Method and device for producing micron-sized superfine iron powder through regenerative iron red

A technology of ultra-fine iron powder and micron level, which is applied in the field of metallurgical powder making, can solve the problems of difficulty in realizing large-scale industrial production and popularization and application, inability to realize continuous production well, high cost of carbonyl iron powder, etc., and achieve the source of raw materials Sufficient, less stressful, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

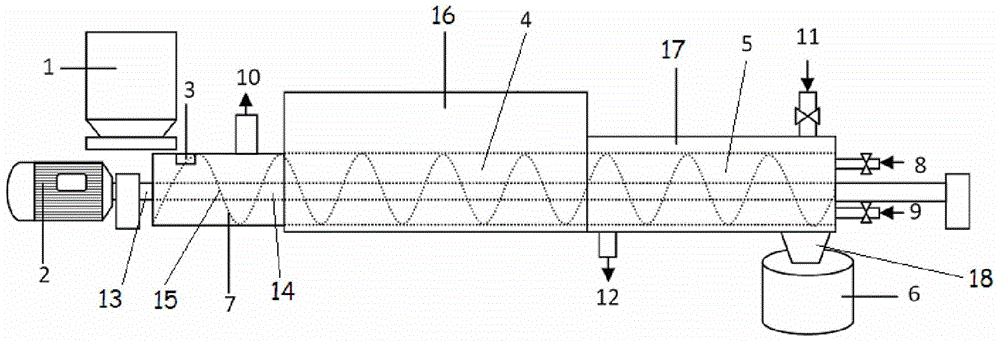

[0026] Fe in raw material recycled iron red 2 o 3 The content is 98.5%, the particle size range is 0.5-10 μm, and the average particle size is 0.85 μm. The rotating speed of the spiral blade is 5r / min, the reducing gas H 2 The flow rate is 0.35m 3 / min, the reducing gas inlet pressure is controlled at 0.3MPa, the reducing temperature is 550°C, and the reaction time is 20min. The protective gas is nitrogen, and the flow rate is controlled at 1 / 8 of the reducing gas flow rate during normal production. Finally, the iron content of the nano-scale superfine iron powder is 99.4%, the average particle size of the particles is about 0.8 μm, and the reduction yield is 99.3%.

Embodiment 2

[0028] Fe in raw material recycled iron red 2 o 3 The content is 98.5%, the particle size range is 0.5-10 μm, and the average particle size is 2.5 μm. The rotation speed of the spiral blade is 10r / min, and the CO flow rate of the reducing gas is 0.5m 3 / min, the reducing gas inlet pressure is controlled at 0.4MPa, the reducing temperature is 260°C, and the reaction time is 40min. The protective gas is nitrogen, and the flow rate is controlled at 1 / 10 of the reducing gas flow rate during normal production. Finally, the iron content of the nano-scale superfine iron powder is 98.8%, the average particle size of the particles is about 0.83 μm, and the reduction yield is 99.0%.

Embodiment 3

[0030] Fe in raw material recycled iron red 2 o 3 The content is 98.0%, the particle size range is 0.5-10 μm, and the average particle size is 1 μm. The rotating speed of the spiral blade is 2r / min, the reducing gas H 2 The flow rate is 0.2m 3 / min, the reducing gas inlet pressure is controlled at 0.2MPa, the reducing temperature is 600°C, and the reaction time is 15min. The protective gas is nitrogen, and the flow rate is controlled at 1 / 5 of the reducing gas flow rate during normal production. Finally, the iron content of the nano-scale superfine iron powder is 98.4%, the average particle size of the particles is about 0.81 μm, and the reduction yield is 99.1%.

[0031] The final product prepared by the present invention is micron-sized ultra-fine iron powder, the degree of reduction of which is over 99%, and its microscopic shape and particle size are relatively uniform, and the average particle size can be controlled within the range of 0.5-10 μm according to requireme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com