Process of comprehensively utilizing caustic sludge from papermaking industry

A solid waste residue and papermaking industry technology, applied in the field of comprehensive utilization of solid waste residue recovered by alkali in the papermaking industry, can solve the problems of lime mud whiteness, uniformity, and poor particle surface strength and purity, and achieve the goal of reducing processing and operating costs and improving economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

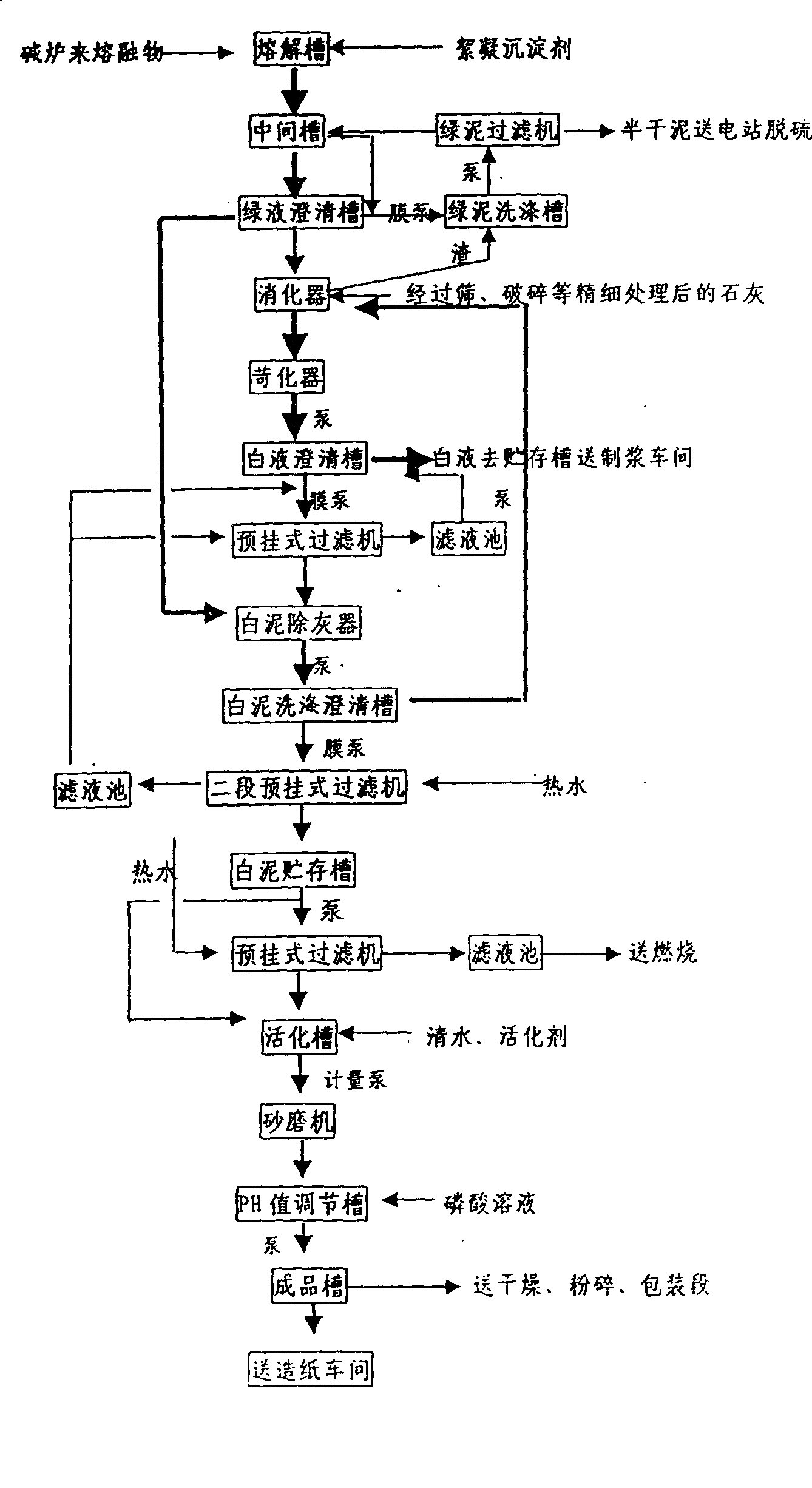

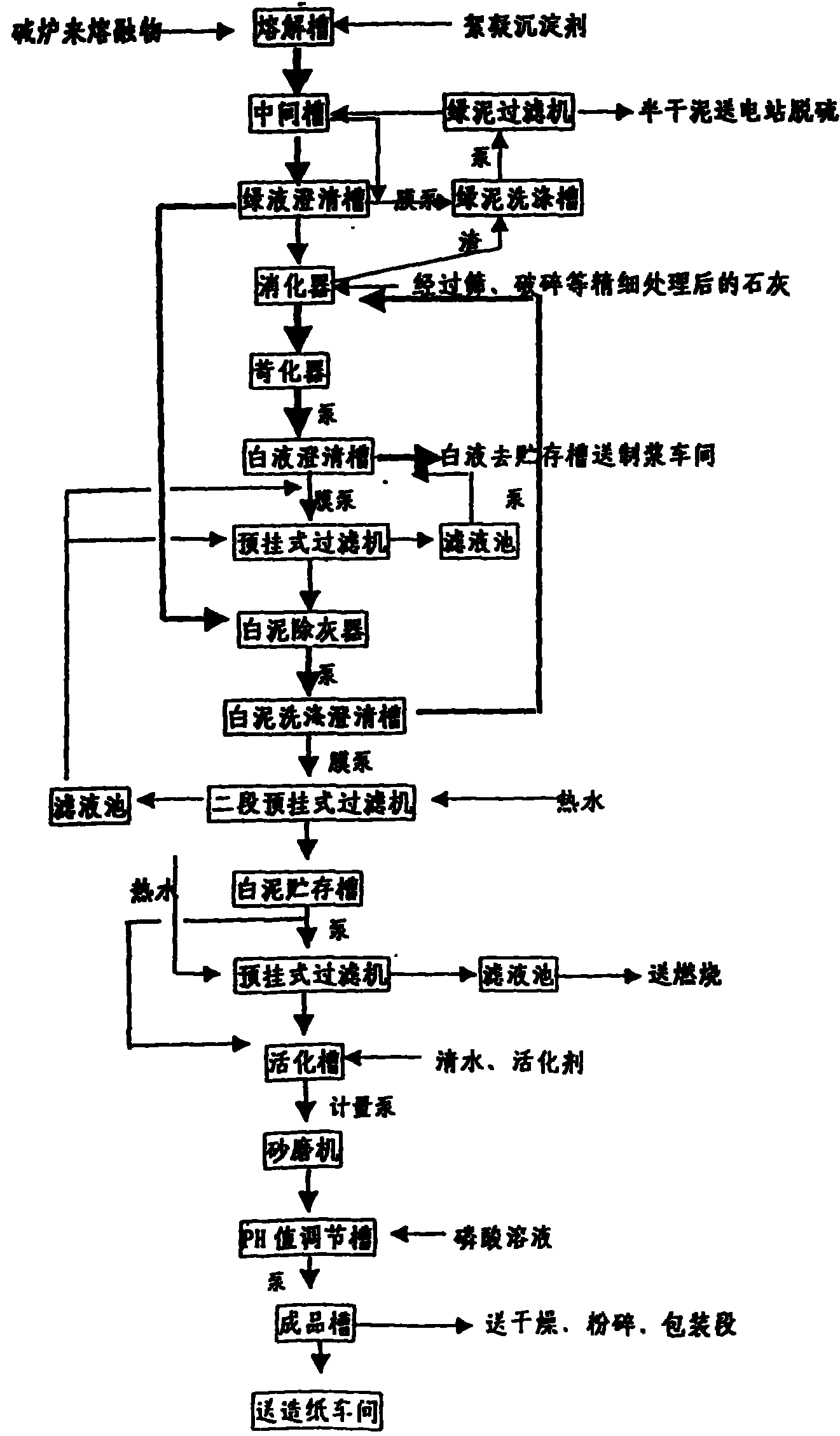

Method used

Image

Examples

specific Embodiment approach 2

[0046] Carry out according to specific embodiment one, just change the add-on of flocculation sedimentation aid into 3% molten matter amount in step (1); Change the mesh sieve in step (2) into 7 mesh and carry out sieving process, extract slag Sieve with 250 mesh sieves in the process; The vacuum degree in step (3) is adjusted to 550mmHg and carries out vacuum washing slag dehydration; Change the reaction condition in step (4) to reaction concentration 25%, reaction temperature 95 ℃, reaction The reaction time is 100 minutes. After the reaction, the pH value is adjusted to PH10, and fully stirred; the steam is passed into step (5) and the temperature is raised to 72 ° C, and 2% of the treated activator is added, and wet activation treatment is carried out in the activation tank Wash after 40 minutes, adjust the concentration and adjust the pH value to pH10 after grinding to form a calcium carbonate emulsion.

specific Embodiment approach 3

[0047] Carry out according to specific embodiment one, just change the add-on of flocculation sedimentation aid into 4% melt amount in step (1); Change the mesh sieve in step (2) into 9 mesh and carry out sieving process, extract slag Sieve with 250 mesh sieves in the process; The vacuum degree in step (3) is adjusted to 550mmHg and carries out vacuum washing slag dehydration; Change the reaction condition in step (4) to reaction concentration 25%, reaction temperature 100 ℃, reaction The reaction time is 110 minutes. After the reaction, the pH value is adjusted to PH10 and fully stirred; the temperature is raised to 74°C by introducing steam in step (5), adding 2% of the treated activator, and performing wet activation treatment in the activation tank Wash after 40 minutes, adjust the concentration and adjust the pH value to pH10 after grinding to form a calcium carbonate emulsion.

specific Embodiment approach 4

[0048] Carry out according to specific embodiment 1, just change the add-on of flocculation sedimentation aid into 5% melt amount in step (1); Change the mesh sieve in step (2) into 10 mesh and carry out sieving process, extract slag Use 300 mesh sieves to sieve in the processing; The vacuum in the step (3) is adjusted to 600mmHg to carry out vacuum washing slag dehydration; Change the reaction condition in the step (4) into reaction concentration 30%, reaction temperature 105 ℃, reaction The reaction time is 120 minutes. After the reaction, the pH value is adjusted to PH10.5, and fully stirred; the steam in step (5) is heated to 75 ° C, and 3% of the treated activator is added, and the wet method is carried out in the activation tank. Wash after 40 minutes of activation treatment, adjust the concentration and adjust the pH value to PH10.5 after grinding treatment to form a calcium carbonate emulsion.

[0049] The present invention is implemented according to the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com