Method and device for processing sludge

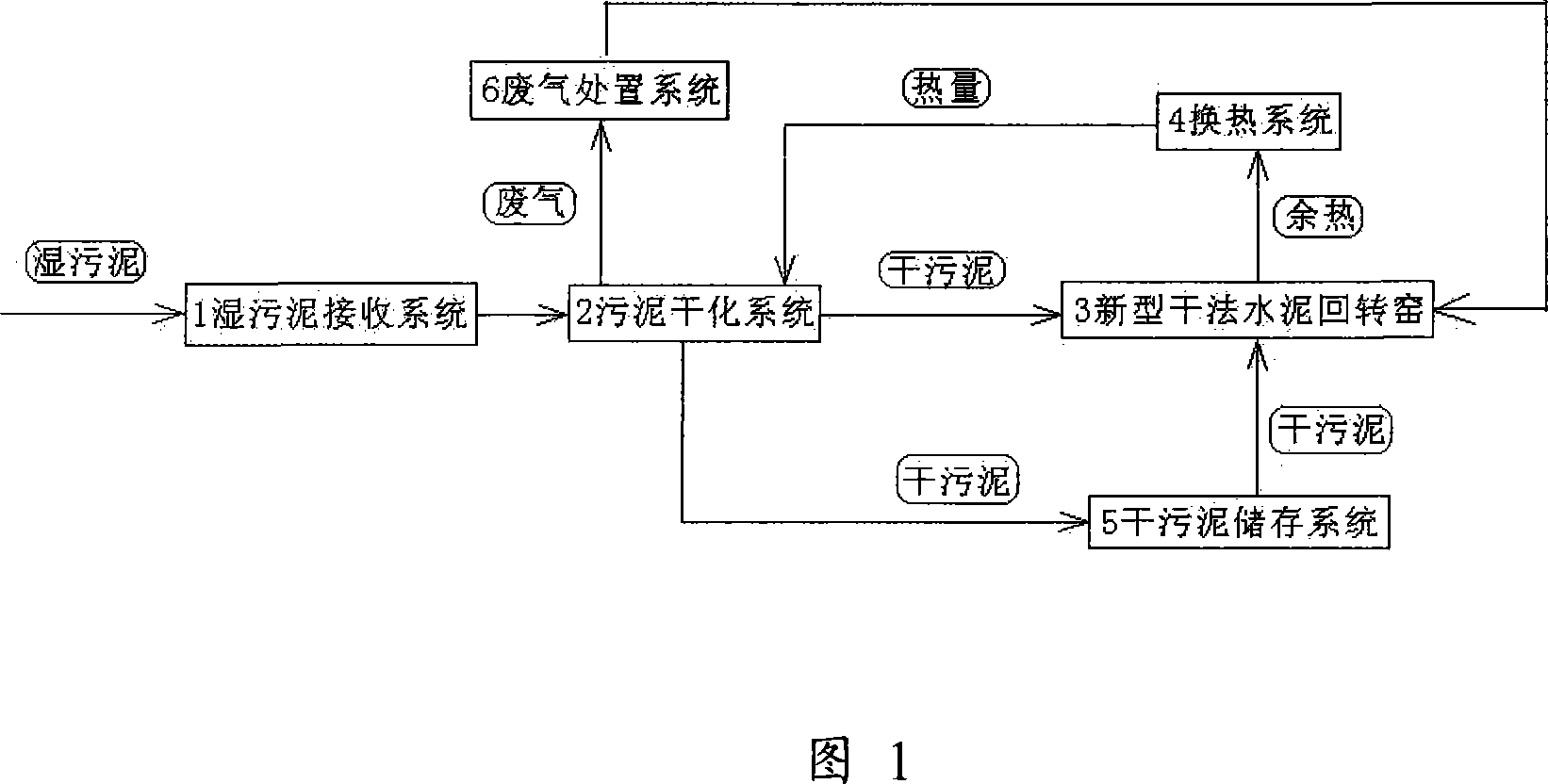

A technology for sludge and dry sludge, which is applied in the oxidation treatment of sludge, dewatering/drying/concentrating sludge treatment, and by-product vaporization, etc., which can solve the problems of high cost, pollution of waste gas and residue, and high energy consumption of sludge treatment. , to achieve the effect of saving fuel costs, saving raw coal and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

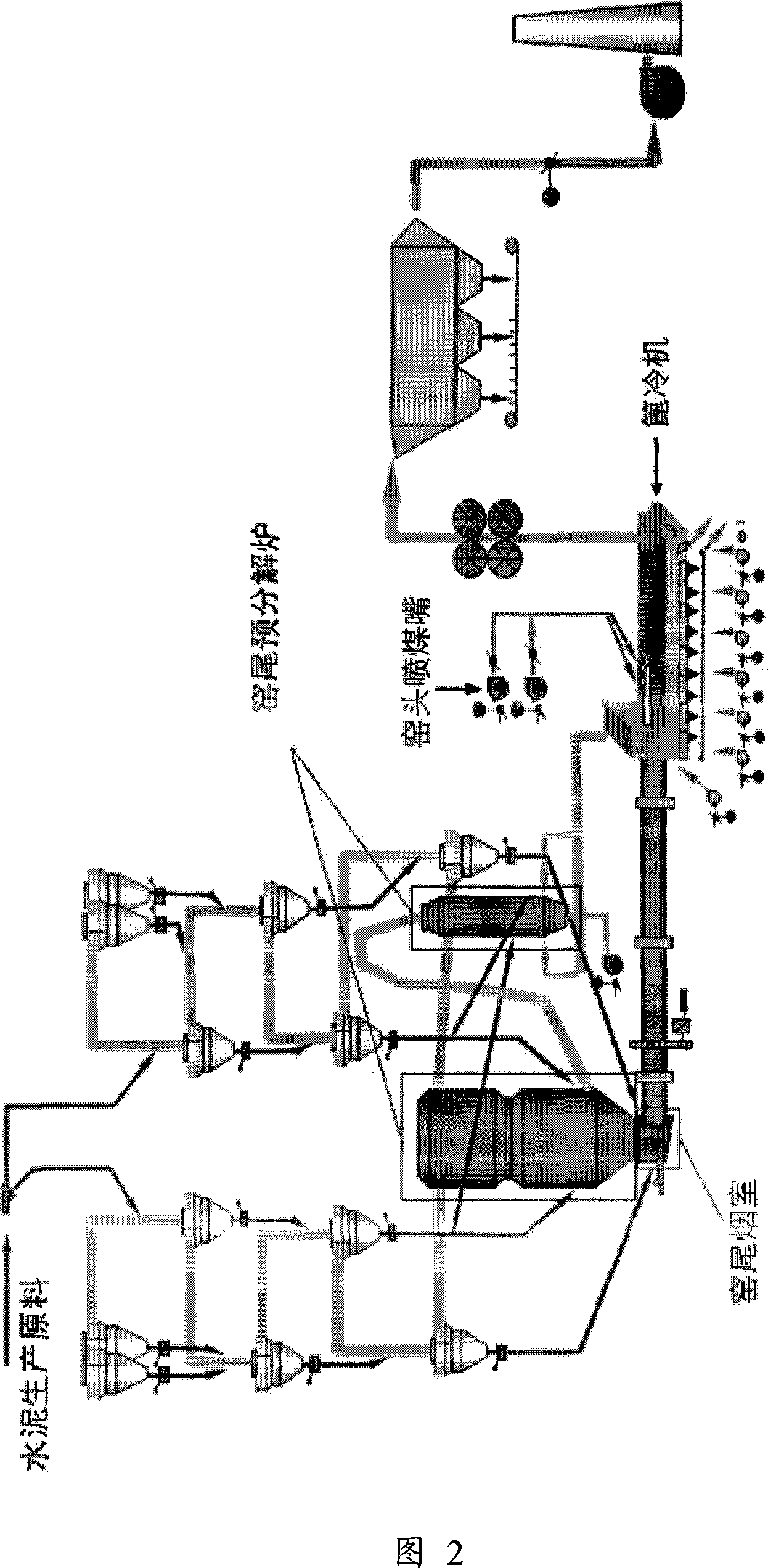

[0041] Transport 300 tons of wet sludge with a water content of 83% from the urban sewage plant to a cement plant (the cement plant produces 3,000 tons of clinker per day) and store it in the wet sludge receiving system. Transported to the sludge drying system through the transport system. According to production needs, the wet sludge with a moisture content of 83% is dried to dry sludge with a moisture content of 2% to 10%. The dried sludge can be directly imported into the new dry process cement rotary kiln for incineration, or it can be stored in the dry sludge storage system first. After drying, the dry sludge with a moisture content of 2% to 10% is put into the kiln for incineration through the coal injection nozzle at the kiln head of the new dry process cement rotary kiln or the precalciner at the kiln tail. The incineration conditions are 1450-1800°C for 10-30 minutes. The composition and content of the incinerated sludge residue are listed in Table 3. The heat in t...

Embodiment 2

[0043] The sludge produced by the urban sewage plant is dried and incinerated as described in Example 1, except that the wet sludge is dried to a moisture content of 10% to 35% in the sludge drying system, and the new dry process cement The kiln tail precalciner in the rotary kiln is incinerated. The composition and content of the incinerated sludge residue are listed in Table 3.

Embodiment 3

[0045] Mechanically dehydrate the river bottom sludge to a water content of 70% to 95%, and determine the amount of sludge to be disposed of according to the production scale of the cement plant and the specific components of the sludge every day. That is, according to the heat generated by the cement plant, the amount of wet sludge that can be dried is determined. Then determine the amount of sludge disposal according to the content of heavy metals in the river bottom sludge, and calculate whether the cement produced after using these sludge as raw materials for cement production meets the national standard. If it does not meet the standard, reduce the amount of sludge disposal.

[0046] The river bottom sludge is then transported to the cement plant and stored in the wet sludge receiving system. First transport to the sludge drying system through the transport system, and dry the sludge with a water content of 70% to 95% to 2% to 35% according to the same method as in Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com