Patents

Literature

103results about How to "Achieve comprehensive utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

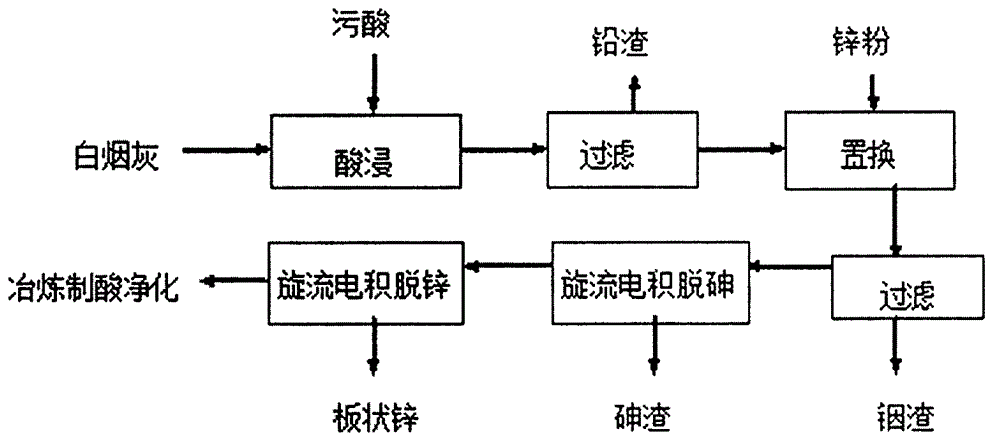

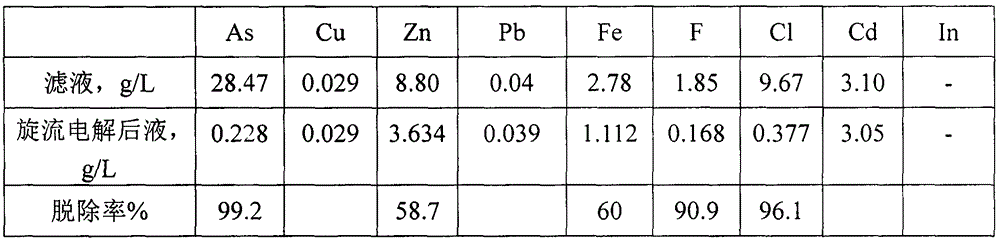

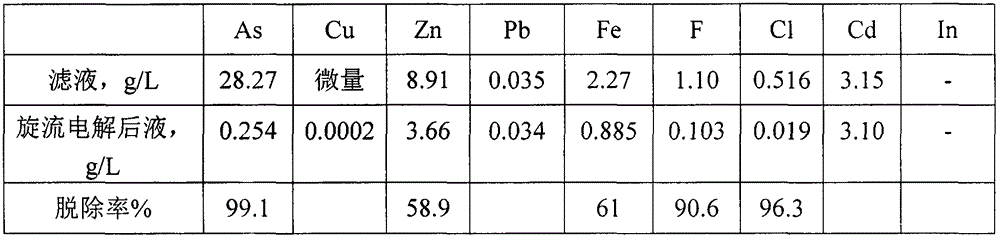

Method of recycling valuable metals from arsenic-containing soot

The invention relates to a method of recycling valuable metals from arsenic-containing soot. The method comprises the following steps: (1) mixing acidic wastewater with white soot, controlling the pH value to 2.5-3.0, performing acid leaching at a temperature of 70-80 DEG C, and filtering to obtain leachate and lead slag; (2) replacing indium for the leachate by using zinc powder, and filtering to obtain indium slag; (3) performing rotational-flow electrodeposition arsenic removal and zinc removal on filtrate in sequence to obtain arsenic slag and zinc slag. The method disclosed by the invention can be used for purifying the acidic wastewater to reach a condition for recycling the acidic wastewater to a smelting acid manufacturing and purifying section, so that the treated acidic wastewater can be directly returned to the acid manufacturing and purifying section, and therefore, the gypsum slag is completely removed to truly achieve the purpose of zero emission. Meanwhile, the method disclosed by the invention can also be used for achieving the treatment of white soot and recycling the valuable metals, so that environmental protection and resource comprehensive utilization are achieved.

Owner:五矿铜业(湖南)有限公司 +3

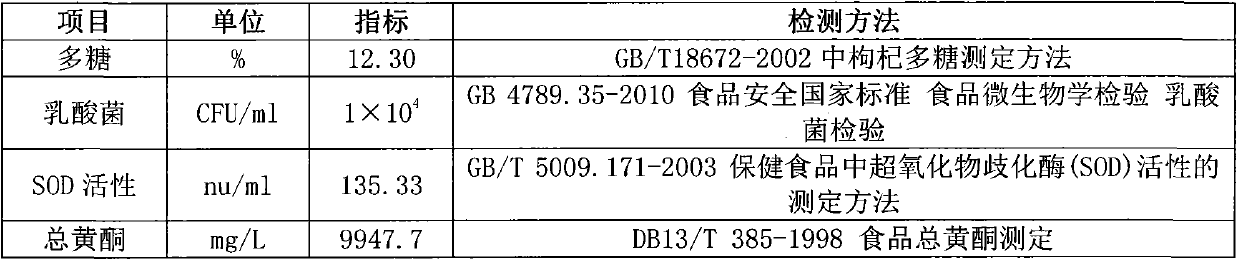

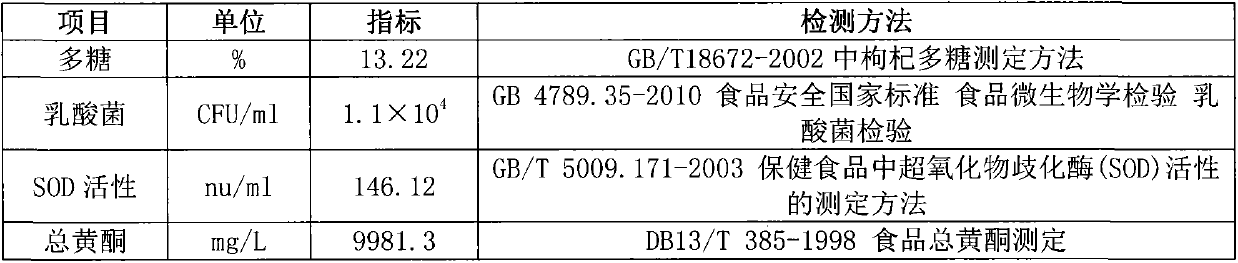

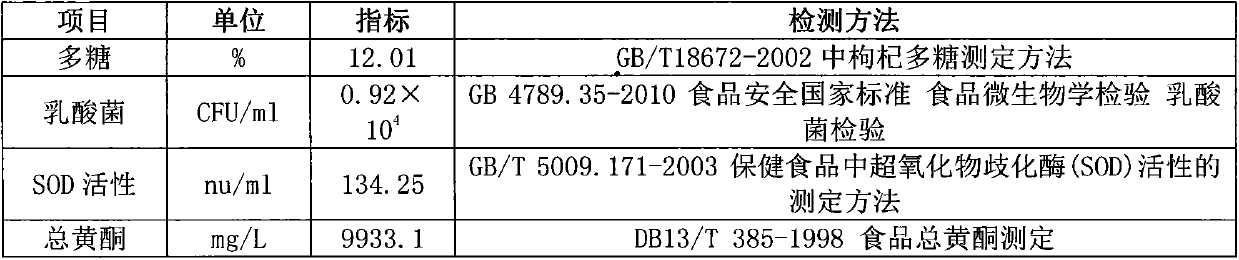

Chinese wolfberry ferment preparation method

InactiveCN104187602AHigh content of active substancesReduce wasteFood preparationLactic acid fermentationFermentation

The invention relates to a Chinese wolfberry ferment preparation method, aims to provide Chinese wolfberry ferment prepared by Chinese wolfberry treatment, enzymolysis, glucose reduction fermentation, lactic acid fermentation, ultrasonic low temperature concentration, blending, drying, crushing and other processes, , the method has the advantages of simple process, less addition agent and no residue, by the use of Chinese wolfberry defective products, the active substance content in the Chinese wolfberry ferment product can be promoted, the waste of resources can be reduced, the purposes of the comprehensive utilization of resources and improvement of the product added value can be achieved, and good economic and environmental benefits are obtained.

Owner:青海柴馥有机枸杞有限公司

Method for pellet formation using steel-making slurry

InactiveCN1594607ARaw material balling performance improvementReduce the requirement of raw material particle sizePellet FormationWater content

The invention relates to a pelletizing method using sludge of steel production and belongs to pelletizing technology in metallurgy field. The method comprises: adjusting sludge concentration to 10-40%, adding 3-10% (weight percentage) sludge in mixture of iron ore powder and bentonite, continuously spraying it in palletizing disk, The advantage of the method : material sphericity is improved greatly. Bentonite usage can reduce greatly in mixture, which promote the pelletizing quality. Pelletizing disk don't take on sandification. Aqueous sludge can minimize the extra water. The enterprise has electric furnace, open-hearth furnace, revolving furnace and pelletizing line can use the method.

Owner:攀钢集团成都钢铁有限责任公司

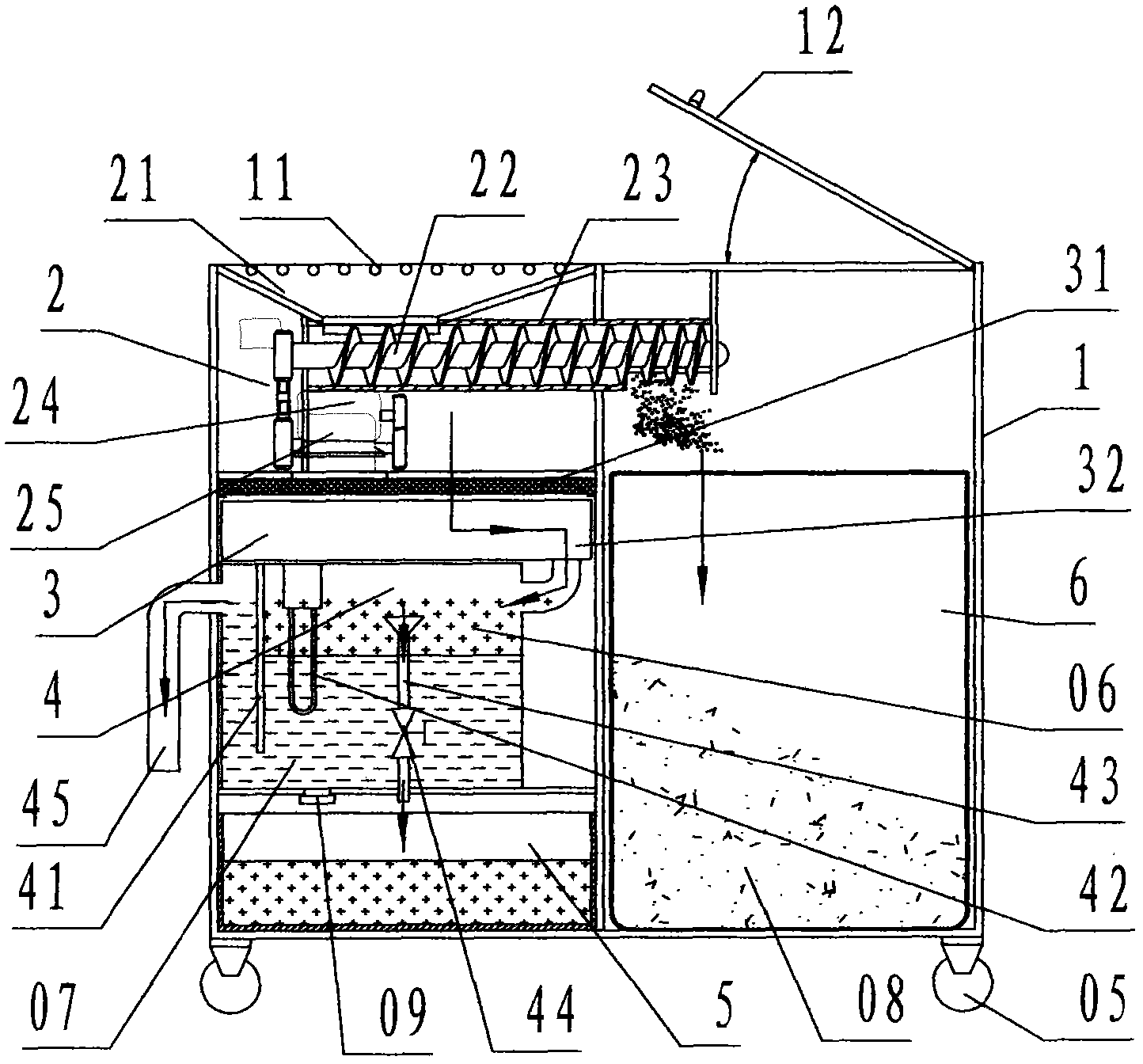

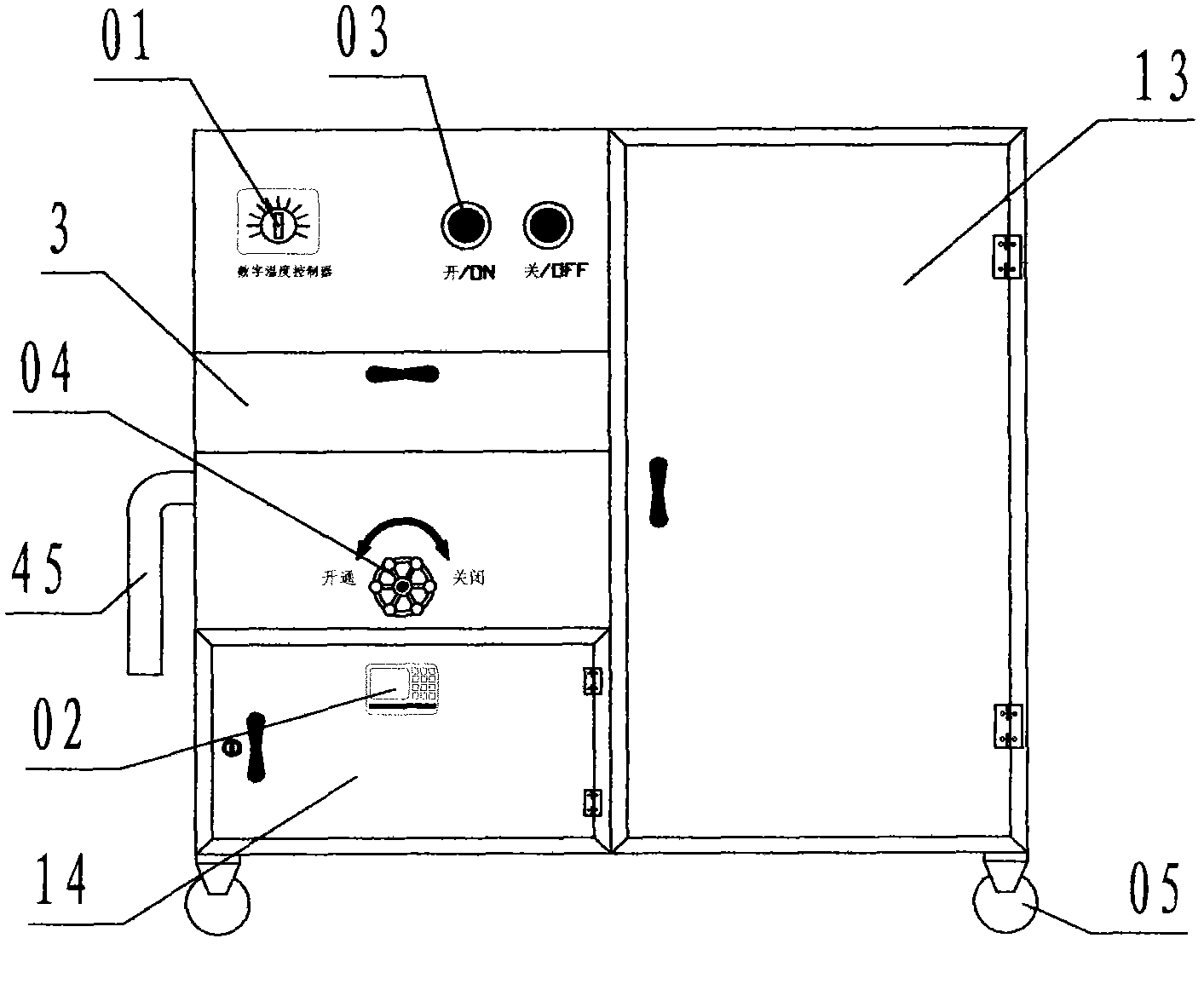

Kitchen food waste disposer for automatically separating oil and water residues

ActiveCN103447282AAvoid condensationGood for cleaning and environmental protectionSolid waste disposalLiquid separationLitterFuel tank

The invention discloses a kitchen food waste disposer for automatically separating oil and water residues. The kitchen food waste disposer comprises a housing (1), a residue-liquid separator (2), a water pan drawer (3), an oil-water separation tank (4), an oil storage tank (5) and a dry material tank (6). According to the invention, the kitchen food waste disposer composed of the components is adopted. The housing is provided with a grate bar inlet, an upper shaking cover, a dry material bin door, an oil tank bin door and castors. The residue-liquid separator is composed of a hopper, a threaded rod, a hollow charging barrel, a motor and a speed reducer, wherein leaking holes are uniformly distributed in the hollow charging barrel. The water pan drawer is composed of a water pan and a filter screen plate, and the oil-water separation tank is provided with an oil baffle plate, an electrical heated pipe, an oil exit pipe, an oil pipe valve and a water drainage pipe. Through a technical scheme that kitchen food wastes are automatically separated into oil, water and solid residues so as to be transformed into available resources, the kitchen food waste disposer overcomes the defects of polluting environment and obstructing sewers in the prior art and achieves the purposes of comprehensive utilization, cleanness, environmental protection and unobstructed sewers.

Owner:NINGBO JIADUOMEI MACHINERY SCI & TECH

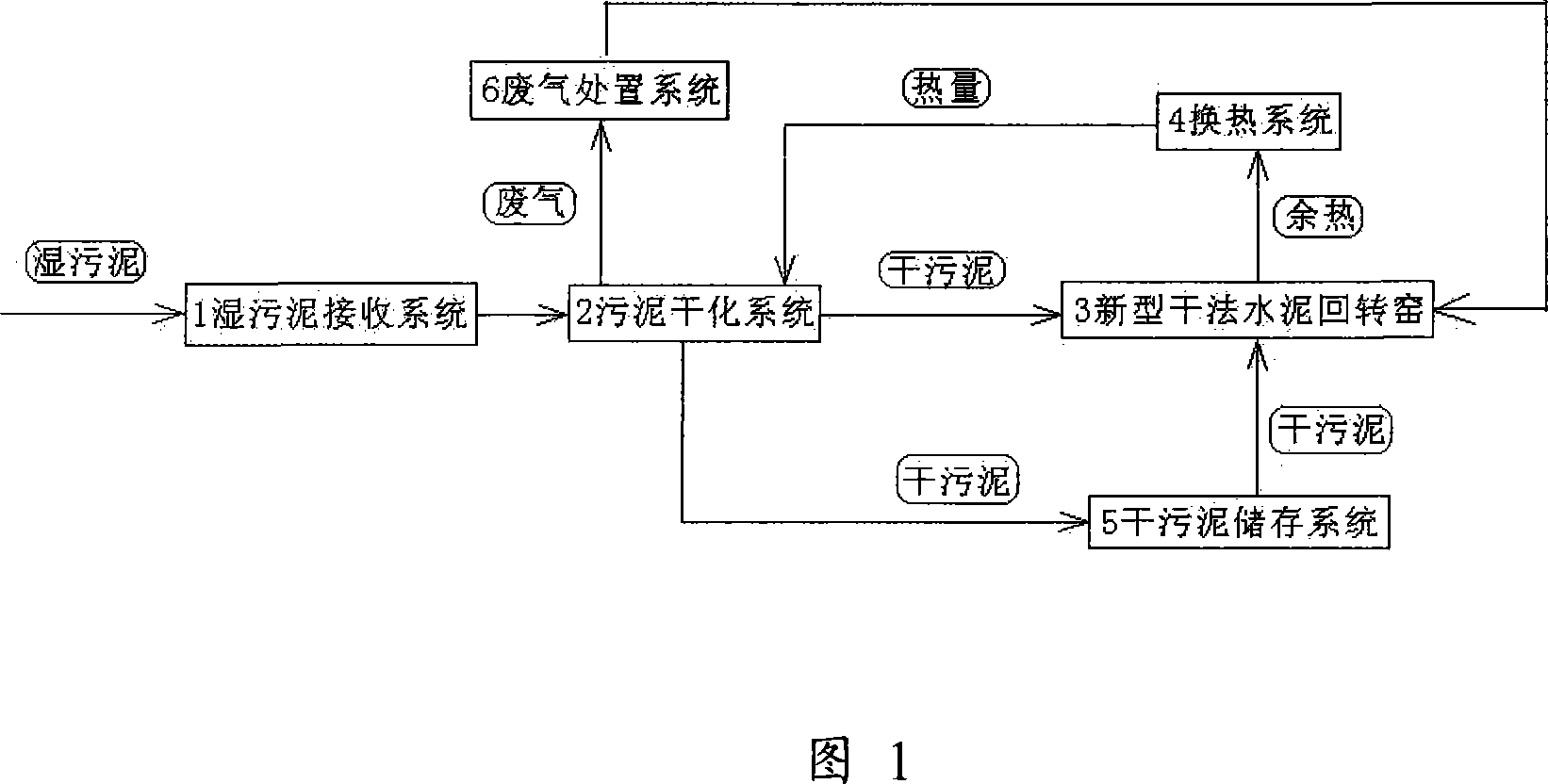

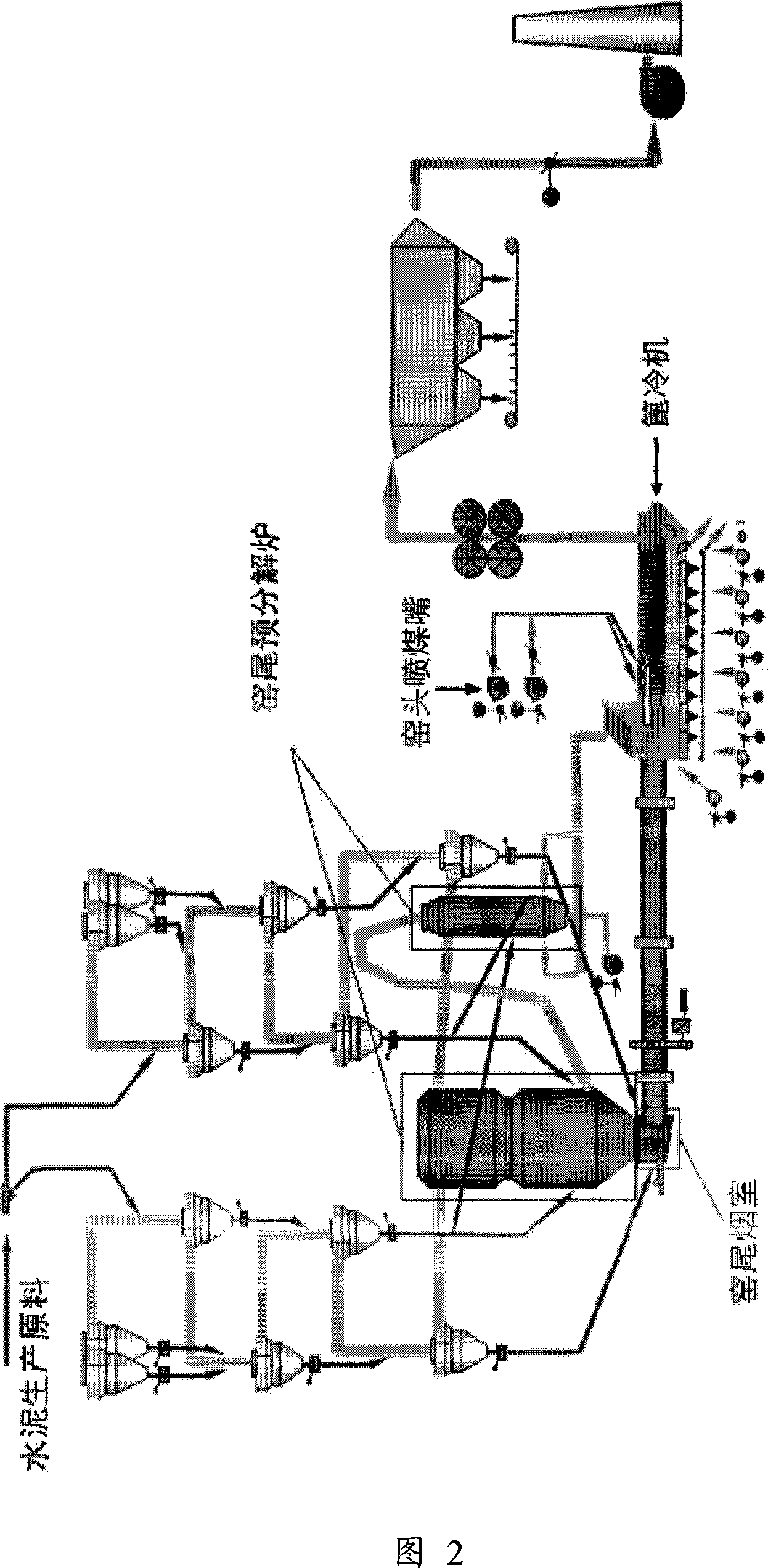

Method and device for processing sludge

ActiveCN101177331ALower fuel costsSave raw coalSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationProcess systemsCombustion

The invention provides a sludge treatment method and the device, in particular to a drying and treating sludge method and the device with a new type drying cement rotary kiln adopted as the sludge incineration system. The invention comprises the following steps to treat the sludge: the sludge is dried with the residual heat produced in the work course of the sludge incineration system; the waste gas produced during the drying course is directed and processed in a waste gas process system until reaching the standard, and then the waste gas is discharged out; the obtained dry sludge is delivered in the sludge incineration system and directly burnt without adding any auxiliary combustion materials, and the obtained residue is used to produce cement. The invention has the advantages of saving the fuels for drying sludge, avoiding the pollution of waste gas and residue, saving the processing cost of waste gas and residue, thus achieving the aims of energy saving and environment protection.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH +1

Technique for extracting rare earth from rare earth tailing and preparing calcium sulfate whiskers

InactiveCN102382979AReduce consumptionNo emissionsPolycrystalline material growthFrom normal temperature solutionsOrganic solventSulfate

The invention relates to a separation and extraction technique for rare earth and calcium resources, in particular to a technique for extracting rare earth from a rare earth tailing and preparing calcium sulfate whiskers. The invention provides an organic solvent crystallization process for extracting rare earth from the rare earth tailing and preparing the calcium sulfate whiskers, which consists of three technical operations to realize the chemical purpose of extracting and separating rare earth and calcium elements. The three technical operations include: 1, a process of leaching sulfuric acid and diluted hydrochloric acid from the rare earth tailing; 2, a process of removing Fe2+ from hydrochloric acid leaching solution; and 3, a process of preparing calcium sulfate whiskers by adopting the organic solvent crystallization. The technique is applicable to extraction and separation of the calcium elements from various calciferous minerals and industrial wastes and has high feasibility, high product purity, simple process operation and low cost. Therefore, the technique has great significance in realizing the comprehensive utilization of the tailings and industrial wastes and reducing the environmental pollution and resource waste.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

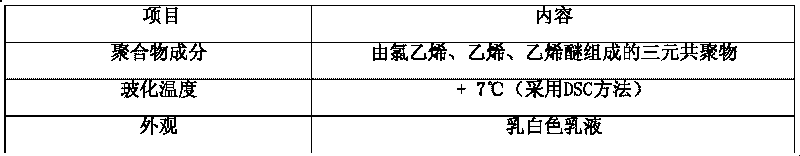

Mortar for building and plastering PTB aerated concrete blocks and using method thereof

ActiveCN101691290AGet comprehensive utilizationHave the ability to deformCovering/liningsBuilding material handlingEmulsionEconomic benefits

The invention provides mortar for building and plastering PTB aerated concrete blocks, which belongs to the technical field of building materials. Raw materials of the mortar are PTB aqueous solution and PTB powder, wherein the PTB aqueous solution is prepared by diluting PTB emulsion (COMPAKTUNA PRO) and water in a certain proportion; and the PTB powder comprises waste PTB aerated concrete blocks. The PTB aqueous solution and the PTB powder are stirred uniformly to form the mortar for building and plastering the PTB aerated concrete blocks. The mortar has good cohesiveness, water resistance, water retention and deformation capacity, comprehensively uses the waste aerated concrete blocks, has significant environmental protection benefit, is suitable for large-scale popularization and application, and has significant economic benefit.

Owner:FUJIAN TONGLI BUILDING MATERIALS SCI & TECH

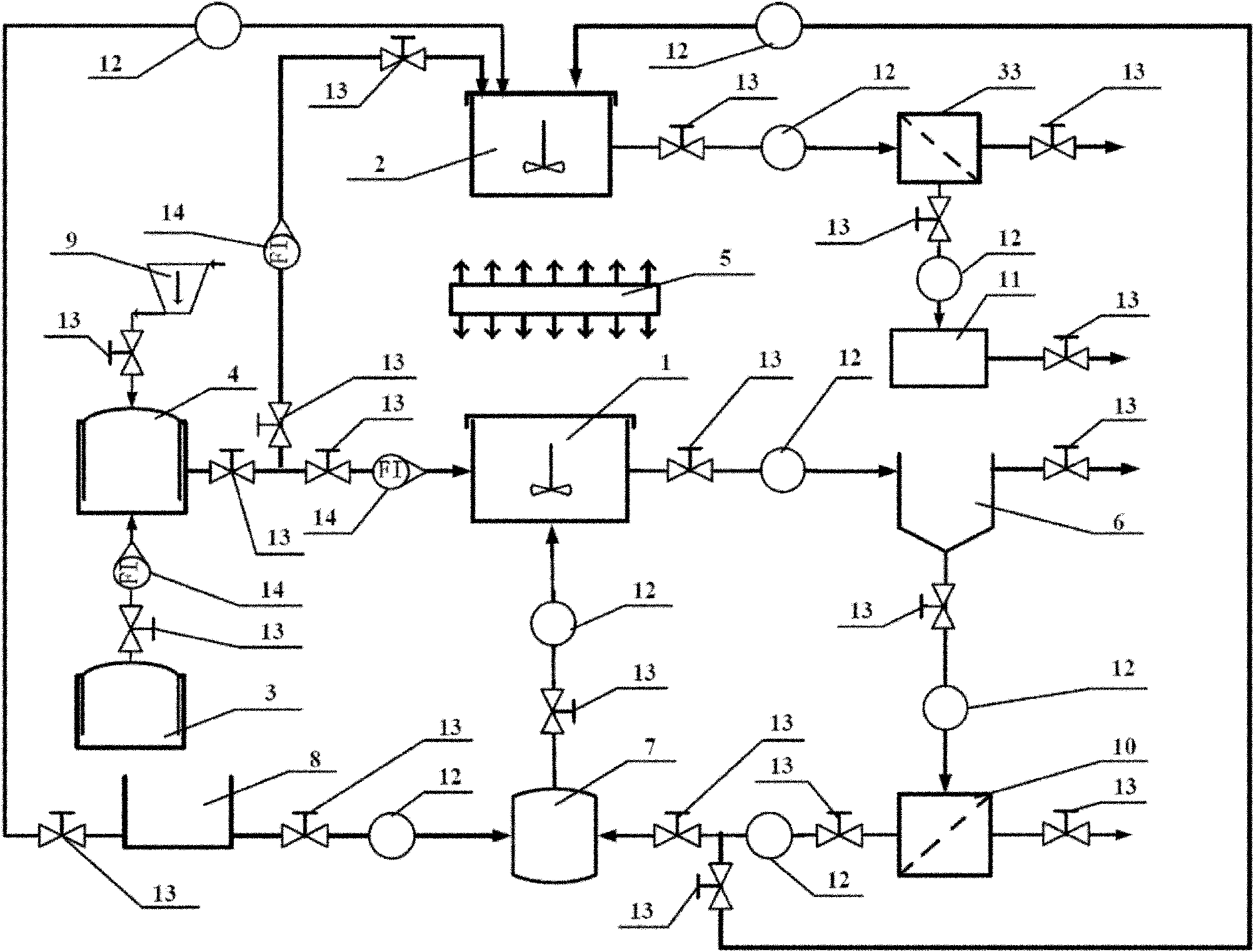

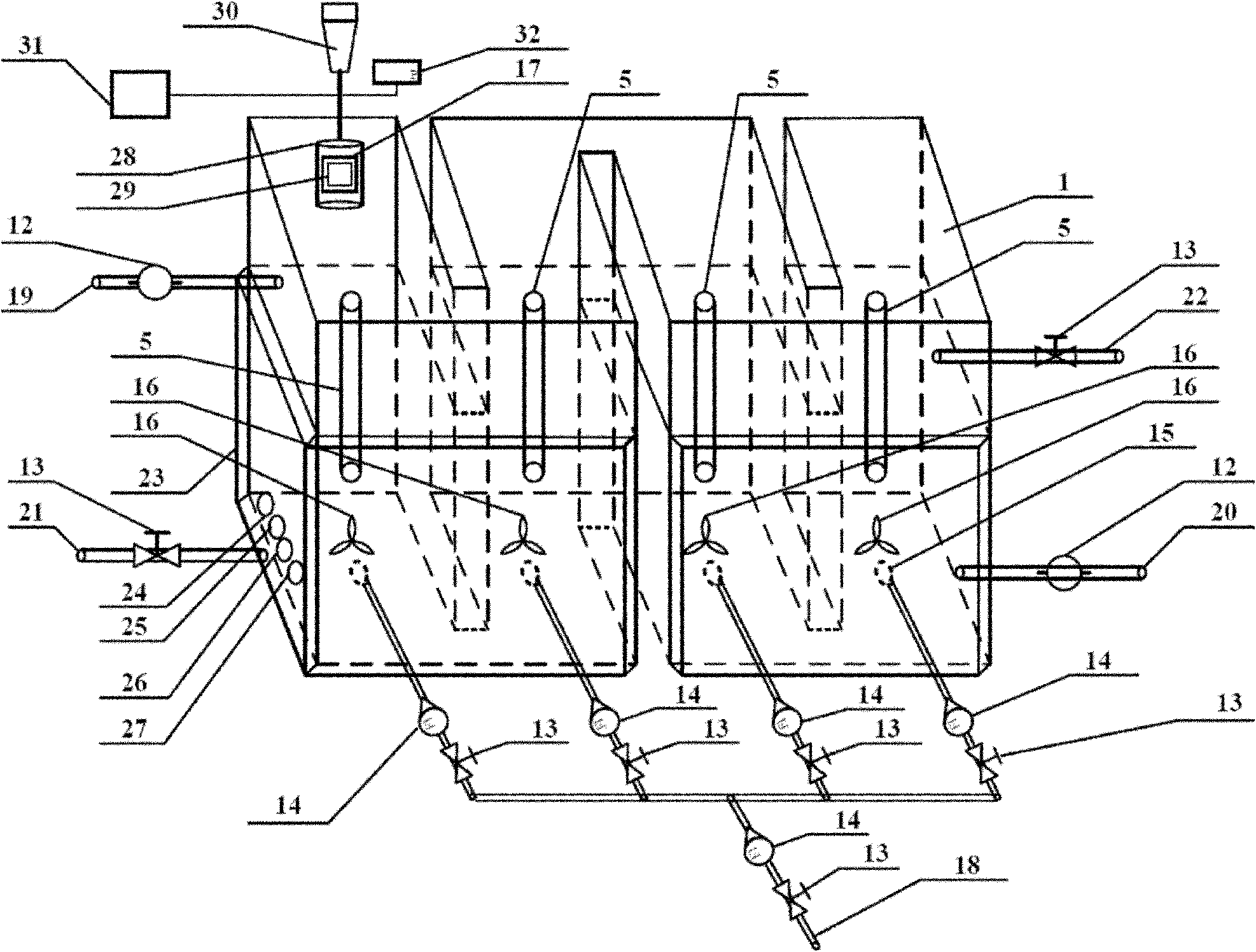

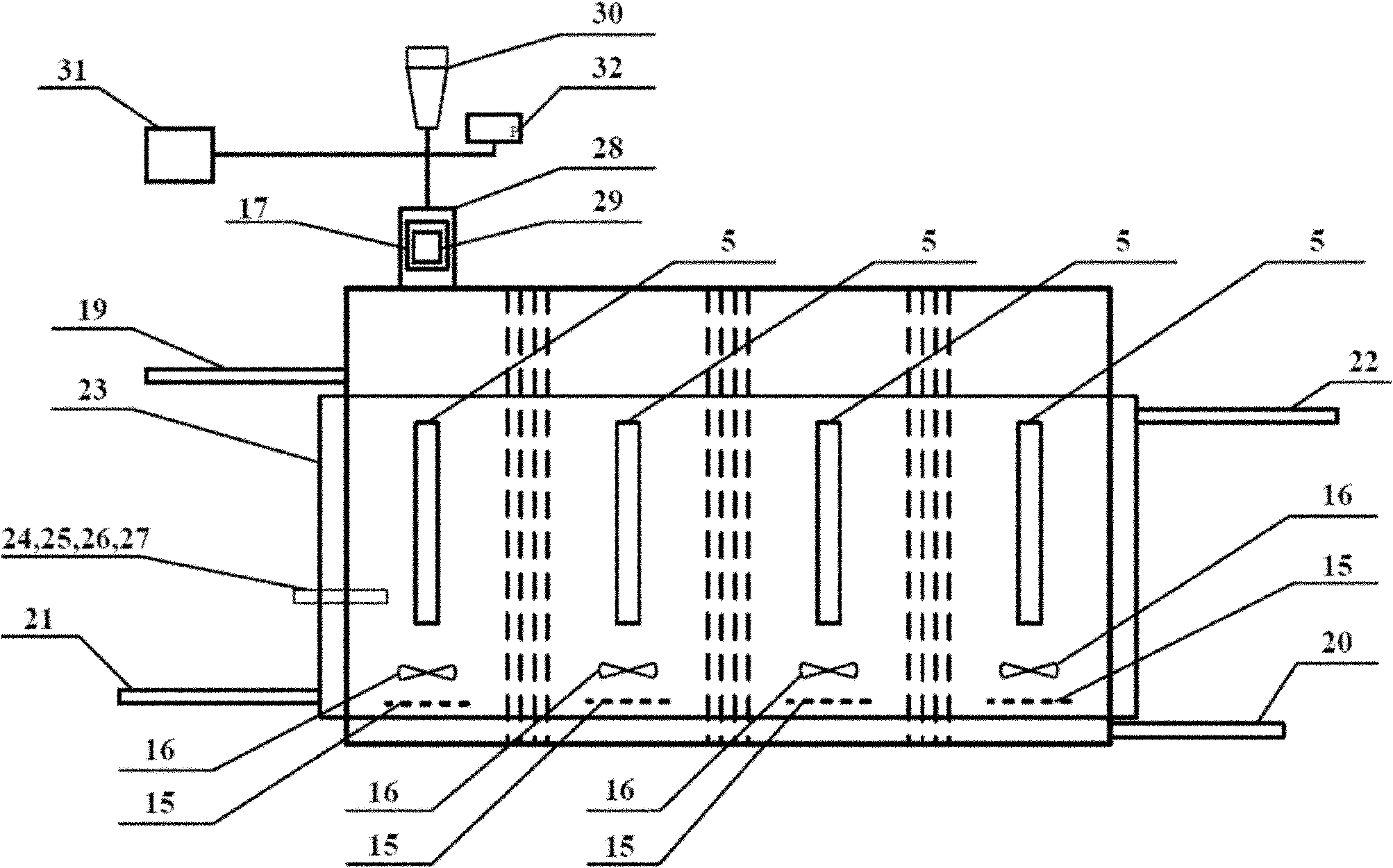

System for treating sewage and producing biological oil by using microalgae and method

ActiveCN102583767AReduced batch processing timeImprove utilization efficiencyEnergy based wastewater treatmentFermentationOil and greaseMixing tank

The invention provides a system for treating sewage and producing biological oil by using microalgae. A first light source device and a second light source device of the system are respectively arranged in a photo-biological reactor and an oil accumulating tank; a CO2 gas supply device is respectively connected with the photo-biological reactor and the oil accumulating tank through air passages; a sewage sedimentation tank is connected with the oil accumulating tank through a pipeline and connected with the photo-biological reactor via a pipeline through a microalgal liquid mixing tank; the photo-biological reactor is respectively connected with the microalgal liquid mixing tank and the oil accumulating tank via pipelines through a first microalgal liquid separating device; and the oil accumulating tank is connected with a second separating device through a pipeline. The invention further provides a method for using the system to treat sewage and produce biological oil. Through the use of the invention, the production of biological energy sources and other byproducts (such as protein, cosmetic raw materials, animal feed and the like) is realized while sewage is treated, so that the production cost is lowered, and the comprehensive utilization of waste resources and the energy-saving and emission-reducing green production are achieved. The invention is suitable for cultivating microalgae from a laboratory to a factory, is skillful and unique in design, and is applicable to large-scale promotion and application.

Owner:JIANGNAN UNIV

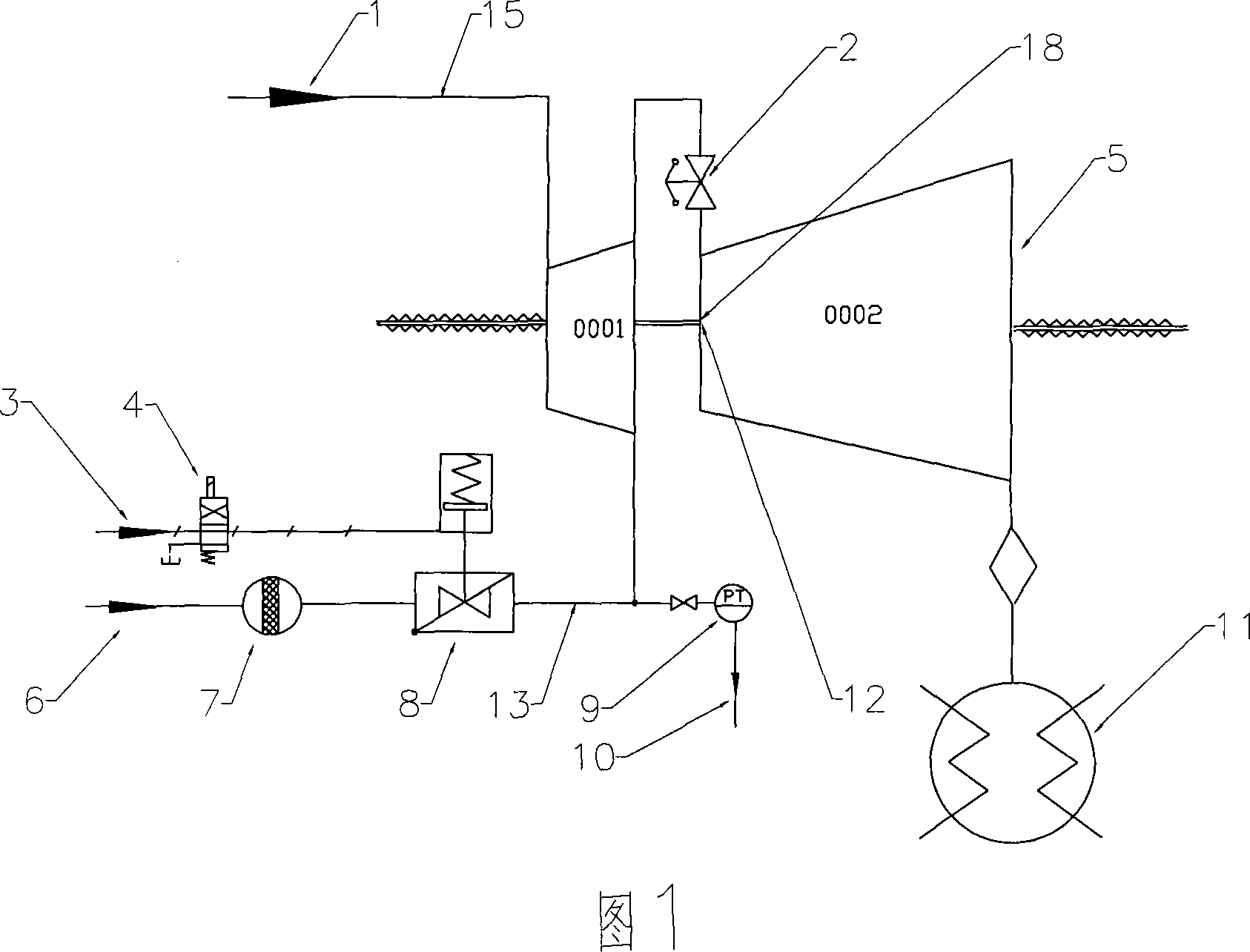

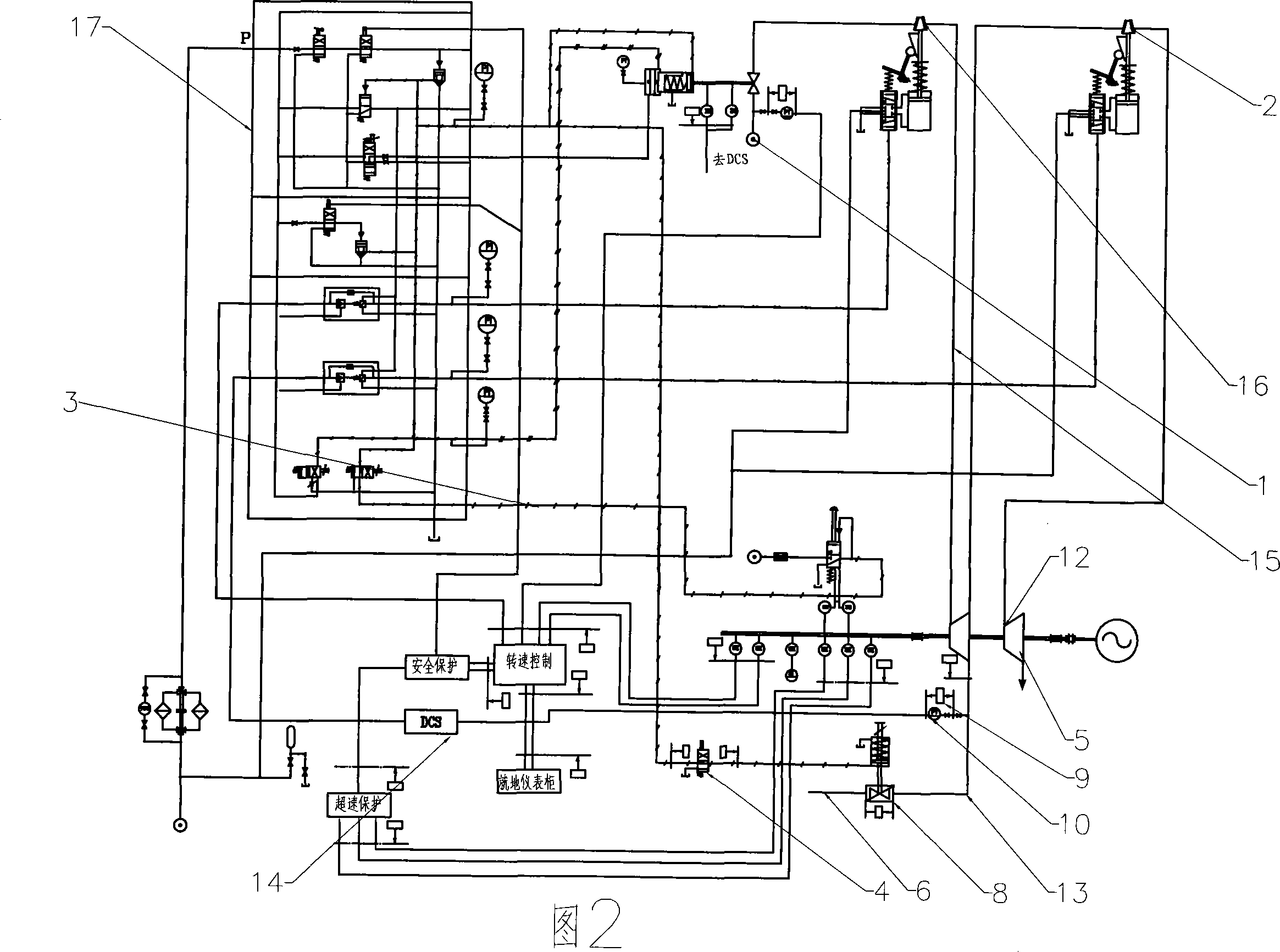

Exhaust heat steam turbine air-supplementary regulation system and its control method

ActiveCN101235732AAchieve self-regulationGuaranteed uptimeEngine componentsSteam engine plantsWet steamControl signal

The invention discloses a residual heat utilization steam turbine steam complementing adjusting system and a control method, which comprises an adjustable steam complementing adjusting steam valve, a pressure steam turbine, a transducer, a steam-water separator and an adjustor, a steam complementing hole is arranged on the interpolar position of a steam turbine, a steam complementing pipeline is connected on the steam complementing hole, a steam-water separator is arranged on the steam complementing pipeline, the adjustable steam complementing adjusting steam valve is arranged on the steam complementing pipeline between the steam-water separator and the steam complementing hole, executing signals of the adjustable steam complementing adjusting steam valve are connected with the adjuster output control signals, a pressure transducer is arranged on the steam complementing pipeline, the steam complementing signals of the pressure transducer is connected with the adjuster pressure output signals. Steam complementing steam firstly passes through the steam-water separator, and wet steam is conversed to be dry steam to reduce waterworn. The residual heat utilization steam turbine steam complementing adjusting system which is got by the invention effectively solves the problem which exists in the existing technique, the system achieves automatic adjustment of steam complementing when a steam complementing system which is stably operated is guaranteed. Thereby residual heat utilization is led to be the highest.

Owner:HANGZHOU ZHONGNENG STEAM TURBINE POWER CO LTD

Method of extracting squalene from bottom sediment with natural vitamin E extracted

ActiveCN105367370AReduce loadReduce difficulty and costDistillation purification/separationHydrocarbonsChemistrySqualene

The invention discloses a method of extracting squalene from bottom sediment with natural vitamin E extracted. The bottom sediment with the natural vitamin E extracted is used as the raw material to prepare high-content squalene through a saponification, rectification and silica gel column chromatography combined process. The method specifically comprises the steps that firstly, the bottom sediment is subjected to a saponification reaction, unsaponifiable matter obtained through extraction is subjected to separation in a secondary rectifying tower, distillate obtained through secondary rectification is used as the raw material and subjected to silica gel column chromatography separation, three organic solvents with different polarities are used for elution, and fractional collection is conducted to obtain a plant hydrocarbon component, a squalene component, a natural vitamin E component and a sterol component, wherein the squalene content of the squalene component is more than 95%. According to the method, the bottom sediment with the natural vitamin E extracted is used as the raw material for extraction of the squalene, the process is simple and convenient, separation efficiency is high, industrial production is easy, the obtained squalene content is high, crude natural vitamin E and sterol can also be obtained, and comprehensive utilization of effective ingredients in the bottom sediment is achieved.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

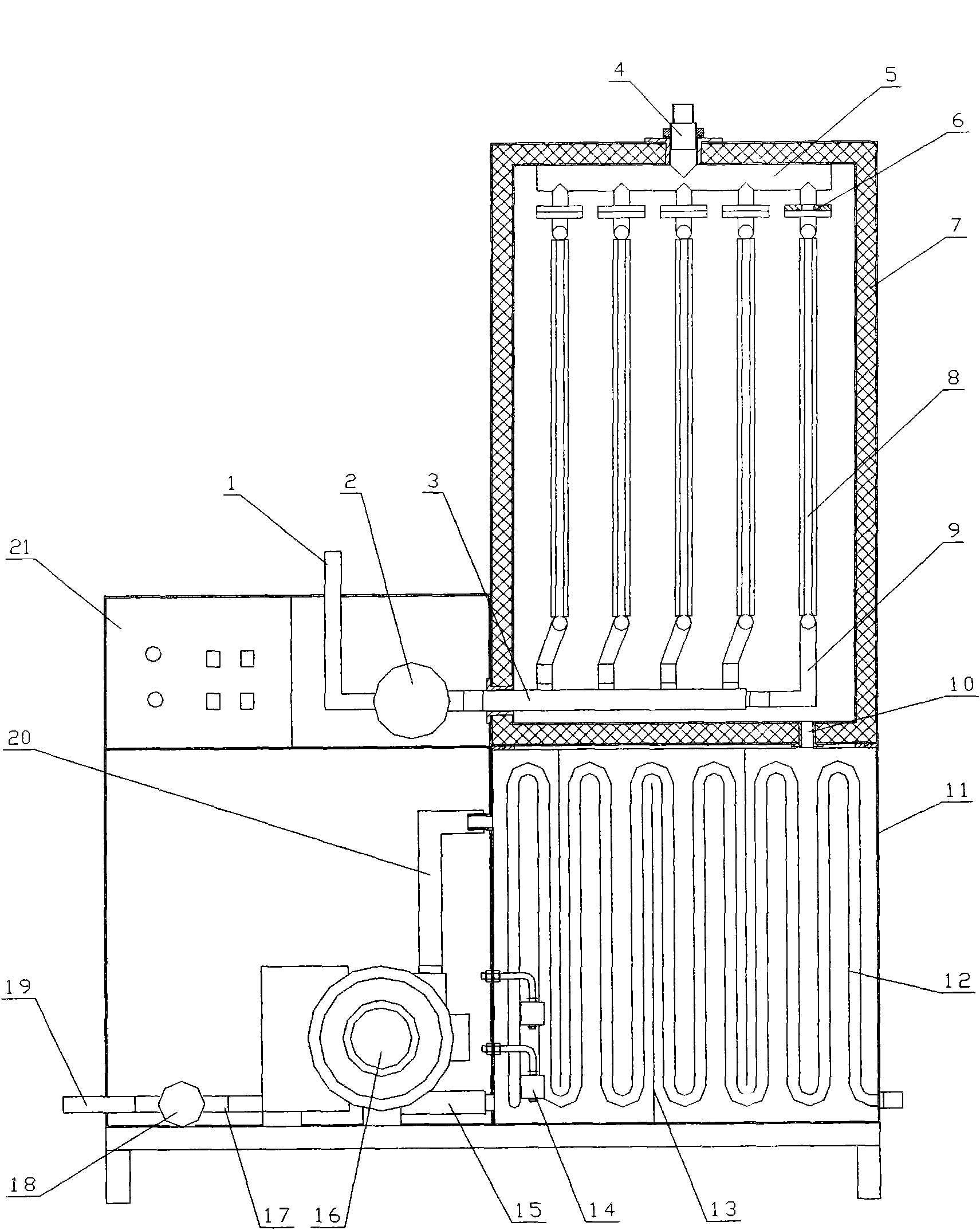

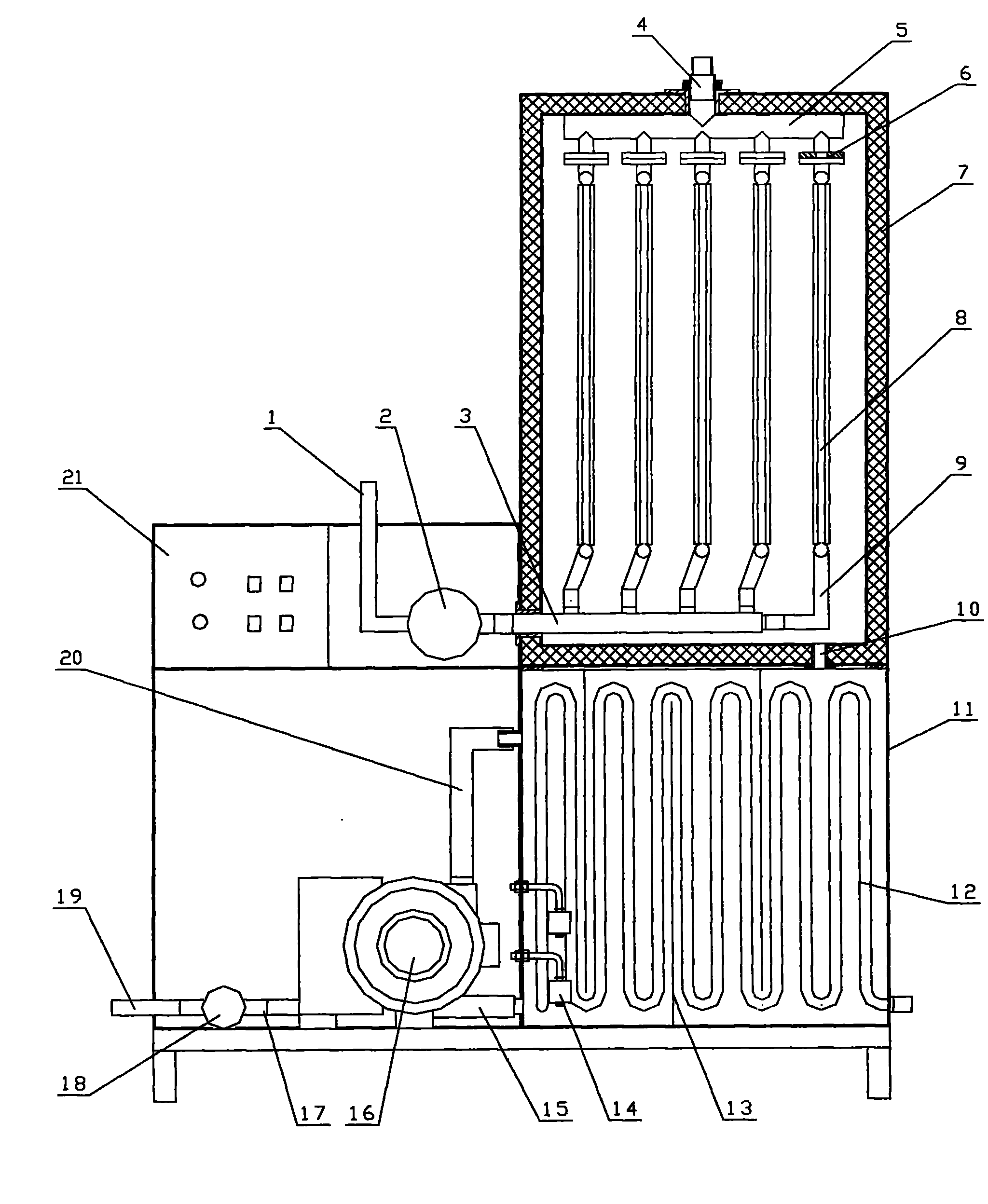

Vacuum membrane distillation water-treatment plant utilizing solar energy

InactiveCN101767841ALow costReduce energy consumptionGeneral water supply conservationEnergy based wastewater treatmentAutomatic controlDistillation

The invention provides a vacuum membrane distillation water-treatment plant utilizing solar energy or waste heat, which belongs to the field of water treatment. The vacuum membrane distillation water-treatment plant comprises a membrane module, a distillation box, a cooling cylinder, a vacuum pump, a control system and a circulating system. The invention uses a vacuum membrane distillation method which has the separation principle that hot raw water to be treated passes through one side of the separation membrane, and the other side is vacuumized so as to form transfer vapor pressure difference on the two sides of the membrane; and the vacuum side only generates water vapor, and the water vapor is condensed into drinking water, thereby separating and purifying the raw water. The invention utilizes cheap energy sources, such as solar energy, low-grade waste heat and afterheat, or the like, and can recycle latent heat of condensation, thereby reducing the energy consumption. The vacuum membrane distillation water-treatment plant has the advantages of simple structure, small occupied area, low cost, high desalination rate, large membrane flux and the like, and can be operated continuously and realize automatic control.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

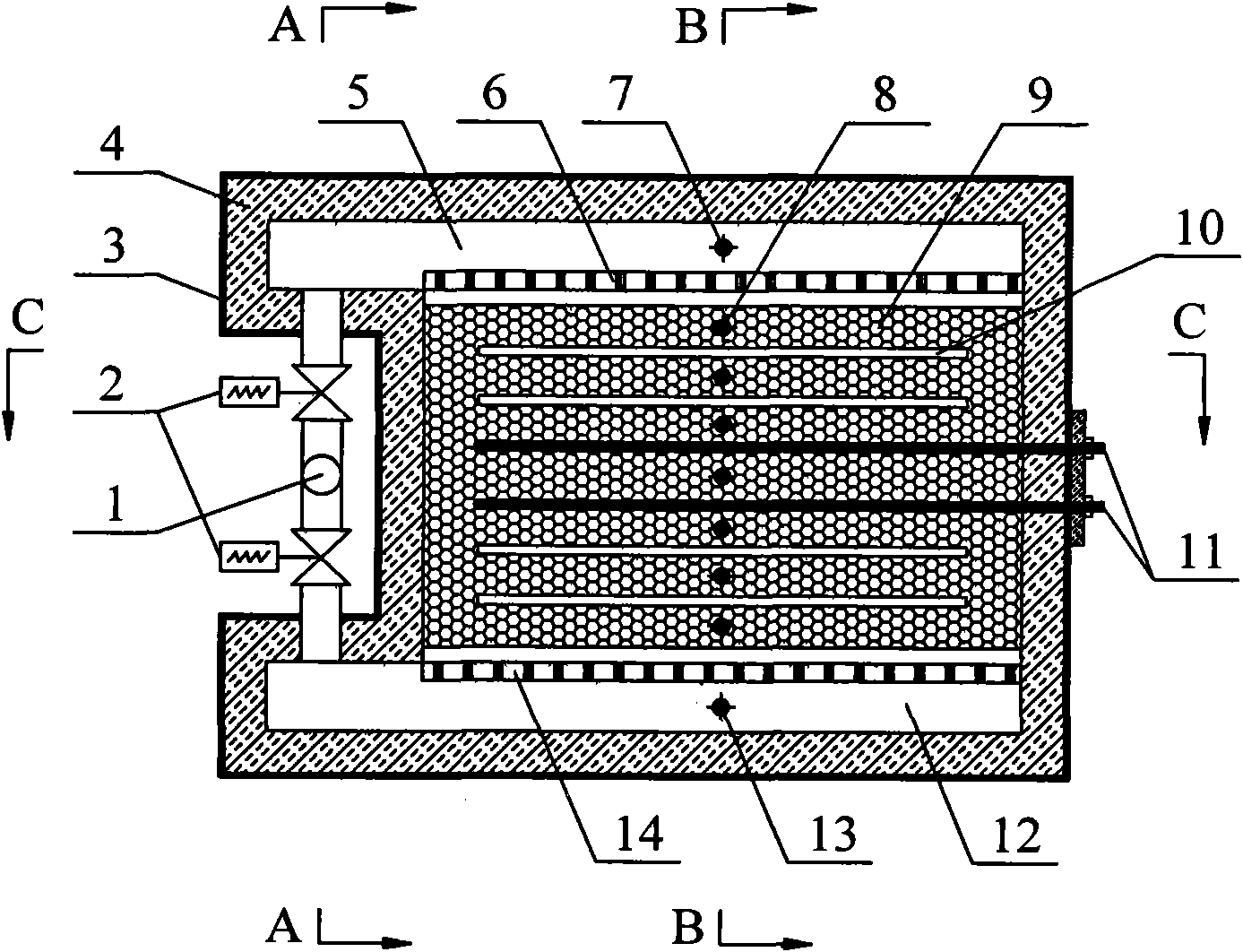

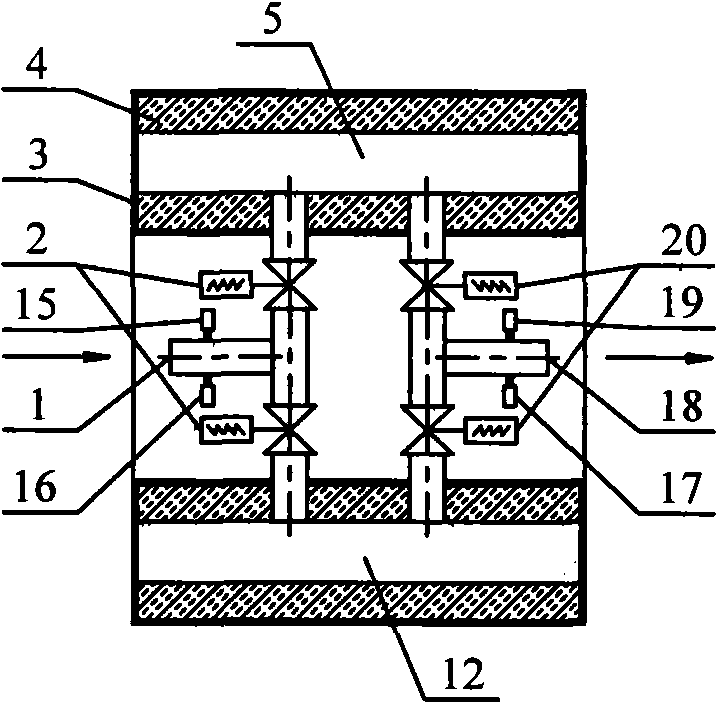

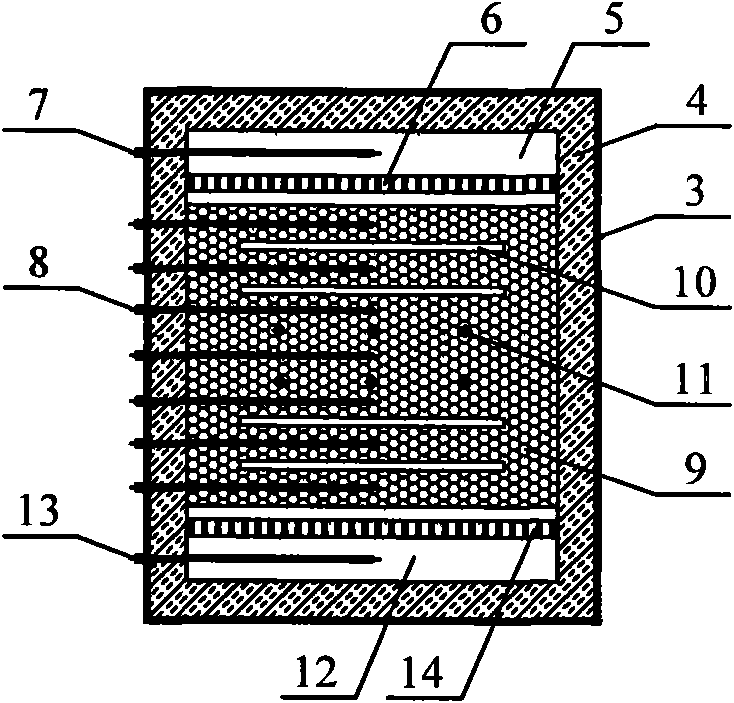

Coal mine methane gas oxidation device

InactiveCN101915117AAchieve multi-stage superheatingAvoid temperatureGas removalInsulation layerCoal mine methane

The invention relates to a coal mine methane gas oxidation device, comprising an outer shell and a honeycomb ceramic oxidation bed, wherein a heat insulation layer is distributed on the inner wall of the outer shell; the upper and lower ends of the honeycomb ceramic oxidation bed are respectively provided with upper and lower rectifying chambers; the side parts of the upper and lower rectifying chambers are provided with ports which are respectively communicated with an intake pipe and an exhaust pipe; the intake pipe and the exhaust pipe are respectively provided with an intake reversing valve, an exhaust reversing valve, an intake pipe temperature sensor, an exhaust pipe temperature sensor, an intake pipe gas concentration sensor and an exhaust pipe gas concentration sensor; the upper and lower parts of the honeycomb ceramic oxidation bed are respectively provided with upper and lower flow homogenizers; the middle part of the honeycomb ceramic oxidation bed is provided with a starting electric heater; the upper and lower parts of the starting electric heater are provided with built-in heat exchangers at intervals; and the back of the shell is provided with an upper rectifying chamber temperature sensor in the middle of the upper rectifying chamber, a temperature sensor at the middle of the honeycomb ceramic oxidation bed and a lower rectifying chamber temperature sensor at the middle of the lower rectifying chamber which are inserted at intervals. The invention has the advantages of compact structure, convenient operation, small occupied area and low investment and operation cost.

Owner:CHINA UNIV OF MINING & TECH

Method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red

InactiveCN102674480AReduce consumptionNo emissionsFerric oxidesIron sulfatesSludgeAmmonium Hydrogen Carbonate

The invention discloses a method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red and relates to a technological method for chemical extraction and separation. The method is an organic solvent effect crystallization process for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red, consists of four technical processes and realizes the chemical goal of extracting and separating iron and preparing ferrous sulfate and iron oxide red. The four technical processes are respectively as follows: 1) a diluted sulfuric acid leaching process of industrial waste iron sludge; 2) an iron crystallization and separation process under the effect of monobasic alcohol serving as organic solvent; 3) an iron oxide red preparation process through reaction between ferrous sulfate solution and ammonium hydrogen carbonate and oxidizing roasting of sediment; and 4) an ammonium sulfate preparation process through evaporative crystallization of sedimentation solution. The method is suitable for extracting and separating iron element from all kinds of iron-containing minerals and industrial waste residues, valuable components are comprehensively utilized and the environmental pollution and the resource wastage are reduced.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

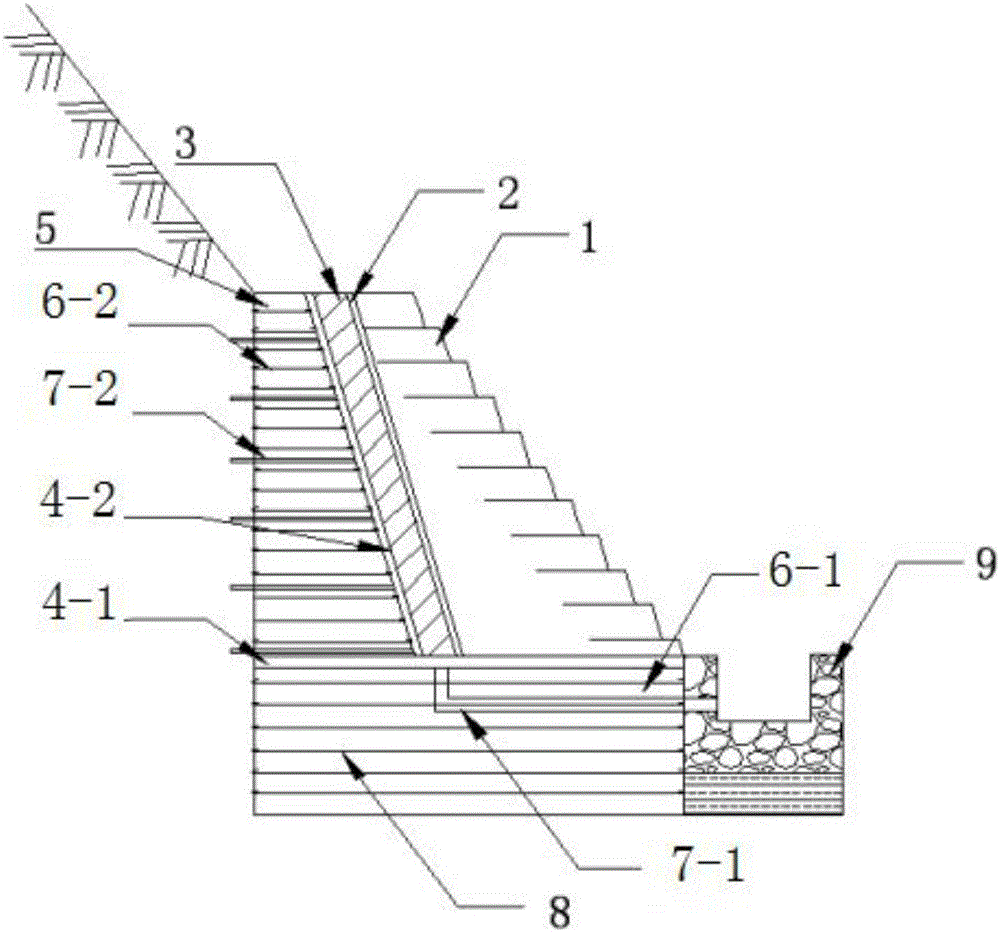

Honeycomb geocell earth retaining wall with ecological restoration function and construction method thereof

InactiveCN106368238AWith ecological restoration functionPrevent infiltrationArtificial islandsExcavationsCrushed stoneEngineering

The invention provides a honeycomb geocell earth retaining wall with an ecological restoration function and a construction method thereof. The honeycomb geocell earth retaining wall comprises a foundation arranged on the ground and a wall body arranged on the foundation; the wall body comprises a reinforced bed course, a composite geo-membrane, reinforced polypropylene water storing and draining modules, a filament geotextile and honeycomb geocells, wherein the reinforced bed course, the composite geo-membrane, the reinforced polypropylene water storing and draining modules, the filament geotextile and the honeycomb geocells are sequentially arranged on the surface of a slope in a paving mode; the foundation and the reinforced bed course each comprise reinforced lime earth improving loess, polypropylene two-way geogrids and a drain pipe; the multiple polypropylene two-way geogrids are parallelly arranged in the reinforced lime earth improving loess; and the drain pipe in the reinforced bed course and the drain pipe in the foundation are connected with the reinforced polypropylene water storing and draining modules correspondingly. The provided honeycomb geocell earth retaining wall with the ecological restoration function is high in bearing capacity, dynamics performance, slide resistance and erosion resistance and can be filled with a gravel soil layer, grass is planted in the gravel soil layer, not only can water and soil erosion be effectively prevented, but also a greening function is achieved, and accordingly, effective combination of ecological restoration and engineering management is achieved; and the construction method is simple, construction is convenient, and the cost is low.

Owner:NORTHWEST UNIV(CN)

High concentration saliferous organic waste liquor recycling chemical intermediate and waste heat utilizing boiler system

ActiveCN103868079ABreakthrough handlingBreak through unificationIncinerator apparatusHigh concentrationCombustion chamber

The invention discloses a high concentration saliferous organic waste liquor recycling chemical intermediate and waste heat utilizing boiler system which comprises an incineration boiler, a first-level dust collecting device, a secondary combustion device, a waste heat boiler and a second-level dust collecting device. An exhaust gas outlet of the incineration boiler is communicated with the first-level dust collecting device through a pipeline, an outlet of the first-level dust collecting device is communicated with the secondary combustion device through a pipeline, an outlet of the secondary combustion device is connected with the waste heat boiler through a pipeline, an outlet of the waste heat coiler is connected with the second-level dust collecting device through a pipeline, and exhaust gas of the second-level dust collecting device is introduced in a chimney through a draught fan and is exhausted. According to the high concentration saliferous organic waste liquor recycling chemical intermediate and waste heat utilizing boiler system, a combustion mode combining layer combustion and chamber combustion is adopted, spray mist drying, dry distillation, evaporation and combination reaction are carried out in a primary combustion chamber, the spray mist drying technology is adopted, the treatment mode of single incineration waste disposal and a centralized waste disposal mode are broken through, the simultaneous efficient multi-time incineration disposal of liquid, gas and solid diversified waste is achieved, and precious chemical intermediate raw materials are further generated.

Owner:大连科林能源工程技术开发有限公司

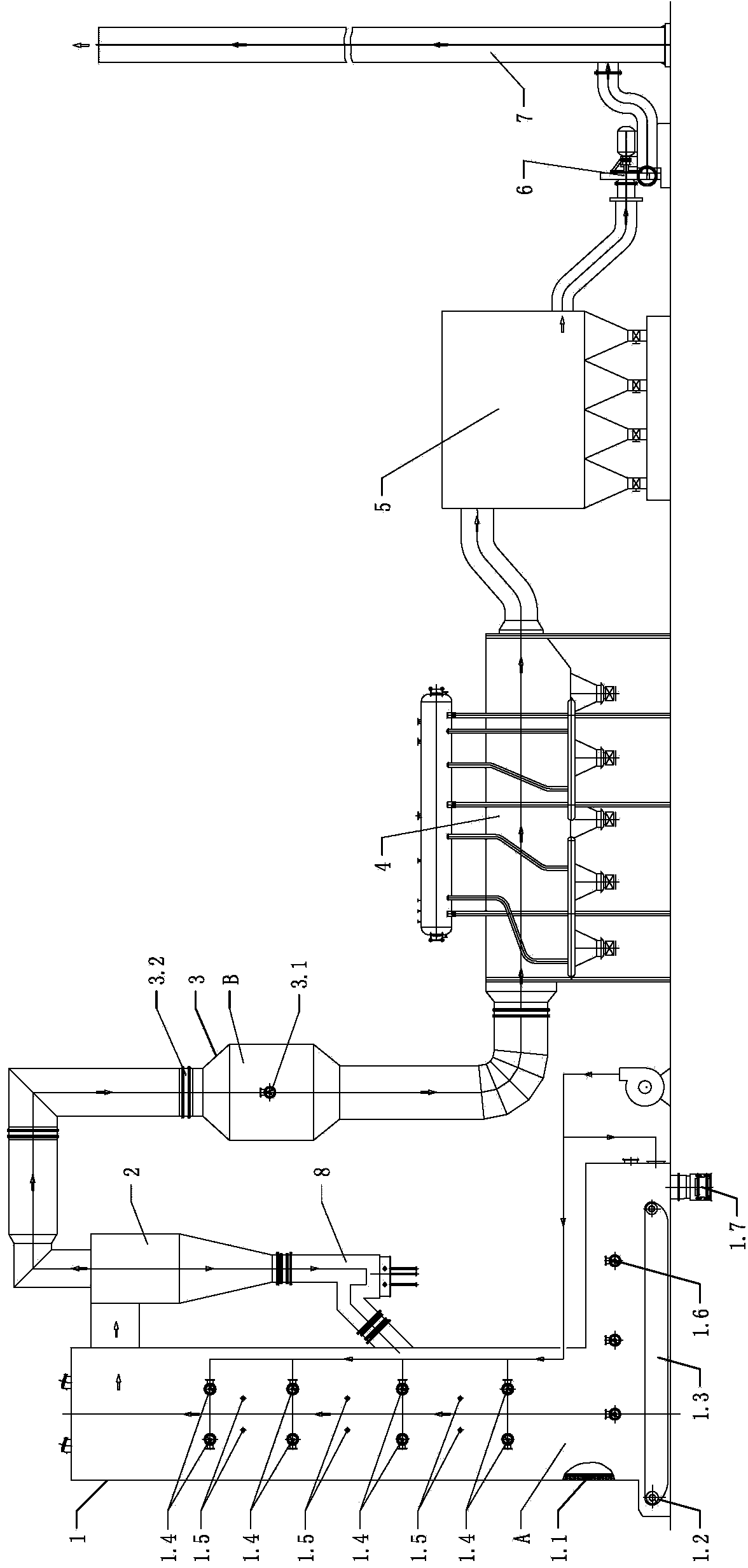

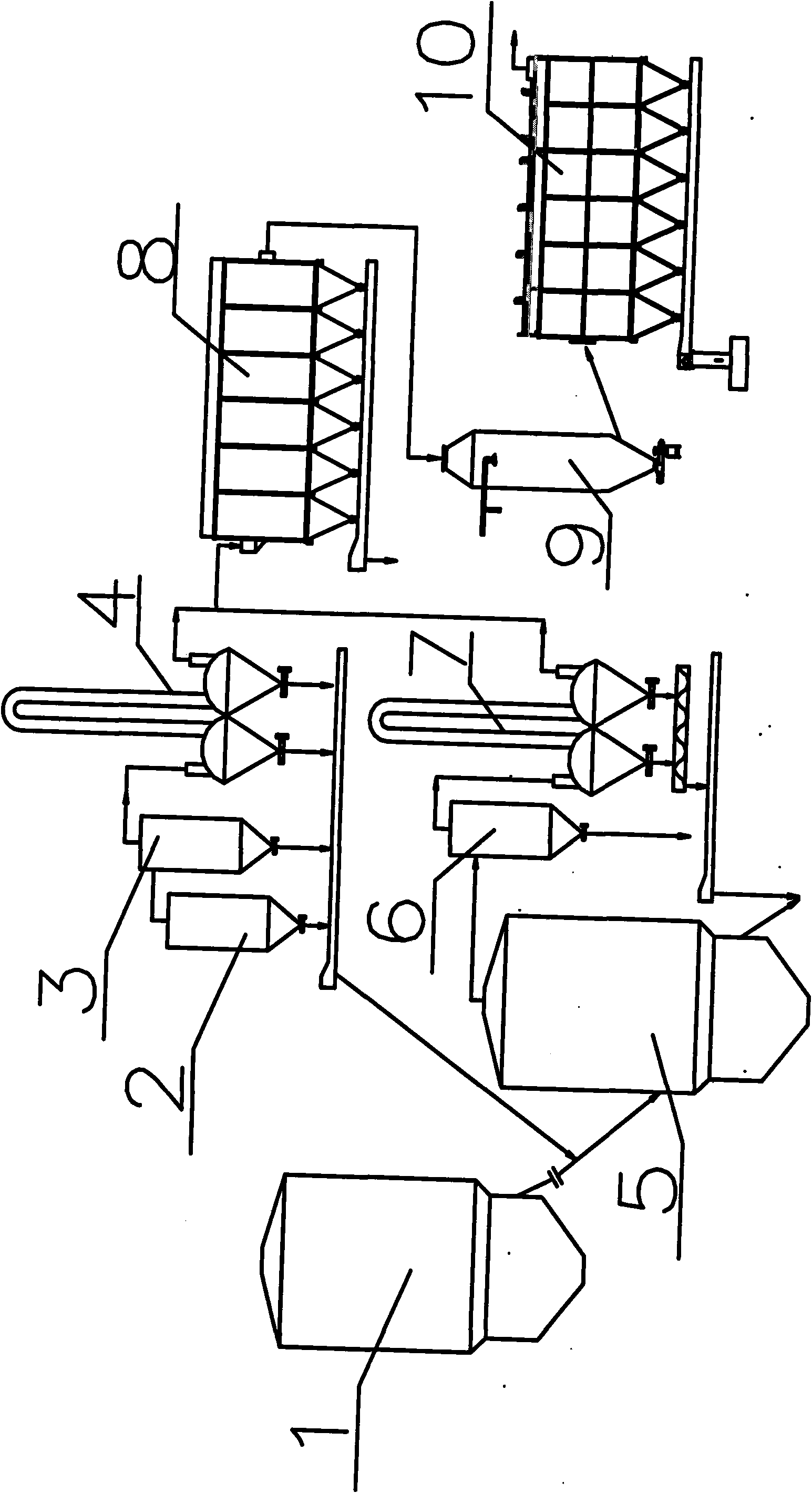

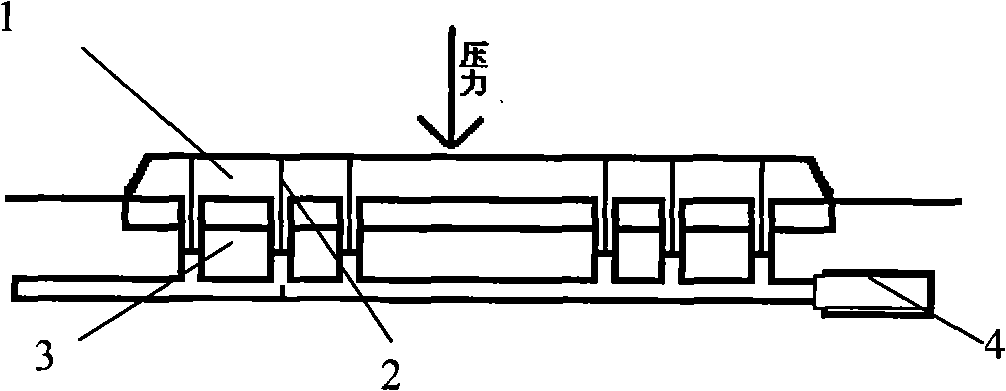

Method for heightening two-stage roasting arsenic collecting efficiency and special equipment

The invention discloses a method for heightening two-stage roasting arsenic collecting efficiency and special equipment. The method comprises the following steps: furnace gas, which is generated by one-stage roasting, is dedusted by means of reducing temperature through a two-stage whirlwind furnace cooler, and is again dedusted by means of removing electricity with furnace gas which is generated by two-stage roasting and be dedusted by means of reducing temperature through a one-stage whirlwind furnace cooler; the temperature of the dedusted furnace gas is reduced through a quench tower, and the arsenic of the dedusted furnace is recycled through a cloth bag arsenic collector; the remaining furnace gas is used for producing aid; and the dust and roasting slag, which are collected by the furnace cooler by means of the one-stage roasting, are put into the two-stage roasting. The equipment comprises a one-stage roasting furnace (1) and a two-stage roasting furnace (5). The equipment is characterized in that the one-stage roasting furnace (1) is connected with the two whirlwind devices and the furnace cooler by means of sealing in sequence; the bottom end of the one-stage roasting furnace (1) is communicated with the two-stage roasting furnace (5); the two-stage roasting furnace (5) is connected with one of the whirlwind devices and the furnace cooler by means of sealing in sequence; the bottom of the two-stage roasting furnace (5) is connected with a water quenching system; and the furnace cooler is communicated with an electric deduster (8), a cold collecting tower (9) and a cloth bag arsenic collecting device (10) in sequence. The invention has high arsenic collecting efficiency, does not frequently stop vehicles to clean the cloth bag, and increases productivity effect.

Owner:SHANDONG HUMON SMELTING

Technique for extracting and separating rare earth-iron resources from rare earth tailings

InactiveCN102337398AUnique processing methodSimple production processProcess efficiency improvementMineralogySulfuric acid

The invention discloses a technique for extracting and separating rare earth-iron resources from rare earth tailings, which is a technique for extracting and separating rare earth-iron from rare earth tailings through crystallization under the action of organic solvents. The technique disclosed by the invention comprises three technical operations which are respectively as follows: 1, a sulfuric acid leaching-diluted hydrochloric acid leaching technique of rare earth tailings; 2, an Fe<3+> reduction technique of a sulfuric acid leaching solution; and 3, a ferric sulfate crystallization technique under the action of organic solvents. A chemical purpose of extracting and separating rare earth-iron elements is achieved by using the technique disclosed by the invention. The technique is suitable for extracting and separating rare earth-iron elements from various types of ores containing the rare earth-iron and industrial residues, has stronger feasibility and higher product purity, is simple in operation and low in cost, and plays an important role in comprehensively utilizing the tailings and relieving environment pollution and resource waste.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Harmless sintering treatment method of fly ash in waste incineration power plant

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

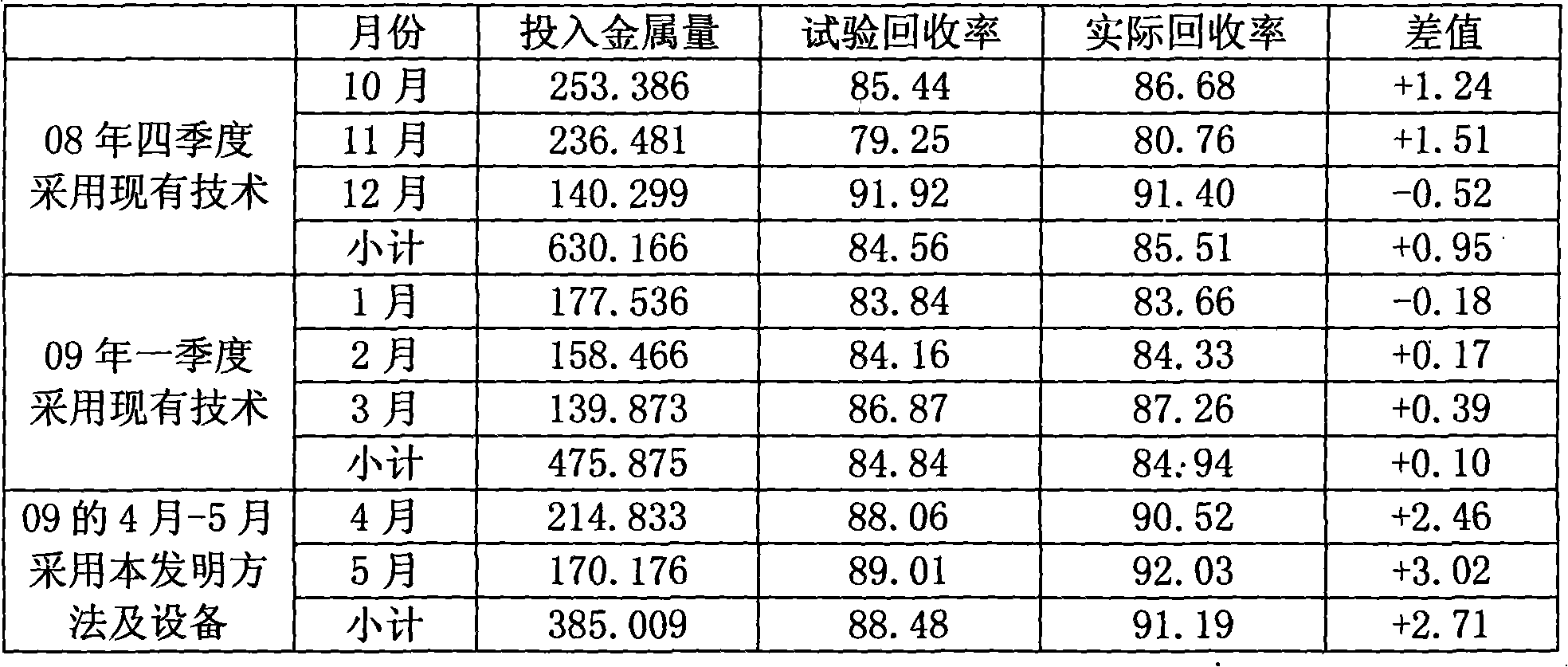

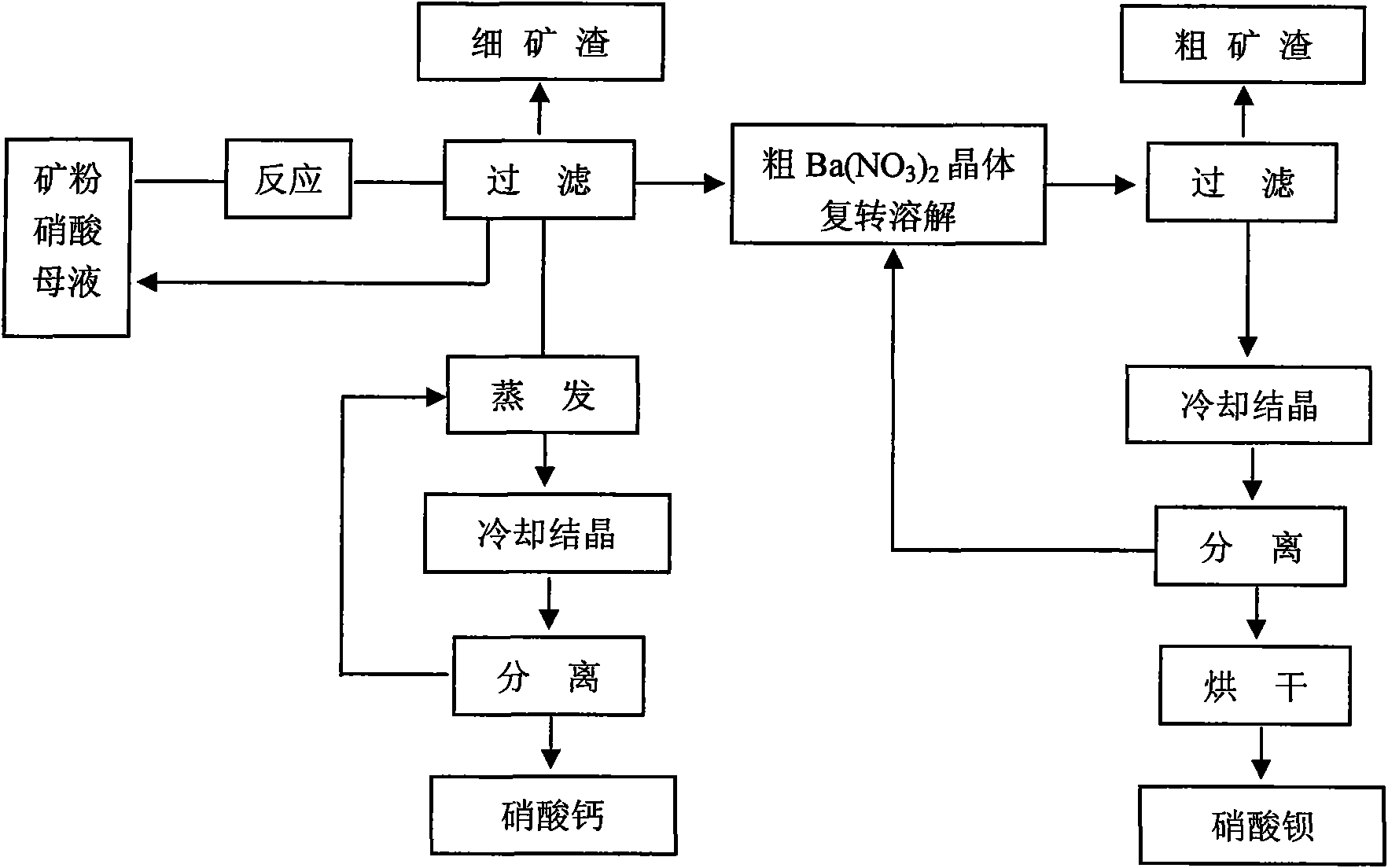

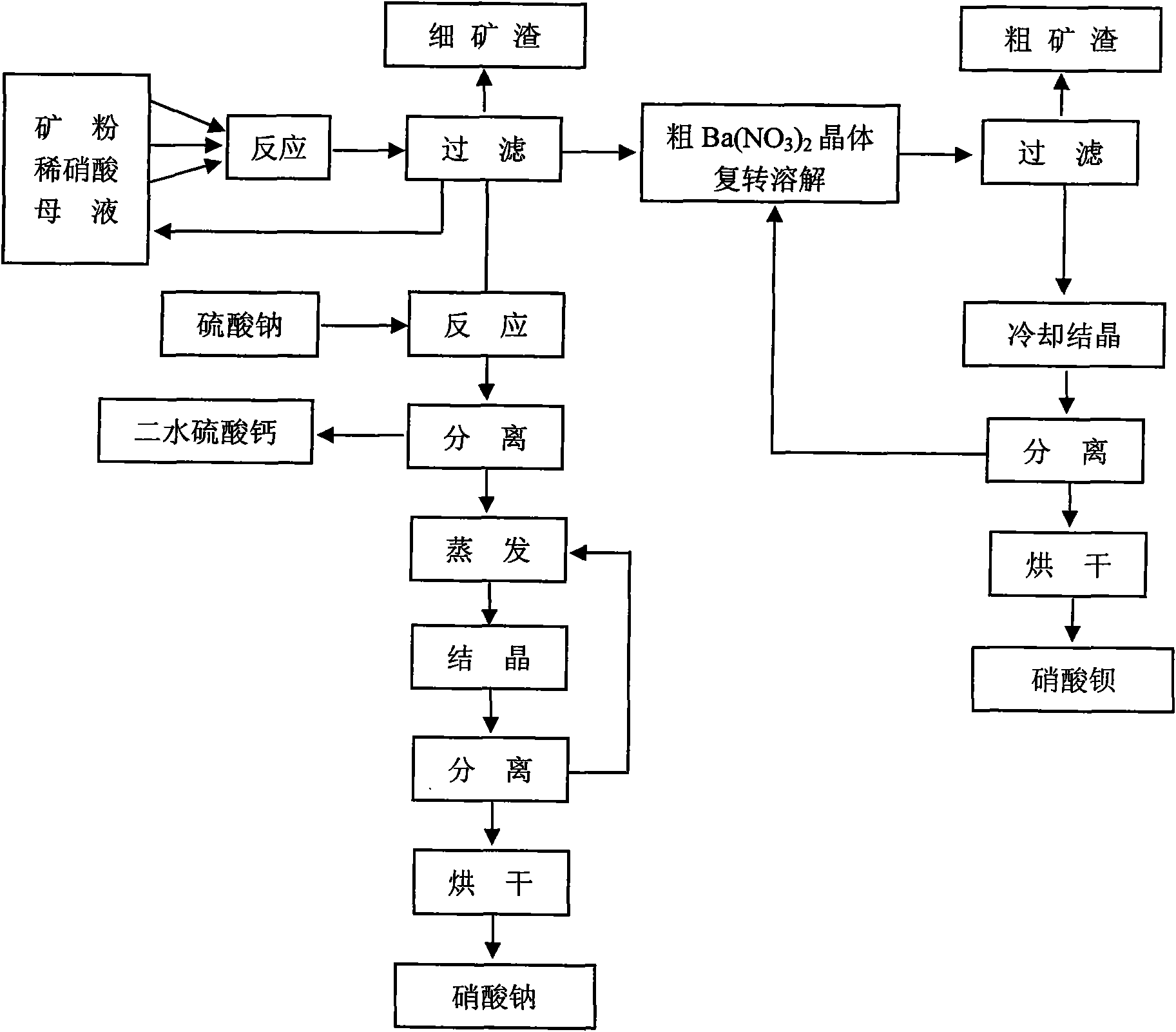

Method for preparing barium nitrate, calcium nitrate, calcium sulfate and sodium nitrate by utilizing middle and low grade barium carbonate ore

InactiveCN101559967AAchieve comprehensive utilizationLow costCalcium/strontium/barium sulfatesAlkali metal nitrate preparationBarium nitrateSulfate

The invention discloses a method for preparing barium nitrate, calcium nitrate, calcium sulfate and sodium nitrate by utilizing a middle and low grade barium carbonate ore, which is characterized in that the middle and low grade ore of BaCo3 with the content of between 30 and 72 weight percent and CaCO3 with the content of between 15 and 45 weight percent and nitric acid react to prepare the barium nitrate and the calcium nitrate; or the middle and low grade ore and the nitric acid react to prepare the barium nitrate, the double decomposition reaction of a residual mother solution (a calcium nitrate solution) and sodium sulfate are performed to prepare the calcium sulfate and the sodium nitrate, and a small amount of acid undissolved substance is used for cement additive. The method achieves the comprehensive utilization of raw materials, has no discharge of three wastes, and has the advantages of cleanliness, environmental protection, high product quality, and low cost.

Owner:SICHUAN UNIV

Low-energy consumption aeration-free domestic sewage recycling apparatus

InactiveCN103922468AAchieve comprehensive utilizationAchieve removalTreatment with anaerobic digestion processesAutomatic controlSolenoid valve

The invention provides a low-energy consumption aeration-free domestic sewage recycling apparatus. The apparatus is mainly such structured that the bottom of the shell of an anaerobic reactor equipped with a stirrer is provided with a water inlet pipe and a sludge discharging and emptying pipe, an outer deflecting cover is arranged in the shell, an inner deflecting cover is arranged in the lower part of the outer deflecting cover, a gas vent is arranged in the top cover of the shell, an epitaxial part at the upper part of the shell is provided with internal and external vertical baffle plates, one end of a water draining pipeline is connected with the outer side of the external vertical baffle plate, the other end of the water draining pipeline is connected with the water inlet of a membrane module, the upper part of the membrane module is provided with a clear water outlet, one branch pipe of a concentrated water outlet pipeline of the membrane module is connected with a concentrated water outlet, the other concentrated water branch pipe is connected with a water inlet pipe on the top cover of the shell, and a sensor of a pH / ORP / temperature monitor is arranged in the shell. A liquid level automatic control system is composed of a pressure transducer, a liquid level controller, an electric actuator, a sewage pump and a solenoid valve, wherein the pressure transducer is disposed in the reactor. The low-energy consumption aeration-free domestic sewage recycling apparatus provided by the invention can treat domestic sewage, enables treated domestic sewage to reach the standard and retains nutrients like nitrogen, phosphorus and potassium in domestic sewage.

Owner:DALIAN NATIONALITIES UNIVERSITY

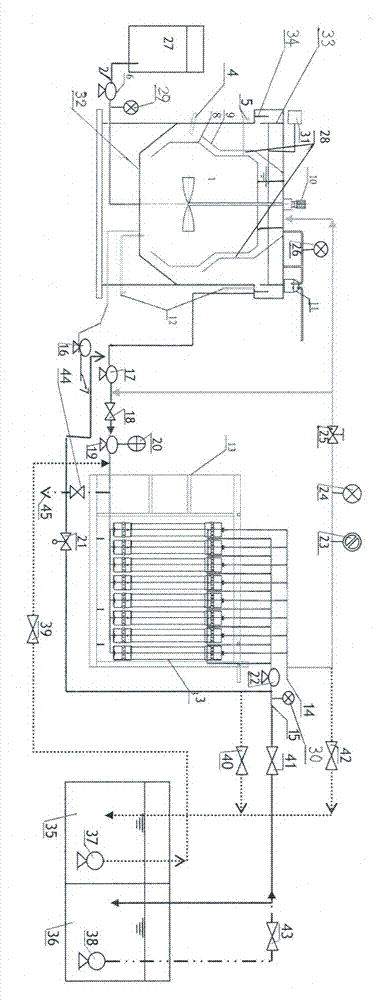

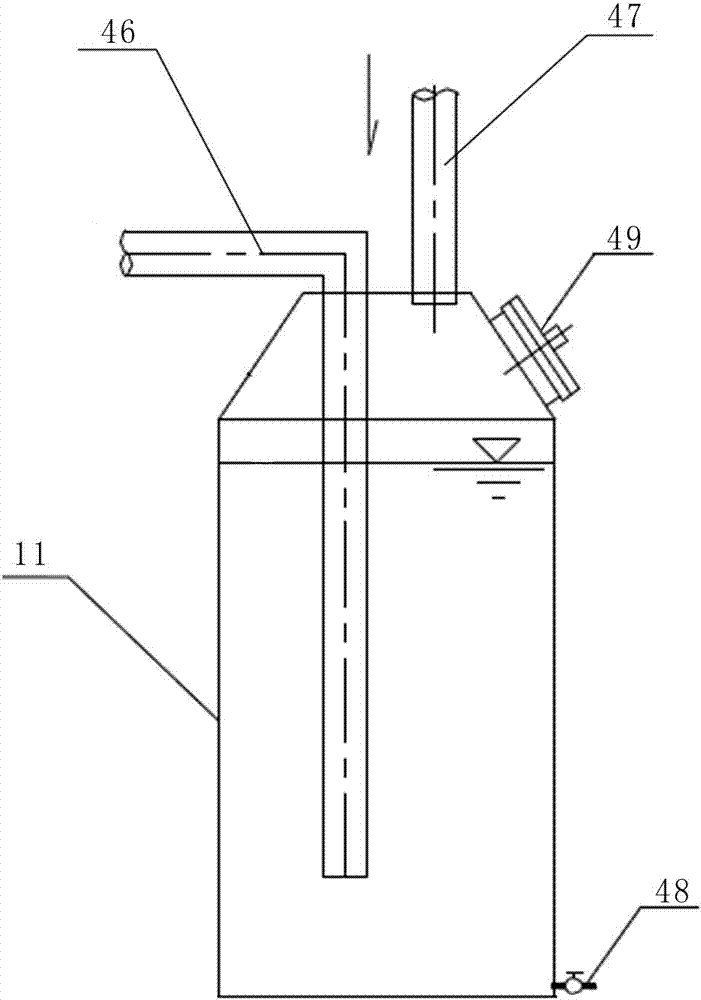

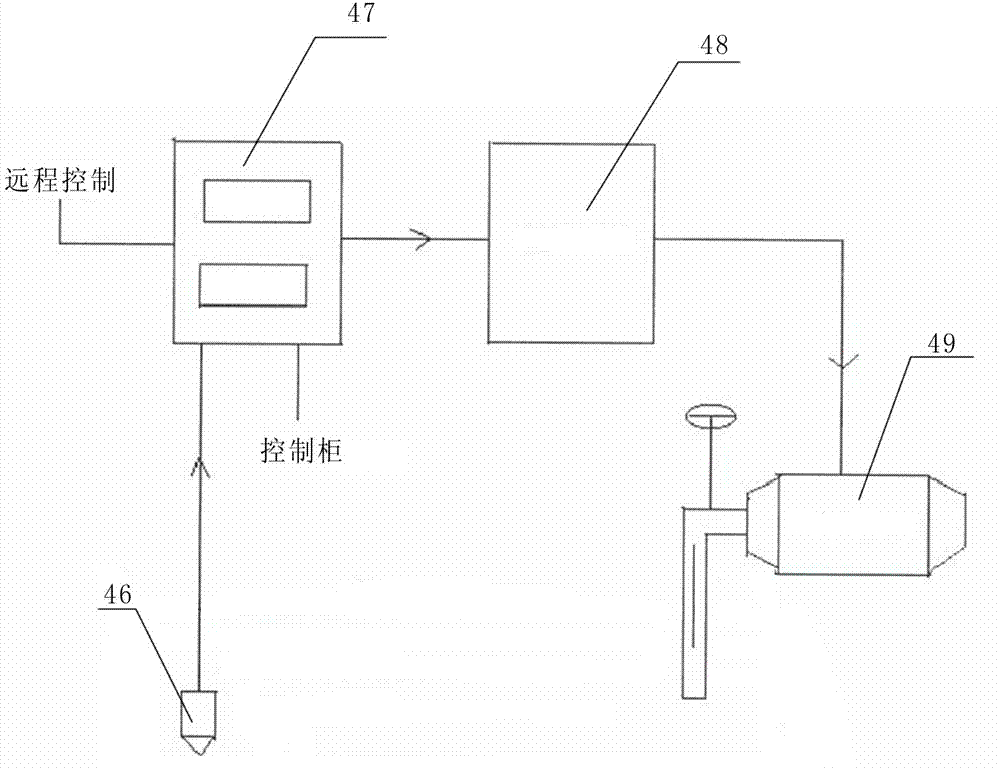

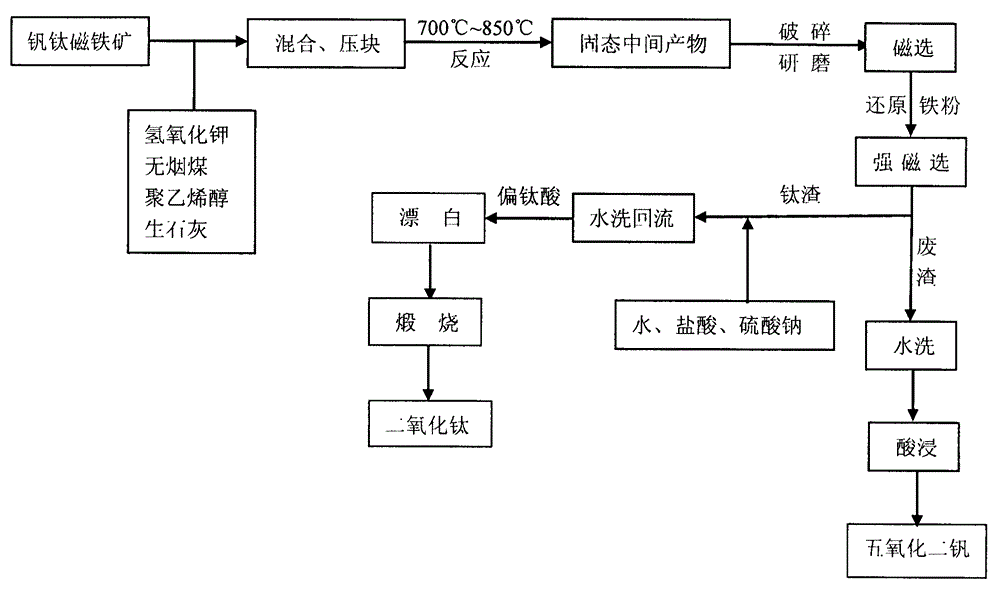

Process of adopting vanadium titano-magnetite or titanium middling as raw material to produce titanium dioxide

InactiveCN106145187ALow costReduce the temperatureVanadium oxidesTitanium dioxideHigh energyResource utilization

The invention aims to overcome the defects of high energy consumption, environment pollution and low resource utilization rate in existing titanium, iron and vanadium separation and titanium dioxide powder production methods and provides a novel process of adopting vanadium titano-magnetite or titanium middling as a raw material to produce titanium dioxide. The novel process is high in operability, free of environment pollution and high in comprehensive utilization rate. The process mainly includes: utilizing potassium hydroxide and hydrochloric acid as media to produce reduced iron powder and titanium dioxide, wherein vanadium pentoxide can be extracted effectively: using vanadium titano-magnetite of Sichuan as the raw material, well mixing with potassium hydroxide, anthracite, polyvinyl alcohol and quicklime, briquetting, and reducing at 700-850 DEG C to obtain an intermediate product; smashing, grinding, performing magnetic separation, strong magnetic separation, water washing and acid leaching, hydrolyzing and calcining to obtain the reduced iron powder, vanadium pentoxide and titanium dioxide.

Owner:四川云钛科技有限公司

Method for preparation of polysilicate aluminum flocculant from silicon aluminum slag

ActiveCN106745582AAchieve comprehensive utilization of secondary resourcesAchieve comprehensive utilizationAluminium silicatesWater/sewage treatment by flocculation/precipitationProcess equipmentSilicic acid

The invention discloses a method for preparation of a polysilicate aluminum flocculant from silicon aluminum slag. The method includes: conducting microwave activation and high temperature calcination on silicon aluminum slag, and performing acid solution leaching to obtain an aluminum-containing aqueous solution; dissolving the solid material separated by acid solution leaching in an alkaline solution, and performing separation, introducing CO2 gas into alkaline leachate to perform carbonization, and then conducting separation and washing to obtain silicic acid hydrate; mixing the aluminum-containing aqueous solution obtained by acid solution leaching with the silicic acid hydrate, and adding an aluminum source to regulate Al / Si mole ratio of the mixed system, and carrying out polymerization and aging to obtain the polysilicate aluminum flocculant. The method provided by the invention has the advantages of simple process equipment, easy operation and safety, is a technological route utilizing industrial waste to produce water treatment agents with wide application scope and realizing effective utilization of resources, can achieve comprehensive utilization of secondary resources, and reaches the purposes of recycling economy, energy saving and emission reduction.

Owner:KUNMING UNIV OF SCI & TECH

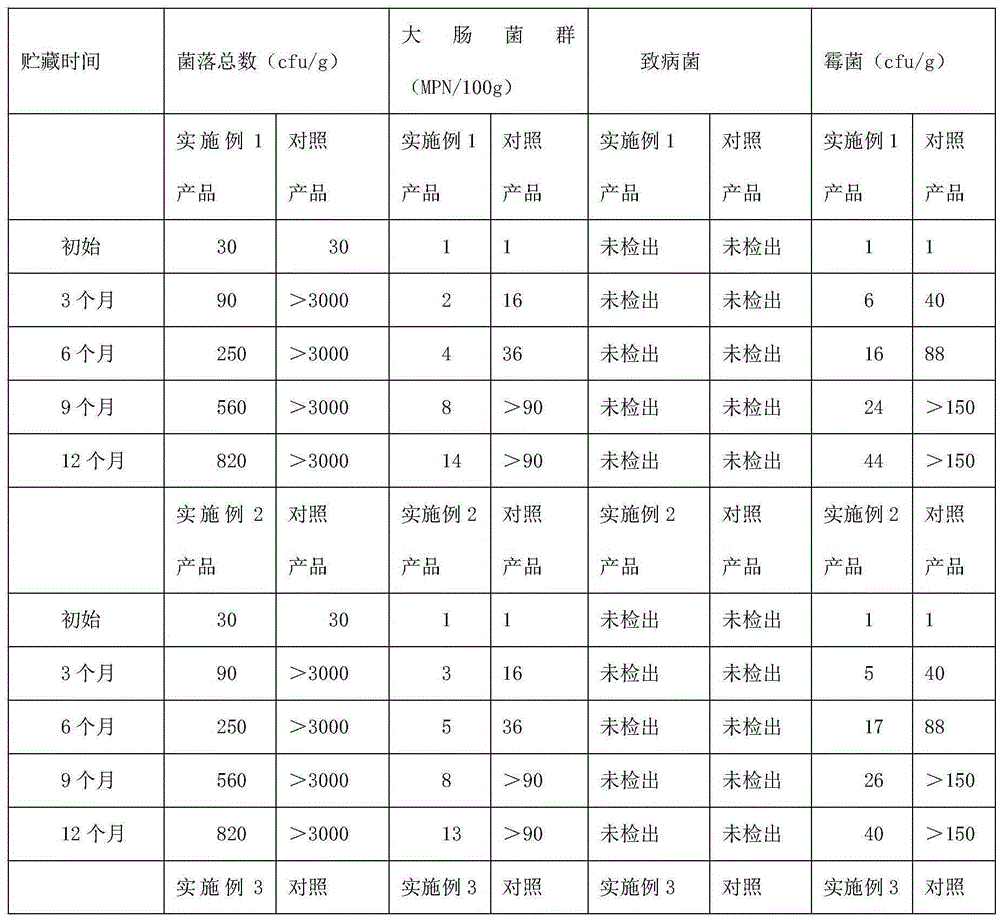

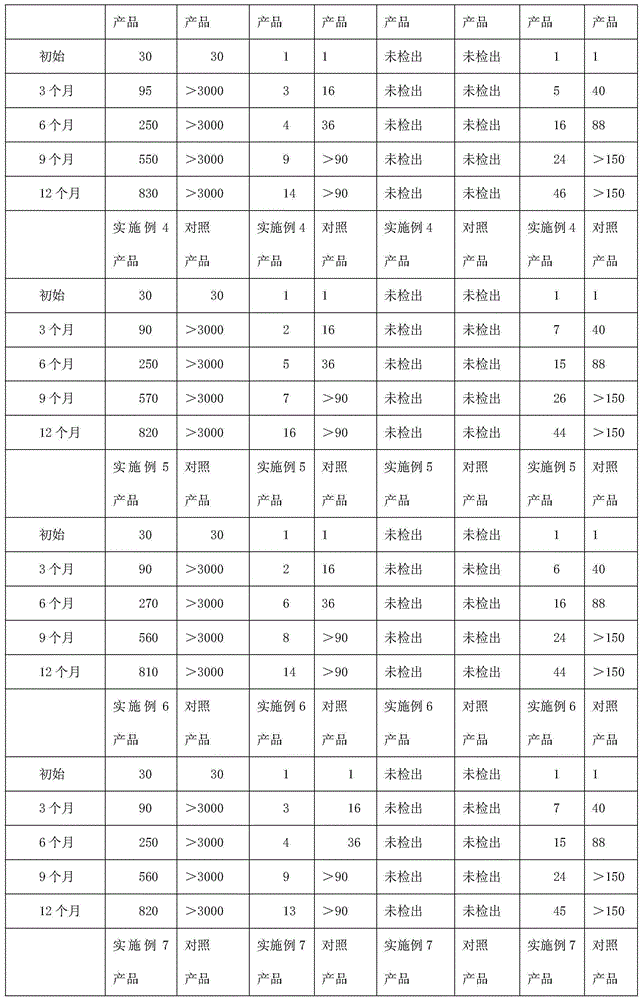

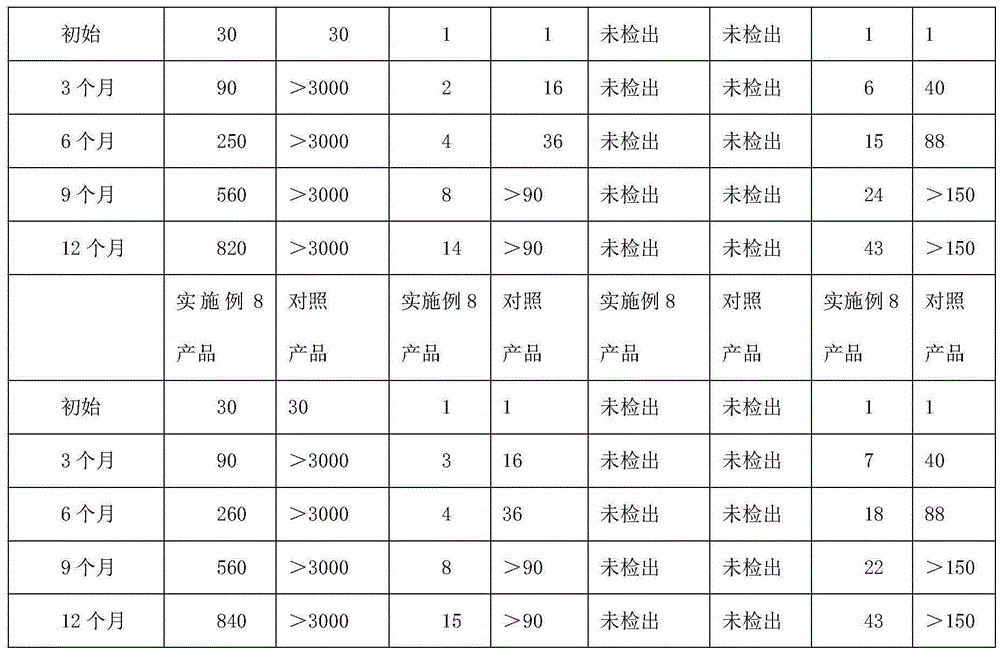

Fresh keeping coating agent and application thereof in fresh keeping of medium-humidity dried longan pulp and medium-humidity dried litchi pulp

InactiveCN105285078AEnhanced inhibitory effectExtended shelf lifeFruits/vegetable preservation by coatingSnow moldEssence oil

The invention discloses a fresh keeping coating agent and application thereof in the fresh keeping of medium-humidity dried longan pulp and medium-humidity dried litchi pulp. According to the fresh keeping coating agent disclosed by the invention, waste products in the processing course of the dried longan pulp and the dried litchi pulp, namely longan husks, longan seeds, litchi husks and litchi seeds are used as raw materials and are scientifically extracted so that a extract mixture is obtained, and the synergistic bacteriostasis effects of the extract mixture, pimaricin, honeysuckle essential oil and mint essential oil are sufficiently exerted to have better effects of restraining bacteria, yeast and / or mould, which are easy to produce in the fresh keeping process of dried fruits. Based on the extract mixture, chitosan in a reasonable proportion is utilized so that a film is successfully formed, the quality guarantee period of medium-humidity dried fruits is successfully prolonged in a manner of coating fresh keeping for the dried fruits, and the effects of comprehensively utilizing the raw materials and turning waste into wealth are achieved.

Owner:HUIZHOU SIJIXIAN GREEN FOOD +1

Method for preparing ceramsite by using coal chemical processing wastes and refinery oily sludge

InactiveCN108455969AAvoid high energy consumptionEasy to operateCeramic materials productionCeramicwareCinderScrap

The invention discloses a method for preparing ceramsite by using coal chemical processing wastes and refinery oily sludge. Fly ash from chemical processing of coals, refinery oil sludge, coal chemical processing cinder and a special proppant are evenly mixed, the mixture is added with water, and pelletized in a disk grain making machine, and then the pellets are sent to a calcining furnace for high-temperature sintering, then cooled for discharging, and placed at room temperature to prepare ceramsite. According to the method provided by the invention, reduced oil sludge, homogenization-drying-sorting integrated treatment and a rotary kiln high-temperature melting solid waste treatment coupling technology are adopted to carry out harmless treatment and resource utilization on oily sludge.The method provided by the invention can effectively reduce the landfill treatment capacity of coal chemical processing residues and converts the residues into a light wall material available for construction. On the other hand, based on the proppant developed by a large number of researches on basic components of oily sludge, the defect of insufficient ceramsite cylinder compressive strength after burning of the oil sludge and coal chemical processing residues is successfully solved. The resource utilization and harmless treatment of the oil sludge is truly realized and sustainable economic development is achieved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

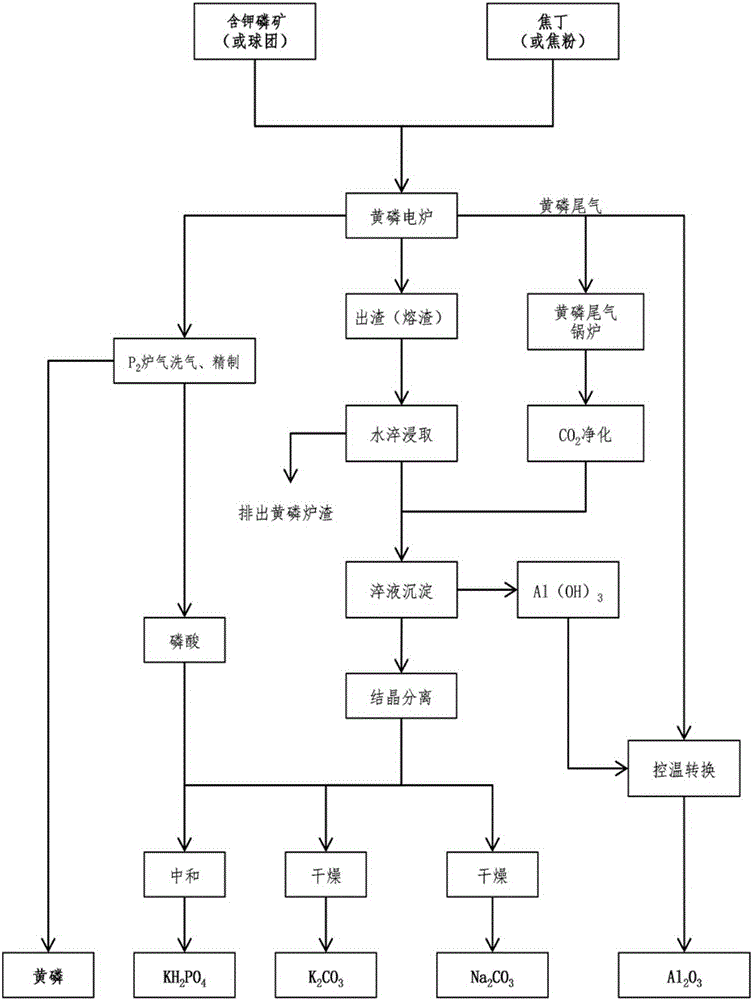

Energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite

ActiveCN105197901AReduce manufacturing costTake advantage ofChemical industryAlkali metal carbonatesFiltrationQuenching

The invention relates to an energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite. The method comprises the steps that the potassium-bearing phosphorite and coke nuts are added into a yellow phosphorus electric furnace to be reacted to obtain furnace gas containing P2; washing is conducted on the furnace gas, crude phosphorous is collected, refining is conducted, and high quality yellow phosphorus is obtained; water quenching is conducted on yellow phosphorus slags, the slags are removed, KAlO2 is dissolved out, filtration is conducted, Al(OH)3 is settled after CO2 is added, and water quench filtrate is obtained. The Al(OH)3 is converted through temperature control to obtain Al2O3, crystal separation and drying are conducted on the water quench filtrate, and K2CO3 and Na2CO3 are obtained. According to the energy-saving method for preparing the yellow phosphorus, the sylvite, the sodium carbonate and the aluminum oxide through the potassium-bearing phosphorite, series of problems that for a traditional electrothermal method that the potassium-bearing phosphorite is used for producing the yellow phosphorus through the yellow phosphorus electric furnace, the reaction is complex, the efficiency is low, furnace ore is unstable, and the benefit is poor are solved; compared with preparing K2CO3 through a traditional orthoclase sintering method, a high-temperature melting method, a hydrothermal method, a blast furnace smelting method and a low-temperature decomposition method, the energy consumption, material consumption and production cost can be greatly reduced, product profit margins are improved, and meanwhile environmental pollution is reduced.

Owner:黄钰雪

Power generation system using speed reduction slope

InactiveCN101294552ASimple structurePractical and convenientMachines/enginesMechanical energy handlingEngineeringCrankshaft

The invention discloses a power generation system by adopting a deceleration slope to generate power. The system comprises a deceleration slope body, and is characterized in that the underside of the deceleration slope body is connected with a ram pump through a connecting bar; the ram pump is connected with a hydraulic crankshaft; one end of the crankshaft is connected with the neck of a telescopic link of a pressure cylinder, the other end of the crankshaft is connected with a gear cluster and the gear cluster is connected with a generator. The deceleration slope power generation system designed by the invention is characterized by simple structure, practicality and convenience, and is beneficial to comprehensive use of resources.

Owner:SHANGHAI YANGPU SENIOR MIDDLE SCHOOL

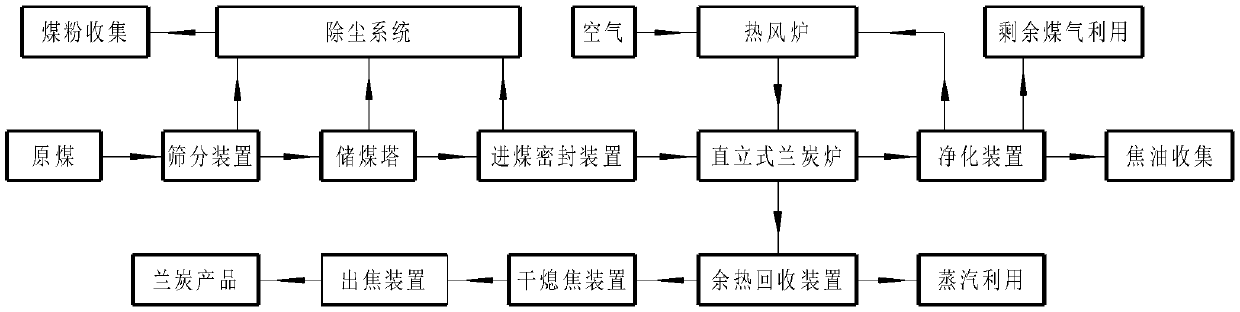

Method for producing semi-coke by carbonizing lump coal through vertical circular furnace

InactiveCN107641520ANo leaksQuality improvementCoke quenchingIndirect and direct heating destructive distillationResource utilizationFlue gas

The invention discloses a method for producing semi-coke by carbonizing lump coal through a vertical circular furnace. The method comprises the following steps: raw coal is sieved into the lump coal and fine coal; the lump coal enters a charged coal sealing device of the vertical circular furnace; coal dust is centrally collected and treated; the lump coal at a drying section of the furnace body makes contact with high-temperature raw coke oven gas generated by the carbonizing the lump coal at a carbonization section of a furnace body, so that water in the lump coal is removed; dried and dehydrated lump coal enters the carbonization section; coal gas and air are mixed and then are combusted in a hot air furnace to generate high-temperature flue gas; two-section heat is provided for the carbonization section of the furnace body so as to carbonize the lump coal, and further the semi-coke and the raw coke oven gas are generated; the raw coke oven gas passes through the drying section andwater in the lump coal is taken away for educing; the semi-coke enters a waste heat recycling device, and generated steam is subjected to waste heat power generation or is supplied to a steam using device in a factory; the semi-coke is quenched to obtain a finished semi-coke product; the raw coke oven gas is sprayed, washed and cooled and then enters a tar and coal gas separating and purifying device for separating and purifying to obtain finished products of tar and coal gas. The method disclosed by the invention has the advantages of safe and stable technological process, energy conservation, environmental protection and high resources utilization ratio.

Owner:西安三瑞煤化工科技有限公司

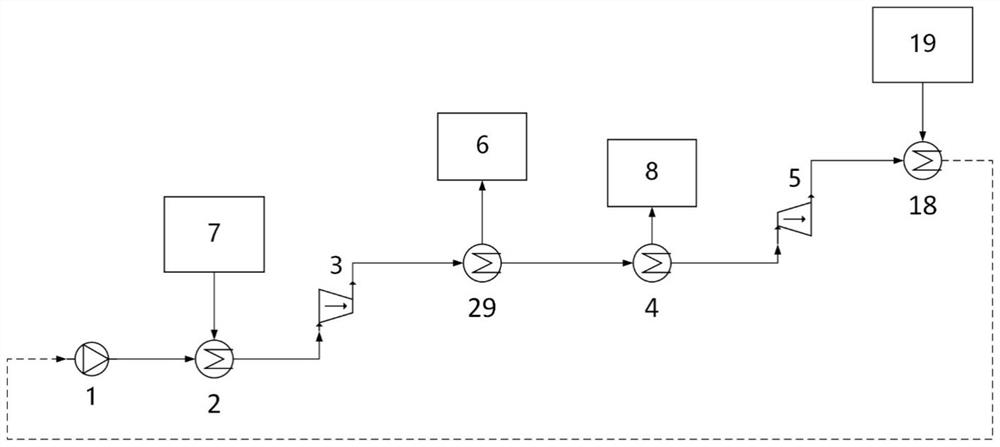

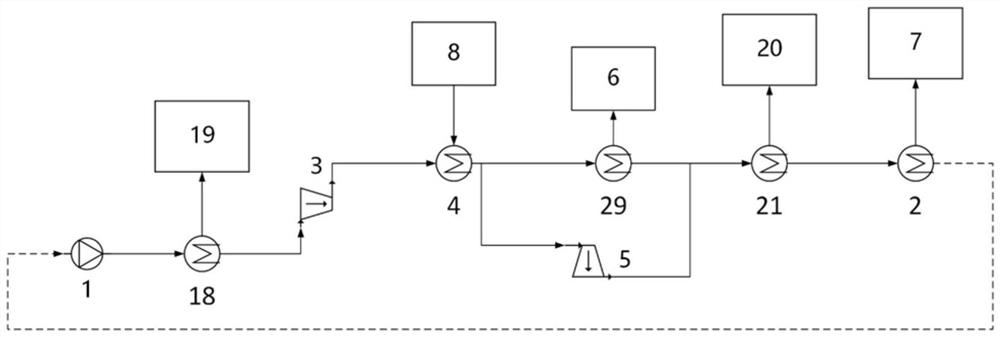

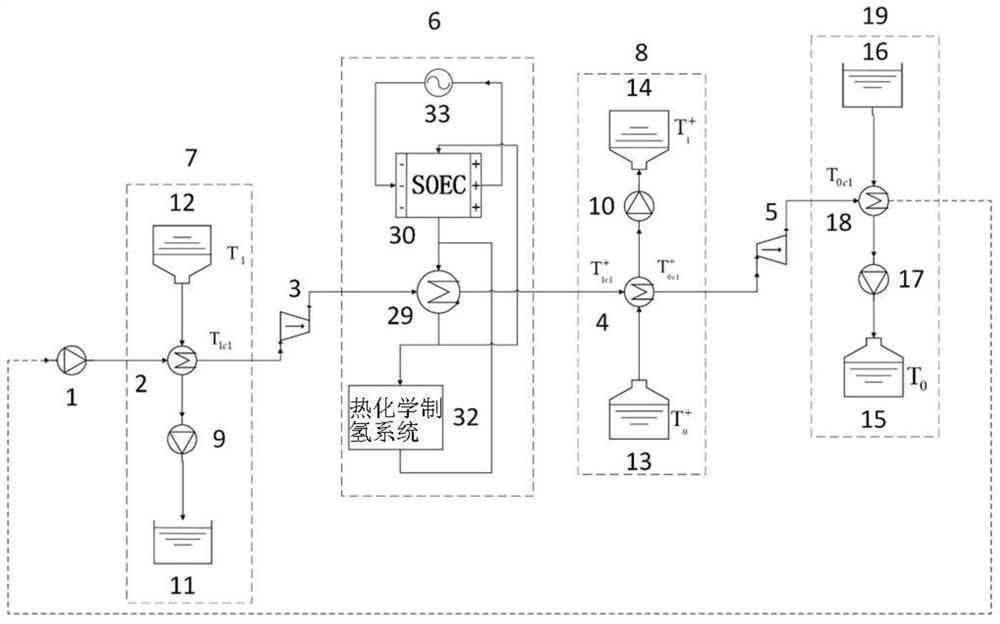

Heat pump type-hydrogen energy composite energy storage power generation method and device

ActiveCN113540504AImprove power generation efficiencyAchieve comprehensive utilizationFuel cell heat exchangeHeat storage plantsThermal dilatationBrayton cycle

The invention provides a heat pump type-hydrogen energy composite energy storage power generation method. In an energy storage hydrogen production mode, a normal-temperature working medium is subjected to adiabatic compression through a compressor and then releases heat through a hydrogen energy system, and at the moment, the hydrogen energy system produces hydrogen; then the main heat storage system carries out an isobaric heat release process to complete heat storage and energy storage, the working medium enters a turbine to carry out adiabatic expansion to do work outwards, and finally, the discharged working medium circulates or is released to the outside; in a power generation mode, a normal-temperature working medium is subjected to adiabatic compression through the compressor and then is subjected to isobaric heat absorption through the main heat storage system; one path of the working medium enters a turbine to adiabatically expand to apply work outwards, and the other path of the working medium releases heat through a hydrogen energy system; and at the moment, the hydrogen energy system generates power, and finally, the working medium circulates or is released to the outside. The invention further provides a corresponding device. According to the energy storage power generation method, high-temperature heat is provided for the fuel cell while Brayton cycle power generation is carried out, so that the power generation efficiency of the hydrogen energy system is remarkably improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

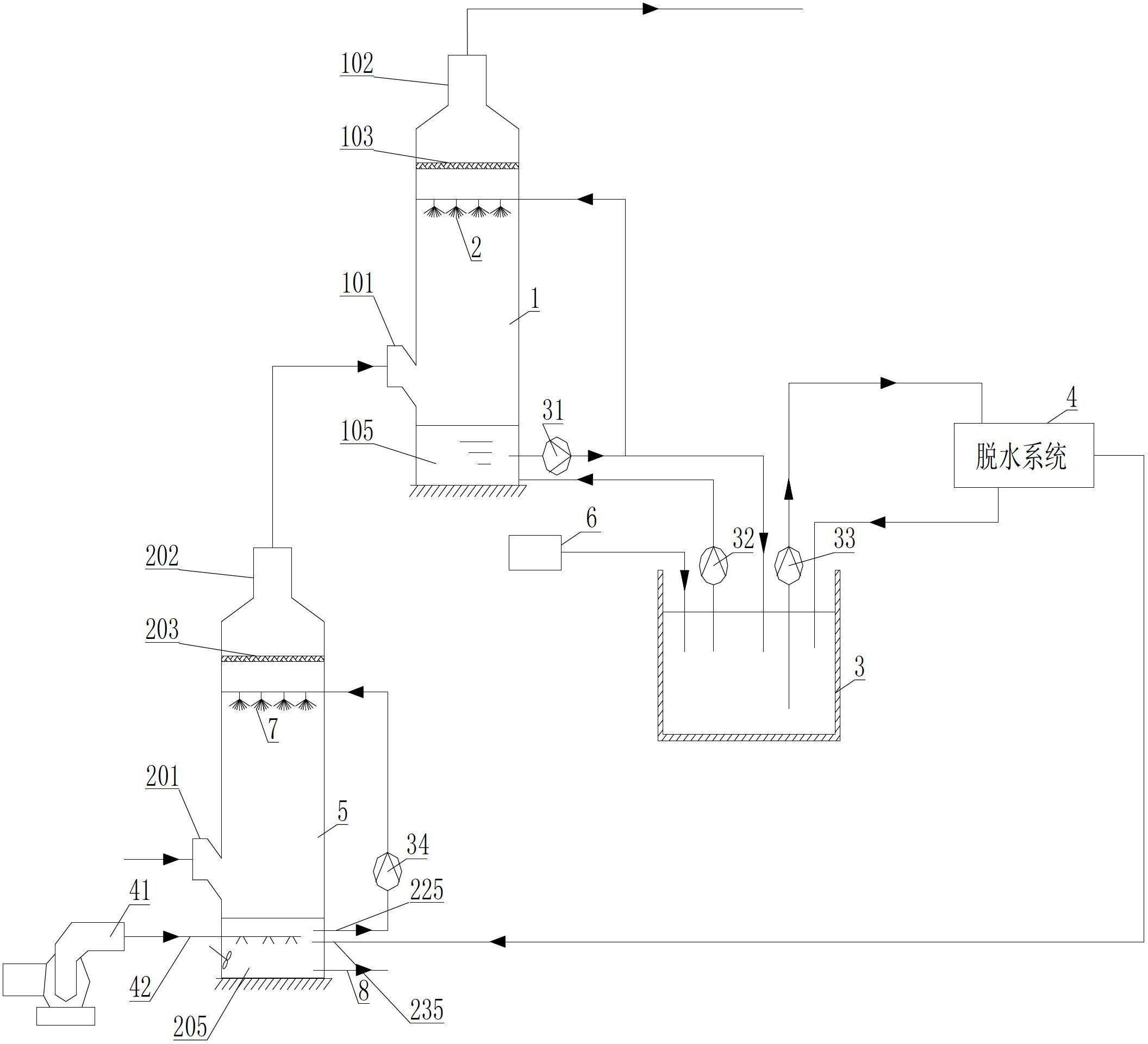

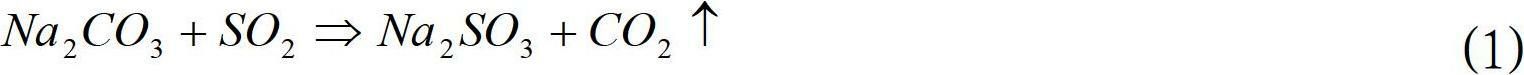

Flue gas desulfurization system and method

InactiveCN102688685ATake advantage ofAchieve comprehensive utilizationDispersed particle separationSlurryTower

The invention discloses a flue gas desulfurization system and method. The system is characterized in that a prepositive desulfurization tower is arranged in front of a main desulfurization tower; a prepositive desulfurization smoke inlet is formed in the middle of the prepositive desulfurization tower; a prepositive desulfurization smoke outlet and a prepositive spray device positioned below the prepositive desulfurization smoke outlet are arranged on the top of the prepositive desulfurization tower; a reaction tank is arranged at the bottom of the prepositive desulfurization tower and is provided with an oxidized air inlet, a slurry outlet, a feeding hole and a gypsum discharging hole; a regeneration pool is connected with the feeding hole at the bottom of the prepositive desulfurization tower by virtue of a delivery pump and a dehydration device; the slurry outlet is connected with the prepositive spray device by virtue of a third circulating pump; and the prepositive desulfurization smoke outlet is connected with the smoke inlet of the main desulfurization tower. The desulfurization system and method have the advantages that desulfurization products generated by a double-alkali method are fully utilized, pollution is avoided, and desulfurization efficiency is improved.

Owner:SHANGHAI HANZHUO ENERGY TECH

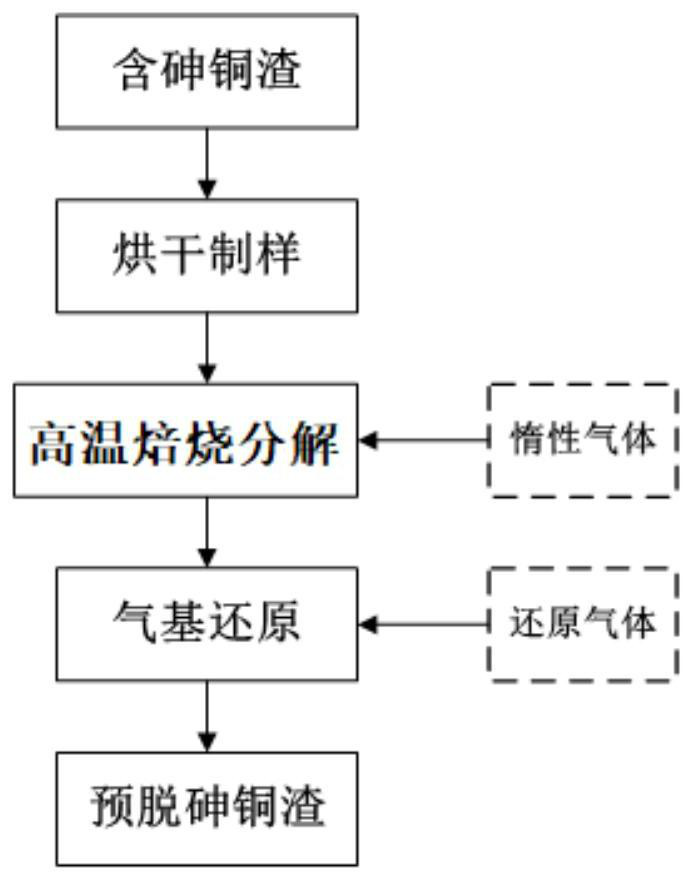

Roasting gas-based reduction arsenic removal method for arsenic-containing copper slag

ActiveCN111647738AReduce arsenic levelsAchieve comprehensive utilizationSulfur preparation/purificationArsenateArsenic oxide

The invention relates to a roasting gas-based reduction arsenic removal method for arsenic-containing copper slag, and belongs to the field of solid waste treatment and utilization in the non-ferrousmetallurgy industry. The problem that an arsenic content in a reduced iron product exceeds the standard in the prior art is solved. The roasting gas-based reduction arsenic removal method for the arsenic-containing copper slag comprises the following steps of 1, grinding the arsenic-containing copper slag, and drying slag powder to remove free water, and specifically, the arsenic-containing copperslag contains arsenic oxide, arsenic sulfide and arsenate; 2, carrying out high-temperature roasting on the slag powder, introducing inert gas in a high-temperature roasting process, carrying out high-temperature roasting decomposition on the arsenic oxide and the arsenic sulfide in the arsenic-containing copper slag, then volatilizing in a gas form, and forming arsenic roasting slag from non-volatile components; and 3, continuously introducing reducing gas into the arsenic roasting slag for 40-100 minutes at the reducing temperature of 650-1200 DEG C, and gasifying and removing the arsenatein the arsenic roasting slag to obtain arsenic-removed slag charge of the arsenic-containing copper slag. According to the roasting gas-based reduction arsenic removal method, the arsenic content in the slag can be obviously reduced, and raw material with the qualified arsenic content is provided for subsequent continuous treatment of the copper slag.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com