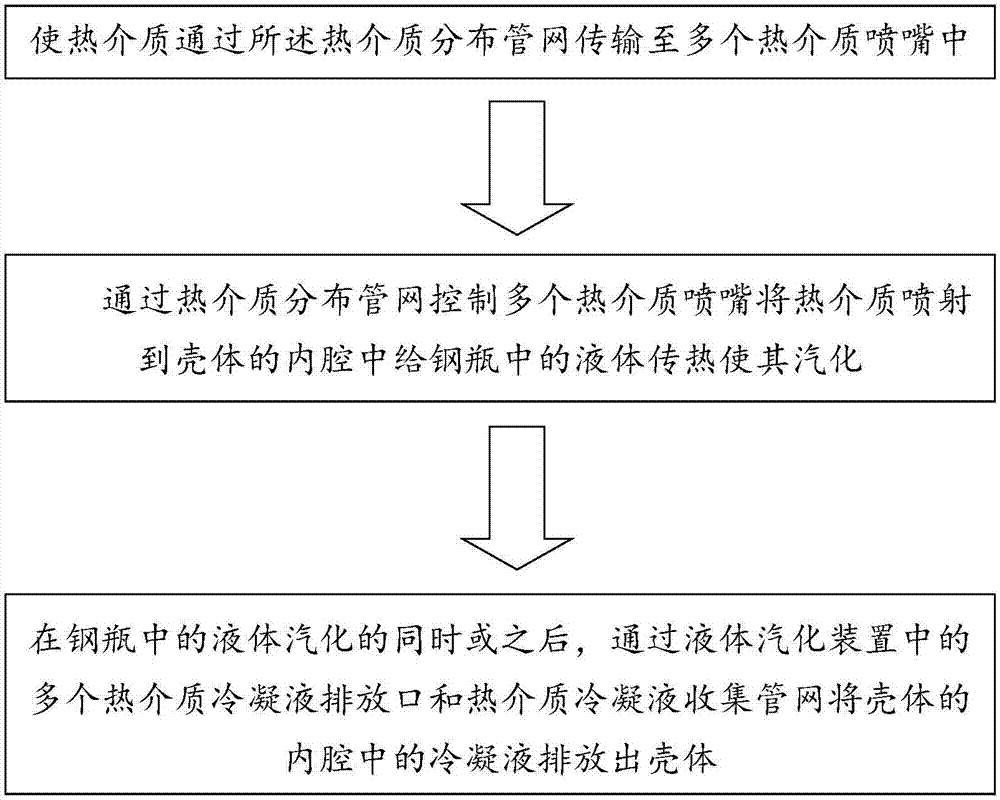

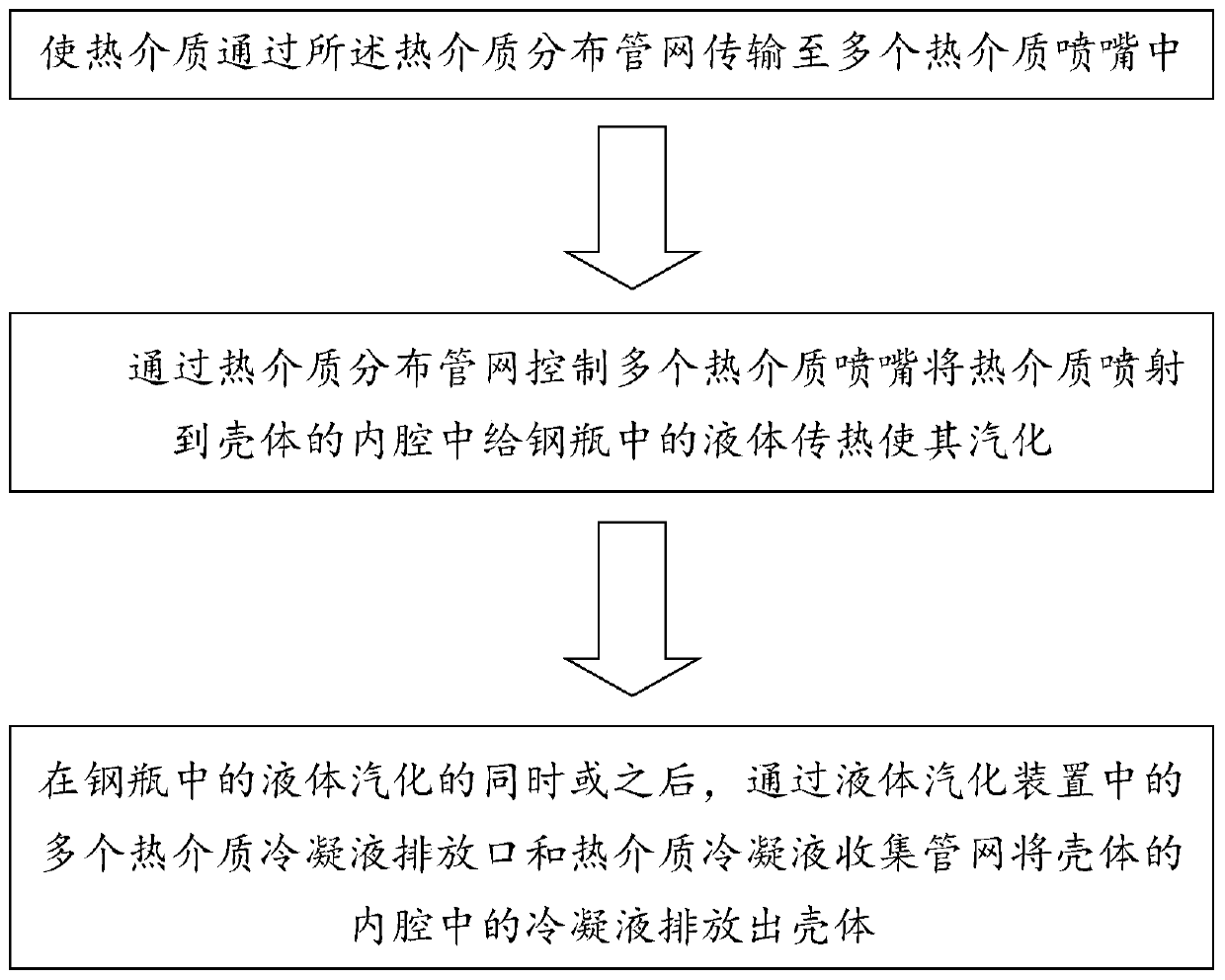

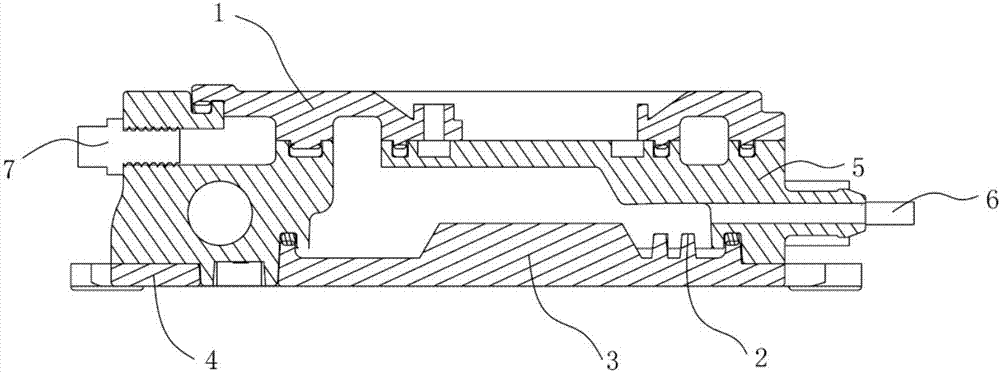

Liquid gasifying device and gasifying method thereof

ActiveCN107314233AReduce frostbiteLow costContainer filling methodsPressure vesselsChemical industryFrost

The invention discloses a liquid gasifying device and a gasifying method thereof and belongs to the field of energy chemical industry. The liquid gasifying device comprises a shell, multiple heat medium nozzles and a heat medium distribution pipe net. The shell is provided with an inner cavity. The inner cavity is used for containing a steel bottle and a heat medium enabling liquid contained in the steel bottle to be gasified. The shell is provided with a shell opening used for placing and taking out the steel bottle. The multiple heat medium nozzles are arranged on the shell and used for injecting the heat medium into the inner cavity of the shell. The heat medium distribution pipe net communicates with the multiple heat medium nozzles and are used for transferring the heat medium to the multiple heat medium nozzles and controlling the injection amount and the injection speed of the multiple heat medium nozzles. The liquid gasifying device and the gasifying method thereof have the beneficial effects of being capable of improving use efficiency of the heat medium and gasifying efficiency of liquid, being capable of reducing frost damage to a pipeline and equipment from liquid, and thus prolonging the service life of the equipment. The liquid gasifying device and the gasifying method thereof improve responsiveness and precision of liquid to temperature in the gasifying process.

Owner:TAIYUAN UNIV OF TECH

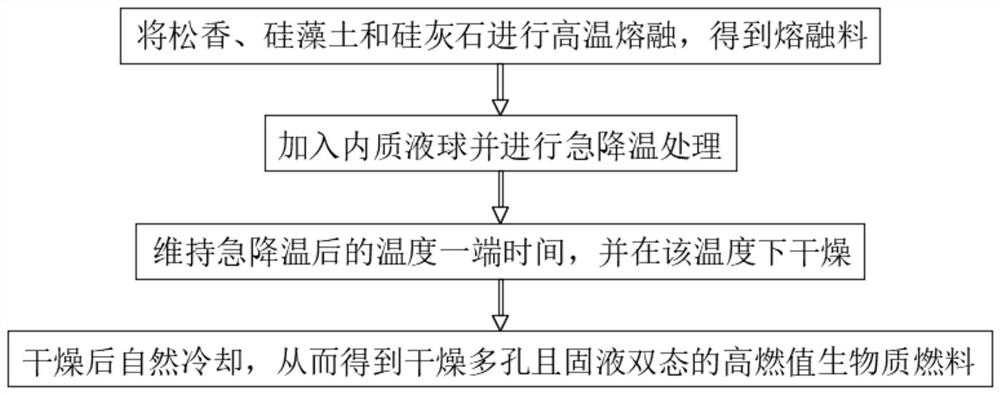

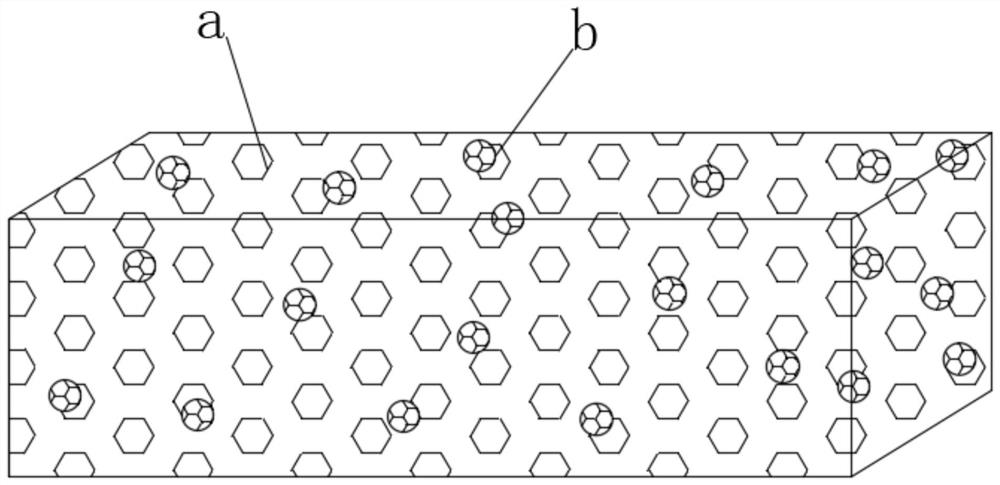

A kind of solid-liquid two-state high combustion value biomass fuel preparation method

The invention discloses a method for preparing a solid-liquid two-state high-burning value biomass fuel, which belongs to the field of biomass fuels. It is a preparation method for a solid-liquid two-state high-burning value biomass fuel. The ball and the molten material are subjected to rapid cooling treatment. Due to the high temperature, water and light oil will vaporize rapidly. After vaporization, the gaseous water and light oil will overflow to the outside. On the one hand, porous holes will be formed inside the molten material. , the vaporized light oil will adhere to the inner wall of the formed hole, so that when it burns, its interior can also fully contact with oxygen. Due to the flammability of light oil, the combustion value of this biomass fuel can be effectively improved, effectively Reduce the waste of fuel caused by incomplete combustion. At the same time, the overflow of liquid combustion accelerant during the combustion process can add combustion accelerant to the interior of the biomass fuel during the combustion process, thereby further increasing the internal combustion rate and increasing the combustion value.

Owner:昌鎏源源新能源科技有限公司

Method and device for vaporizing hydrogen chloride in tail gas in polycrystalline silicon production

ActiveCN102039082BGood vaporization effectImprove the effect of energy saving and consumption reductionDispersed particle separationPhysical chemistryHydrogen chloride

The invention discloses a method and a device for vaporizing hydrogen chloride in tail gas in polycrystalline silicon production. The method is characterized in that: low-temperature hydrogen chloride liquid separated from the top of a hydrogen chloride separating tower exchanges heat with high-temperature chlorosilane liquid output from the bottom of the hydrogen chloride separating tower through heat exchange equipment, so that the low-temperature hydrogen chloride liquid absorbs the heat and is completely vaporized, the temperature of high-temperature chlorosilane is reduced, and chlorosilane serving as low-temperature absorption liquid enters an absorption tower to continuously absorb the hydrogen chloride in the tail gas. The device comprises a hydrogen chloride condensation storage tank, a heat exchanger and a demister, wherein a chlorosilane storage tank is arranged below the heat exchanger and connected with the heat exchanger. Heat quantity and cold quantity in a tail gas recovery system are mutually converted, so that energy is fully utilized and saved.

Owner:XINTE ENERGY

Liquid vaporization device and vaporization method thereof

ActiveCN107314233BReduce frostbiteLow costContainer filling methodsPressure vesselsChemical industryFrost

Owner:TAIYUAN UNIV OF TECH

Steam mop boiler

InactiveCN107536572ASimple structureIncrease vaporization areaCarpet cleanersFloor cleanersSteam mopVaporization

The invention provides a steam mop boiler, which includes an upper casing, a heating plate, a boiler body, a temperature detection device and a heating tube; one end of the boiler body is provided with a water inlet, and the other end is provided with a steam outlet; the heating tube is connected to the The boiler body is directly die-casted; the upper shell and the boiler body are clamped and fixed; the temperature detection device is arranged on one side of the boiler body; the heating plate is arranged in the boiler body. The invention has the advantages of simple structure, large vaporization area and good vaporization effect.

Owner:YUYAO JIJIA ELECTRICAL APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com