Liquid vaporization device and vaporization method thereof

A vaporization device and liquid technology, which is applied in container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve the problems of inability to meet downstream sections, frost and ice, and blocked pipelines, and achieves low cost, The effect of stable vaporization and controllable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

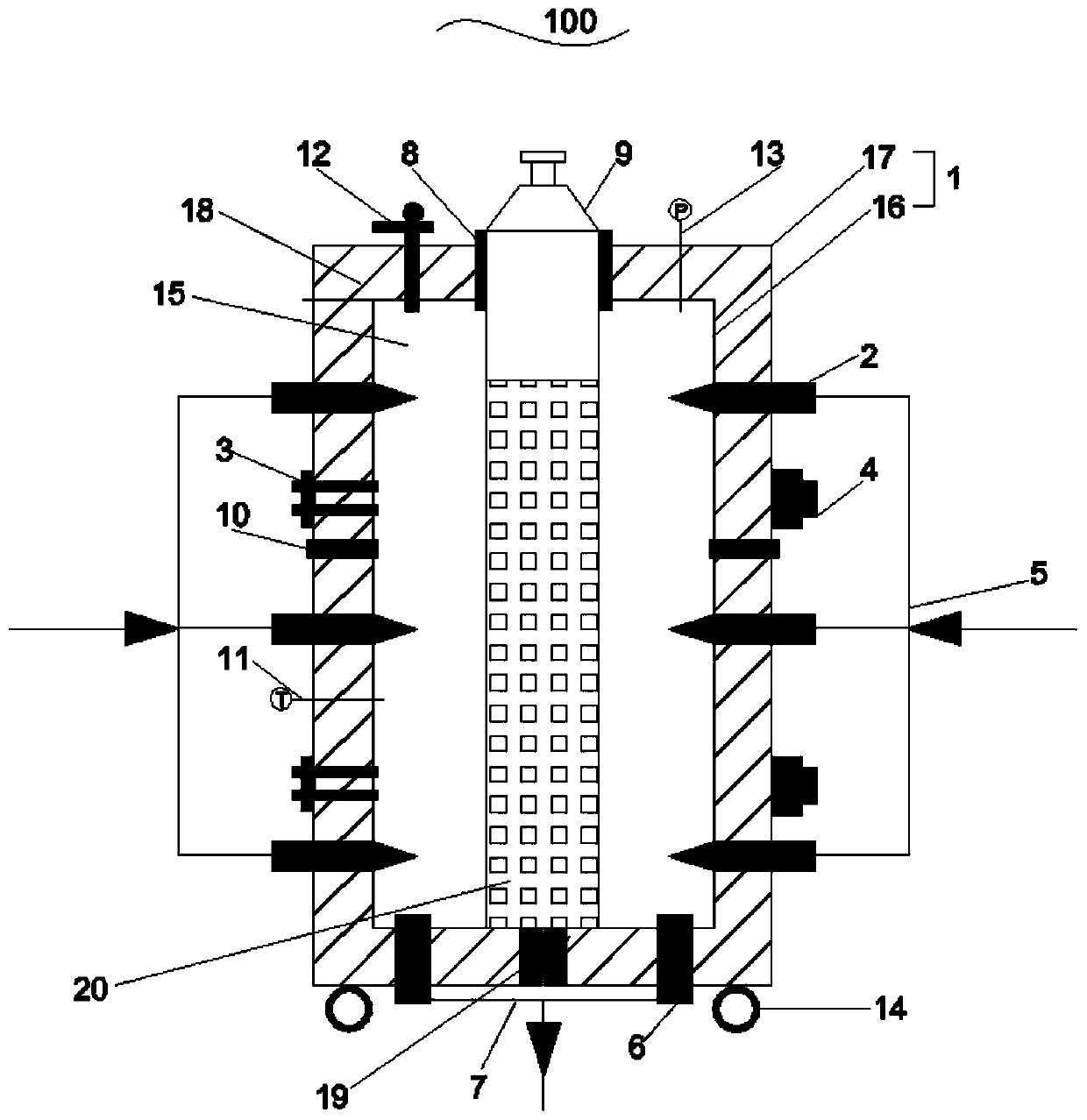

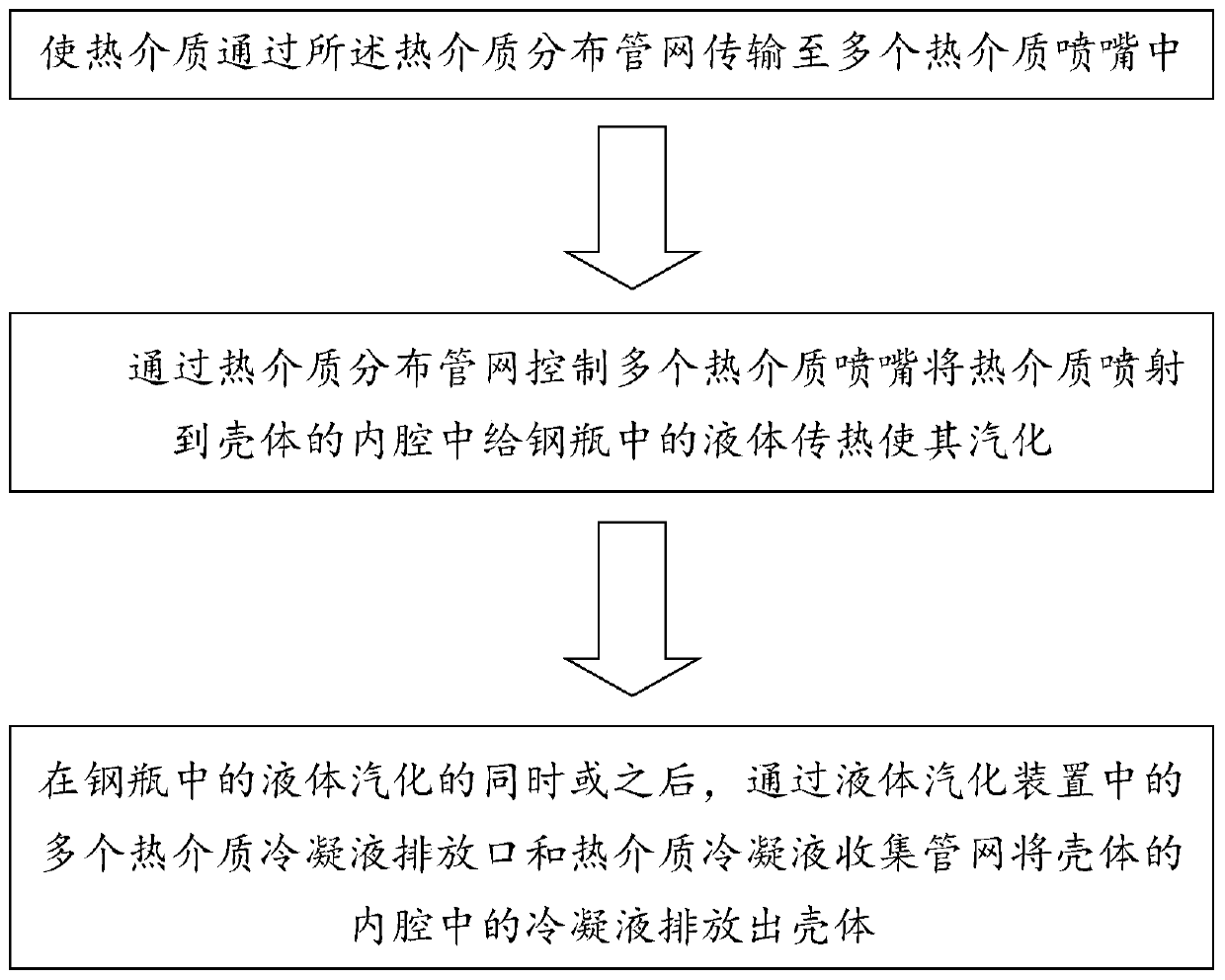

[0043] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0044] The liquid 20 contained in the cylinder, such as carbon dioxide, liquid methane, liquid nitrogen, liquid oxygen, etc., is a common raw material in industry or experiment, and generally needs to be vaporized before use. The vaporization process is an endothermic process. If the vaporization rate is too fast, the water vapor inside and outside the pipeline will condense and freeze to block the pipeline. If the vaporization rate is too slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com