Patents

Literature

87results about How to "Prevent reoxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

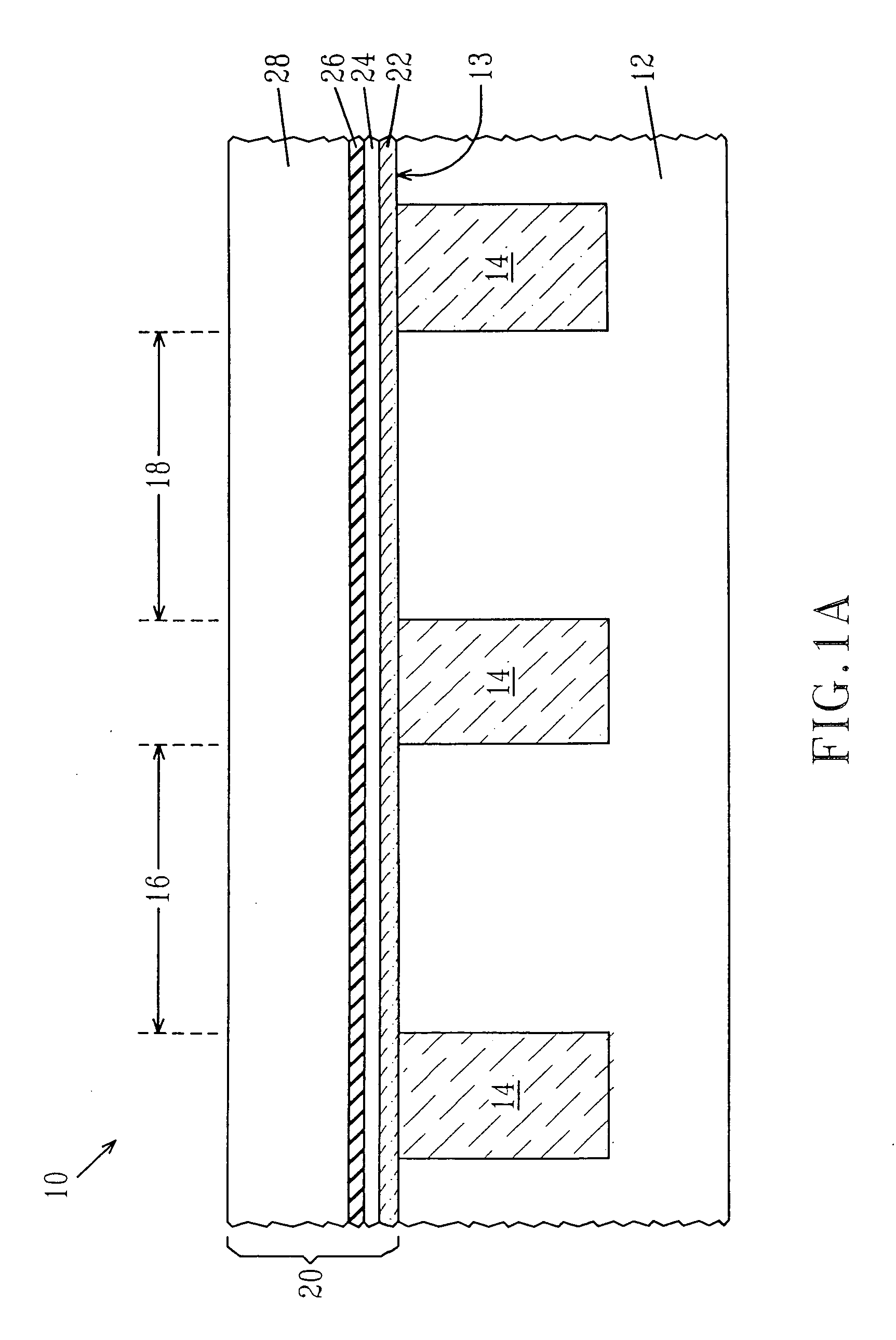

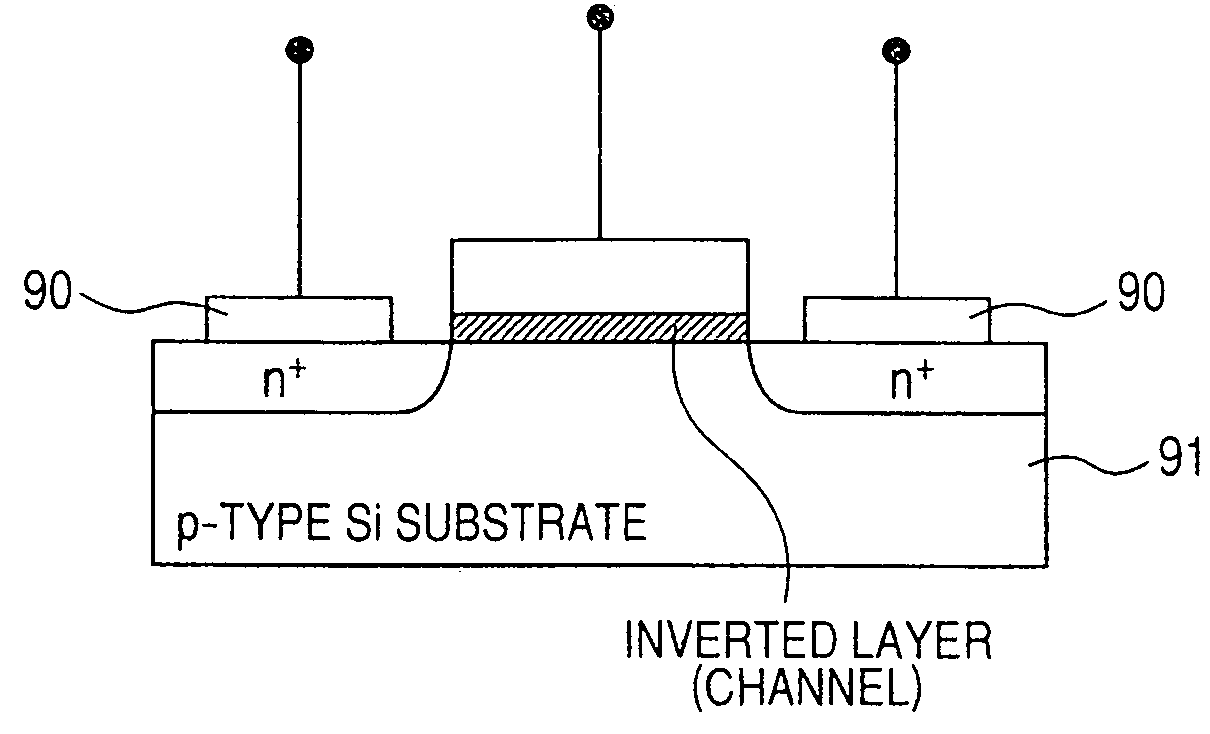

Removal of charged defects from metal oxide-gate stacks

InactiveUS7488656B2High carrier mobilityEliminate oxygen vacanciesTransistorSemiconductor/solid-state device manufacturingCapacitanceDielectric

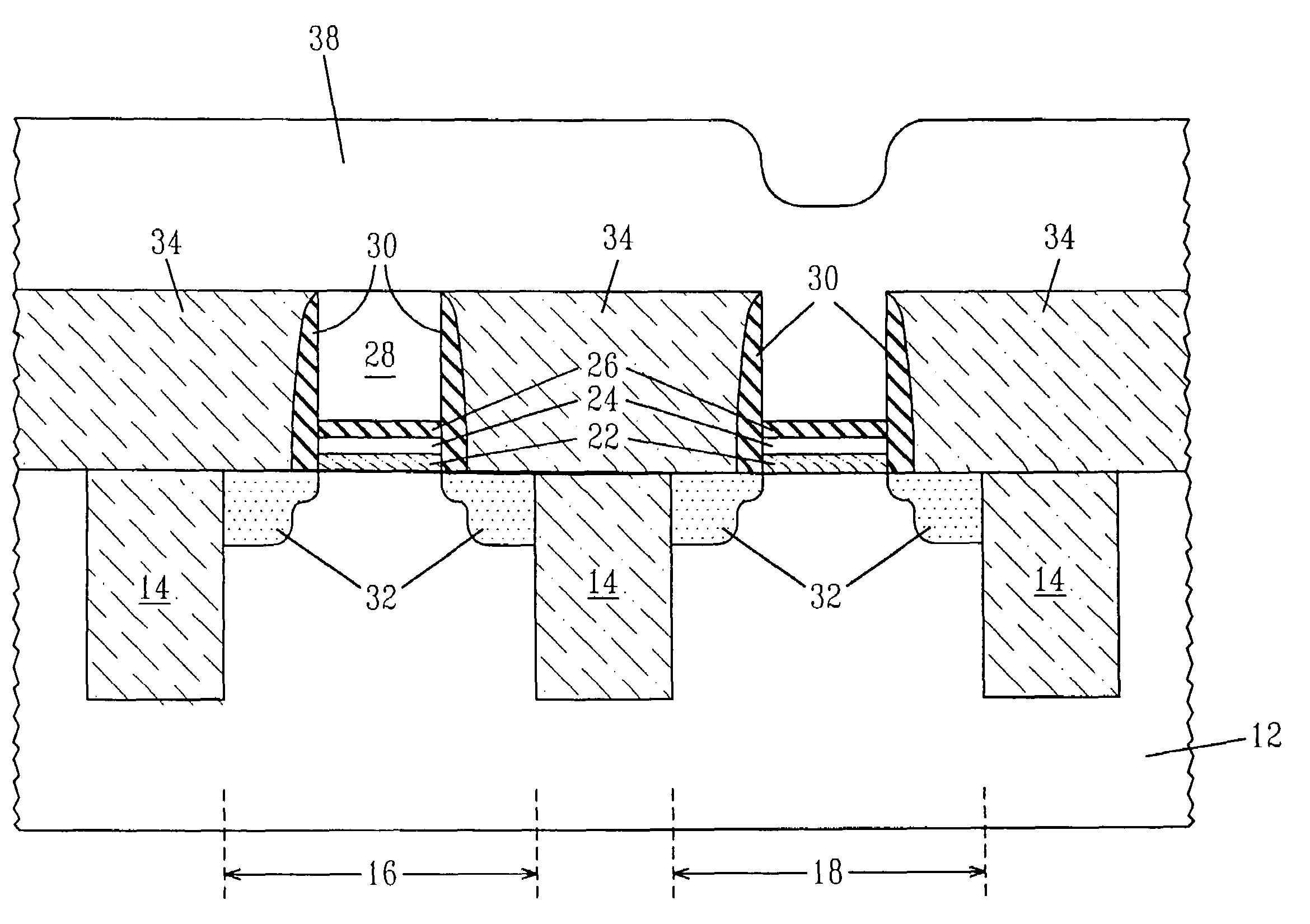

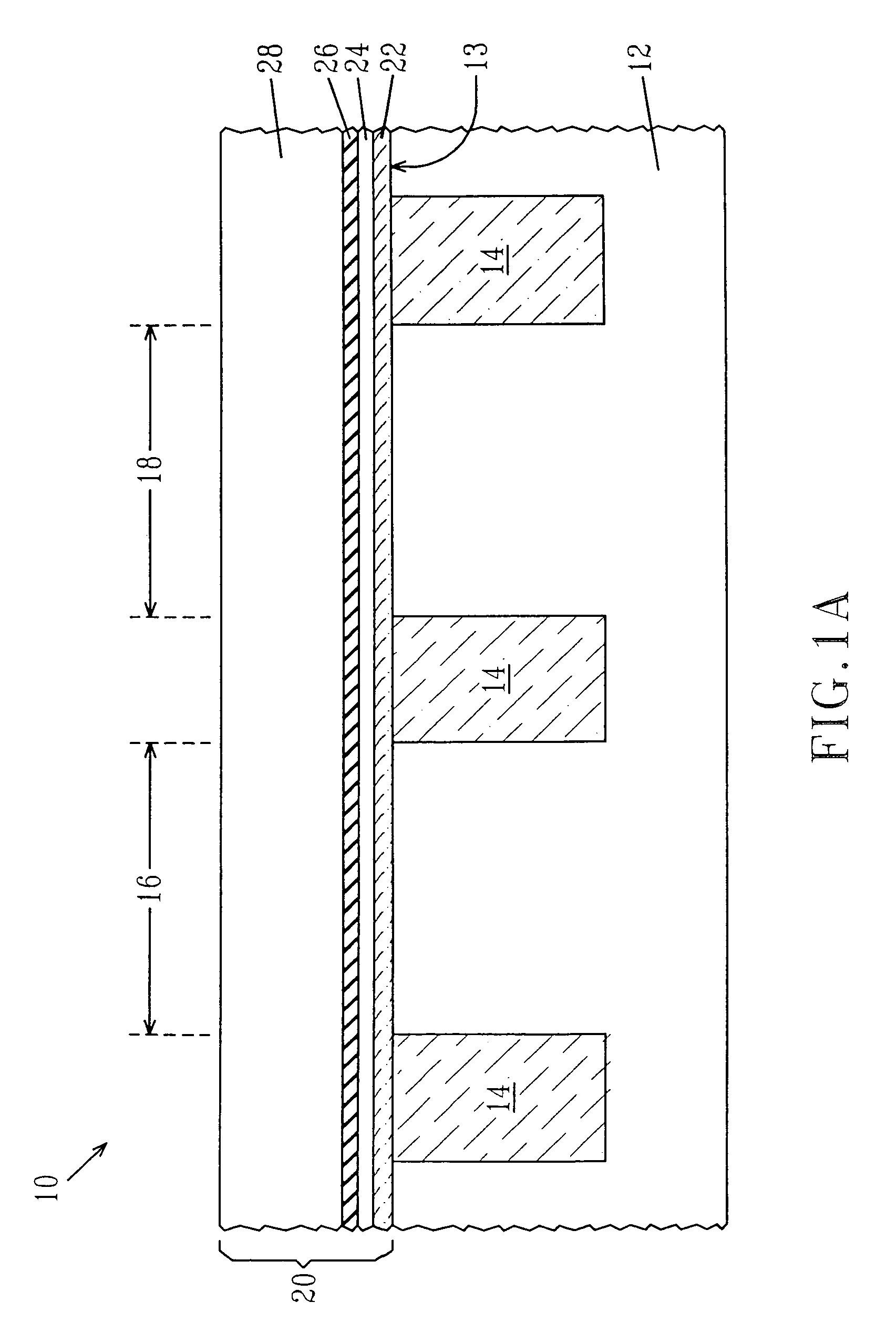

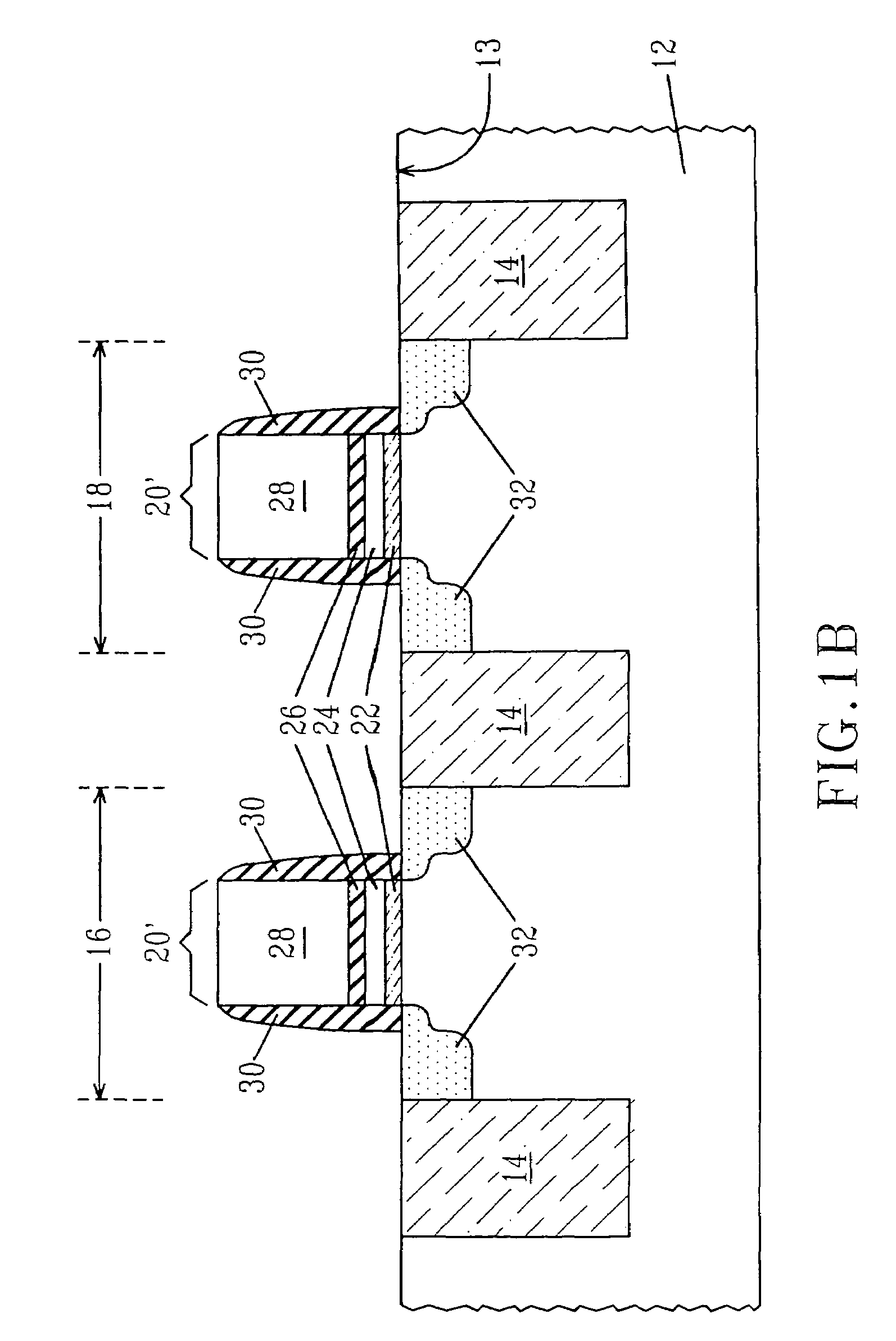

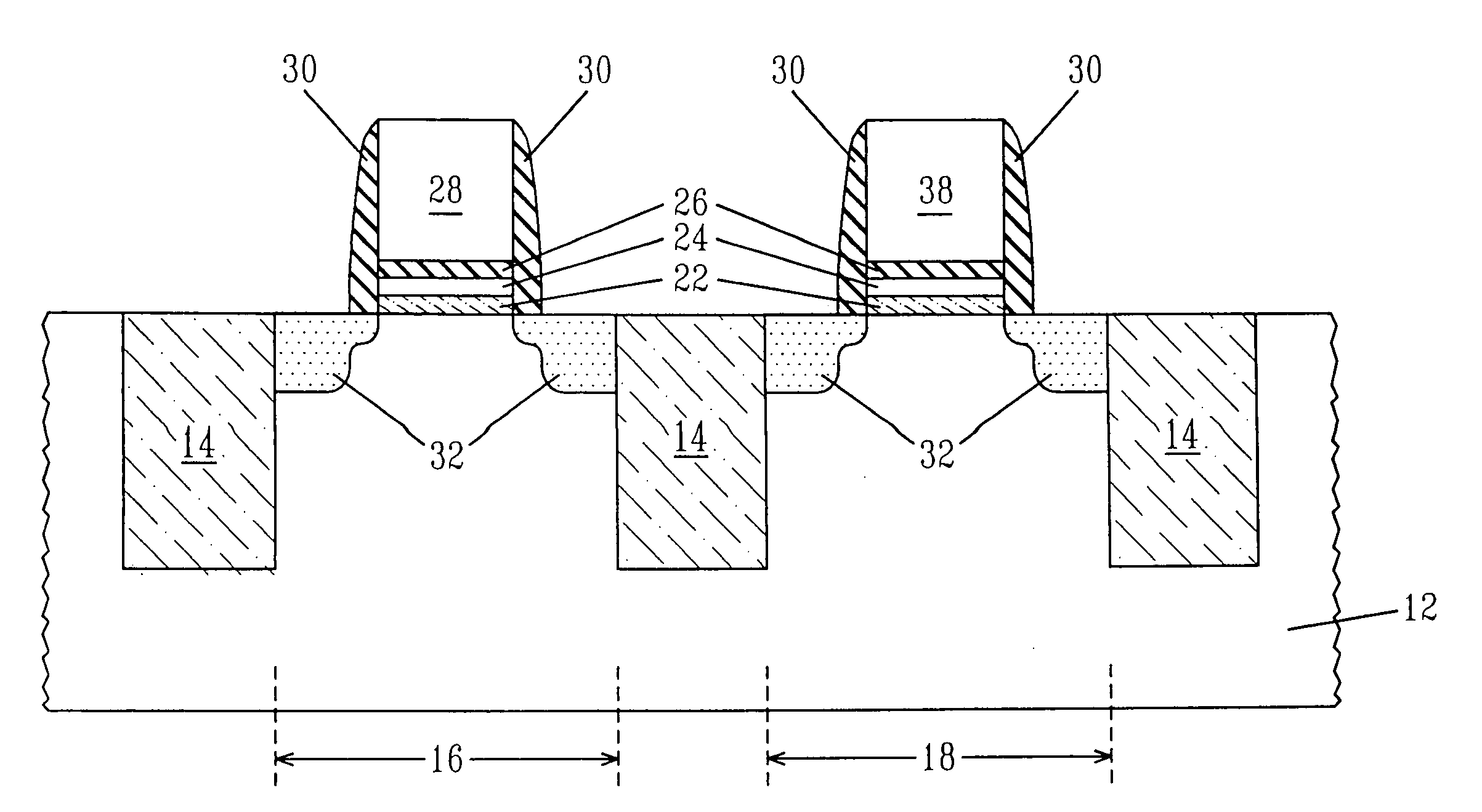

The present invention provides a method for removing charged defects from a material stack including a high k gate dielectric and a metal contact such that the final gate stack, which is useful in forming a pFET device, has a threshold voltage substantially within the silicon band gap and good carrier mobility. Specifically, the present invention provides a re-oxidation procedure that will restore the high k dielectric of a pFET device to its initial, low-defect state. It was unexpectedly determined that by exposing a material stack including a high k gate dielectric and a metal to dilute oxygen at low temperatures will substantially eliminate oxygen vacancies, resorting the device threshold to its proper value. Furthermore, it was determined that if dilute oxygen is used, it is possible to avoid undue oxidation of the underlying semiconductor substrate which would have a deleterious effect on the capacitance of the final metal-containing gate stack. The present invention also provides a semiconductor structure that includes at least one gate stack that has a threshold voltage within a control range and has good carrier mobility.

Owner:INT BUSINESS MASCH CORP

Removal of charged defects from metal oxide-gate stacks

InactiveUS20060246740A1Good carrier mobilityHigh carrier mobilityTransistorSemiconductor/solid-state device manufacturingOxygen vacancyCapacitance

The present invention provides a method for removing charged defects from a material stack including a high k gate dielectric and a metal contact such that the final gate stack, which is useful in forming a pFET device, has a threshold voltage substantially within the silicon band gap and good carrier mobility. Specifically, the present invention provides a re-oxidation procedure that will restore the high k dielectric of a pFET device to its initial, low-defect state. It was unexpectedly determined that by exposing a material stack including a high k gate dielectric and a metal to dilute oxygen at low temperatures will substantially eliminate oxygen vacancies, resorting the device threshold to its proper value. Furthermore, it was determined that if dilute oxygen is used, it is possible to avoid undue oxidation of the underlying semiconductor substrate which would have a deleterious effect on the capacitance of the final metal-containing gate stack. The present invention also provides a semiconductor structure that includes at least one gate stack that has a threshold voltage within a control range and has good carrier mobility.

Owner:IBM CORP

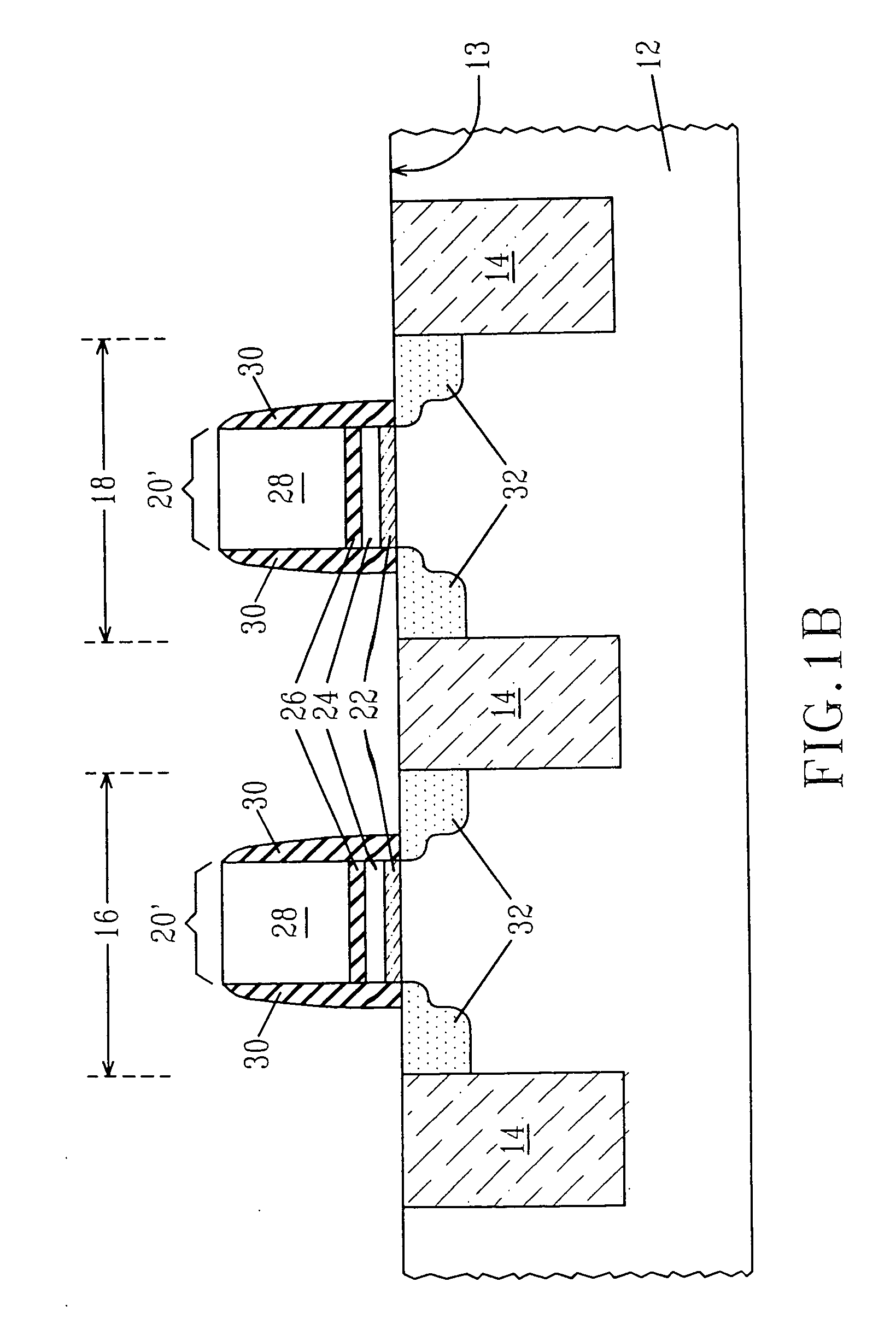

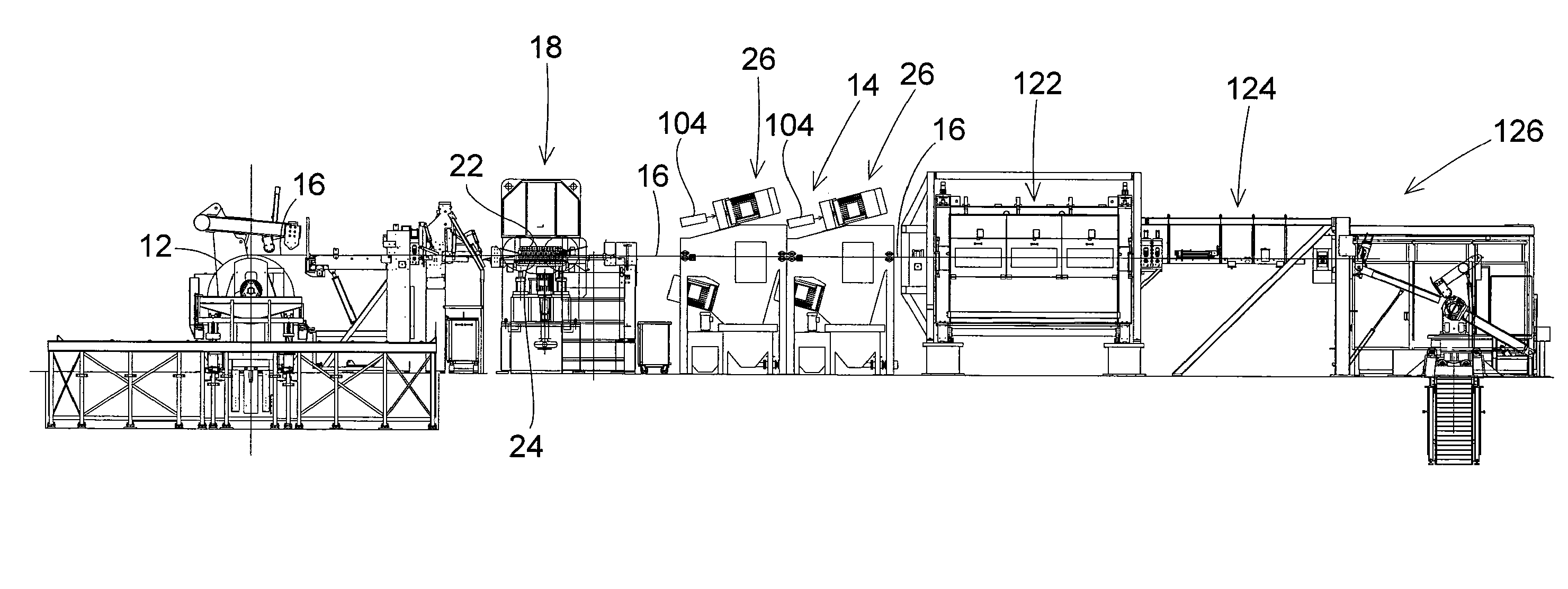

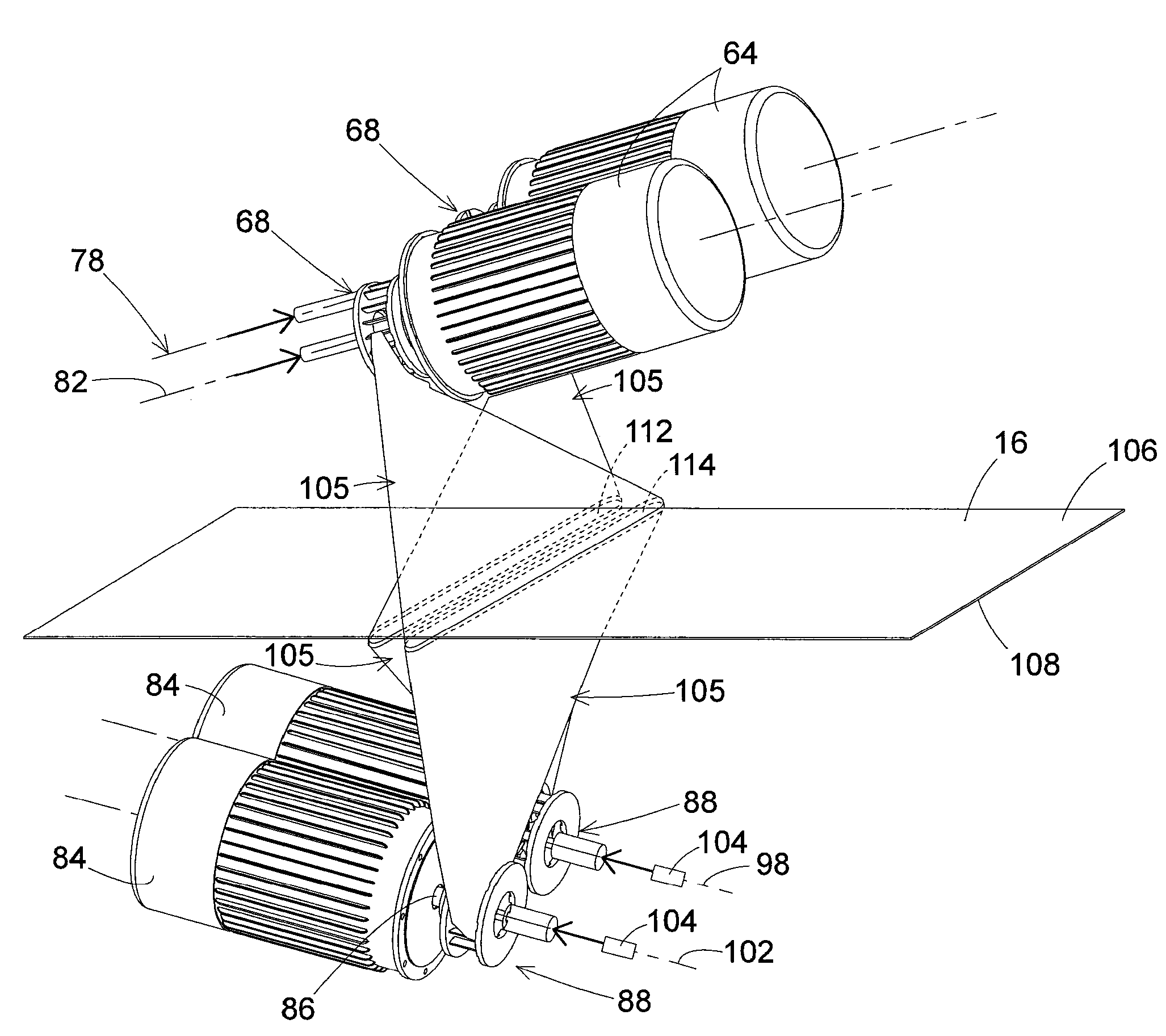

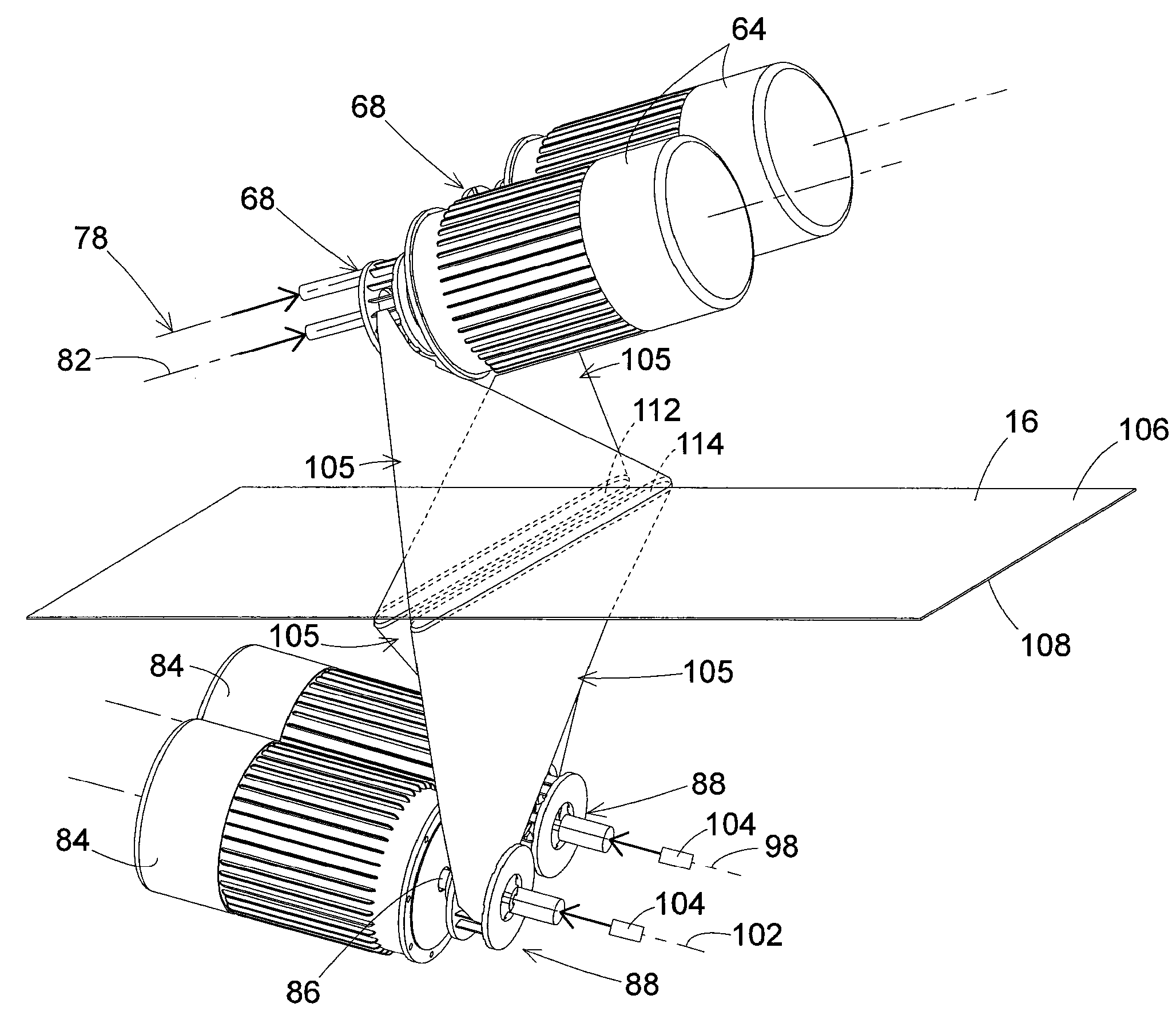

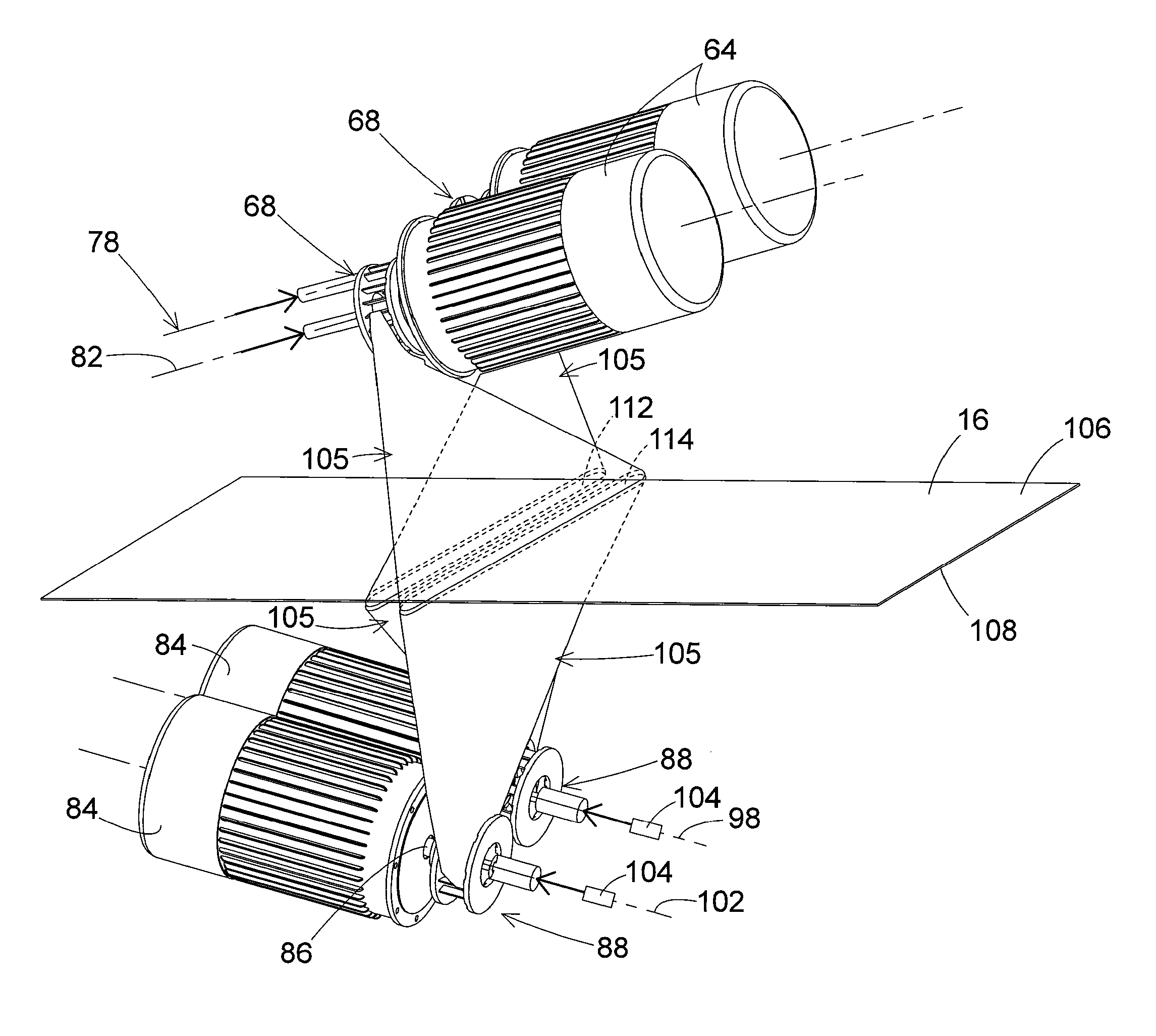

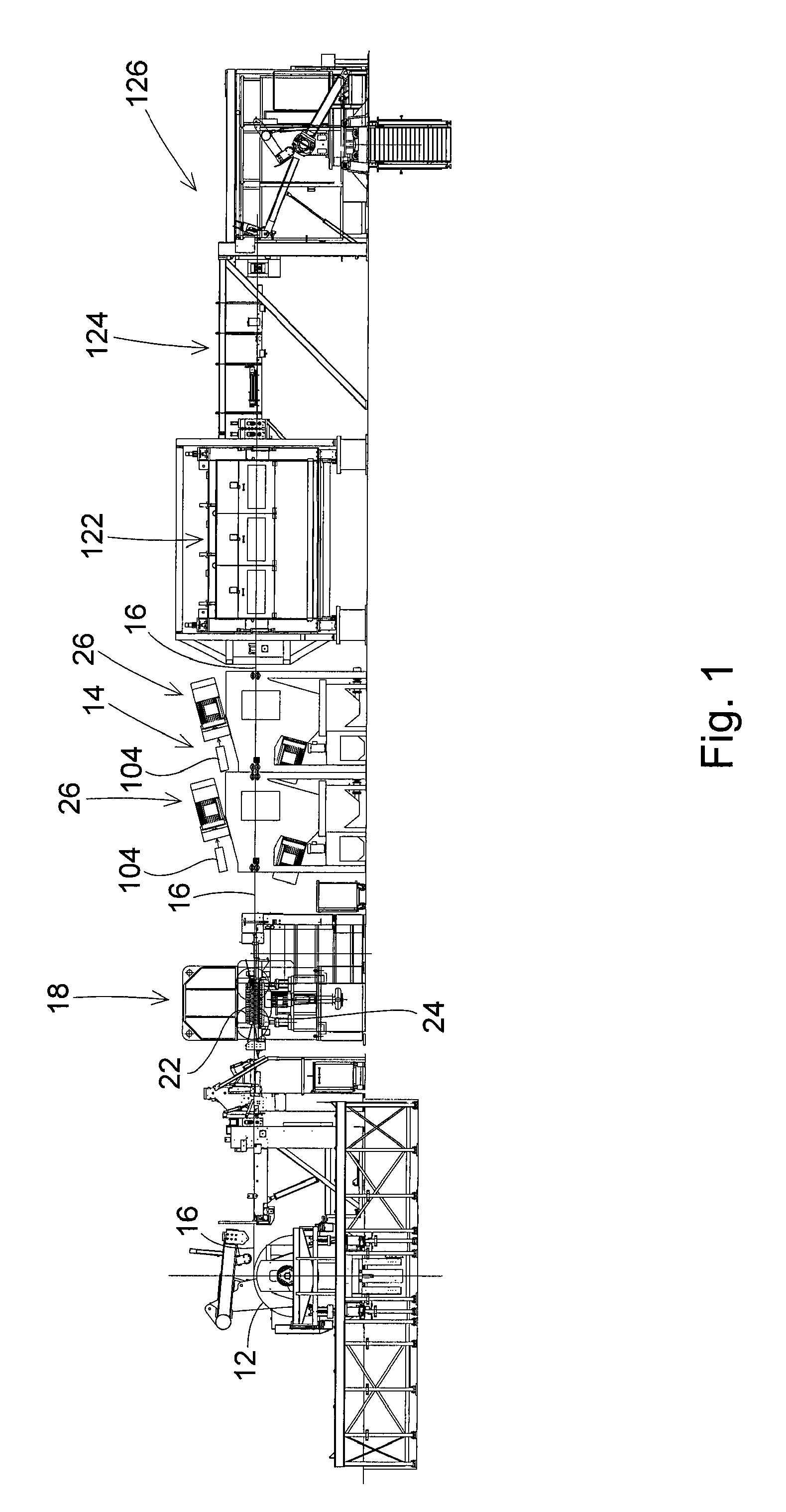

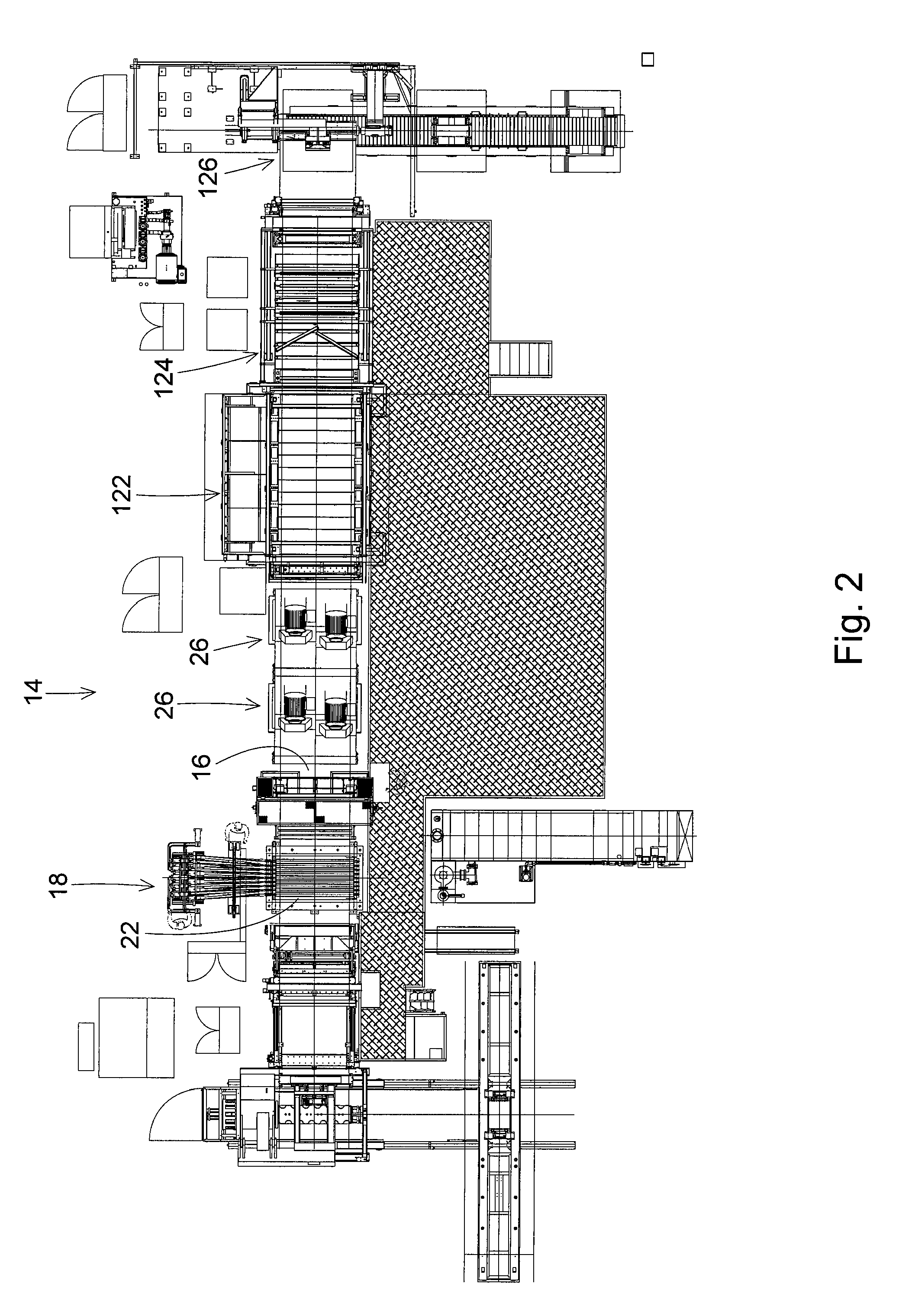

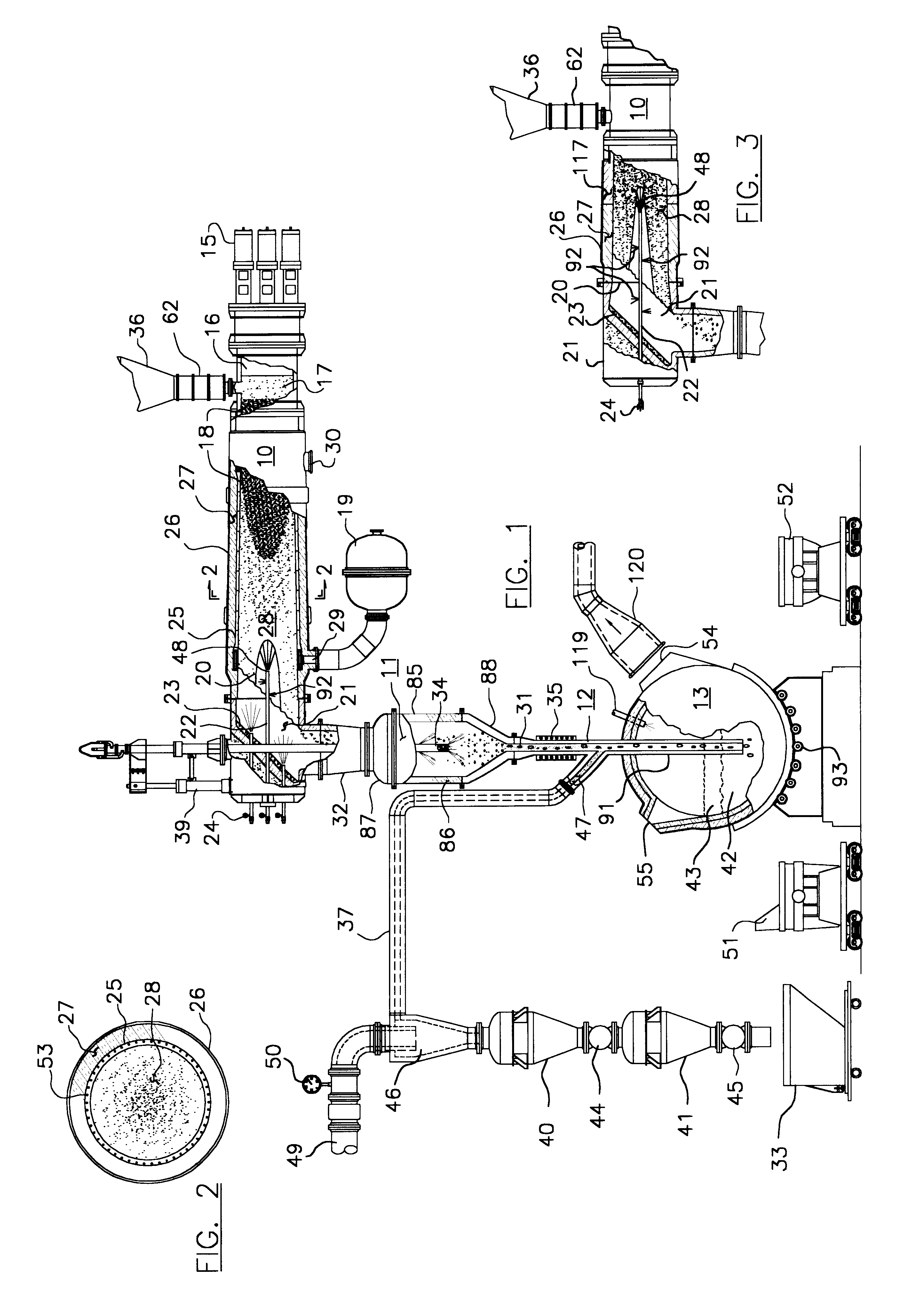

Slurry Blasting Apparatus for Removing Scale From Sheet Metal

ActiveUS20080182486A1Prevent reoxidationAvoid contact damageImpeller wheelsRotor bladesEngineeringMetal

Owner:THE MATERIAL WORKS

Slurry Blasting Apparatus for Removing Scale from Sheet Metal

ActiveUS20080108281A1Prevent reoxidationAvoid contact damageEdge grinding machinesImpeller wheelsEngineeringMetal

Owner:THE MATERIAL WORKS

Slurry blasting apparatus for removing scale from sheet metal

ActiveUS7601226B2Prevent reoxidationAvoid contact damageEdge grinding machinesImpeller wheelsEngineeringMetal

Owner:THE MATERIAL WORKS

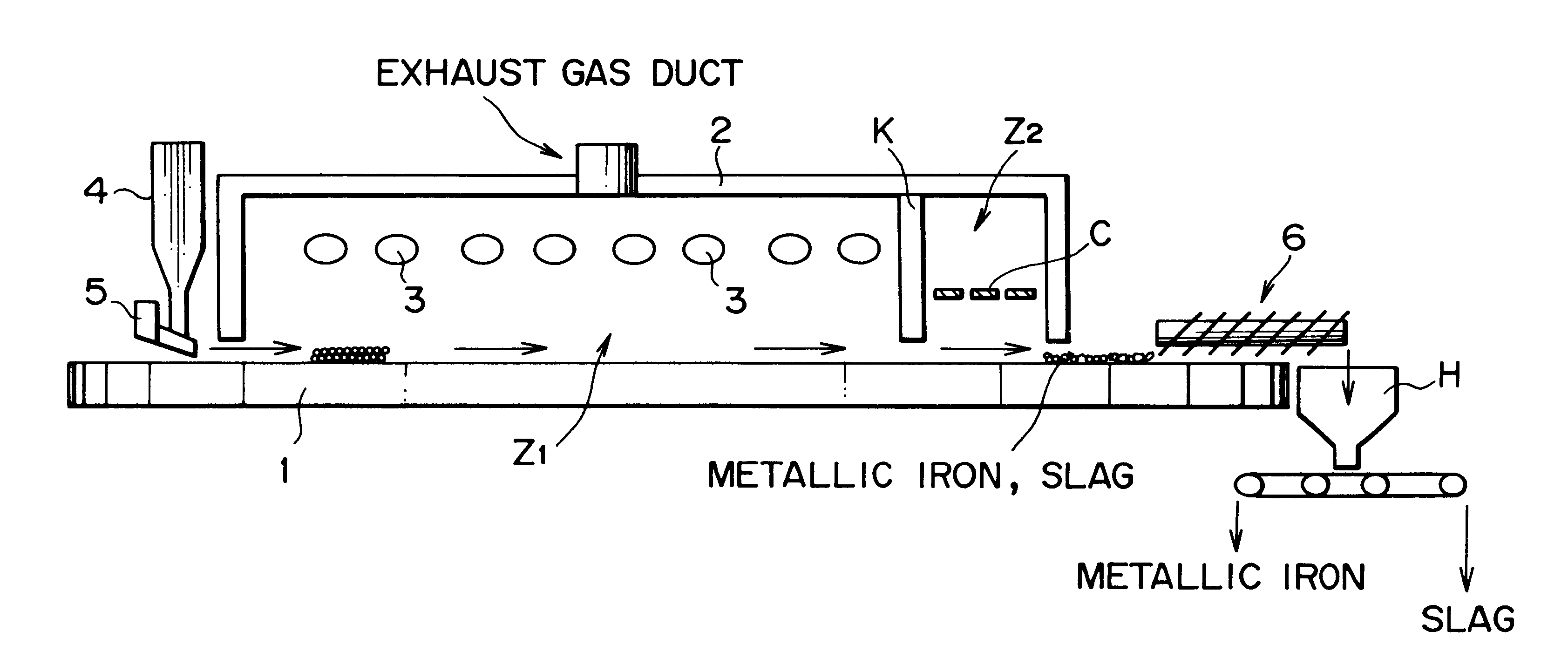

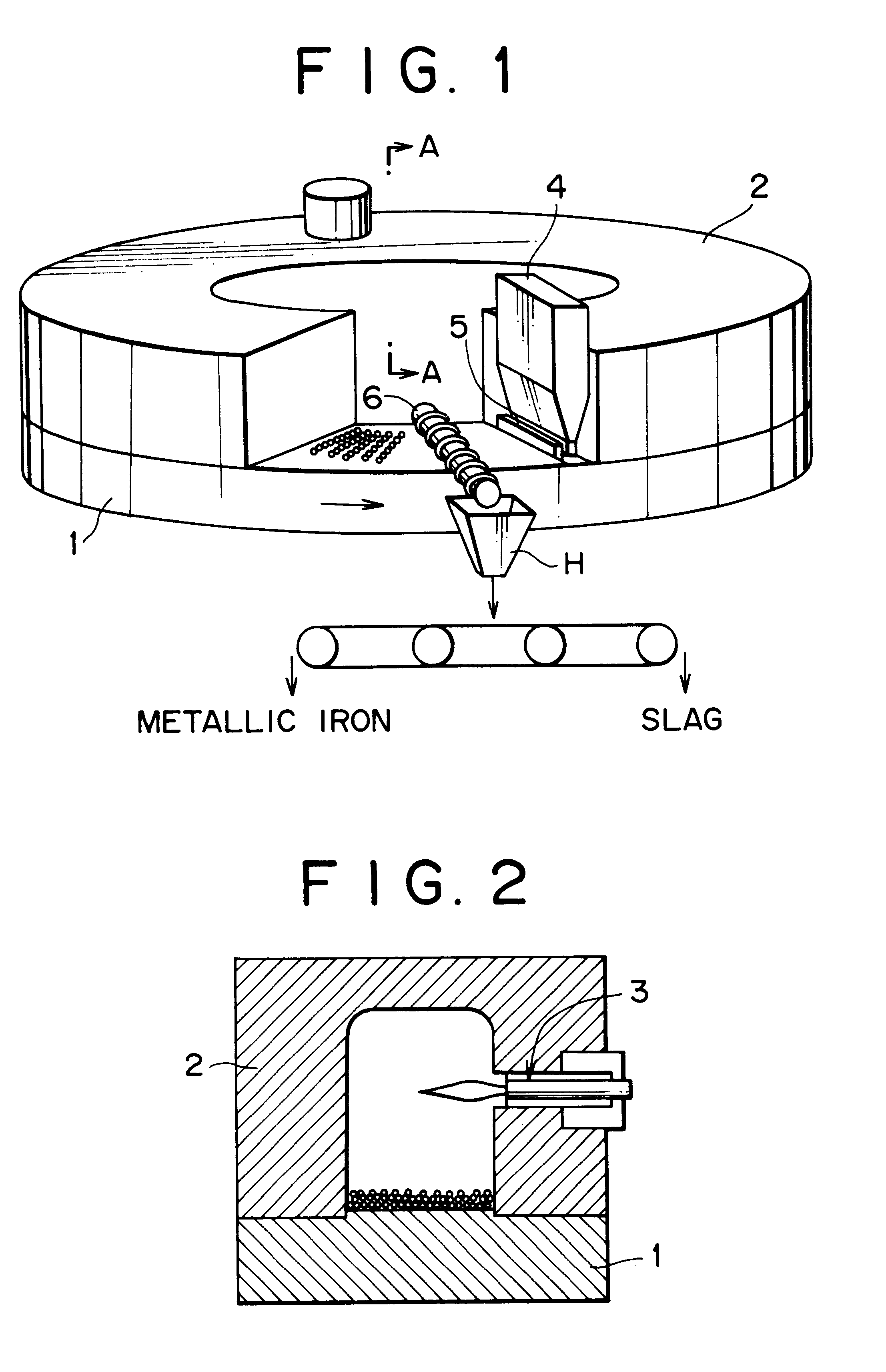

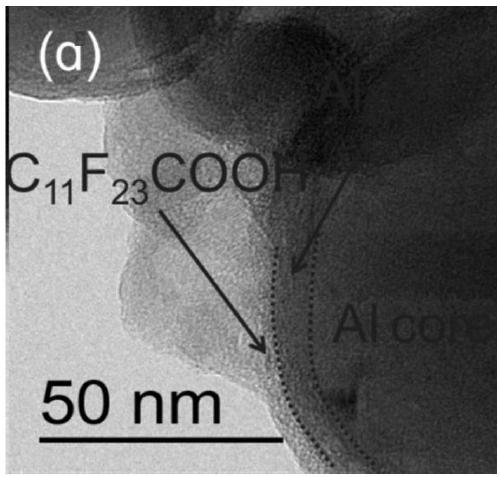

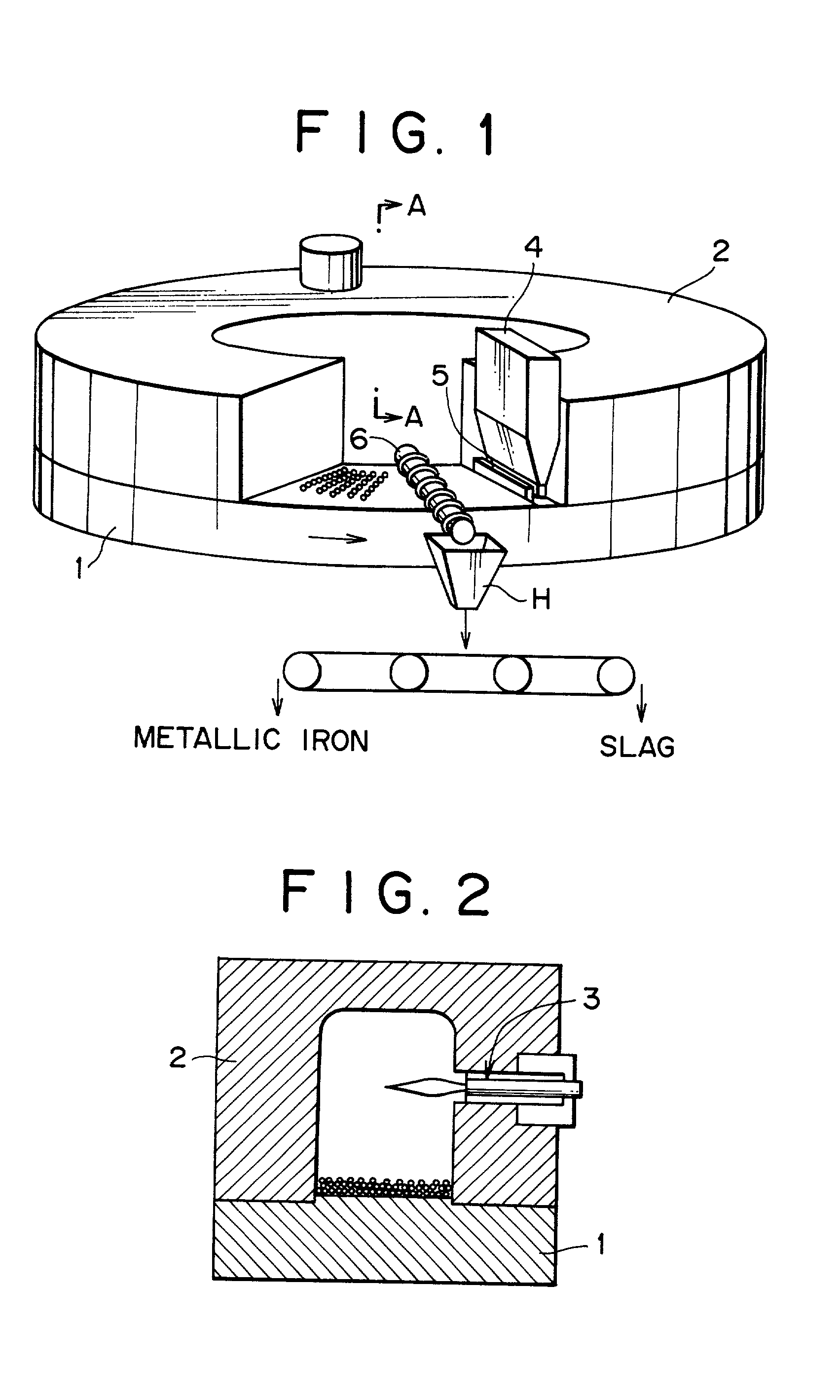

Method of producing iron nuggets

InactiveUS6592649B2Avoid smallImprove productivityProcess efficiency improvementGas emission reductionProduction rateSlag

The present invention provides a method of producing metallic iron nuggets with a high yield and good productivity, and more particularly a method which can produce metallic iron nuggets which have a high Fe purity and are excellent in transporting and handling due to a large grain diameter with a high yield and good productivity, when they are produced by reducing and melting raw material containing iron oxide such as iron ore and carbonaceous reducing agent such as coke. The method of producing metallic iron nuggets comprises steps of: heating raw material containing carbonaceous reducing agent and iron oxide-containing material in a reducing / melting furnace, reducing iron oxide in the raw material, and then heating and melting the metallic iron produced by the reduction and simultaneously making it coalesce while separating the metallic iron nuggets from slag components characterized in that the fixed carbon content ratio as the carbonaceous reducing agent is at least 73% and the volatile matter content in the raw material is not more than 3.9% are used, and the mixing content of carbonaceous reducing agent is restrained to be not more than 45% in relation to the iron oxide components, which is contained in the iron oxide-containing material of the raw material.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

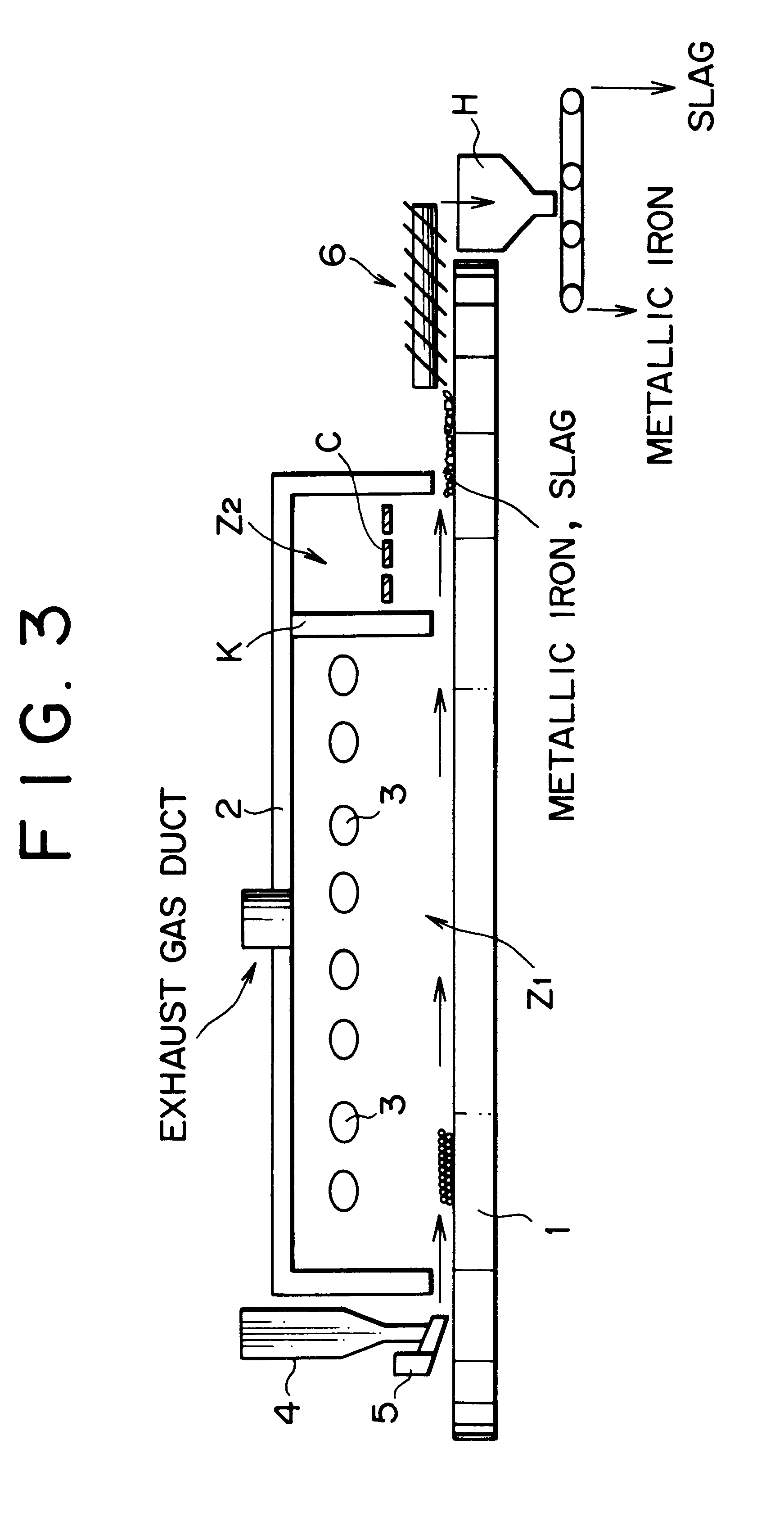

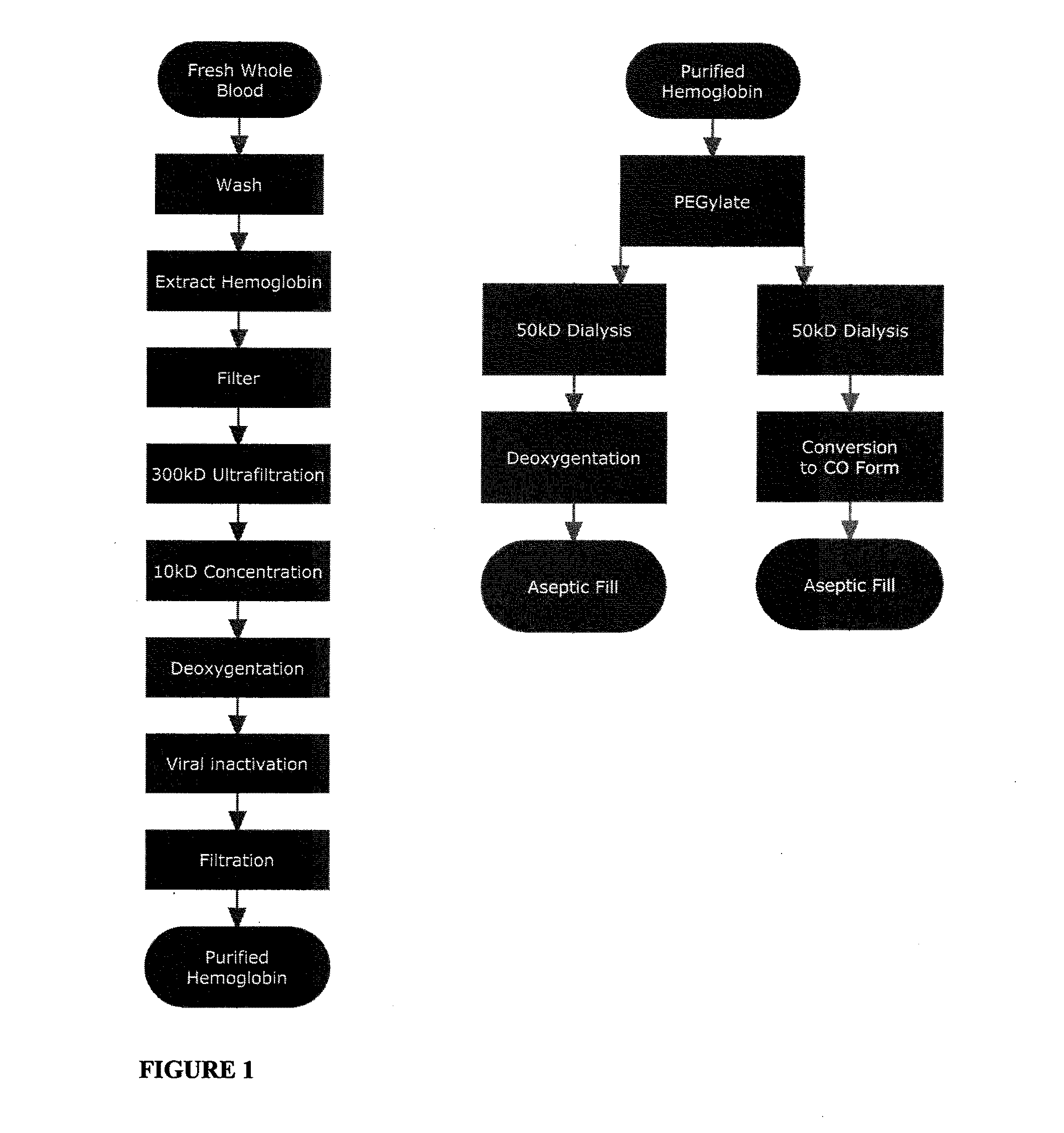

Hemoglobin compositions

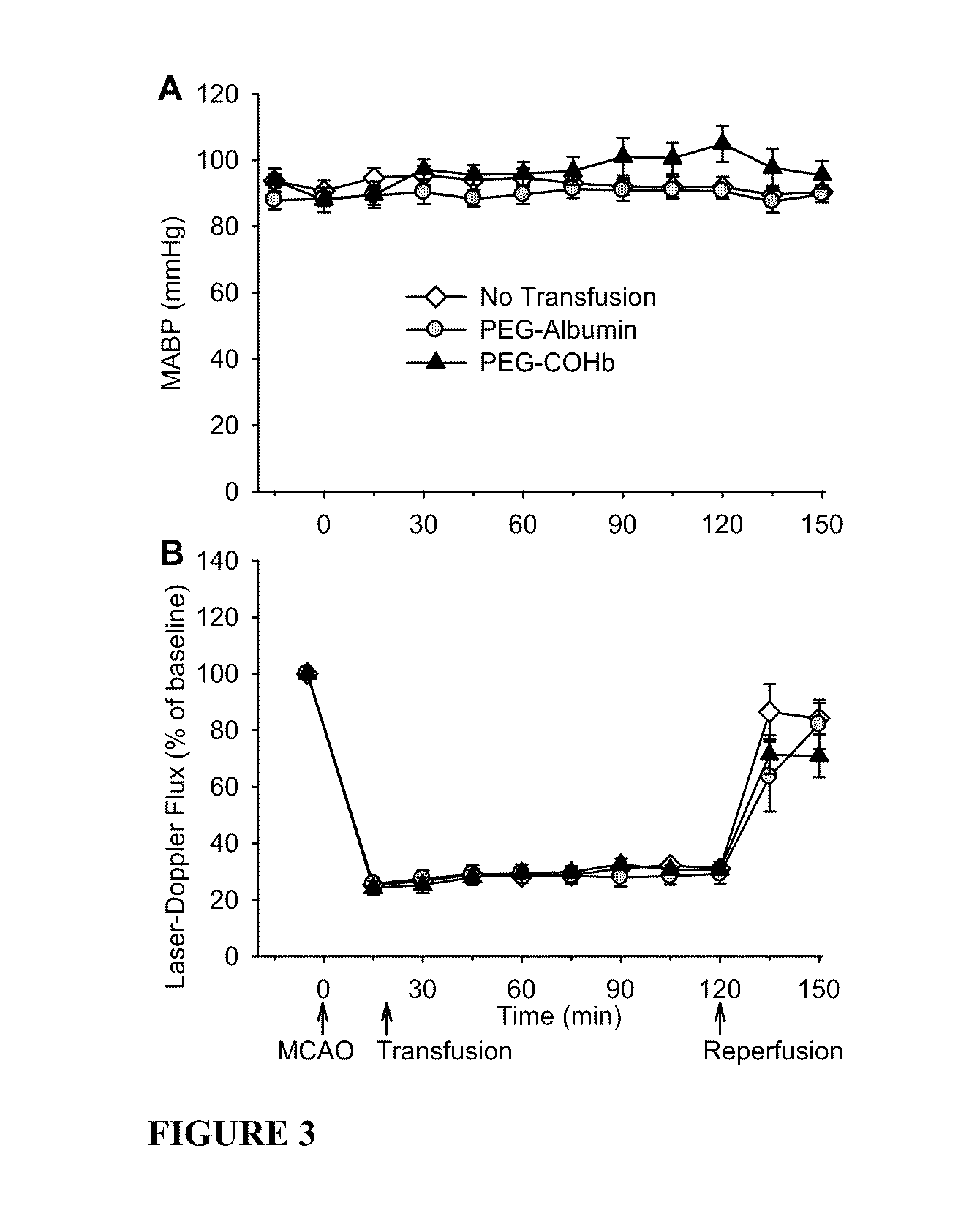

ActiveUS20100311657A1Extended half-lifeReduce chancePeptide/protein ingredientsEnergy modified materialsDiseaseHEMOGLOBIN I

The invention provides compositions containing hemoglobin, particularly PEGylated hemoglobin. The PEGylated hemoglobin molecule is capable of transferring oxygen or carbon monoxide bound thereto to a tissue with which it is in proximity. Exemplary PEGylated hemoglobin formulations of the invention are virally inactivated. Various compositions of the invention include deoxygenated hemoglobin, which may be conjugated with one or more water-soluble polymer. PEGylated hemoglobin includes those species in which the iron atom of the hemoglobin molecule is not bound to oxygen or any other species, and hemoglobin molecules in which a species other than oxygen, e.g., carbon monoxide, is bound to the iron atom. The compositions of the invention are formulated as hypo-, iso- or hypertonic solutions of the PEGylated hemoglobin. The compositions are of use to treat and / or ameliorate disease, injury and insult by providing for the oxygenation of tissues and / organs.

Owner:PROLONG PHARMA

Method for forming fine copper particle sintered product type of electric conductor having fine shape, method for forming fine copper wiring and thin copper film using said method

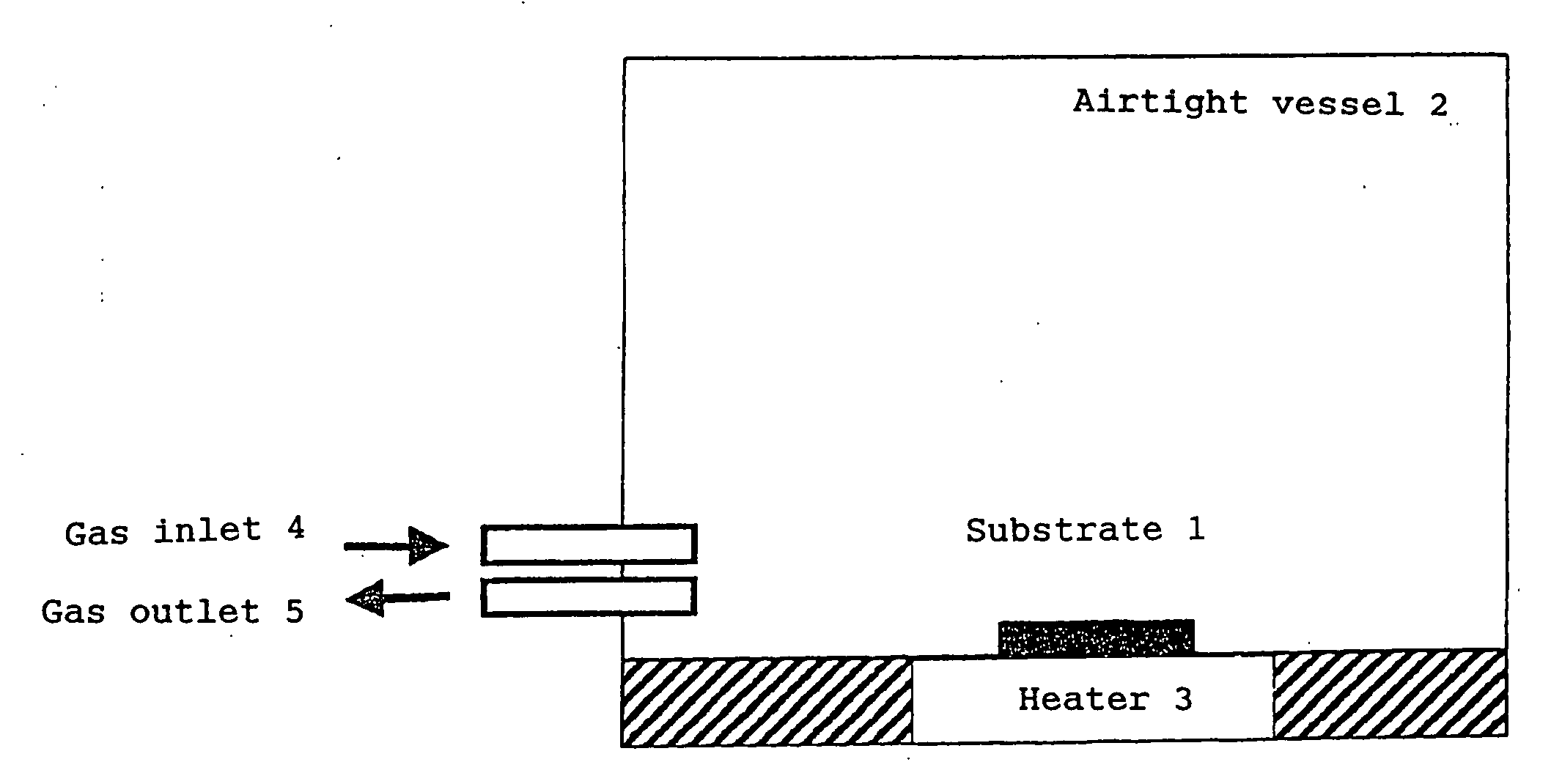

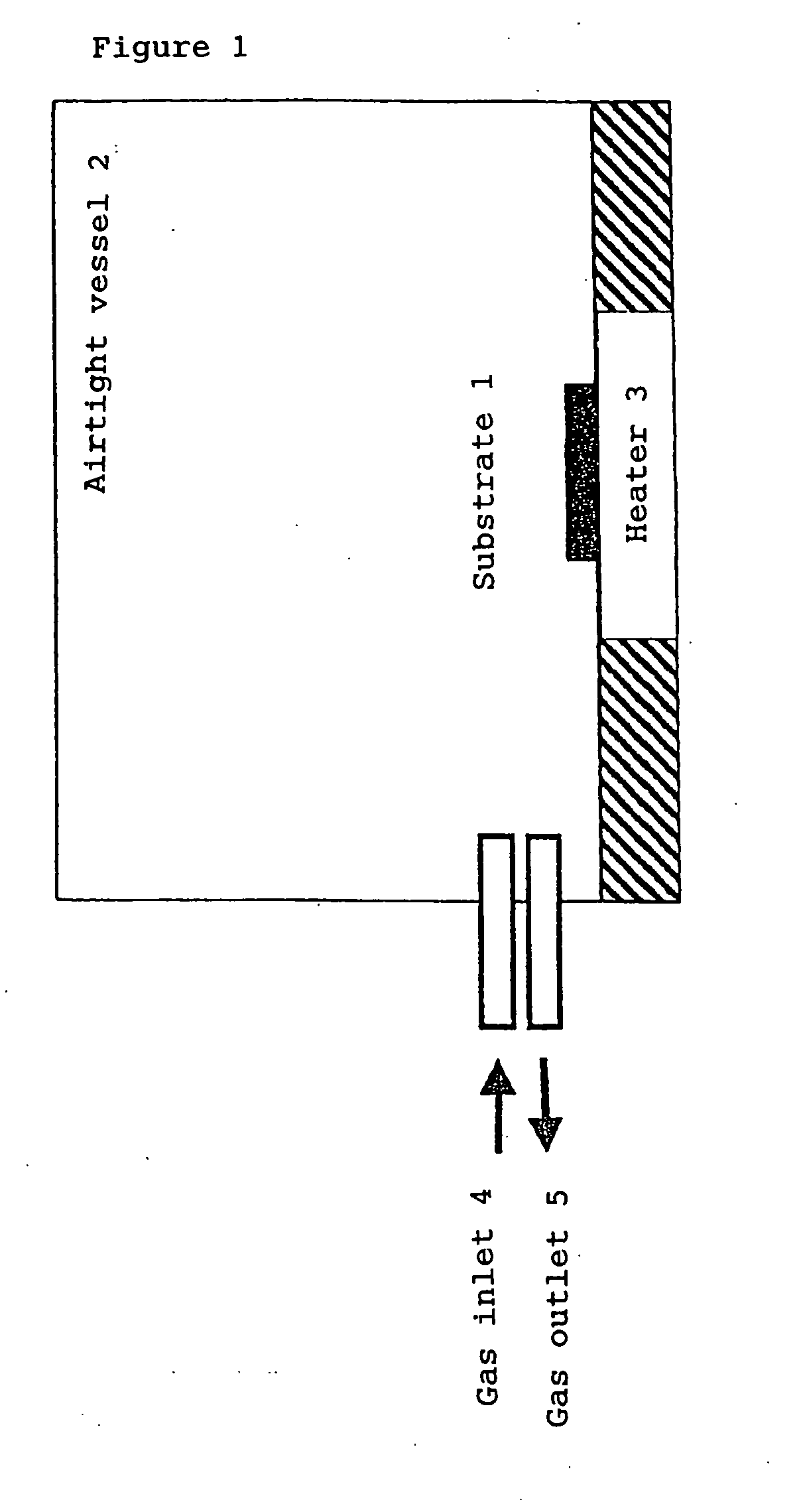

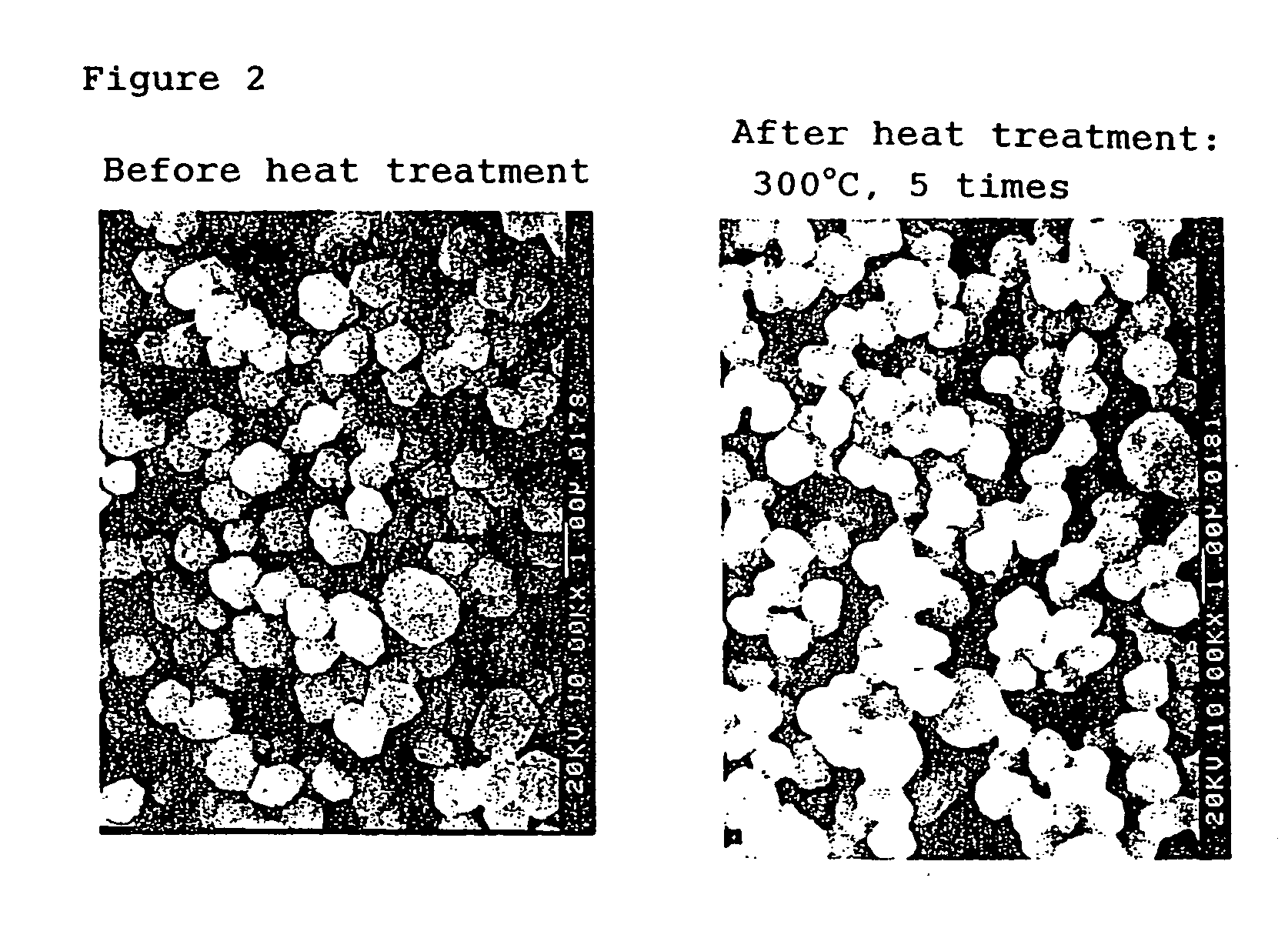

ActiveUS20060210705A1Good reproducibilityBroaden spectrumPrinted circuit aspectsPretreated surfacesSurface oxideProduct gas

The present invention provides a process for forming a copper fine particle sintered product type of a fine-shaped electric conductor showing superior electroconductivity, which comprises steps of drawing a fine pattern with the use of a dispersion containing the copper fine particles having a surface oxide film layer, conducting a treatment for reducing the copper fine particles with the surface oxide film layer or copper oxide fine particles included in the pattern at a comparatively low temperature, and baking the resultant copper fine particles. Specifically, the process carries out the processes of; applying a dispersion containing the copper fine particles having the surface oxide film layer thereon or the copper oxide fine particles with an average particle diameter of 10 μm or smaller onto a substrate; and then performing a series of the heat treatment steps of heating the particles in the coated layer at temperature of 350° C. or lower under an atmosphere containing a vapor and a gas of a compound having reducibility to reduce the oxide film by a reduction reaction which used the compound having reducibility as a reducing agent, subsequently repeating a heat treatment combining an oxidizing treatment of a short time with a re-reducing treatment, and sintering the resultant copper fine particles with each other to form a layer of the sintered product.

Owner:HARIMA CHEM INC

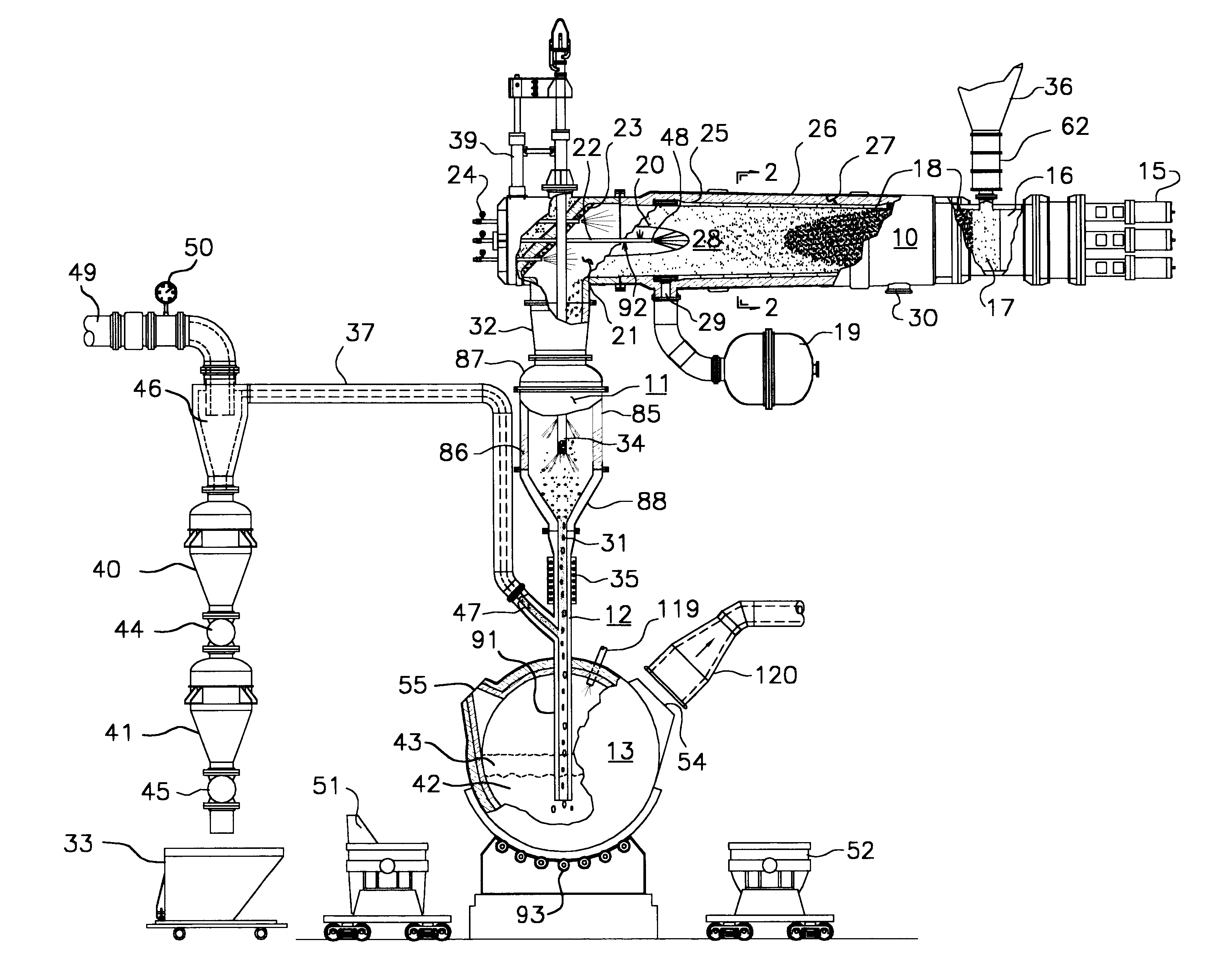

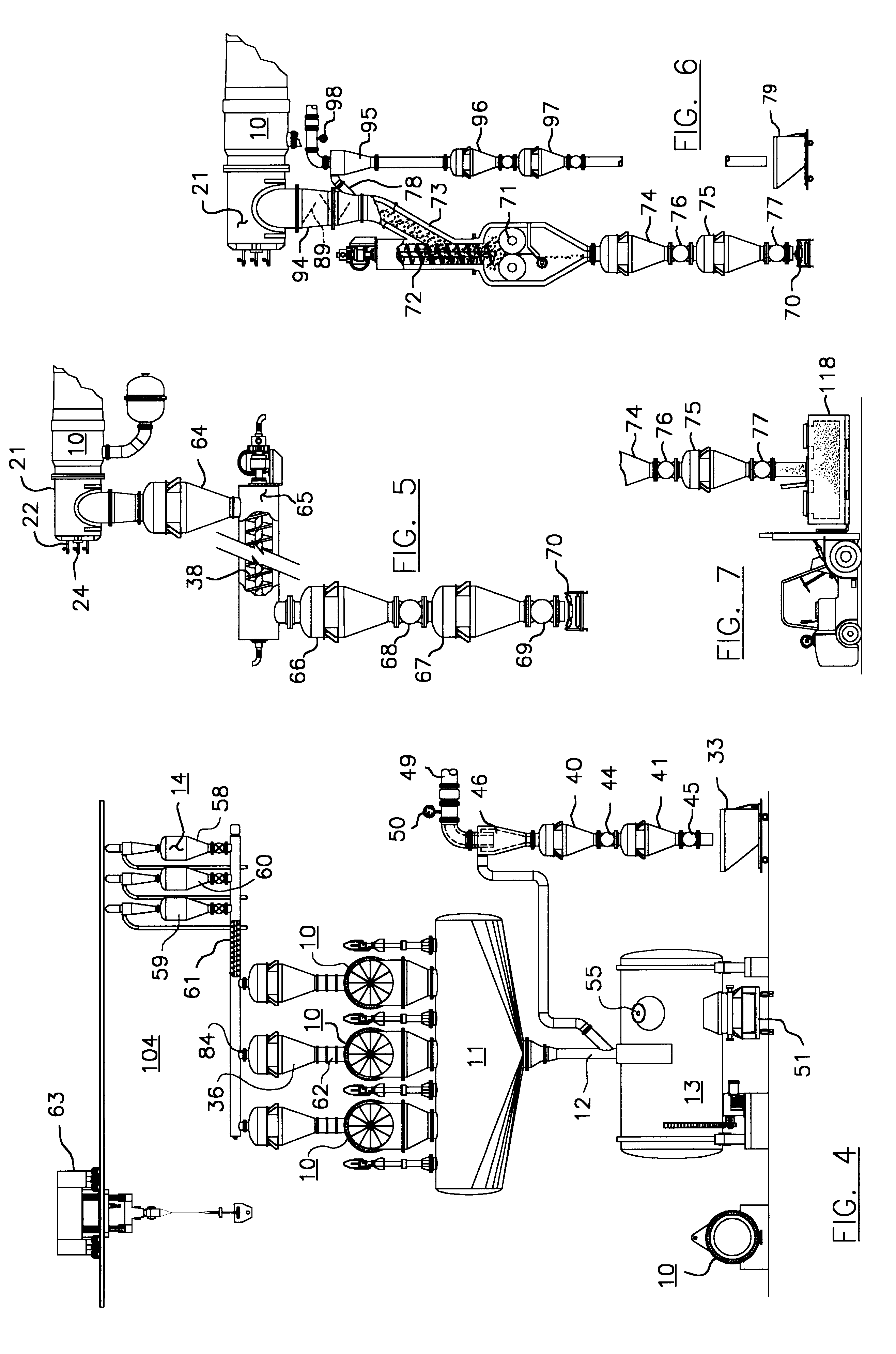

Method and apparatus for practicing carbonaceous-based metallurgy

InactiveUS6409790B1Low costReduce capital investmentMaintainance of heating chambersBlast furnace detailsThermal energyOperational costs

An energy efficient, coal-based method and apparatus that are environmentally friendly which produce under pressure metallized / carbon product and molten metal directly from abundant coal or other carbonaceous material, and low cost fines (or ore concentrate) wherein the metal is devoid of gangue material and possesses the inherent advantage of retaining the heat for subsequent processing. This method and apparatus which are modular and highly integrated significantly reduce capital and operating costs; they also provide the capability selective placement of the reductant for the delivery of high levels of thermal energy input which leads to ease of desulflurization and high productivity. The technology herein disclosed is entirely closed and is applicable to various ores including ferrous and non-ferrous.

Owner:CALDERON ENERGY OF BOWLING GREEN

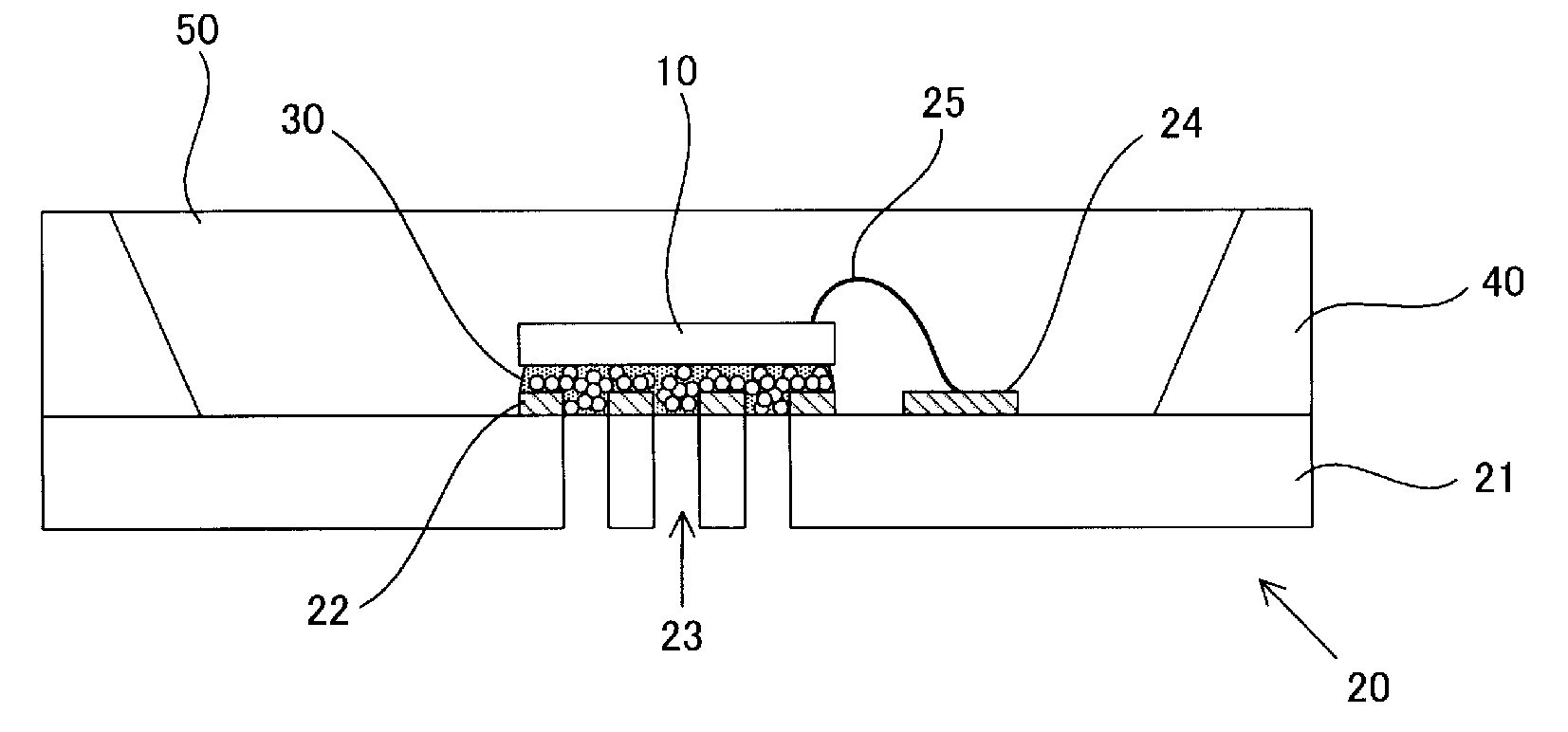

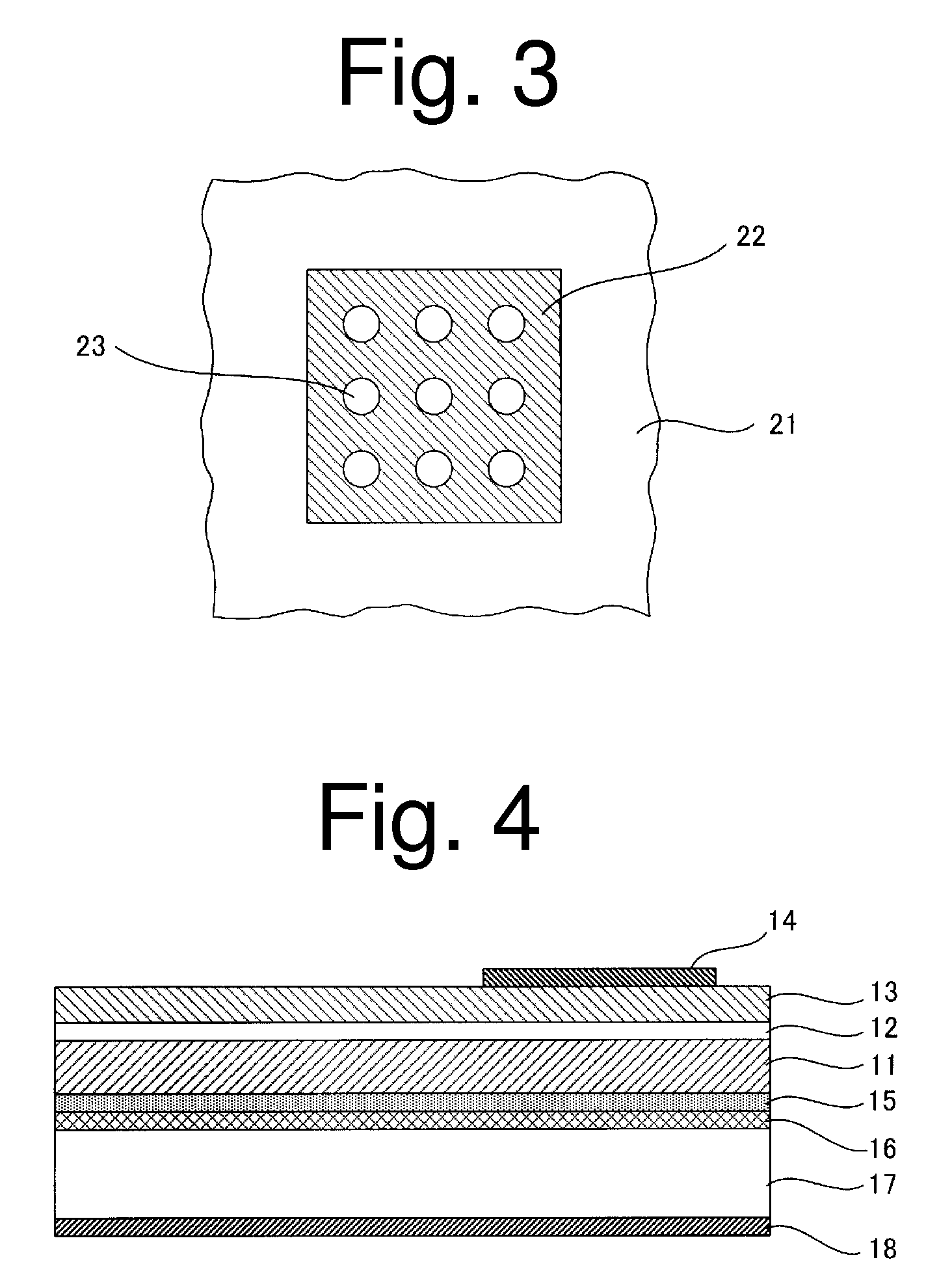

Optical semiconductor apparatus and method for producing the same

InactiveUS20100123162A1Treatment time be reducePrevent reoxidationSolid-state devicesSemiconductor/solid-state device manufacturingSolder pasteEngineering

An optical semiconductor apparatus can be configured by mounting an optical semiconductor element on a package substrate using a solder paste. The optical semiconductor apparatus can include a package substrate and a metal die pad formed on the substrate, and an optical semiconductor element bonded to the die pad with a solder material. The substrate can be made of a ceramic base material. A plurality of through holes can be formed in the substrate so that the through holes penetrate both the substrate base material and the die pad. Each of the through holes can have an inner surface where the ceramic base material is exposed. Each through hole can have an opening diameter greater than or equal to 40 μm and less than or equal to 100 μm. The plurality of through holes can be formed such that the total area of the openings of the through holes is 50% or less of the bonded area between the optical semiconductor element and the die pad including the through holes covered with the solder material. The through holes can be covered with the solder material at the upper end thereof where the optical semiconductor element and the die pad are bonded to each other.

Owner:STANLEY ELECTRIC CO LTD

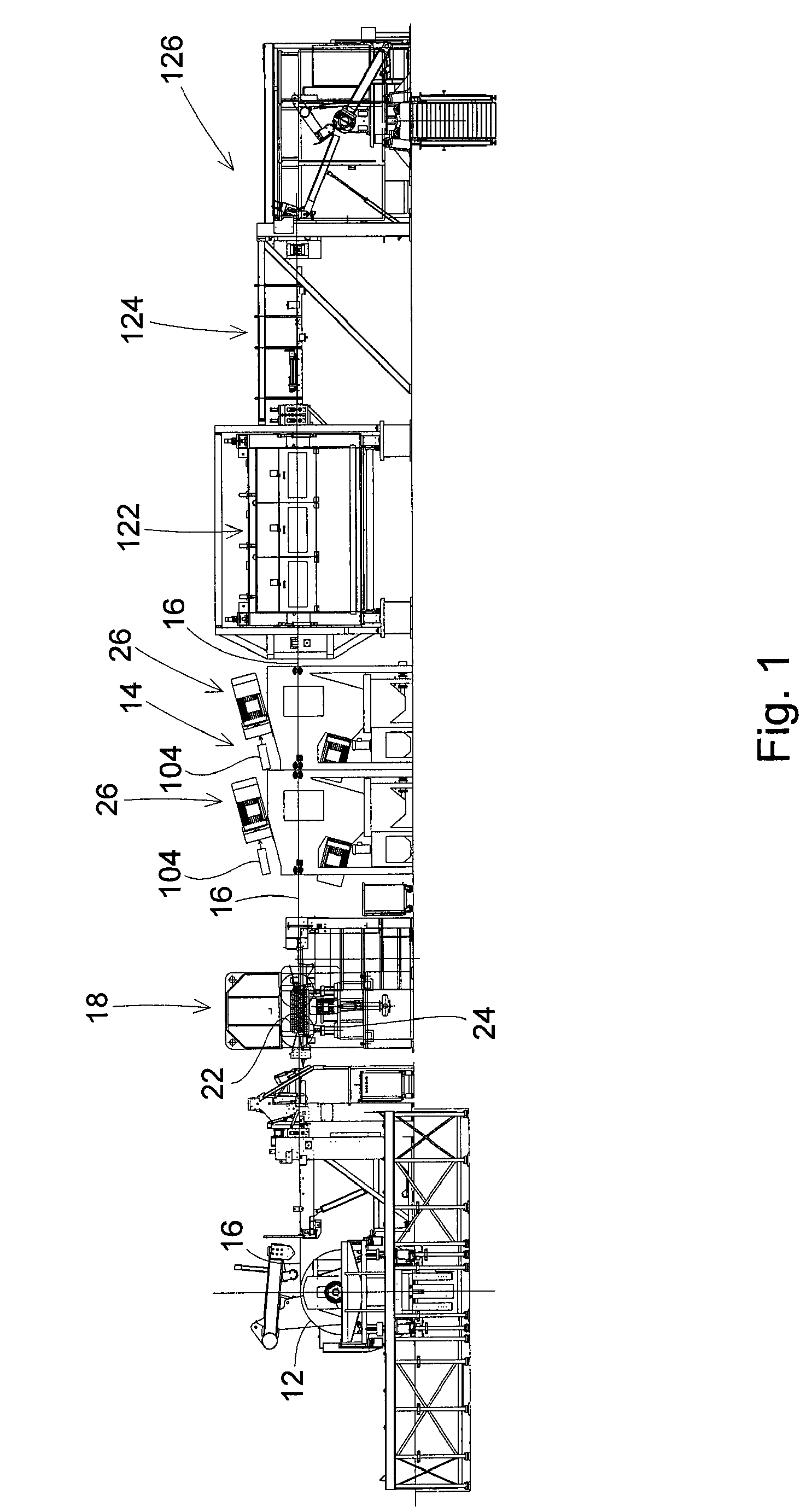

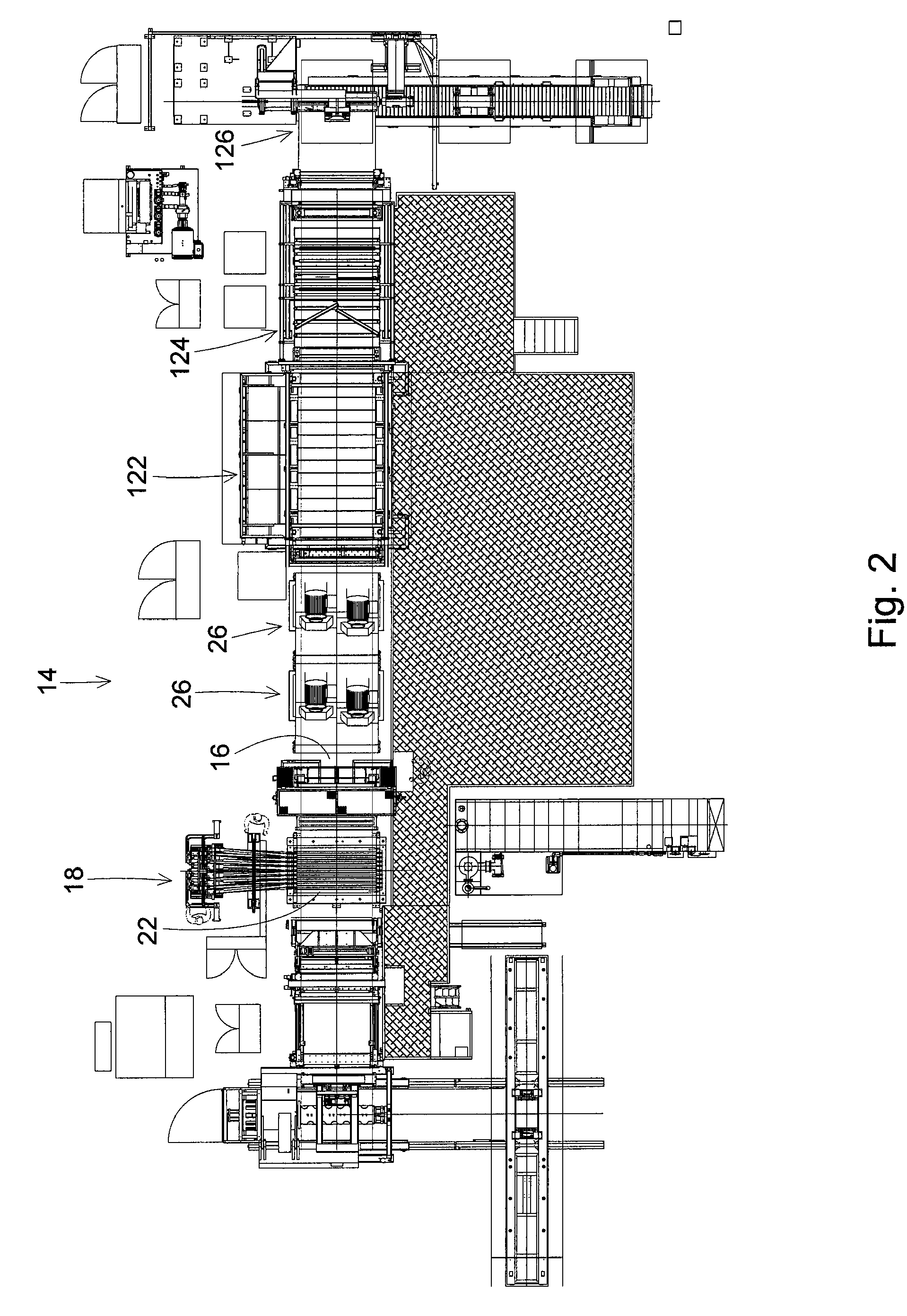

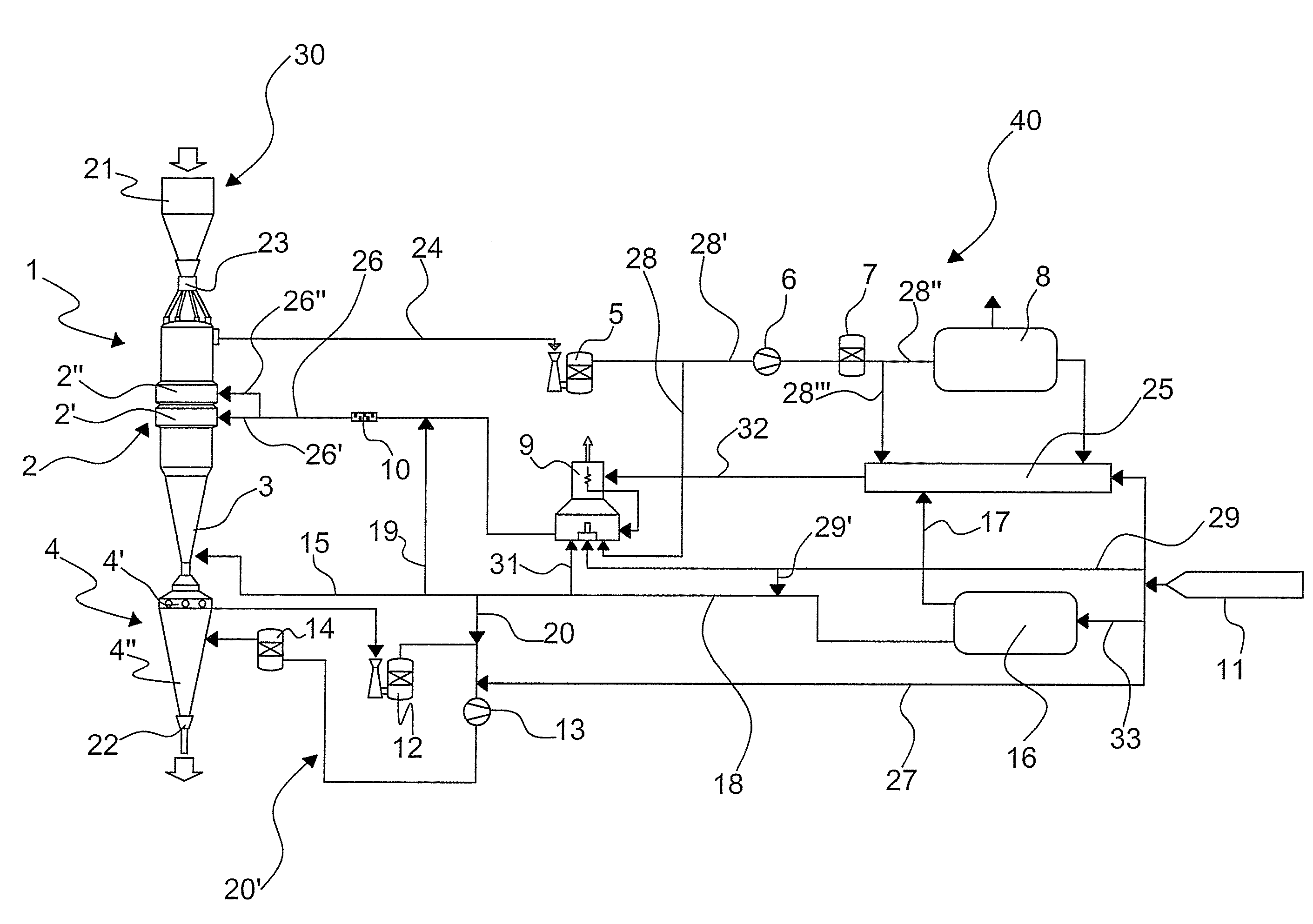

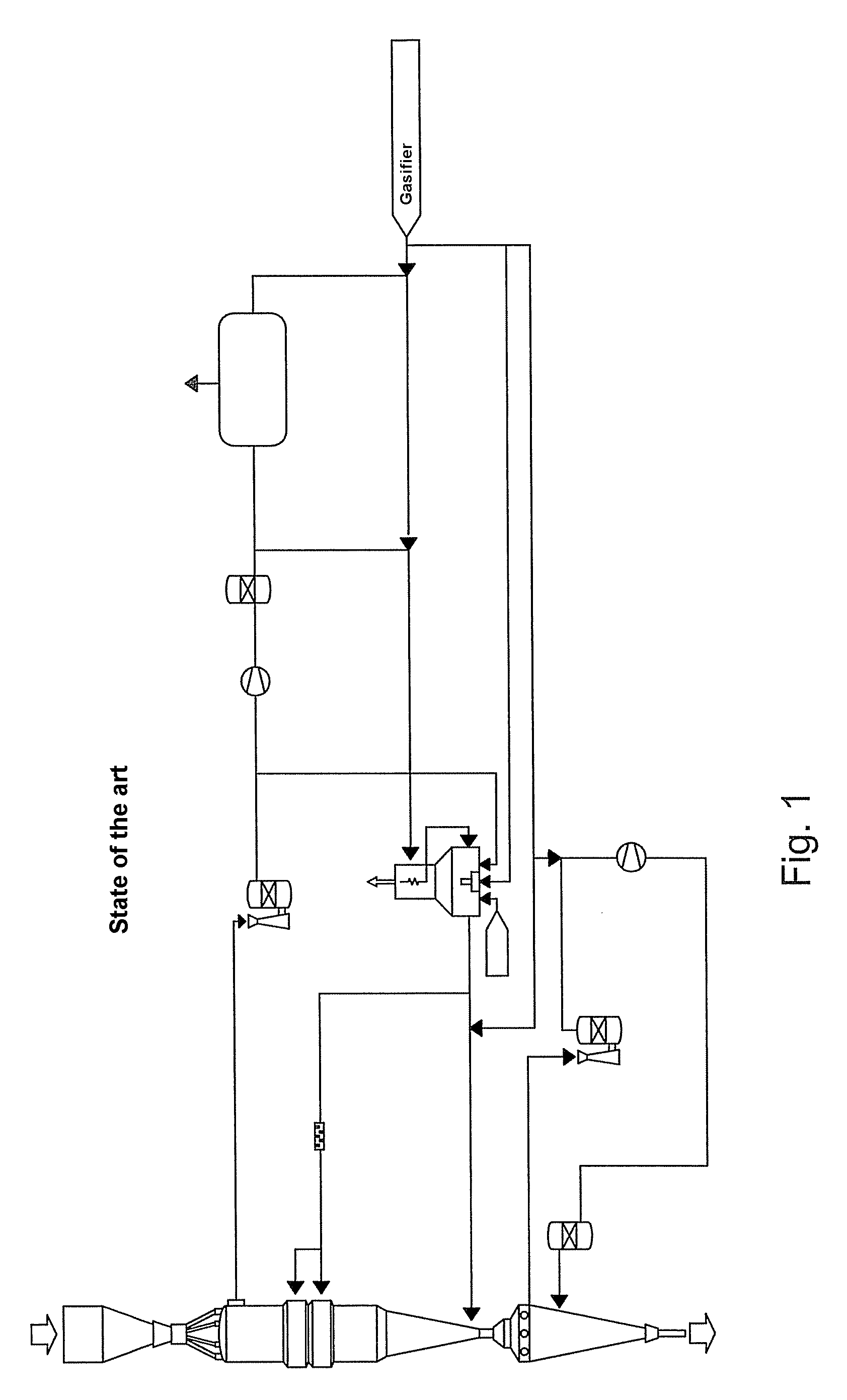

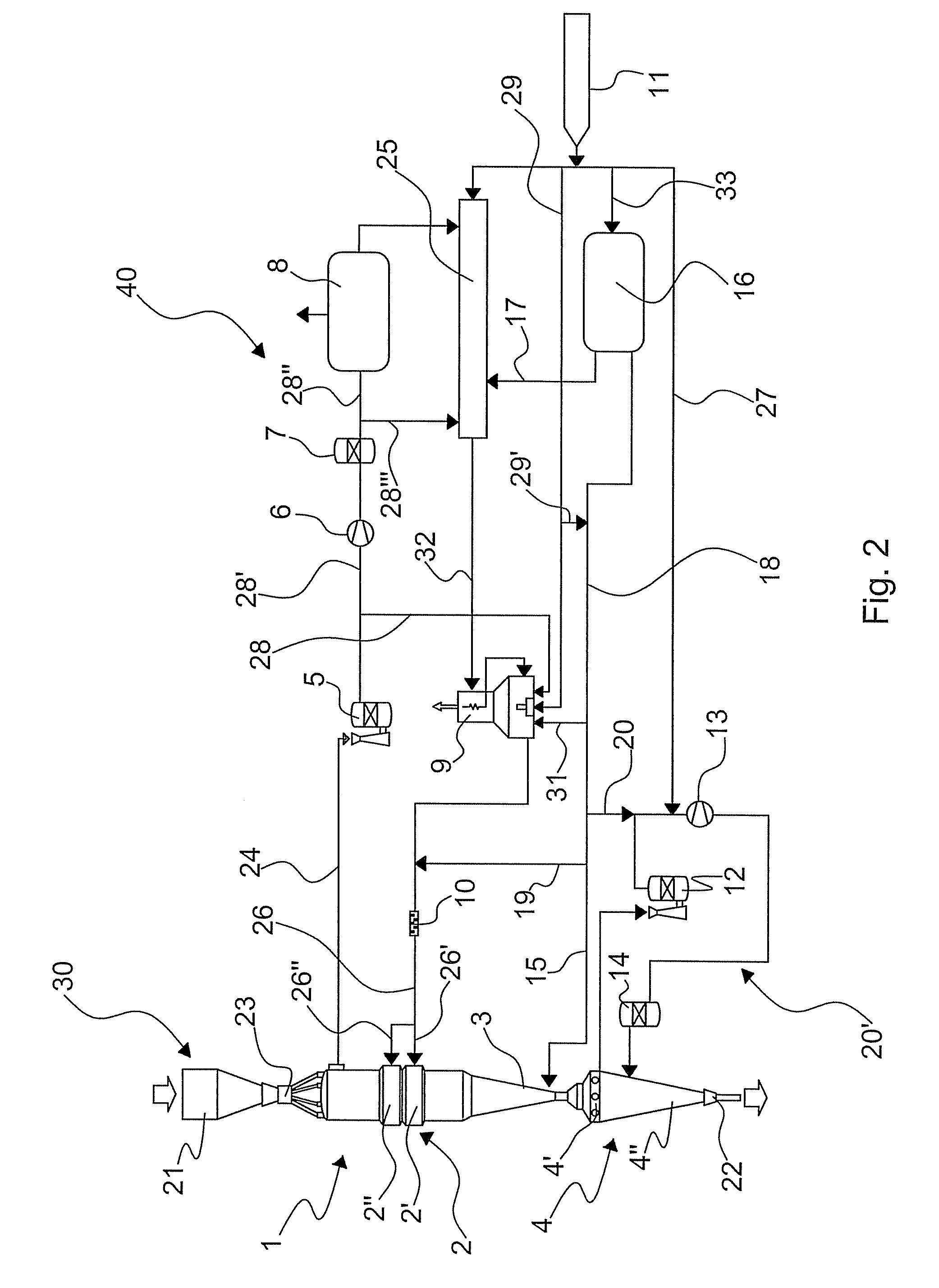

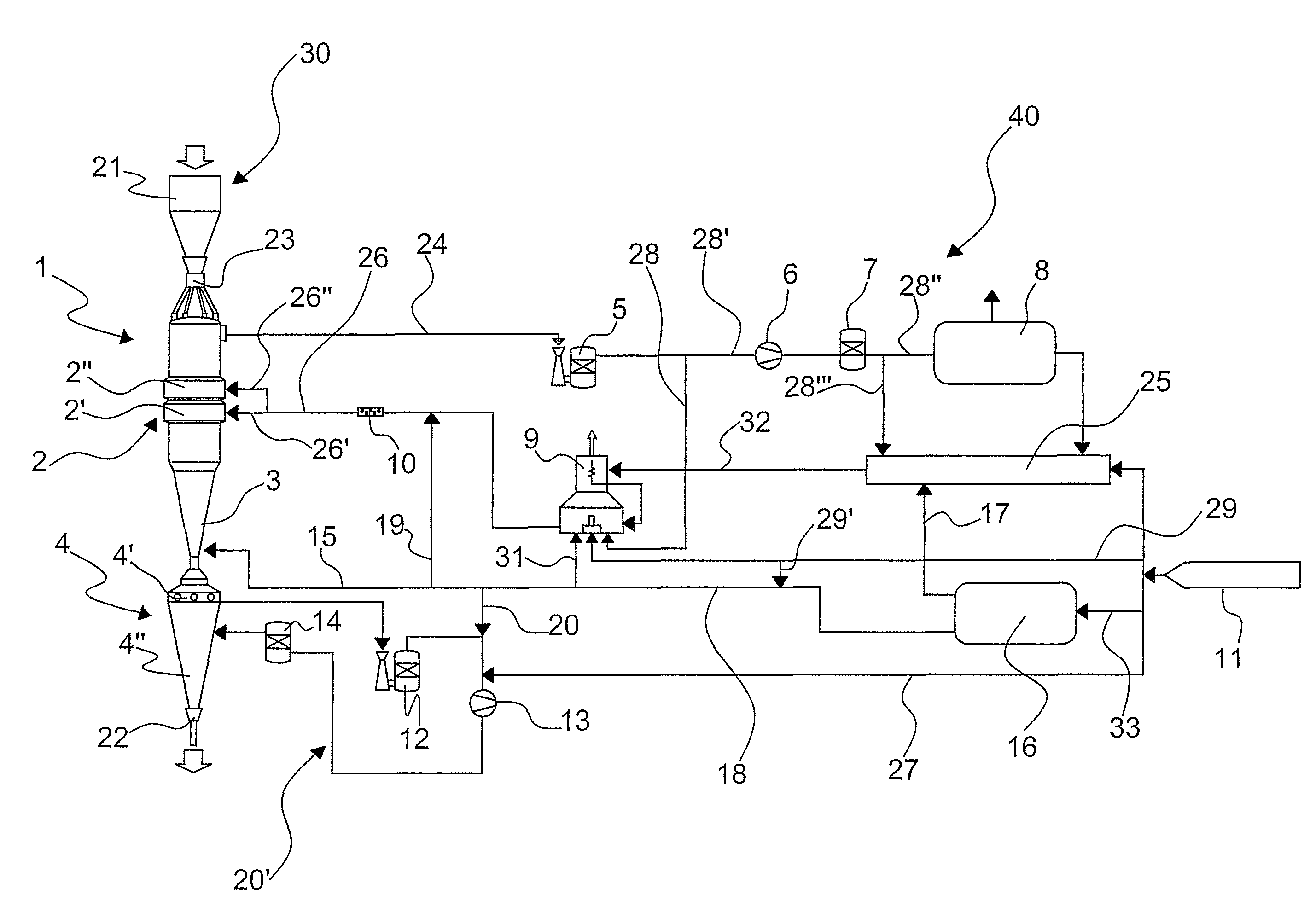

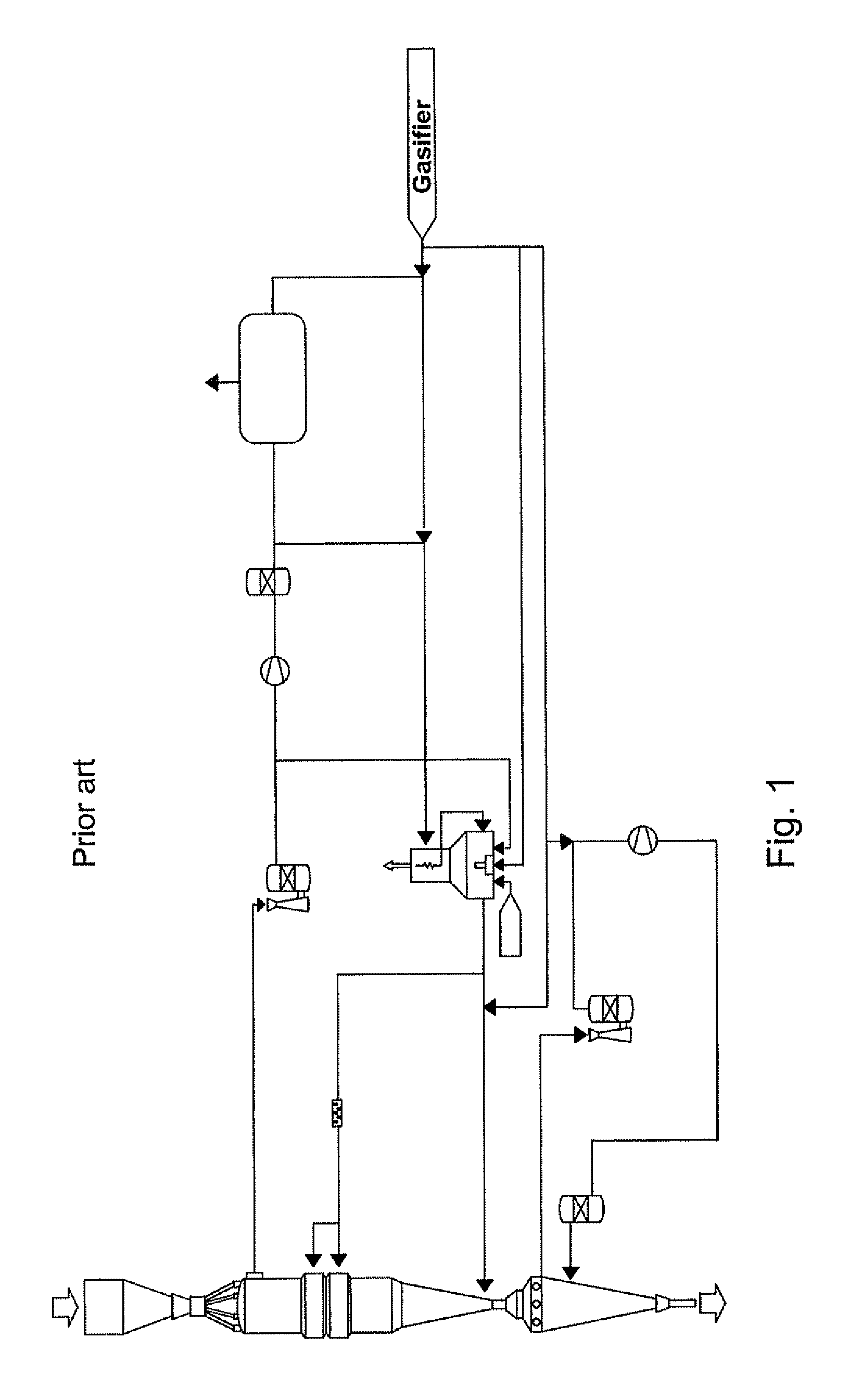

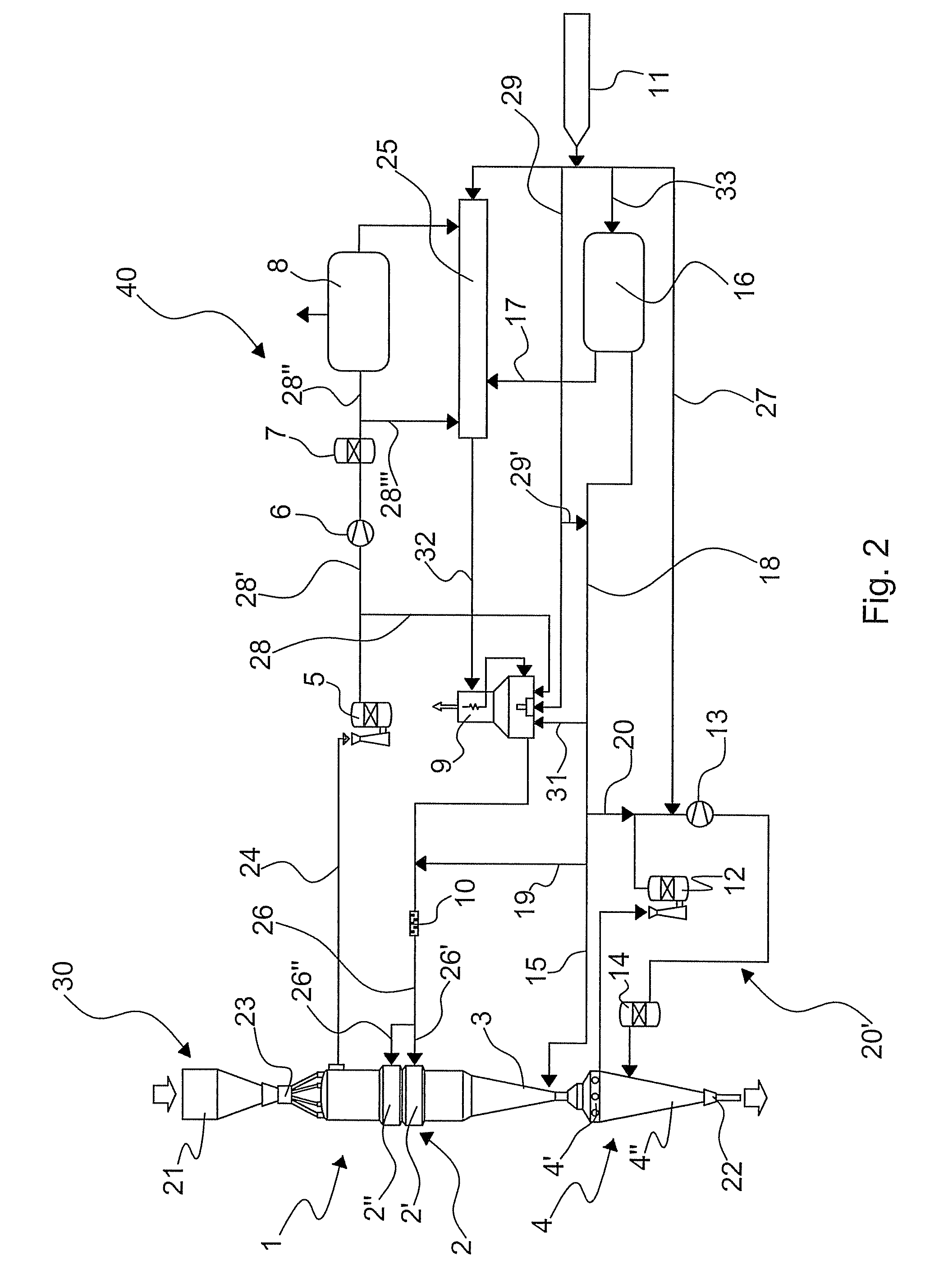

Reduction Process and Plant

ActiveUS20090013828A1Prevent reoxidationSmall sizeTuyeresBell-and-hopper arrangementSyngasProcess engineering

Reduction process and relative plant for the production of metallic iron by means of the direct reduction of iron ore, in which a reduction shaft is connected to a source of reducing gas obtained from the gasification of coal. The process advantageously comprises a step in which a portion or all of the synthesis gas entering the plant circuit is processed to separate the methane from the rest of the components of said synthesis gas. The advantageous management of the extracted methane enables the entire reduction process to be optimized, making the efficiency of the process independent of the methane content in the original synthesis gas and making it possible to control the carbon content of the product more accurately and more easily.

Owner:DANIELI & C OFF MEC SPA

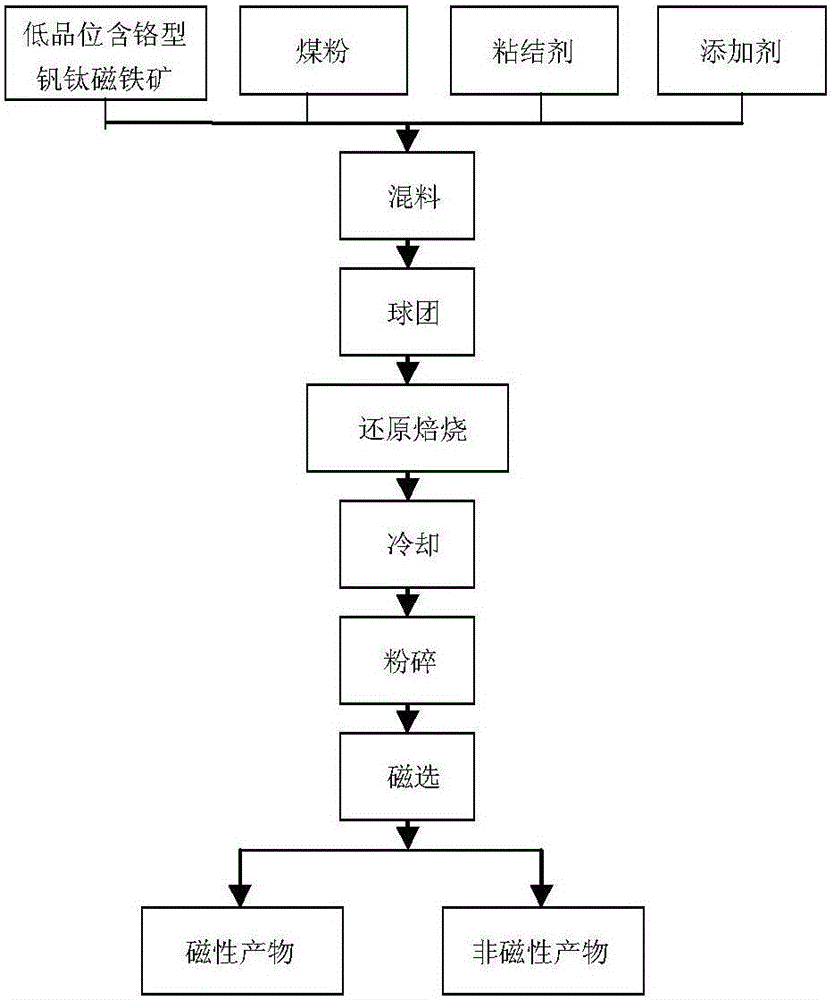

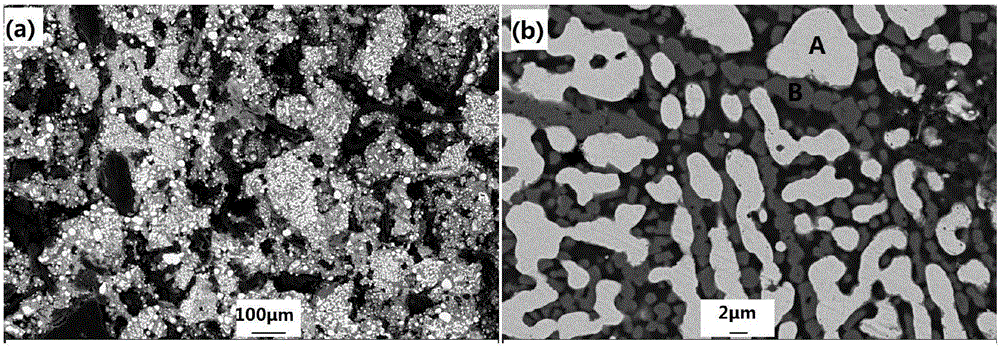

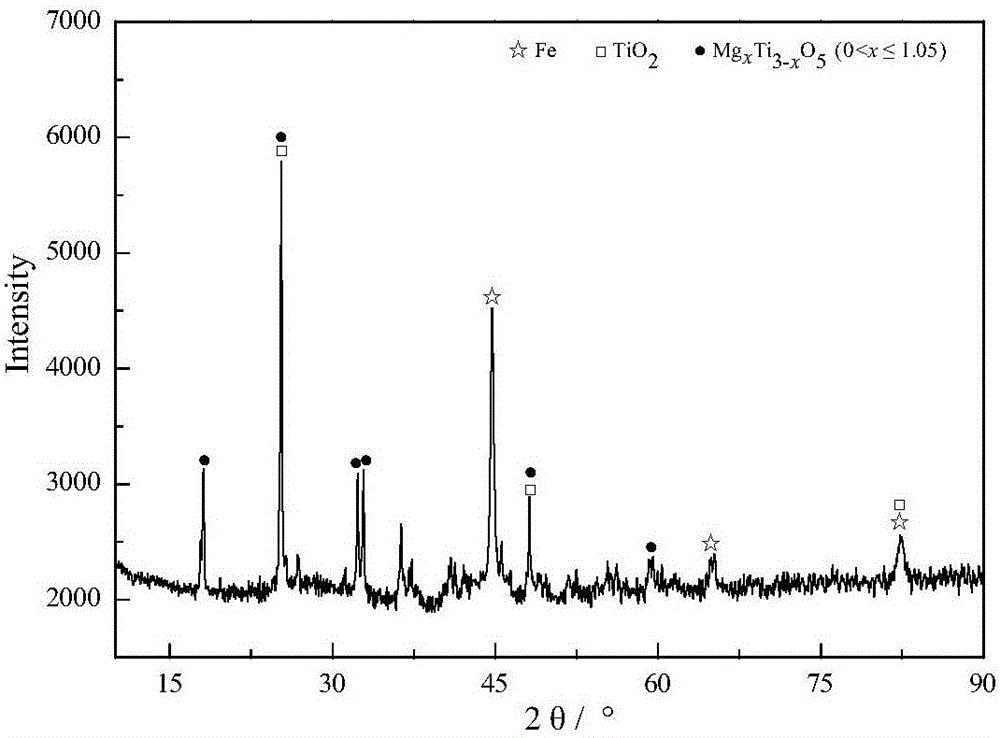

Magnetic separation method for low-grade chromium-containing vanadium titanium magnetite metalized pellet

The invention discloses a magnetic separation method for a low-grade chromium-containing vanadium titanium magnetite metalized pellet, belonging to the technical field of non-blast furnace smelting in comprehensive utilization methods of low-grade chromium-containing vanadium titanium magnetite powder. The method is carried out through the following steps of (1) mixing low-grade chromium-containing vanadium titanium magnetite powder, reduced pulverized coal, a binder and an additive by weighing; (2) preparing a pellet from the mixture, and drying; (3) carrying out coal-based pellet self-reduction high-temperature roasting on the dried pellet; (4) cooling the metalized pellet subjected to high-temperature roasting; and (5) smashing the cooled metalized pellet to obtain metalized pellet powder, and then, carrying out magnetic separation by using a magnetic separation tube to obtain an iron-enriched magnetic matter and titanium-enriched nonmagnetic matters. By using the method, the utilization ratios of strategic metal vanadium, titanium and chromium are maximized on the premise that the metallization ratio and iron recovery ratio for coal-based forced reduction of the low-grade chromium-containing vanadium titanium magnetite metalized pellet are increased.

Owner:NORTHEASTERN UNIV

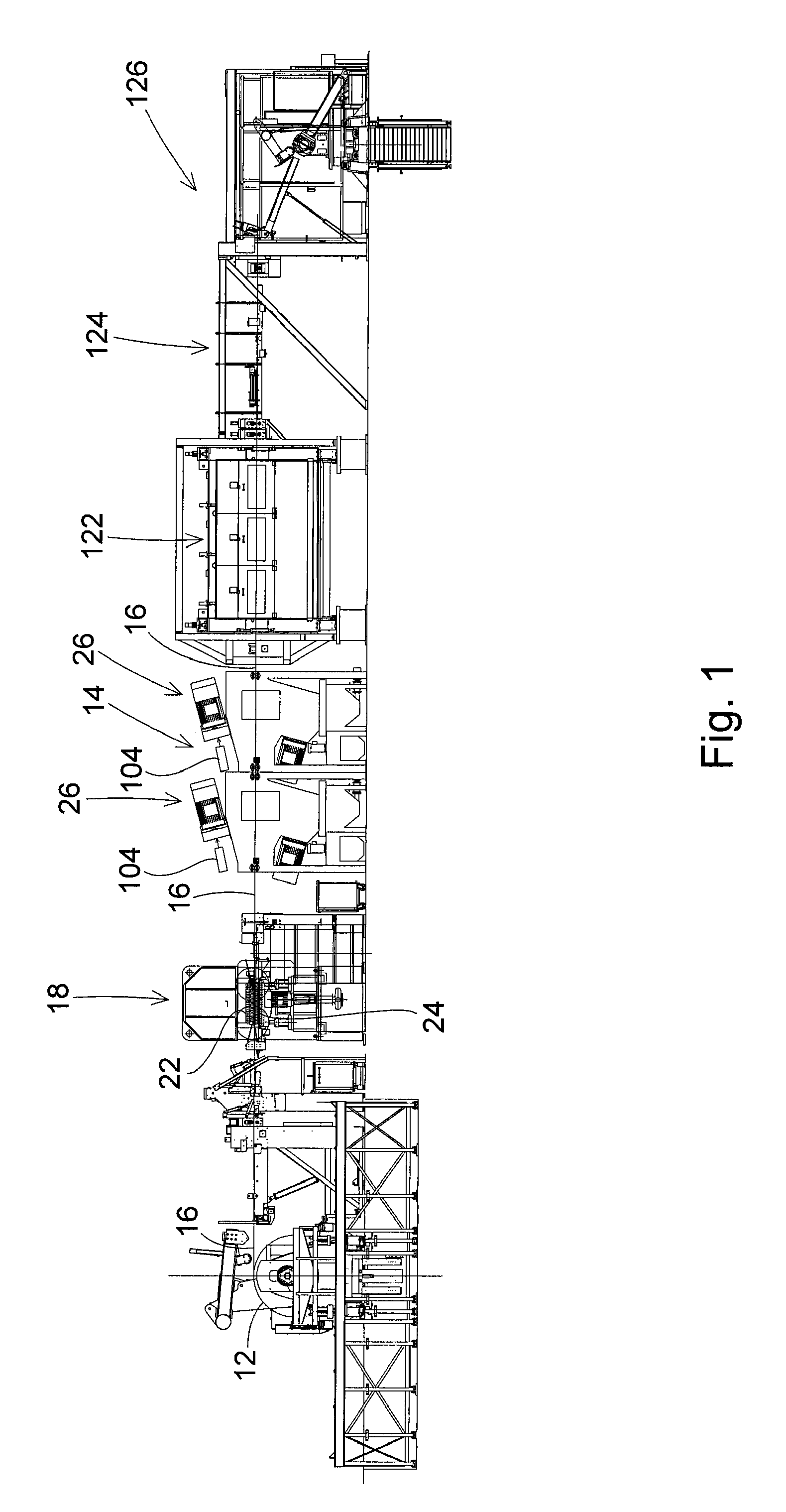

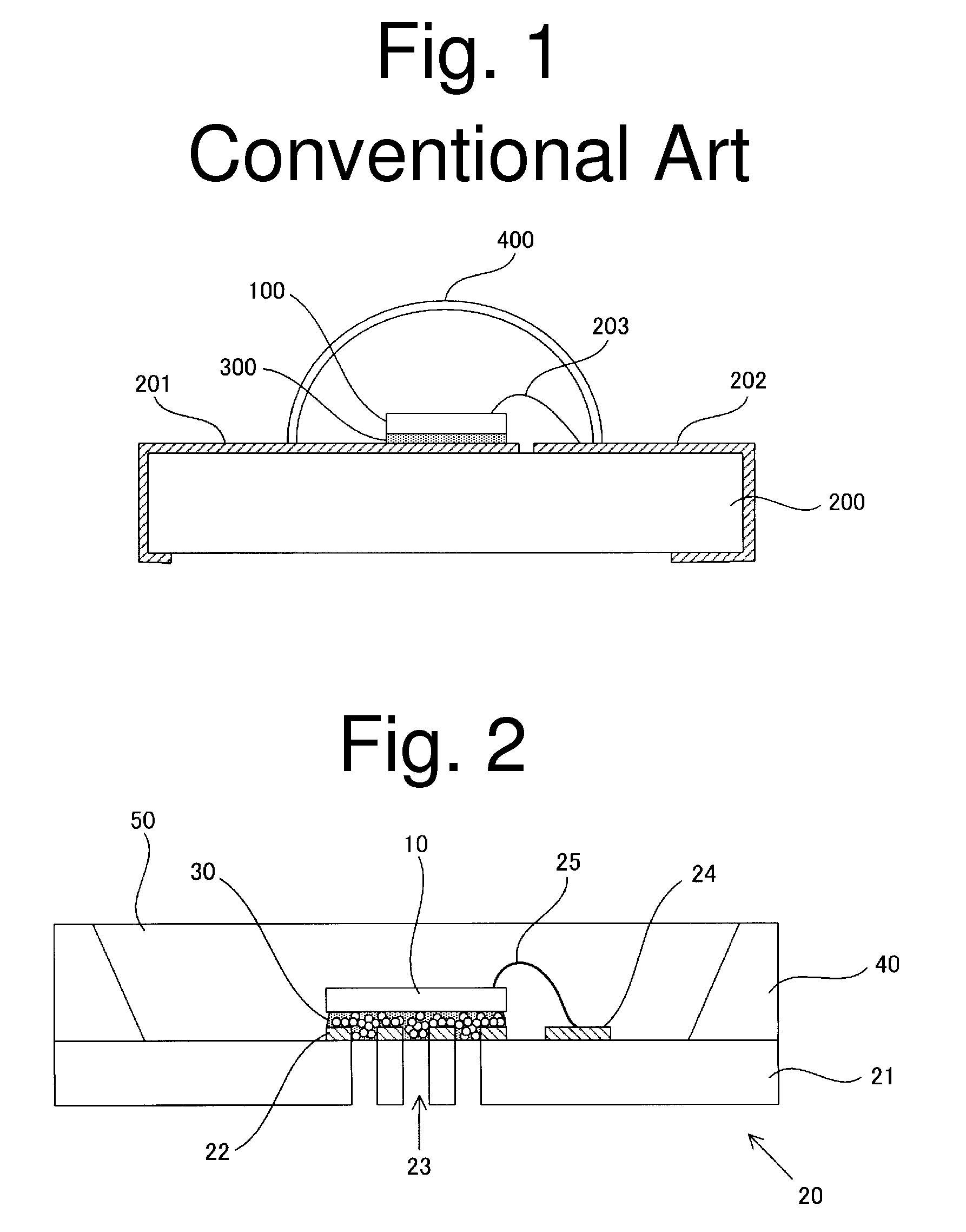

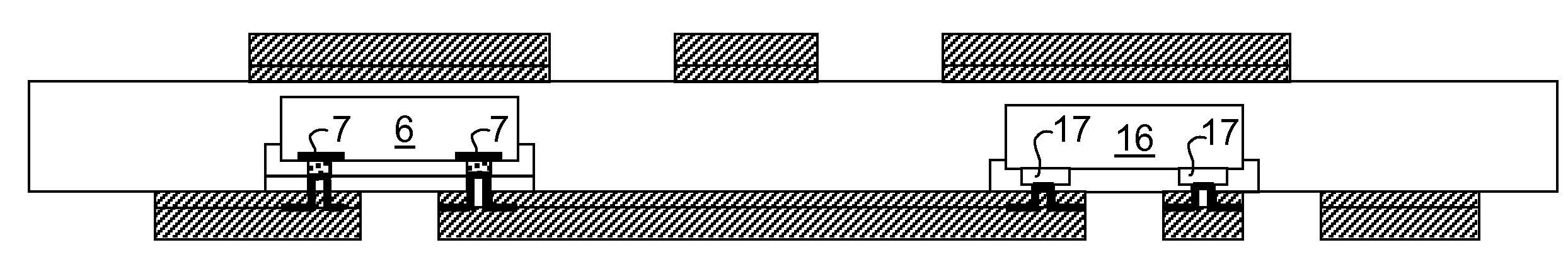

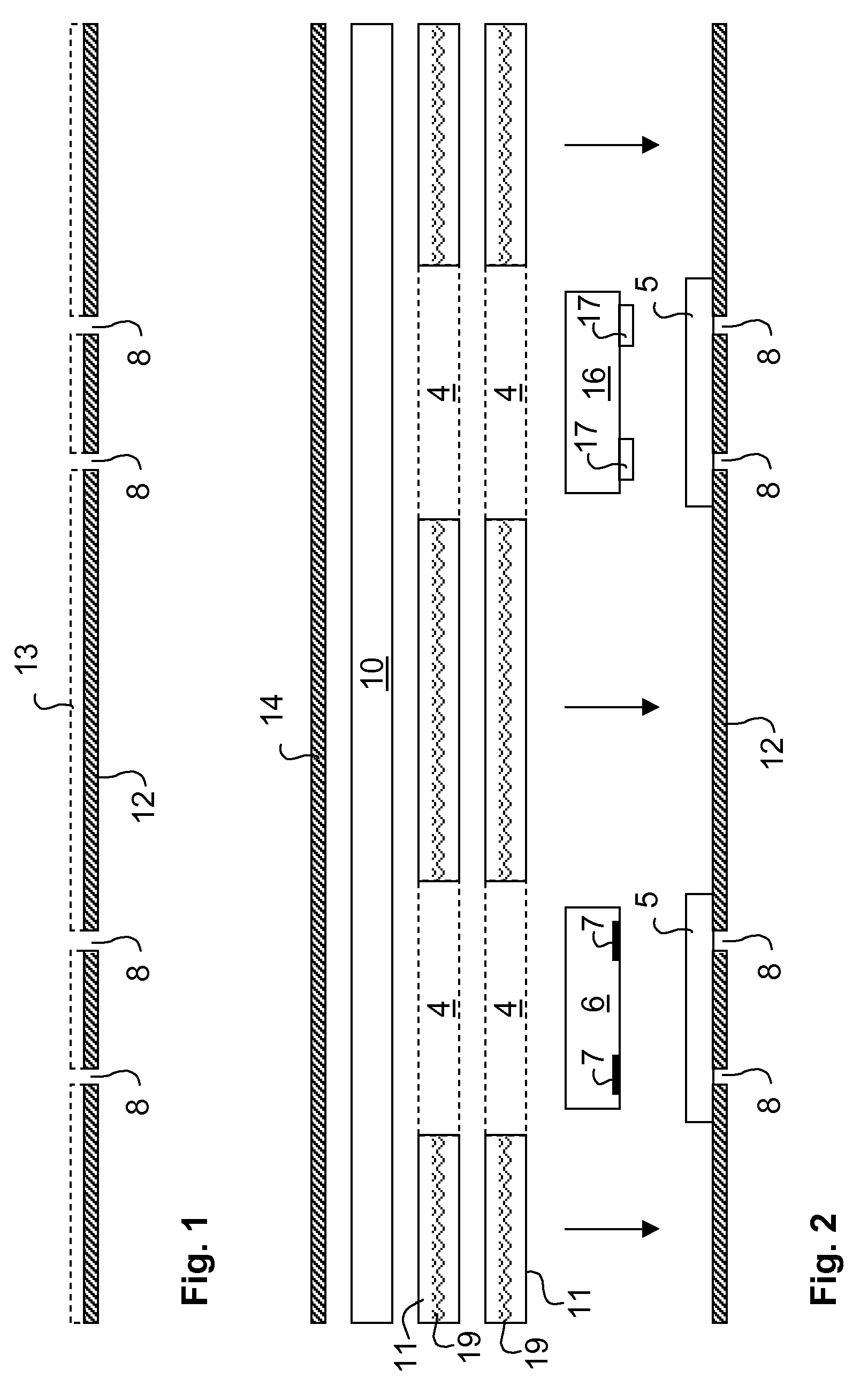

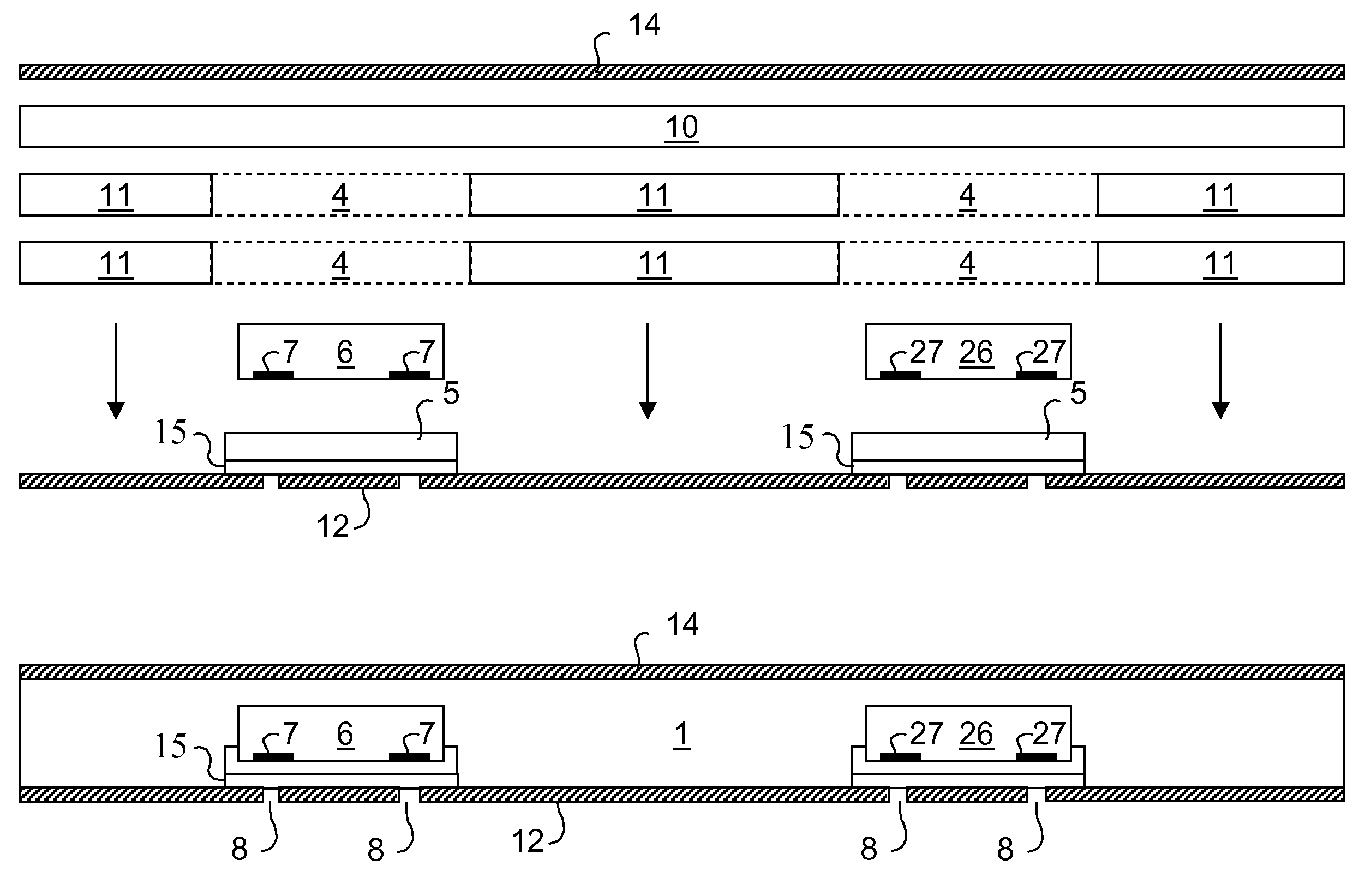

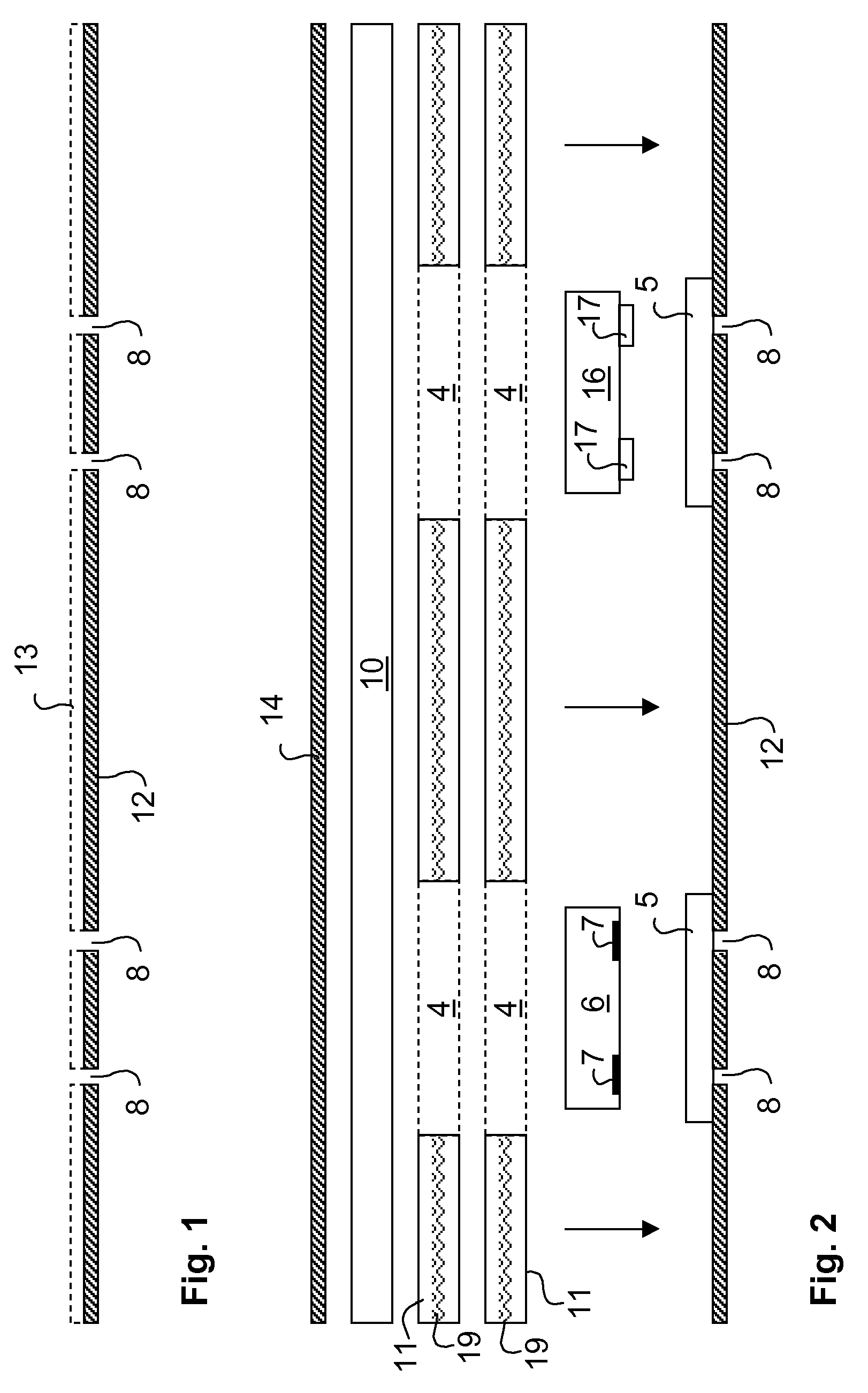

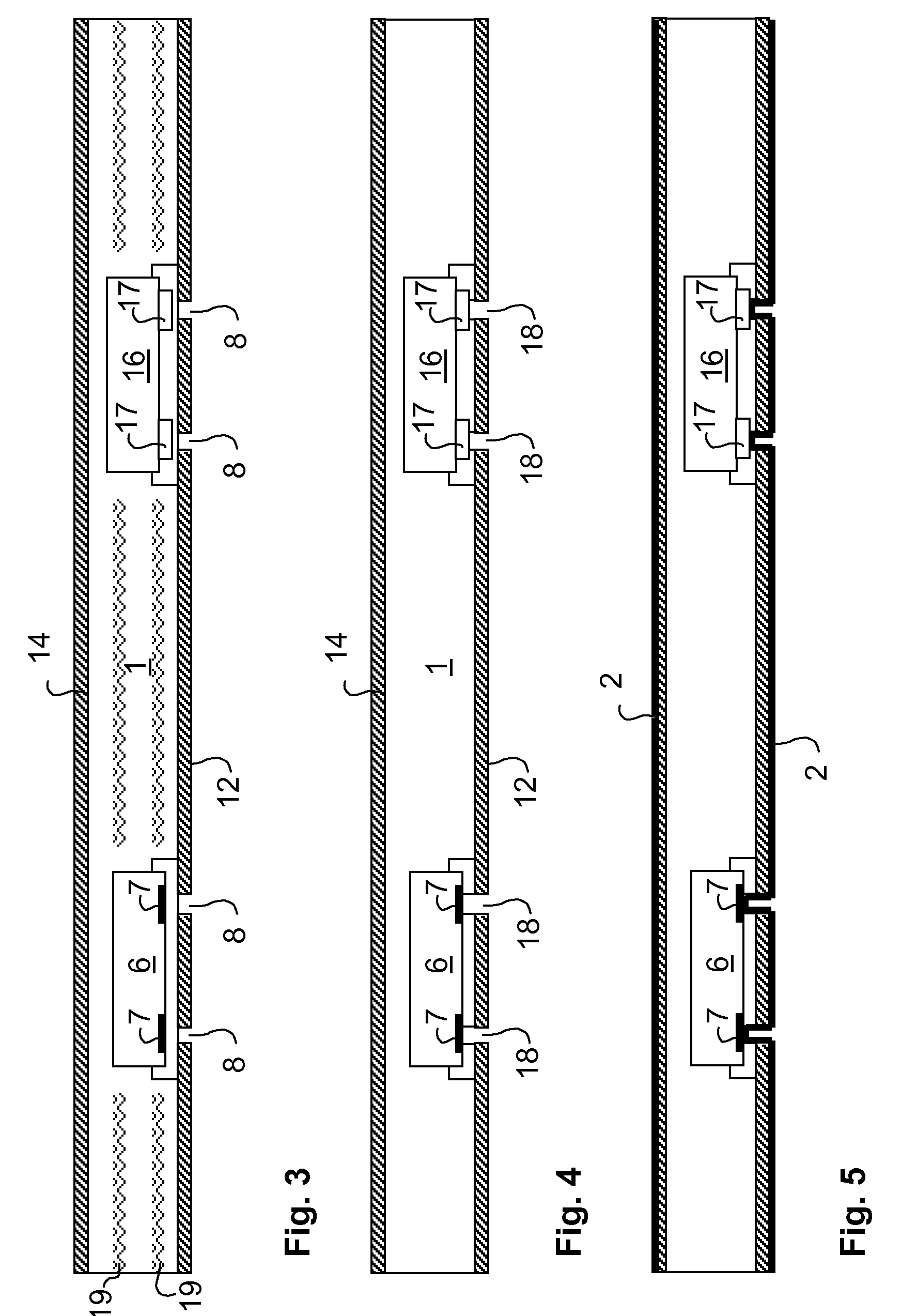

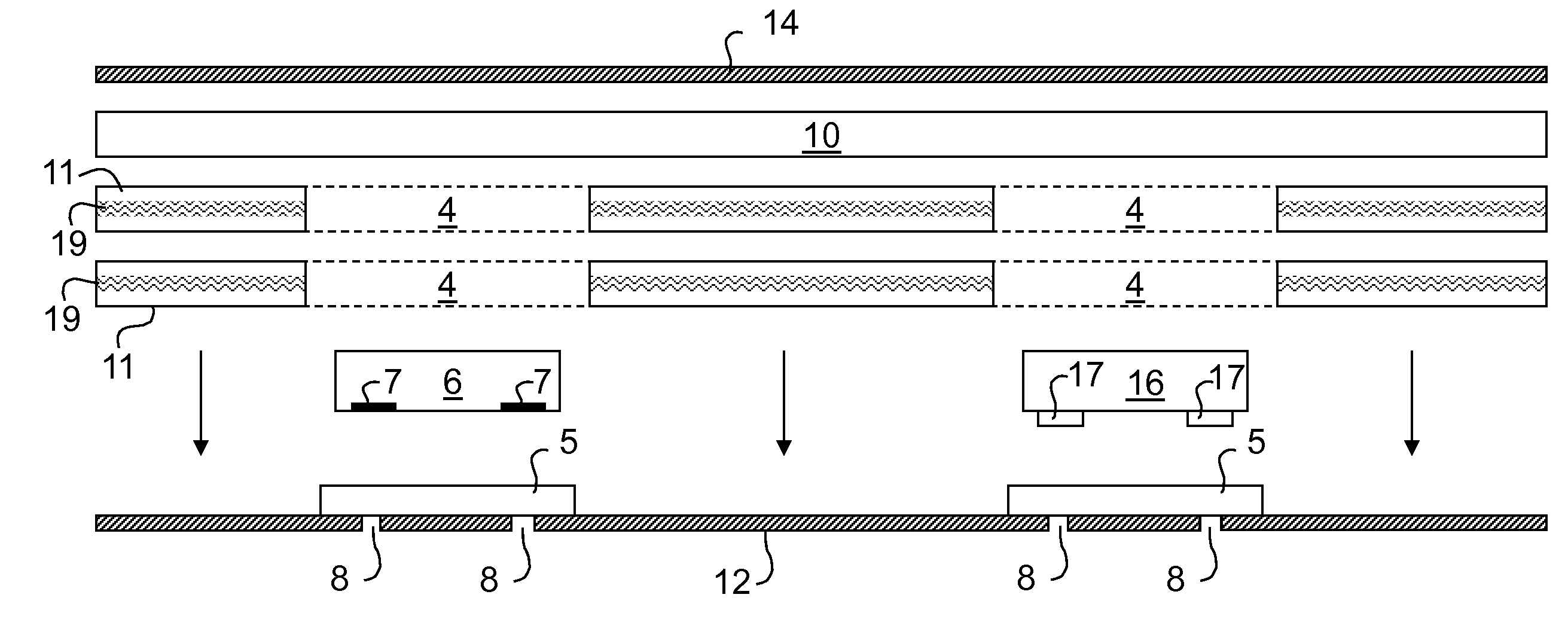

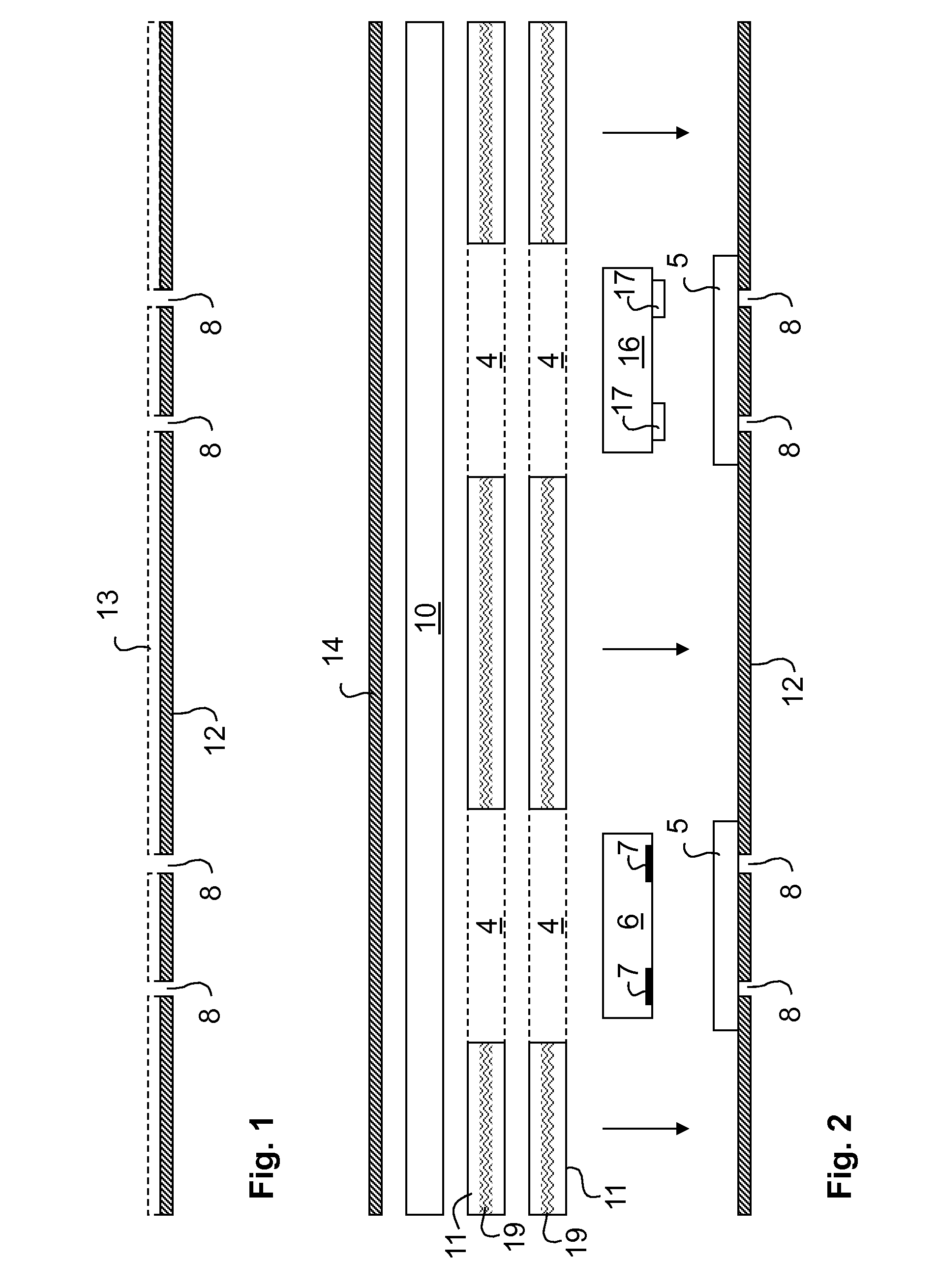

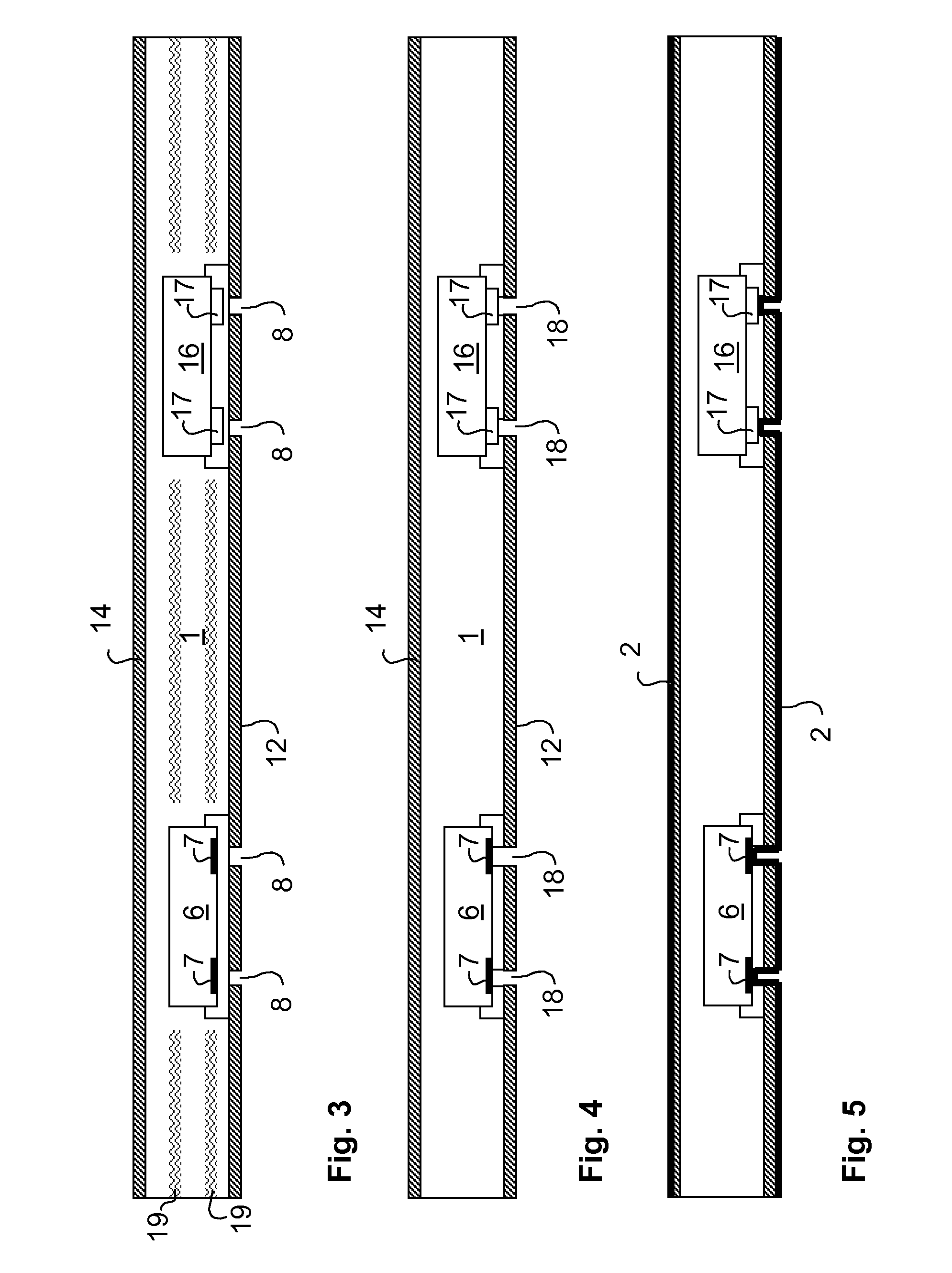

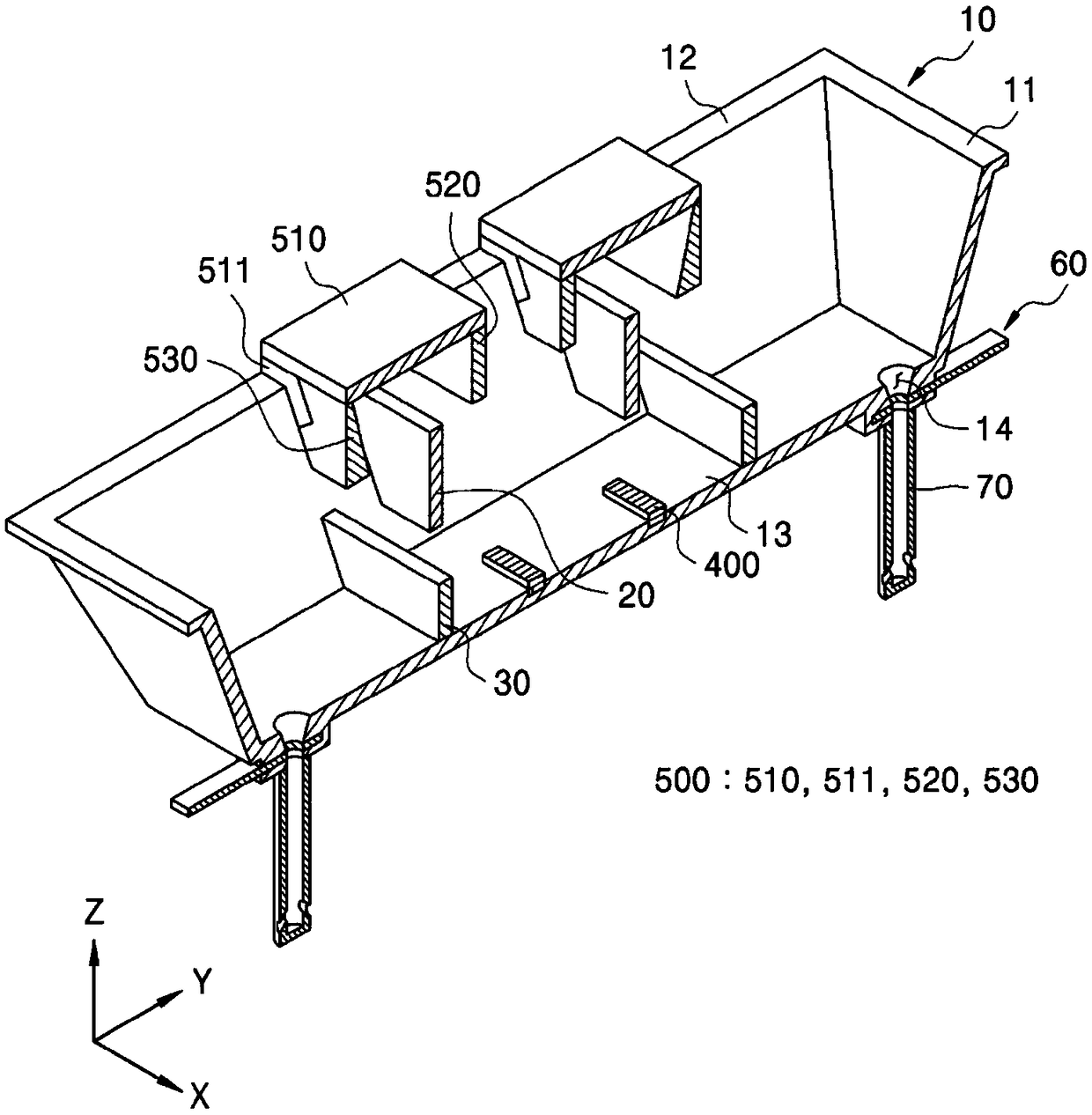

Circuit module and method of manufacturing the same

ActiveUS20110061909A1Improve adhesionPrevent reoxidationLine/current collector detailsSemiconductor/solid-state device detailsBiomedical engineeringElectrical conductor

Manufacturing method and circuit module, which comprises an insulator layer (1) and, inside the insulator layer (1), at least one component (6), which comprises contact areas (7), the material of which contains a first metal. On the surface of the insulator layer (1) are conductors (22), which comprise at least a first layer (12) and a second layer (32), in such a way that at least the second layer (32) contains a second metal. The circuit module comprises contact elements between the contact areas (7) and the conductors (22) for forming electrical contacts. The contact elements, for their part, comprise, on the surface of the material of the contact area (7), an intermediate layer (2), which contains a third metal, in such a way that the first, second, and third metals are different metals and the contact surface area (ACONT 1), between the intermediate layer (2) and the contact area (7) is less that the surface area (APAD) of the contact area (7).

Owner:IMBERATEK LLC

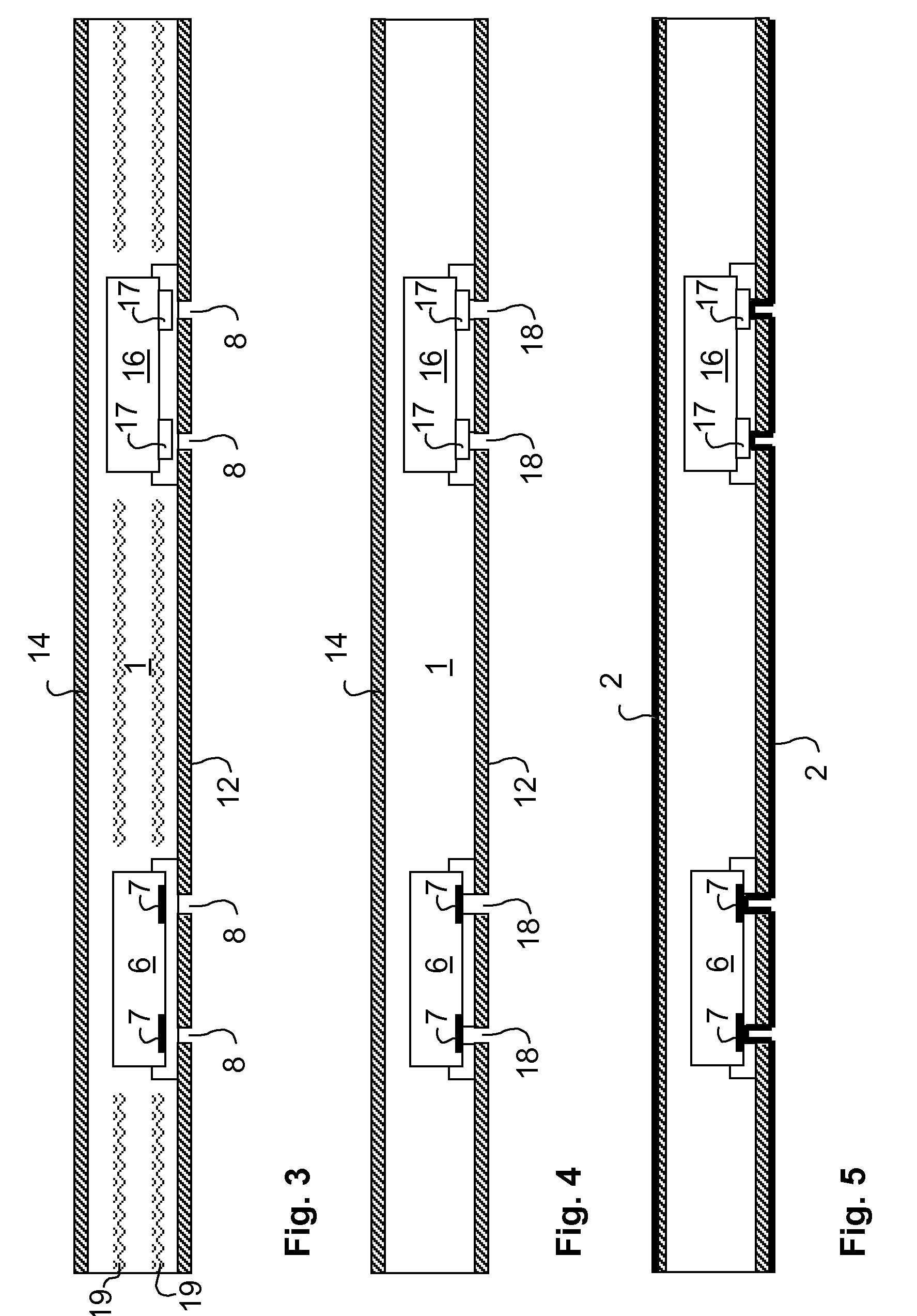

Aluminum powder surface self-activation method

InactiveCN109293463APrevent reoxidationRapid responseExplosive ingredient compoundingIgnition delayAluminium powder

The invention discloses an aluminum powder surface self-activation method. The method includes steps: adding aluminum powder into an anhydrous solvent, mixing, and stirring to disperse uniformly to form aluminum powder dispersion liquid; dissolving organic fluoride into a solvent to form organic fluorine solution, adding the organic fluorine solution into the aluminum powder dispersion liquid by acertain rate, and stirring to volatilize the solvent in which the organic fluoride is dissolved at a certain temperature, so that organic fluoride is slowly separated out by crystallization on the aluminum powder surface to form a compact surface activation layer; centrifugally separating to remove the solvent, washing, and performing vacuum drying at 60 DEG C to obtain organic fluorine surface self-activated aluminum powder. By forming of the organic fluorine self-activation layer on the aluminum powder surface, the aluminum powder ignition temperature can be effectively lowered while ignition delay time is shortened, combustion efficiency of aluminum powder in oxidants is improved while the energy releasing rate is increased, and the organic fluorine surface activation layer is effective in aluminum powder oxidation, so that stability is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method of producing iron nuggets

InactiveUS20020033075A1Avoid smallImprove productivityProcess efficiency improvementGas emission reductionProduction rateSlag

The present invention provides a method of producing metallic iron nuggets with a high yield and good productivity, and more particularly a method which can produce metallic iron nuggets which have a high Fe purity and are excellent in transporting and handling due to a large grain diameter with a high yield and good productivity, when they are produced by reducing and melting raw material containing iron oxide such as iron ore and carbonaceous reducing agent such as coke. The method of producing metallic iron nuggets comprises steps of: heating raw material containing carbonaceous reducing agent and iron oxide-containing material in a reducing / melting furnace, reducing iron oxide in the raw material, and then heating and melting the metallic iron produced by the reduction and simultaneously making it coalesce while separating the metallic iron nuggets from slag components characterized in that the fixed carbon content ratio as the carbonaceous reducing agent is at least 73% and the volatile matter content in the raw material is not more than 3.9% are used, and the mixing content of carbonaceous reducing agent is restrained to be not more than 45% in relation to the iron oxide components, which is contained in the iron oxide-containing material of the raw material.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

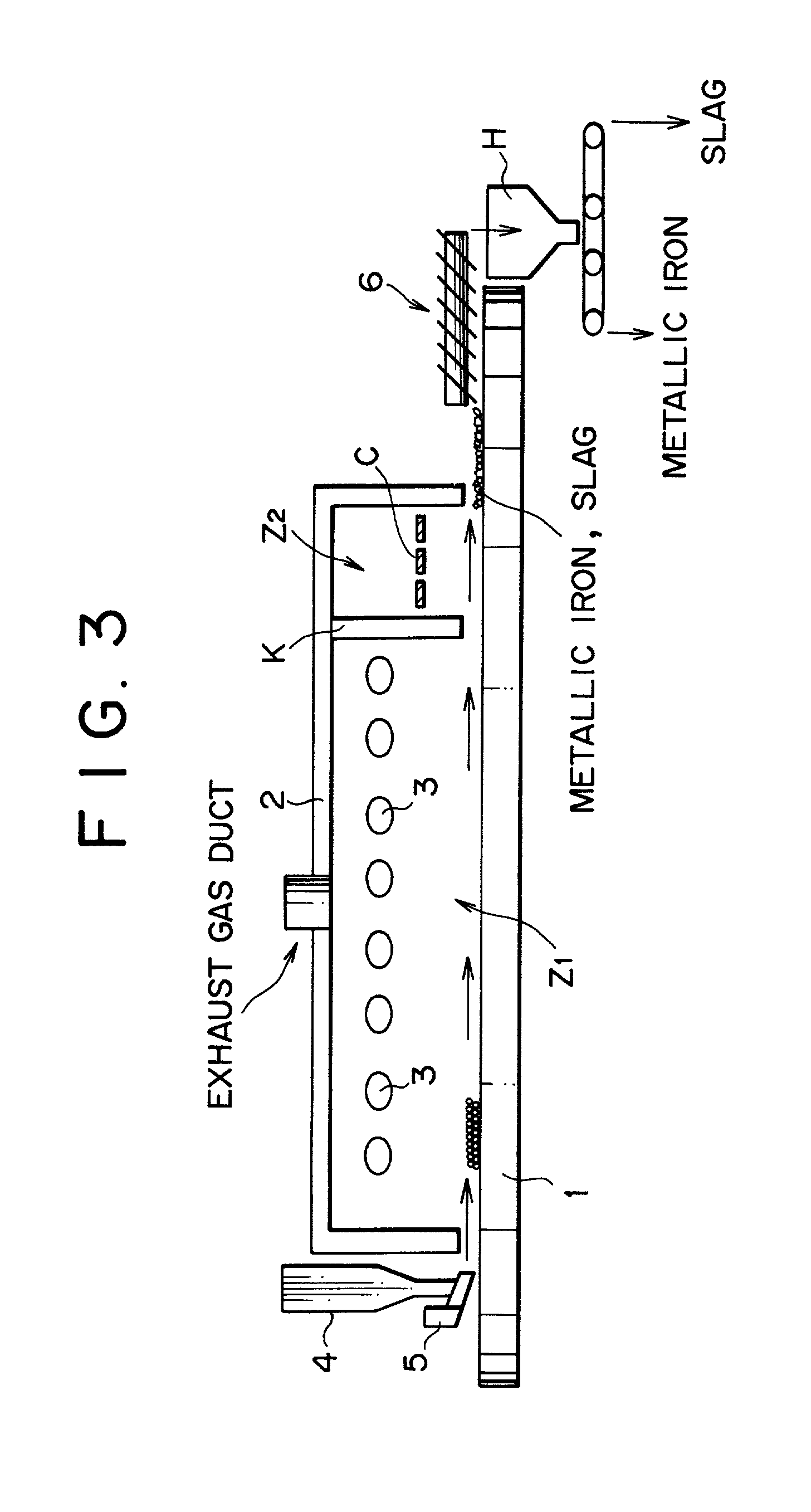

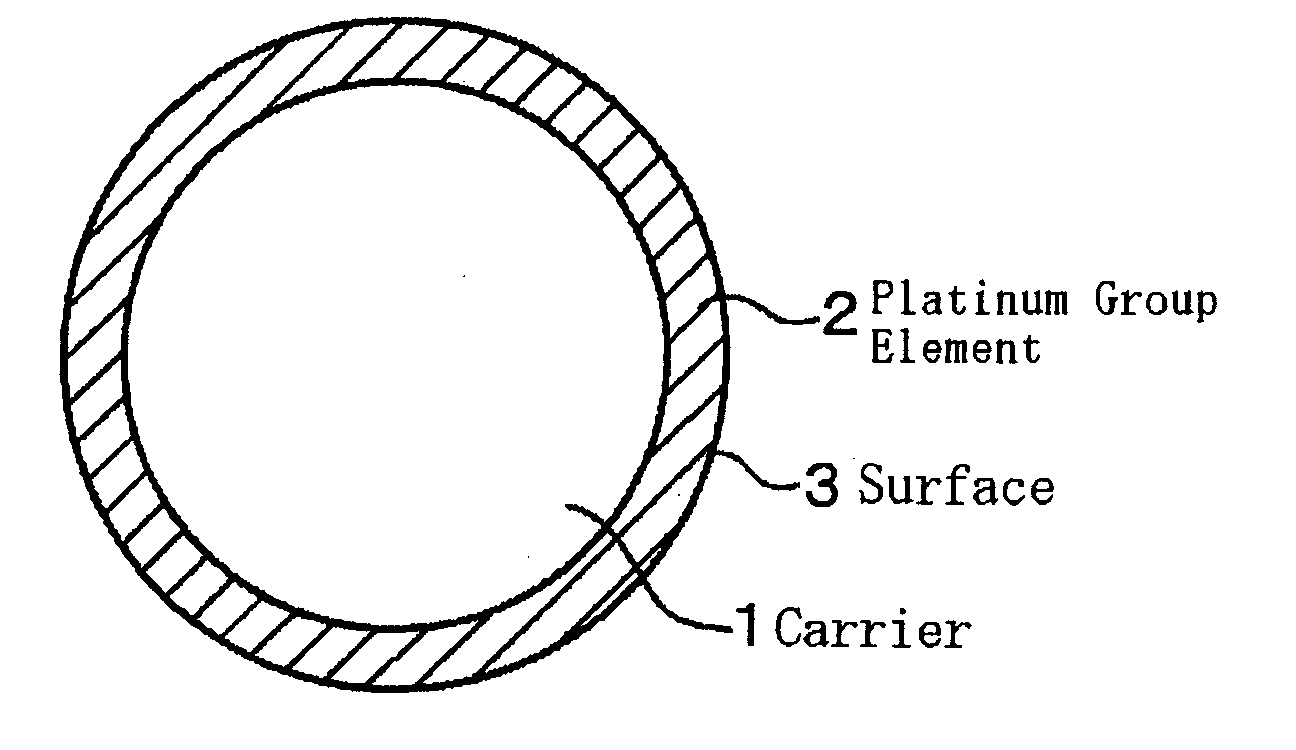

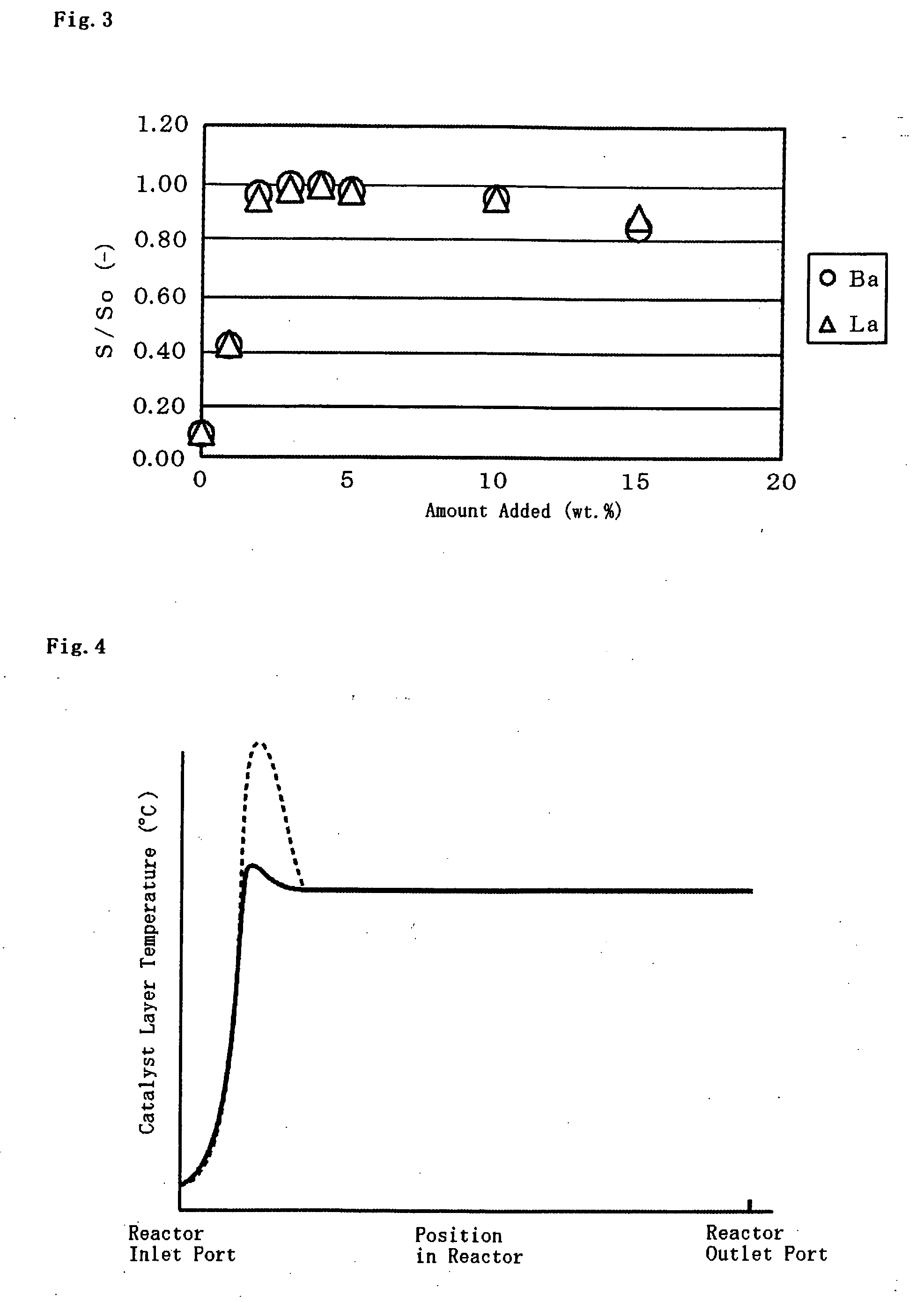

Catalyst for Catalytic Partial Oxidation of Hydrocarbon, and Method for Producing Synthetic Gas

InactiveUS20080224097A1High activityInhibition formationHydrogenHydrocarbon from carbon oxidesAluminatePartial oxidation

[Problem] To provide a catalyst for catalytic partial oxidation having a high activity and a long-term durability; and to provide a method capable of attaining long-term stable catalytic partial oxidation.[Means for Solution] The catalyst for catalytic partial oxidation comprises a carrier obtained by adding nickel and at least one of barium and lanthanum to alumina or an alumina precursor followed by firing it, and a platinum group element such as rhodium held by the carrier. The carrier is obtained, for example, by firing at a temperature not lower than 600° C., and in the firing step, nickel aluminate is formed. The catalyst is filled into a heat-insulating reactor; and oxygen and steam and hydrogen are added to a starting hydrocarbon (when the starting hydrocarbon contains hydrogen, adding hydrogen thereto is unnecessary), and this is fed into the reactor.

Owner:OSAKA GAS CO LTD +1

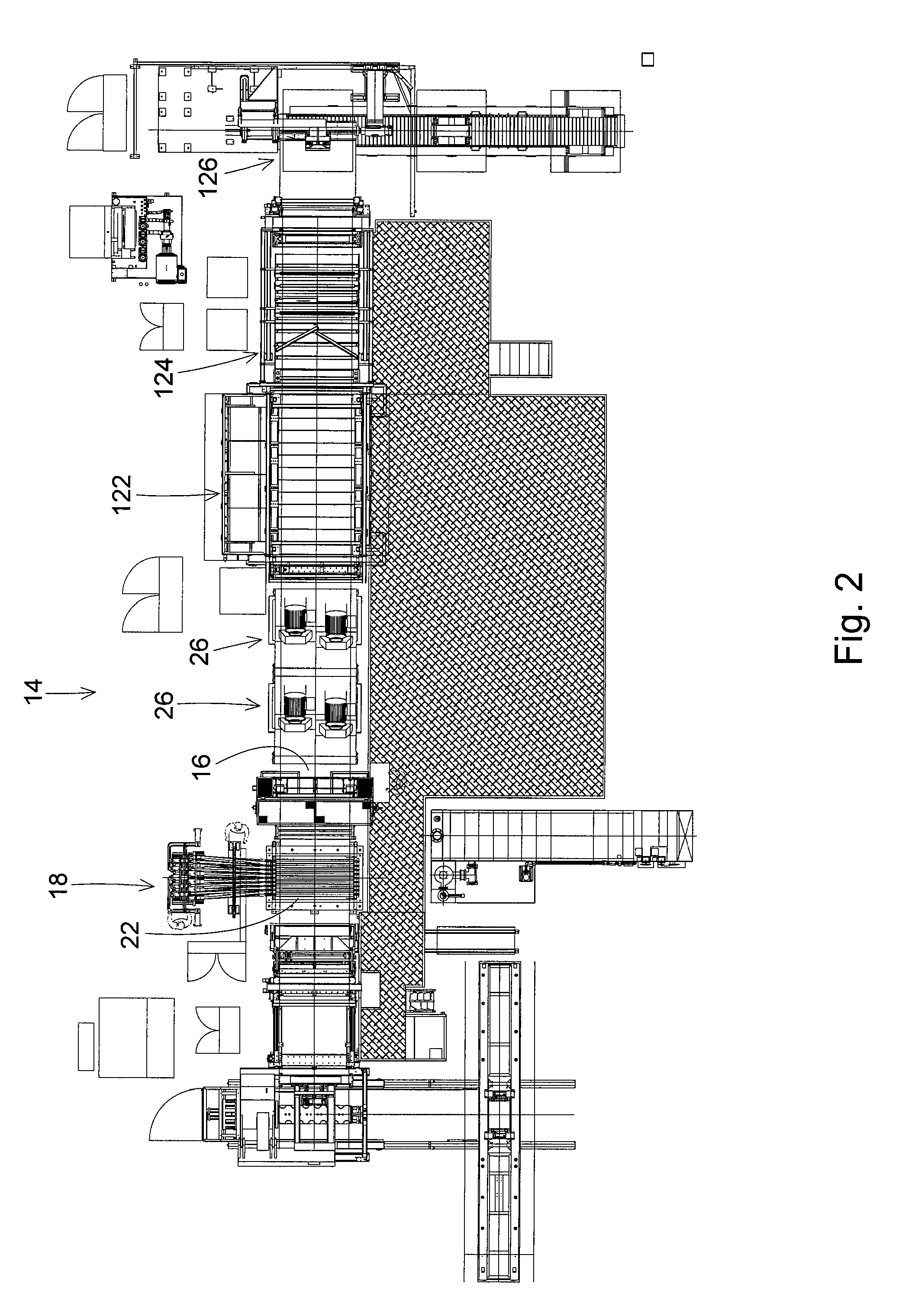

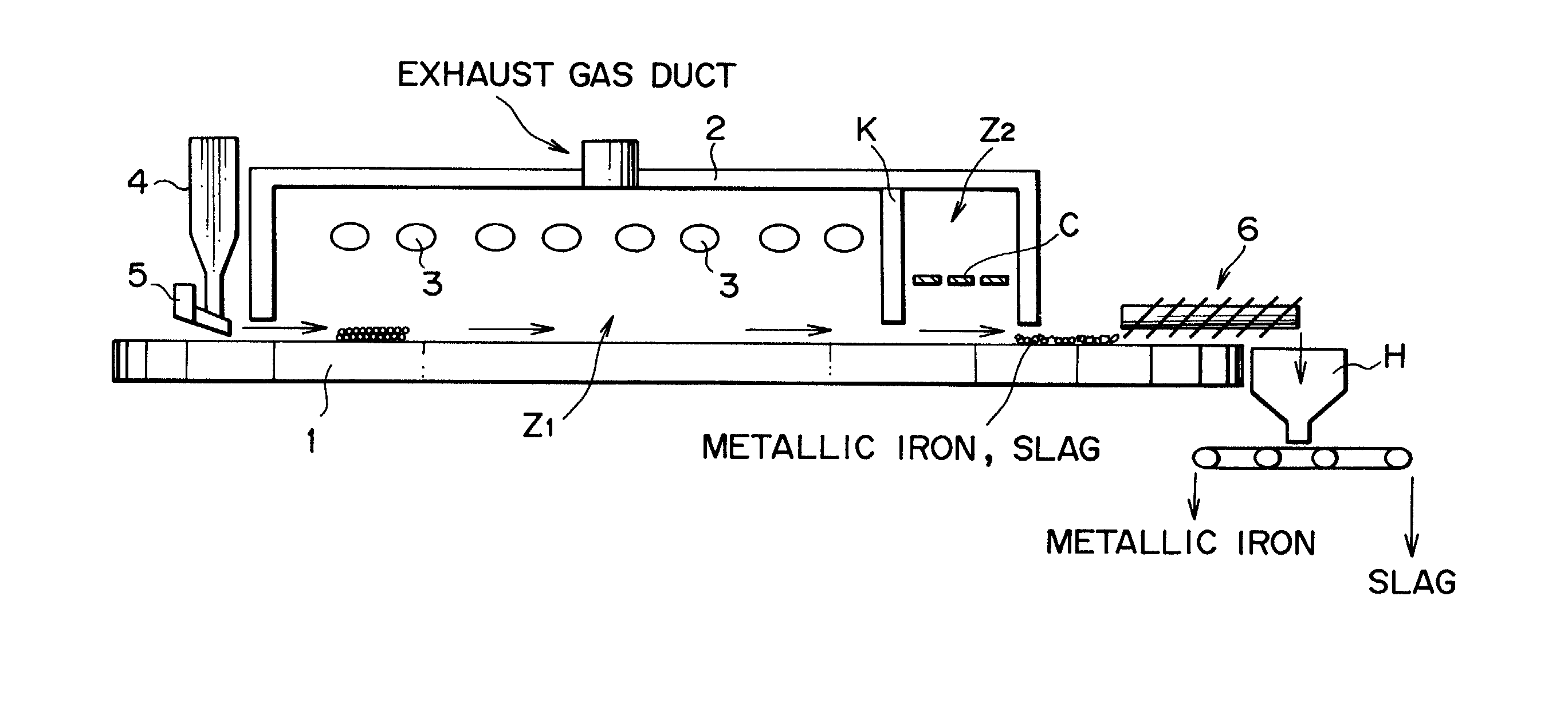

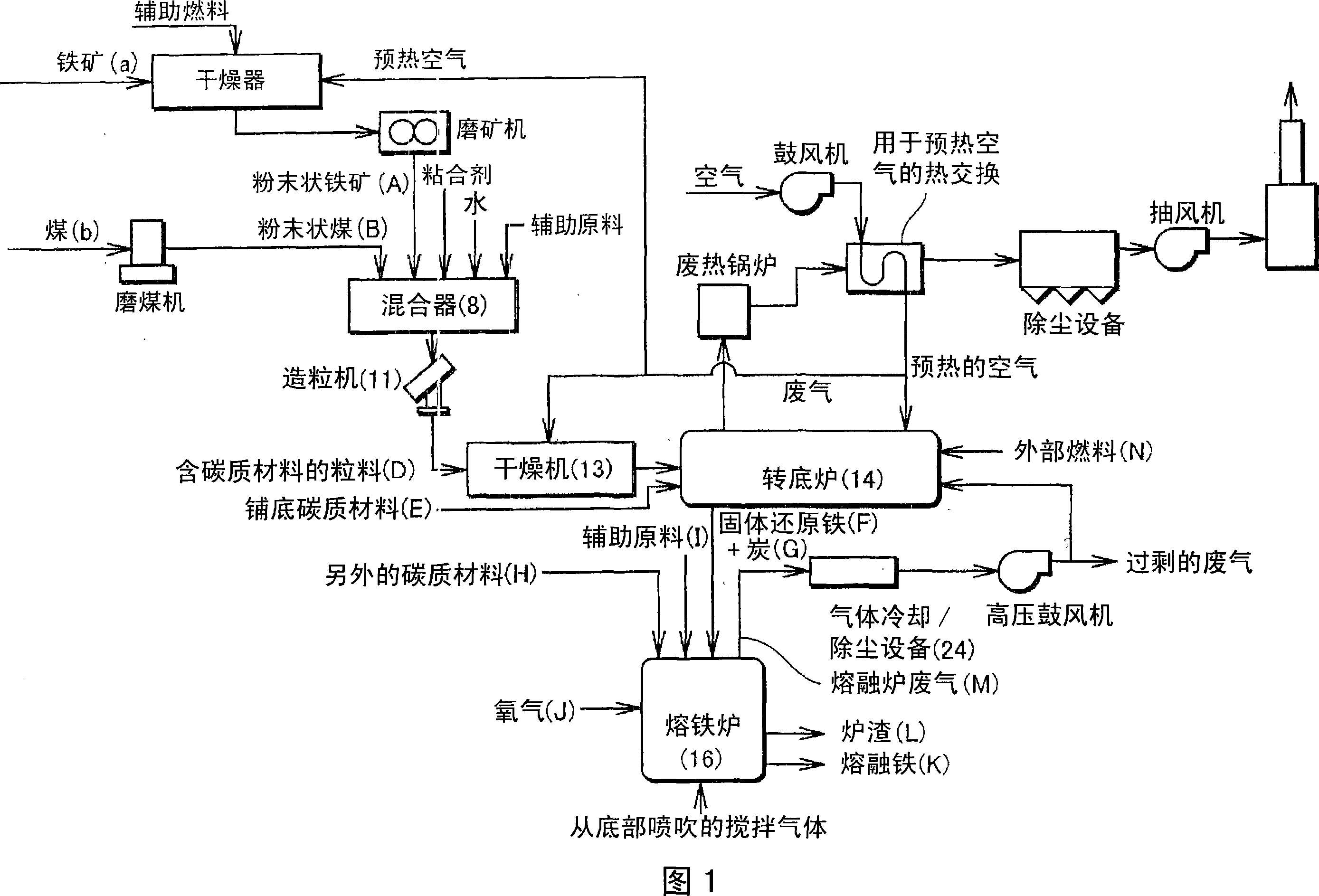

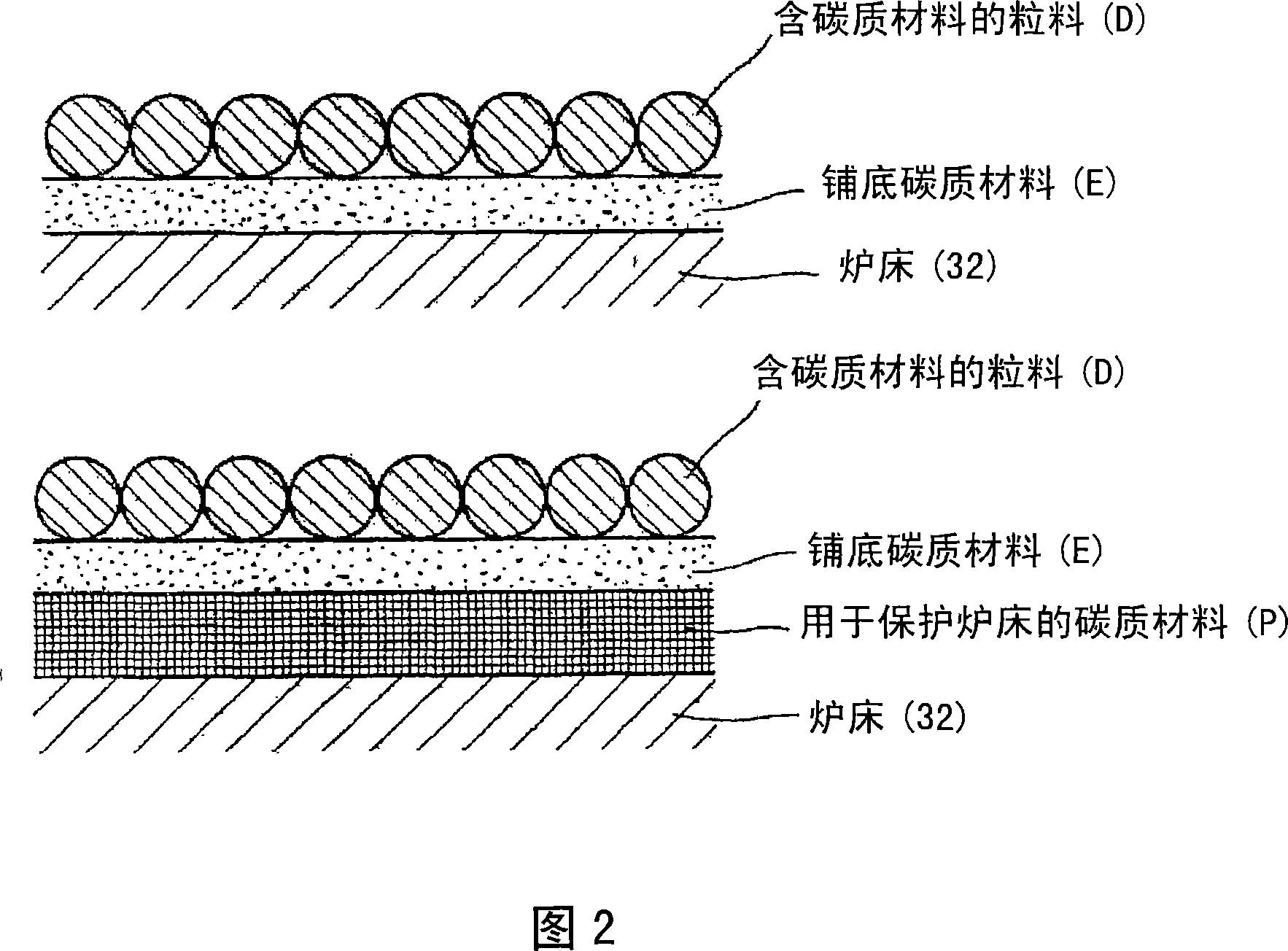

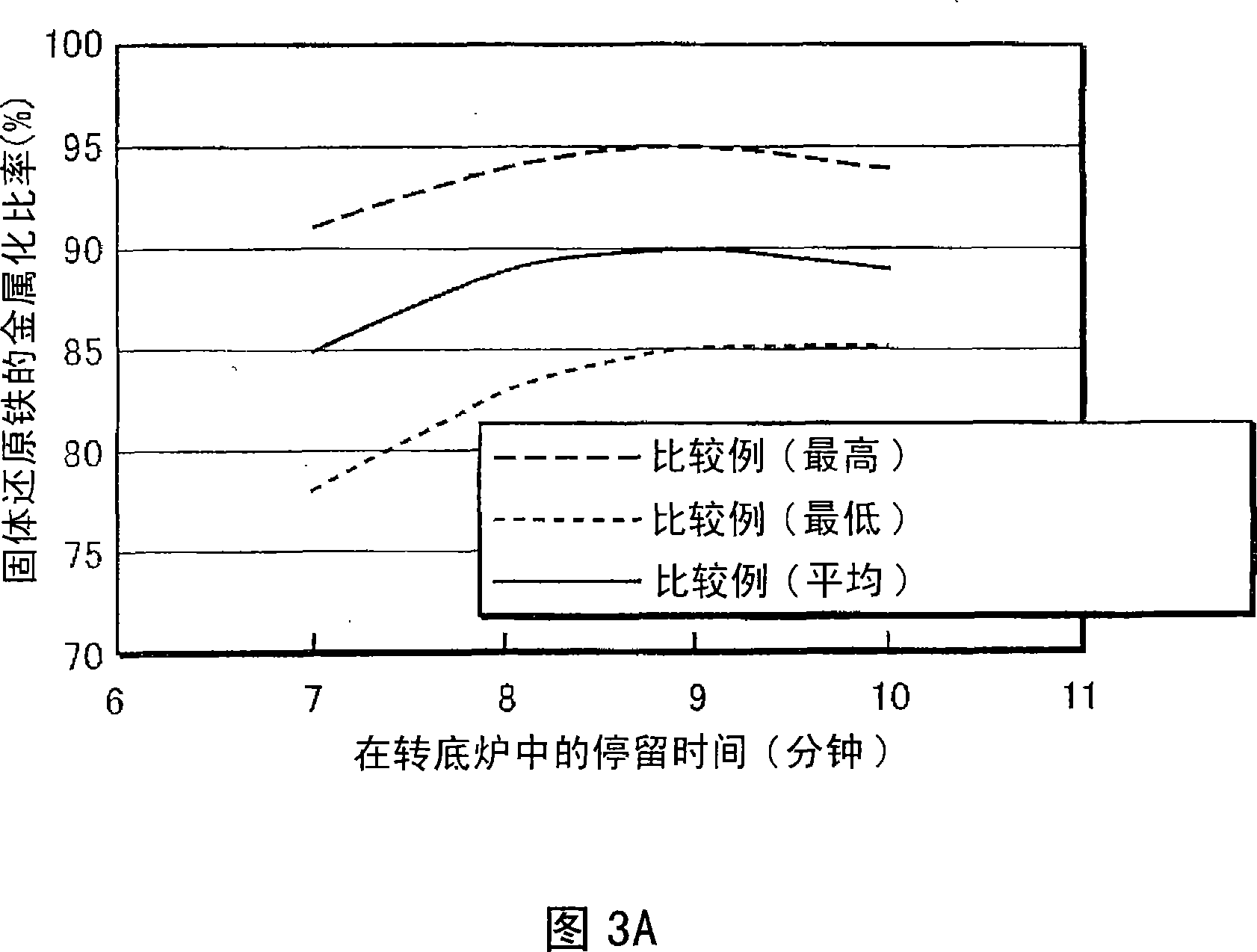

Process for producing molten iron and apparatus therefor

Bedding carbon material (H) is charged onto the hearth of rotary hearth furnace (14), and carbon-material-incorporated pellets (D) containing powdery iron ore (A) and powdery coal (B) are placed on the bedding carbon material (H). The hearth is caused to pass through the inside of the rotary hearth furnace (14) to thereby attain not only heating reduction of the carbon-material-incorporated pellets (D) into solid reduced iron (F) but also heating dry distillation of the bedding carbon material (H) into char (G). Subsequently, these solid reduced iron (F) and char (G) substantially without cooling are charged into iron bath type melting furnace (16), and simultaneously oxygen gas is blown thereinto. The solid reduced iron (F) is melted, thereby obtaining molten iron (K). At least part of wastegas (M) from the iron bath type melting furnace (16) is subjected to cooling and dust removal and thereafter used as a fuel gas for the rotary hearth furnace (14).

Owner:KOBE STEEL LTD

Circuit module and method of manufacturing the same

ActiveUS8699233B2Improve adhesionPrevent reoxidationPrinted circuit assemblingLine/current collector detailsElectrical conductorContact element

Manufacturing method and circuit module, which comprises an insulator layer (1) and, inside the insulator layer (1), at least one component (6), which comprises contact areas (7), the material of which contains a first metal. On the surface of the insulator layer (1) are conductors (22), which comprise at least a first layer (12) and a second layer (32), in such a way that at least the second layer (32) contains a second metal. The circuit module comprises contact elements between the contact areas (7) and the conductors (22) for forming electrical contacts. The contact elements, for their part, comprise, on the surface of the material of the contact area (7), an intermediate layer (2), which contains a third metal, in such a way that the first, second, and third metals are different metals and the contact surface area (ACONT 1), between the intermediate layer (2) and the contact area (7) is less that the surface area (APAD) of the contact area (7).

Owner:IMBERATEK LLC

Method for preparing metal and magnesium sulfide with metal sulfide

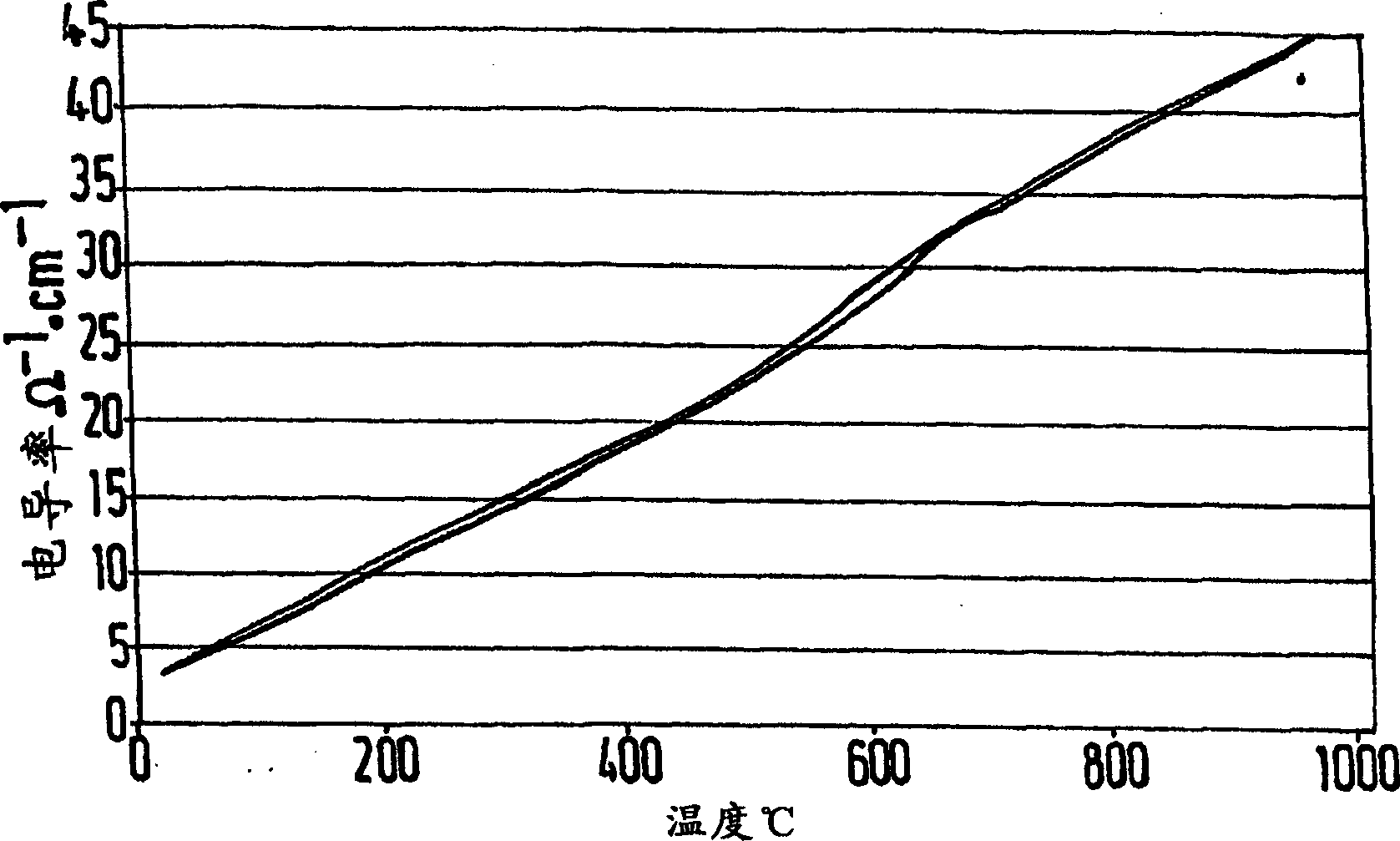

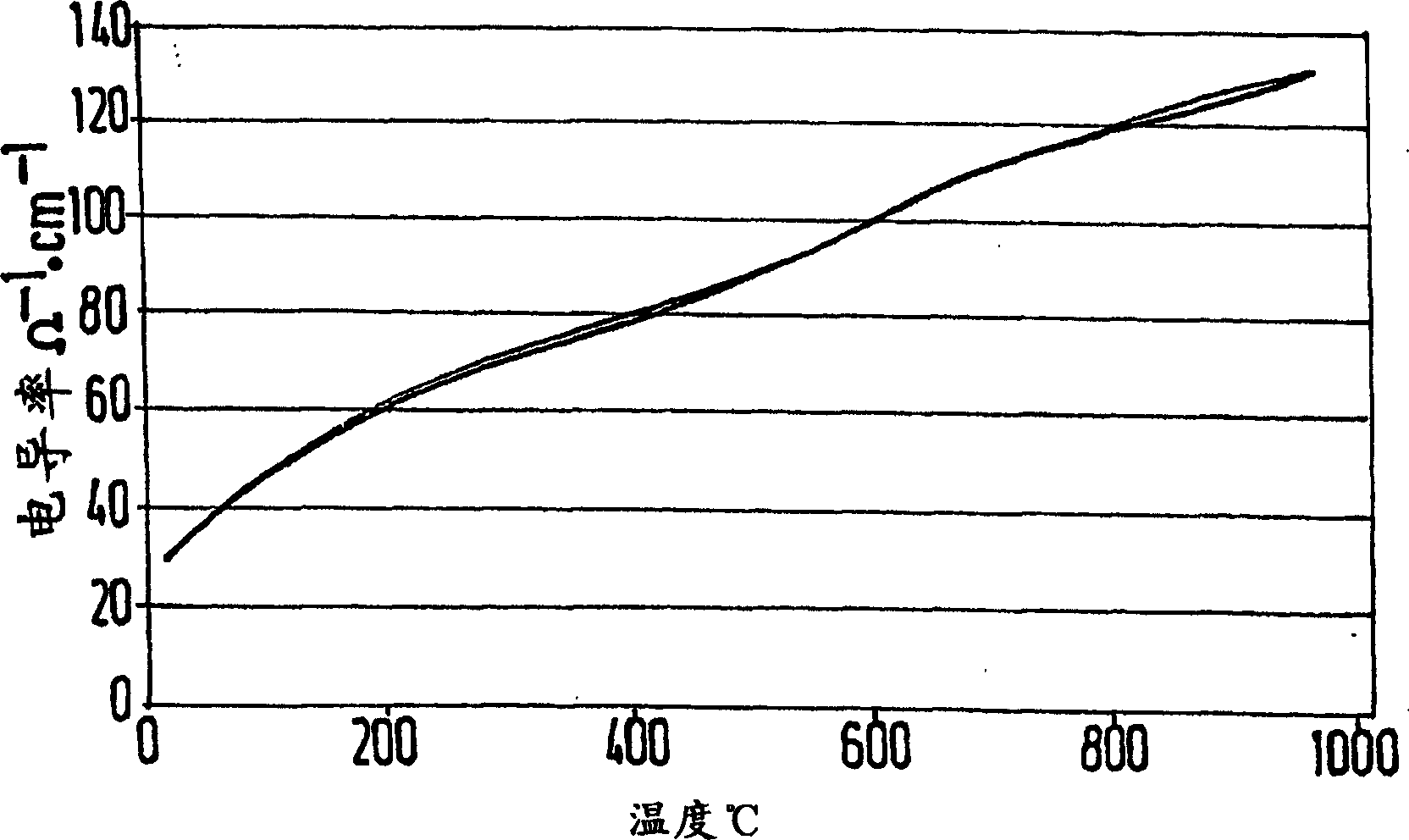

ActiveCN108118364ALow impurity contentAvoid emissionsElectrolysis componentsElectrolysisWorking temperature

The invention discloses a method for preparing metal and magnesium sulfide with metal sulfide. The method is characterized in that metal sulfide powder or a metal sulfide sheet formed by pressing is compounded with a current collector to be used as a cathode, graphite is taken as an anode, electrolyzation is performed for 1-4h in molten magnesium chloride or a mixture of magnesium chloride and alkali metal chloride with the working temperature being 400-750 DEG C and the electrolysis voltage being 1.0-2.6V, wherein the working temperature is higher than a melting point of a corresponding metalproduct, at the inert atmosphere, and a cathode product is corresponding molten metal and the magnesium sulfide; after the product is cooled, and separated metal is taken out, ultrasonic cleaning isperformed by adopting dimethyl sulfoxide to obtain the magnesium sulfide. The invention provides the method for preparing metal and magnesium sulfide with metal sulfide, which is low in energy consumption and safe in process and is environmentally friendly.

Owner:GUANGDONG INST OF RARE METALS

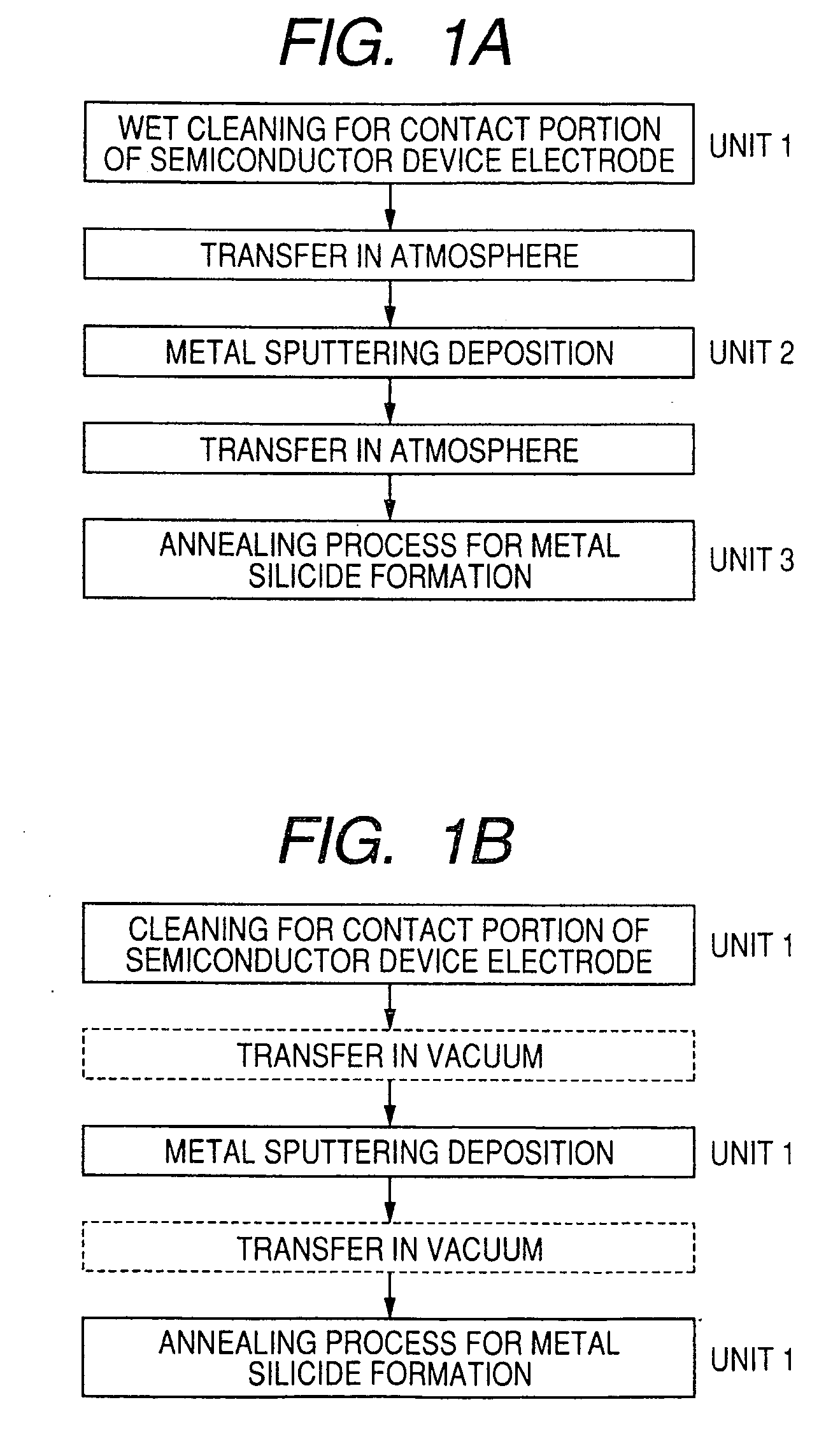

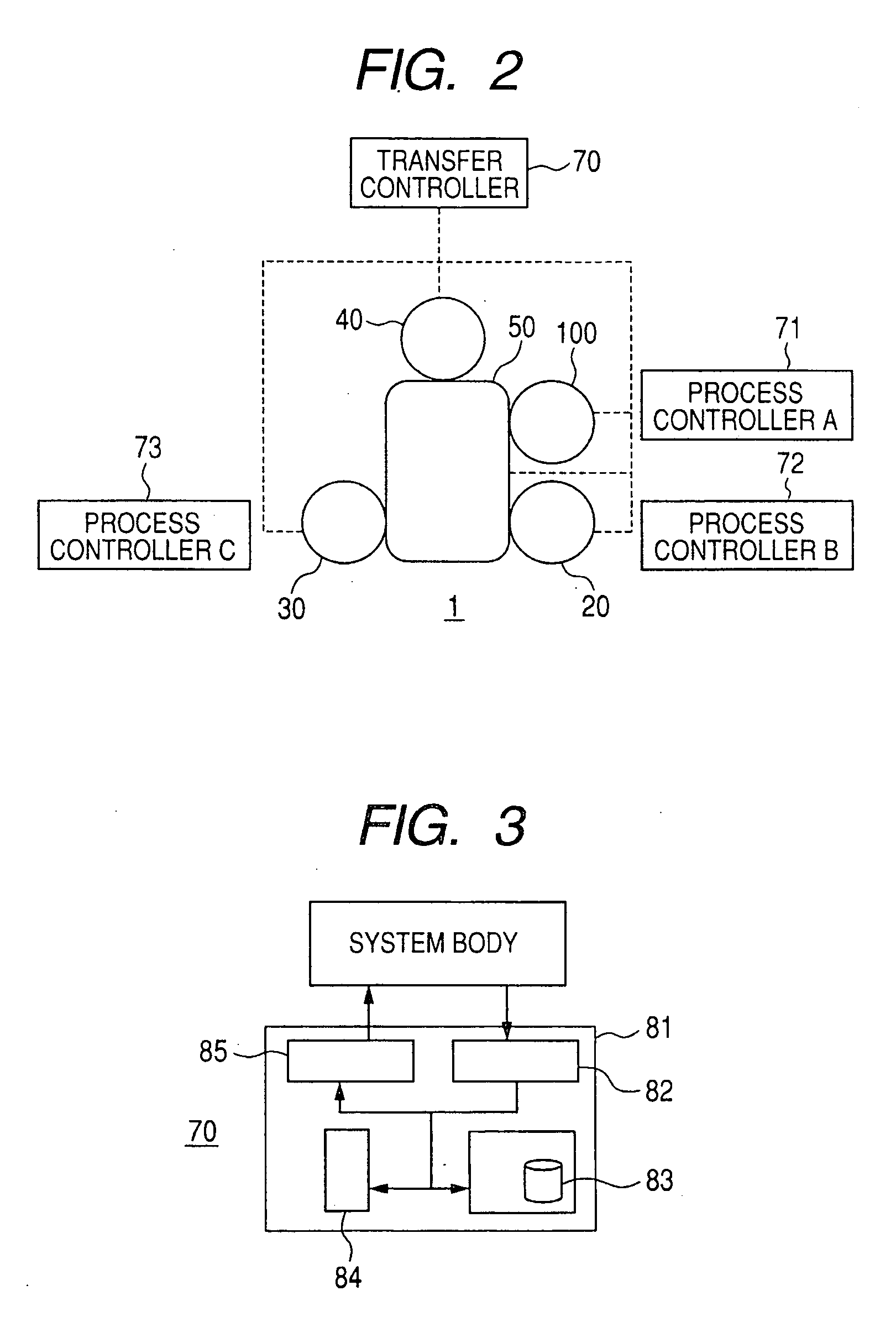

Silicide forming method and system thereof

InactiveUS20090298288A1Reduce impurityCost reductionLiquid surface applicatorsElectric discharge tubesAutoxidationSurface finishing

Radical in a plasma generation chamber is supplied to a process chamber through an introducing aperture, and HF gas is supplied as a process gas from the vicinity of the radical introducing aperture. A native oxide film of the substrate surface of a IV group semiconductor doped an impurity is removed, with a good surface roughness equal to the wet cleaning. The substrate after the surface treatment is deposited with a metal material and metal silicide formation by thermal treatment is performed, and during these processes, the substrate is not exposed to the atmosphere, and a good contact resistance equal to or better than the wet process is obtained.

Owner:CANON ANELVA CORP

Circuit module and method of manufacturing the same

ActiveUS20140210090A1Improve adhesionPrevent reoxidationSemiconductor/solid-state device detailsPrinted circuit aspectsInter layerElectrical conductor

Manufacturing method and circuit module, which comprises an insulator layer and, inside the insulator layer, at least one component, which comprises contact areas, the material of which contains a first metal. On the surface of the insulator layer are conductors, which comprise at least a first layer and a second layer, in such a way that at least the second layer contains a second metal. The circuit module comprises contact elements between the contact areas and the conductors for forming electrical contacts. The contact elements, for their part, comprise, on the surface of the material of the contact area, an intermediate layer, which contains a third metal, in such a way that the first, second, and third metals are different metals and the contact surface area (ACONT 1), between the intermediate layer and the contact area is less that the surface area (APAD) of the contact area.

Owner:IMBERATEK LLC

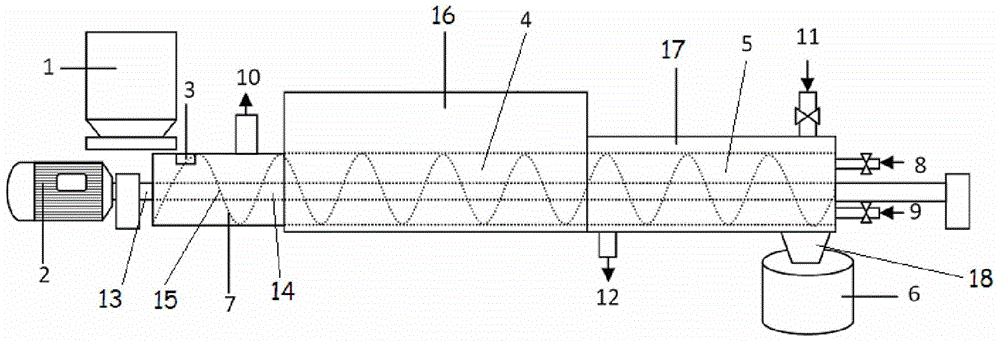

Method and device for producing micron-sized superfine iron powder through regenerative iron red

The invention provides a method and device for producing micron-sized superfine iron powder through regenerative iron red. The method includes the steps that protective gas is injected into a reduction furnace tube, the regenerative iron red recovered in the cold rolling and acid pickling processes serves as a raw material, reducing gas is injected in the reverse direction after the raw material is conveyed to the reduction furnace tube, the raw material and the gas make sufficient contact at the heating section in the reduction furnace tube by rotating spiral blades in the reduction furnace tube, and the regenerative iron red is reduced to micron-sized superfine Fe, and Fe is output and stored through an airflow classifier after reaction. The produced micron-sized superfine iron powder is good in performance, control is easy, continuous production can be achieved, and the device is simple in structure and low in cost.

Owner:武汉钢铁有限公司

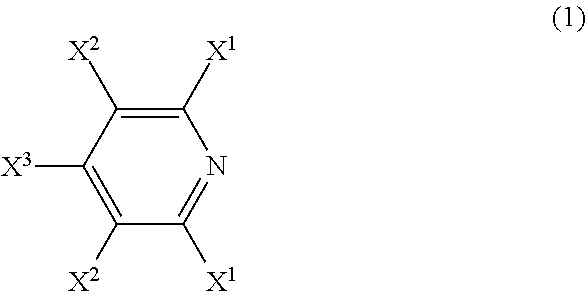

Solder composition and electronic board

ActiveUS20190015937A1Sufficient solder-melting propertySufficient preservation stabilityWelding/cutting media/materialsPrinted circuitsOrganic acidHalogen

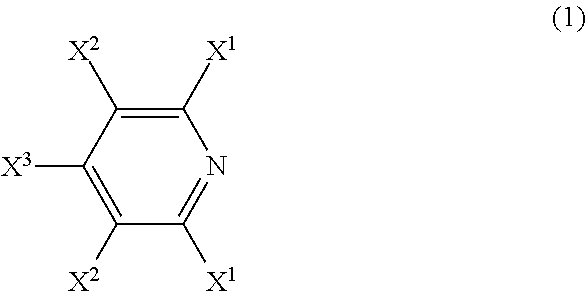

A solder composition of the invention contains solder powders and a flux composition. The flux composition contains (A) a resin and (B) an activator. The (B) component contains (B1) an organic acid, and (B2) a pyridine compound represented by a formula (1) below. A chlorine concentration is 900 mass ppm or less, a bromine concentration is 900 mass ppm or less, an iodine concentration is 900 mass ppm or less and a total halogen concentration is 1500 mass ppm or less in the solder composition.In the formula (1), X1, X2 and X3 are the same or different, each of X1, X2 and X3 representing a hydrogen atom, a hydroxyl group, a methyl group, an ethyl group or a propyl group, and all of X1, X2 and X3 are not simultaneously hydrogen atoms.

Owner:TAMURA KK

Method for recovering iron by utilizing high-iron red mud, and method for extracting aluminum by utilizing high-iron red mud

InactiveCN110863114AAchieve recyclingLow costMagnetic separationProcess efficiency improvementRed mudPetrochemical

The invention provides a method for recovering iron by utilizing high-iron red mud. The method for recovering the iron by utilizing the high-iron red mud comprises the following steps of S1, placing the high-iron red mud in an airtight reduction furnace, feeding flare gas into the reduction furnace, and carrying out heating reduction so as to obtain a reduced material; and S2, after grinding the reduced material, carrying out magnetic separation so as to obtain magnetic separation concentrates and magnetic separation tailings, wherein the magnetic separation concentrates are iron ore concentrates; and the magnetic separation tailings are aluminum oxide enriched ores. The iron therein can be recovered, the flare gas can be utilized at the same time, and the atmospheric pollution produced byflare gas combustion of the petrochemical enterprise is avoided. The invention further provides a method for extracting aluminum by utilizing the high-iron red mud. The method for extracting the aluminum by utilizing the high-iron red mud comprises the steps of A1, treating the high-iron red mud by adopting the method so as to obtain magnetic separation concentrates and magnetic separation tailings; A2, after uniformly mixing the magnetic separation tailings, ammonium sulfate and water, roasting to obtain a roasted clinker; and A3, dissolving out the roasted clinker, and separating to obtainan aluminum-containing solution and residues after extracting the aluminum. The iron, the aluminum and silicon in the magnetic separation tailings are separated, so that the aim on comprehensively utilizing the high-iron red mud is achieved.

Owner:NORTHEASTERN UNIV LIAONING

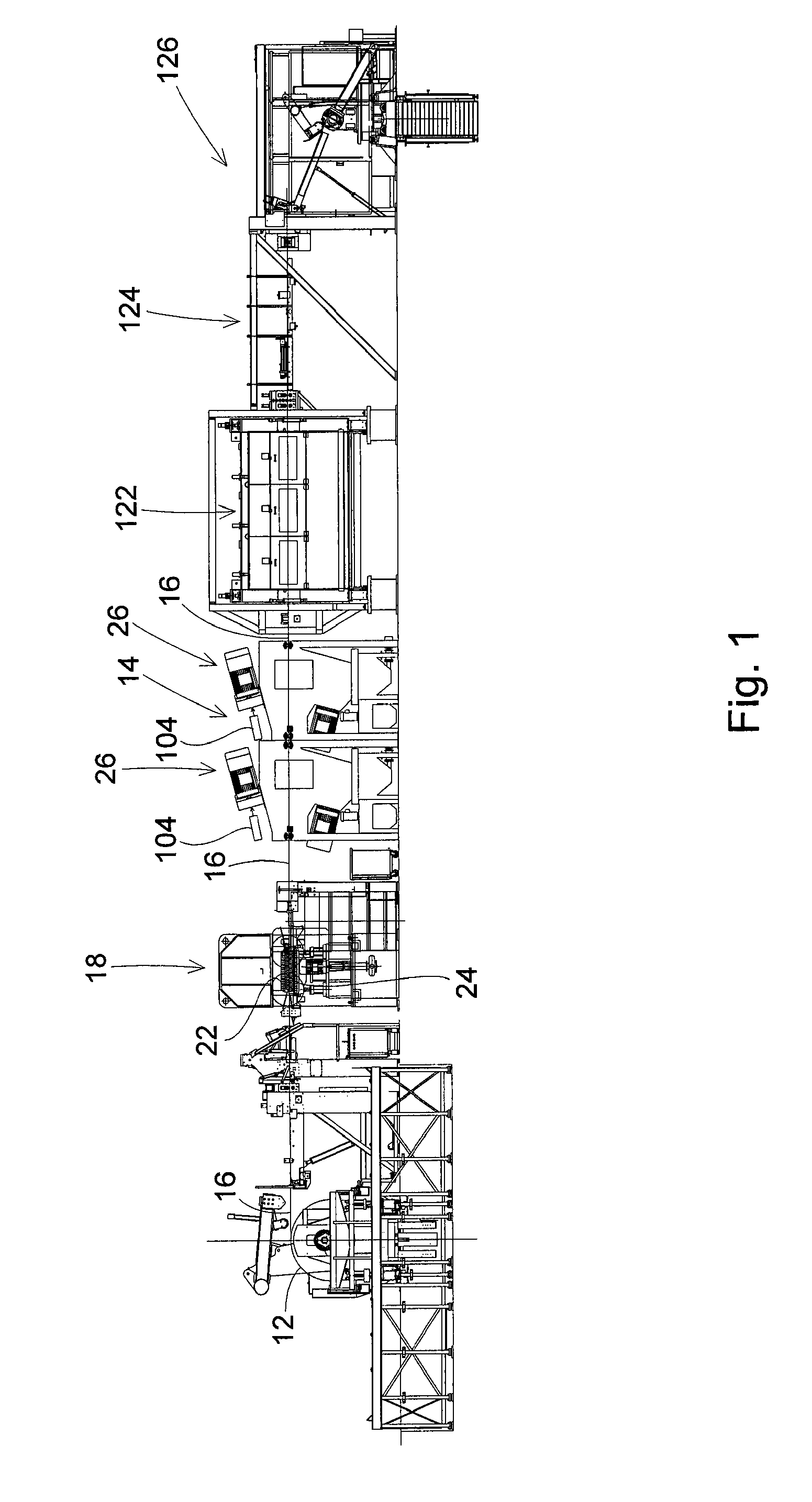

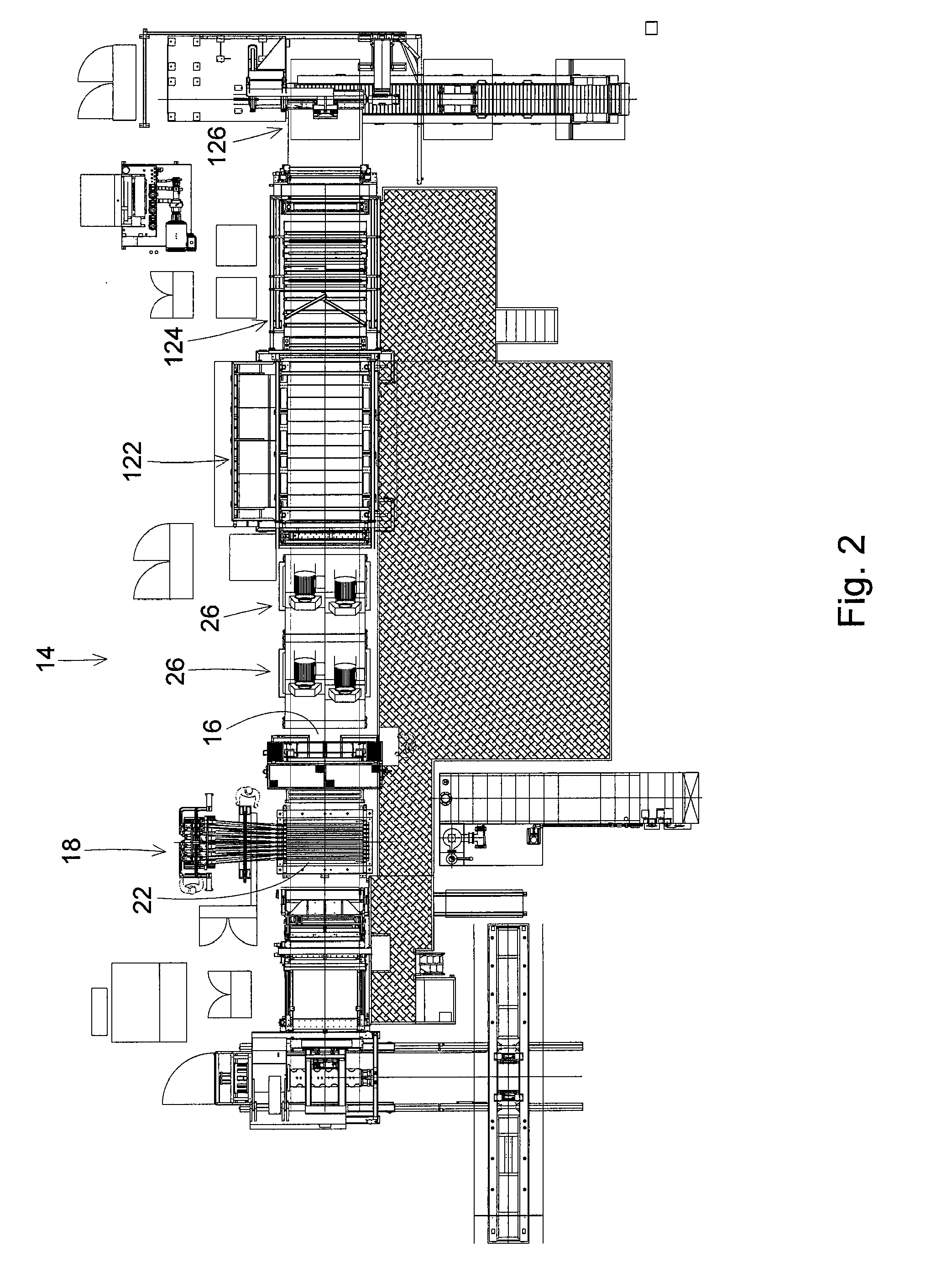

Reduction process and plant

ActiveUS7854786B2Prevent reoxidationSmall sizeTuyeresBell-and-hopper arrangementSyngasProcess engineering

Reduction process and relative plant for the production of metallic iron by means of the direct reduction of iron ore, in which a reduction shaft is connected to a source of reducing gas obtained from the gasification of coal. The process advantageously comprises a step in which a portion or all of the synthesis gas entering the plant circuit is processed to separate the methane from the rest of the components of said synthesis gas. The advantageous management of the extracted methane enables the entire reduction process to be optimized, making the efficiency of the process independent of the methane content in the original synthesis gas and making it possible to control the carbon content of the product more accurately and more easily.

Owner:DANIELI & C OFF MEC SPA

Inert anode for producing aluminium by igneous electrolyse and method for producing said anode

The invention relates to a method for producing a solid part for forming an entire anode or the part thereof for producing aluminium by igneous electrolyse and comprising a cermet made of at least one type of metal oxide such as a spinel mixed oxide containing a R metal in the form of cations in the chemical structure thereof. Said R metal is entirely or partly reducible by a reducing operation during a production process in such a way that the entire metallic phase or the part thereof is formed. The inventive method makes it possible to obtain a cermet whose metallic phase comprises a homogenous distribution of fine metallic particles.

Owner:PECHINEY ALUMINUM

Method for recovering iron from high-iron bauxite, and method for extracting aluminum from high-iron bauxite

InactiveCN110760637AAchieve recyclingAvoid pollutionShaft furnaceProcess efficiency improvementSlagPetrochemical

The invention provides a method for recovering iron from high-iron bauxite. The method comprises the steps that S1, high-iron bauxite powder is placed in a closed reduction furnace, flare gas is introduced into the reduction furnace, heating reduction is conducted, and reduction materials are obtained; and S2, the reduction materials are ground and then subjected to magnetic separation, thus magnetic separation concentrate and magnetic separation tailings are obtained, the magnetic separation concentrate is iron concentrate, and the magnetic separation tailings are aluminum oxide enrichment ores. The iron in the high-iron bauxite can be recovered, meanwhile, the flare gas is utilized, and atmospheric pollution generated by flare gas burning of petrochemical enterprises is avoided. The invention further provides a method for extracting aluminum from the high-iron bauxite. The method comprises the steps that A1, the high-iron bauxite is treated through the method for recovering the ironfrom the high-iron bauxite, and thus magnetic separation concentrate and magnetic separation tailings are obtained; A2, the magnetic separation tailings, ammonium sulfate and water are evenly mixed and then roasted to obtain roasted clinker; and A3, the roasted clinker is dissolved out and separated to obtain an aluminum-containing solution and aluminum-extracting slag. Iron, the aluminum and silicon in the magnetic separation tailings are separated, and the purpose of comprehensive utilization of the high-iron bauxite is achieved.

Owner:NORTHEASTERN UNIV

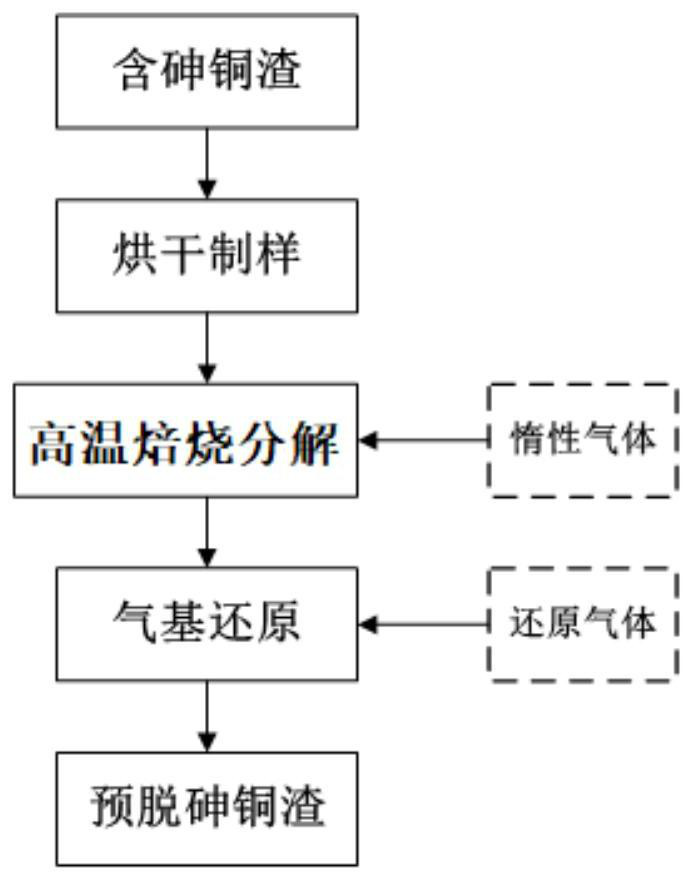

Roasting gas-based reduction arsenic removal method for arsenic-containing copper slag

ActiveCN111647738AReduce arsenic levelsAchieve comprehensive utilizationSulfur preparation/purificationArsenateArsenic oxide

The invention relates to a roasting gas-based reduction arsenic removal method for arsenic-containing copper slag, and belongs to the field of solid waste treatment and utilization in the non-ferrousmetallurgy industry. The problem that an arsenic content in a reduced iron product exceeds the standard in the prior art is solved. The roasting gas-based reduction arsenic removal method for the arsenic-containing copper slag comprises the following steps of 1, grinding the arsenic-containing copper slag, and drying slag powder to remove free water, and specifically, the arsenic-containing copperslag contains arsenic oxide, arsenic sulfide and arsenate; 2, carrying out high-temperature roasting on the slag powder, introducing inert gas in a high-temperature roasting process, carrying out high-temperature roasting decomposition on the arsenic oxide and the arsenic sulfide in the arsenic-containing copper slag, then volatilizing in a gas form, and forming arsenic roasting slag from non-volatile components; and 3, continuously introducing reducing gas into the arsenic roasting slag for 40-100 minutes at the reducing temperature of 650-1200 DEG C, and gasifying and removing the arsenatein the arsenic roasting slag to obtain arsenic-removed slag charge of the arsenic-containing copper slag. According to the roasting gas-based reduction arsenic removal method, the arsenic content in the slag can be obviously reduced, and raw material with the qualified arsenic content is provided for subsequent continuous treatment of the copper slag.

Owner:CENT IRON & STEEL RES INST +1

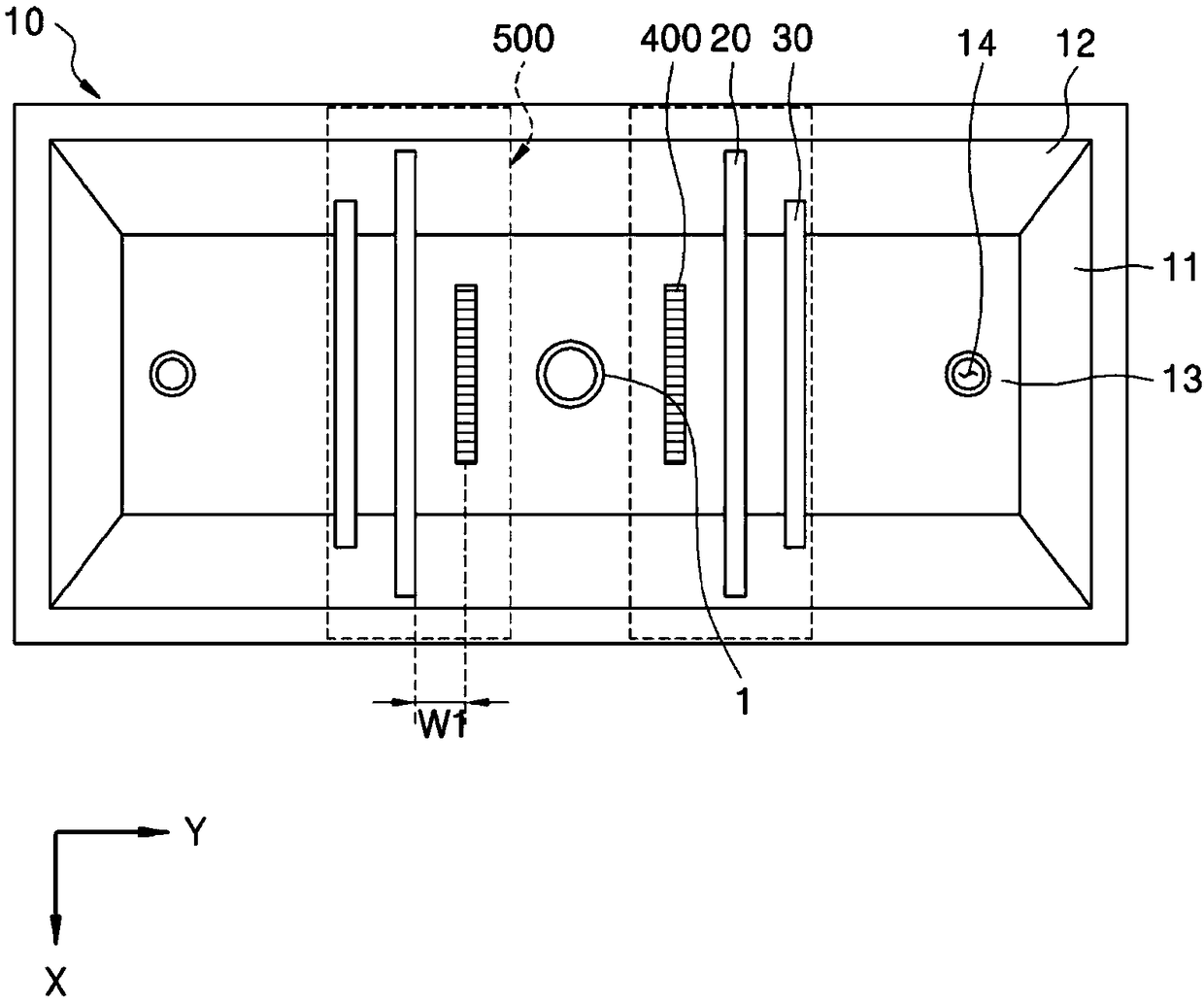

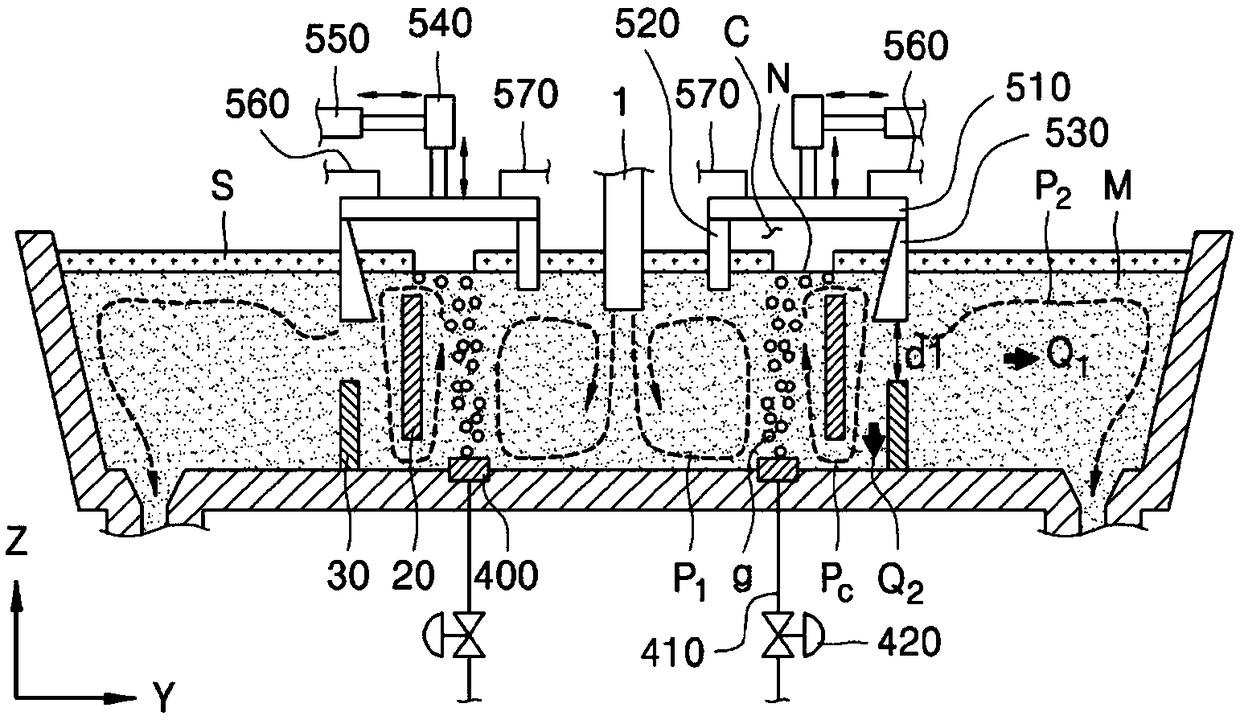

Melt treating apparatus and melt treating method

InactiveCN109311084APrevents reoxidation and contaminationEfficient removalMelt-holding vesselsProduct gasEngineering

Owner:POSCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com