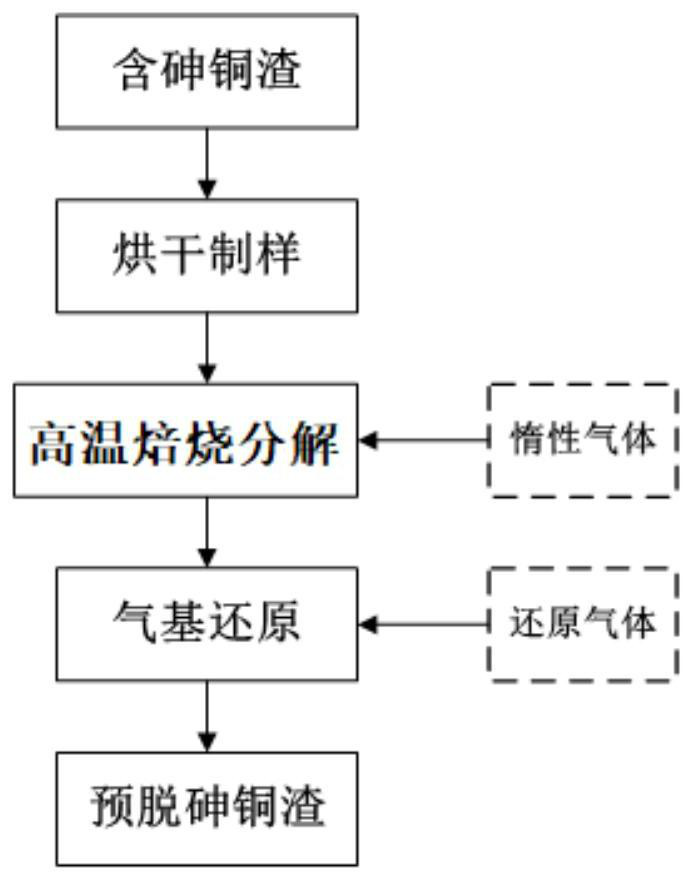

Roasting gas-based reduction arsenic removal method for arsenic-containing copper slag

A copper slag and roasting technology, which is applied in the preparation/purification of sulfur, can solve the problems of excessive arsenic content, achieve the effect of reducing economic benefits and preventing re-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The raw material used in this embodiment is arsenic-containing copper slag, and the slag sample is depleted copper slag obtained by grinding and flotation of flash smelting slag. Its main chemical composition and mass percentage are: TFe 41.03%, SiO 2 33.00%, As 0.30%, Pb0.88%, Zn 2.28%, Cu 0.35%, the content of arsenate is 0.069%, the content of arsenic sulfide is 0.165%, and the content of arsenic oxide is 0.066%.

[0075] Grind arsenic-containing copper slag, select 50g of slag powder with a particle size of 75-100μm, and pre-dry the slag powder at 100-105°C for 3 hours to ensure that most of the free water in the slag powder is removed. The slag powder is placed in a desiccator and cooled to room temperature for later use.

[0076] Put the dried slag sample into the furnace and start to feed argon gas, set the flow rate of argon gas to 3L / min, raise the temperature to 700°C with the furnace, keep it warm for 30min, after the time is up, take a sample of the slag sa...

Embodiment 2

[0079] The raw material of this embodiment adopts arsenic-containing copper slag, and the slag sample is depleted copper slag obtained by grinding and flotation of flash smelting slag. Its main chemical composition and mass percentage are: TFe 41.03%, As 0.30%, wherein The content of arsenate is 0.069%, the content of arsenic sulfide is 0.165%, the content of arsenic oxide is 0.066%,

[0080] Grind the arsenic-containing copper slag, select 50g of 75-100μm slag powder, and dry it at 100-105°C for 3 hours in advance to ensure that most of the free water is removed, and place it in a desiccator to cool to room temperature for later use. Put the dried slag sample into the furnace and start to feed argon gas, set the flow rate of argon gas to 3L / min, heat up to 900°C with the furnace, keep it warm for 90min, after the time is up, take a sample to test the slag sample for arsenic sulfide and arsenic oxide and recovered products The content of metal in the medium; then start to pass...

Embodiment 3

[0083] The raw material used in this example is arsenic-containing copper slag, and the slag sample is depleted copper slag obtained by grinding and flotation of flash smelting slag. Its main chemical composition and mass percentage are: TFe 41.03%, As 0.30% , wherein the content of arsenate is 0.069%, the content of arsenic sulfide is 0.165%, and the content of arsenic oxide is 0.066%.

[0084] Grind the arsenic-containing copper slag, select 50g of 75-100μm slag powder, and dry it at 100-105°C for 3 hours in advance to ensure that most of the free water is removed, and then cool it to room temperature in a desiccator for later use. Put the dried slag sample into the furnace and start to feed argon gas, set the flow rate of argon gas to 3L / min, heat up to 1150°C with the furnace, and keep it warm for 120min. After the time is up, take samples to test the slag samples for arsenic sulfide and arsenic oxide and recovered products The content of metal in the medium; then start to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com