Gasoline vaporization device

A vaporization device and gasoline technology, which is applied to fuel heat treatment devices, charging systems, engine components, etc., can solve the problems of reducing the thermal efficiency of the engine, increasing the exhaust gas of the engine, and preventing the microscopic diameter of the oil mist from being small, so as to achieve a stable vaporization effect. , the effect of maintaining a stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

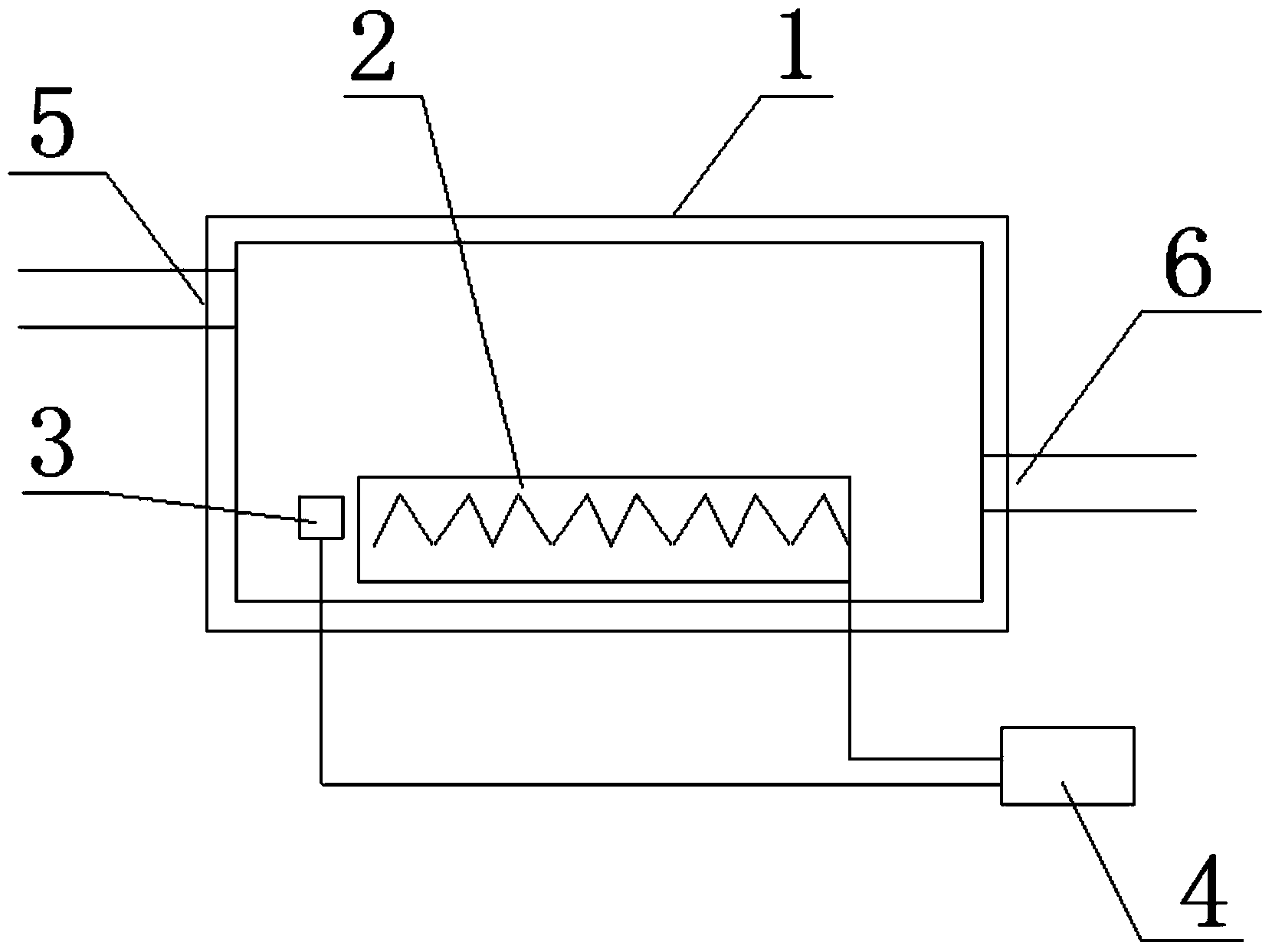

[0028] Example 1: Such as figure 1 As shown, gasoline enters the vaporization tank 1 from the pump oil pipe interface 6, and the gasoline is quickly vaporized under the heating action of the heater 2, and the vaporized gasoline enters the fuel injector from the fuel injection nozzle pipe interface 5; the temperature sensor 3 induces vaporization The temperature in the box 1 is transmitted to the temperature controller 4, and the temperature controller 4 regulates the power supply of the heater 2 according to the temperature sensor signal of the temperature sensor 3. If the temperature sensor signal shows the temperature in the vaporization box 1 If the temperature is too high, the temperature controller 4 stops supplying power to the heater 2. If the temperature sensing signal shows that the temperature in the vaporization box 1 is too low, the temperature controller 4 stops supplying power to the heater 2, thereby regulating the temperature in the vaporization box 1. Maintain s...

Embodiment 2

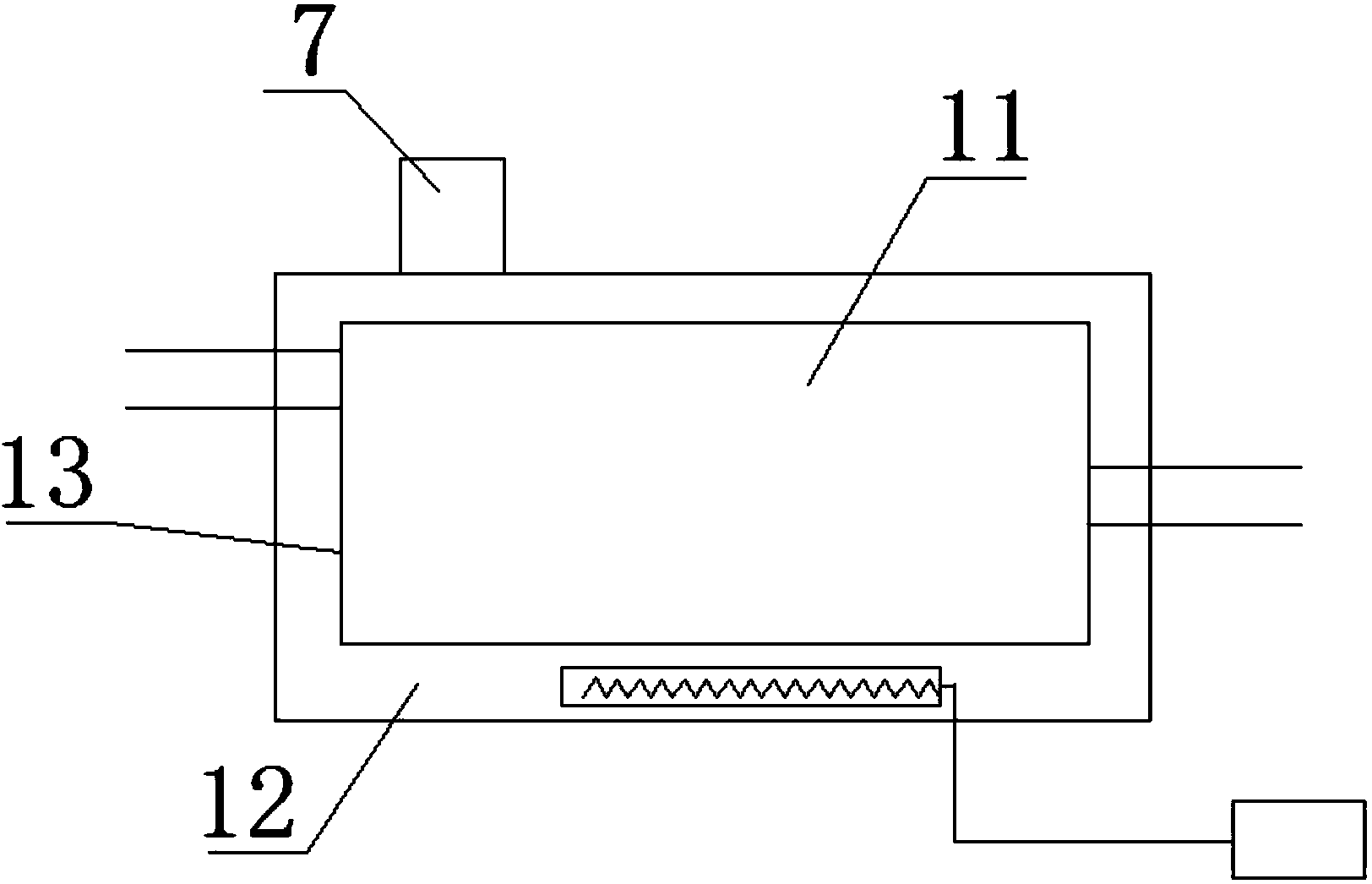

[0029] Embodiment 2: Gasoline is input into the first cavity 11 from the pump oil pipe interface 6, and the second cavity 12 is filled with a liquid with a larger specific heat capacity, and the liquid in the second cavity 12 is heated by the heater 2 to be heated The latter liquid transfers the heat to the first cavity 11 through the isolation plate 13, the gasoline is heated and vaporized in the first cavity 11. The vaporized gasoline enters the fuel injection nozzle from the fuel injection nozzle pipe interface 5, and the air pressure valve 7 can adjust the first cavity 11 The air pressure in the second cavity 12 makes the vaporization efficiency of gasoline high and stable, so that the combustion of gasoline is sufficient and safe, and the purpose of fuel saving is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com