Continuous refinement system and technology of ultra-pure phosphorus oxychloride of 5N grade

A pure phosphorus oxychloride, ultra-high technology, applied in the field of continuous purification system of 5N ultra-high purity phosphorus oxychloride, can solve the problems of high cost, complex process, long continuous purification process route, etc., achieve low cost, The process is simple and easy to operate, and the effect of reducing the probability of production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

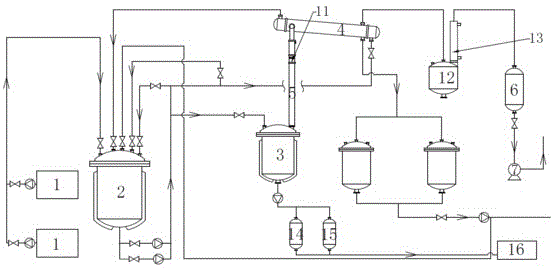

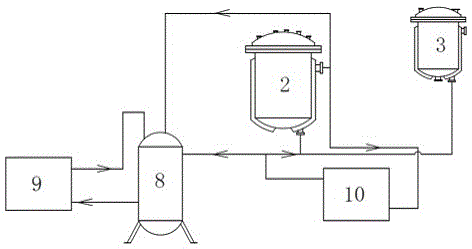

[0027] Such as figure 1 and figure 2 As shown, the continuous purification system of the 5N grade ultra-high purity phosphorus oxychloride of the embodiment comprises a feed storage tank 1, the feed storage tank 1 is communicated with the raw material tundish 2, and the discharge port of the raw material tundish 2 is respectively connected with the refined The feed port of the still 3 is connected with the shell side feed port of the first condenser 4, and the top discharge port of the rectifying still 3 is connected with the tube-side steam feed port of the first condenser 4 through the rectifying tower 5, The shell side discharge port of the first condenser 4 is connected with the feed port of the raw material tundish 2, the tube side condensate discharge port of the first condenser 4 is connected with the finished product collection unit, and the tube side of the first condenser 4 is light The component outlet is connected to the light component processing unit, the heavy...

Embodiment 2

[0039] The difference between Example 2 and Example 1 is that the temperature of the phosphorus oxychloride raw material entering the first condenser as the condensing medium is 60° C.; the operating pressure of the raw material tundish is 0.15 bar.

[0040] The product was detected by ICP-MS, and the content of various metal impurities: Al=10.52ppb, Ag=0.48ppb, As=2.87ppb, Au=0.28ppb, Ba=1.74ppb, Bi=0.25ppb, Ca=13.61ppb, Co= 0.25ppb, Cu=3.34ppb, Fe=7.53ppb, Ga=0.62ppb, Hg=2.82ppb, K=5.2ppb, Li=1.37ppb, Mg=2.47ppb, Mn=1.4ppb, Na=5.95ppb, Ni= =3.68ppb, Nb=1.6ppb, Pb=1.21ppb, Sn=1.1ppb, Sr=0.5ppb, Ti=1.37ppb, Zn=2.17ppb.

Embodiment 3

[0042] The difference between Example 2 and Example 1 is that the temperature of the phosphorus oxychloride raw material entering the first condenser as the condensing medium is 70° C.; the operating pressure of the raw material tundish is 0.2 bar.

[0043] The product was detected by ICP-MS, and the content of various metal impurities: Al=9.53ppb, Ag=0.59ppb, As=3.51ppb, Au=0.6ppb, Ba=1.8ppb, Bi=1.35ppb, Ca=3.85ppb, Co= 0.23ppb, Cu=0.52ppb, Fe=7.41ppb, Ga=0.24ppb, Hg=2.29ppb, K=1.37ppb, Li=3.35ppb, Mg=4.58ppb, Mn=0.57ppb, Na=2.14ppb, Ni= =0.38ppb, Nb=0.74ppb, Pb=2.74ppb, Sn=0.19ppb, Sr=0.1ppb, Ti=0.15ppb, Zn=0.32ppb.

[0044] Considering the heat loss of the material pipeline, the temperature of the raw material tundish needs to be slightly higher than the above-mentioned phosphorus oxychloride feed temperature, the raw material tundish is generally controlled at 70°C, and the product yield is 85%. Phosphorus oxychloride has the highest yield of purified products.

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com