Self-aligning grinding surface nanocrystallization device

A nano-centering and centering technology, applied in the field of material surface rolling processing, can solve the problems of uneven pressure on the rolling head, inconvenient operation, low processing efficiency, etc., and achieve humanized operation, high processing efficiency and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

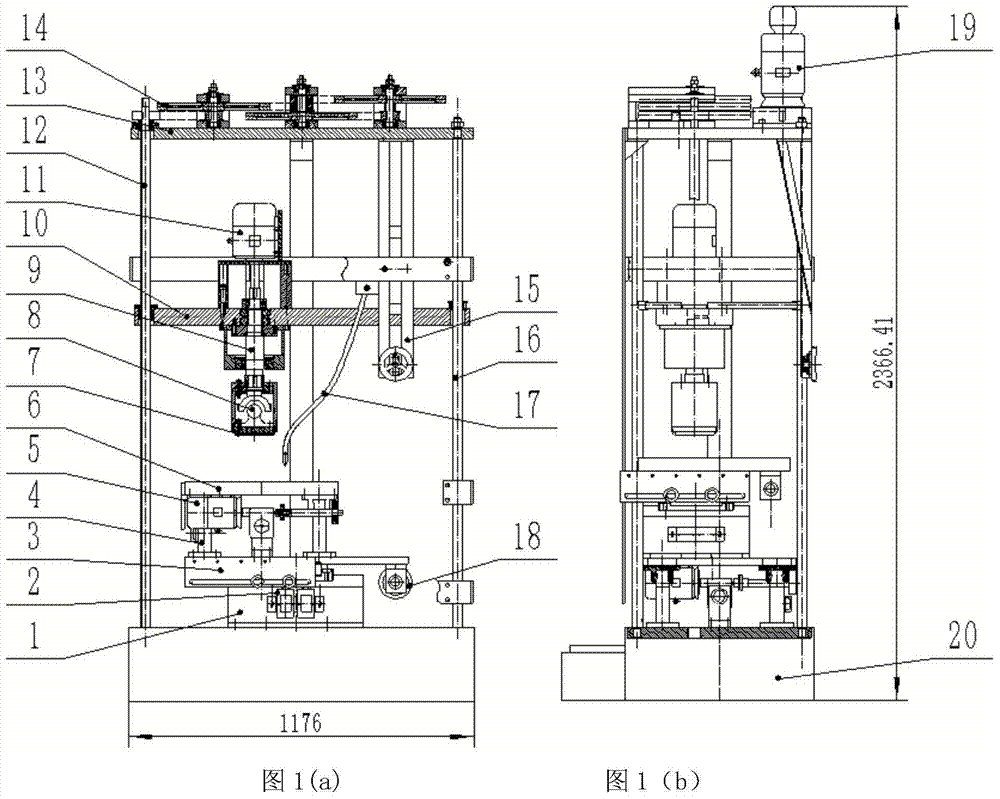

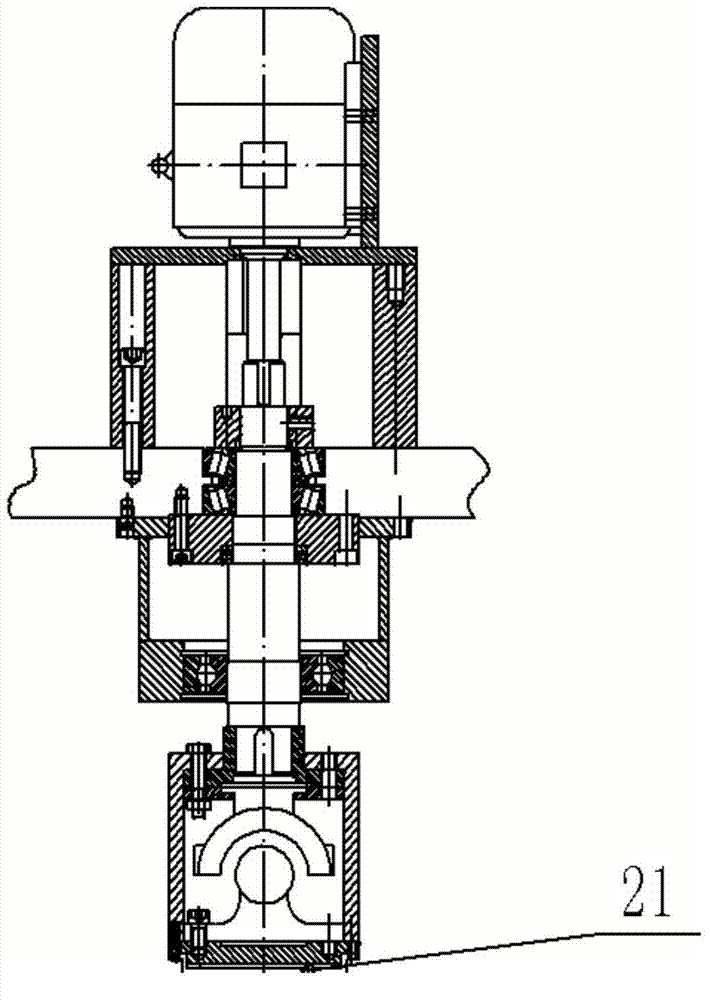

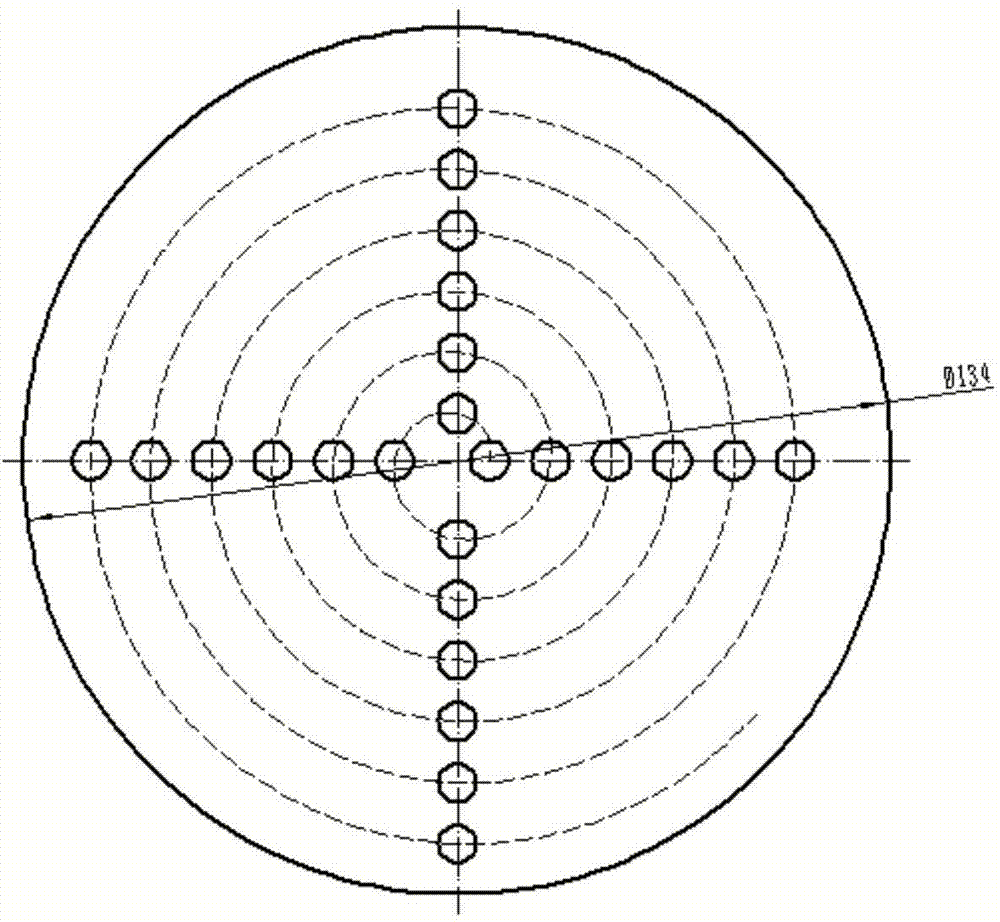

[0034] As shown in Figure 1(a)-(b), the novel device for nano-micronizing the surface of metal materials of the present invention consists of four motors (a variable-speed motor 19 on the top to control the middle beam, a spindle motor 11 to control the speed of the rolling head, two It is composed of five main parts: the feed motor 5 for table control feed, the top spindle lift and speed change pulley group 14, the middle spindle drive shaft system, the combination of rolling head, the workbench and the overall frame of the equipment for realizing horizontal and vertical bidirectional feed. The equipment adopts mechanical transmission and pressurization mode: the variable speed motor 19 controlling the middle beam drives the transmission screw 12 on both sides to rotate through the pulley transmission system, so that the middle beam 10 where the rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com