Chinese wolfberry ferment preparation method

A technology of wolfberry enzyme and wolfberry, which is applied in food preparation, application, food science, etc., can solve the problems of lack of wolfberry enzyme, achieve good environmental protection and economic benefits, increase the content of active substances, and reduce the effect of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

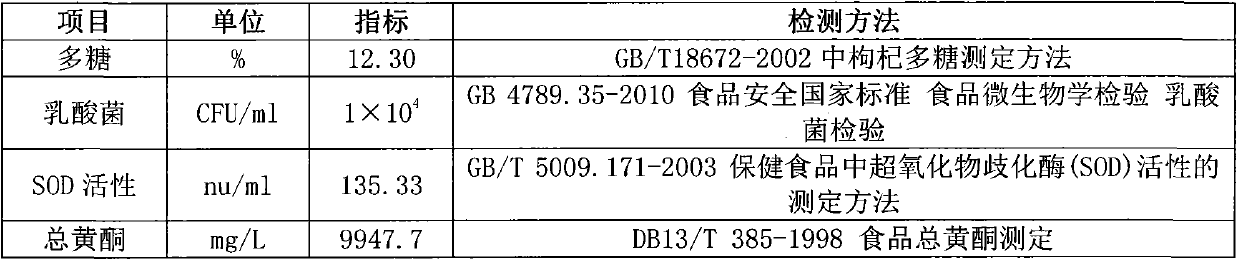

Embodiment 1

[0039] Choose the wolfberry that has no drug residues, soot, dust and other pollutants on the surface, no mechanical damage, disease and insect spots, water stains and other mildew and spoiled fruits and other impurities. Use clean water to rinse, drain, break and beat, and separate it. Seed and skin dregs were separated to obtain juice. The content of Lycium barbarum polysaccharide was detected to be 1.1%, SOD activity ≥74nu / ml, total flavonoids 2450.83mg / L, no lactic acid bacteria were detected; the juice was heated to 50℃, and the weight ratio in the juice was 10g / Add polygalacturonase to the amount of T, enzymatically hydrolyze for 5 hours, and stir 3 times; separate the medlar juice after enzymatic hydrolysis to extract the juice, adjust the pH to 4.0, and add the activated wine yeast to the In the fermenter, the inoculum is 0.3%, and the fermentation is 6 days. When the reducing sugar is ≤20.0g / L, the fermentation is stopped and the supernatant is separated; the supernata...

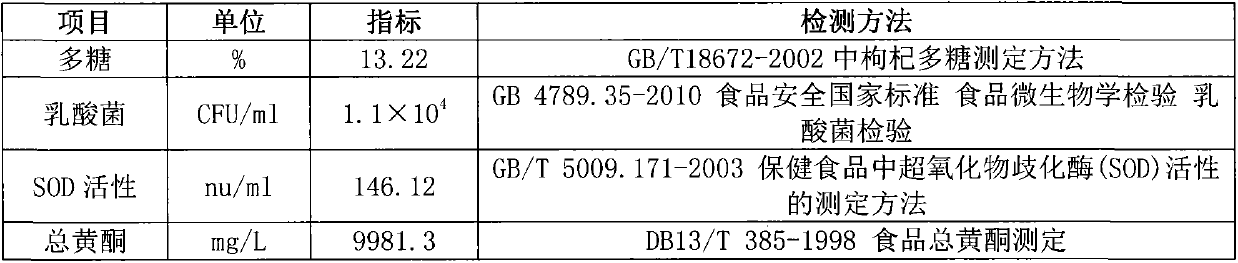

Embodiment 2

[0044] Choose the wolfberry that has no drug residues, soot, dust and other pollutants on the surface, no mechanical damage, disease and insect spots, water stains and other mildew and spoiled fruits and other impurities. Use clean water to rinse, drain, break and beat, and separate it. Seed and skin dregs were separated to obtain juice. The detected content of Lycium barbarum polysaccharide was 1.08%, SOD activity ≥74.5nu / ml, total flavonoids 2445.0mg / L, no lactic acid bacteria were detected; the juice was heated to 50℃, and the juice was 10g by weight. / T, add pectin decomposing enzyme, enzymolyze for 5h, stir 3 times; separate the medlar juice after enzymolysis to extract the juice, adjust the pH 4.0, and when the temperature is 25℃, add the activated beer yeast to the fermenter The inoculum is 0.3%, and the fermentation is 6 days. When the reducing sugar is less than or equal to 20.0g / L, the fermentation is stopped and the supernatant is separated; the supernatant is added w...

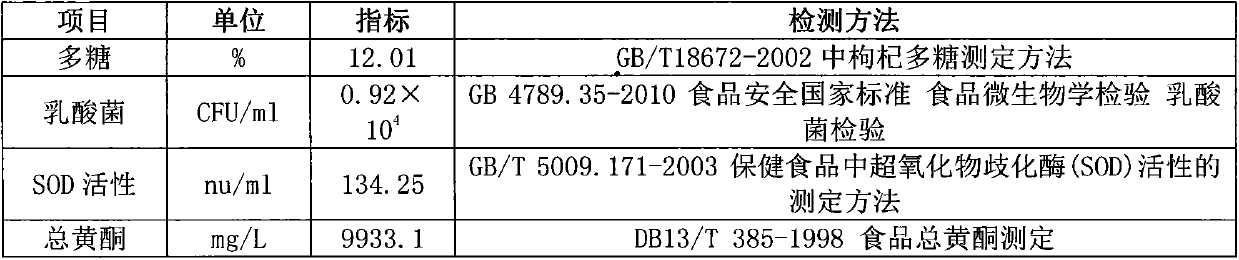

Embodiment 3

[0049] Choose the wolfberry that has no drug residues, soot, dust and other pollutants on the surface, no mechanical damage, disease and insect spots, water stains and other mildew and spoiled fruits and other impurities. Use clean water to rinse, drain, break and beat, and separate it. Seed and skin dregs were separated to obtain juice. The content of Lycium barbarum polysaccharide was detected to be 1.12%, SOD activity ≥75nu / ml, total flavonoids 2451.02mg / L, no lactic acid bacteria were detected; the juice was heated to 48℃, and the weight ratio in the juice was 9g / Add pectin lipase to the amount of T, enzymolyze for 4 hours, stir 3 times; separate the lycium berry juice after enzymolysis to extract the juice, adjust the pH to 3.9, and when the temperature is 23℃, add the activated Aspergillus niger to the fermentation tank The inoculum is 0.2%, and the fermentation is 5 days. When the reducing sugar is ≤20.0g / L, the fermentation is stopped, and the supernatant is separated; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com