Patents

Literature

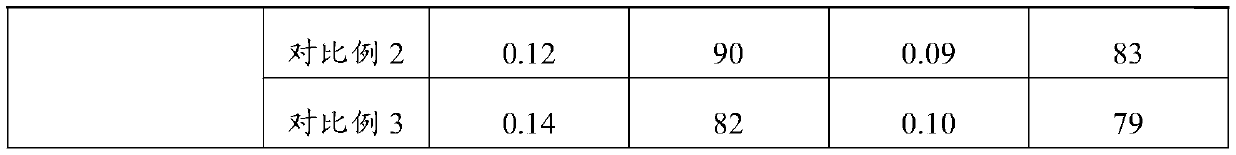

35results about How to "Improve green pellet strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

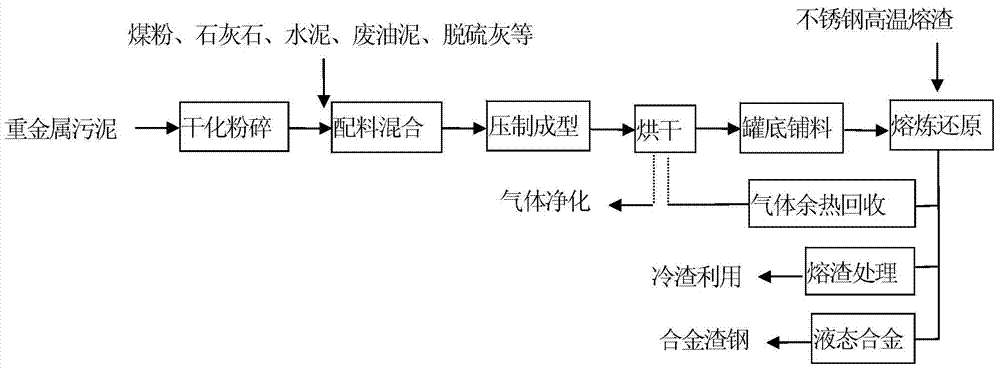

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Iron ore pellet and its preparation method

The invention discloses an iron ore pellet preparing method, Which comprises the following steps: putting 2-4wt% forsterite and 0. 2-0. 8wt% agglomerant in iron ore; mixing up water (the water content of mixture: 6-11wt%); making ball and drying; preheating at the temperature of 900-1000 deg. c for 15-25min; roasting at the temperature of 1260-1320deg. c for 20-40min; mixing up 20-40% jevigating, 5-10% polyacrylamide, 0-5% polypropylene, 0-5% sodium humate, 20-40% twaterproof putty powder, 3-5% caoline and 5-10% copperas in mass fraction to obtain agglomerant. The invention can improve the strength of green-ball and the heat endurance.

Owner:WUHAN UNIV OF SCI & TECH

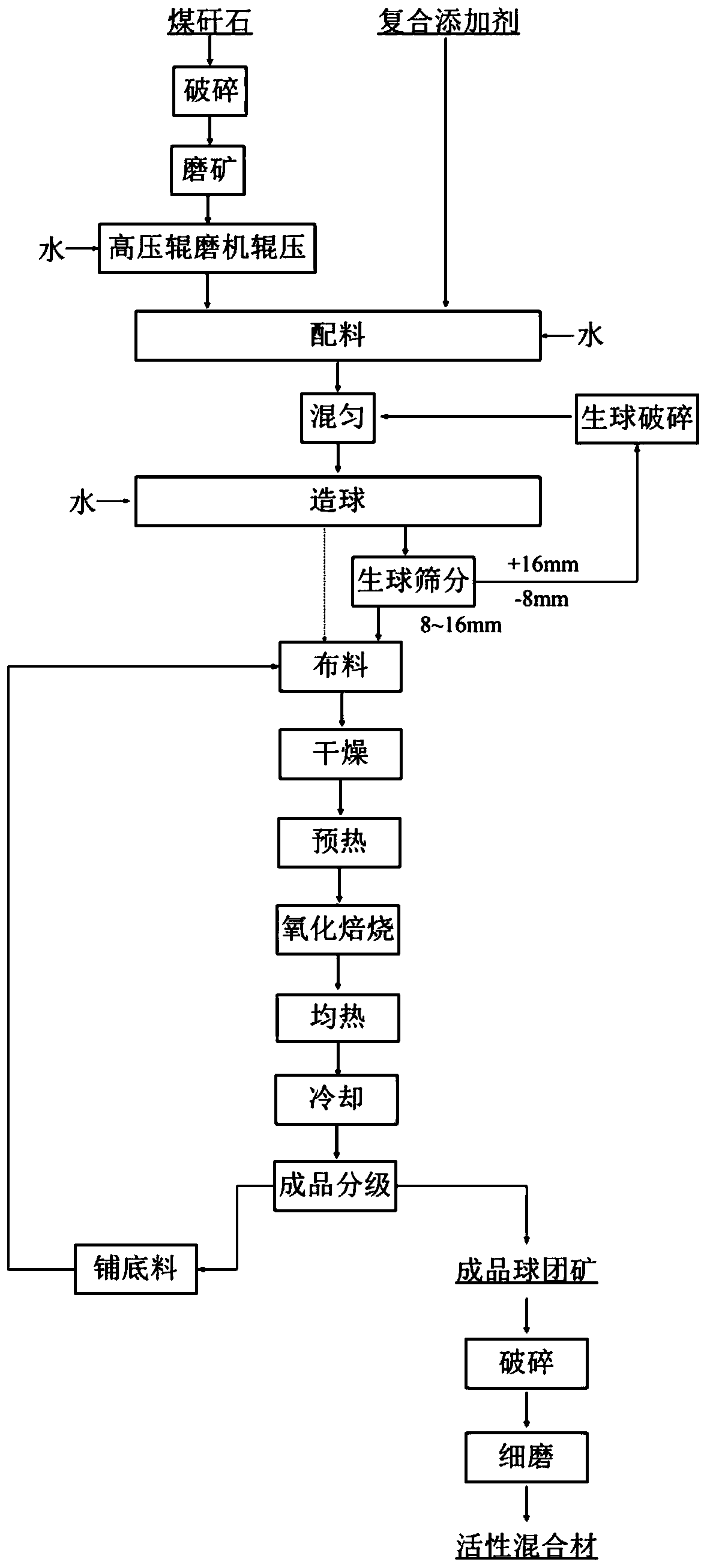

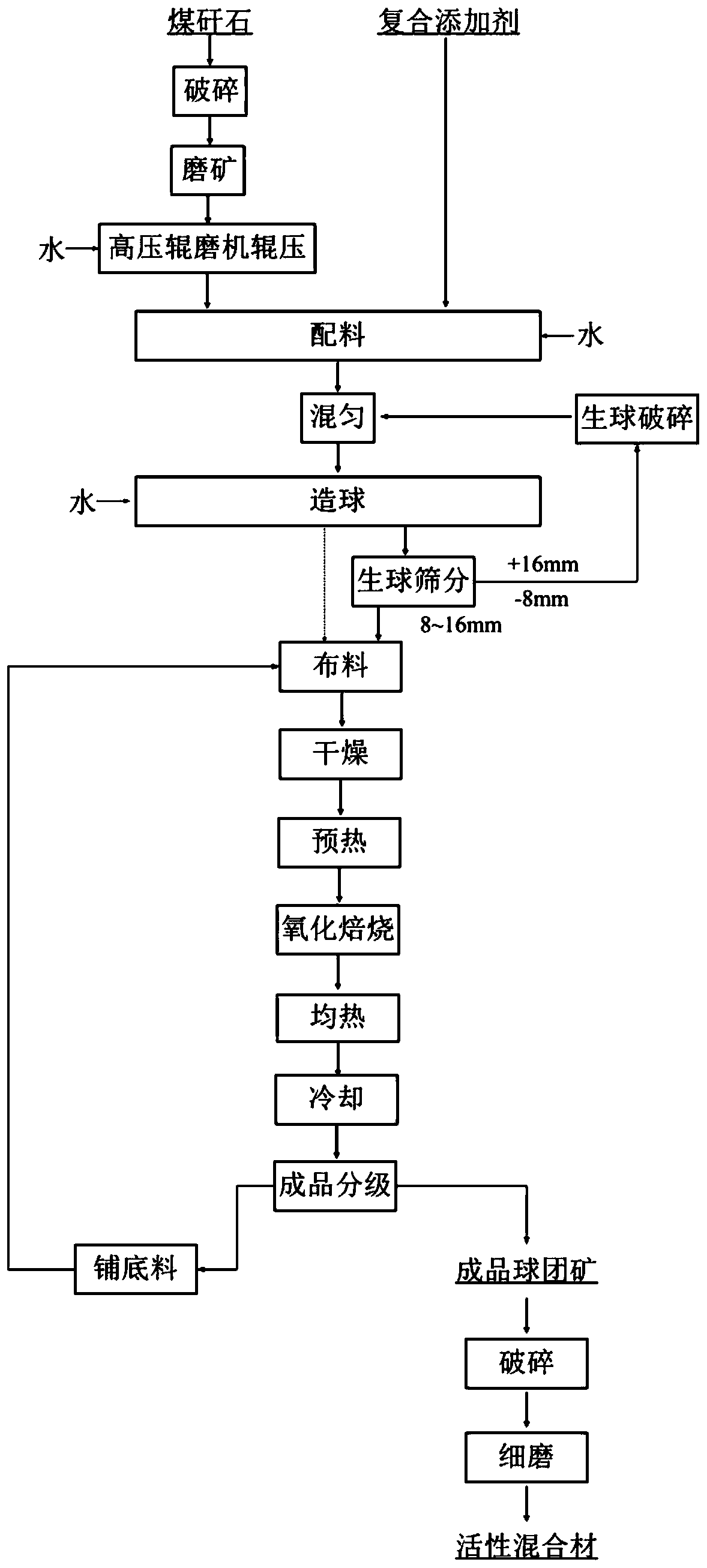

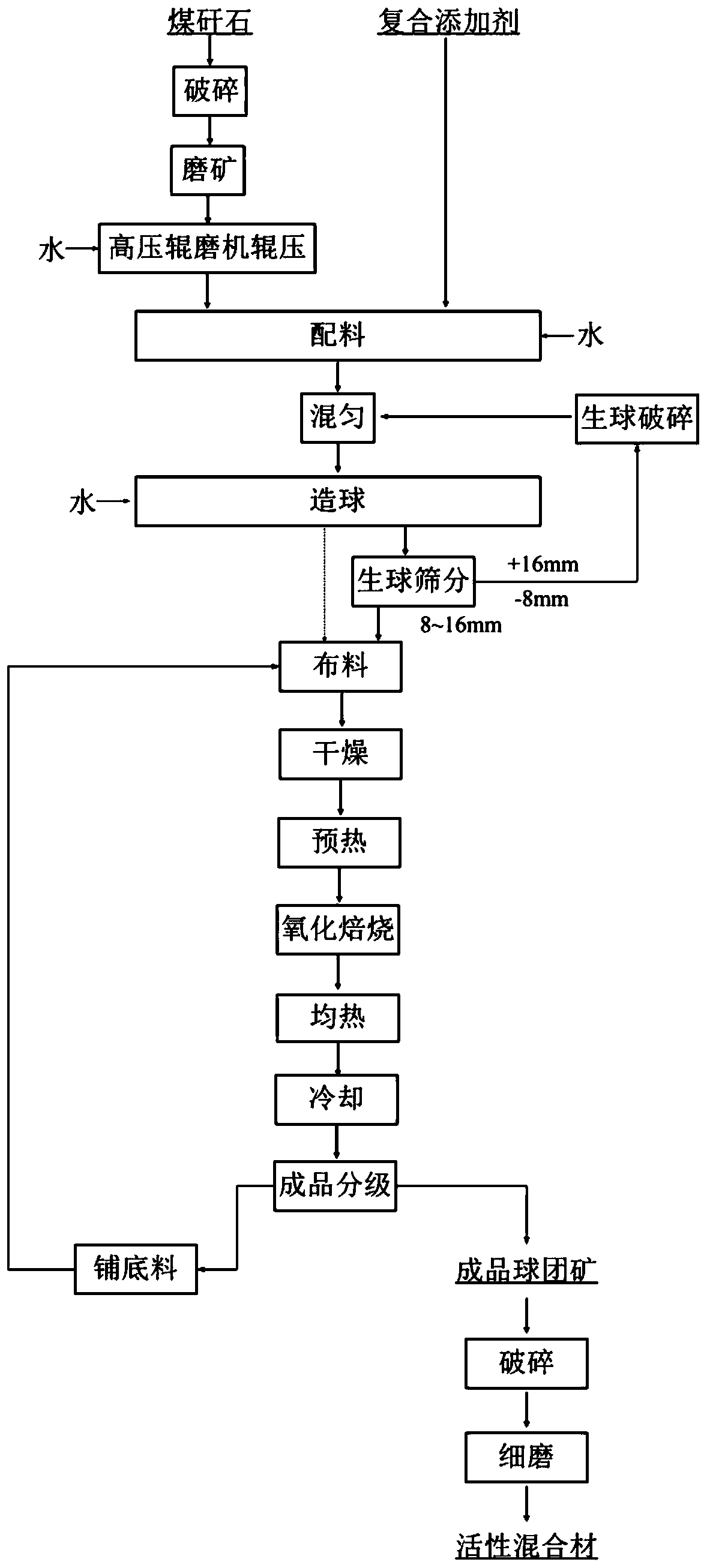

Method for preparing active mixed material through belt type roasting machine pelletizing method

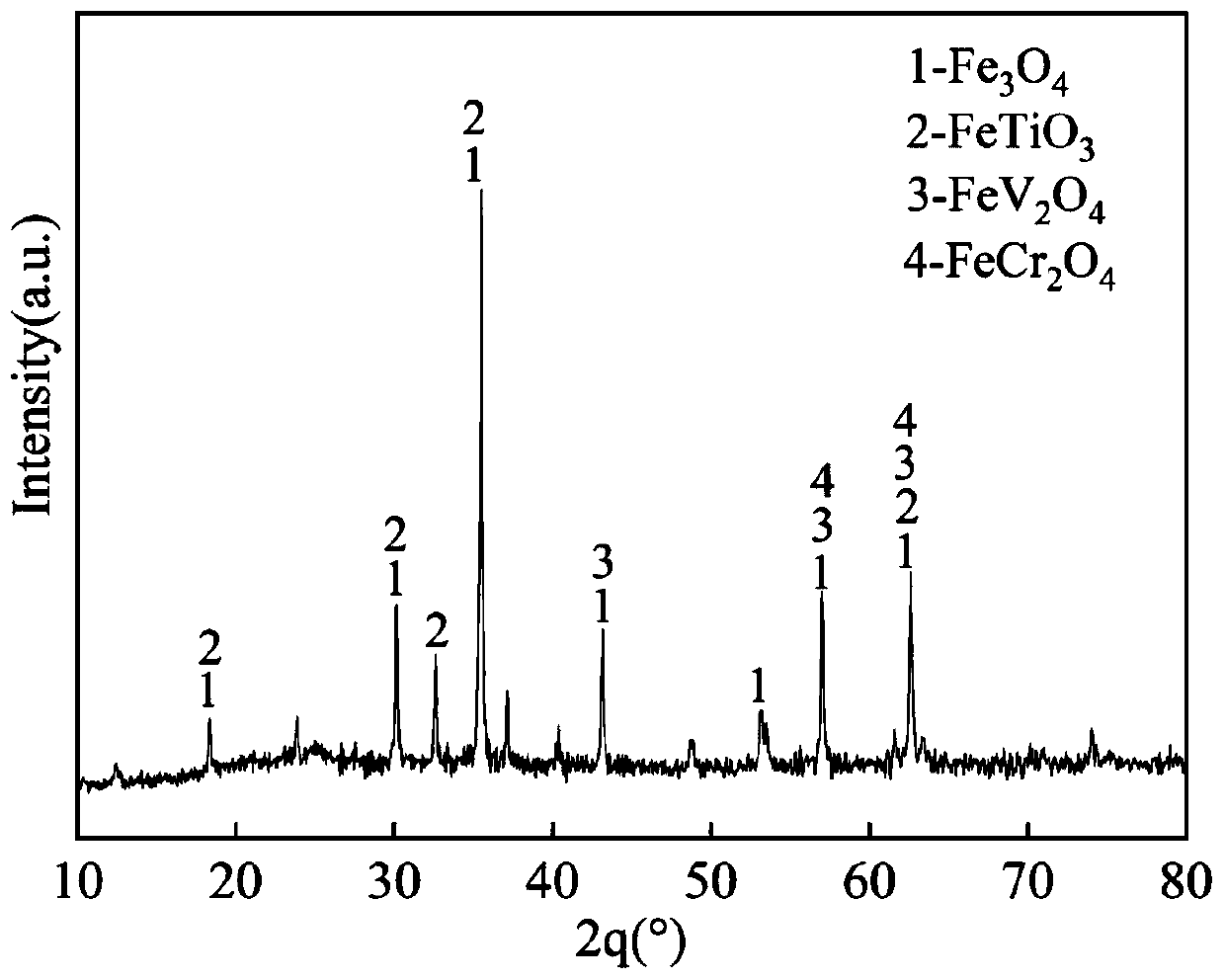

ActiveCN109956737AHigh strengthQuality improvementCeramic materials productionClaywaresGranularityMixed materials

The invention discloses a method for preparing an active mixed material through a belt type roasting machine pelletizing method. The method comprises the following steps: (1) crushing and grinding ore; (2) burdening and uniformly mixing: fully and uniformly mixing the coal gangue subjected to fine grinding, a composite additive and water in an intensive mixer according to predetermined proportion,and fully wetting the materials; (3) pelletization: preparing pellets with preset granularity from the uniformly mixed ores; (4) roasting by a belt type roasting machine: distributing the pellets onthe belt type roasting machine, and drying, preheating, oxidizing and roasting, soaking and cooling the pellets; and (5) crushing and fine grinding: crushing and fine grinding the coal gangue pellet material to a set specific surface area to obtain the active mixed material. The invention provides a method for preparing the active mixed material through the belt type roasting machine pelletizing method. The method is suitable for large-scale production, the usage amount of the coal gangue reaches 85% or above, the coal gangue stockpiling problem can be thoroughly solved, and a high-quality mixed material is provided for the construction industry.

Owner:CENT SOUTH UNIV

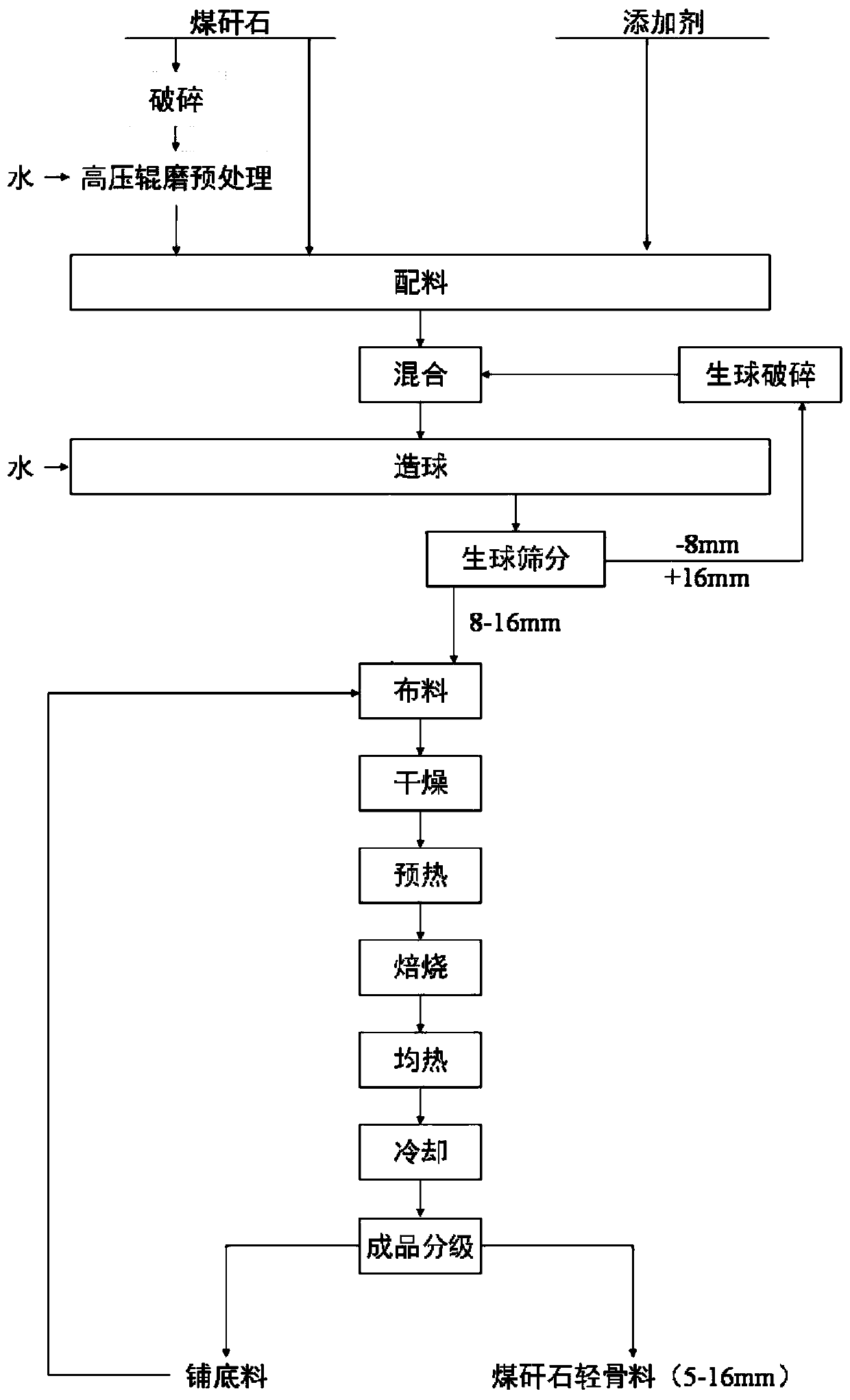

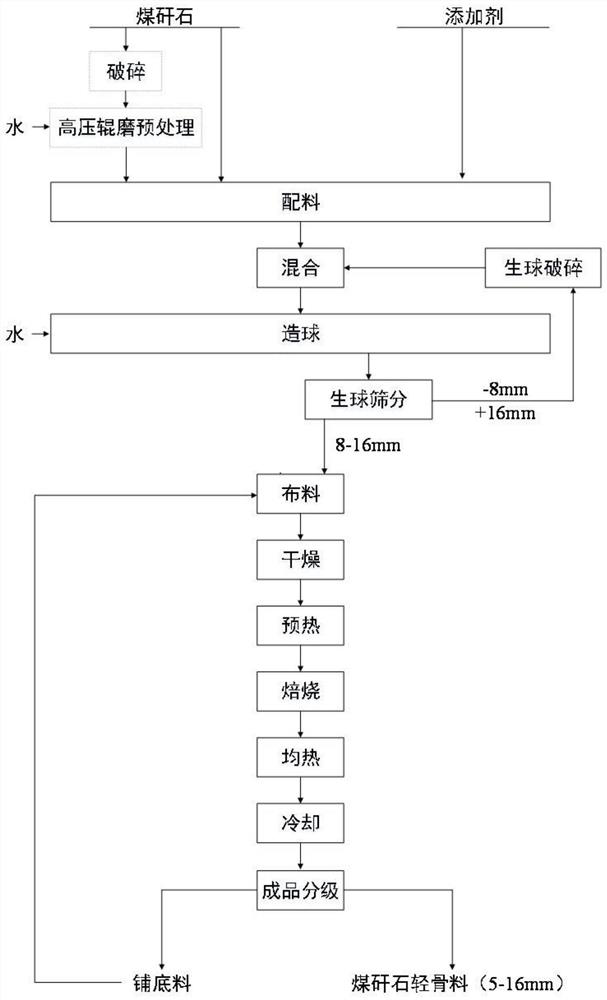

Technology for preparing coal-gangue lightweight aggregate with pelletizing method through belt-type roasting machine

ActiveCN110104975AHigh strengthUniform qualitySolid waste managementFoaming agentUltimate tensile strength

The invention discloses a technology for preparing coal-gangue lightweight aggregate with a pelletizing method through a belt-type roasting machine. The technology includes the following steps of 1) breaking and ore grinding; 2) preparing and even mixing; 3) pelletizing and screening; 4) roasting in the belt-type roasting machine; 5) finished-product grading. The coal-gangue-lightweight-aggregatepelletizing-method preparing technology of the belt-type roasting machine is suitable for large-scale production of high-quality coal-gangue lightweight aggregate, and the obtained product is high instrength, even in mass, low in energy consumption and environmentally friendly; a huge amount of coal gangue may be thoroughly eliminated, the environment problem caused by the coal gangue is solved,and the high-performance lightweight aggregate is produced and provides a high-quality raw material for construction industry; a specific additive is prepared in the technology, the functions of improving the strength of green balls and increasing the yield and the effects of a fluxing agent and a foaming agent are both achieved, the formation temperature of a liquid phase of a system is lowered,swelling of coal-gangue pellets is promoted, the organizational structure of the lightweight aggregate is optimized accordingly, the strength of the lightweight aggregate is remarkably improved, and energy consumption is reduced.

Owner:CENT SOUTH UNIV

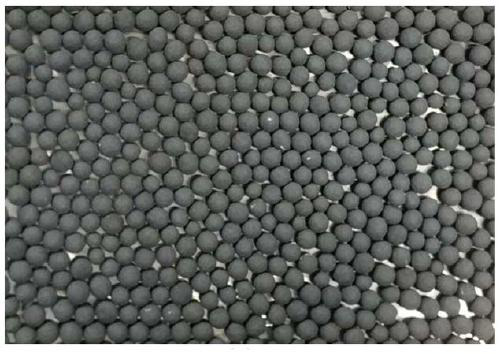

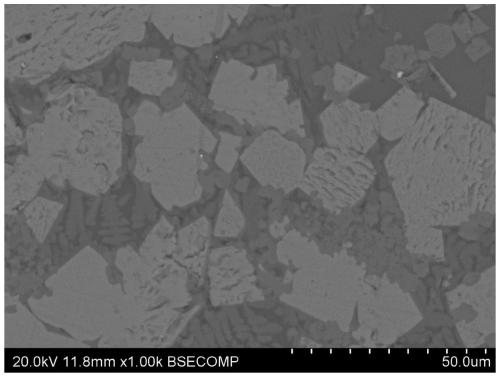

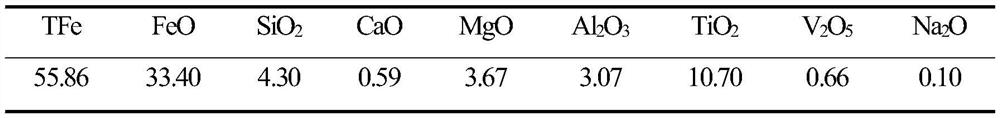

Preparation method of low-temperature solidified metallurgical pellets

The invention belongs to the field of comprehensive utilization of metallurgical residue resources and specifically relates to a preparation method of low-temperature solidified metallurgical pellets.In order to solve the problems that when steel and iron scrap powder are adopted for making pellets, the generated pellets are poor in forming performance, low in sintering intensity, likely to be pulverized and the like. The provided preparation method of the low-temperature solidified metallurgical pellets includes the following steps of a, taking and weighing vanadium titano-magnetite concentrates, steel and iron scraps and a compound bonding agent according to a mass ratio of (28-65):(34-68):(2-4), adding water, uniformly mixing the mixture, and conducting pelleting to obtain raw pellets;b, drying the raw pellets obtained in step a until the moisture content is lower than or equal to 1%, and obtaining dry pellets; c, preheating the dry pellets and conducting sintering to obtain finished pellet products. The preparation method is simple in operation, the prepared pellet products are high in strength, MFe of the finished pellet products is 55-58%, the compressive strength of each pellet is 2,600-3,100 N, the drum index is 90.0-93.5%, and the production cost is low. The new method is provided for comprehensive utilization of the steel and iron scrap powder, and obvious economicbenefits are obtained.

Owner:PANZHIHUA UNIV +1

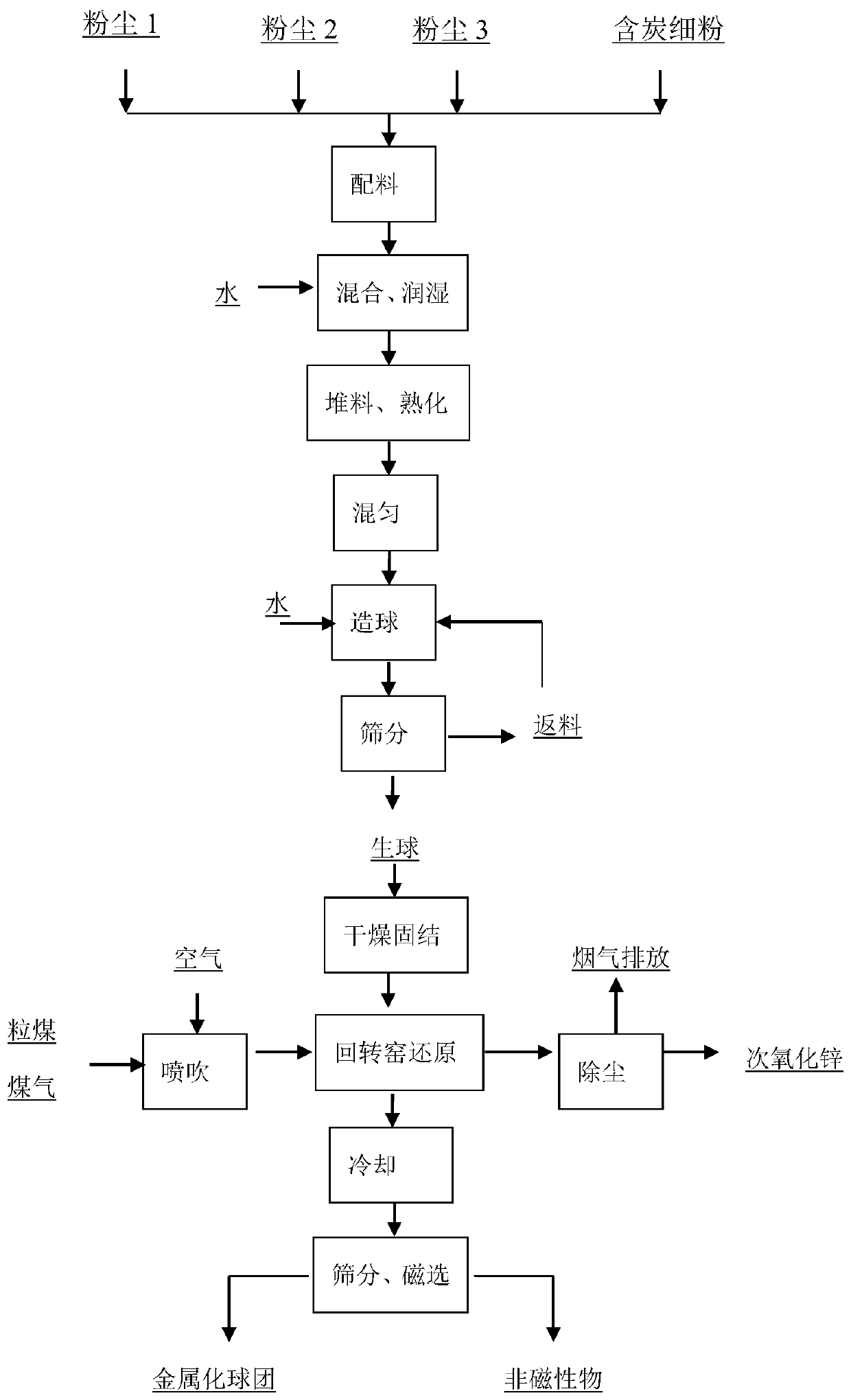

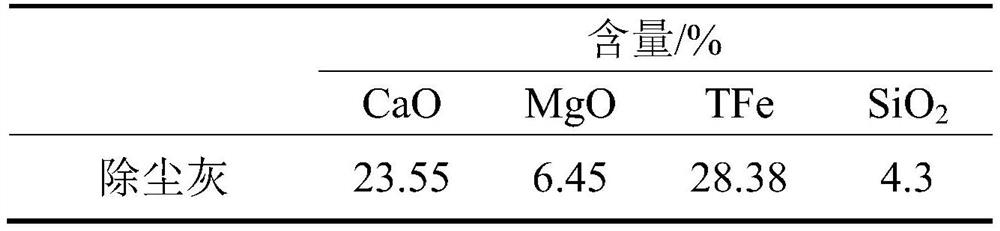

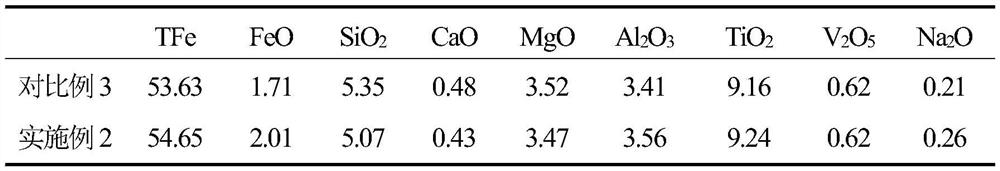

Preparation method of zinc-containing dust pellet

ActiveCN110317949AOvercoming the characteristics of weak ball formationGood ball formingRotary drum furnacesProcess efficiency improvementMixed materialsCompressive strength

The invention provides a preparation method of a zinc-containing dust pellet. The preparation method comprises the following steps of S1, carrying out burdening , mixing the blast furnace cloth bag ash, the steel-making ladle furnace ash, the steel-making converter smoke dust and other zinc-containing dust with the carbon-containing fine powder to obtain a mixture; S2, carrying out pretreatment, adding water into the mixture obtained in the step S1 for wetting, and piling up and curing after wetting; S3, adding a composite binder into the cured mixture, and carrying out uniformly mixing to obtain a uniform mixture; S4, carrying out pelletizing on the uniformly mixed material prepared in the step S3 to obtain a green pellet; and S5, drying the green pellet in the step S4 to obtain the zinc-containing dust dry pellet. The dry pellet has the advantages of high compressive strength and good reducibility, the metallization rate is high in the direct reduction process, the dezincification effect is good, and the preparation method solves the technical problems that an existing zinc-containing dust pellet is easy to break and pulverize in the reduction process.

Owner:CENT SOUTH UNIV

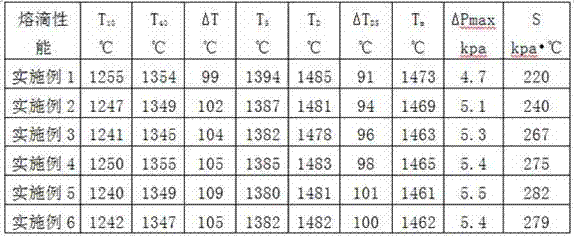

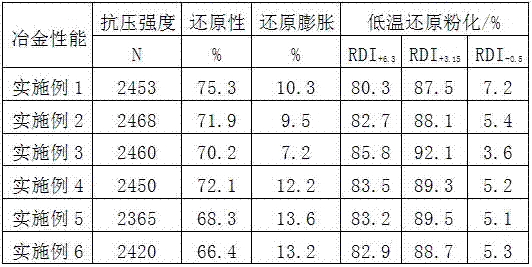

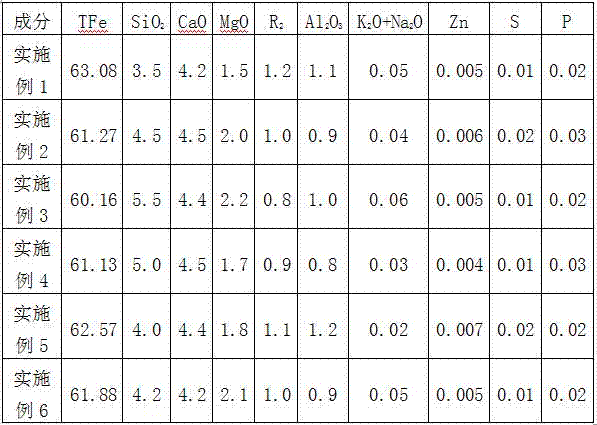

High-silica magnesian fluxed pellet for blast furnace and production method of high-silica magnesian fluxed pellet

InactiveCN106987705AIncrease usage ratioHigh silicon contentBlast furnace detailsAlkalinityHigh silica

The invention discloses a high-silica magnesian fluxed pellet for a blast furnace and a production method of the high-silica magnesian fluxed pellet. The high-silica magnesian fluxed pellet comprises, by mass fraction, 3.5%-5.5% of SiO2, 1.5%-2.2% of MgO, 0.8%-1.2% of basicity, not larger than 1.5% of Al2O3, not larger than 0.1% of K2O and Na2O, not larger than 0.02% of Zn, not larger than 0.05% of S and not larger than 0.07% of P. The silica content of the pellet is high, the pellet can be produced through high-silica iron fine powder, the using proportion of the pellet in the blast furnace is improved, meanwhile, the using scope of the iron fine powder is enlarged, and the using proportion of the iron fine powder inland is improved. By means of the method, the high-silica iron fine powder can be used for producing the magnesian fluxed pellet, the production cost is reduced, meanwhile, the pellet qualified in quality can be obtained, and requirement of the blast furnace for using the high proportion of pellet is met; and by means of the method, the scope of the iron fine powder used for producing the magnesian fluxed pellet can be expanded, and the using amount of the high-silica iron fine powder inland can be particularly improved. The method has the beneficial effects of being low in production cost, simple in process and excellent in product performance.

Owner:TANGSHAN IRON & STEEL GROUP +1

Method for improving pelletizability of low-pelletizability iron concentrate

The invention discloses a method for improving pelletizability of low-pelletizability iron concentrate, which comprises the following steps: adding a small amount of soluble metal salt modifier into the iron concentrate, evenly mixing, adding a small amount of sodium humate into the iron concentrate, carrying out wet grinding pretreatment, and pelletizing. The method is simple to operate and low in facility requests, can effectively enhance the drop strength and compression strength of the iron concentrate crude pellets, enables the other properties to reach the standard, and enhances the iron grade of the finished pellets. The method is especially suitable for pelletizing the low-pelletizability iron concentrate, and can obviously improve the pellet quality of the low-pelletizability iron concentrate.

Owner:CENT SOUTH UNIV

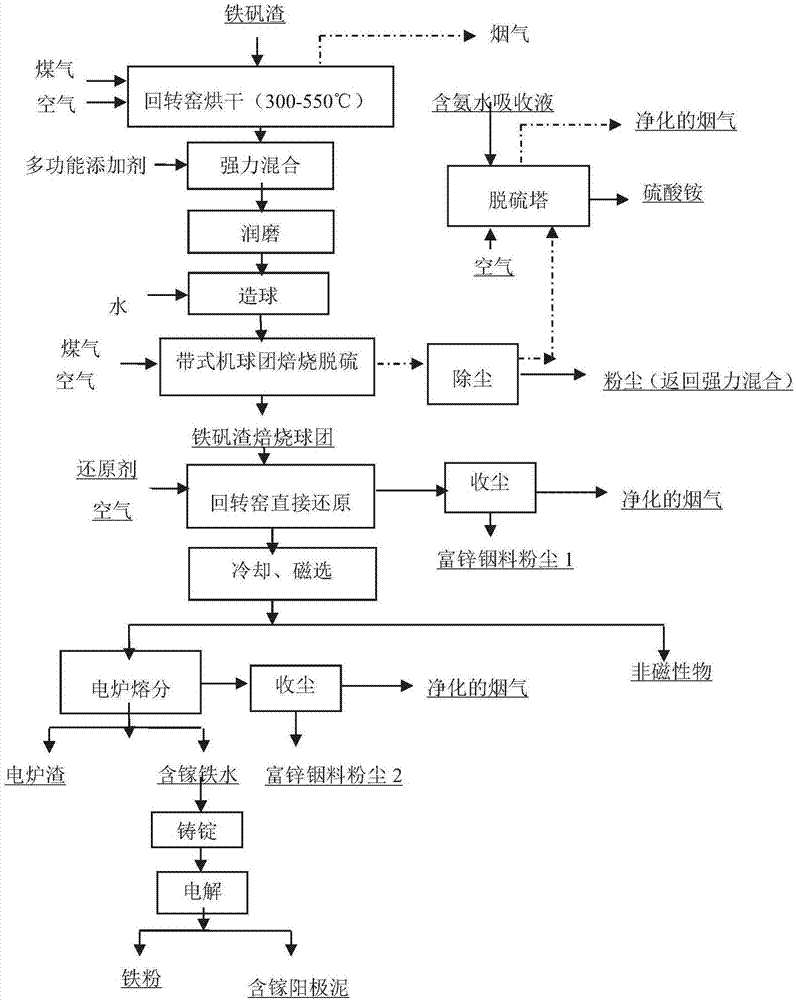

Method for extracting valuable elements from jarosite slag

ActiveCN107267745AReduce expansionImprove reducibilityProcess efficiency improvementIndiumElectrolysis

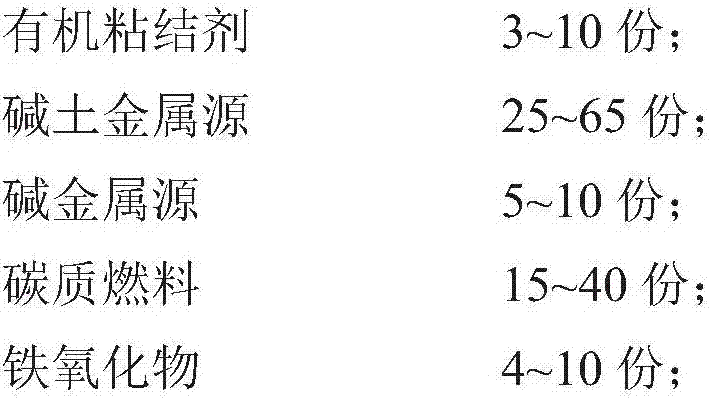

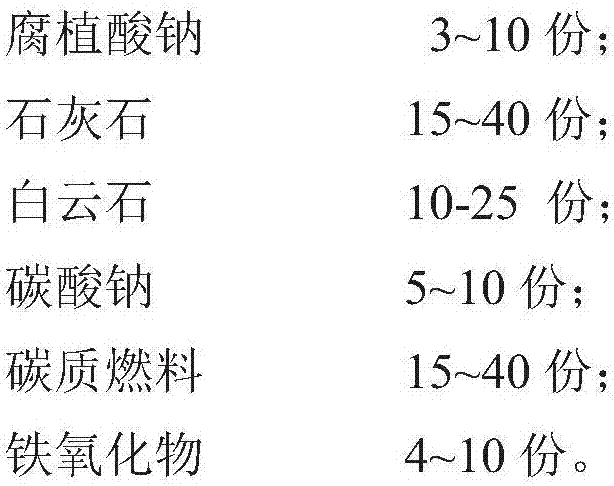

The invention discloses a method for extracting valuable elements from jarosite slag. The method specially includes the steps of pelletization, oxidation roasting desulfurization, direct reduction, smelting separation, ingot casting, electrolysis and the like. A special additive agent disclosed by the invention is adopted in the pelletization process, and the additive agent comprises an organic binder, an alkaline earth metal source, an alkaline metal source, carbonaceous fuel and iron oxide. By the adoption of the method, by means of extensive research and test certification, the additive agent is used so that pelletization can be enhanced, the roasting desulfurization and consolidation effect of pellets is improved, the strength of the roasted pellets is enhanced, the reducibility of the roasted pellets is improved, the reduction swelling rate of the pellets is lowered, the mobility of the slag is improved, desulfurization capacity of the slag is also improved, and the subsequent process is matched to achieve efficient separation and extraction of the various valuable elements like iron, gallium, zinc, indium and sulfur.

Owner:CENT SOUTH UNIV +1

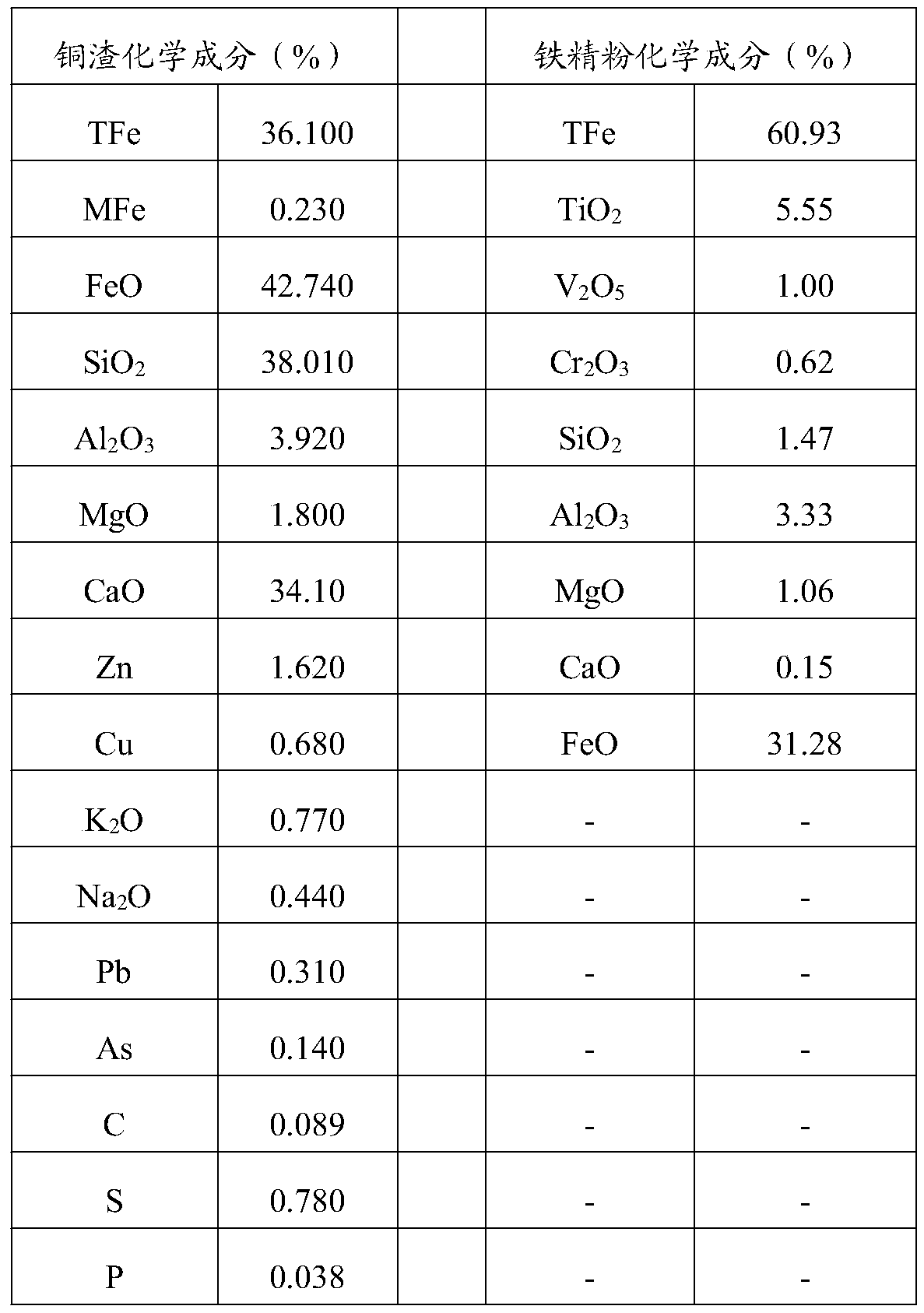

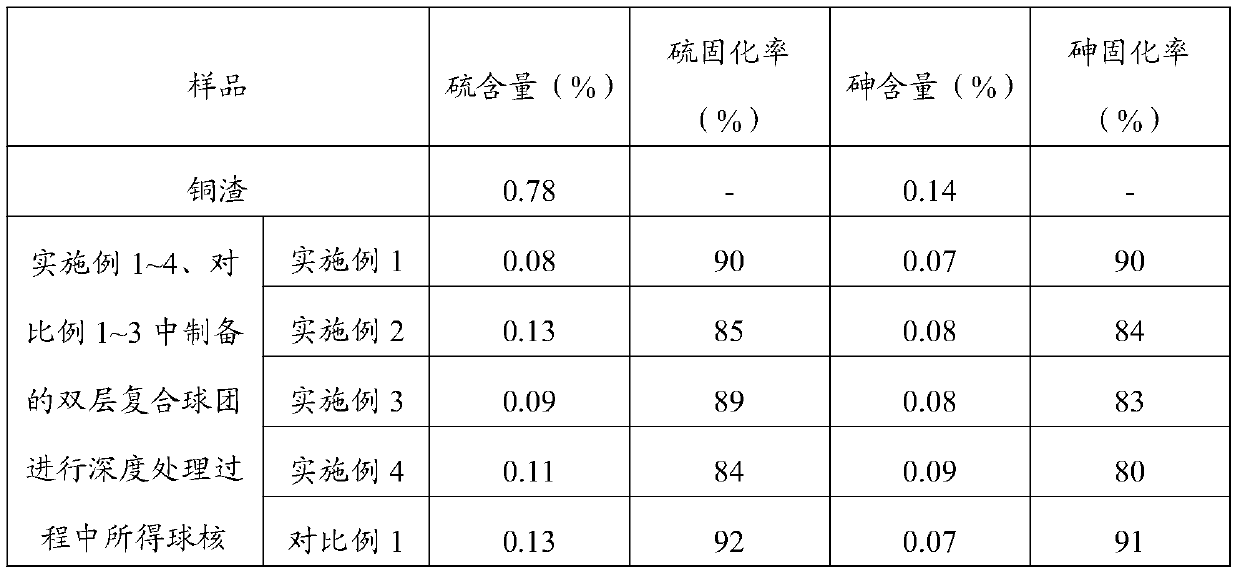

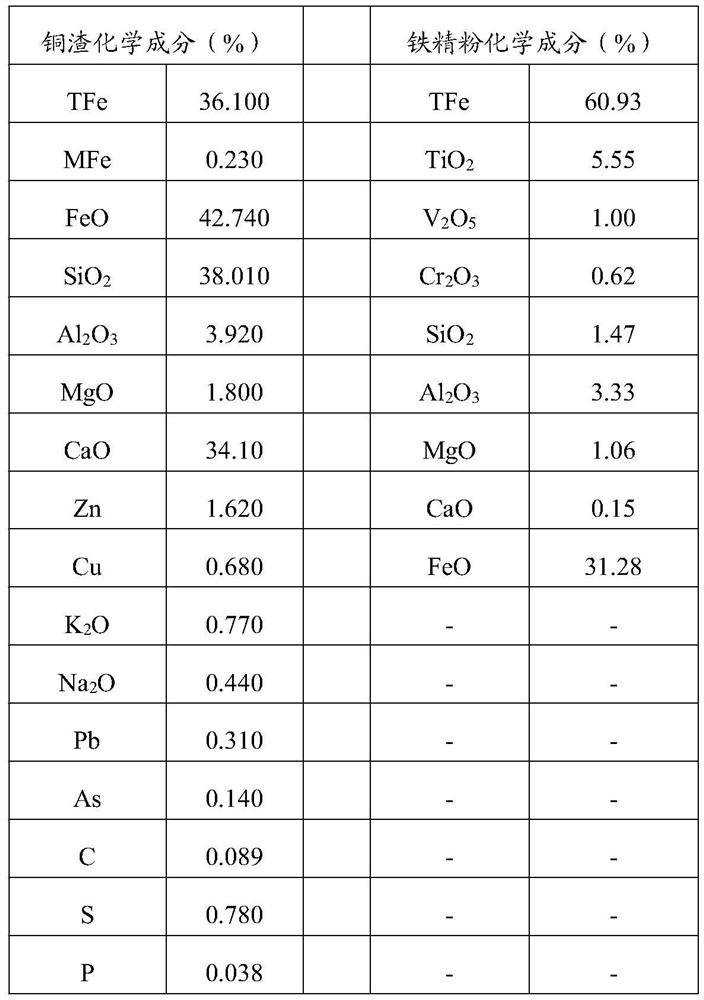

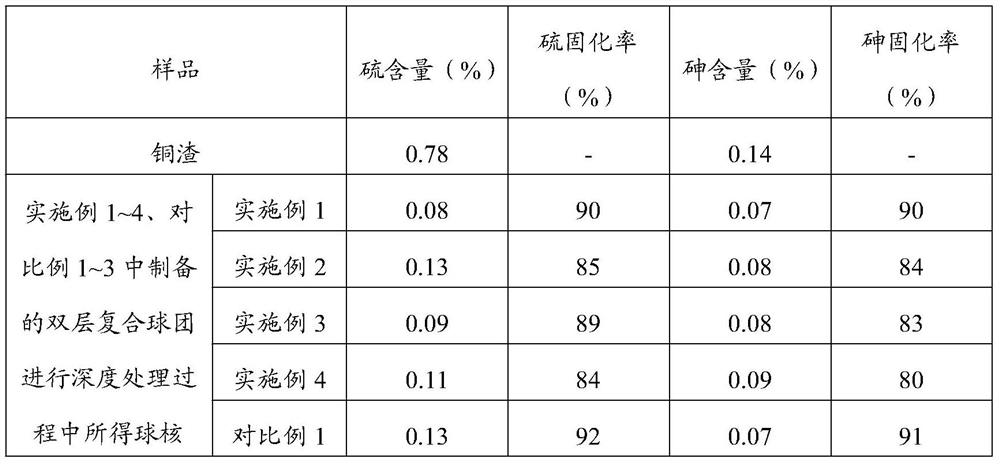

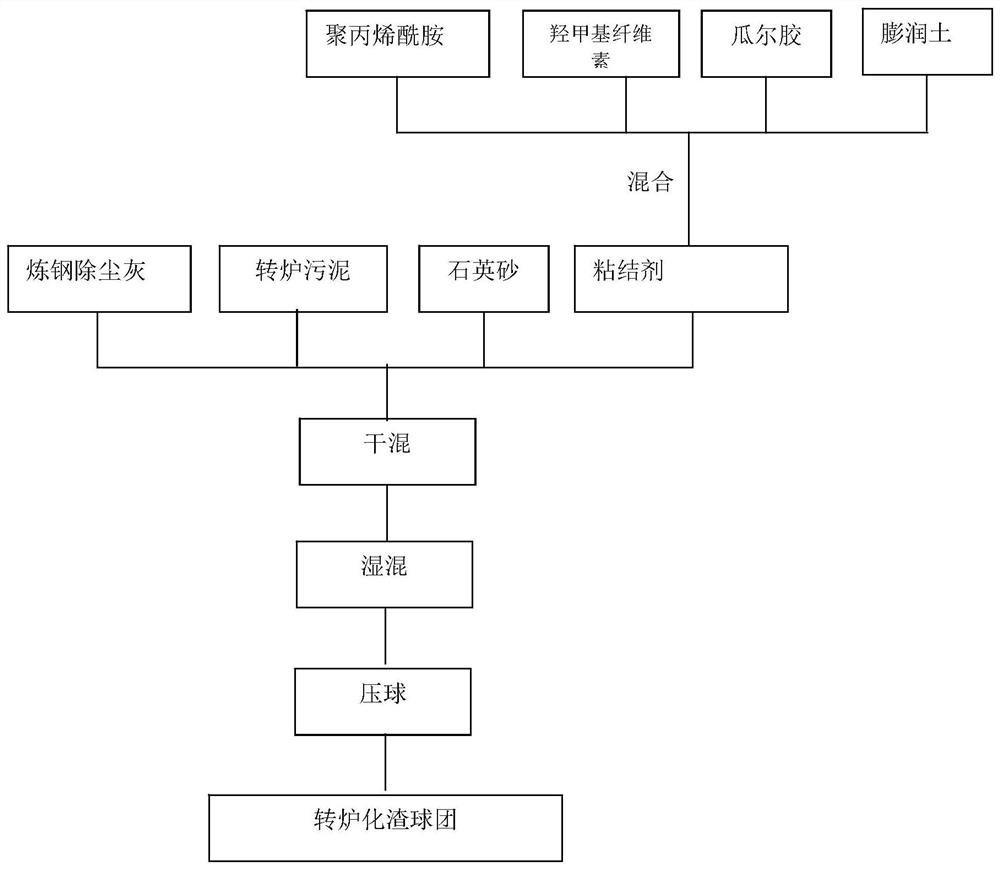

Double-layer composite pellet for treating copper slag and preparation method thereof

The invention relates to the technical field of chemical engineering by-product treatment, in particular to a double-layer composite pellet for treating copper slag and a preparation method thereof. The double-layer composite pellet for treating the copper slag comprises a pellet core and a coating layer adhering to the surface of the pellet core. Preparation raw materials comprise the copper slag, fine iron powder, potassium permanganate, manganese dioxide, a clad material, a bonder, water glass and water. According to the pellet, the fine iron powder can increase the pellet forming rate of the double-layer composite pellet, and is beneficial for promoting nucleation and growth of iron crystal particles in the follow-up heat treatment process, and the recovery rate of valuable elements such as iron and silicon is increased. The water glass forms a transition area between the pellet core and the coating layer, meanwhile, bonding between the clad material and the pellet core is achieved, and the green pellet strength is improved beneficially. Potassium permanganate is decomposed on the high-temperature condition and releases oxygen, meanwhile, manganese dioxide is generated, the oxygen and the manganese dioxide can serve as oxidizing agents to oxidize sulfur and arsenic in the system, and the sulfur and arsenic removing effect is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of cold-consolidated pellets suitable for kiln-process phosphoric acid rotary kiln process

The invention discloses a preparation method of cold-consolidated pellets suitable for a kiln-process phosphoric acid rotary kiln process. The preparation method comprises the following steps: material grinding, material preparation, mixing, pelletizing, internal pellet packaging and drying. According to the preparation method, an inorganic substance bentonite is matched with an organic matte sodium carboxymethyl starch, and the advantages of bentonite and odium carboxymethyl starch to the quality of the pellets are exerted, so that the reliability and the stability of the quality of the pellets are guaranteed; when the pellets are dried, internal moisture can be dispersed to the surfaces of the pellets through capillary tubes to be evaporated, so that the bursting of the pellets in the drying process is prevented, relatively good hard shells can be formed on the surfaces of the pellets, and the strength of the pellets is guaranteed; by virtue of cooperation of organic and inorganic auxiliary materials, the quality requirements of raw pellets and the dried pellets are guaranteed; by virtue of an intensive mixing machine, the raw materials and the auxiliary materials for pelletizing are uniformly mixed, so that the uniformity and the reliability of the mixing of the materials are guaranteed, and the requirements of a solid phase reaction of the kiln-process phosphoric acid rotary kiln process are met.

Owner:JIANGXI WUFENG PHOSPHORUS IND TECH

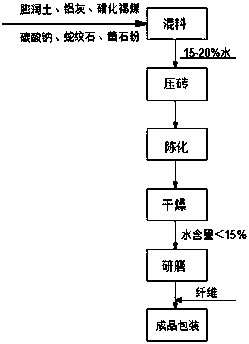

Aluminum ash pellet binder and preparation method thereof

The invention belongs to the field of metallurgical pellet binders and particularly relates to an aluminum ash pellet binder and a preparation method thereof. The binder is formed by processing the following raw materials including, by weight, 60-80% of aluminum ash, 15-30% of bentonite, 2.5-4% of sodium carbonate, 0.5-1.5% of calcined ophiolite, 0.5-1% of fluorite powder, 2-5% of sulfonated lignite and 0.5-2% of fibers. The preparation method comprises the steps of mixing; pressure-formation of bricks; ageing; drying; grinding; and finished product packaging. According to the aluminum ash pellet binder and the preparation method thereof, the pellet binder is prepared by means of aluminum ash, the process is simple, environment friendliness and safety are achieved, goods are saved, the product quality is good, and the economic benefit and environment-friendly benefit are quite high.

Owner:XINYANG CITY SHANGTIANTI YIHE MINERAL PROD RESOURCES DEV

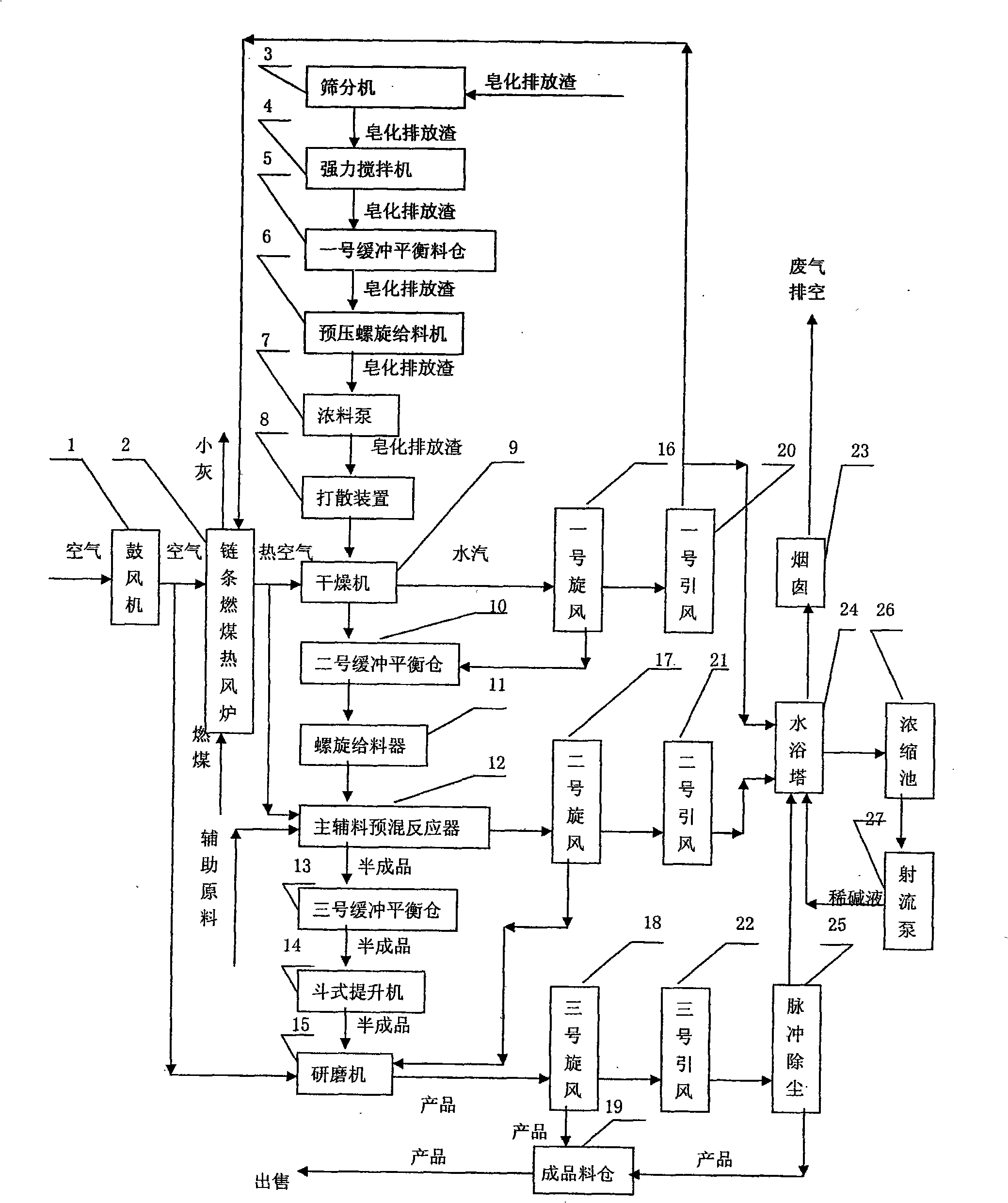

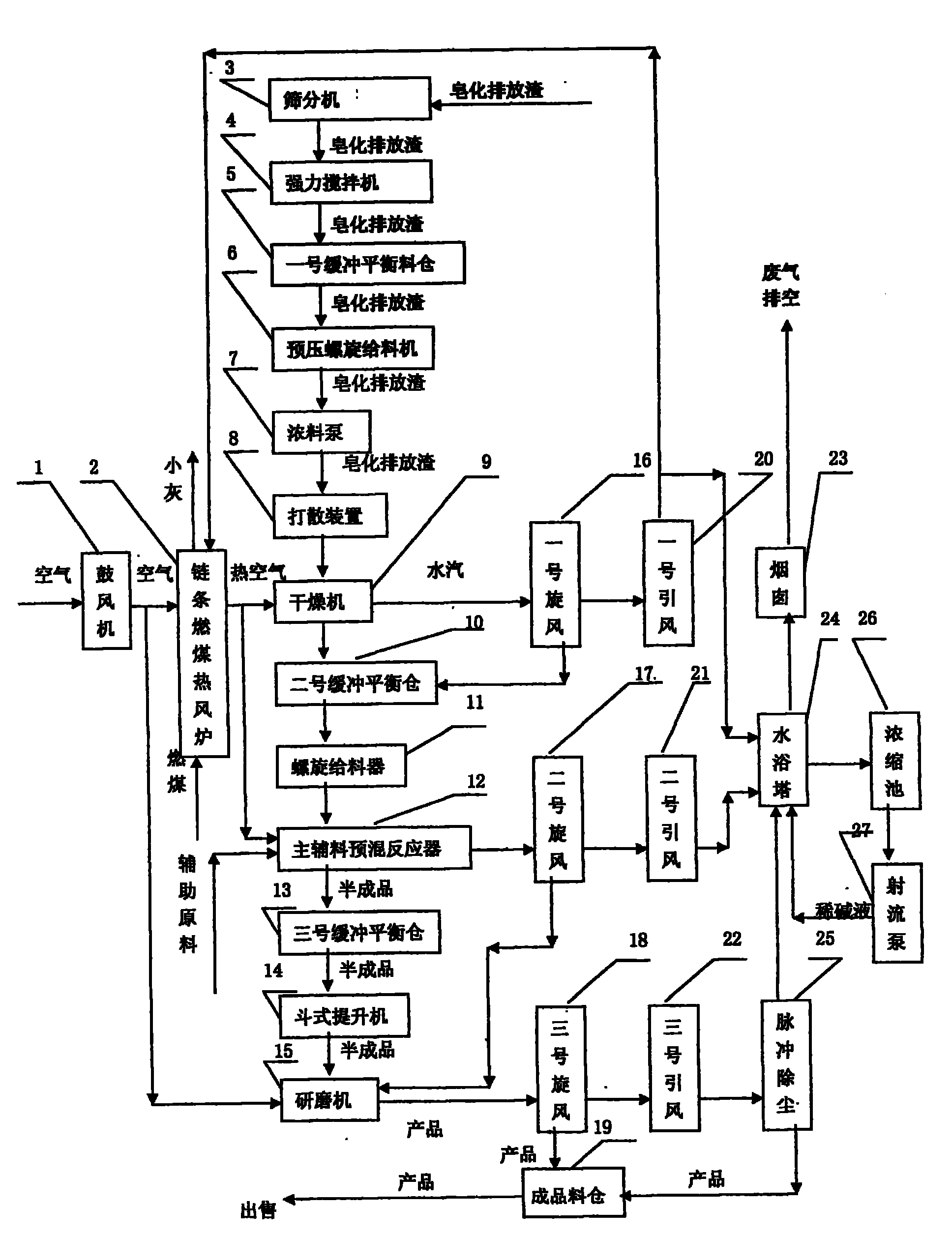

Novel method for producing iron ore pellet binder

The invention relates to a production method of a novel iron ore pellet binder, which is characterized in that saponification emission dregs of propylene oxide by chlorohydrination used as main raw material are sieved, mixed and dried with 8 to 25 percent of water left and then are conveyed to a main and auxiliary materials premixed reactor; the saponification emission dregs of propylene oxide bychlorohydrination after drying treatment, 15 to 35 percent of calcium oxide (CaO) 4 to 5 percent of magnesium oxide (MgO) which function as basic oxygenation agent, 0.7 to 1.2 percent of Na2B4O5(OH)4.8H2O functioning as oxygenation agent borax and 0.3 to 0.7 percent of molybdenum oxide (MO) functioning as stabilizer active are fully mixed and agitated to remove harmful educts in the saponification emission dregs, and then powdery novel iron ore pellet binder with the particle size distribution of between 80 and 300 mesh is made after fine grinding. The production method is low in production cost, chemical solid emissions can be utilized as renewable resources, and secondary waste water and waste residues are not produced in the whole process, thus the production method is environmental-friendly production technology of a new generation of iron ore pellet binder.

Owner:辽宁中生洁源实业有限公司

Composite functional material capable of synchronously removing nitrogen and phosphorus and preparation method thereof

InactiveCN111167403AHigh strengthIncrease loadOther chemical processesWater contaminantsIn situ remediationInorganic nitrogen

The invention discloses a composite functional material capable of synchronously removing nitrogen and phosphorus and a preparation method thereof, belonging to the field of in-situ remediation of surface water. The preparation method comprises the following steps: mixing a powdery nitrogen adsorption component, a permeation component, a bonding component and a rare earth component to obtain a mixture, wherein the mass ratio of the rare earth component in the mixture is 0.5-5%; and granulating the mixture in a granulator, and conducting calcining to obtain a finished filter material. By addingthe rare earth component, the problem that other biological curing materials are not obvious in phosphorus adsorption effect is solved, so synchronous adsorption of nitrogen and phosphorus is achieved; and the finished filter material can be used for synchronous treatment of inorganic nitrogen and soluble phosphorus in surface water, so the problem of nitrogen and phosphorus pollution is effectively solved.

Owner:NANJING UNIV

Method for gas-based direct reduction for iron ore powder

InactiveCN111719031AIncrease the rate of the direct reduction reactionIncrease contact areaGas emission reductionReaction rateDirect reduced iron

The invention belongs to the technical field of non-blast furnace ironmaking and discloses a method for gas-based direct reduction for iron ore powder. The iron ore powder and a carbon-based additiveare mixed evenly and are bonded into pellets through a binder, then drying treatment is conducted, the dried pellets are reduced, wherein the ratio of carbon in the carbon-based additive to oxygen atoms in the iron ore powder is 0.1-0.4, the reduction temperature is 980-1080 DEG C, and reduction time is 1-1.5 h. The method is easy to control and low in energy consumption, the reduction time is reduced, and productivity is improved. The carbon-based additive is added into the pellet raw materials, thus the reduction temperature is controlled to 980-1080 DEG C, pores can be formed in the pellets, the contact area of reduction gas and iron oxide is increased, conversion efficiency of the reductive gas is enhanced, and the gas-based direct reduction reaction rate is effectively increased. Meanwhile the method has the characteristics that pollution is avoided, and the product cleanliness is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

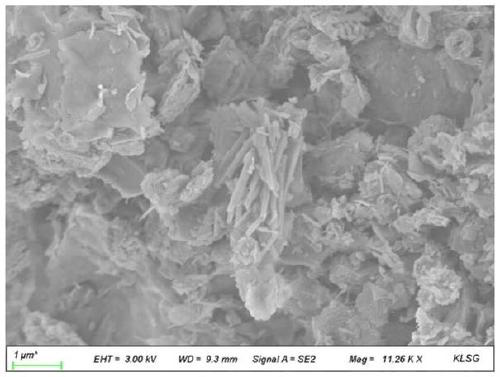

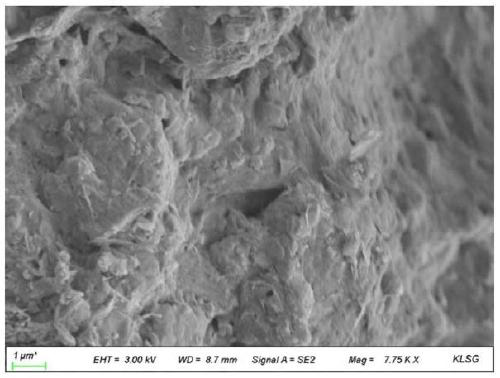

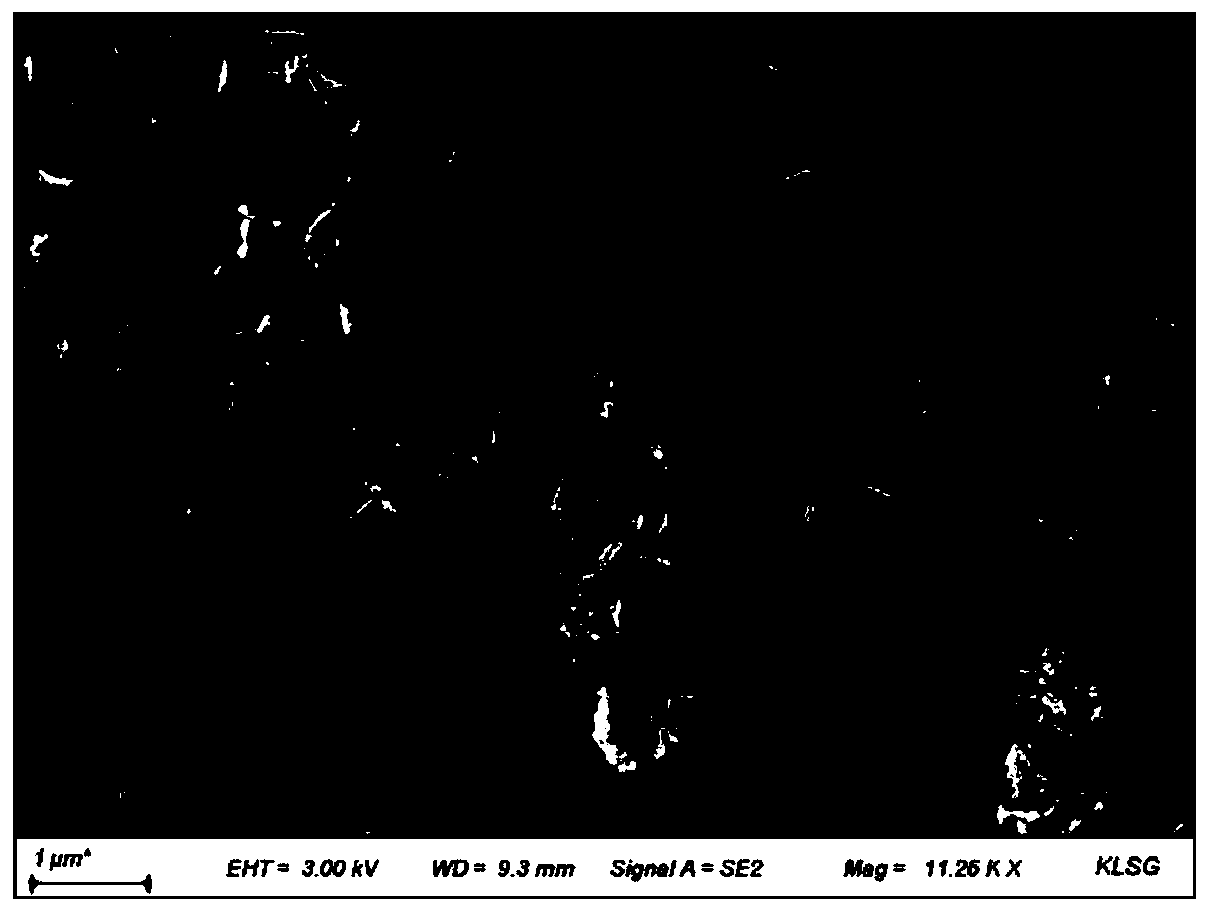

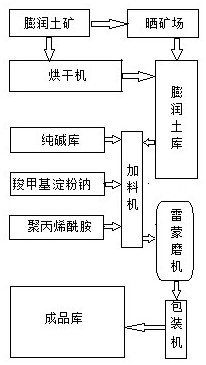

Production process of organic composite bentonite for metallurgical pellet production

PendingCN112795777AGood ball formingLow particle size requirementSimple Organic CompoundsSodium Bentonite

The invention relates to a production process of organic composite bentonite for metallurgical pellet production. The production process is characterized by comprising the following steps that firstly, sodium modification is conducted on calcium bentonite to obtain a finished product sodium bentonite; a certain amount of organic bonding powder is added into the sodium bentonite to prepare organic composite pellet bentonite; sodium carboxymethyl starch (CMS-Na) and polyacrylamide (PAM) are sufficiently and evenly stirred in a stirrer to prepare organic bonding powder; the sodium carboxymethyl starch (CMS-Na) is organic matter and is a water-soluble anionic high-molecular compound; the polyacrylamide is PAM in short and is the high-molecular-weight sodium bentonite easily dissolved in water, and the sodium bentonite and the organic bonding powder are sufficiently mixed to prepare the organic compound bentonite; when metallurgical pellets are produced, the organic composite bentonite is prepared into slurry according to the certain concentration, and then the slurry is sprayed on metallurgical powder in a pelletizing disc of a rotating pelletizer by using a slurry pump for pelletizing; and the combustion of the organic matter has no influence on the quality of metallurgical products and does not pollute the environment.

Owner:湖南飞来峰非金属矿物材料有限公司

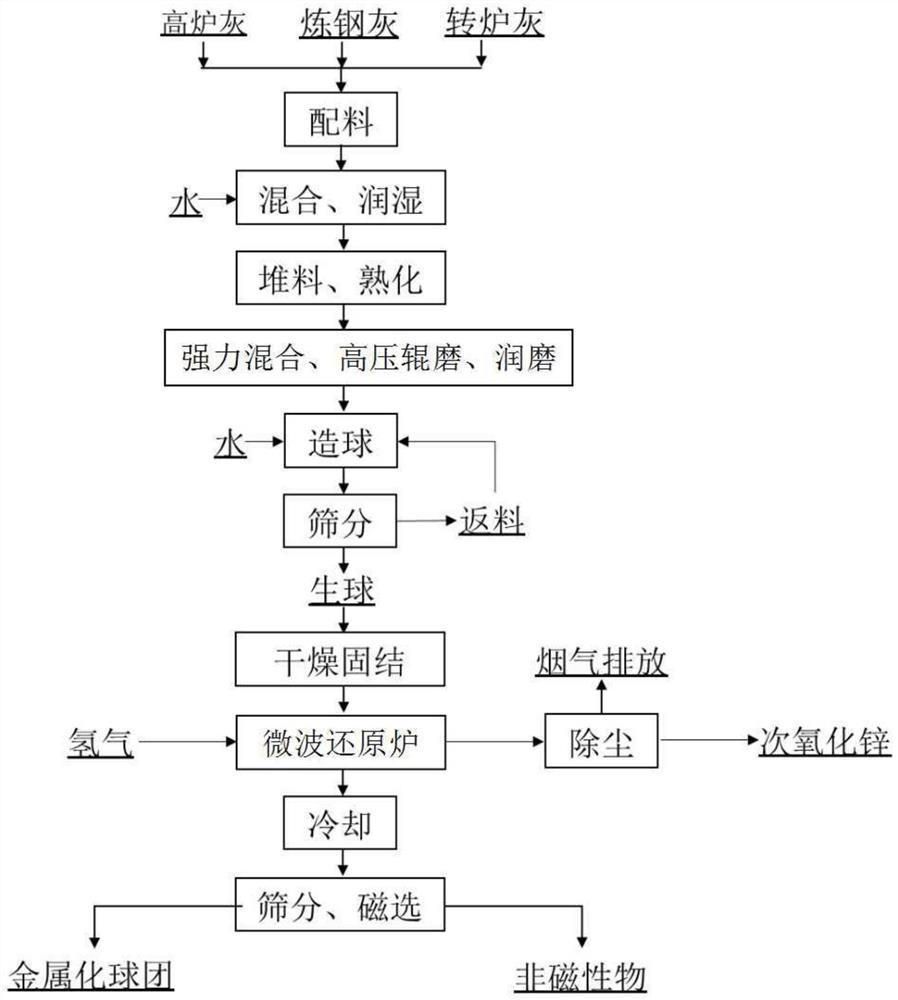

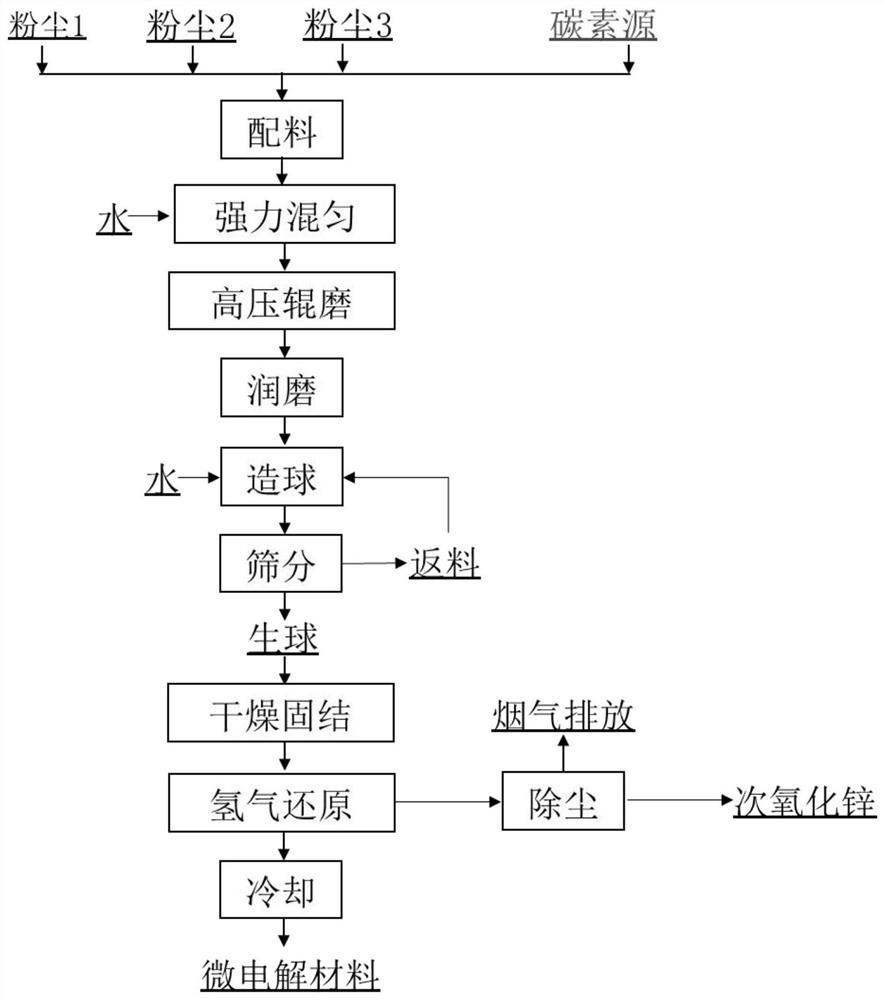

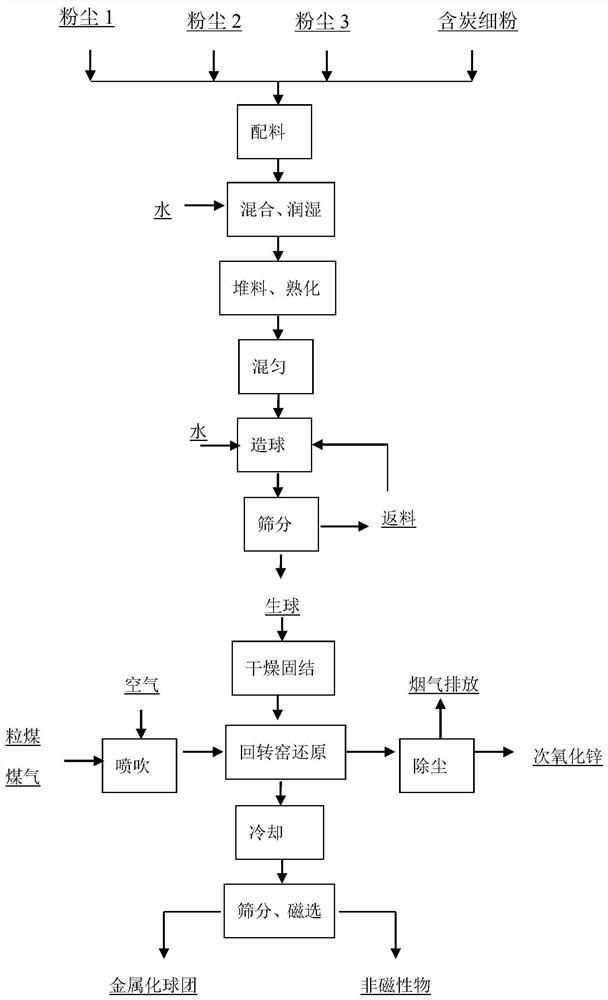

Method for dezincification of zinc-containing dust through microwave hydrogen reduction

PendingCN114525401AHigh carbon contentImprove absorbing performanceProcess efficiency improvementMixed materialsZinc

The invention discloses a method for dezincification of zinc-containing dust through microwave hydrogen reduction, which belongs to the technical field of ferrous metallurgy and comprises the following steps: S1, carrying out optimized ore blending on different types of zinc-containing dust in a steel plant to obtain an ore-blended zinc-containing dust material; s2, a binder is added into the zinc-containing dust material obtained after ore blending, powerful mixing treatment is conducted, then high-pressure roller milling and wet milling combined treatment is conducted, and a uniformly-mixed material is obtained; s3, pelletizing the uniformly mixed material to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls are put into a microwave reduction furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and reduced dezincified balls are obtained. Aiming at the characteristics of high carbon content and excellent wave-absorbing performance in the zinc-containing dust of the iron and steel plant and the characteristics of high heating speed, small heat loss, strong penetrating power, convenience in operation and the like of microwave heating, the defects of high energy consumption and serious pollution of traditional heating can be obviously improved when the zinc-containing dust is heated.

Owner:CENT SOUTH UNIV

Iron ore pellet and its preparation method

The invention discloses an iron ore pellet preparing method, Which comprises the following steps: putting 2-4wt% forsterite and 0. 2-0. 8wt% agglomerant in iron ore; mixing up water (the water content of mixture: 6-11wt%); making ball and drying; preheating at the temperature of 900-1000 deg. c for 15-25min; roasting at the temperature of 1260-1320deg. c for 20-40min; mixing up 20-40% jevigating, 5-10% polyacrylamide, 0-5% polypropylene, 0-5% sodium humate, 20-40% twaterproof putty powder, 3-5% caoline and 5-10% copperas in mass fraction to obtain agglomerant. The invention can improve the strength of green-ball and the heat endurance.

Owner:WUHAN UNIV OF SCI & TECH

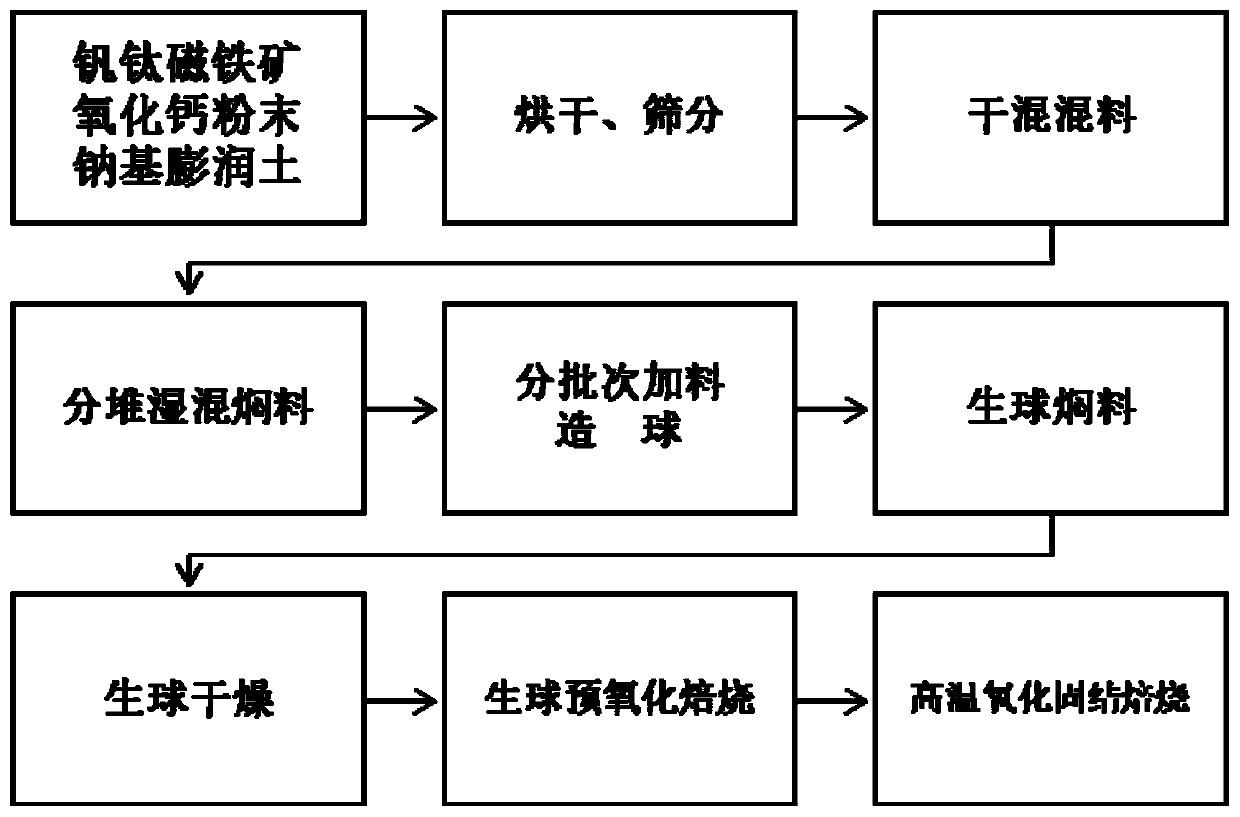

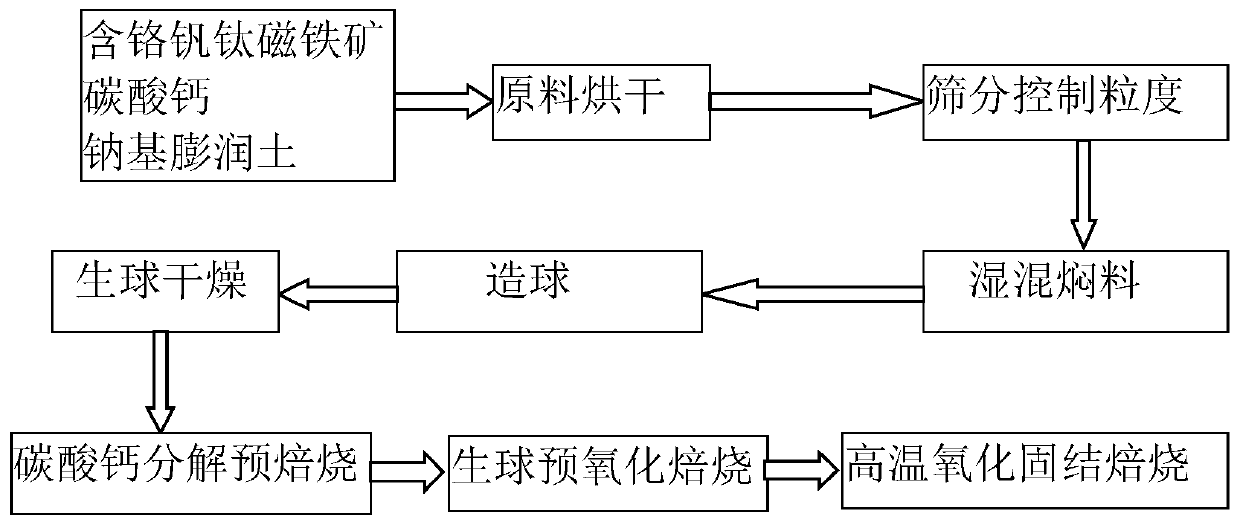

A method for preparing high-basic chromium-vanadium-titanium pellets by using calcium oxide

The invention relates to a method for preparing high-alkalinity chromium-containing vanadium-titanium pellets by using calcium oxide. The method is to batch raw materials including vanadium-titanium magnetite and additives calcium oxide powder and sodium bentonite so that the alkalinity is 1.8 ~2.1, dry and dry mix the materials respectively; divide the mixed mineral materials into two parts evenly, add 3~4% water of the total mass of raw materials to the first part, and add 6~4% of the total mass of raw materials to the second part 8% water, mix evenly, seal and let stand; when making balls, use the first part of the mineral powder during the cue ball forming period, and the second part of the mineral powder for the long term when the cue ball grows. Spray before the cue ball grows. The amount of water is controlled at 1ml / 10g mineral powder ~ 2ml / 10g mineral powder to prevent adhesion between the cue balls, and the interval between each water addition and feeding is 40 to 90 seconds, so that the diameter of the produced pellets is within 8mm ~ 12mm; Carry out green pellet stewing, drying, pre-oxidation roasting, and secondary high-temperature oxidation roasting to obtain high-alkalinity chromium-containing vanadium-titanium pellets.

Owner:NORTHEASTERN UNIV LIAONING

Copper slag and laterite nickel ore co-reduction method for preparing copper-containing, nickel-iron powder

The invention discloses a method for preparing iron powder containing copper and nickel by coreduction of copper slag and nickel laterite ores. The method comprises the following steps: nickel laterite ores, copper slag and a composite binding agent are mixed and pelletized to obtain green balls; the green balls are preheated after drying, and are fed in a rotary kiln; reducing coals are added for reduction to obtain reducing products; and the ore grinding and the magnetic separation are performed on the reducing products to obtain the iron powder containing copper and nickel. The method can realize comprehensive utilization of the copper slag and the nickel laterite ores by one step, and obtains the iron powder containing copper and nickel to provide high-quality burdens for smelting of weather resistant steel; and meanwhile, the excellent soft melting characteristic of the copper slag is used for reinforcing generation of a liquid phase in the reduction process, so that the aggregation and the growth of iron grains are accelerated, and the copper and nickel recovery rates are increased.

Owner:CENT SOUTH UNIV

A double-layer composite pellet for treating copper slag and its preparation method

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

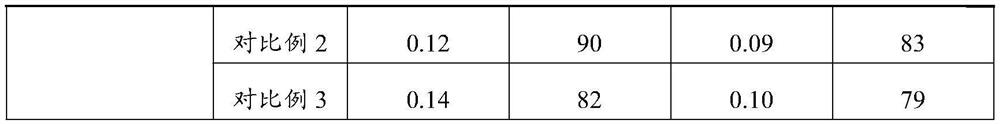

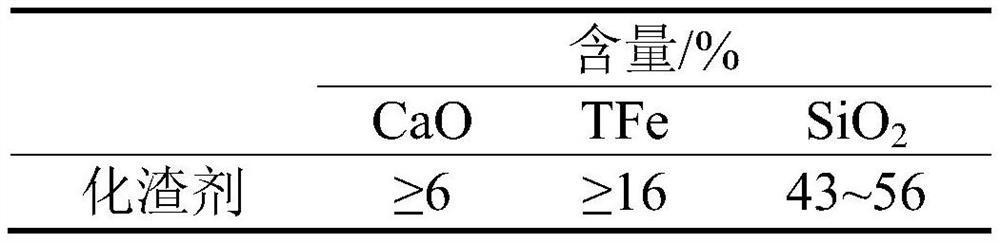

A kind of converter slag pellet and its forming binder

ActiveCN110592374BReduce carryoverImprove green pellet strengthManufacturing convertersCelluloseCarboxymethyl cellulose

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of carbon-containing micro-electrolysis material

ActiveCN114574692AImprove adsorption capacityAchieve recyclingWater contaminantsDispersed particle separationElectrolysisMixed materials

The invention discloses a preparation method of a carbon-containing micro-electrolysis material, which comprises the following steps: S1, optimally proportioning a zinc-containing dust material, a carbon source and a binder to obtain a mixture; s2, intensively and uniformly mixing the mixture obtained in the step S1, and then carrying out high-pressure roller milling and wet milling combined treatment to obtain a uniformly mixed material; s3, pelletizing the uniformly mixed material obtained in the step S2 to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls obtained in the step S3 are loaded into a gas-based shaft furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and the carbon-containing micro-electrolysis material is obtained. According to the preparation method of the carbon-containing micro-electrolysis material, Fe and C contained in zinc-containing dust are fully utilized, dezincification of the zinc-containing dust and preparation of the micro-electrolysis material are achieved in one step through a reduction method, the traditional preparation process of the micro-electrolysis material is changed, and short-process and high-value comprehensive utilization of the zinc-containing dust is achieved.

Owner:CENT SOUTH UNIV

Preparation method of low temperature consolidated metallurgical pellets

ActiveCN109266847BImprove ball formingLower sintering temperatureMetallurgical slagCompressive resistance

The invention belongs to the field of comprehensive utilization of metallurgical residue resources and specifically relates to a preparation method of low-temperature solidified metallurgical pellets.In order to solve the problems that when steel and iron scrap powder are adopted for making pellets, the generated pellets are poor in forming performance, low in sintering intensity, likely to be pulverized and the like. The provided preparation method of the low-temperature solidified metallurgical pellets includes the following steps of a, taking and weighing vanadium titano-magnetite concentrates, steel and iron scraps and a compound bonding agent according to a mass ratio of (28-65):(34-68):(2-4), adding water, uniformly mixing the mixture, and conducting pelleting to obtain raw pellets;b, drying the raw pellets obtained in step a until the moisture content is lower than or equal to 1%, and obtaining dry pellets; c, preheating the dry pellets and conducting sintering to obtain finished pellet products. The preparation method is simple in operation, the prepared pellet products are high in strength, MFe of the finished pellet products is 55-58%, the compressive strength of each pellet is 2,600-3,100 N, the drum index is 90.0-93.5%, and the production cost is low. The new method is provided for comprehensive utilization of the steel and iron scrap powder, and obvious economicbenefits are obtained.

Owner:PANZHIHUA UNIV +1

A method for preparing self-fluxing pellets of medium-low alkalinity chromium-containing all-vanadium-titanium

The invention relates to a method for preparing medium-low alkalinity chromium-containing all-vanadium titanium self-fluxing pellets, which includes the steps: S1: Ingredients: adding calcium carbonate and sodium bentonite to red grid chromium-containing vanadium titanium magnetite; Prepare a mixture with medium and low alkalinity; S2: Wet mixed stew material: add water not exceeding 7% of the mass of the mixture, mix evenly, and then let it stand to make the humidity distribution uniform; S3: Ball making: Make it in a disc The ball machine is used to make balls at a speed of 30r / min-45r / min. During the cue ball forming period, the water spray volume is controlled at 1-2ml / 10g of mineral material to fully roll and compact the mineral material; during the cue ball growth period, increase Spray the amount of water to make pellets with a diameter of 6mm-13mm; S4: Dry the green balls; S5: Place the green balls in the furnace and raise the temperature to 900℃-950℃ for calcium carbonate decomposition and pre-baking; while maintaining heat, Insufficient air is introduced into the furnace for pre-oxidation roasting, and the roasting time is 10min-20min; S6: High-temperature oxidation consolidation roasting: Injecting incremental air into the furnace at 1250℃-1300℃ to increase the oxidizing atmosphere, and perform high-temperature oxidation After consolidation and roasting, and then cooling to room temperature, medium-low basicity chromium-containing all-vanadium-titanium self-fluxing pellets are obtained.

Owner:NORTHEASTERN UNIV LIAONING

A method for preparing active mixture by belt roaster pellet method

ActiveCN109956737BCementitious effectHigh porosityCeramic materials productionClaywaresEngineeringMixed materials

The invention discloses a method for preparing an active mixed material through a belt type roasting machine pelletizing method. The method comprises the following steps: (1) crushing and grinding ore; (2) burdening and uniformly mixing: fully and uniformly mixing the coal gangue subjected to fine grinding, a composite additive and water in an intensive mixer according to predetermined proportion,and fully wetting the materials; (3) pelletization: preparing pellets with preset granularity from the uniformly mixed ores; (4) roasting by a belt type roasting machine: distributing the pellets onthe belt type roasting machine, and drying, preheating, oxidizing and roasting, soaking and cooling the pellets; and (5) crushing and fine grinding: crushing and fine grinding the coal gangue pellet material to a set specific surface area to obtain the active mixed material. The invention provides a method for preparing the active mixed material through the belt type roasting machine pelletizing method. The method is suitable for large-scale production, the usage amount of the coal gangue reaches 85% or above, the coal gangue stockpiling problem can be thoroughly solved, and a high-quality mixed material is provided for the construction industry.

Owner:CENT SOUTH UNIV

A process for preparing coal gangue lightweight aggregate by belt roaster pellet method

ActiveCN110104975BHigh strengthUniform qualitySolid waste managementFoaming agentProcess engineering

Owner:CENT SOUTH UNIV

A kind of oxidized pellet binder made from low-rank coal and its preparation method and application

The invention discloses an oxidized pellet binder made from low-rank coal and its preparation method and application. After the low-rank coal is broken, it is oxidized and fermented, then solid caustic and water are added to prepare the slurry, and it is obtained by heating and stirring. Oxidized pellet binder: The oxidized pellet binder is added to iron ore powder for pelletizing to obtain green iron ore pellets for oxidized pellets. The invention uses low-rank coal as raw material, through simple oxidative fermentation, and then synchronously extracts humic acid and pulping to obtain the oxidized pellet binder. The raw material is cheap and has a wide source, and the process is simple. With good performance and strong applicability, it can not only significantly improve the pelletizing performance of refractory nodular iron ore resources, but also has no impact on the iron grade of the finished pellets.

Owner:CENT SOUTH UNIV

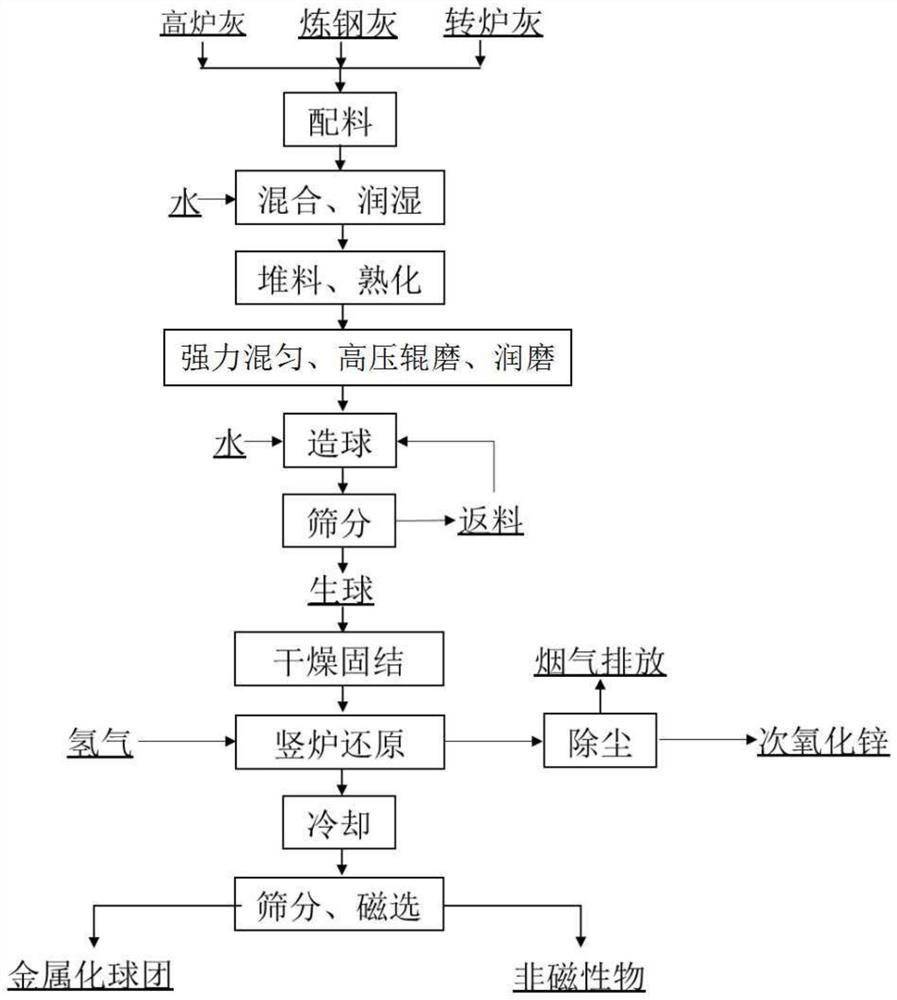

Method for dezincification of zinc-containing dust through hydrogen reduction

PendingCN114561545AGood use effectImprove protectionProcess efficiency improvementMixed materialsShaft furnace

The invention discloses a zinc-containing dust hydrogen reduction dezincification method which comprises the following steps: S1, adding water into a zinc-containing dust material for wetting, stacking after wetting, covering, heating and curing to obtain a cured material; s2, a binder is added into the cured material, strong uniform mixing treatment is conducted, then high-pressure roller grinding and wet grinding combined treatment is conducted, and a uniformly mixed material is obtained; s3, pelletizing the uniformly mixed material, and then drying green pellets to obtain dry pellets; and S4, the dry balls are loaded into a gas-based shaft furnace for hydrogen reduction, the reduction temperature ranges from 800 DEG C to 950 DEG C, cooling is conducted under the protective atmosphere after reduction, and the reduced dezincified balls are obtained. According to the method, the advantages of low hydrogen reduction temperature, high reduction rate, low energy consumption, high efficiency and no carbon emission are utilized, the zinc-containing dust pellets are reduced, so that many problems existing in traditional carbon thermal reduction are solved, the reduction effect can be improved, the comprehensive utilization effect of the zinc-containing dust can be improved, and environmental protection is facilitated.

Owner:CENT SOUTH UNIV

A kind of preparation method of zinc-containing dust pellet

ActiveCN110317949BOvercoming the characteristics of weak ball formationGood ball formingRotary drum furnacesProcess efficiency improvementSteelmakingPhysical chemistry

The invention provides a method for preparing zinc-containing dust pellets, comprising steps: S1, ingredients: mixing zinc-containing dust such as blast furnace bag ash, steel-making ladle furnace ash, steel-making converter dust and carbon-containing fine powder to obtain a mixture ; S2, pretreatment: add water to the mixture in the step S1 for wetting, after wetting, stockpile and cover the material for curing; S3, add a composite binder to the mature mixture and mix to obtain a mixture Uniform material; S4, pelletizing the mixed material prepared in the step S3 to obtain green pellets; S5, drying the green pellets in the step S4 to obtain the zinc-containing dust dry pellets. This kind of dry pellets has high compressive strength, good reducibility, high metallization rate and good dezincification effect in the direct reduction process, which solves the existing technology that the zinc-containing dust pellets are easy to break and pulverize during the reduction process question.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com