Method for producing tungsten-molybdenum product by processing tungsten-molybdenum symbiotic mixed ore

A technology of mixing ore, tungsten and molybdenum, applied in the direction of improving process efficiency, can solve the problems of difficult separation, environmental pollution, high cost, etc., and achieve the effect of short process flow, lower production cost, and protection of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The method for processing and producing tungsten-molybdenum products from the tungsten-molybdenum symbiotic mixed ore of the present invention will be further described in detail below.

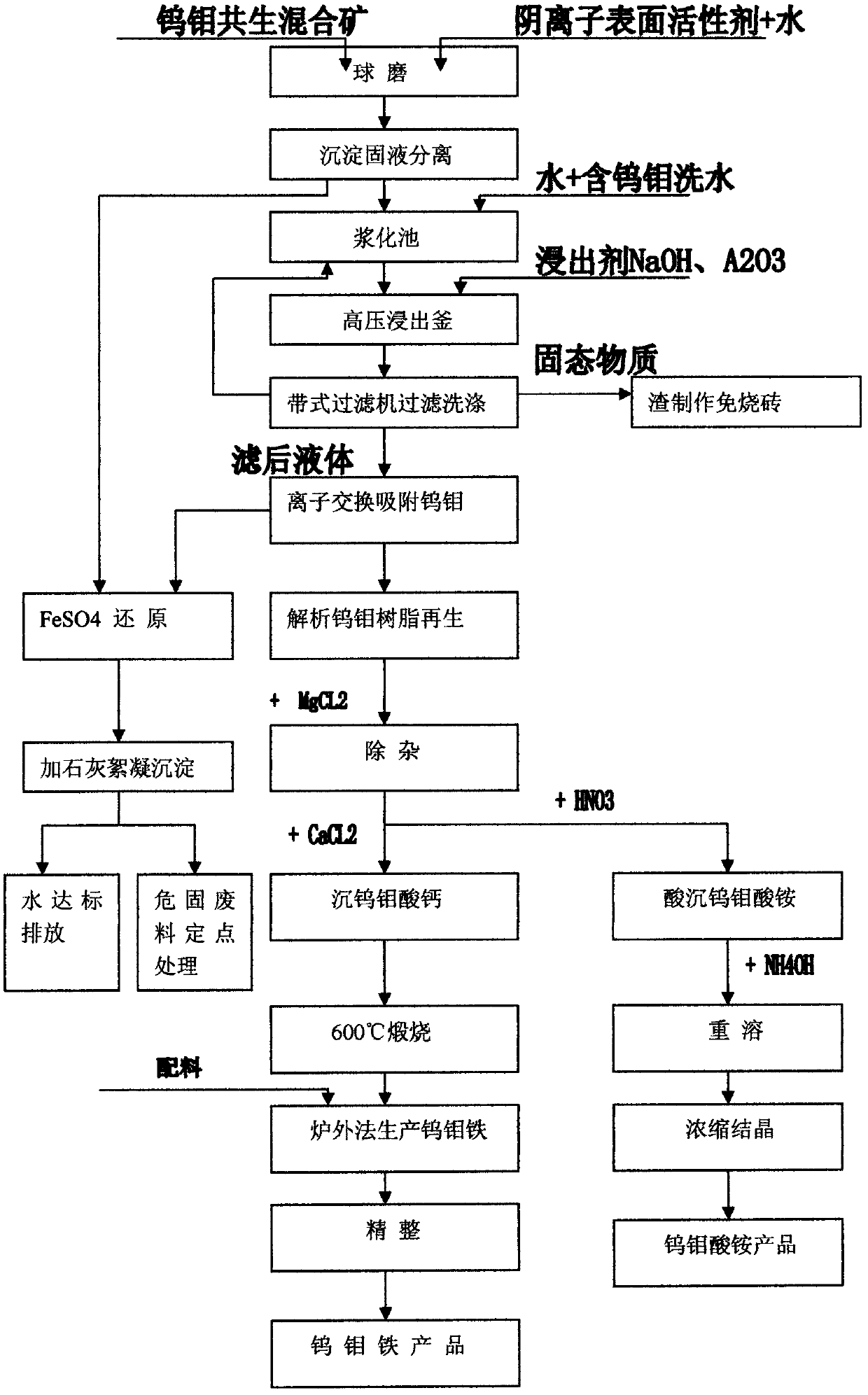

[0039] As shown in Fig. 1, a kind of tungsten-molybdenum symbiotic mixed ore processing method of the present invention produces tungsten-molybdenum product, comprises the following steps:

[0040] 1) The tungsten-molybdenum symbiotic mixed ore is mixed with water according to the solid-liquid volume ratio of 1:3, and then an anionic surfactant of 1% by weight of the tungsten-molybdenum symbiotic mixed ore is added;

[0041] 2) Carry out solid-liquid separation after ball milling with a vibration ball mill;

[0042] 3) The filtered liquid enters the wastewater treatment tank for treatment, and the solid is pumped into the pulping tank;

[0043] 4) Mix the obtained tungsten-molybdenum symbiotic mixed ore solid with water in a ratio of 1:3 solid-liquid volume in the slurry tank, add lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com