Mortar for building and plastering PTB aerated concrete blocks and using method thereof

A technology of air-entrained concrete and plastering mortar, which is applied in the direction of construction, building structure, and building materials, and can solve the problems of cracks in the walls of air-entrained concrete blocks, large drying shrinkage, and long dehumidification time and other problems, to achieve good water retention, improve water retention, and increase resistance to deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

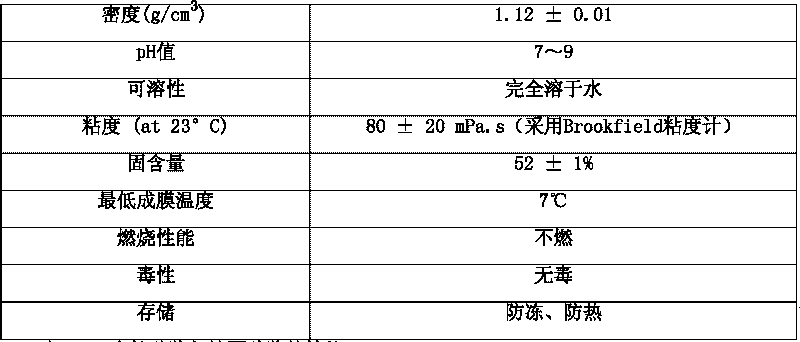

[0019] Raw materials: PTB aqueous solution and PTB powder, the weight ratio of PTB aqueous solution to PTB powder is: (0.1-0.3): 1, PTB emulsion (ie COMPAKTUNA PRO) and water in a volume ratio of 1: (1-40), mix Evenly into PTB aqueous solution.

[0020] PTB powder is: according to weight percentage, ordinary portland cement 20-40%, fine sand 30-40%, aerated concrete block waste 30-40%, the ordinary portland cement, fine sand and aerated The weight sum of concrete block waste is 100%; cellulose ether is added to the three raw materials: the amount of the cellulose ether is 0.2-0.4wt% of the cement amount, and the mixture is uniform.

[0021] The aerated concrete block waste is: the aerated concrete block waste generated when the aerated concrete block is used is crushed into fragments with a particle size within the range of 30 to 100 mesh; the cellulose ether is made of methyl fiber plain ether.

[0022] Instructions:

[0023] Masonry Mortar:

[0024] 1) Slowly add the PTB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com