High concentration saliferous organic waste liquor recycling chemical intermediate and waste heat utilizing boiler system

A high-concentration salt-containing and organic waste liquid technology, which is applied to incinerators, lighting and heating equipment, and combustion methods, can solve the problems of single combustion methods in incinerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

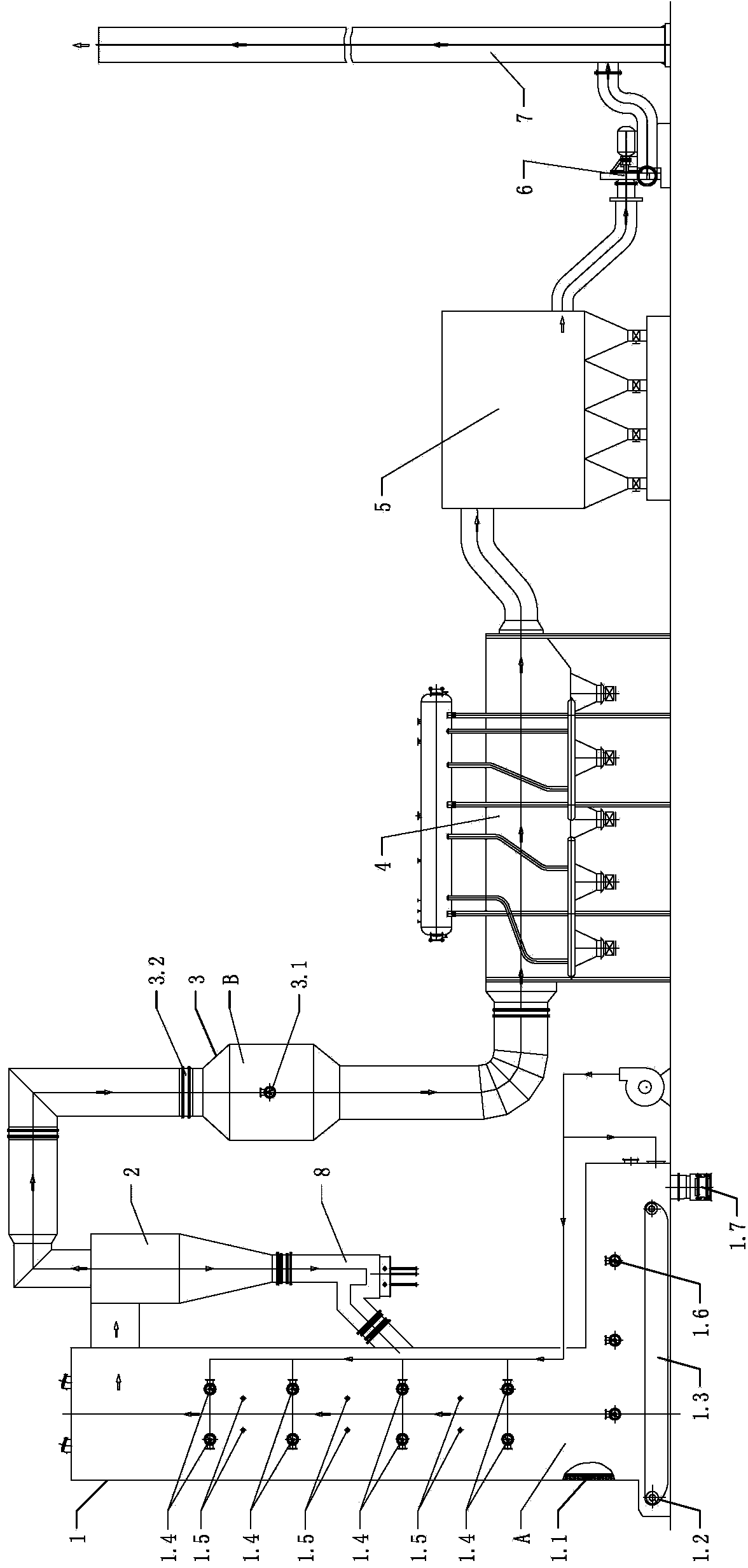

[0044] Such as figure 1 A boiler system for the recovery of chemical intermediates and waste heat utilization of high-concentration salt-containing organic waste liquid is shown, including: an incineration boiler 1, a primary dust removal device 2, a secondary combustion device 3, a waste heat boiler 4, and a secondary dust removal device 5;

[0045] The incineration boiler 1 is surrounded by a boiler shell and a refractory furnace lining 1.1 together to form a primary combustion chamber A; a horizontal chamber is arranged at the lower part of the primary combustion chamber A, and a beam type chain grate 1.2 is arranged in the horizontal chamber, that is, a beam type chain furnace Row 1.2 and horizontal chamber form tunnel kiln 1.3;

[0046] The primary combustion chamber A is equipped with several layers of burners 1.4 from top to next, and there are waste liquid nozzles 1.5 between every two adjacent layers of burners 1.4; natural gas or other combustible gases are burned through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com