Device and method for supplying fuel or reducing agent, and plasma torch

A plasma and fuel supply technology, applied in the field of plasma torches, can solve problems such as the reduction of energy plasma density, and achieve the effects of suppressing the generation of soot, reducing energy consumption, and improving contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

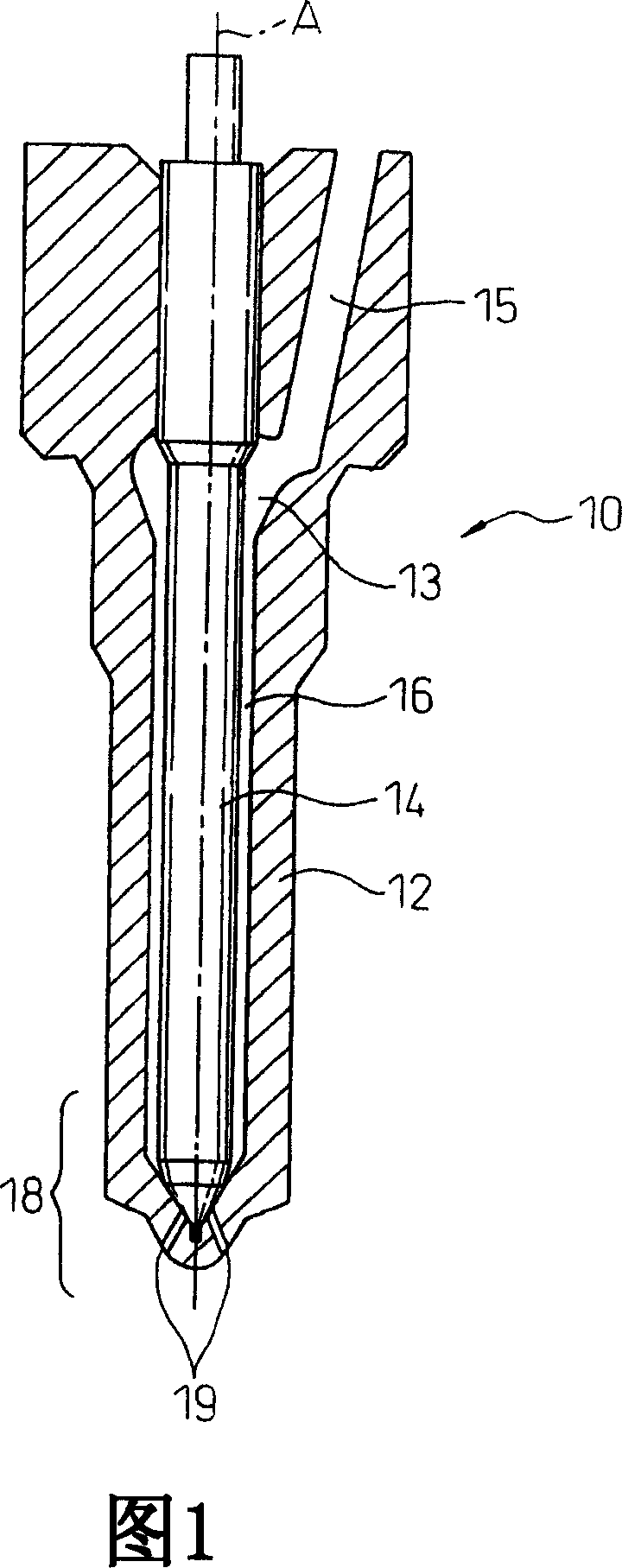

[0052] The present invention will be specifically described below based on the embodiments shown in the drawings, each of which is a diagram showing the principle of the present invention, but the present invention is not limited to these embodiments.

[0053]

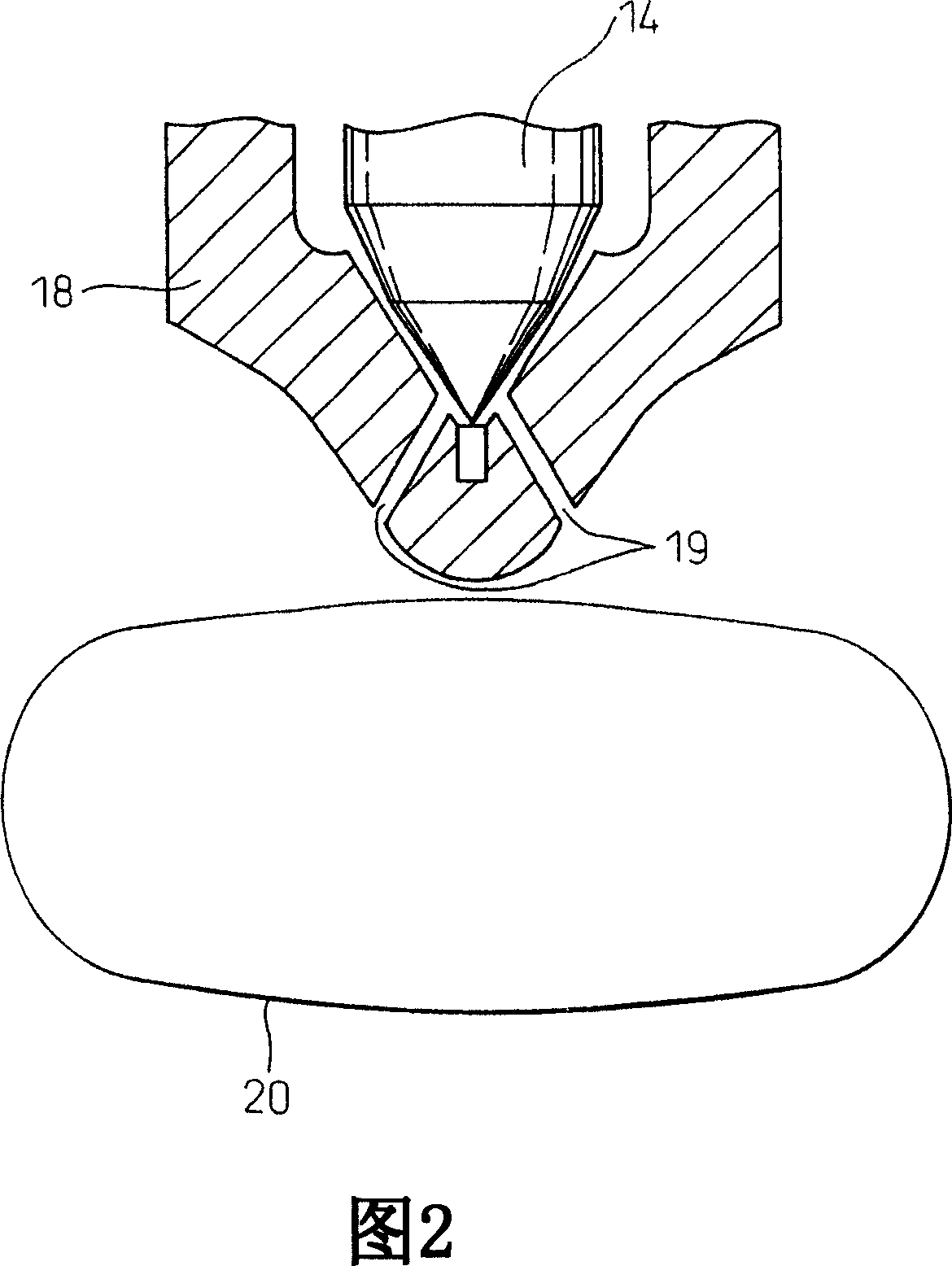

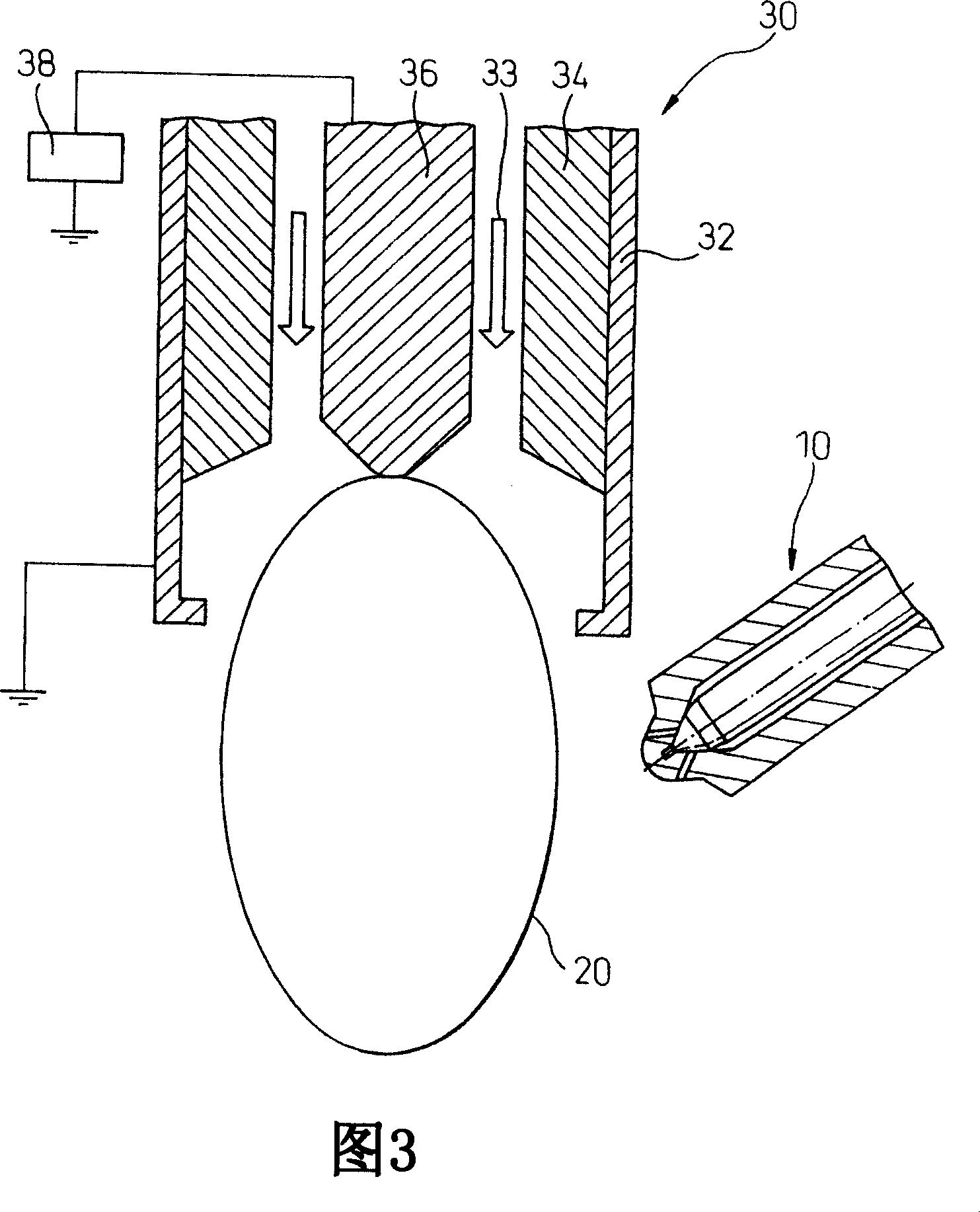

[0054] The device for supplying fuel or reducing agent of the present invention can be schematically described by referring to FIG. 2 .

[0055] In the device for supplying fuel or reducing agent of the present invention, the fuel or reducing agent injected from the injector can be at least partially converted into plasma. As shown in FIG. 2 , this can be accomplished by injecting fuel or reducing agent from injection ports 19 located at the nozzle tip portion 18 into the plasma region, in particular, the plasma region 20 near the injection ports 19 .

[0056] The plasma region can be formed by converting gas such as nitrogen, air, argon, and recirculated exhaust gas into plasma, and then ejecting (supplying) the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com