3d track alloy sulfide material as well as preparation method and application thereof

A technology of sulfide and mixed materials, applied in the direction of electrochemical generators, delayed action cells, electrodes of primary batteries, etc., can solve the problems that do not involve the crystal structure, physical properties and electrochemical performance of the third metal element, conversion type Problems such as unusable transition metal sulfides and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

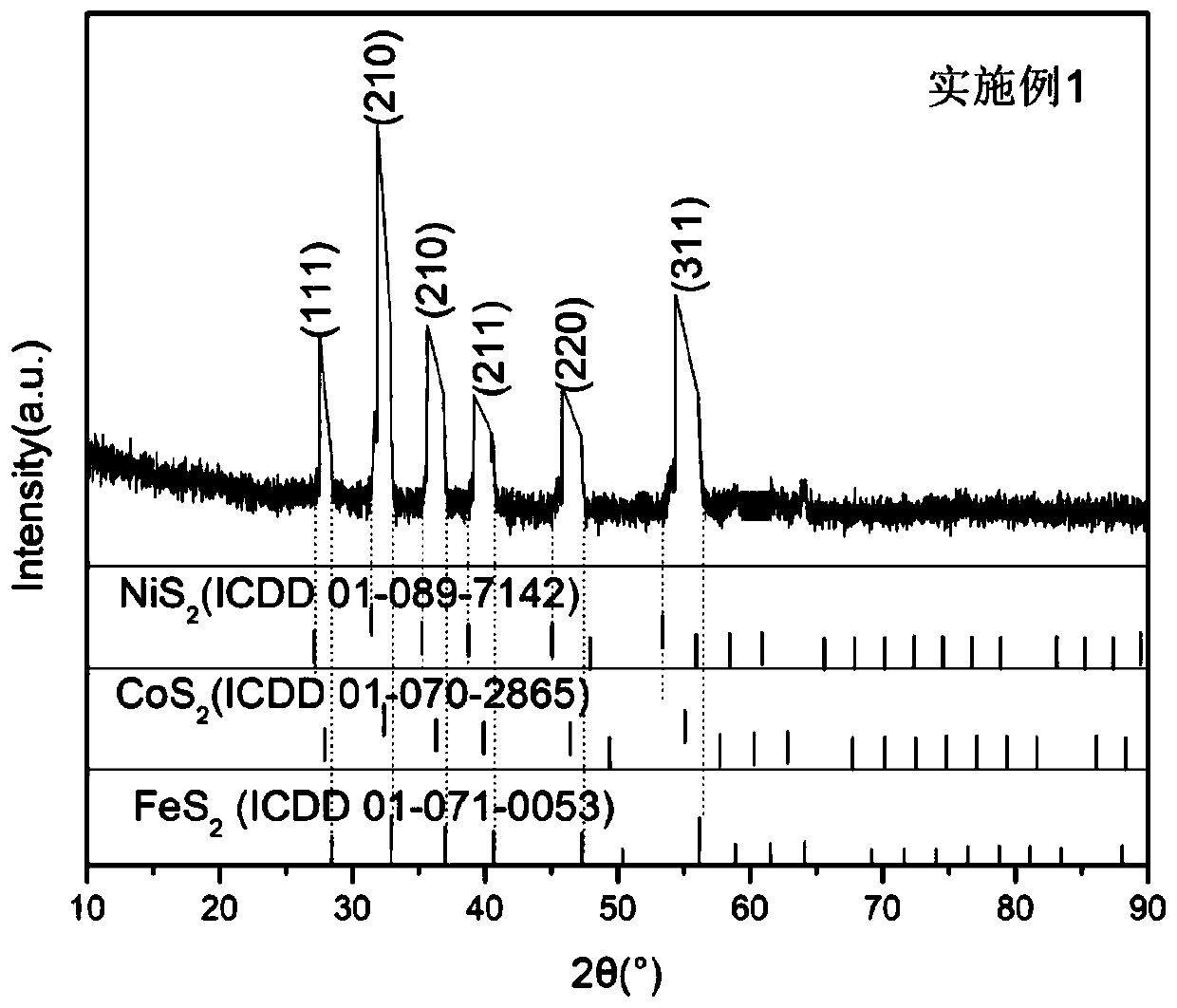

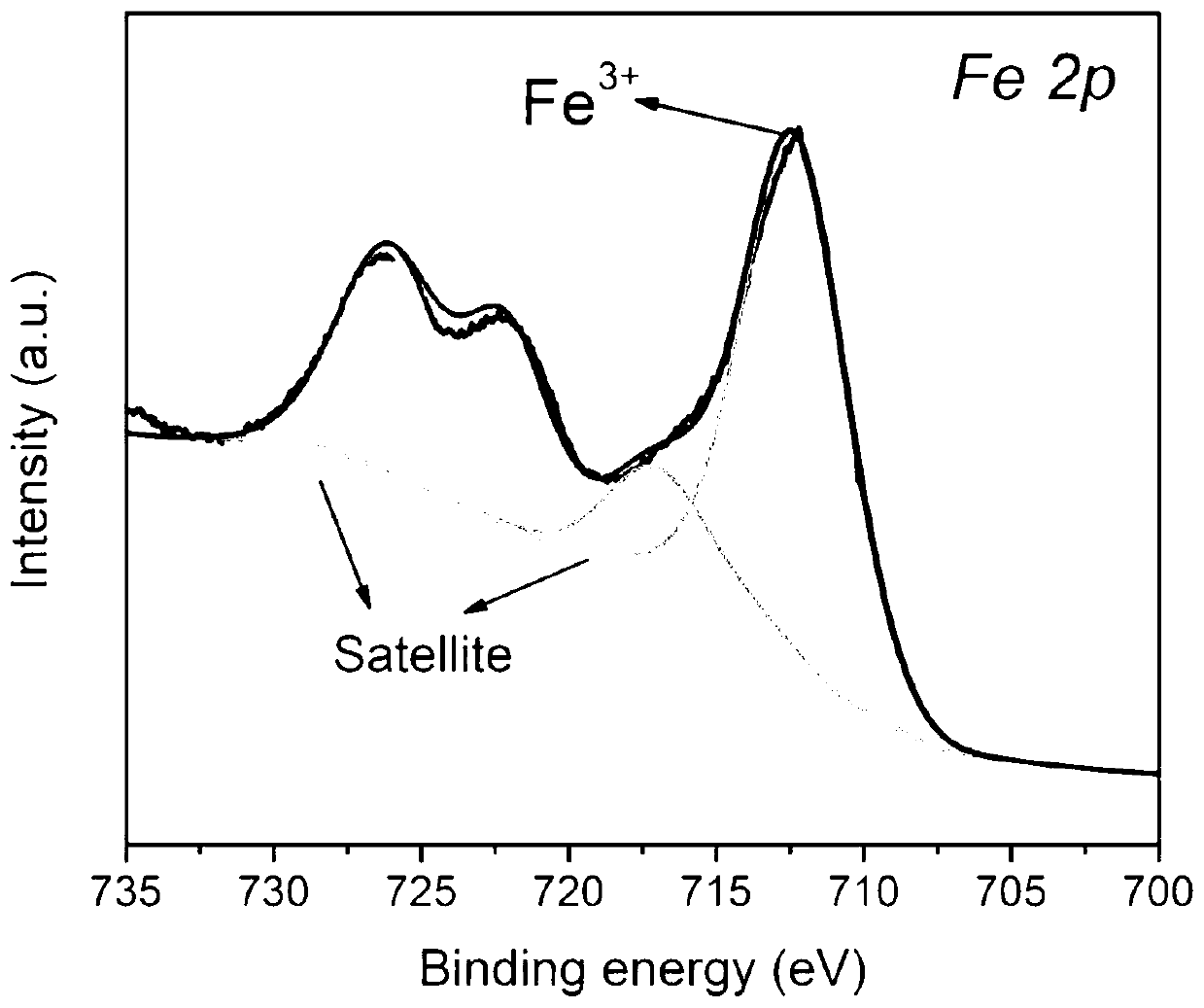

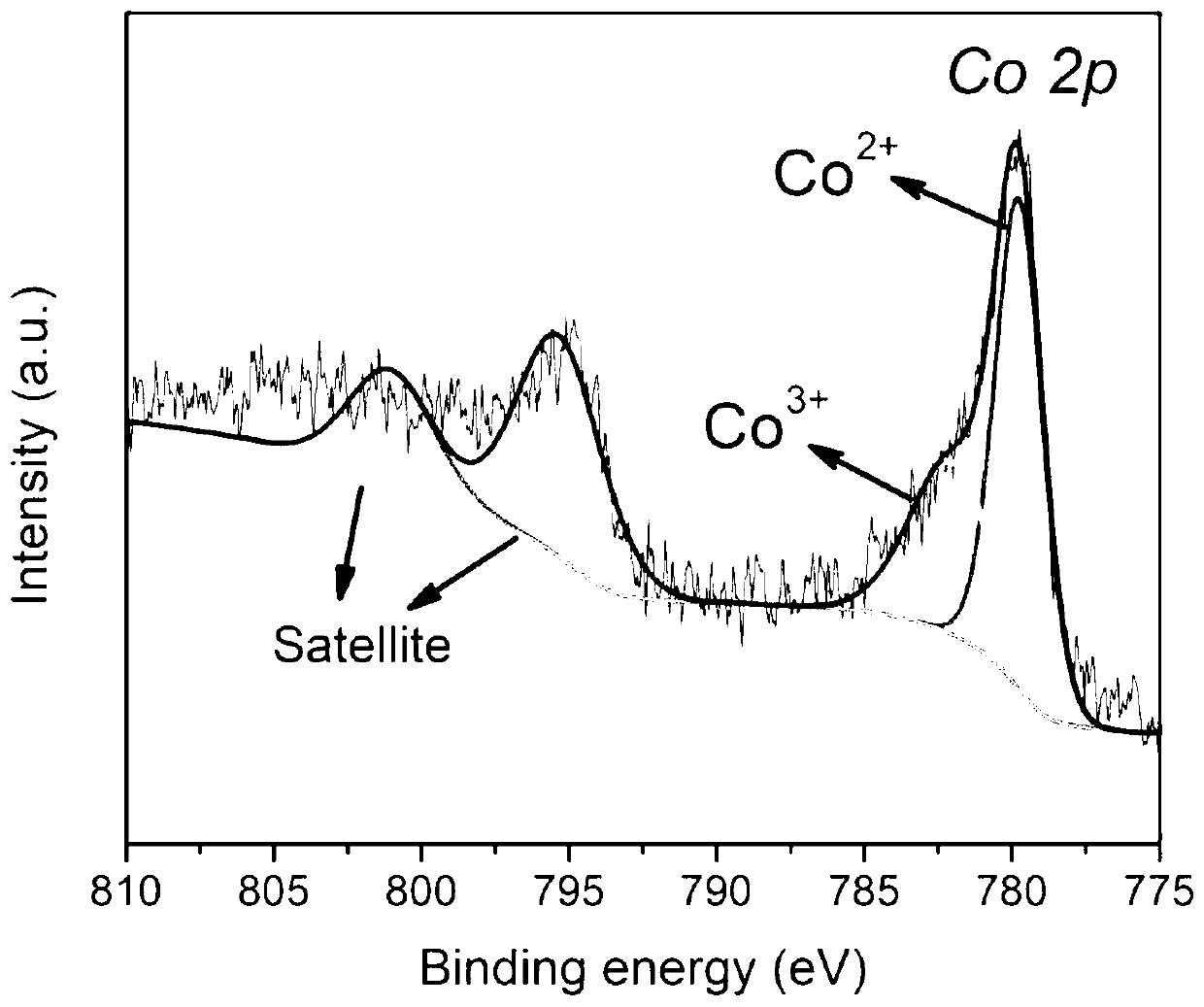

Embodiment 1

[0108] A 3d orbital alloy sulfide material Fe 0.5 co 0.2 Ni 0.3 S 2 The preparation method comprises the steps of:

[0109] (1) Pulverization: According to Fe 0.5 co 0.2 Ni 0.3 S 2 The stoichiometric ratio takes transition metal salt and sodium thiosulfate pentahydrate, transition metal salt is ferrous sulfate heptahydrate, cobalt sulfate heptahydrate, nickel sulfate hexahydrate, and makes sodium thiosulfate pentahydrate the transition metal salt molar ratio 2.6 times that of ferrous sulfate heptahydrate; after crushing ferrous sulfate heptahydrate at a speed of 3000r / min for 1min in a high-energy pulverizer, nickel sulfate hexahydrate and cobalt sulfate heptahydrate were added at the same time, and after crushing at a speed of 3000r / min for 1min, add five Sodium thiosulfate in water was crushed for 30s at a speed of 3000r / min, and passed through a 100-mesh sieve to obtain a pink mixed product;

[0110] (2) Melting: Put the pink mixed product prepared in step (1) into ...

Embodiment 2

[0120] A 3d orbital alloy sulfide material Fe 0.5 co 0.1 Ni 0.4 S 2 The preparation method is as follows:

[0121] (1) Pulverization: According to Fe 0.5 co 0.1 Ni 0.4 S 2 The stoichiometric ratio takes transition metal salt and sodium thiosulfate pentahydrate, wherein the transition metal salt is ferric chloride hexahydrate, cobalt sulfate heptahydrate, nickel sulfate hexahydrate, so that sodium thiosulfate pentahydrate is the transition metal salt mole 2.7 times the ratio; put ferrous sulfate heptahydrate into a high-energy pulverizer and crush at a speed of 3000r / min for 40s, then add nickel sulfate hexahydrate and cobalt sulfate heptahydrate at a speed of 3000r / min for 40s, then add Sodium thiosulfate pentahydrate is crushed at a speed of 3000r / min for 40s, and passed through a 100-mesh sieve. If there are unsieved objects, it is crushed several times at a speed of 3000r / min, each time for 30s, until all the products are passed through a sieve. After 100 mesh sieve...

Embodiment 3

[0130] A 3d orbital alloy sulfide material Fe 0.5 co 0.15 Ni 0.35 S 2 The preparation method is as follows:

[0131] (1) Pulverization: According to Fe 0.5 co 0.15 Ni 0.35 S 2 Stoichiometric ratio takes transition metal salt and sodium thiosulfate, wherein transition metal salt is ferric nitrate nonahydrate, cobalt sulfate, nickel sulfate, and controls sodium thiosulfate to be 3 times of transition metal salt mol ratio; Put it into a high-energy pulverizer and crush at a speed of 3000r / min for 30s, then add nickel sulfate and cobalt sulfate at the same time, crush again at a speed of 3000r / min for 30s, add sodium thiosulfate and crush at a speed of 3000r / min for 1min, and pass 100-mesh sieve, the material that cannot pass through the sieve continues to be crushed several times at a speed of 3000r / min until it passes through a 100-mesh sieve, and the crushing time is 30s each time to obtain a pink mixed product;

[0132] (2) Melting: After putting the pink mixed product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com