Decorative chromium plating method of aluminum and aluminum alloy parts

A technology of aluminum alloy parts and pre-nickel plating, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of poor bonding force, peeling, blistering, etc., and achieve the solution of blistering and peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

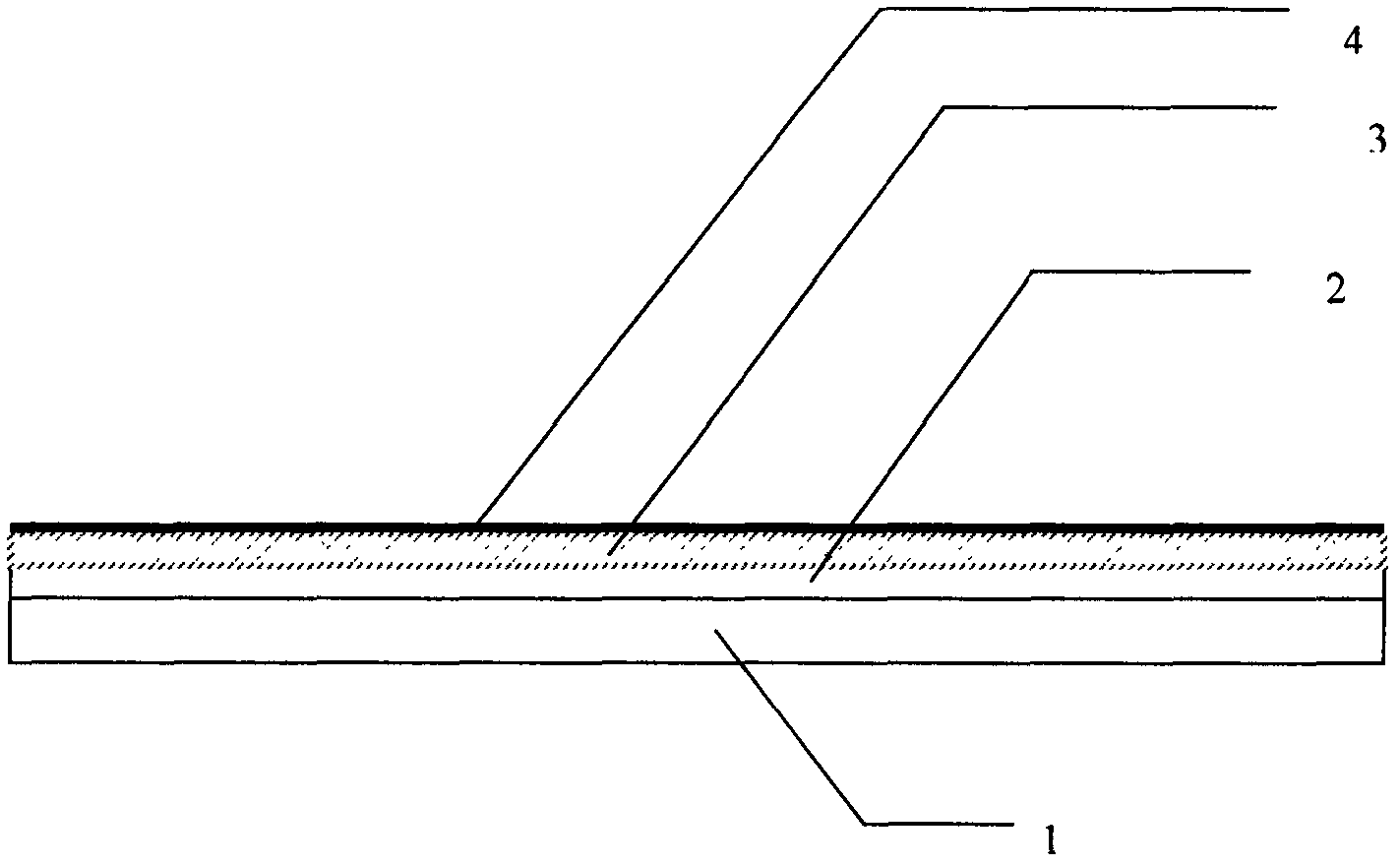

Image

Examples

Embodiment Construction

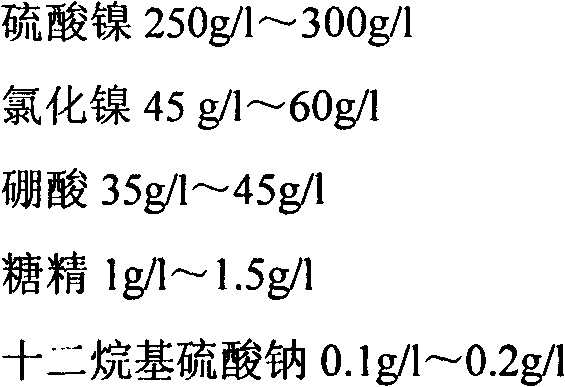

[0010] The embodiment of chemical galvanizing among the present invention is as follows:

[0011] The electroplating effect on aluminum and aluminum alloy substrates mainly depends on the meticulousness of the pre-plating preparation, so the chemical galvanizing process is strictly controlled as a key step in the entire electroplating process. According to the process requirements, the aluminum parts that have undergone pretreatments such as degreasing and alkali corrosion are chemically galvanized in zincate. Aluminum is more active, and when the oxide film on the surface and aluminum are dissolved in the solution, an equal amount of zinc is replaced, and the reaction is as follows:

[0012] 2Al+3Zn 2+ →3Zn+2Al 3+

[0013] The reaction stops when the very thin zinc layer is completely covered.

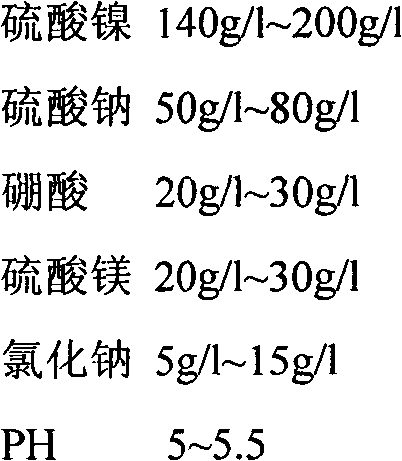

[0014] The zinc dipping process used in the existing electroplating decorative chromium process is as follows, and the zinc dipping solution is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com