Exhaust heat steam turbine air-supplementary regulation system and its control method

A technology for regulating systems and steam turbines, applied to steam engine devices, mechanical equipment, engine components, etc., can solve problems such as non-adjustability, low-pressure steam temperature, and environmental pollution, and achieve improved stability, power generation, and high efficiency of waste heat utilization , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

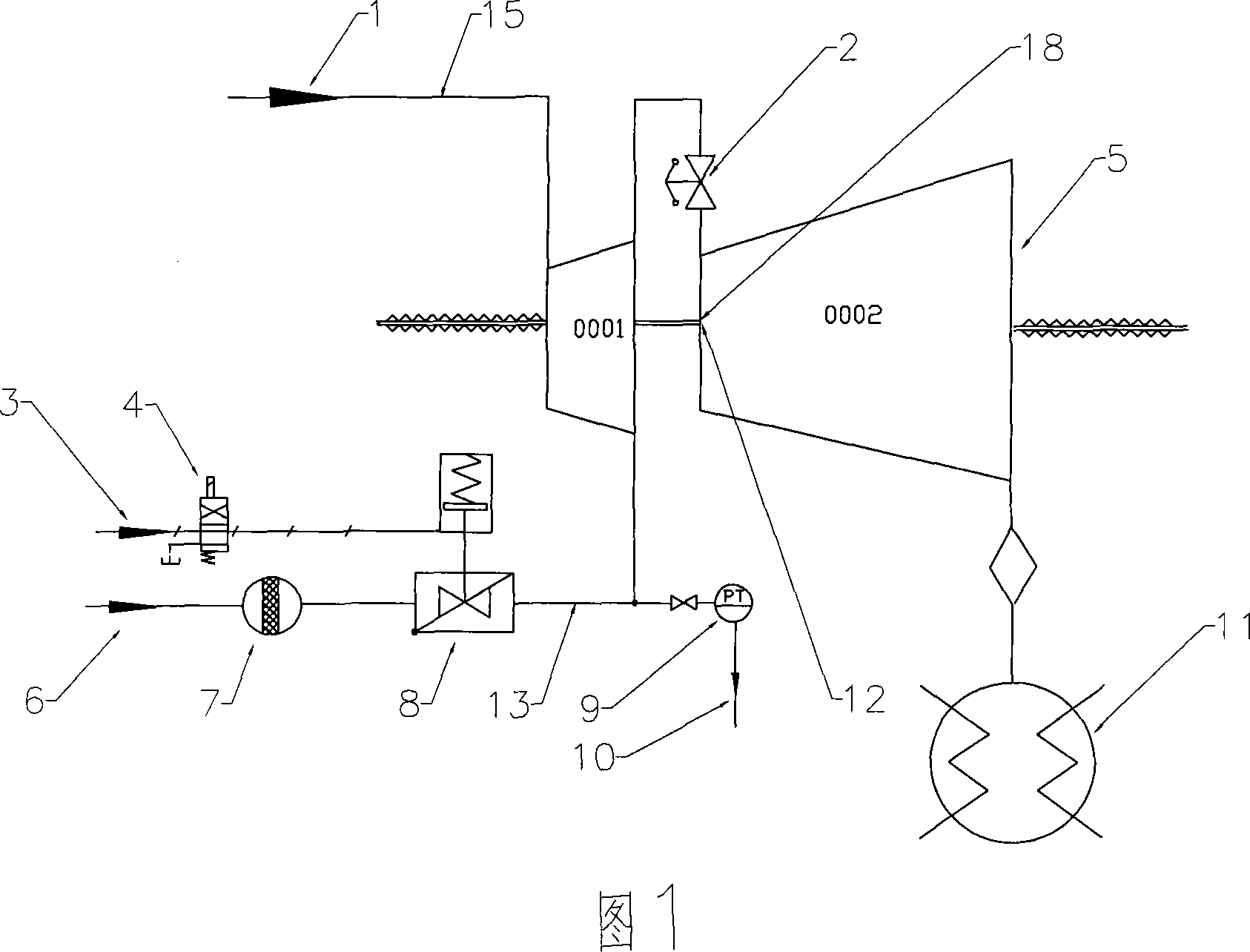

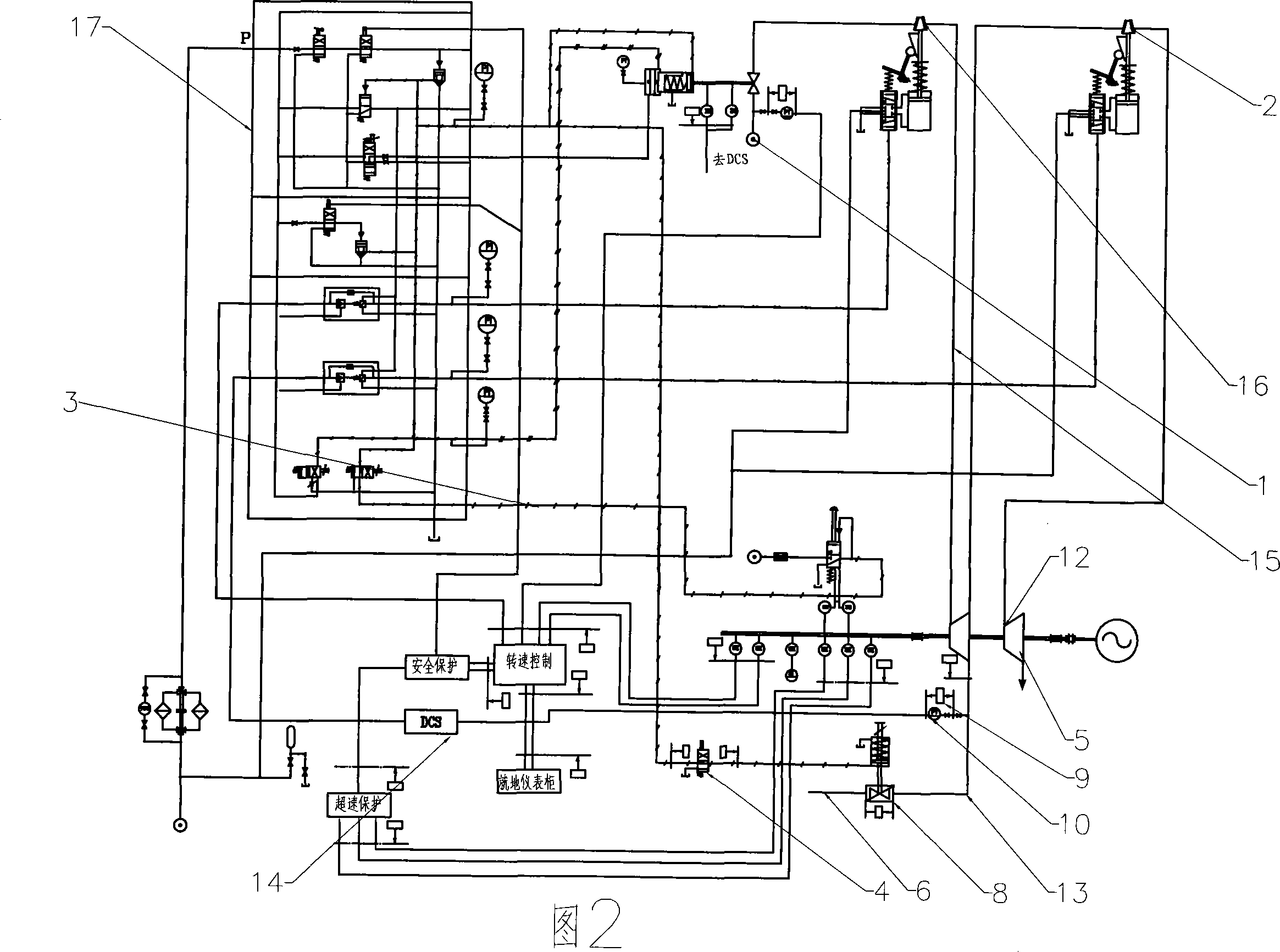

Embodiment 1

[0015] As shown in Figure 1, a waste heat utilization steam turbine supplementary steam adjustment system described in this embodiment includes an adjustable steam supplementary steam adjustment valve 2, a pressure steam turbine 5, a transmitter 9, a steam-water separator 7, and a regulator 14, The interstage position 18 of the steam turbine 5 is provided with a steam supply port 12, and the steam supply port 12 is connected with a steam supply pipeline 13, and the steam supply pipeline 13 is provided with a steam-water separator 7, between the steam-water separator 7 and the steam supply port 12 The steam supply pipeline 13 between is provided with an adjustable steam supply regulating steam valve 2, the execution signal of the adjustable steam supply regulating steam valve 2 is connected with the output control signal of the regulator 14, and a pressure transmitter 9 is set on the supply steam pipeline 13 , the admission steam pressure signal 10 of the pressure transmitter 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com