Rotary-type sugar crop vaporizing device

A vaporization device and rotary technology, applied in confectionery, confectionery industry, chemical instruments and methods, etc., can solve problems such as uneven heating, uneven heating of sugar material, easy leakage of sugar material heating, etc., and shorten the processing cycle , reduce energy consumption, good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

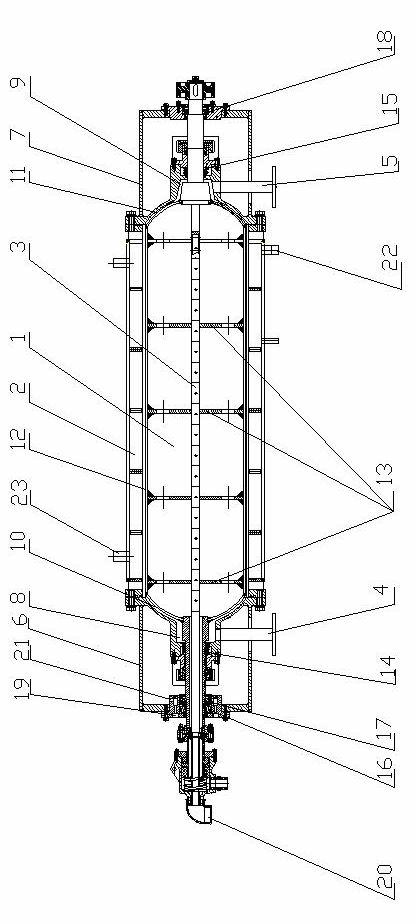

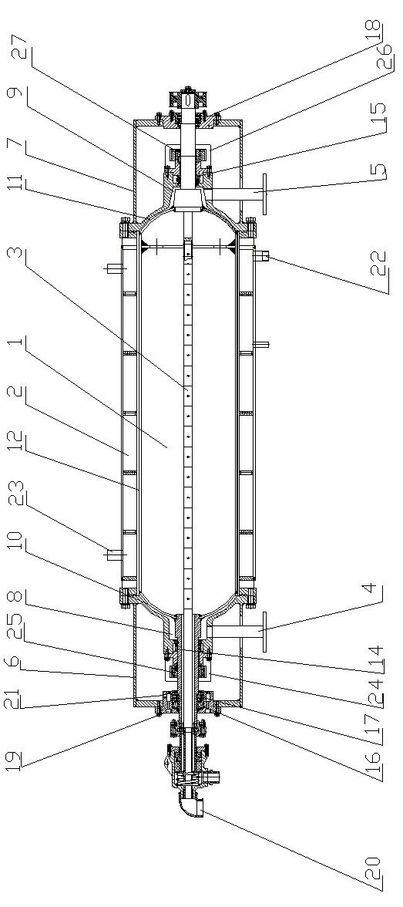

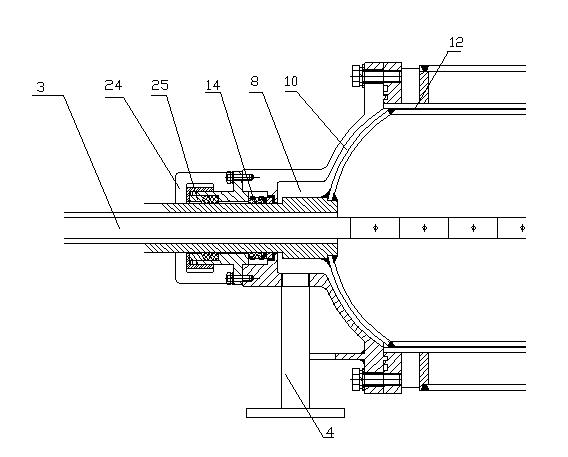

[0027] The rotary sugar vaporization device includes an inner cylinder 1, an outer cylinder 2, a driving device, a main shaft 3, a sugar inlet 4 and a sugar outlet 5 arranged on the outer cylinder 2, and the main shaft 3 runs through the inner cylinder 1 and the outer cylinder 2 Connected with the driving device and drives the inner cylinder 1 to rotate, the inner cylinder 1 is located in the outer cylinder 2, forming the first annular gap 8, the second annular gap 10, the third annular gap 12, the fourth annular gap 11 and the fifth annular gap 9 , the spacing of the first annular gap 8, the second annular gap 10 and the third annular gap 12 decreases in turn, the spacing of the fourth annular gap 11 and the second annular gap 10 is the same, the fifth annular gap 9 and the second annular gap The spacing of the gaps 8 is the same.

Embodiment 2

[0029] The rotary sugar vaporization device includes an inner cylinder 1, an outer cylinder 2, a driving device, a main shaft 3, a sugar inlet 4 and a sugar outlet 5 arranged on the outer cylinder 2, and the main shaft 3 runs through the inner cylinder 1 and the outer cylinder 2 Connected with the driving device and drives the inner cylinder 1 to rotate, the inner cylinder 1 is located in the outer cylinder 2, forming the first annular gap 8, the second annular gap 10, the third annular gap 12, the fourth annular gap 11 and the fifth annular gap 9 , the spacing of the first annular gap 8, the second annular gap 10 and the third annular gap 12 decreases in turn, the spacing of the fourth annular gap 11 and the second annular gap 10 is the same, the fifth annular gap 9 and the second annular gap The spacing of the gaps 8 is the same. The pitch of the third annular gap 12 is 1.4mm.

Embodiment 3

[0031] The rotary sugar vaporization device includes an inner cylinder 1, an outer cylinder 2, a driving device, a main shaft 3, a sugar inlet 4 and a sugar outlet 5 arranged on the outer cylinder 2, and the main shaft 3 runs through the inner cylinder 1 and the outer cylinder 2 Connected with the driving device and drives the inner cylinder 1 to rotate, the inner cylinder 1 is located in the outer cylinder 2, forming the first annular gap 8, the second annular gap 10, the third annular gap 12, the fourth annular gap 11 and the fifth annular gap 9 , the spacing of the first annular gap 8, the second annular gap 10 and the third annular gap 12 decreases in turn, the spacing of the fourth annular gap 11 and the second annular gap 10 is the same, the fifth annular gap 9 and the second annular gap The spacing of the gaps 8 is the same. The pitch of the third annular gap 12 is 1.5mm. The main shaft 3 is a hollow cylinder, and a section of the main shaft located in the inner cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com