Method of recycling valuable metals from arsenic-containing soot

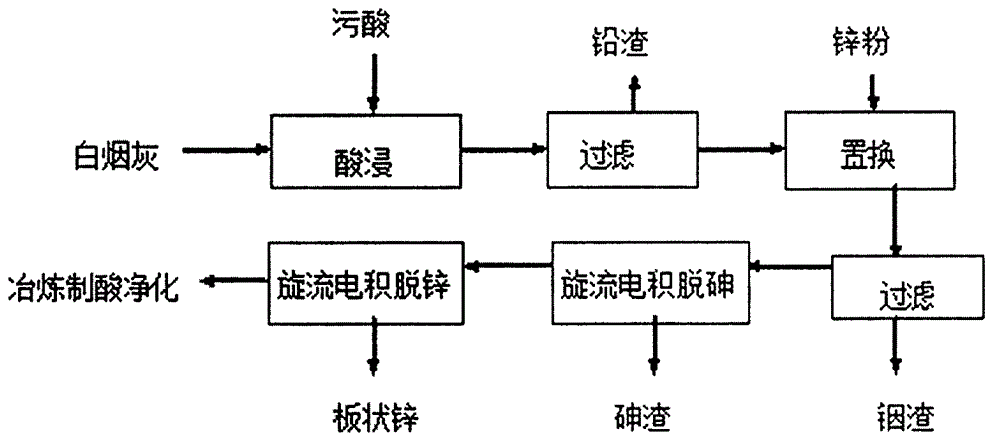

A technology for valuable metals and soot, which is applied in the field of recovery of valuable metals from arsenic-containing soot, can solve the problems of land occupation, environmental pollution, etc., and achieve the effects of short process flow, small footprint and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The dirty acid used in this example is lead smelting dirty acid, and the specific components are shown in Table 1; the white soot is copper smelting soot, and the specific components are shown in Table 2.

[0015] (1) The dirty acid and white soot are mixed according to the liquid-solid ratio of 5:1, the pH value is controlled at 2.5-3.0, and 500ml is taken for acid leaching at a temperature of 70°C for 2 hours. Filter to obtain leachate and lead slag. After testing, the leaching solution was 380ml, the lead slag was 78.8g, the leaching rate of As was 95.4%, the leaching rate of Zn was 83.1%, and the leaching rate of Pb was only 2.34%. The specific leaching data are shown in Table 3;

[0016] (2) the leaching solution is replaced with zinc powder for indium, and filtered to obtain indium slag;

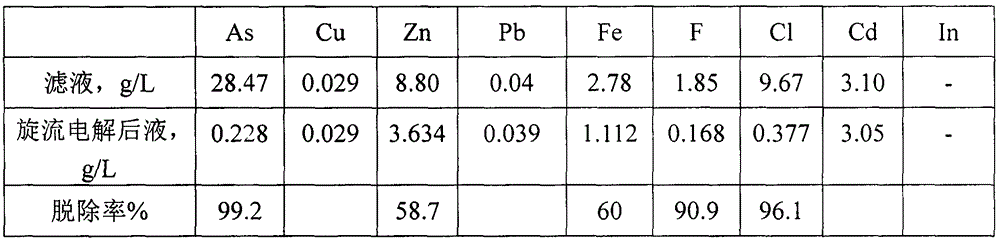

[0017] (3) The filtrate was de-arsenized and de-zincified by cyclone electrowinning, and arsenic slag and zinc slag were recovered. The de-arsenic rate was 99.2%, and the de-zi...

Embodiment 2

[0029] The dirty acid used in this example is zinc smelting dirty acid, and the specific components are shown in Table 5; the white soot is copper smelting soot, and the specific components are shown in Table 6.

[0030] (1) The dirty acid and white soot are mixed according to the liquid-solid ratio of 5:1, the pH value is controlled at 2.5-3.0, and 500ml is taken for acid leaching at a temperature of 80°C for 2 hours. Filter to obtain leachate and lead slag. After testing, the leaching rate of As was 95.7%, the leaching rate of Zn was 82.8%, and the leaching rate of Pb was only 2.37%. The specific leaching data are shown in Table 7;

[0031] (2) the leaching solution is replaced with zinc powder for indium, and filtered to obtain indium slag;

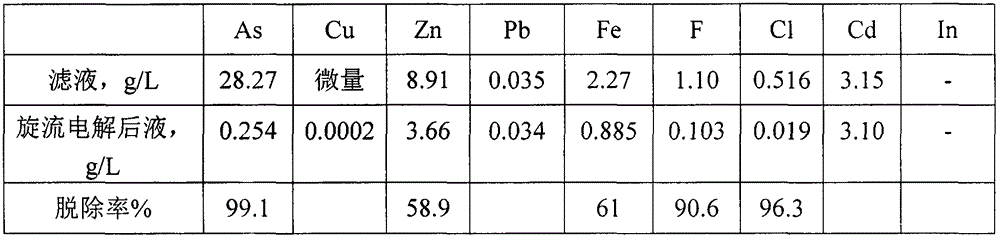

[0032] (3) The filtrate was de-arsenized and de-zincified by cyclone electrowinning, and arsenic slag and zinc slag were recovered. The de-arsenic rate was 99.1%, and the de-zinc rate was 58.9%. The specific data are shown in Table 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com