Comprehensive treatment process for semi-coking wastewater

A semi-coke wastewater and comprehensive treatment technology, applied in the direction of water/sewage multi-stage treatment, degassed water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex process and high treatment cost, and achieve the goal of protecting the ecological environment, The effect of reducing the gas-water ratio and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

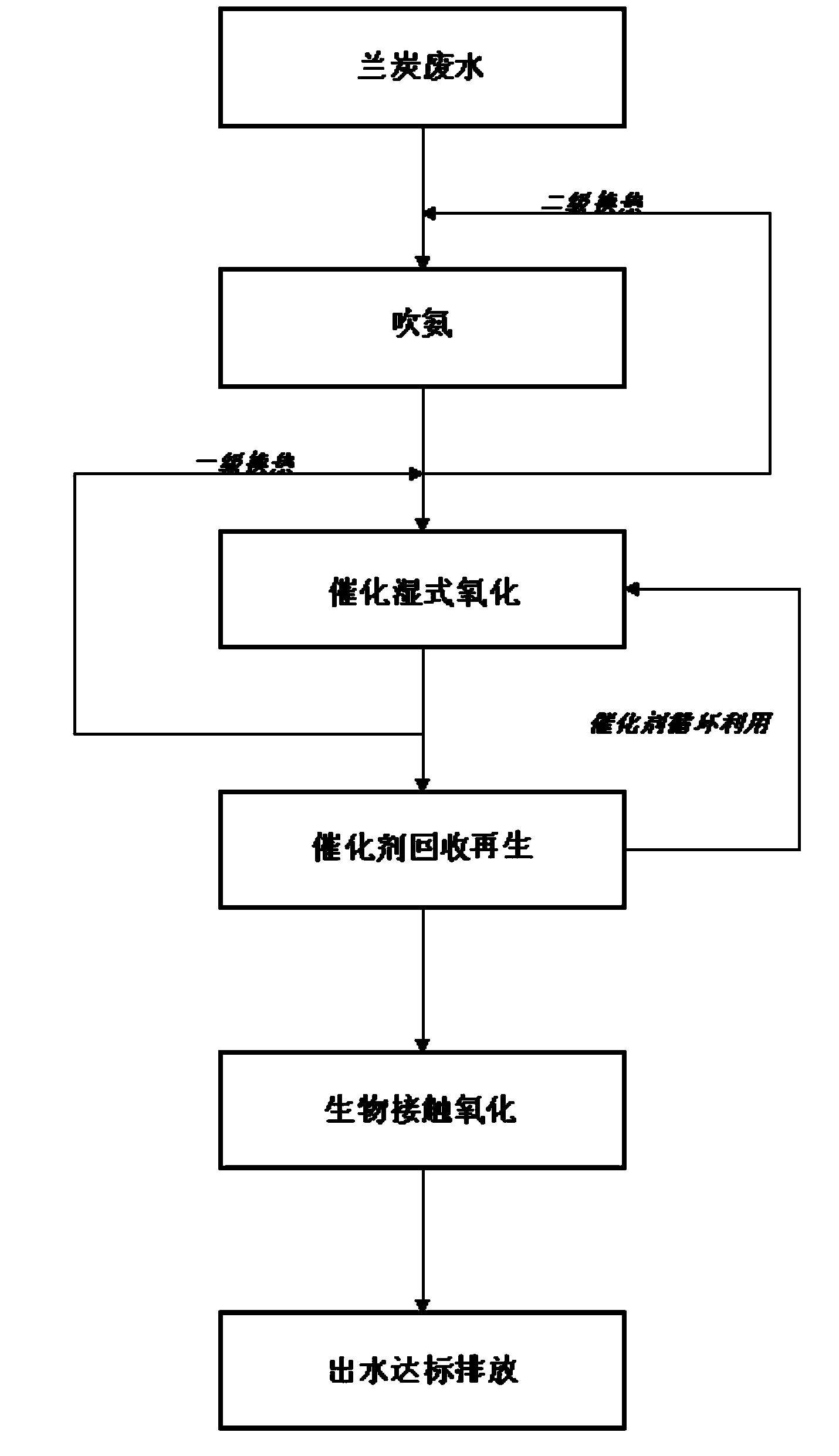

[0021] See figure 1 , is a flow chart of a comprehensive treatment process for semi-coke wastewater of the present invention. The process includes ammonia blowing, catalytic wet oxidation, catalyst recovery and regeneration, and biological contact oxidation treatment processes, which are carried out in the order of the above processes. The ammonia blowing and catalytic wet oxidation The process is supplemented by a gas-liquid mixer to pretreat the semi-coke wastewater. On the one hand, it reduces the concentration of pollutants; The biodegradability of wastewater is then treated through biological contact oxidation to make the treated water meet the discharge requirements.

[0022] The ammonia blowing process is to control the pH of the semi-coke wastewater to 8.5-10 without adding any catalyst, denitrification agent or defoamer, and send the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com