Ultra-high purity gas heat exchanger and implementation method thereof

A pure gas and heat exchanger technology, applied in the field of ultra-high-purity gas heat exchangers, can solve the problems of low production efficiency, short working time, difficult temperature control, etc., and achieve high production efficiency, stable vaporization and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

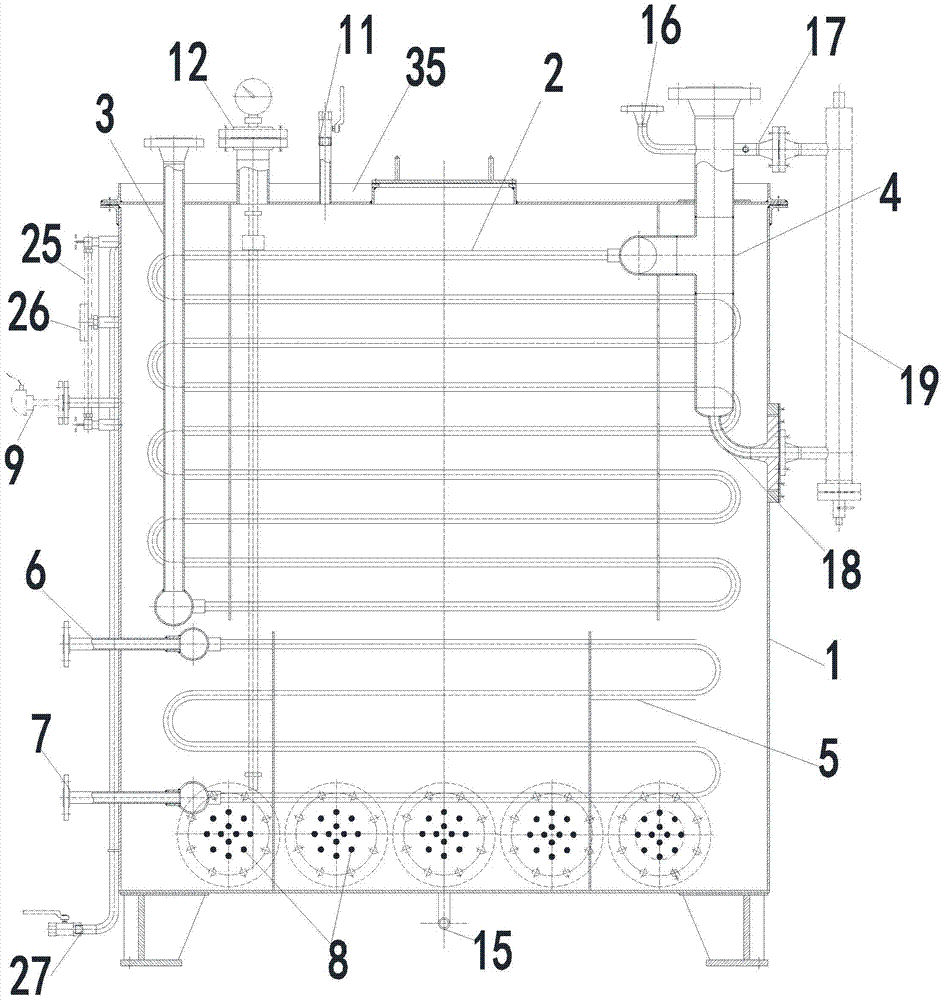

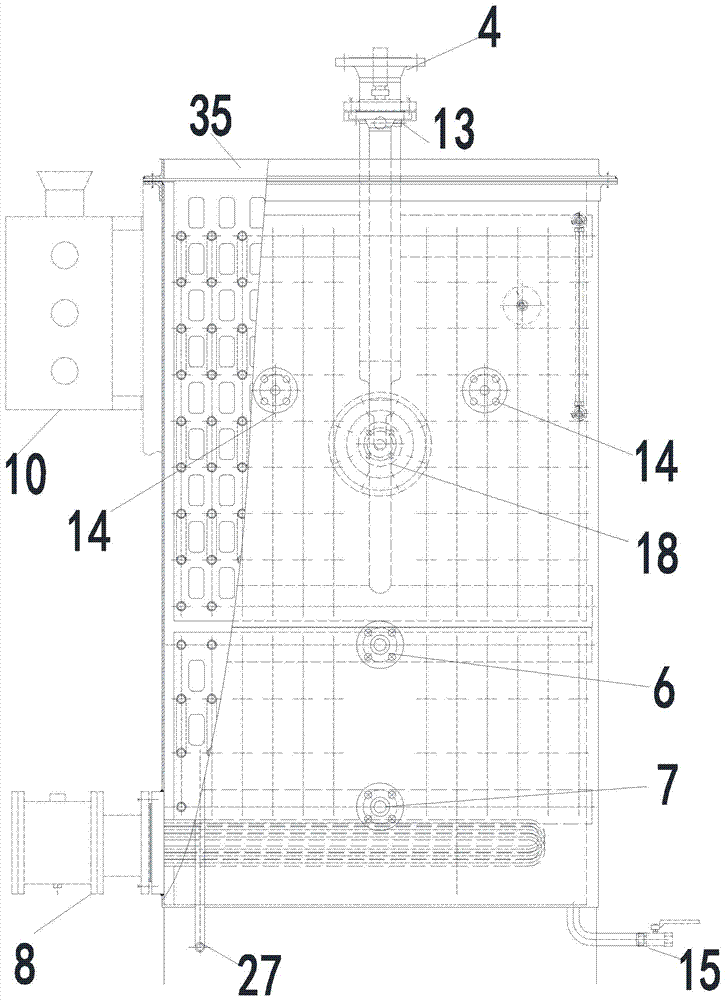

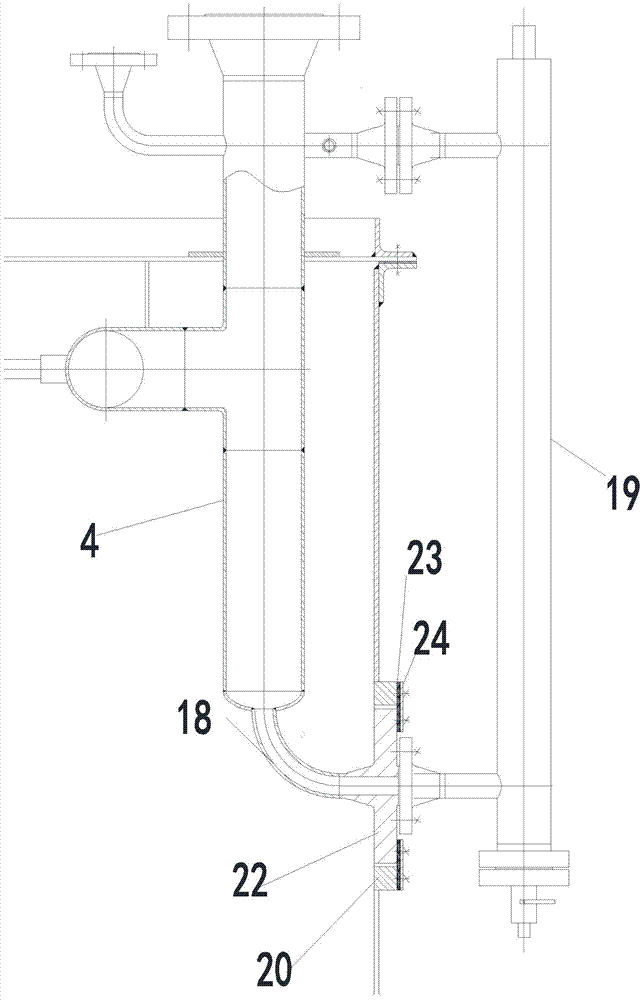

[0047] Such as Figure 1~5 As shown, the ultra-high-purity gas heat exchanger includes a shell 1, and the shell 1 is filled with water. The left heat exchange tube support fixing plate and the right heat exchange tube support fixing plate are respectively arranged on the left and right sides of the shell 1, and the left heat exchange tube is supported and fixed. The ammonia circulation coil assembly 2 is arranged between the plate and the right heat exchange tube support fixing plate, the bottom inlet of the ammonia circulation coil assembly 2 is connected to the feed pipe 3, and the top outlet of the ammonia circulation coil assembly 2 is connected to the discharge pipe 4 A hot water circulation coil assembly 5 is arranged below the ammonia circulation coil assembly 2, the upper end of the hot water circulation coil assembly 5 is a hot water inlet 6, and the lower end of the hot water circulation coil assembly 5 is a hot water outlet 7, in this embodiment The hot water inlet ...

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that there are 6 groups of plug-in electric heaters 8 in this embodiment, and they are arranged in an isosceles triangle shape. and the lower semicircle isolation cover 29, the upper semicircle isolation cover 28 and the lower semicircle isolation cover 29 are evenly provided with a number of through holes 30, the horizontal distance between the inner end of the plug-in electric heater 8 and the inner surface of the shell 1 is 130-150 mm, and the shell 1 An insulating layer 35 is provided on the outer surface.

[0068] The plug-in electric heaters 8 in the step (4) are 6 groups and arranged in an isosceles triangle; when the collected temperature is lower than 30°C, the PID controller controls 6 groups of plug-in electric heaters after calculation 8. Simultaneous heating work; when the collected temperature is between 30°C and 60°C, the PID controller performs calculations to control the top 1 group in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com