Environmental-friendly chimney device for removing stains of inner wall in manner of heating and circulating water vapor by waste gas afterheat

A heating cycle and smoke exhaust device technology, applied in exhaust gas devices, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of falling, difficult to clean the inside of the equipment, cumbersome activated carbon replacement process, etc. The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

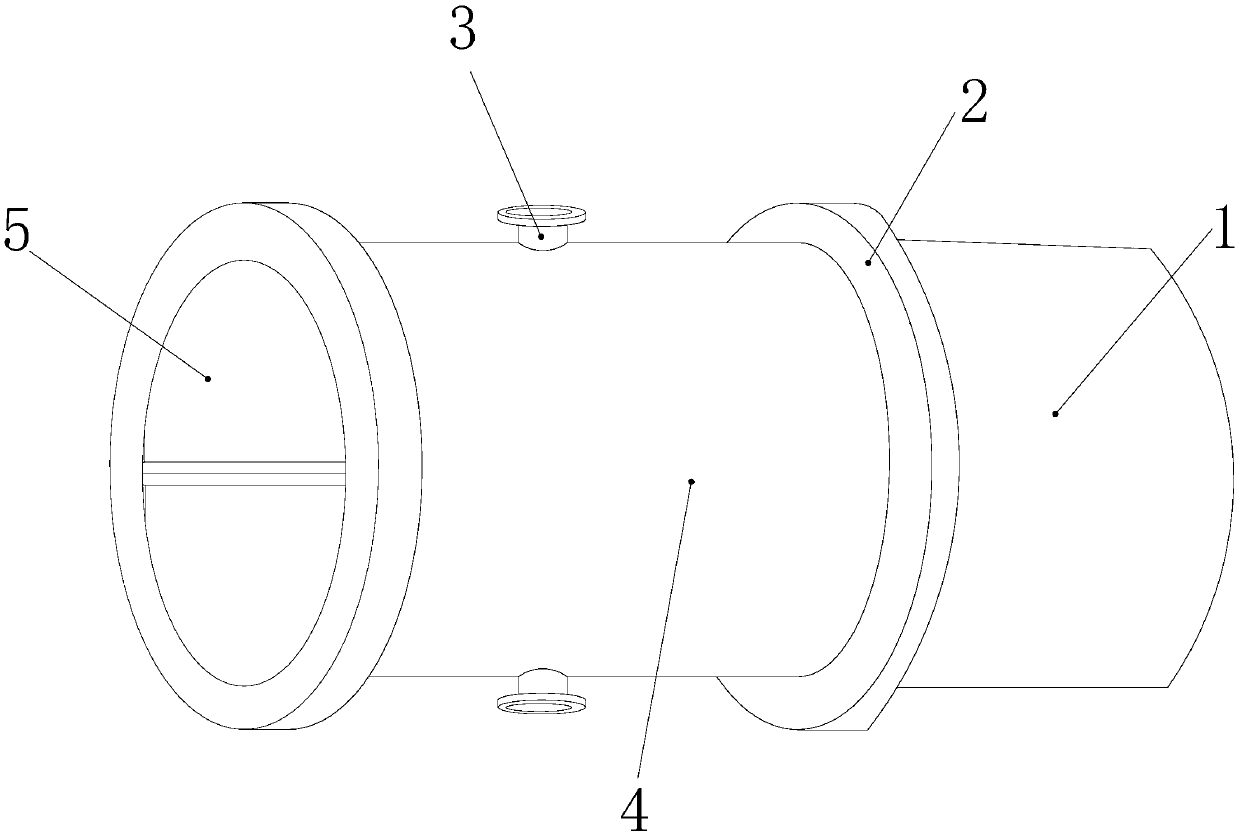

[0025] see figure 1 , the present invention provides an environmentally friendly smoke exhaust pipe device that uses waste heat of exhaust gas to heat circulating water vapor for decontamination of the inner wall. The movable smoke exhaust device 5 is located inside the device housing 4 and is fixedly connected to the device housing 4. The water inlet pipe 3 is arranged on the upper end surface of the device housing 4 and connected through the device housing 4. The junction pipe 1 The right side end face of the movable seat 2 is connected with the movable seat 2 at the same time, the movable seat 2 is arranged on the right side of the device housing 4 and is an integral structure with the device housing 4, and the outer end face of the water inlet pipe 3 is provided A flange with multiple bolt holes for connection.

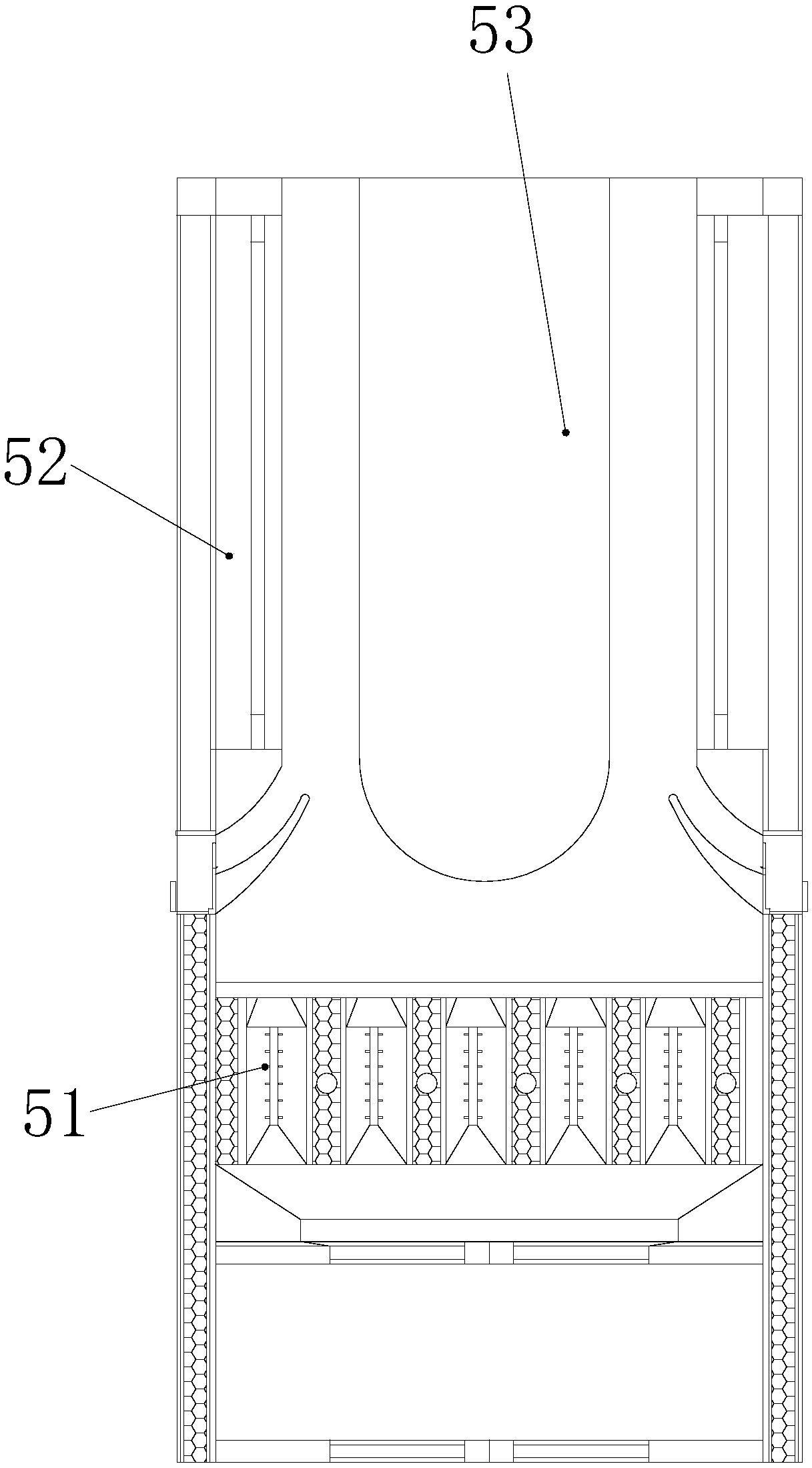

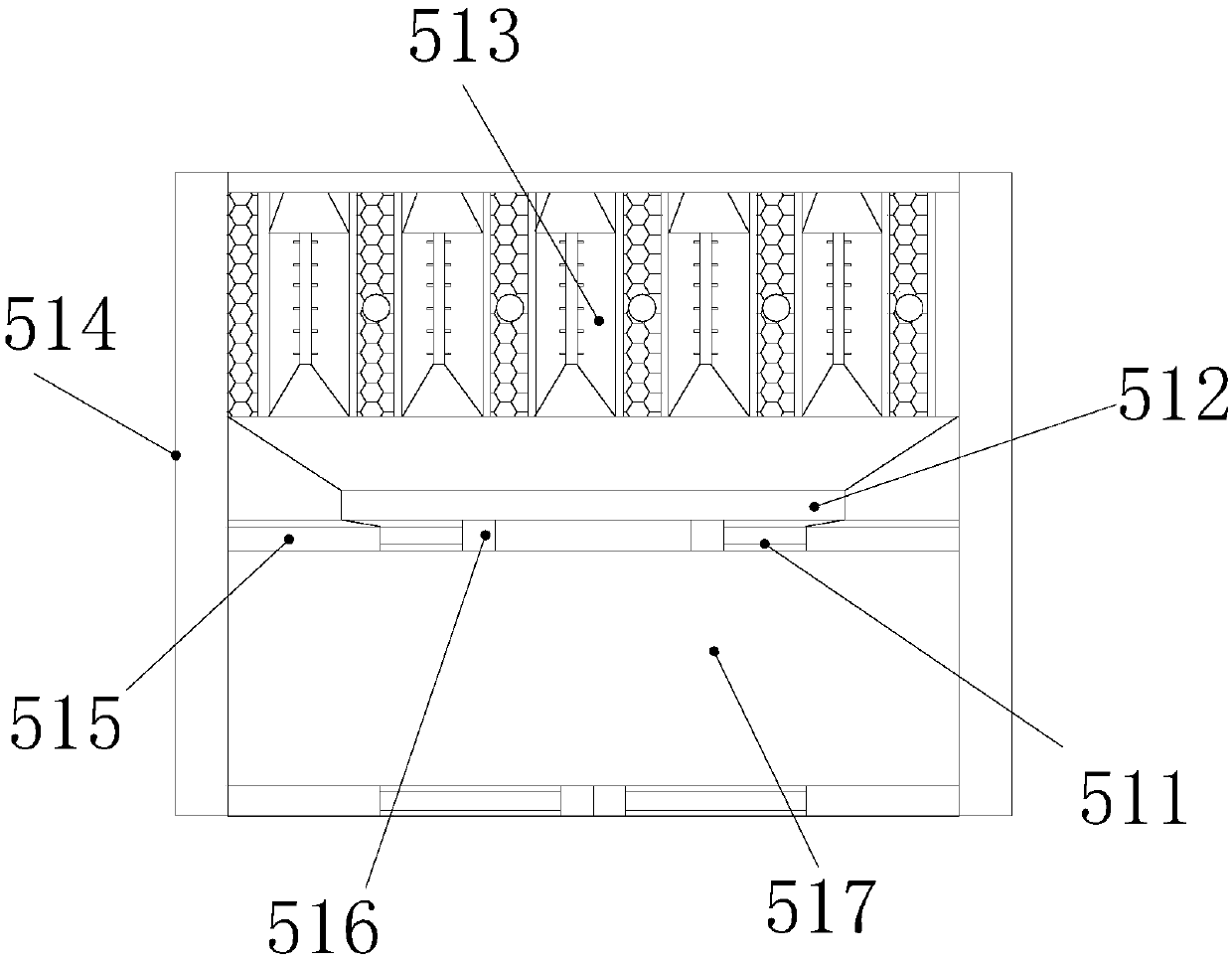

[0026] see figure 2 , the present invention provides an environmentally friendly smoke exhaust device that uses waste heat of exhaust gas to heat circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com